Electrolyte for realizing blackening of magnesium alloy surface and blackening process method

A process method, magnesium alloy technology, applied in the direction of surface reaction electrolytic coating, electrolytic coating, process efficiency improvement, etc., can solve the problems of rough surface of the film layer, accompanied by cracks, cumbersome process, etc., to reduce the instability of yield properties, increase the thickness and compactness, and the effect of dense film structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

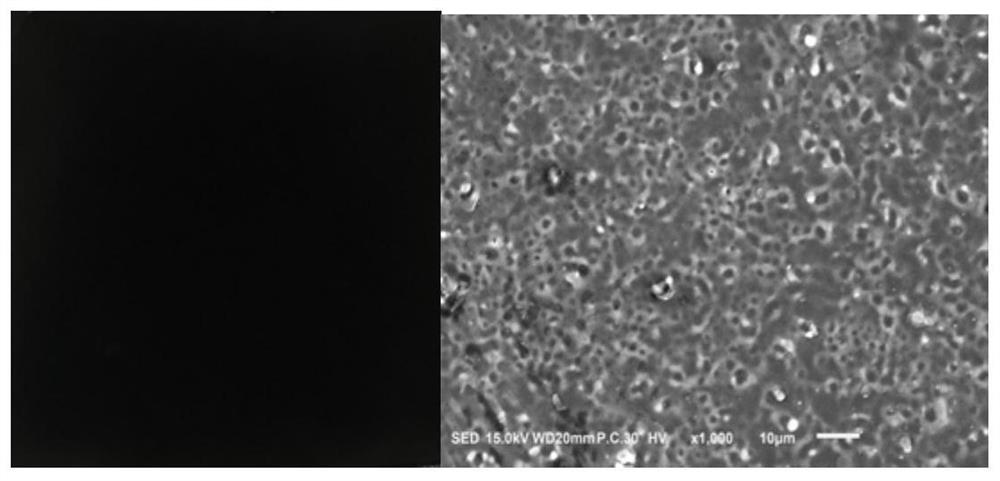

Image

Examples

Embodiment 1

[0022] (1) The first step is to prepare the colored electrolyte: add 20g of silicate, 10g of potassium fluoride, 10g of sodium hydroxide, 10g of ferric ammonium citrate, 5g dihydroxyethylglycine, 4g methyl benzotriazole, use high-speed homogenizer to disperse the solution for 5 minutes, and prepare colored electrolyte.

[0023] (2) Under the double-pulse micro-arc oxidation power supply of HNMAO-20A-500DPM, two-step constant current micro-arc oxidation treatment is performed: the polished magnesium alloy is used as the anode, the stainless steel plate is used as the cathode, and the anode is soaked in the step (1 ) described in the colored electrolyte, and set the process parameters, the first step is specifically: the forward current density is 8A / dm 2 , the negative current density is 2A / dm 2 , the positive duty ratio is 30%, the negative duty ratio is 30%, and the frequency is 400Hz. Under these process parameters, the first step of constant current micro-arc oxidation tre...

Embodiment 2

[0026] (1) The first step is to prepare the colored electrolyte: add 30g silicate, 10g potassium fluoride, 10g sodium hydroxide, 10g ferric ammonium citrate, 10g bishydroxyethylglycine, 4g methyl benzotriazole, use the high-speed homogenizer to disperse the solution for 5 minutes, and prepare the colored electrolyte.

[0027] (2) Under the double-pulse micro-arc oxidation power supply of HNMAO-20A-500DPM, two-step constant current micro-arc oxidation treatment is performed: the polished magnesium alloy is used as the anode, the stainless steel plate is used as the cathode, and the anode is soaked in the step (1 ) described in the colored electrolyte, and set the process parameters, the first step is specifically: the forward current density is 7A / dm 2 , the negative current density is 3A / dm 2 , the positive duty ratio is 30%, the negative duty ratio is 30%, and the frequency is 400Hz. Under these process parameters, the first step of constant current micro-arc oxidation treat...

Embodiment 3

[0030] (1) The first step is to prepare the colored electrolyte: add 40g of silicate, 10g of potassium fluoride, 10g of sodium hydroxide, 15g of ferric ammonium citrate, 10g bishydroxyethylglycine, 4g methyl benzotriazole, use the high-speed homogenizer to disperse the solution for 5 minutes, and prepare the colored electrolyte.

[0031] (2) Under the double-pulse micro-arc oxidation power supply of HNMAO-20A-500DPM, two-step constant current micro-arc oxidation treatment is performed: the polished magnesium alloy is used as the anode, the stainless steel plate is used as the cathode, and the anode is soaked in the step (1 ) described in the colored electrolyte, and set the process parameters, the first step is specifically: the forward current density is 6A / dm 2 , the negative current density is 5A / dm 2 , the positive duty ratio is 30%, the negative duty ratio is 30%, and the frequency is 400Hz. Under these process parameters, the first step of constant current micro-arc oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com