Mercerized wool smoothing finishing agent and preparation method thereof

A technology of mercerized wool and finishing agent, which is applied in the direction of improved handle fibers and animal fibers, which can solve the problems of poor fabric softness, macular phenomenon, and poor handle, so as to promote diffusion filling, reduce dynamic and static friction coefficients, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

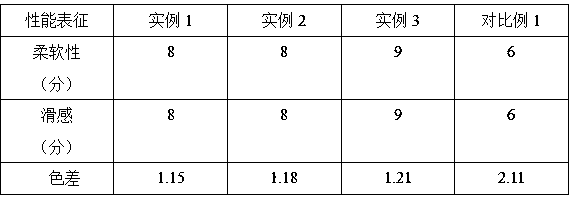

Examples

example 1

[0027] Take 100g octamethylcyclotetrasiloxane, 120g aminoethylaminopropyl polydimethylsiloxane, 3.0g silane coupling agent HD-109, 1.0g silane coupling agent HD-110, put into four ports In the flask, stir and heat at 300r / min to 80°C, then add 0.03g of lithium hydroxide, continue to stir for 20min, then raise the temperature to 130°C, keep warm for 3h to obtain the modified silicone oil mixture, then cool down to 120°C, and turn on the vacuum pump , evacuate the four-neck flask to a pressure of 60kPa in the bottle, keep warm and continue to evacuate until no low boilers are distilled out, cool to room temperature and discharge to obtain modified silicone oil, take 100g of wool, wash it with deionized water and put it into In an oven, dry at 50°C for 2 hours, then transfer the dried wool to a pulverizer and crush it into 1mm fragments, add the wool fragments to 1kg of 2% sodium hydroxide solution, and place them in a constant temperature water bath at 80°C React for 3 hours, fi...

example 2

[0029] Take 125g octamethylcyclotetrasiloxane, 150g aminoethylaminopropyl polydimethylsiloxane, 3.7g silane coupling agent HD-109, 1.25g silane coupling agent HD-110, put into four In the flask, stir and heat at 350r / min to 85°C, then add 0.04g of lithium hydroxide, continue to stir for 25min, then raise the temperature to 135°C, keep warm for 4h to obtain the modified silicone oil mixture, then cool down to 123°C, and turn on the vacuum pump , evacuate the four-necked flask to a pressure of 75kPa in the bottle, keep warm and continue to evacuate until no low boilers are distilled out, cool to room temperature and discharge to obtain modified silicone oil, take 150g of wool, wash it with deionized water and put it into In an oven, dry at 53°C for 2 hours, then transfer the dried wool to a pulverizer and crush it into 3mm fragments, add the wool fragments to 1.5kg of 2% sodium hydroxide solution in a constant temperature water bath at 83°C React for 4 hours, filter the filtrate...

example 3

[0031]Take 150g octamethylcyclotetrasiloxane, 180g aminoethylaminopropyl polydimethylsiloxane, 4.5g silane coupling agent HD-109, 1.5g silane coupling agent HD-110, put into four In the flask, stir and heat at 400r / min to 90°C, then add 0.05g of lithium hydroxide, continue to stir for 30min, then raise the temperature to 140°C, keep warm for 5h to obtain a modified silicone oil mixture, then cool down to 125°C, and turn on the vacuum pump , evacuate the four-necked flask to a pressure of 90kPa in the bottle, keep warm and continue to evacuate until no low boilers are distilled out, cool to room temperature and discharge to obtain modified silicone oil, take 200g of wool, wash it with deionized water and put it into In an oven, dry at 55°C for 3 hours, then transfer the dried wool to a pulverizer and crush it into 5mm fragments, add the wool fragments to 2kg of 2% sodium hydroxide solution, and place them in a constant temperature water bath at 85°C React for 5 hours, filter th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com