Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Achieve superhydrophobic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

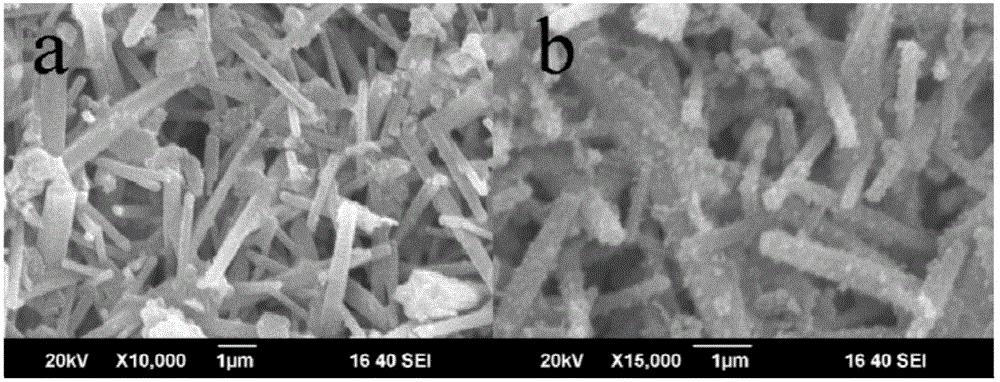

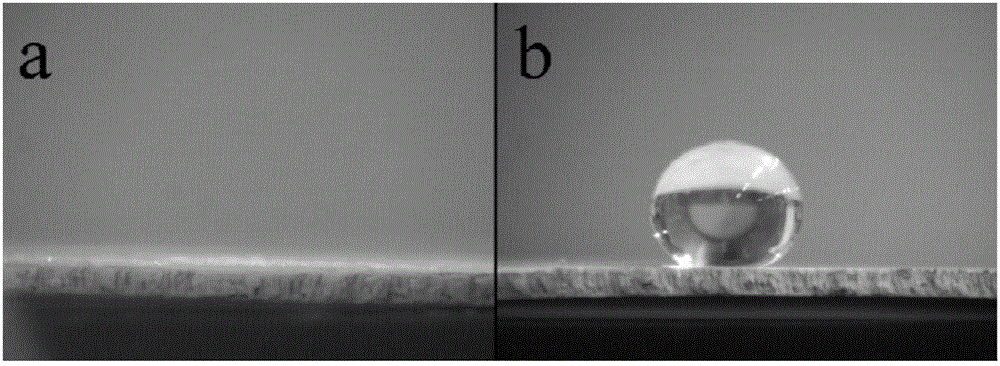

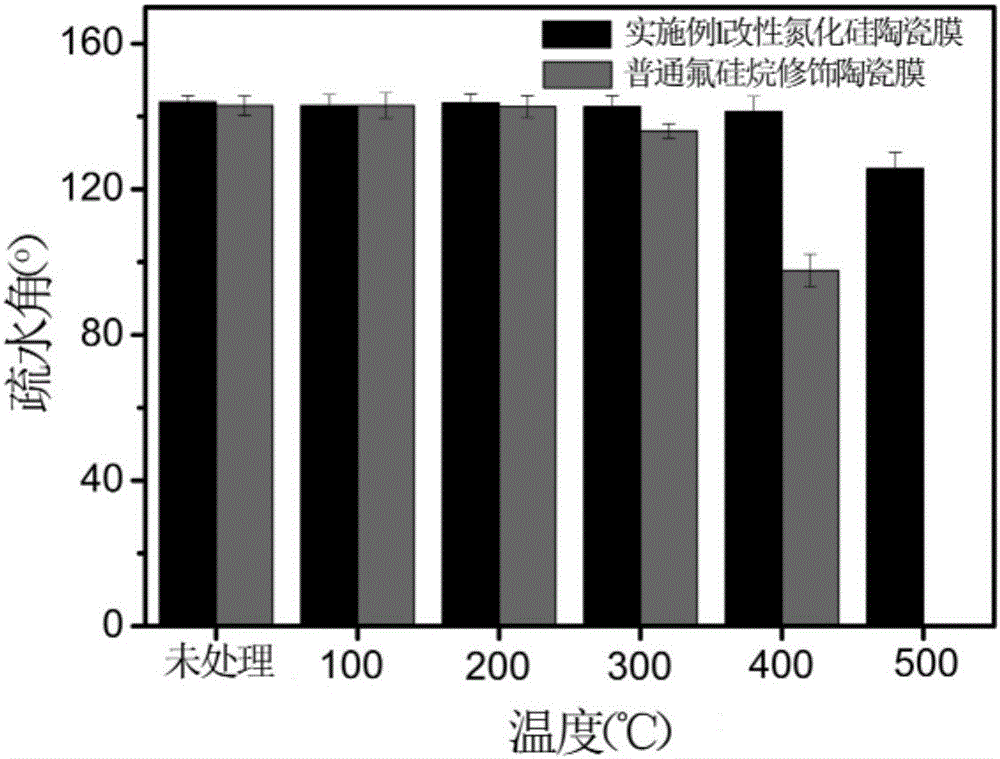

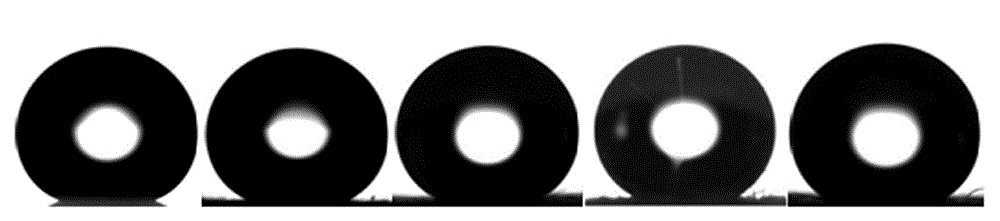

Modification method of ceramic membrane and modified ceramic membrane

ActiveCN106669440AGood chemical stabilityExtended service lifeSemi-permeable membranesSilane compoundsDesalination

The invention provides a modification method of a ceramic membrane and a modified ceramic membrane. The modification method of the ceramic membrane comprises the following steps: performing surface treatment on the ceramic membrane to obtain a fresh ceramic membrane; coating the surface of the ceramic membrane with a silane compound through an impregnation method or a sedimentation method; performing thermal treatment on the coated ceramic membrane under a protective atmosphere, naturally cooling to obtain the modified ceramic membrane after the modification. The modification method of the ceramic membrane provided by the invention has advantages that the modification process is simple, the raw material cost is low, and secondary pollution on the environment can be avoided in the modification process; compared with the common organic modification material, the modified ceramic membrane prepared through modification has the features of high long-term stability, strong acid-base resistance, and strong hydrophobic property; and the modified ceramic membrane can be extensively applied to sea water desalinization, oil-water separation, wastewater treatment and other fields.

Owner:PETROCHINA CO LTD +1

Method for preparing good-stability super-hydrophobic fabrics

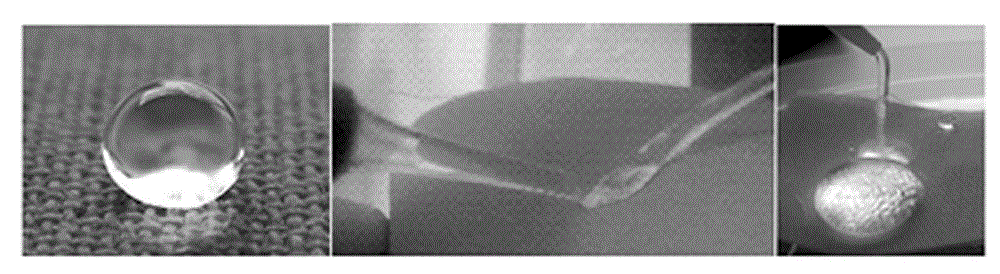

The invention discloses a method for preparing good-stability super-hydrophobic fabrics, which comprises the following steps: dispersing organosilane polymers into an organic solvent so as to obtain 2-50 mg / mL of an organosilane polymer solution; coating the organosilane polymer solution on the surface of a fabric in a dip-coating or spray-coating mode; and carrying out curing processing on the fabric in an ultrasonic and / or heat treatment mode so as to obtain a super-hydrophobic fabric. The super-hydrophobic fabric prepared by using the method disclosed by the invention is excellent in super-hydrophobicity and hydrophobic stability, and keeps the natural mechanical properties and luster and the like of fabrics, therefore, the fabric has wide application in the fields of self-cleaning fibers and fabrics. In addition, the method disclosed by the invention is simple in preparation process, mild in reaction conditions, low in cost, and convenient for mass production.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Making method of single-face-super-hydrophobic and single-face-hydrophilic Janus-type fabric

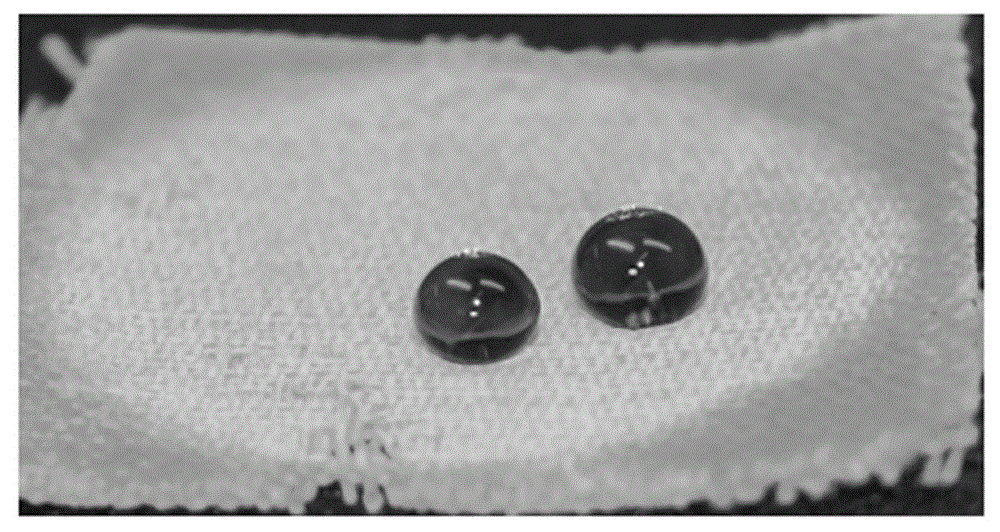

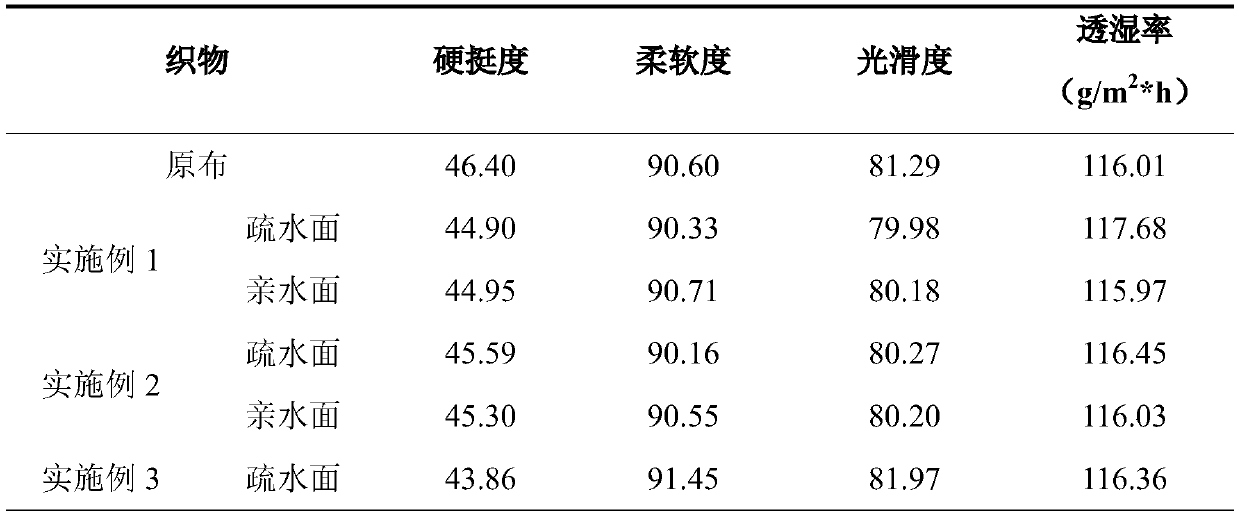

InactiveCN109706735AGood softnessGood performanceUltrasonic/sonic fibre treatmentVegetal fibresGlow dischargeWoven fabric

The invention relates to a making method of a fabric, in particular to a making method of a single-face-super-hydrophobic and single-face-hydrophilic Janus-type fabric and belongs to the field of textile function arrangement. The method comprises the following steps that 1, the fabric is cleaned and then dried for use; 2, the single face of the fabric is protected, under the condition of constantoxygen pressure intensity, plasma glow discharge treatment is conducted on the single face of the fabric, after oxygen is switched off, under the condition of constant steam pressure intensity of a grafting monomer, plasma glow discharge treatment is conducted again, and the single-face-super-hydrophobic and single-face-hydrophilic Janus-type fabric is obtained. According to plasma glow dischargetreatment, a cold plasma treatment instrument is used for generating plasma glow, the plasma treatment power is within 30-120 W, and the time is within 1-10 min. According to the method, the technology is simple and easy to control, the method is suitable for single-face treatment of various cotton fabrics and acetate fiber non-woven fabrics, the functionality demand is met, and the method also has good wearing performance.

Owner:ZHEJIANG SCI-TECH UNIV

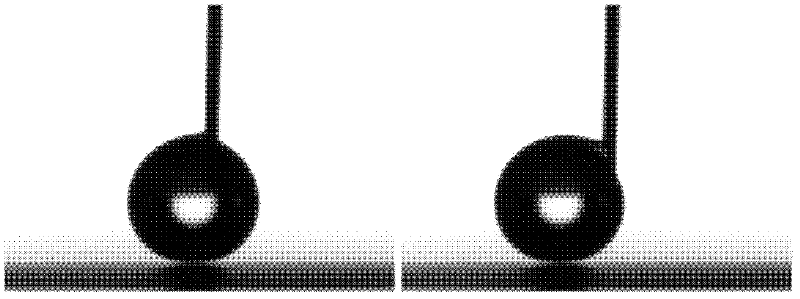

Preparation method and application of super-hydrophobic antibacterial finishing agent for cotton fabrics

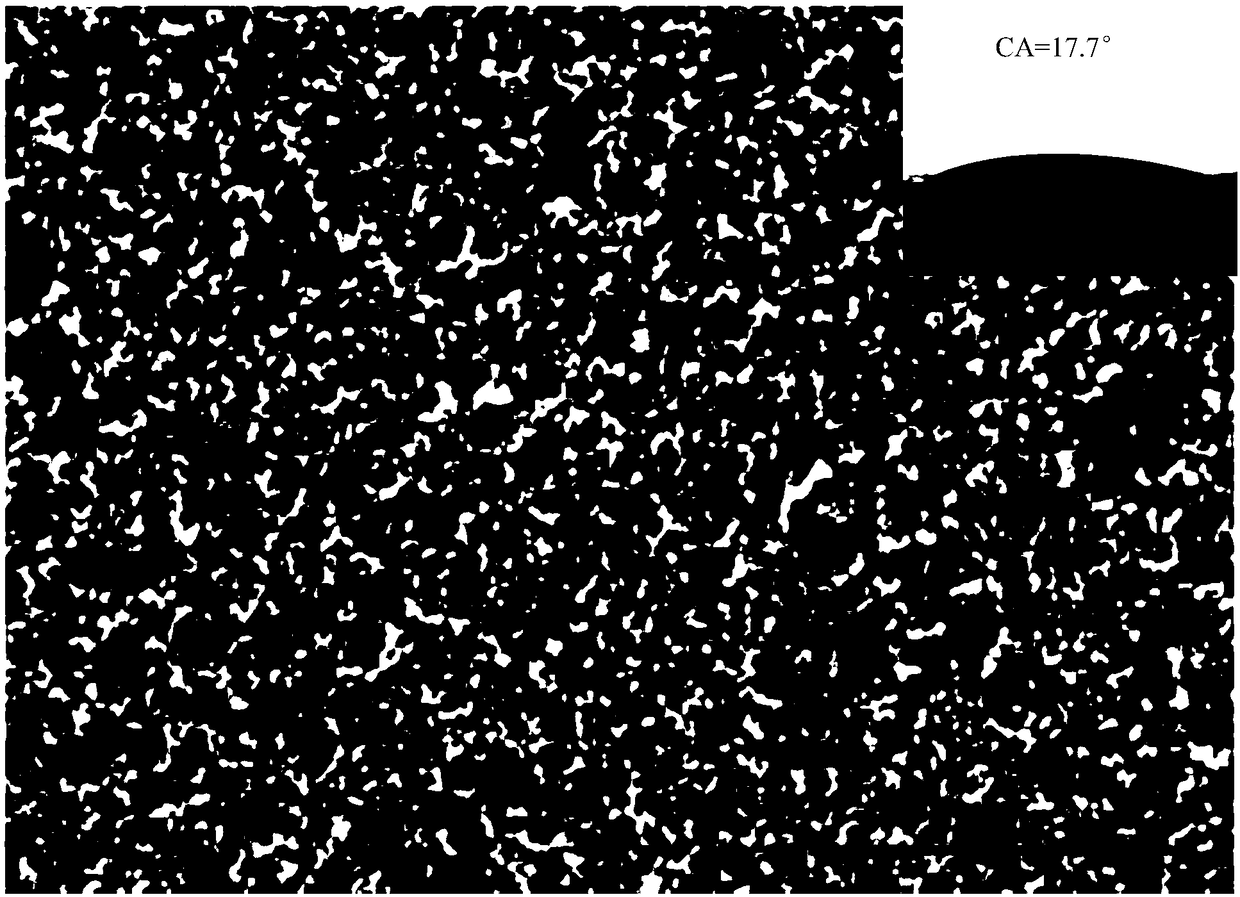

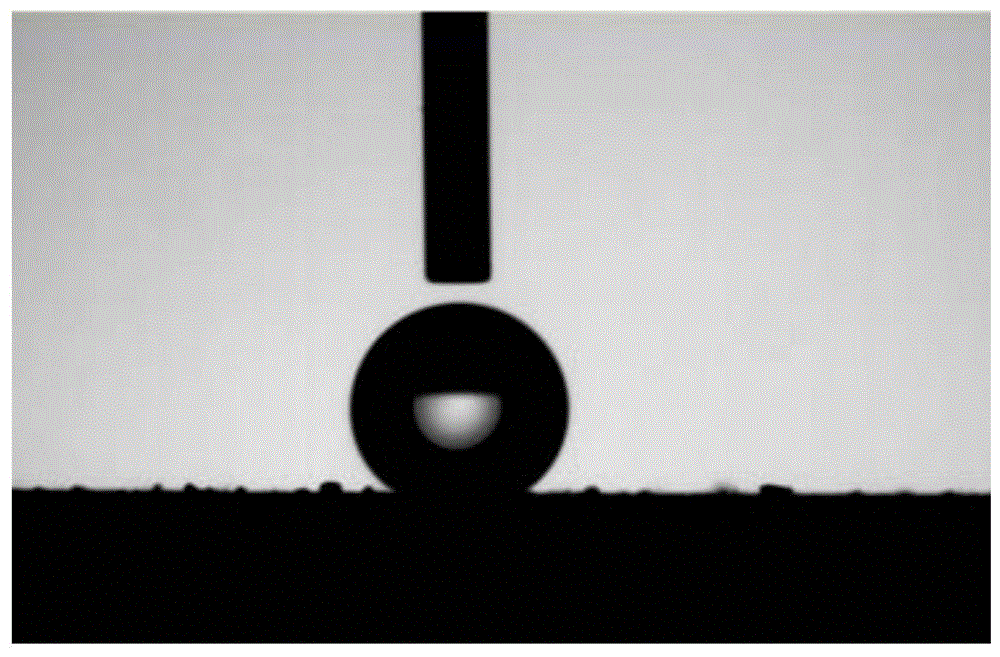

InactiveCN104131468AAchieve superhydrophobic effectExcellent antibacterial and anti-mildew functionVegetal fibresPolymer scienceOrganosolv

The invention relates to a super-hydrophobic antibacterial finishing agent for cotton fabrics. The super-hydrophobic antibacterial finishing agent comprises following components: long-chain alkyl alkoxy siloxane, nano zinc oxide and silane behenyl trimethyl ammonium chloride used as an emulsifier antibacterial agent. Long-chain alkyl alkoxy siloxane and nano zinc oxide are used as super-hydrophobic raw materials and silane behenyl trimethyl ammonium chloride is used as the emulsifier antibacterial agent to prepare the super-hydrophobic antibacterial finishing agent for fabrics, particularly the cotton fabrics; water is used as a dispersion medium so that the disadvantage of existing patented technologies at home and abroad that an organic solvent is taken as a carrier to prepare the super-hydrophobic fabrics is overcome; the contact angle between the cotton fabrics treated by the super-hydrophobic antibacterial finishing agent and water drops is larger than 150 degrees and the super-hydrophobic effect of a lotus leaf is realized; the water drops roll on the surfaces of the cotton fabrics and are not absorbed by the cotton fabrics for long time; meanwhile, the super-hydrophobic antibacterial finishing agent has good antibacterial and mould-proof functions.

Owner:NANXIONG DING CHENG NEW MATERIAL TECH CO LTD

Preparation method of water-based super-hydrophobic material

InactiveCN108641050ANot easy to fall offImprove wear resistanceAntifouling/underwater paintsPaints with biocidesWater basedPolymer science

The invention discloses a preparation method of a water-based super-hydrophobic material. The method comprises the steps that 1, a silane coupling agent is used for modifying the surface of silicon dioxide, and the silicon dioxide with double bonds on the surface is obtained; 2, an emulsion polymerization method is adopted for grafting hydrophobic polymer long chains to the surface, and the water-based super-hydrophobic material is prepared. When the polymer is under the glass-transition temperature or above, chains of the polymer begin to move, the chains can be twisted, micro-balls of materials are combined more tightly, and therefore the nano-particles are not likely to be disengaged, the abrasion resistance of the material is enhanced, and the defects caused by adopting an adhesive areavoided. By adopting the emulsion polymerization method, no organic solvent is adopted, environment contaminations are small, the cost is low, and the preparation process is simple.

Owner:HEBEI UNIV OF TECH

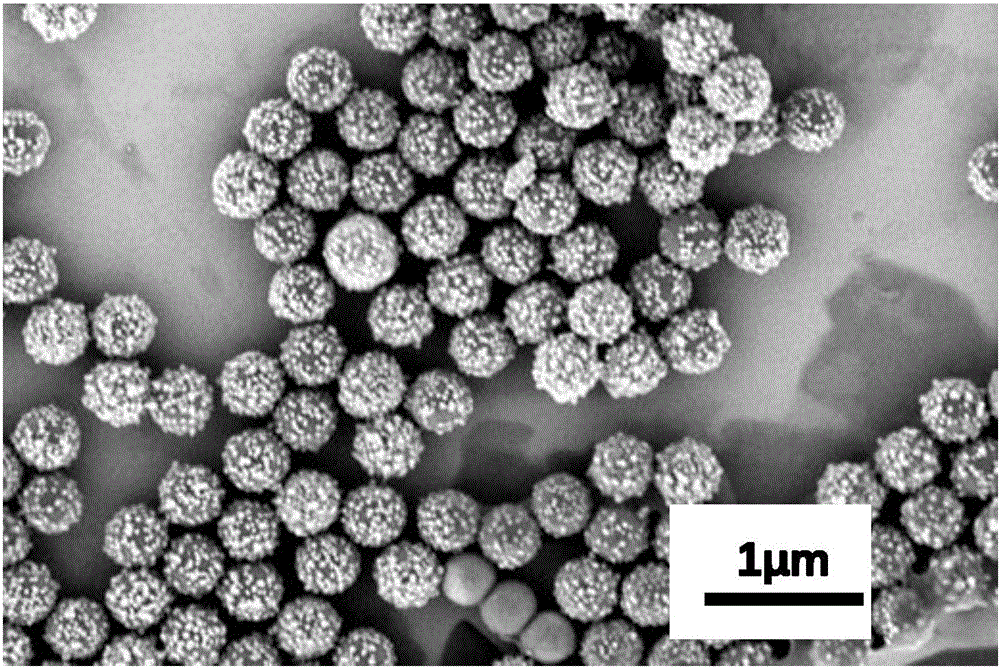

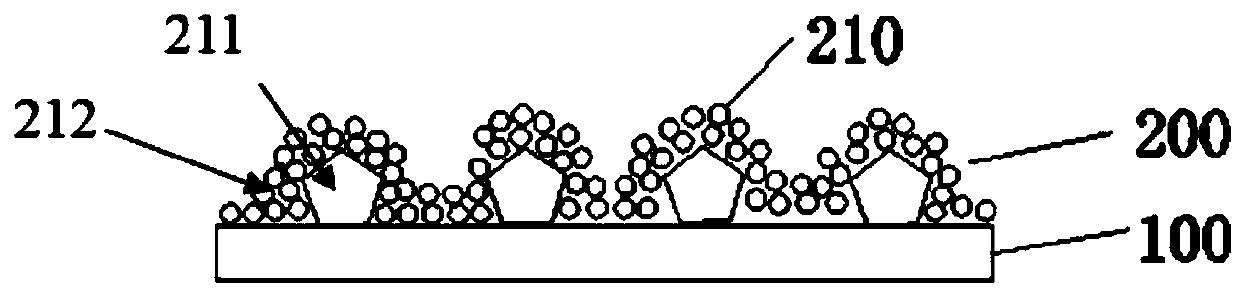

Strawberry-shaped super-hydrophobic composite microsphere and application thereof

InactiveCN106311103AGood durabilityWide range of applicationsMicroballoon preparationEpoxy resin coatingsSolventChemistry

The invention relates to a strawberry-shaped super-hydrophobic composite microsphere and application thereof. The microsphere is prepared through the following steps that (1) an amino polystyrene microsphere, ethyl alcohol, ethyl orthosilicate and distilled water are added into a reactor, and take a reaction for 24h at room temperature; the product is washed with ethyl alcohol; after vacuum drying is performed, a strawberry-shaped composite microsphere is obtained; (2) the strawberry-shaped composite microsphere, a solvent and a silane coupling agent are added into the reactor; the reaction is performed for 5 to 15h under the condition of 25 DEG C to 100 DEG C; the product is centrifuged to obtain the strawberry-shaped super-hydrophobic composite microsphere. The strawberry-shaped super-hydrophobic composite microsphere and epoxy resin are matched to be used as a super-hydrophobic coating; the excellent and stable super-hydrophobic performance is realized; muddy water is splashed on the prepared super-hydrophobic surface; the super-hydrophobic surface cannot be polluted by the muddy water, so that the self cleaning function of the surface is realized.

Owner:天津傲卓菲科技有限公司

Preparation method for fluoride-free super-hydrophobic cotton fabric

InactiveCN105350282AHas super hydrophobic propertiesWith self-cleaning functionLiquid/gas/vapor removalVegetal fibresCooking & bakingFiber

The invention discloses a preparation method for a fluoride-free super-hydrophobic cotton fabric, and belongs to the field of textile function finishing and processing. The preparation method comprises the steps that rolling-drying-baking finishing is performed on a cotton fabric by adopting nano titanium dioxide sol to improve the roughness of the surface of the fabric, and then hydrophobic modification is performed on the fabric by adopting a low-surface-energy substance-molten wax substance; the contact angle of the prepared cotton fabric and a water drop is larger than 150 degrees. According to the method, through a chemical reaction between hydroxyl of cotton fiber and hydroxyl in the nano TiO2 hydrosol, the constructed rough surface has the good firmness; through the structural characteristics of the bionic lotus leaf surface, the molten wax substance is adopted to be cured and crystallized on the rough surface of an oxide for organic modification, not only can the super-hydrophobic effect can achieved, but also the influences of introducing a fluorine-containing organic modifier and other organic solvent or a surfactant on the hydrophobicity of the fabric can be avoided, and therefore the super hydrophobicity of the prepared fabric has the excellent stability.

Owner:ZHONGYUAN ENGINEERING COLLEGE

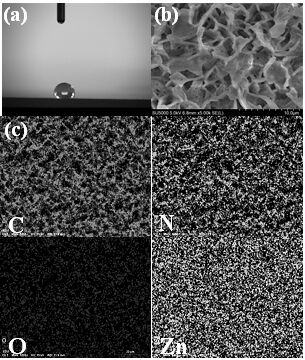

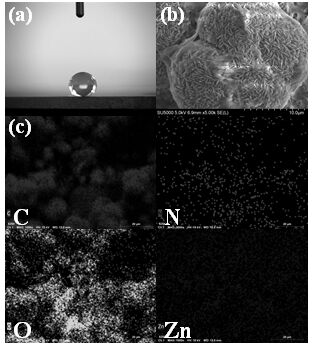

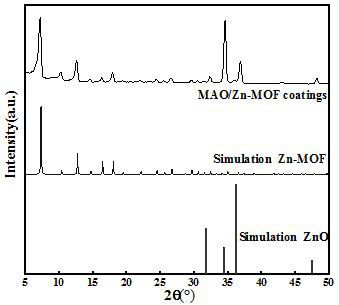

Fluorine-free super-hydrophobic Zn-MOF composite coating on surface of magnesium alloy and preparation method thereof

ActiveCN112522703AImprove bindingAchieve superhydrophobic effectAnodisationSuperimposed coating processMicro arc oxidationStearic acid

The invention discloses a fluorine-free super-hydrophobic Zn-MOF composite coating on the surface of a magnesium alloy and a preparation method thereof. The fluoride-free super-hydrophobic Zn-MOF composite coating on the surface of the magnesium alloy specifically comprises a micro-arc oxidation layer, a Zn-MOF layer and a stearic acid layer which are sequentially attached to the surface of the magnesium alloy. A magnesium alloy matrix is sequentially subjected to grinding and polishing, oil removal and ultrasonic cleaning, then micro-arc oxidation treatment is carried out, after a micro-arc oxidation film is formed on the surface of the magnesium alloy matrix, the micro-arc oxidation film is placed in a polytetrafluoroethylene reaction kettle for high-temperature and high-pressure reaction to form the Zn-MOF coating, and finally the Zn-MOF coating is treated with a low-surface-energy substance stearic acid, and the fluorine-free super-hydrophobic Zn-MOF composite coating on the surface of the magnesium alloy is obtained after drying. The method is simple in preparation process and free of fluorine, the composite coating and a magnesium alloy base material have good binding force,the composite coating can be evenly distributed on the surface of the magnesium alloy, the corrosion current density is low, the super-hydrophobic effect is achieved, and good corrosion resistance isshown.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

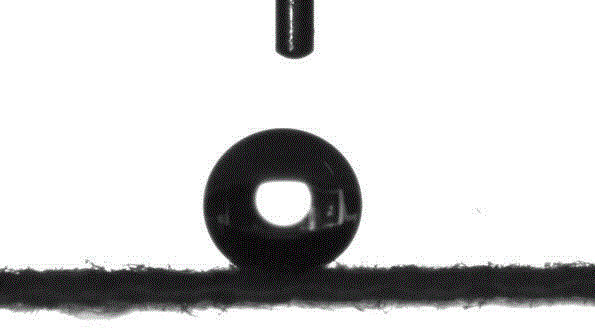

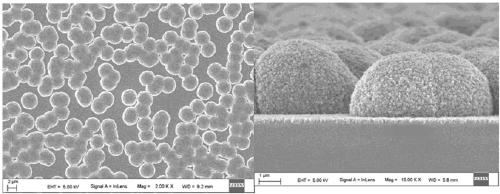

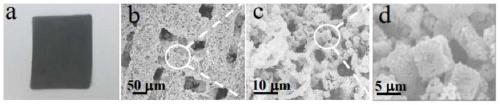

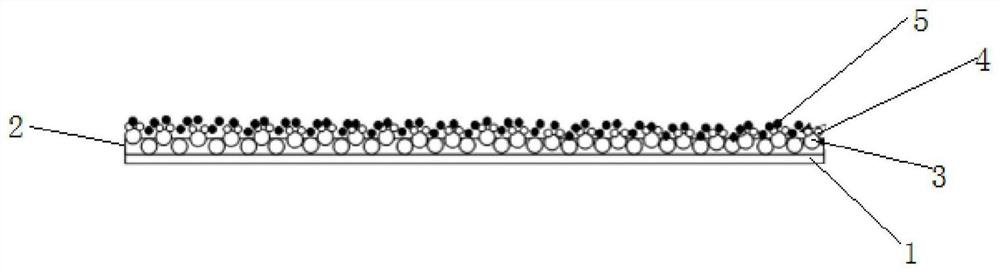

Boron-doped diamond film and preparation method thereof, oil-water separation element, water treatment electrode and preparation method thereof and water treatment device

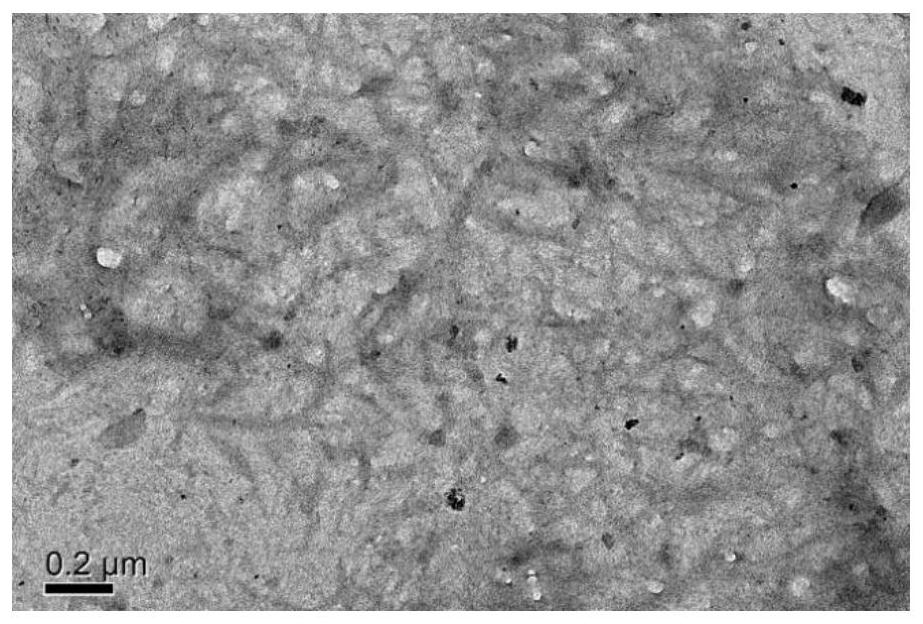

ActiveCN111334779AChemically stableImprove impact performanceWater treatment compoundsWater/sewage treatment by electrochemical methodsNano structuringNanoparticle

The invention provides a boron-doped diamond film and a preparation method thereof, an oil-water separation element, a water treatment electrode and a preparation method thereof and a water treatmentdevice, and relates to the technical field of diamond films. The boron-doped diamond film comprise a boron-doped diamond micrometer layer and a boron-doped diamond nanometer layer; the surface of theboron-doped diamond micrometer layer is provided with convex micrometer particles; the boron-doped diamond nanometer layer is formed on the surface of the boron-doped diamond micrometer layer, and thesurface of the boron-doped diamond nanometer layer is provided with nanometer particles; and the boron-doped diamond micrometer layer and the boron-doped diamond nanometer layer form a lotus leaf-like multilevel micro-nano structure. The boron-doped diamond film has the lotus leaf-like multilevel micro-nano structure, a bionic superhydrophobic surface is formed, the filtering function and the electrocatalytic water purification function are taken into account concurrently, and a foundation is laid for development of a new-generation field living water supply system.

Owner:SHENZHEN INST OF ADVANCED TECH

Superhydrophobic coating and preparation method thereof

InactiveCN105507061AWide range of usesWith self-cleaning abilityWater-repelling agents additionNon-macromolecular organic additionSurface energyMicro nano

The invention belongs to the field of material surface and inorganic porous material and specifically relates to a superhydrophobic coating and its preparation method. The preparation method comprises the following steps: a, adding 1-5 parts by weight of natural zeolite into 50-100 parts by weight of ethanol, carrying out ultrasonic dispersion for 10-30 min, adding 0.15-0.85 part by weight of perfluorodecyltrichlorosilane, and continuously carrying out ultrasonic dispersion for 10-30 min to obtain a dispersion liquid; b, immersing a base material into the dispersion liquid obtained in the step a for 3-5 min, taking out the base material and drying the base material at 50-70 DEG C for more than 30 min; and c, repeating the step b for two to three times so as to form the superhydrophobic coating on the surface of the base material. Natural zeolite belongs to an inorganic porous material and is easy to form a micro-nano structure in the coating. Meanwhile, there exist many hydroxide radicals on the surface of zeolite, and its surface energy is reduced after condensation between perfluorodecyltrichlorosilane and hydroxide radicals. Thus, the superhydrophobic effect is achieved. The natural zeolite is cheap and easily available. The preparation method is simple and easy for industrialization. The coating of the invention has a self-cleaning ability, is applicable to many base materials and is widely applied.

Owner:HUBEI UNIV

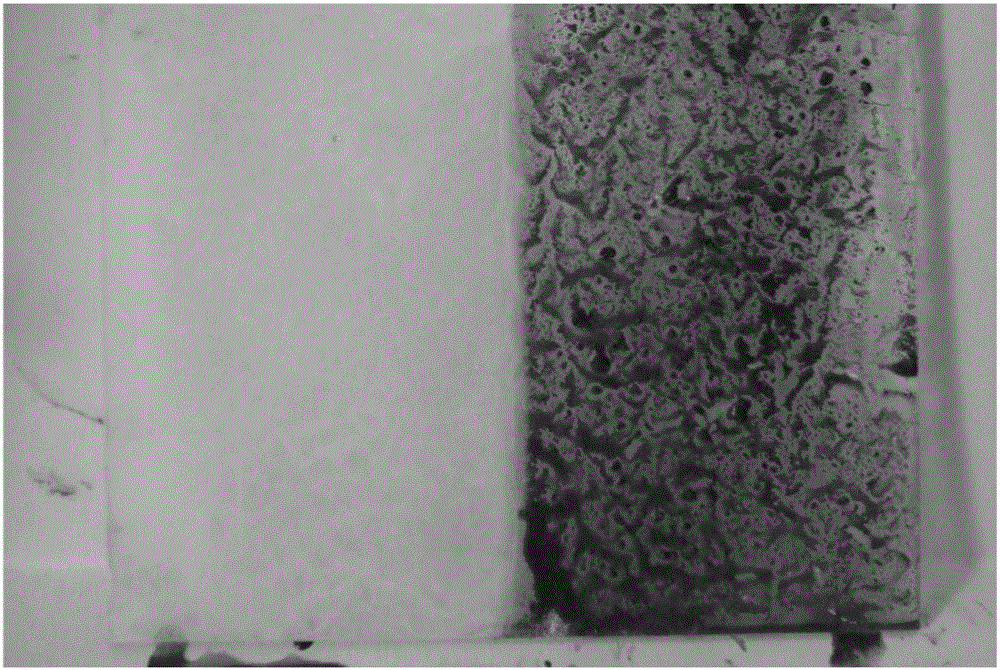

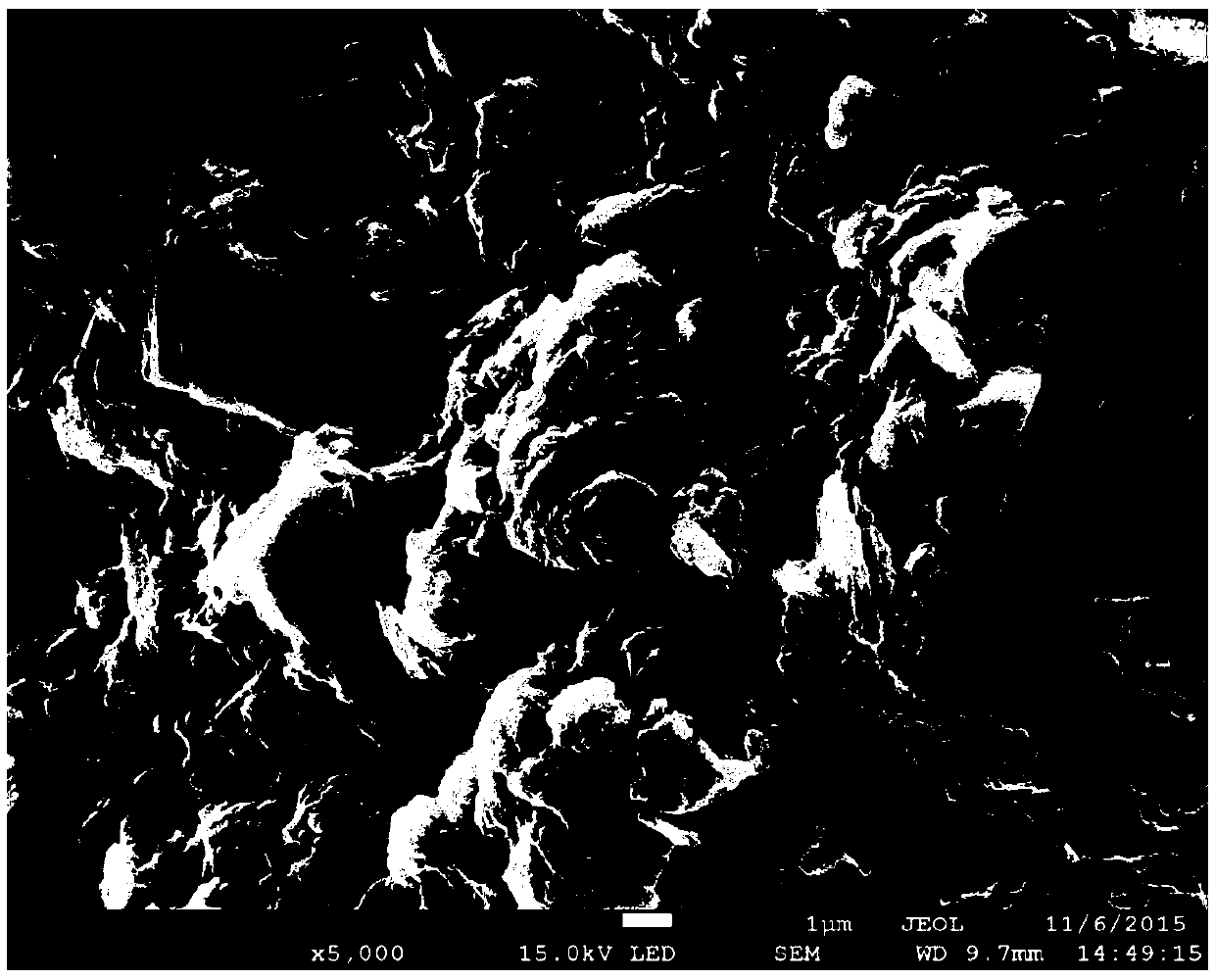

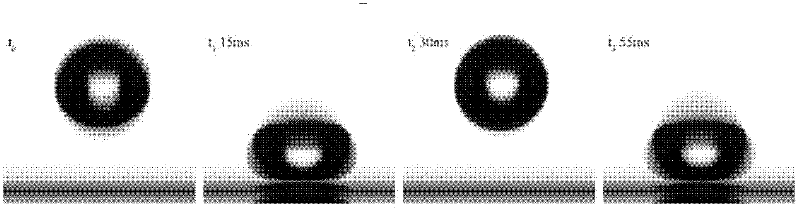

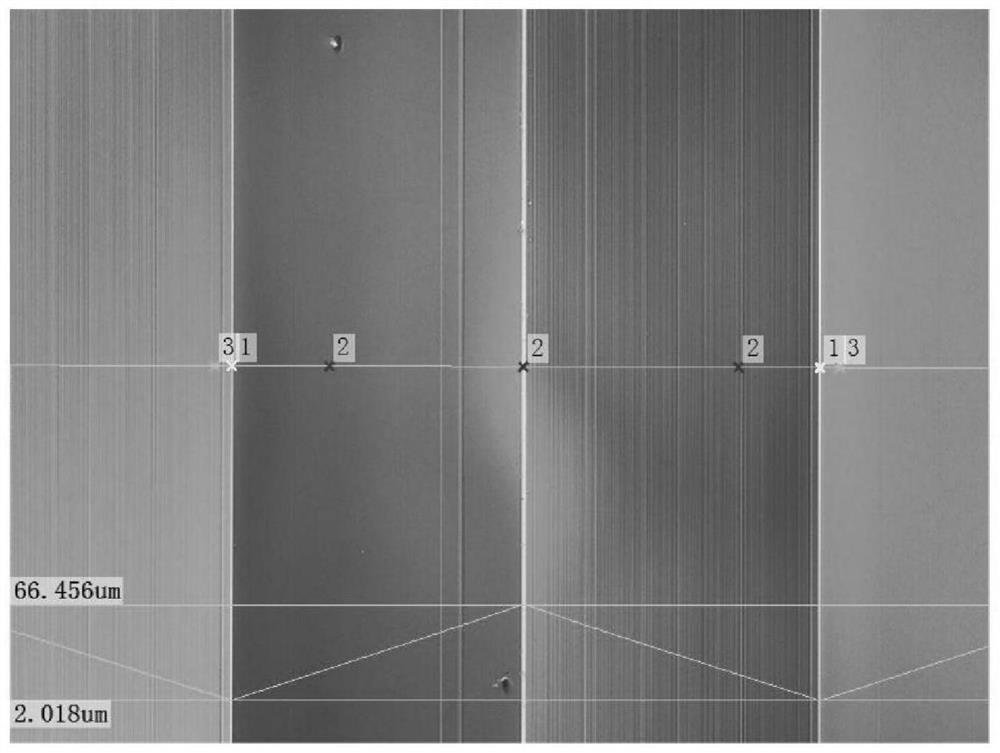

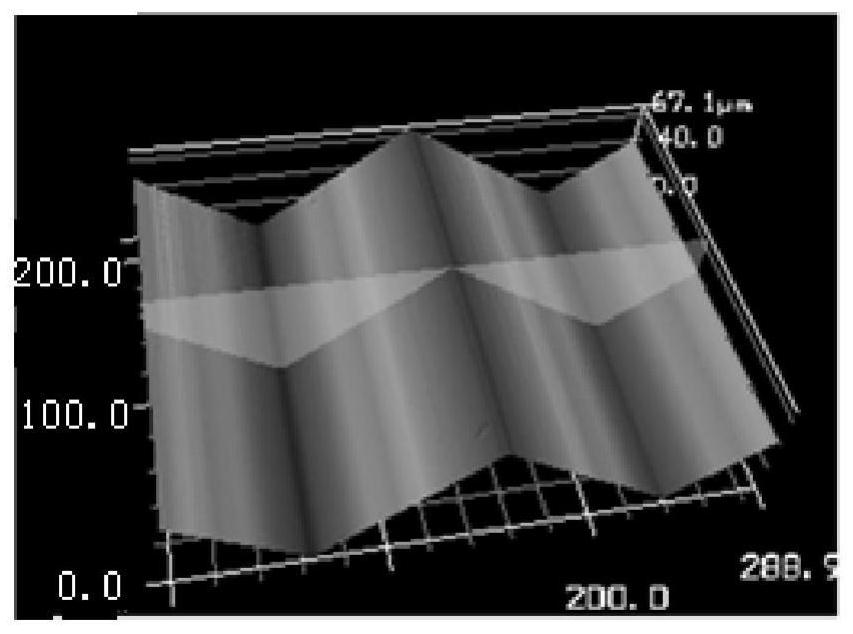

Method for modifying microporous membrane wettability by utilizing low pressure-forced Cassie state effect

ActiveCN102366712AAchieve superhydrophobic effectLower free energySemi-permeable membranesMicro nanoFine structure

The invention discloses a method for modifying microporous membrane wettability by utilizing a low pressure-forced Cassie state effect. The method comprises the step of: inducing a liquid drop on a microporous membrane with the aperture of 10-100 mu m to be changed from a Wenzel state to a Cassie state at the room temperature by utilizing relative pressure of 100-300 Pa, so as to modify interfacial wettability property of the microporous membrane. Before the implementation of the above-mentioned step, preferably, surface finish is performed on the microporous membrane by adopting a surface modification technology. Under a same micropore structure, the larger the contact angle of the liquid drop on the surface of the modified microporous membrane is, the smaller the critical pressure of the forced Cassie state of the microporous membrane is. The invention provides a novel approach for designing a superhydrophobic surface. Compared with the common superhydrophobic surface, the microporous membrane has the advantages of reducing the degree of dependence on a low surface energy substance and a surface micro-nano fine structure, and decreasing the probability of failure of the surface superhydrophobic function when external pressure and the surface fine structure are damaged, therefore wide application prospect is obtained.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of hydrophobic nanocellulose material

InactiveCN112898441AGood biocompatibilityPromote degradationCellulose derivative coatingsCross linkerBiocompatibility

The invention belongs to the field of preparation of hydrophobic materials, and particularly relates to a preparation method of hydrophobic nanocellulose. According to the preparation method of the hydrophobic nanocellulose, tannic acid or dopamine with good biocompatibility is used as a cross-linking agent, alkylamine is grafted to the surface of the nanocellulose through covalent bonds, an alkylamine-nanocellulose hydrophobic material is used as a hydrophobic coating, and after the hydrophobic coating is sprayed on the surface of a base material, on one hand, the chemical hydrophobic capacity of alkylamine is reserved, on the other hand, a coarse micro-nano structure is formed on the surface of the material in cooperation with nanocellulose, the good hydrophobic effect is achieved, the hydrophobic performance and durability are obviously improved, and the super-hydrophobic effect of the material can be achieved.

Owner:湖州闪思新材料科技有限公司

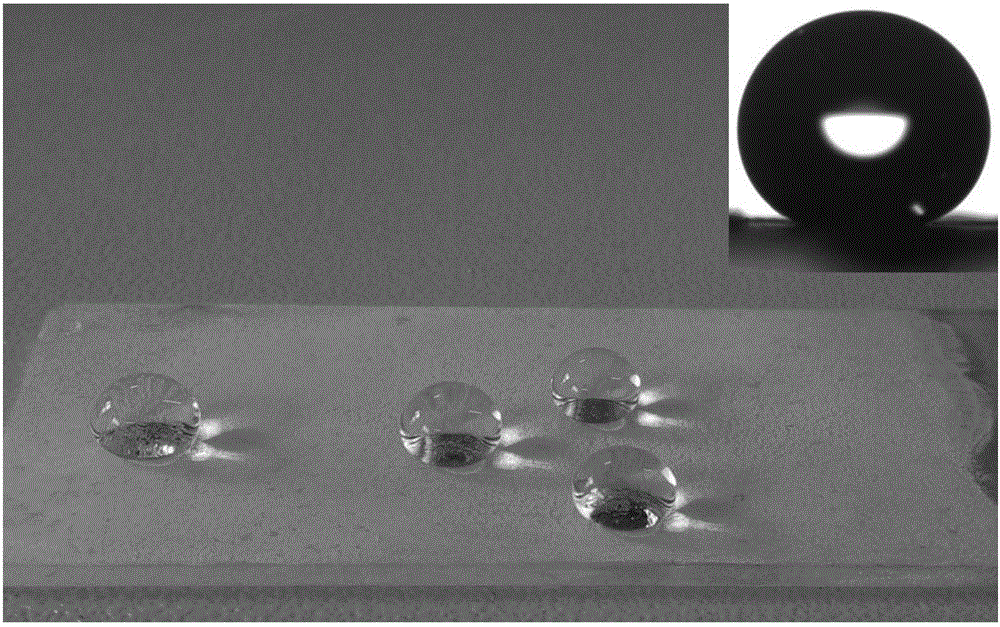

Preparation method of sanitary ware with super-hydrophobicity surface

InactiveCN101724166AAchieve superhydrophobic effectSimple production processPolymer scienceRolling angle

The invention discloses a preparation method of a sanitary ware with a super-hydrophobicity surface, belonging to the field of surface modification of high polymer materials and polymer-based sanitary ware article materials. The invention comprises the following steps of firstly preparing a plastic plate with a certain size by using ultra high molecular weight polyethylene materials through press forming or extrusion forming, then carrying out heating treatment on the ultra high molecular weight polyethylene plate, carrying out vacuum suction moulding under the temperature of about 120 DEG C, and carrying out wind cooling shaping so as to enable the ultra high molecular weight polyethylene plate to become a household sanitary ware plastic panel. The sanitary ware panel after forming is treated three times by fast surface etching treatment by using hot solution including xylene through a physical method, and therefore, the material surface has larger static contact angle and also a smaller rolling angle so as to enable the sanitary ware material surface to display the effect of a water drop dripping on a lotus leaf, and the invention becomes the sanitary ware article materials with the super-hydrophobicity surface.

Owner:JIANGNAN UNIV +1

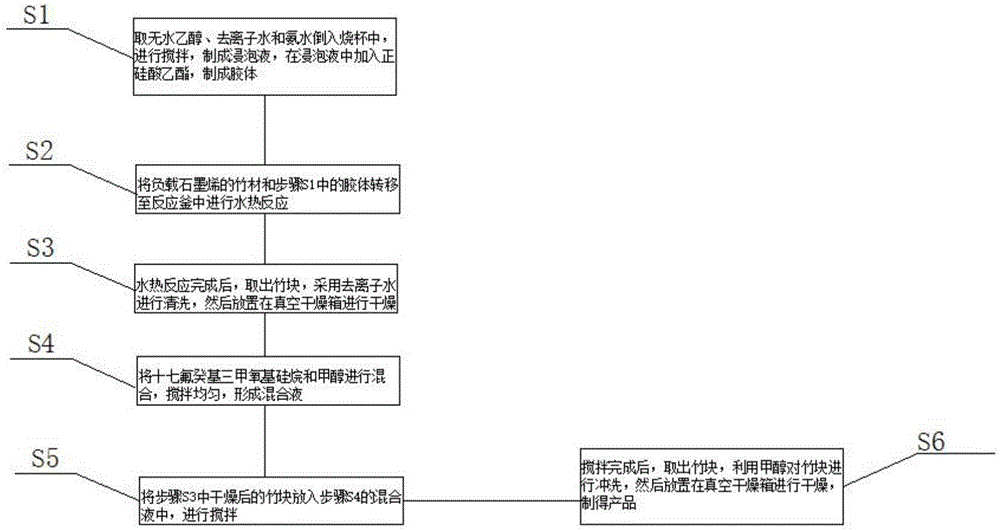

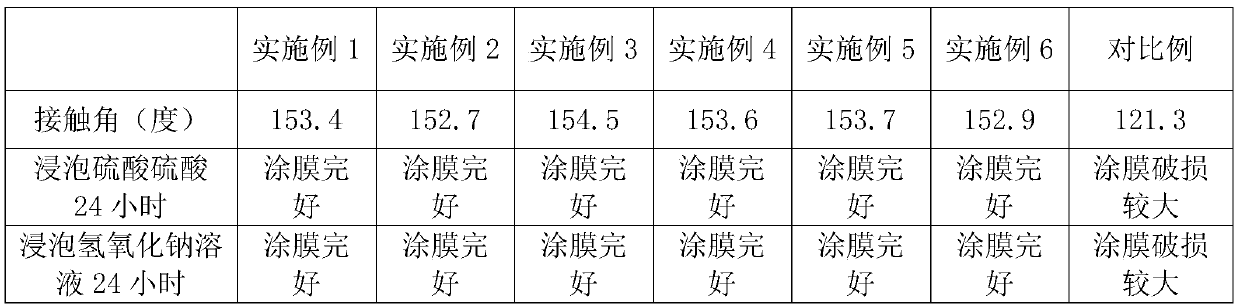

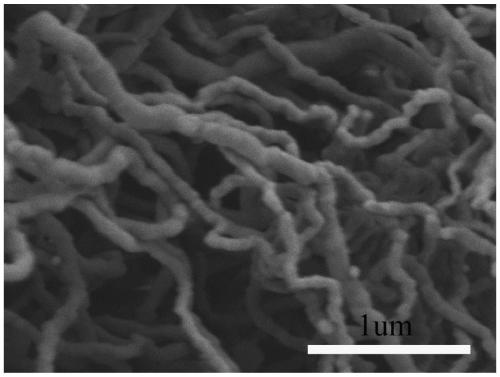

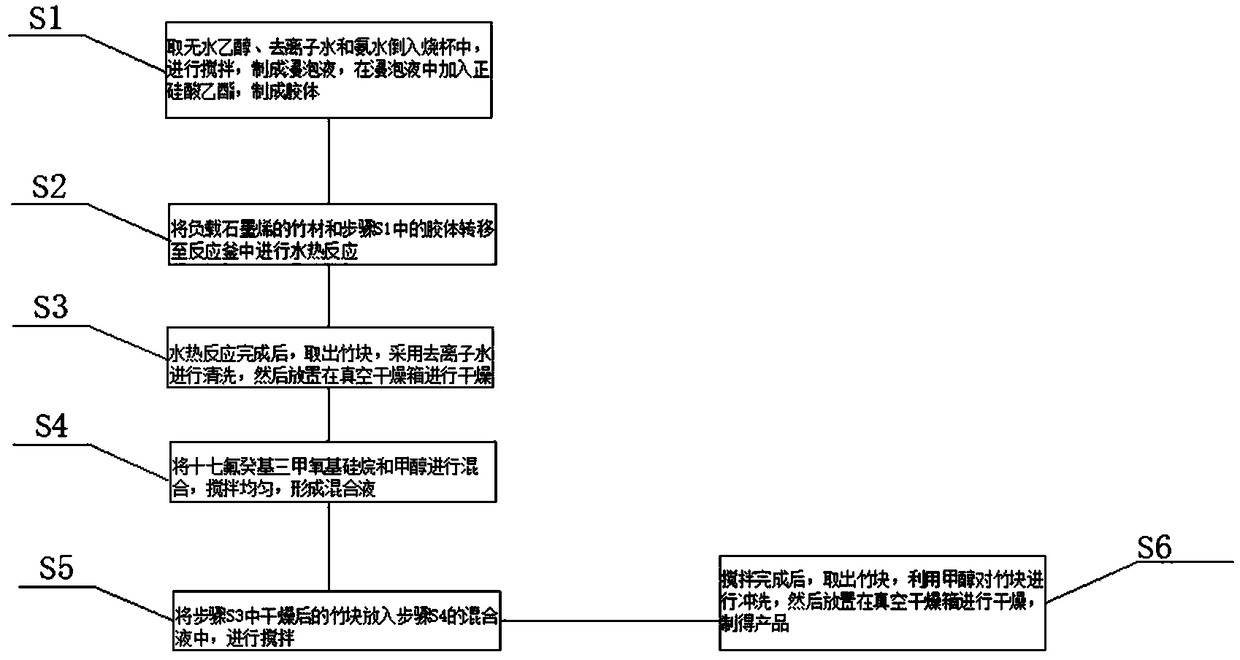

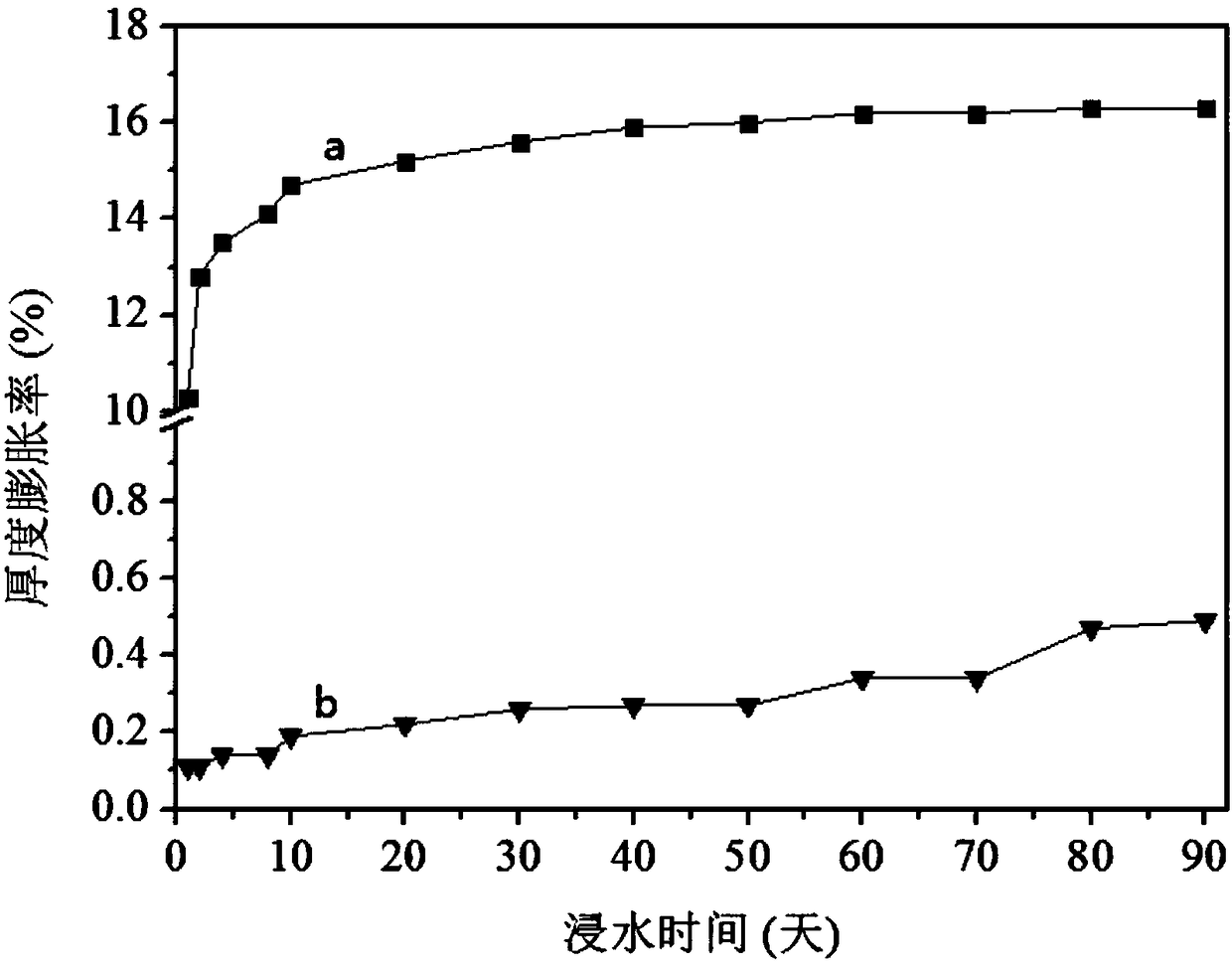

Hydrophobic bamboo wood with surface being loaded with oxidized graphene and silicon dioxide and production technology thereof

ActiveCN106827139AImprove hydrophobicityLower surface energyWood treatment detailsReed/straw treatmentAlcoholSilanes

The invention discloses a production technology of hydrophobic bamboo wood with the surface being loaded with oxidized graphene and silicon dioxide, and relates to the technical field of composite materials. The production technology includes the following steps that S1, absolute ethyl alcohol, deionized water and ammonia water are collected to be poured into a beaker for stirring, so that a soak solution is prepared, and TEOS is added into the soak solution to obtain colloid; S2, the bamboo wood loaded with the oxidized graphene and the colloid in the step S1 are transferred into a reaction still to carry out a hydrothermal reaction; S3, after the hydrothermal reaction is completed, a bamboo block is taken out and cleaned with the deionized water, and then the bamboo block is put into a vacuum drying oven to be dried; S4, heptadecafluorodecyl trimethoxy-silane and methyl alcohol are mixed to be evenly stirred, so that mixed liquor is formed; S5, the bamboo block dried in the step S3 is put into the mixed liquor of the step S4 to be stirred; and S6, after stirring is completed, the bamboo block is taken out and is washed with the methyl alcohol, and then the bamboo block is put into the vacuum drying oven to be dried so that a product can be prepared. By the adoption of the production technology, the technical problem that bamboo wood prepared in the prior art cannot meet the hydrophobic requirement is solved.

Owner:ZHEJIANG FORESTRY ACAD

A preparation method and product of a superhydrophobic polymer composite coating containing nanoparticles

ActiveCN103992701BEliminate tedious preparation stepsAchieve superhydrophobic effectCoatingsPigment treatment with organosilicon compoundsHydrophobic polymerSuperhydrophobic coating

The invention discloses a method for preparing a super hydrophobic polymer composite coating containing nano particles. The method comprises the following steps: firstly, mixing a coupling agent with a hydrolysis promoter and deionized water to carry out hydrolysis at normal temperature; adding the nano particles, reacting at 50-100 DEG C for 0.25-5 hours under magnetic agitation, so as to obtain modified nano particle powder by post-treatment; sieving the modified nano particle powder, and mixing with a fluorine-containing polymer emulsion; and evenly agitating after diluting by a diluent, coating on a metal substrate, and cooling to room temperature after high-temperature solidification and annealing treatment. The invention proposes a simple method for preparing the super hydrophobic polymer composite coating containing the nano particles. The nano particles are modified by the coupling agent, meanwhile, the adjusting process of pH in the hydrophobic treating process of the nano particles is removed, the modified nano particles are added to the polymer composite coating, and the stable target is achieved by interaction of bonding of a nano particle-coupling agent and a fluorine-containing polymer molecular chain.

Owner:中国人民武装警察部队杭州士官学校

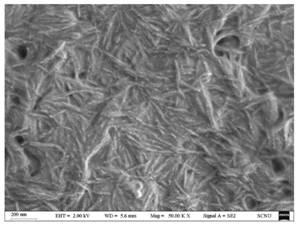

Diamond thin film of multi-level micro-nano structure and preparation method and application thereof

ActiveCN111334777AChemically stableImprove impact performanceChemical vapor deposition coatingSuperhydrophobeNano structuring

The invention discloses a diamond thin film of a multi-level micro-nano structure and a preparation method and application thereof and relates to the technical field of diamond thin films. The diamondthin film comprises a discontinued micron-sized diamond island which is formed from the surface of a substrate to the exterior in sequence and the multi-level micro-nano structure which is similar tothe mastoid process of the lotus leaf and is formed by a nano diamond film layer composed of continuous nano-sized diamond grains. The preparation method of the diamond thin film comprises the following steps that first, low-density crystal implantation is performed on the substrate, and primary growth of diamond is performed through a heat wire chemical vapor deposition method; and then, high-density crystal implantation is performed on the primary growth diamond thin film, and secondary growth of diamond is performed through the heat wire chemical vapor deposition method. The diamond thin film is of the multi-level micro-nano structure similar to the mastoid process of the lotus leaf, forms a bionic super-hydrophobic surface, and is high in hydrophobicity and self-cleaning capacity, resistant to corrosion and long in service life. The preparation method is easy to implement, high in applicability and suitable for industrial production and has a simple and stable process.

Owner:SHENZHEN INST OF ADVANCED TECH

Super-hydrophobic modification method of nanocellulose

InactiveCN113773404ALoose structureReinforced hydrophobic long chainsUltrasonic oscillationCarboxylic group

The invention relates to super-hydrophobic modification of nanocellulose, and provides a super-hydrophobic modification method of nanocellulose. The method comprises the following steps: preparing nanocellulose with different carboxyl contents by utilizing a method of combining a TEMPO / NaClO / NaBr oxidation system and ultrasonic oscillation, and selecting octadecylamine with low surface energy as a hydrophobic modifier, wherein a hydrophobic long chain can be grafted on the surface of the nanocellulose by carboxyl in the nanocellulose and amino in the octadecylamine through complexation reaction; and selecting an adhesive substance polydopamine, and coating the surface of the modified nanofiber with the selected substrate, so that not only can an octadecylamine long chain grafted with the nanocellulose be protected, but also free octadecylamine in a system can be adsorbed on the surface of the nanocellulose. The prepared hydrophobic nano cellulose film is applied to the fields of oil-water separation, waterproof films and the like.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

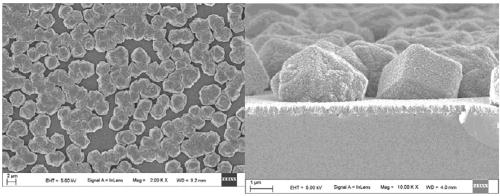

Electrolyte for realizing blackening of magnesium alloy surface and blackening process method

ActiveCN111910238AColor has no effectColor effectAnodisationProcess efficiency improvementElectrolytic agentMicro arc oxidation

The invention provides an electrolyte for realizing blackening of a magnesium alloy surface and a blackening process method. A coloring solution of a silicic acid system is adopted, and the coloring solution comprises additives such as ferric ammonium citrate and the like. In the coloring process, a magnesium alloy is subjected to down-current two-step constant-current micro-arc oxidation treatment in a prepared micro-arc oxidation solution to prepare a black ceramic membrane. In order to further improve the corrosion resistance and the stability of a membrane layer, hole sealing treatment iscarried out in hole sealing liquid. The coloring micro-arc oxidation solution is safe, environmentally friendly and high in stability, by optimizing a micro-arc oxidation manner, positive and negativecurrent density parameters are adjusted, self-repairing hole sealing is carried out on the interior of the membrane layer, the problems that the surface is loose and porous, and the thickness of a compact inner layer is small are solved, membrane layer compactness control is achieved, the membrane layer is thicker and more compact, finally the hole sealing liquid is good in stability, the influence on the color of the membrane layer does not exist, and the corrosion resistance is improved. By means of the technology, blackening treatment of the magnesium alloy is achieved, and the applicationfield of the magnesium alloy is broadened.

Owner:CHANGZHOU UNIV

Organosilicone-acrylate nanometer emulsion and preparation method thereof

ActiveCN105504141AGood acid and alkali resistanceIncrease contact angleNanotechnologyAnti-corrosive paintsZinc hydroxideEmulsion

The invention provides organosilicone-acrylate nanometer emulsion. The organosilicone-acrylate nanometer emulsion is prepared through the following steps that 1, nanometer zinc hydroxide is prepared; 2, organizing treatment is performed on the nanometer zinc hydroxide; 3, a mixed monomer is prepared and mixed with the organized zinc hydroxide to form a monomer mixture, and an initiator solution and an emulsifier solution are prepared; 4, the monomer mixture and an organosilicone monomer are processed through emulsion polymerization through the initiator and the emulsifier. The organosilicone-acrylate nanometer emulsion has the super hydrophobicity and the very good acid and alkali resistance.

Owner:济南实成有机硅科技有限公司

Method for preparing sprayable super-hydrophobic coating with heat storage capacity

ActiveCN111375536AImprove wear resistanceGood acid and alkali resistanceAnti-corrosive paintsSpecial surfacesPolymer scienceSpinning

The invention relates to a method for preparing a sprayable super-hydrophobic coating with heat storage capacity. According to the method, mesoporous crosslinked polystyrene nanotubes and fluorated silicon dioxide pellets are dispersed into the volatile solvent dissolved with a tackiness agent and a phase-change material, and a blended spinning solution is sprayed onto a substrate material with aone-step method. By adoption of the method, the super-hydrophobic energy storage coating is prepared through the one-step spraying method, and the process of preparing composite phase-change materialsis omitted; and moreover, the heat storage capacity and super-hydrophobic performance are excellent, and a new road is opened up for practical preparation applications of the super-hydrophobic energystorage coating.

Owner:HEBEI UNIV OF TECH

Preparation method of mushroom-shaped metal column array surface with stratum structure

ActiveCN107574464AAchieve superhydrophobic effectHigh mechanical strengthNanotechnologyMicro structureApplication areas

The invention relates to a preparation method of a mushroom-shaped metal column array surface with a stratum structure. According to the preparation method, with a double-layer polycarbonate film withnano-holes and micron holes as a mold plate, a mushroom-shaped metal column array with the micro-nano stratum structure is prepared on the metal surface through an electroplating process. The mushroom-shaped metal column array has superhydrophobic performance after surface fluorination. According to the method, no expensive instrument equipment or complicated process procedures are needed, the method is simple and economical, the prepared surface micro structure is high in mechanical strength and high in durability, and the application field of super moistened surfaces can be extremely widened.

Owner:HUAQIAO UNIVERSITY

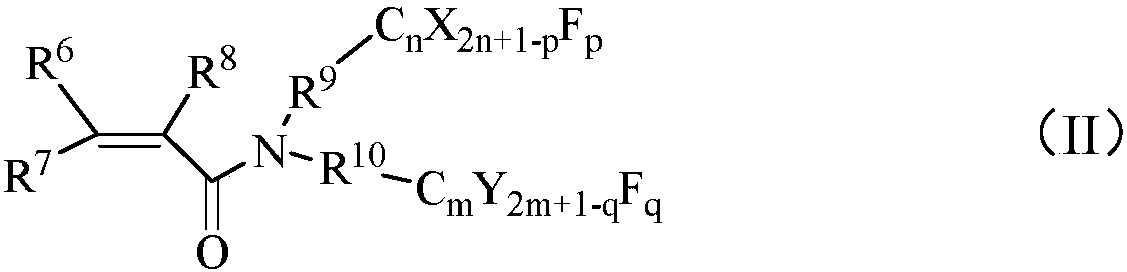

Acrylamide nano coating and preparation method thereof

ActiveCN109267040AReduce dosageTo achieve the protective effectChemical vapor deposition coatingConvex structureChemical reaction

The invention provides an acrylamide nano coating and a preparation method thereof. The acrylamide nano coating is characterized in that a substrate is exposed in a monomer steam atmosphere, and a chemical reaction is formed on the surface of the substrate through plasma discharge to form a protective coating; monomer steam is vaporizable monomer 1 or monomer 2, or a mixture of the monomer 1 and monomer 2. Through adoption of the method provided by the invention, a denser and more exquisite micro-convex structure is formed on the surface of the substrate, so that the coating with nano size hasexcellent acid and alkali resistance, corrosion resistance and a super-hydrophobic effect, and a contact angle can reach 150 degrees or above.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

Super-hydrophobic heat-resistant coating for aluminum alloy and preparation method of super-hydrophobic heat-resistant coating

InactiveCN114395326AAchieve superhydrophobicityAchieve heat resistanceMolten spray coatingPretreated surfacesThioureaCarboxylic acid

The invention discloses a super-hydrophobic heat-resistant coating for an aluminum alloy and a preparation method of the super-hydrophobic heat-resistant coating, and relates to the technical field of coatings. The heat-resistant coating is formed on the surface of the aluminum alloy through the spraying pretreatment process and the second-time spraying treatment in sequence, the heat-resistant coating and the aluminum alloy form a firm cross-linked interpenetrating network structure, the heat resistance of the coating is improved, and the phenomenon that the service life of the aluminum alloy is shortened in a high-temperature environment is reduced; and then third spraying treatment is conducted, a corrosion inhibitor serves as an inner core solution, stearic acid serves as a shell solution, a super-hydrophobic coating is formed through coaxial electrostatic spraying, the corrosion inhibitor is prepared from isoquinocarboxylic acid, dipropylene triamine and p-methoxyphenyl thiourea, the surface of the aluminum alloy is isolated from an environment medium, and corrosion of an acid medium and chloride ions is inhibited. The prepared super-hydrophobic heat-resistant coating for the aluminum alloy has the heat-resistant, super-hydrophobic and corrosion-resistant effects.

Owner:严平

A kind of hydrophobic bamboo with graphene oxide and silicon dioxide on its surface and its production process

ActiveCN106827139BImprove hydrophobicityLower surface energyWood treatment detailsReed/straw treatmentAlcoholSilanes

The invention discloses a production technology of hydrophobic bamboo wood with the surface being loaded with oxidized graphene and silicon dioxide, and relates to the technical field of composite materials. The production technology includes the following steps that S1, absolute ethyl alcohol, deionized water and ammonia water are collected to be poured into a beaker for stirring, so that a soak solution is prepared, and TEOS is added into the soak solution to obtain colloid; S2, the bamboo wood loaded with the oxidized graphene and the colloid in the step S1 are transferred into a reaction still to carry out a hydrothermal reaction; S3, after the hydrothermal reaction is completed, a bamboo block is taken out and cleaned with the deionized water, and then the bamboo block is put into a vacuum drying oven to be dried; S4, heptadecafluorodecyl trimethoxy-silane and methyl alcohol are mixed to be evenly stirred, so that mixed liquor is formed; S5, the bamboo block dried in the step S3 is put into the mixed liquor of the step S4 to be stirred; and S6, after stirring is completed, the bamboo block is taken out and is washed with the methyl alcohol, and then the bamboo block is put into the vacuum drying oven to be dried so that a product can be prepared. By the adoption of the production technology, the technical problem that bamboo wood prepared in the prior art cannot meet the hydrophobic requirement is solved.

Owner:ZHEJIANG FORESTRY ACAD

Method for preparing super hydrophobic polymeric coating using non-crystalline polymer

InactiveCN1272114CExcellent anticoagulant propertiesAchieve superhydrophobic effectSpecial surfacesPolycarbonate coatingsPhysical chemistrySolvent

The present invention relates to a method for preparing ultrahydrophobic high-molecular coating layer coated on the surface of solid by utilizing phase separation film-forming technique in the volatilizing process of noncrystalline high molecular in solvent under the normal temperature and normal pressure. Said method includes: dissolving noncrystalline high molecule in poor solvent at normal temperature, said solution concentration is 0.001-5 g / ml, then coating said poor solvent in which the noncrystalline high molecule is dissolved on the surface of solid to form film, making the solvent be volatilized and making noncrystalline high molecular soltue and poor solvent implement slow phase separation, finally forming rough ultrahydrophobic high-molecular coating layer on the surface of solid. Said invented ultrahydrophobic surface has good anticoagulant property.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Multifunctional oil-water separating material and preparing method and application thereof

ActiveCN110102083AIncrease roughnessAchieve superhydrophobic effectWater/sewage treatment by irradiationNon-miscible liquid separationOil waterCopper

The invention discloses a preparing method of a multifunctional oil-water separating material. The preparing method includes the following steps of S1, preprocessing a copper net to remove impuritieson the surface; S2, soaking the preprocessed copper net in a chloroauric acid solution for 1-2 hours to obtain a copper net loaded with Au / CuCl particles; S3, soaking the copper net obtained in the step S2 in a silver salt solution for 1-2 hours to obtain a copper net loaded with Au / AgCl particles on the surface; S4, modifying the surface of the copper net obtained in the step S3 through the PFDTto obtain the multifunctional oil-water separating material. The invention further discloses the multifunctional oil-water separating material prepared through the method and application of the material. The prepared multifunctional oil-water separating material can separate an oil-water mixture, can also detect low-concentration pollutants in oil-water mixed liquid and can effectively conduct photolysis on the pollutants.

Owner:SUZHOU UNIV

Preparation method of flexible fluoride-free super-hydrophobic coating with photothermal conversion and heat storage functions

ActiveCN114085610AStrong light-to-heat conversion abilityGood flexibilityChemical industryAnti-corrosive paintsAdhesive cementMesoporous silica

The invention relates to a preparation method of a flexible fluoride-free super-hydrophobic coating with photothermal conversion and heat storage functions. According to the method, polydimethylsiloxane is introduced as an adhesive, the adhesive and a phase change material are dissolved in a solvent, then carbon-doped mesoporous silica nanotubes are dispersed in the system, and finally a blended solution is sprayed on a substrate in a spraying manner, so that the flexible fluorine-free super-hydrophobic coating with photothermal conversion and heat storage functions is obtained. The process of preparing a composite phase change material and hydrophobic modification is omitted, and the coating not only has excellent photothermal conversion capacity, but also has good flexibility and excellent super-hydrophobic performance, is simple to construct and low in preparation cost, and has huge practical application value.

Owner:HEBEI UNIV OF TECH

Preparation method of super-hydrophobic and dust-proof stainless steel filter screen

ActiveCN109364581AImprove stabilityImprove surface roughnessDispersed particle filtrationMembrane filtersAir purifiersFresh air

The invention belongs to the field of new materials, and provides a preparation method of a super-hydrophobic and dust-proof stainless steel filter screen. The method comprises the steps: forming a gully-like structure on the surface of a stainless steel filter screen by etching, further attaching a super-hydrophobic and photocatalytic substance coating to obtain the super-hydrophobic filter screen. The filter screen has low surface energy and catalytic properties of nano materials, and can reduce the adhesion of dust, oils and dirt, catalyze the degradation of harmful gases, and has antibacterial activity, and can be used in air purification systems such as air purifiers and fresh air systems, and household filtering systems such as kitchen ventilator, refrigerators and air conditioners.The preparation method of the filter screen is simple, mild in reaction conditions and suitable for large-scale production.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

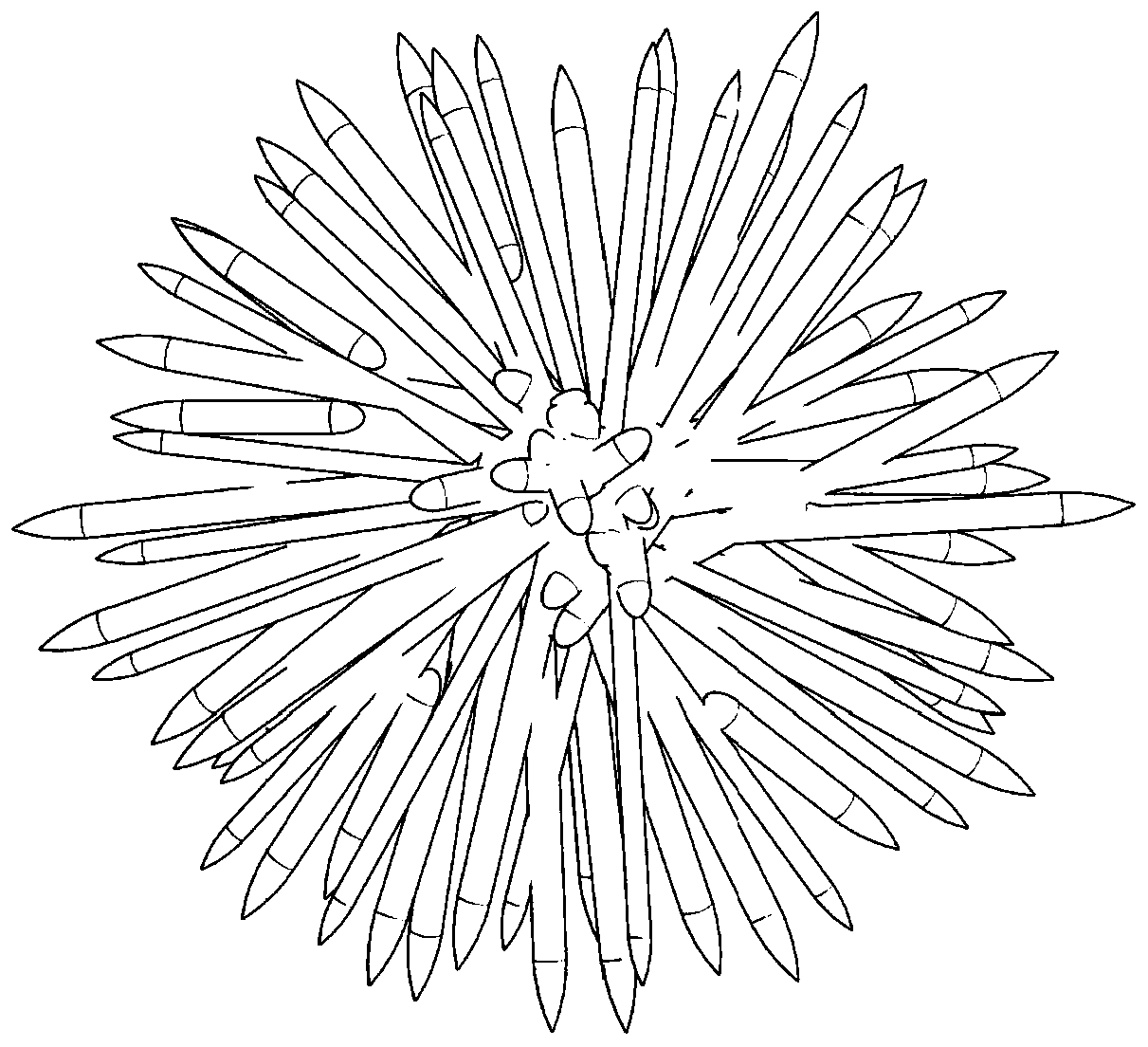

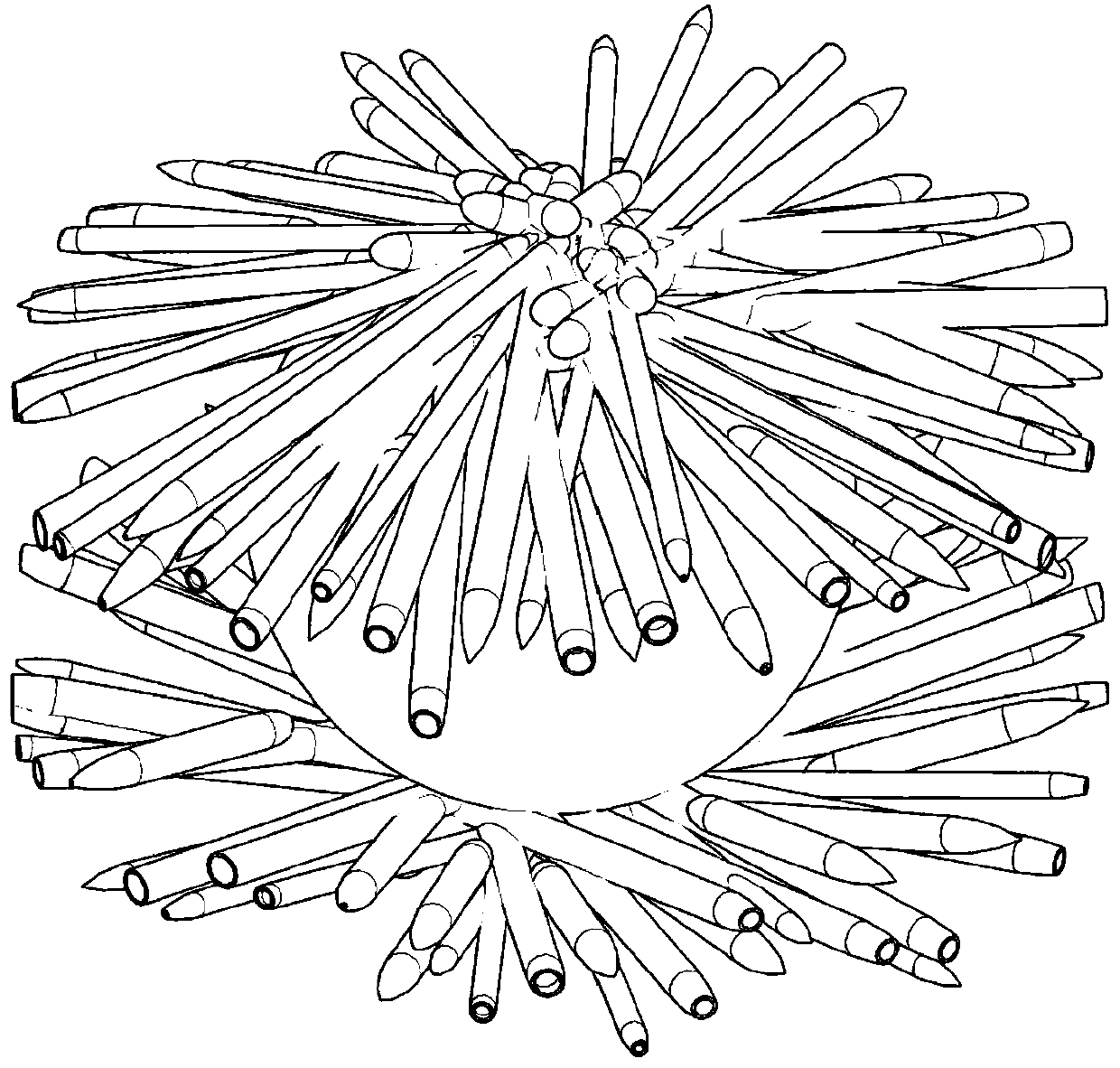

Preparation method of super-hydrophobic anticorrosive self-assembled three-dimensional nano material

ActiveCN109971231AImprove solvencyImprove liquidityAnti-corrosive paintsBulk chemical productionCoating systemCorrosion resistant

The invention discloses a preparation method of a super-hydrophobic anticorrosive self-assembled three-dimensional nano material. The method comprises the following steps: firstly, preparing dahlia-like carbon nanohorns by adopting an electric arc discharge method, and performing transient oxidation treatment on the carbon nanohorns to obtain an open-cell carbon nanohorn material; and fully mixingnano zinc ethanol slurry and the carbon nanohorn material, and performing self-assembly compounding on the carbon nanohorns and nano zinc by adopting a supercritical fluid method to form the three-dimensional pearl mussel-like structural material. According to the preparation method provided by the invention, the carbon nanohorn-nano zinc composite material prepared by adopting the method has a simple process, synergy of a super-hydrophobic structure of the carbon nanohorns and corrosion resistance of the nano zinc in the coating system can physically block a reaction of a metal surface withan active medium, and effectively protect elemental zinc against corrosion by a liquid and oxidation by the air, thereby greatly improving a zinc utilization rate and corrosion resistant efficiency; and the composite material can be widely used in the fields of architectural coatings and industrial anticorrosive coatings to improve compactness, barrier properties, mechanical properties and corrosion resistance of films.

Owner:上海利物盛纳米科技有限公司

A kind of photocuring coating, ultraviolet light curing hydrophobic anti-adhesion film surface and preparation method thereof

ActiveCN109181521BImprove hydrophobicityThe water contact angle does not decreaseAntifouling/underwater paintsPaints with biocidesPhotoinitiatorMicrostructure

The invention provides a light-cured coating, an ultraviolet light-cured hydrophobic anti-adhesion film surface and a preparation method thereof. The light-cured coating comprises the following components in parts by weight: 15-30 parts of polyurethane acrylate, 10-30 parts of nano Particles, 2-4 parts of photoinitiator, 1-15 parts of perfluoropolyether, 5-15 parts of perfluoro-modified long-chain alkylsilane and 30-50 parts of solvent. The invention uses polyurethane acrylate, perfluoropolyether and perfluoromodified long-chain alkyl silane to compound nanoparticles, so that the photocurable coating is crosslinked through photocuring reaction to form a tight coating, which has wear resistance and forms a cured coating. The super-hydrophobic microstructure of the substance enhances its hydrophobicity. Through the microstructure formation and ultraviolet curing methods, a concave-convex microstructure is produced on the surface of the prepared film, which produces a lotus leaf effect, enhances hydrophobicity, and achieves superhydrophobicity. Production Afterwards, it can be rolled directly without the need for a protective film, saving costs.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com