Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

190results about How to "With self-cleaning ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional graphene/high-molecular composite material water permeable membrane, preparation method, and application thereof

InactiveCN106492654AGood acid and alkali resistanceImprove antibacterial and anti-pollution abilitySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPolymer scienceFiltration

The invention relates to a multifunctional graphene / high-molecular composite material water permeable membrane, a preparation method, and an application thereof. A high-molecular moisture-conductive polymer and a graphene-based composite material are organically bonded in a manner of forming effective chemical bonds, such as a hydrogen bond, an ionic bond, a covalent bond and the like, through polar functional groups, thereby forming a water permeation channel with reinforced hydrophilic-hydrophobic groups on the basis of the moisture-conductive polymer, and meanwhile, significantly improving the mechanical strength, anti-friction strength and acid- and alkali-resistant property, anti-bacterial and anti-fouling capabilities, heat conductivity and heat resistance and the like characters. The multifunctional composite water permeable membrane has long service life, is free of replacement during operation and has self-cleaning capability, and can be applied in the field of whole-heat exchanger, humidity conditioner, sewage treatment and other fields requiring water permeation or water filtration.

Owner:中山市创思泰新材料科技股份有限公司

Treatment method of zinc-bearing dust for steel works

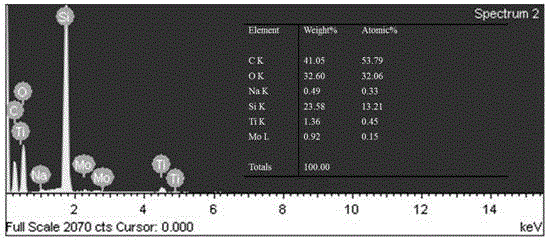

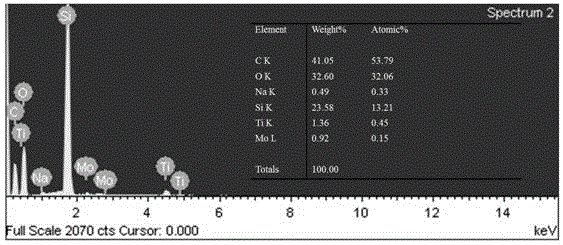

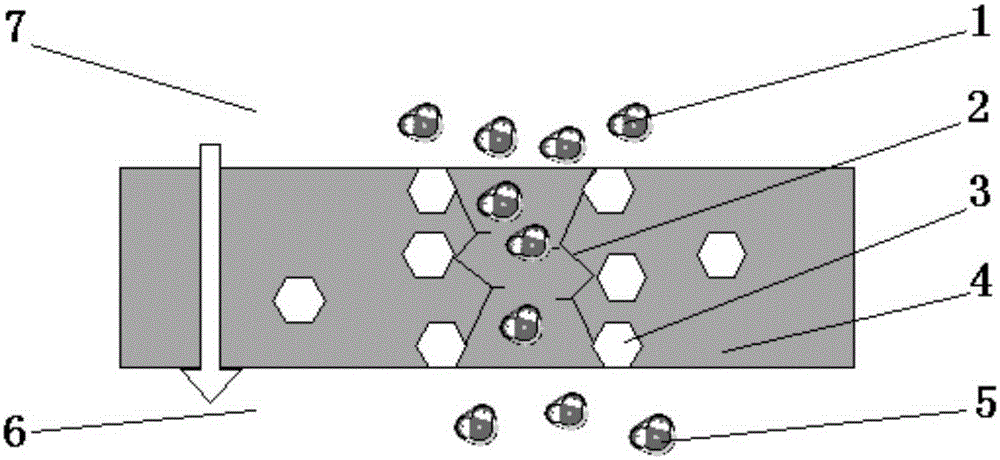

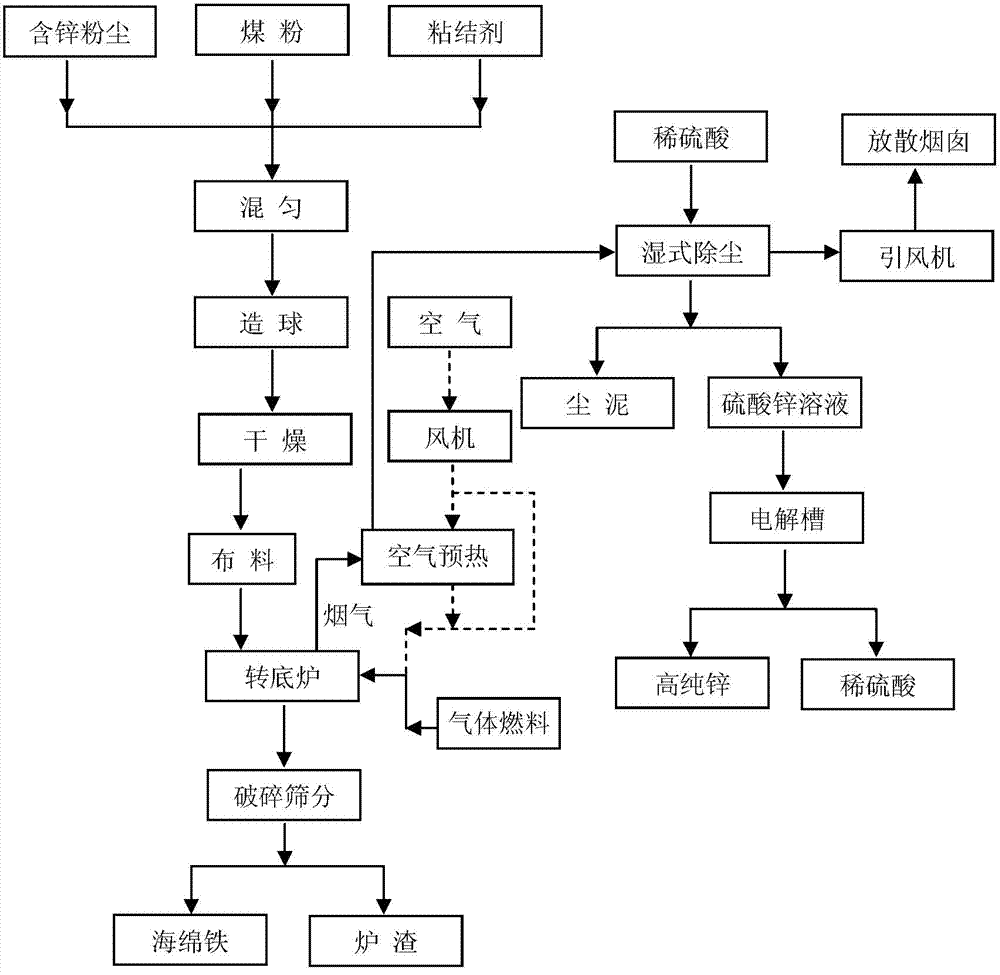

InactiveCN102776309AAvoid affecting smooth operationWith self-cleaning abilityGas emission reductionHearth type furnacesHearthTreatment system

The invention relates to a treatment method of zinc-bearing dust for steel works. The treatment method includes mixing the zinc-bearing dust, pulverized coal and binder prior to pelletizing, feeding pellets into a rotary hearth furnace, reducing ferric oxide into sponge iron and cinder in the high-temperature reducing atmosphere in the rotary hearth furnace, exhausting the reduced zinc out of the rotary hearth furnace with smoke of the rotary hearth furnace, using the high-temperature smoke to preheat rotary hearth furnace combustion air, introducing the smoke into a wet dust remover, allowing the zinc in the rotary hearth furnace to react with dilute sulfuric acid sprayed into the wet dust remover to generate zinc sulfate solution, electrolyzing the zinc sulfate solution to obtain high purity zinc, and exhausting the purified smoke from a dispersing chimney. By the treatment method, affection of operation of a whole smoke treatment system by accumulation and bulging of zinc vapor in the smoke treatment system is avoided, and operating efficiency of the rotary hearth furnace is improved. In addition, the invention provides the zinc-bearing dust treatment method which can also be used to produce high purity zinc.

Owner:WISDRI ENG & RES INC LTD

Nano inorganic germicide and its preparation method

InactiveCN1589630AImprove antibacterial propertiesGood effectBiocideAnimal repellantsChemical compositionCompound (substance)

An inorganic nano-bacterial agent is prepared from nano-zinc oxide and water-soluble metal salt through chemical coposition, washing, drying and calcining.

Owner:骆天荣

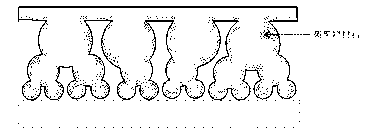

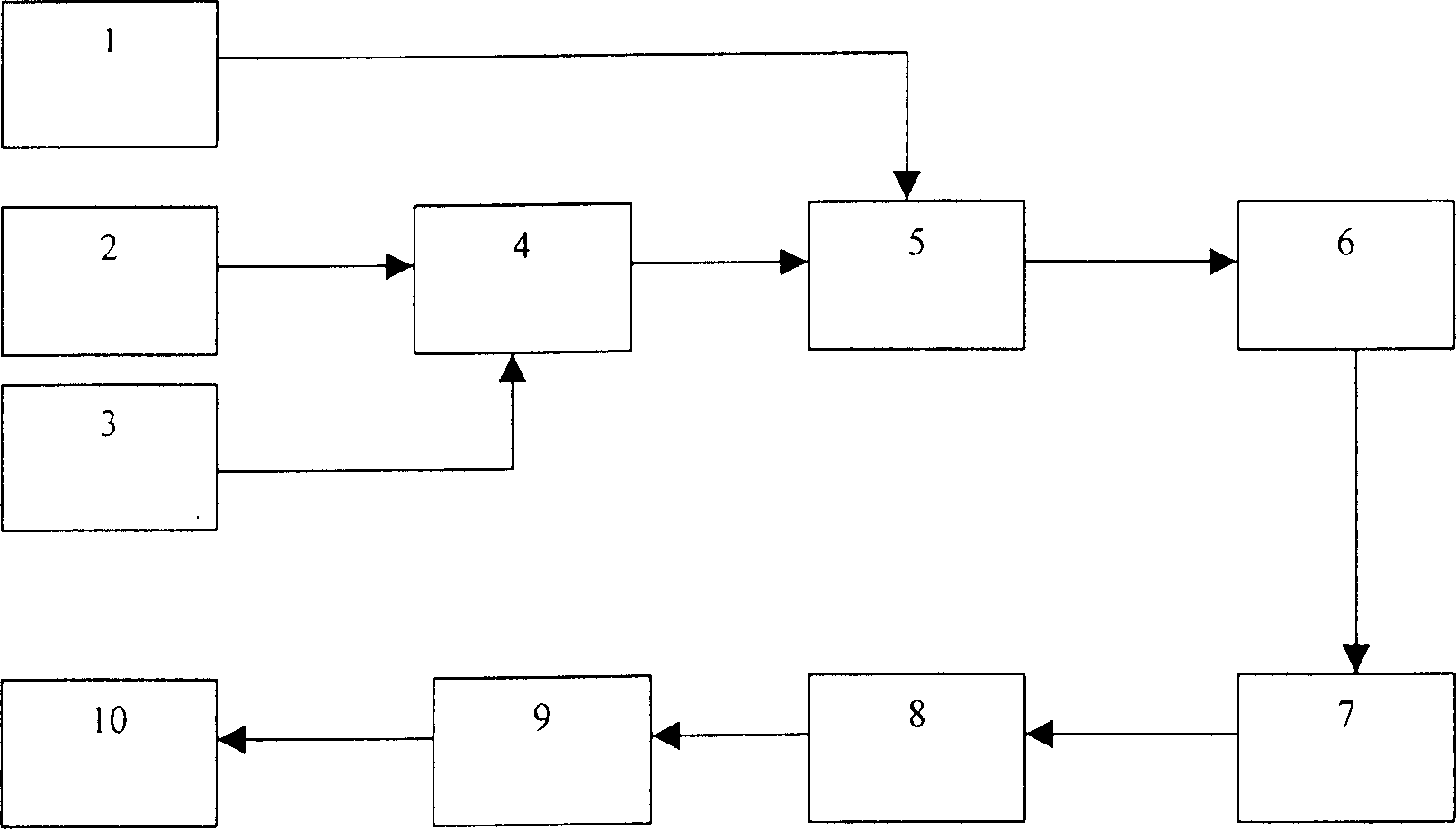

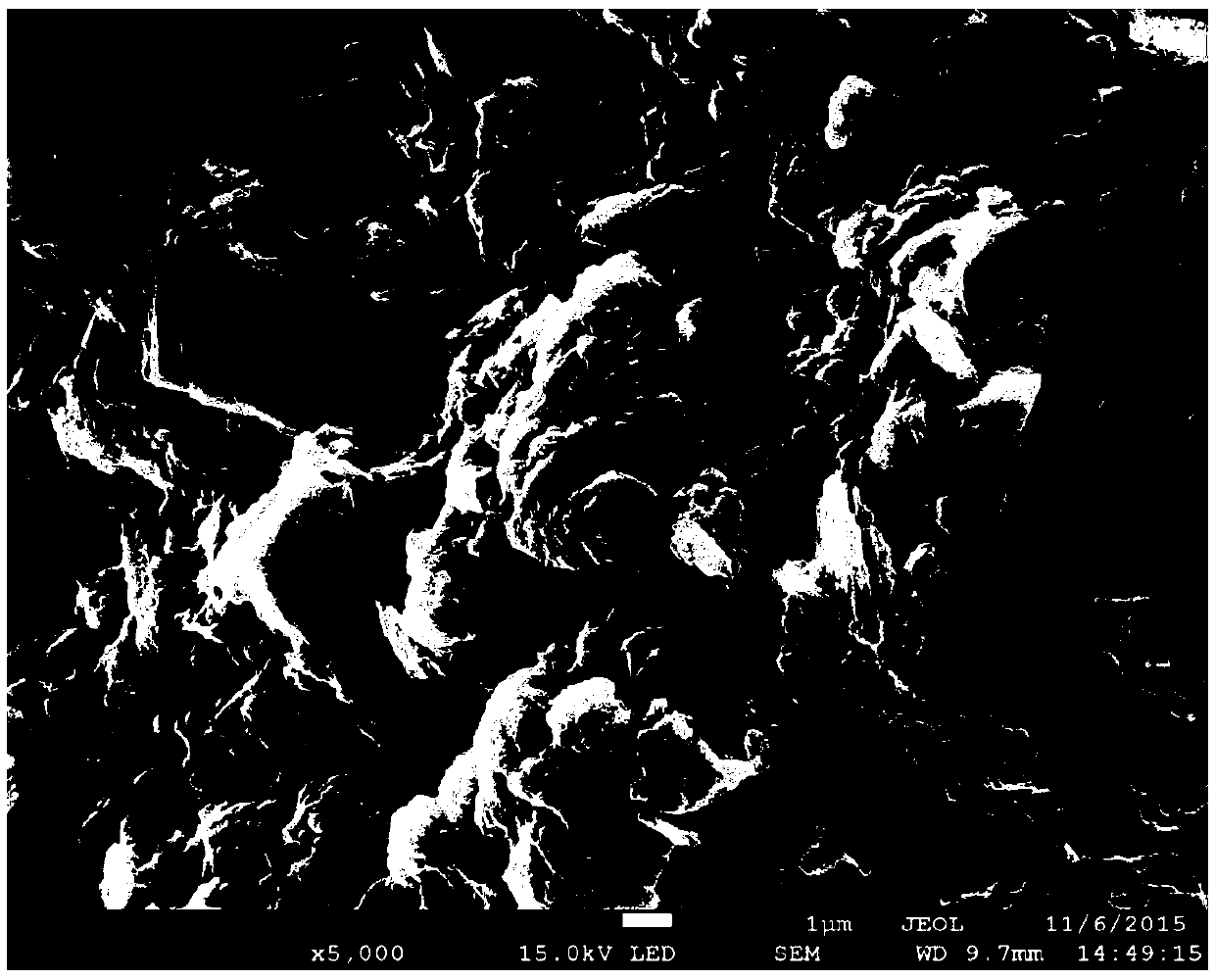

Preparation method of gecko structure simulating adhesive

InactiveCN103274354AGood removal effectLow costNon-macromolecular adhesive additivesDecorative surface effectsAdhesiveElectrochemistry

The invention discloses a preparation method of a gecko structure simulating adhesive and relates to a preparation method of a gecko foot simulating microarray. The preparation method of the gecko structure simulating adhesive, disclosed by the invention comprises the following steps of: (1) preparing a porous metal film by using a hydrogen bubble template method; (2) mixing a high polymer with a cross-linking agent, vacuumizing, pouring the mixed liquor on a template of the porous metal plate for curing; and (3) removing a base and the porous metal template by using chemical and electrochemical methods. The preparation method disclosed by the invention is easy to operate and needs no complex instruments; experiment parameters are controllable; and a prepared gecko foot simulating microarray structure has very high adsorption capacity, also can be easily separated from the absorptive surface and simultaneously has super-hydrophobicity and self-cleaning capability. For the gecko foot simulating microarray prepared by using the hydrogen bubble template method and taking porous metal as a template, the area is 0.1-5 square centimeters, the diameter is 0.5-100 micrometers, the height is 0.5-20 micrometers, the elasticity modulus of a material is 1-15GPa, and the shear strength is 1-150kPa.

Owner:HARBIN INST OF TECH

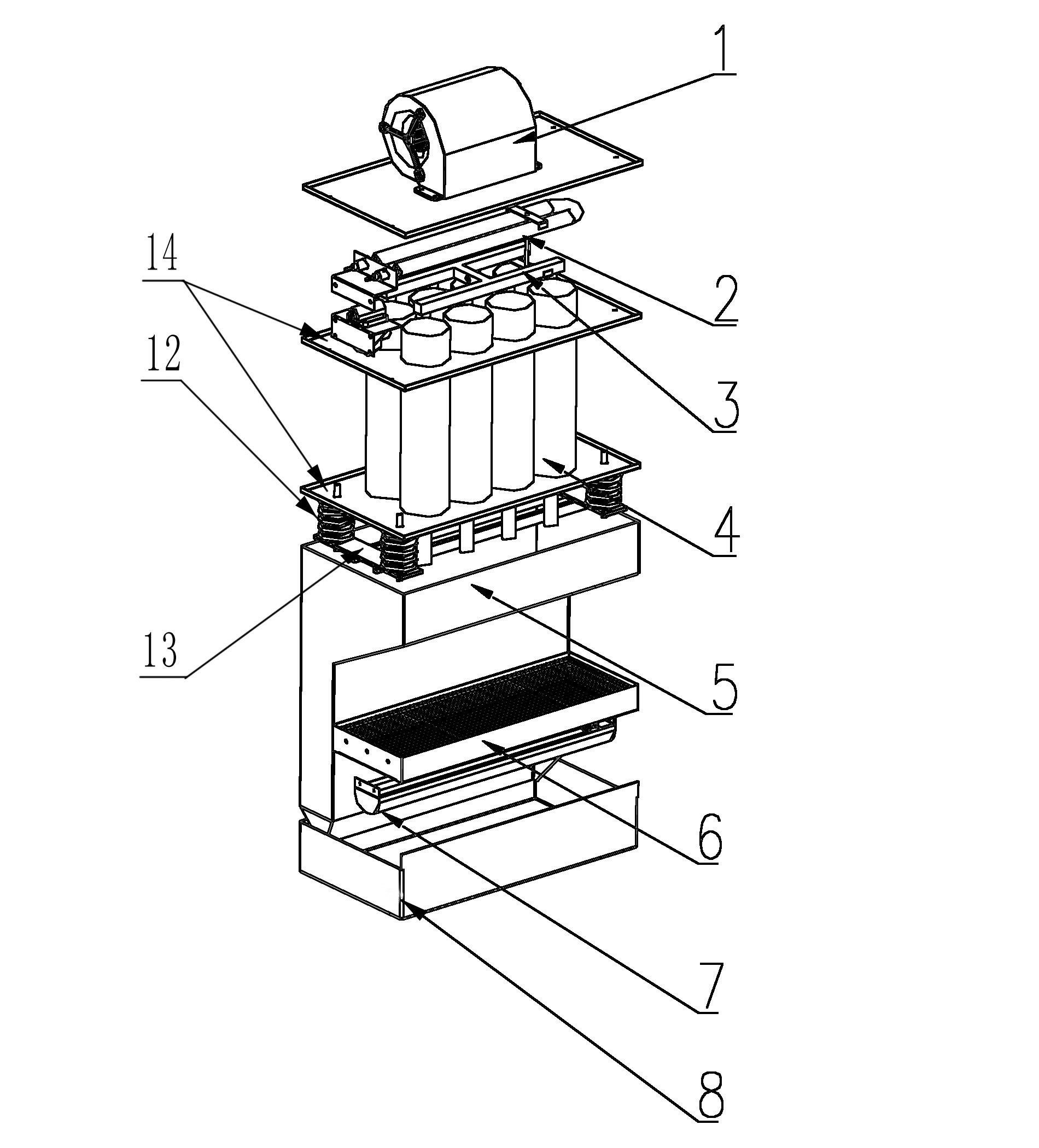

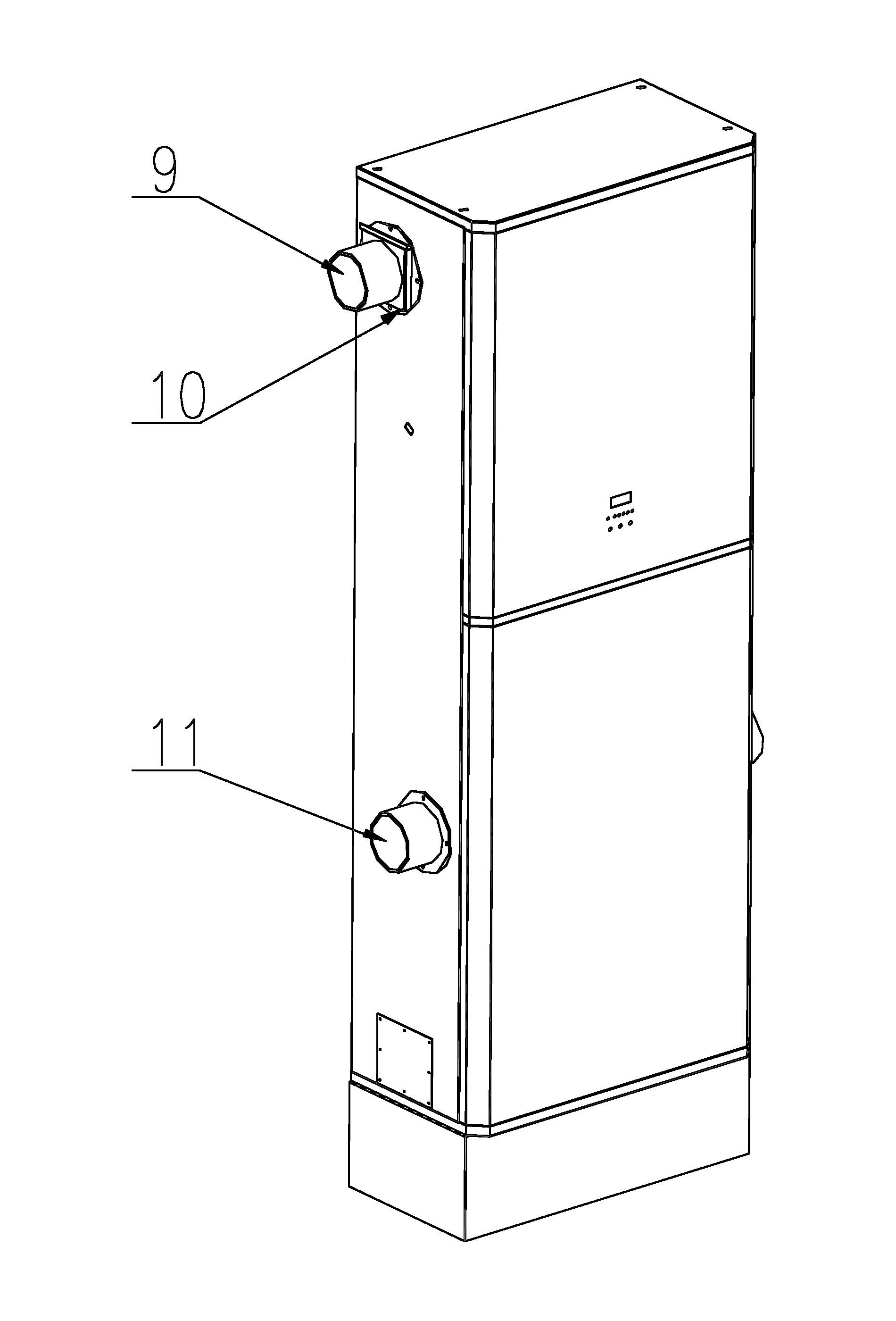

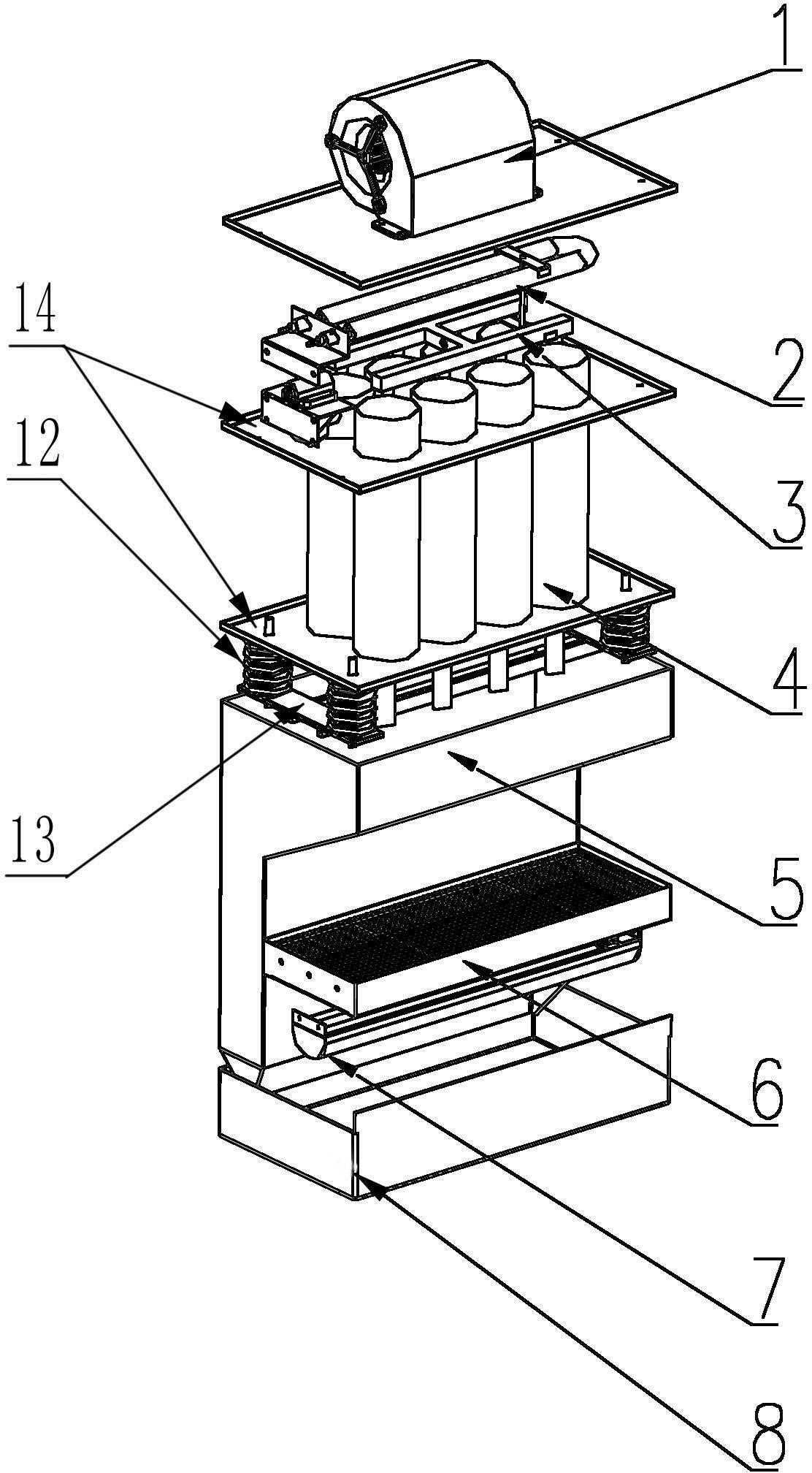

Indoor air purification device

InactiveCN102512924AExtended service lifeNo secondary pollutionDispersed particle separationDeodrantsUltraviolet lightsPlasma generator

The invention discloses an indoor air purification device, which comprises a shell, wherein an air inlet and an air outlet are formed in the shell; the air inlet is communicated with an air flue of the air outlet; a fan, a drying device, a cleaning device, a low-temperature plasma generator, an air box, an ultraviolet ray lamp, a nanometer photocatalyst device and an ozone elimination device are arranged on the air flue sequentially along the direction of air flowing; the fan, the drying device, the cleaning device, the low-temperature plasma generator and the air box are arranged sequentially from top to bottom; the ultraviolet ray lamp, the nanometer photocatalyst device and the ozone elimination device are arranged sequentially from bottom to top between an opening in the lower end of the air box and the low-temperature plasma generator; the opening in the lower end of the air box is formed below the ultraviolet ray lamp; a water receiving disc is arranged below the air box; and anautomatic control device for controlling the actions of the ultraviolet ray lamp, the low-temperature plasma generator, the cleaning device, the drying device and the fan is arranged on the shell. The air purification device has the automatically-cleaned capacity, is applicable to environment in which air pollution is severe, and is suitable to be used indoors.

Owner:CLEAR ENVIRONMENT TECH SUZHOU

Hydroxyapatite overlength nanowire flameproof paper with waterproof function

ActiveCN106522015AWaterproofWith waterproof functionWater-repelling agents additionPaper/cardboardNanowireApatite

The invention relates to hydroxyapatite overlength nanowire flameproof paper with a waterproof function. The hydroxyapatite overlength nanowire flameproof paper with the waterproof function has super-hydrophobicity and fireproof and flame-retardant functions. The main component of the flameproof paper is hydroxyapatite overlength nanowire. The product also contains fatty acid salt or a perfluorinated compound modified on the hydroxyapatite overlength nanowire. The fatty acid salt or the perfluorinated compound carries out surface modification on the hydroxyapatite overlength nanowire. As hydroxyapatite overlength nanowire has rich surface reactive groups, the hydroxyapatite overlength nanowire is easy to undergo surface modification. Thus, the hydroxyapatite overlength nanowire is easy to combine with the fatty acid salt or the perfluorinated compound such that the hydroxyapatite overlength nanowire flameproof paper is endowed with an excellent waterproof function.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Composite nano germicide and its prepn

InactiveCN1387763ALarge specific surface areaReduce dosageBiocideAnimal repellantsAnti bacterialWater soluble

The present invention relates to nano scale composite antibacterial agent and its preparation method, it is characterized in that during the preparation of nano scale zinc oxide, water soluble metallic salt is added, and uses organic modifier to proceed modification, and passes through the processes of coprecipitation, washing, drying, calcination etc. to obtain the nano grade antibacterial agent. The invented nano composite antibacterial agent is excellent in anti bacterial performance and possesses the advantages of fast, high effect, broad spectrum, durable, no resistance to chemical agentetc.

Owner:骆天荣

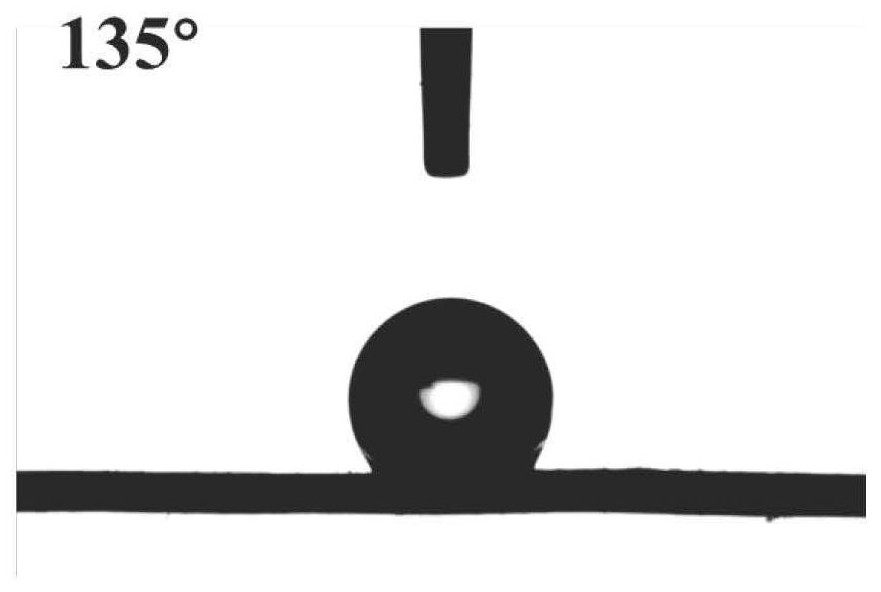

Method for preparing hydrophobic wood

InactiveCN102001117AWith self-cleaning abilityStrong self-cleaningPressure impregnationWood impregnation detailsRoom temperatureWater contact

The invention discloses a method for preparing hydrophobic wood, relates to a method for modifying wood, and solves the problems that a modifier has high toxicity and peculiar smell and changes wood color, the treatment process is complex and only single performance of the wood can be improved in the conventional wood modification method. The method comprises the following steps of: mixing a fluorine-containing polymerizable monomer, an unsaturated monomer and an initiator to prepare impregnation liquid; adding the wood and the impregnation liquid into a reaction tank, vacuumizing, performing pressure treatment so as to inject the impregnation liquid into a pore structure of the wood, coating a test piece and ageing at room temperature and constant pressure; and heating and performing vacuum drying to prepare the hydrophobic wood. The method is simple, the wood color is not changed, peculiar smell is absent, the parallel-to-grain compressive strength is 70 to 98 MPa, the expansion resistance rate after the wood is continuously soaked in water for 200 hours is 48 to 65 percent, the weight loss ratio after 12 weeks of fungi erosion is 6 to 13 percent, the water contact angle is more than 130 degrees, and the wood can be widely used as indoor and outdoor structural materials and decorative materials.

Owner:NORTHEAST FORESTRY UNIVERSITY

Self-propelled wave force power generation platform and moving and berthing method thereof

InactiveCN105197189AStrong ability to absorb wavesEasy to operatePropulsion power plantsMachines/enginesSpace environmentMooring system

The invention relates to a self-propelled wave force power generation platform and a moving and berthing method thereof. The self-propelled wave force power generation platform comprises a rear elbow and a buoyancy compartment arranged on the rear elbow, the rear end of the rear elbow is located below the sea surface, and the front end of the rear elbow is located above the sea surface and is connected with an air turbine. A wave force generator is connected to the air turbine, a deck covers the buoyancy compartment, extends all the way to the upper portion of a rear end opening of the rear elbow, and is supported by supporting columns, the four corners of the deck are each provided with an anchor windlass, and an electric propeller and an electric rudder are arranged below the rear end of the rear elbow. Through the combined application of the electric propeller, the electric rudder and the electric anchor windlasses, anchoring, anchor housing and moving operation of the wave force generator can be quickly achieved, the self-propelled wave force power generation platform is simple and easy to achieve, oceaneering cost is low, a self-cleaning effect on the underwater space environment is achieved, and a mooring system can be conveniently maintained. Meanwhile, energy generated by the self-propelled wave force power generation platform is effectively utilized, energy is saved, and environment friendliness is achieved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

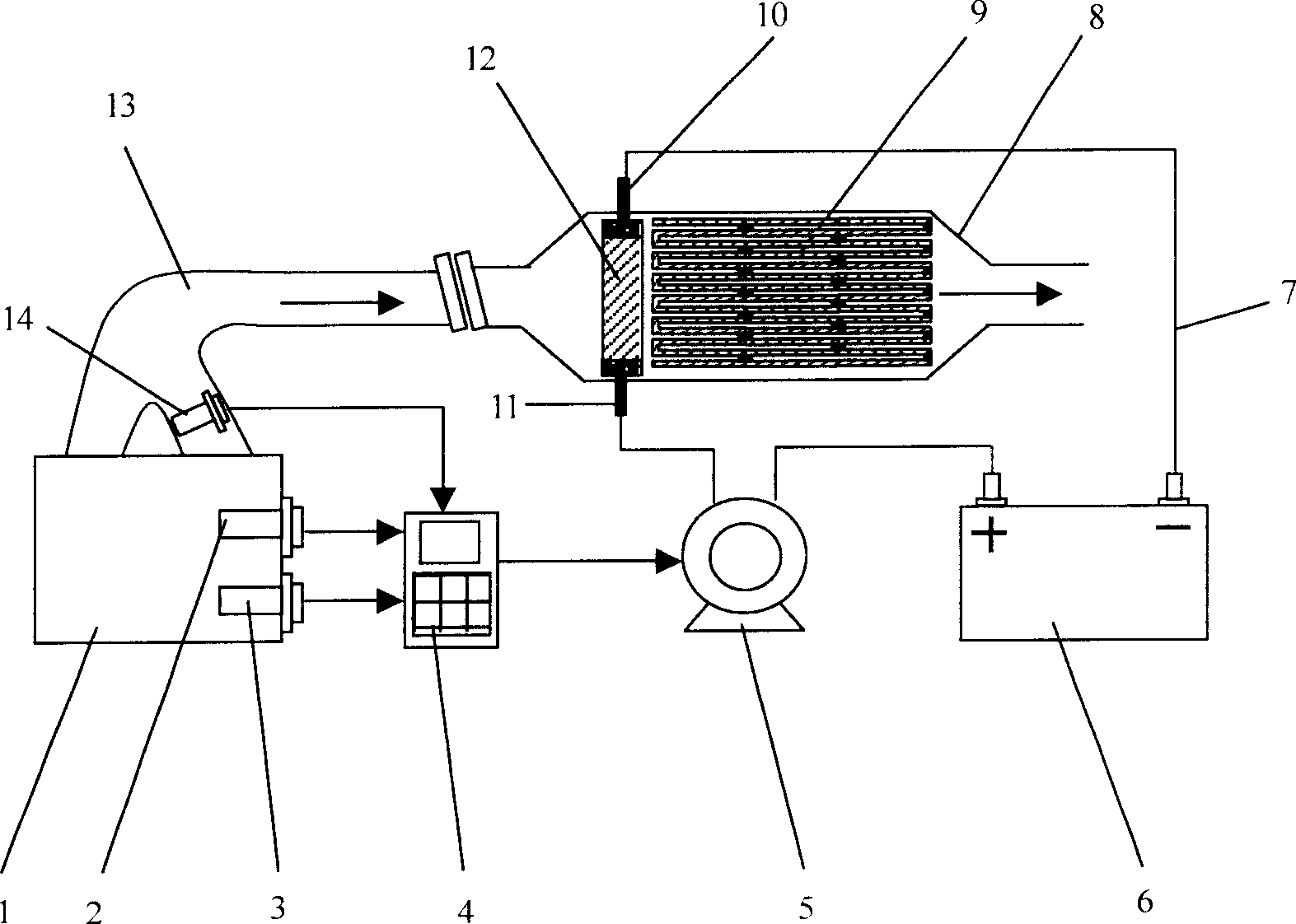

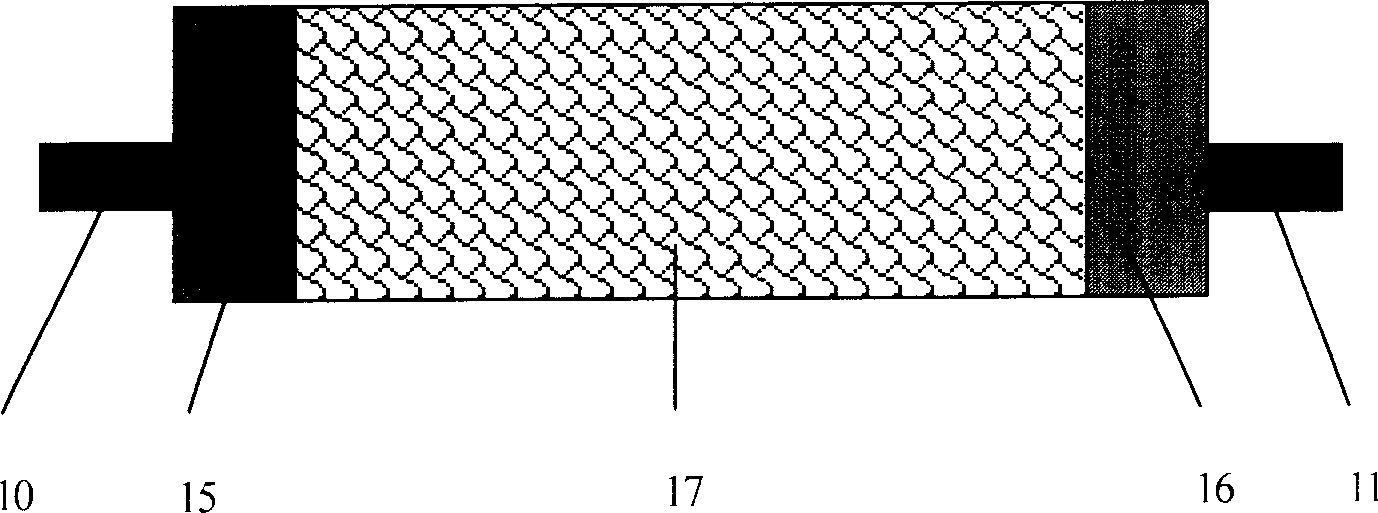

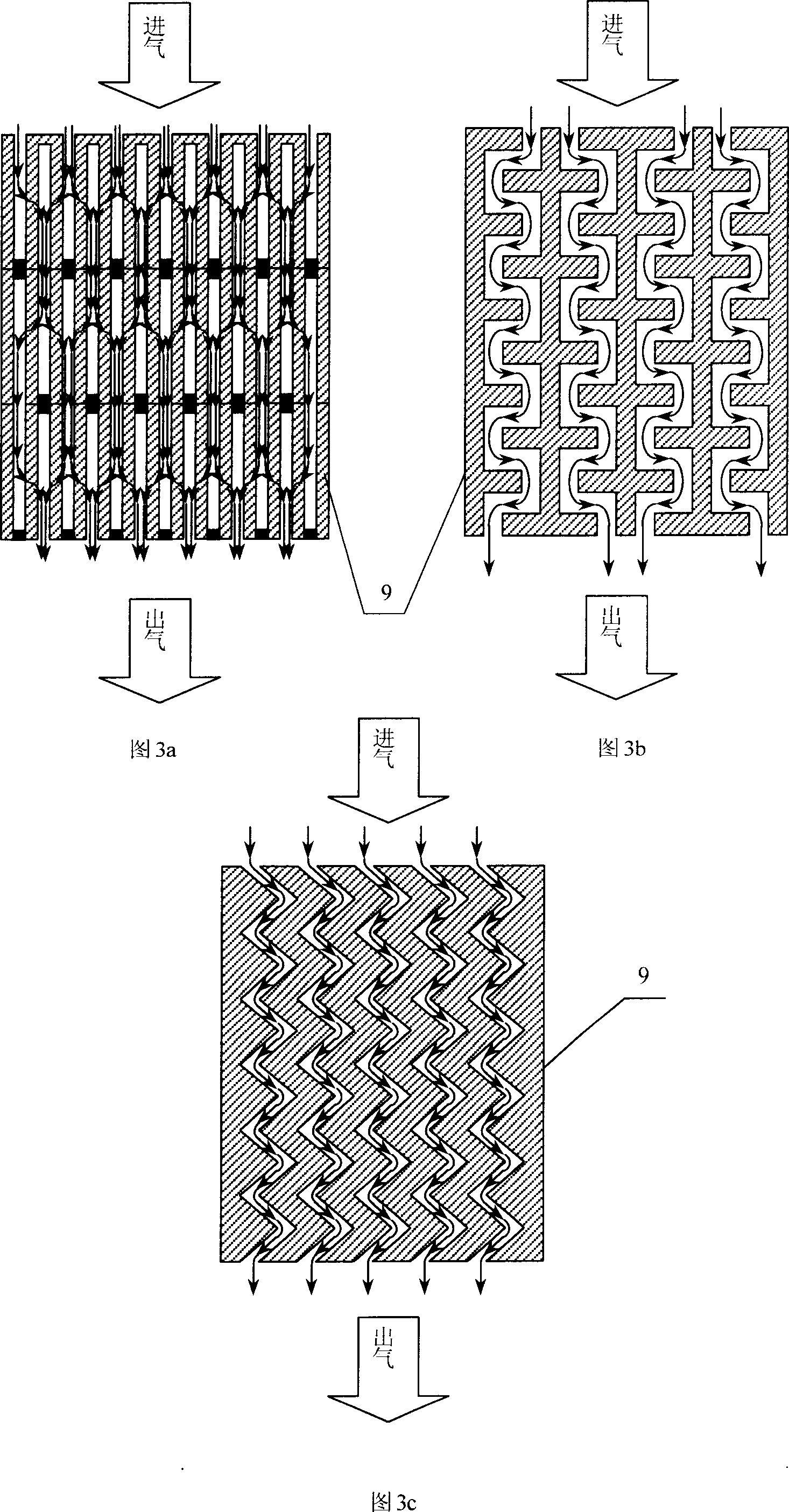

Carbon black filtering and electric direct-heating type regeneration device for diesel truck

InactiveCN1865669AUniform temperature distributionFast heat conductionExhaust apparatusSilencing apparatusElectricityEngineering

The invention relates to a carbon smoke filter - electric heating regenerator of diesel vehicle, which comprises an electric controller, an electric heater, and a foam ceramic main filter. Wherein, the electric heater and the foam ceramic main filter are mounted inside the sealing frame of purifier connected with the ventilate tube; the electric heater is formed by one or several foam ceramic electric heating units, that uses integrated heating or dispersed heating method; the foam ceramic main filter is made from silicon carbide foam ceramic, with wall-flow or meshed tooth shape. The invention has controllable conductive property, which can effectively filter the carbon smoke; and it is powered by carrier power source. In addition, it ahs lower cost, on-site regeneration and long service life.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

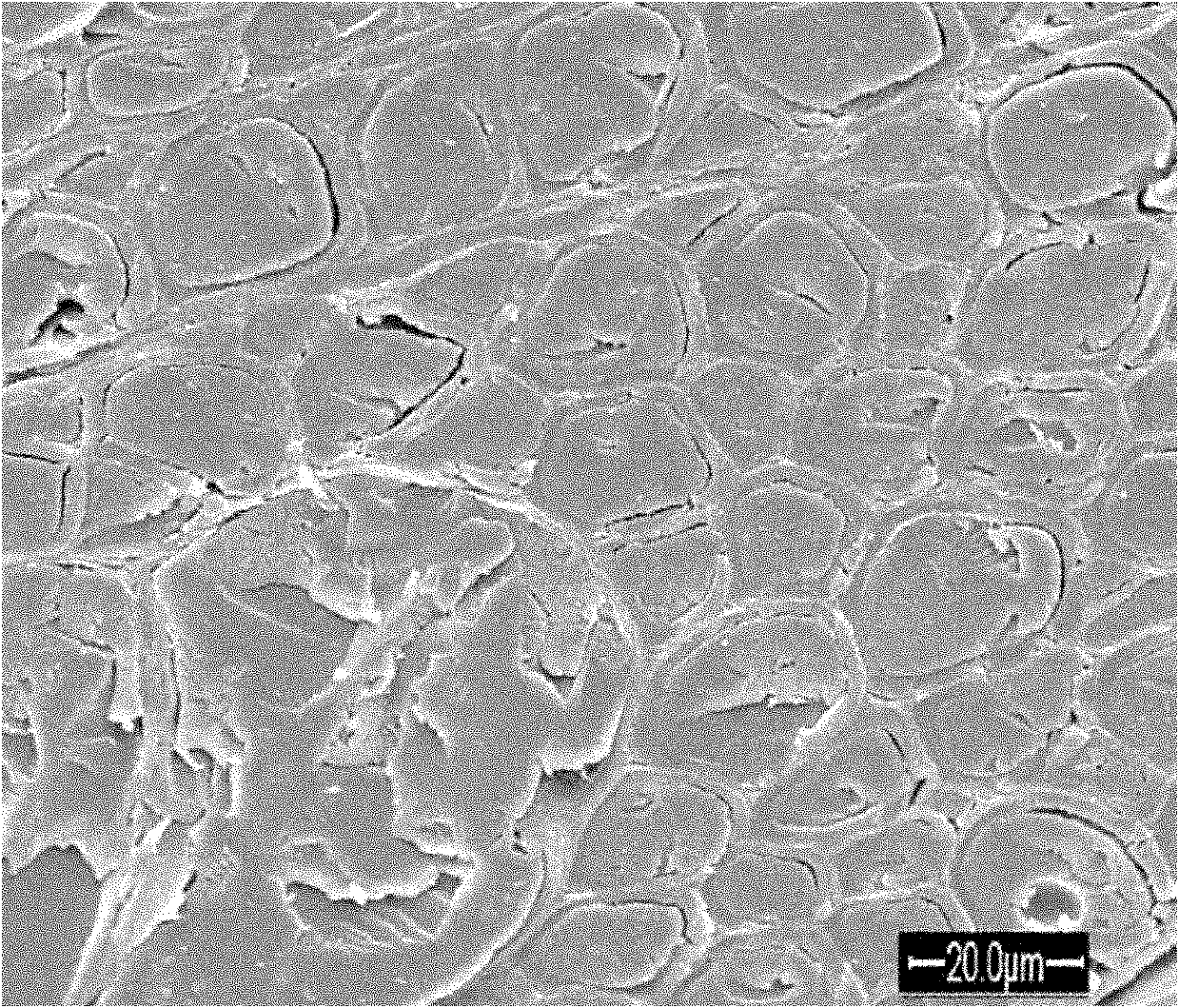

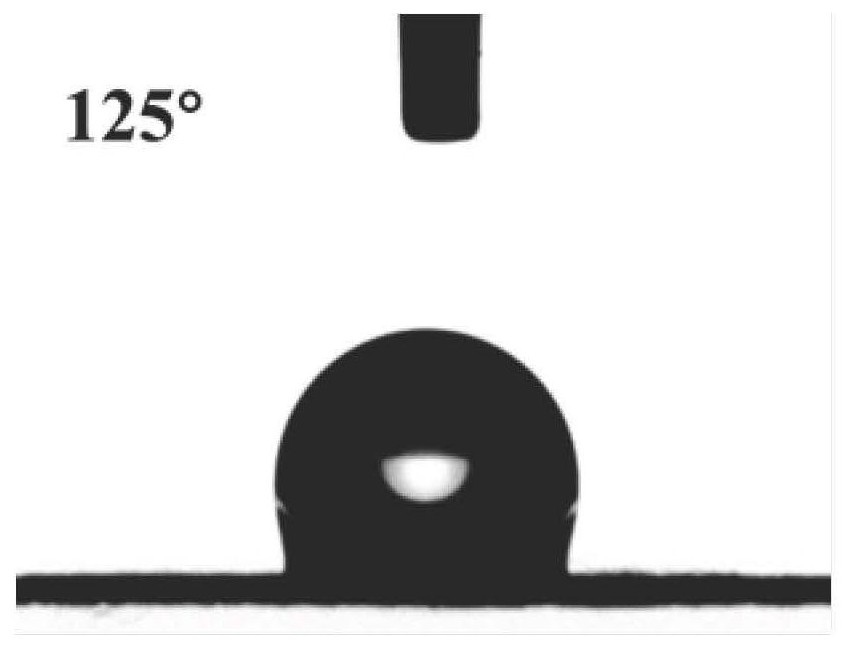

Preparation method of lotus-like super-hydrophobic self-cleaning surface

The invention discloses a preparation method of a lotus-like super-hydrophobic self-cleaning surface. The method comprises the following steps: (1) electroplating a layer of porous metal film on the surface of a metal sheet by adopting a hydrogen bubble template method; (2) putting the prepared porous metal film into an electric heating furnace for oxidizing to obtain a porous metal oxide template; (3) proportionally mixing a high polymer curing system, adding normal hexane, pouring into the porous metal oxide template for curing, and removing the template after curing to obtain the lotus-like super-hydrophobic self-cleaning surface. The method has the advantages of easiness, convenience, environmental friendliness, no need of large-sized instruments, controllability of experimental parameters and low cost, and can be used for manufacturing a lotus-like micromorphology surface. A micro-protruding structure has the characteristics of super hydrophobicity, self-cleaning capability, high mechanical stability, high acid-base resistance and good application prospect, and can be industrialized.

Owner:黑龙江德明科技开发有限公司

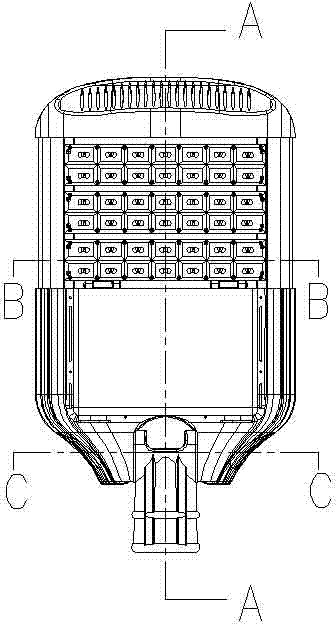

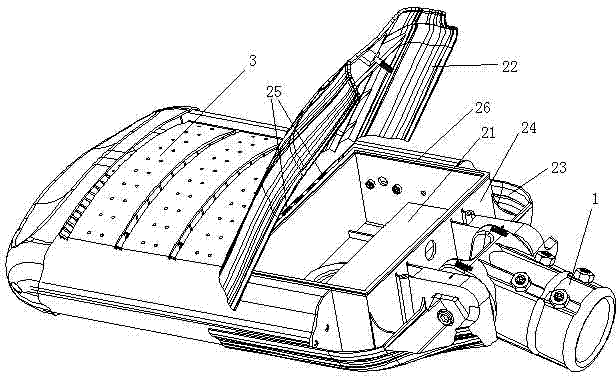

LED road lamp

ActiveCN102734711ASpeed up the flowOptimized for enhanced convectionPoint-like light sourceLighting heating/cooling arrangementsWater vapor permeabilityEngineering

The invention discloses a LED road lamp, comprising a connecting seat, a power bin connected with the connecting seat, power provided inside the power bin and a LED light group connected to the power bin. The LED light group comprises a plurality of LED modules. The plurality of LED modules is fixed via two side covers and front covers, and the side covers are connected to the power bin via screws. The LED modules comprise a module aluminum substrate for arranging LED, a module radiator arranged on the backside of the module aluminum substrate, and a module lens arranging on the module aluminum substrate. Gaps are among the LED modules and are evenly distributed. Heat dissipation energy efficiency is greatly enhanced through uniformly spaced distributed LED modules and upper and lower permeability of the LED modules. A LED light emitting module is sealed between the module lens and the module radiator by using a sealing ring, waterproof effect is good, and screws with rubber pads are used to prevent water vapor permeability. Light source and power source radiate independently, resist water independently with no need of glue, and have better heat dissipation and waterproof effects.

Owner:天宝精密科技(惠州市)有限公司

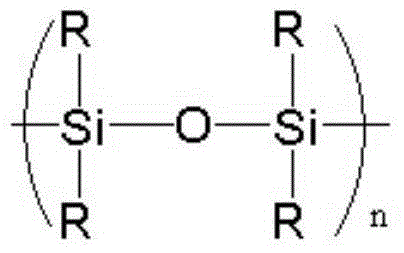

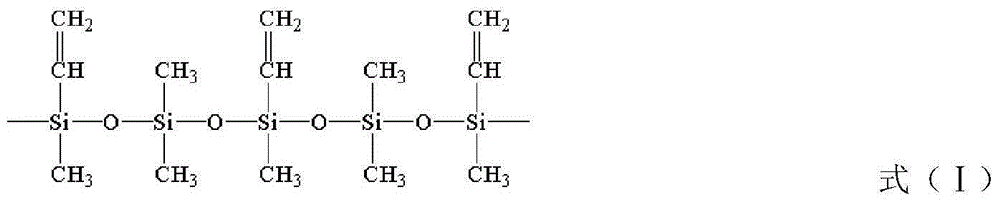

Organosilicon coating

The present invention provides an organosilicon coating, comprising 20-40 parts by weight of a methyl vinyl organosilicon polymer, 1-6 parts by weight of methyl phenyl organosilicon polymer, 5-15 parts by weight of hydrogen-containing silicone oil, 5-10 parts by weight of fluorine-containing acrylate monomer, 5-15 parts by weight of silica, 0.2-2 parts by weight of an inhibitor, 0.1-1 part by weight of an additive, 0.1-1 part by weight of a thermal initiator, 30-50 parts by weight of an organic solvent and 2-5 parts by weight of a metal catalyst. The organosilicon coating provided by the present invention has good adhesion on a silicone rubber or a fluorine rubber substrate without surface treatment; specifically, after the coating is disposed on the surface of fluorine rubber or silicone rubber substrate, the substrate immersed in boiling water for 120 min has no abnormity or adhesion damage on the surface.

Owner:HUNAN SOKAN NEW MATERIAL

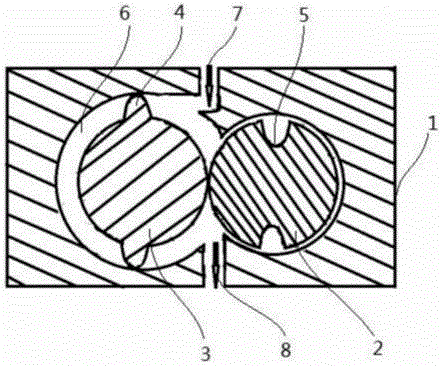

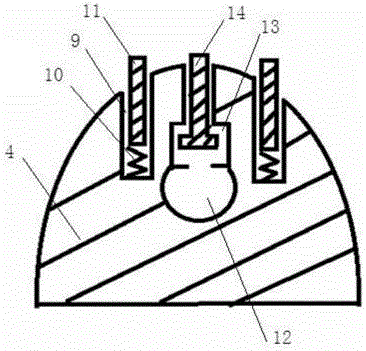

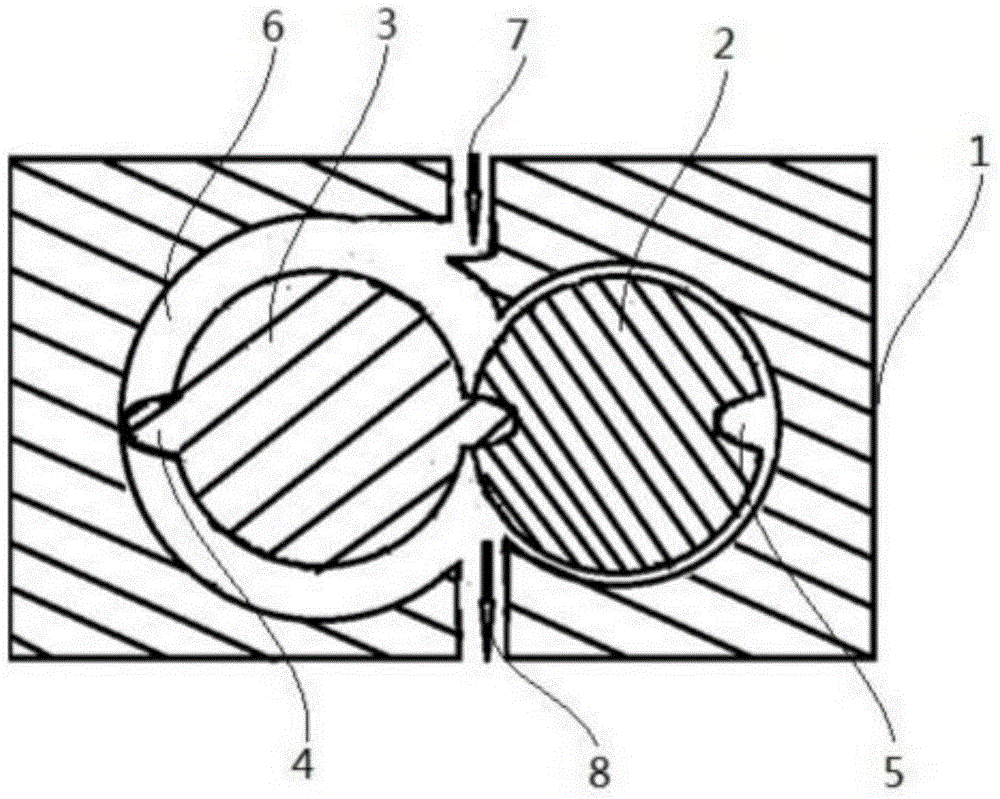

Rotor expander

InactiveCN104863640ANot a small lossReasonable structureSealing arrangement for pumpsEngine of counter-engagement typeEngineeringCylinder block

The invention discloses a rotor expander, and relates to the technical field of rotating piston type machines or engines. The rotor expander comprises a cylinder, a female rotor in the cylinder, and at least one male rotor, wherein two vertical grooves are formed in a projected blade, and extend to the inner wall direction of the cylinder; springs and cuboid air seals are arranged in the two vertical grooves; one ends of the springs are fixedly connected with the vertical grooves, and the other ends of the springs are connected with the cuboid air seals in the vertical grooves; a machine oil channel parallel to a main shaft and an inverted T-shaped machine oil outlet communicated with the machine oil channel are arranged between the two vertical grooves; an inverted T-shaped oil ring matched with the inverted T-shaped machine oil outlet is arranged in the inverted T-shaped machine oil outlet; and the inverted T-shaped oil ring extends to the inner wall of the cylinder. The expander has the characteristics of high mechanical efficiency, easy processing, no wearable parts, long service life and low operation and maintenance costs.

Owner:张茂岽

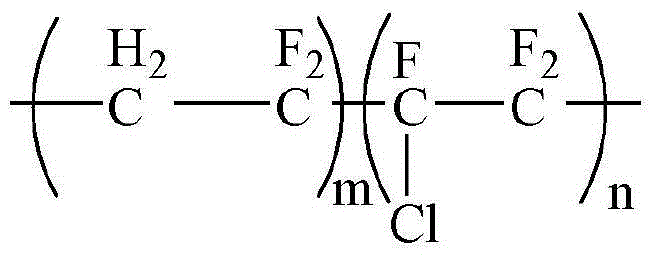

Hydrophobic oleophobic microporous membrane paster for protection of welded car lamp and manufacturing method thereof

ActiveCN103980831AAvoid stickingWith self-cleaning abilityFilm/foil adhesivesCoatingsCooking & bakingViscosity

The invention discloses a hydrophobic oleophobic microporous membrane paster for protection of a welded car lamp and a manufacturing method thereof. The microporous membrane paster comprises a hydrophobic oleophobic finishing agent, a microporous membrane and a low-viscosity PE adhesive tape, wherein one surface of the microporous membrane is coated with the hydrophobic oleophobic finishing agent, and the low-viscosity PE adhesive tape is adhered on the other surface of the microporous membrane. The manufacturing method comprises the following steps: manufacturing of the microporous membrane; preparation of the hydrophobic oleophobic finishing agent; preparation of a hydrophobic oleophobic microporous membrane: a step of feeding the hydrophobic oleophobic finishing agent in a roller coater, unreeling the microporous membrane, allowing one surface of the microporous membrane and a roller to contact a coating and successively carrying out heating and predrying of the roller, baking and rolling; and process preparation: a step of compounding the other surface of the microporous membrane with the low-viscosity PE adhesive tape, carrying out molding and die cutting, discharging waste leftover materials and successively carrying out inspection, rolling and packaging. The hydrophobic oleophobic microporous membrane paster has self-cleaning capability as a lotus leaf does, a better effect on resistance of pollution by automobile exhaust gas is obtained when the hydrophobic oleophobic microporous membrane paster is used for protection of car lamps, and the hydrophobic oleophobic microporous membrane paster is superior to other protection modes and is an ideal method to overcome environmental load.

Owner:PAN ASIAN MICROVENT TECH JIANGSU CORP

Fuel oil and fuel gas angle pipe boiler structure for strengthening convection pipe screen through needle fins

ActiveCN104154661AReduce manufacturing costImprove heat transfer effectFluid heatersFeed-water heatersEvaporationEngineering

The invention discloses a fuel oil and fuel gas angle pipe boiler structure for strengthening a convection pipe screen through needle fins. A steam boiler is composed of a boiler cylinder, a hearth and a convection heating surface. The hearth is composed of a front wall, a rear wall, a left side wall membrane water wall and a right side wall membrane water wall. The convection heating surface is composed of a side-by-side convection pipe screen, a convection vertical shaft front wall, a convection vertical shaft rear wall, two side walls and other additional heating surfaces, wherein the side-by-side convection pipe screen is formed by connecting 1 to n sets of needle-shaped evaporation pipe bundles, 1 to m sets of economizer pipe bundles and a collection box. A water boiler is free of boiler cylinders. A hearth of the water boiler is composed of a front wall, a rear wall, a left side wall I membrane water wall and a right side wall II membrane water wall. A convection heating surface is composed of a side-by-side convection pipe screen, a convection vertical shaft front wall, a convection vertical shaft rear wall, two side walls and other additional heating surfaces, wherein the side-by-side convection pipe screen is formed by connecting 1 to n sets of needle-shaped pipe bundles and a collection box. The convection pipe bundles are strengthened through the needle fins in a segmented mode, the length of the needle fins gradually increases according to the temperature decrease of smoke, the average heat transfer coefficient is increased, and the heat exchange area is enlarged; the boiler is compact in structure, high in air tightness, less in air leakage and high in combustion efficiency and has an ultra-strong power outage protection function.

Owner:XI AN JIAOTONG UNIV

Method for preparing cellulose/nanometer titanium dioxide blending material in ionic liquid solvent

InactiveCN101724929ALow process energy consumption and operating costsAvoid pollutionArtificial filaments from cellulose solutionsWet spinning methodsUltraviolet absorptionIon

The invention provides a method for preparing a cellulose / nanometer titanium dioxide blending material in an ionic liquid solvent, wherein a fiber consists of the cellulose and nanometer titanium dioxide particles. The ionic liquid solvent can directly dissolve the cellulose to avoid a complicated process for traditionally dissolving the cellulose; the nanometer titanium dioxide can be added to form uniform and stable spinning solution of cellulose / nanometer titanium dioxide; and the cellulose / nanometer titanium dioxide blending fiber material can be obtained through fiber spinning plasticizing, stretching, washing and drying. The composite material prepared by the method has the advantages of strong intensity, breaking elongation and flexibility, maintains the performance of regenerated cellulose filament, and has the functions of antibacterial activity and ultraviolet absorption. In the composite material prepared by the method, the cellulose is firmly combined with the nanometer titanium dioxide, and the nanometer titanium dioxide is evenly distributed and is difficult to run off. An ionic liquid is used as the solvent to prepare the cellulose composite material, so the method has the advantages of simple and convenient process, recyclable solvent, convenient operation and low cost, and is suitable for large-scale industrial application.

Owner:DALIAN POLYTECHNIC UNIVERSITY

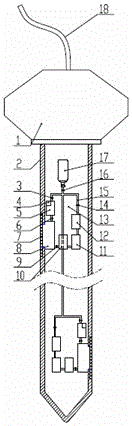

Apparatus for acquisition of marine sediment porewater and on-line in-situ detection of gas in porewater, and control method thereof

ActiveCN105842005AAcquisition speed is fastRealize cycle workAnalysing gaseous mixturesWithdrawing sample devicesGas cylinderGas composition

The invention provides an apparatus for acquisition of marine sediment porewater and on-line in-situ detection of gas in the porewater. The apparatus can realize in-situ, rapid and cyclic acquisition of the porewater and on-line in-situ detection of the composition and content of gas in the porewater. According to a technical scheme in the invention, the apparatus is characterized by comprising a counterweight (1), a shell (2), a gas cylinder (17) and a single-layer sampling point device (13), wherein the counterweight (1) is connected with the shell (2), the counterweight (1) is provided with a power supply and a signal path device (18), and the gas cylinder (17) and the single-layer sampling point device (13) are arranged in the shell (2) and connected with each other. The invention also discloses a control method for the apparatus.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

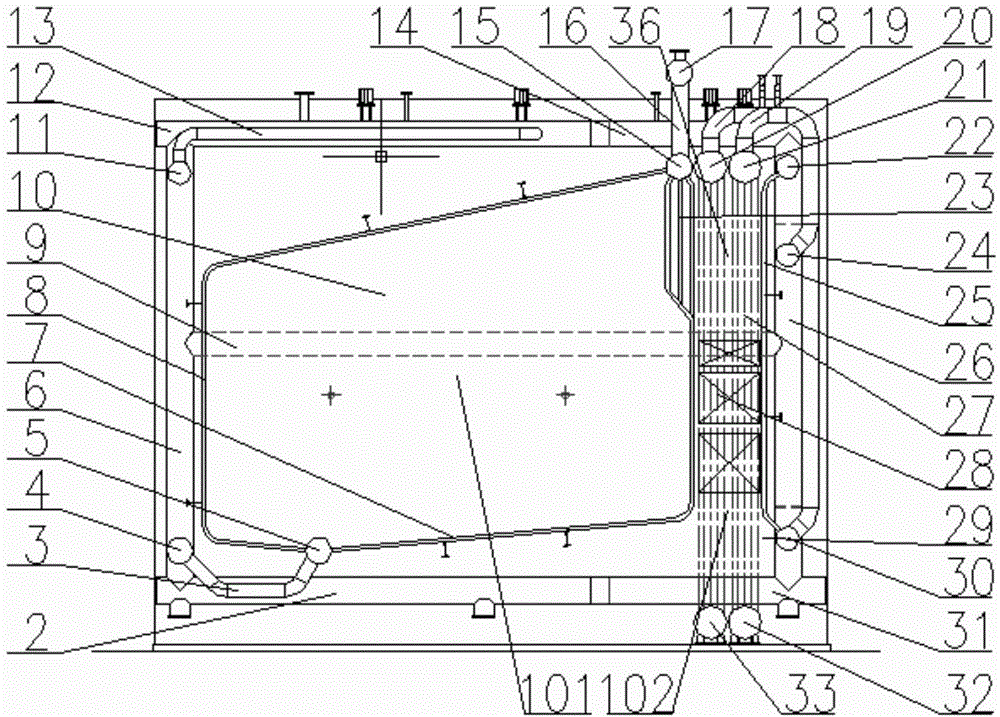

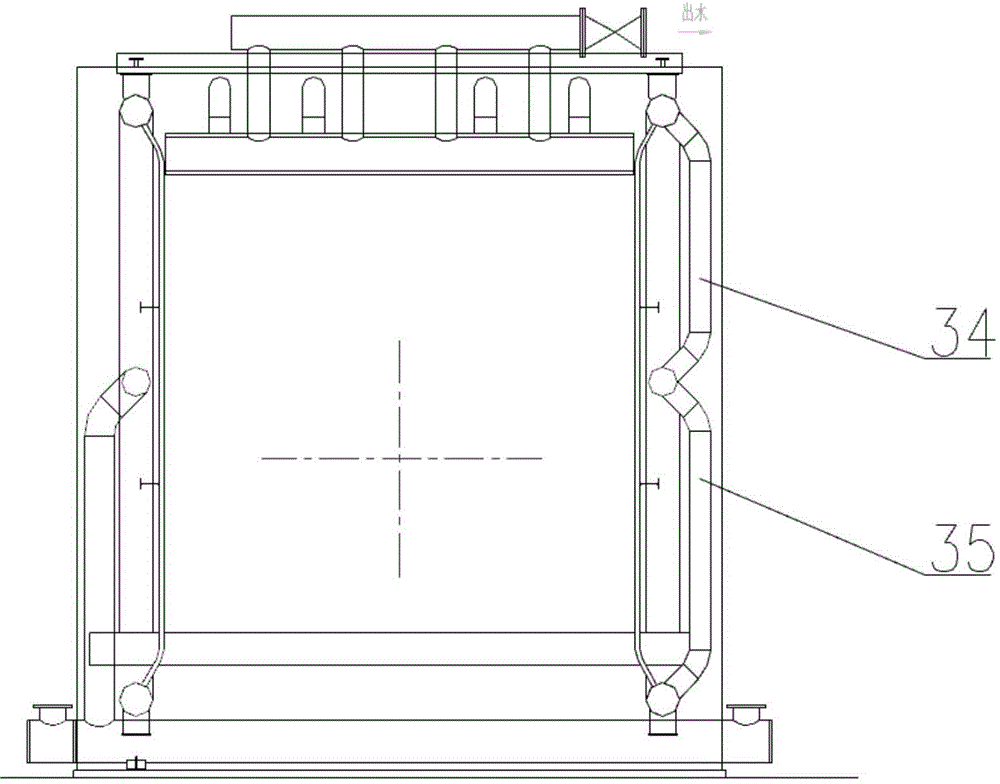

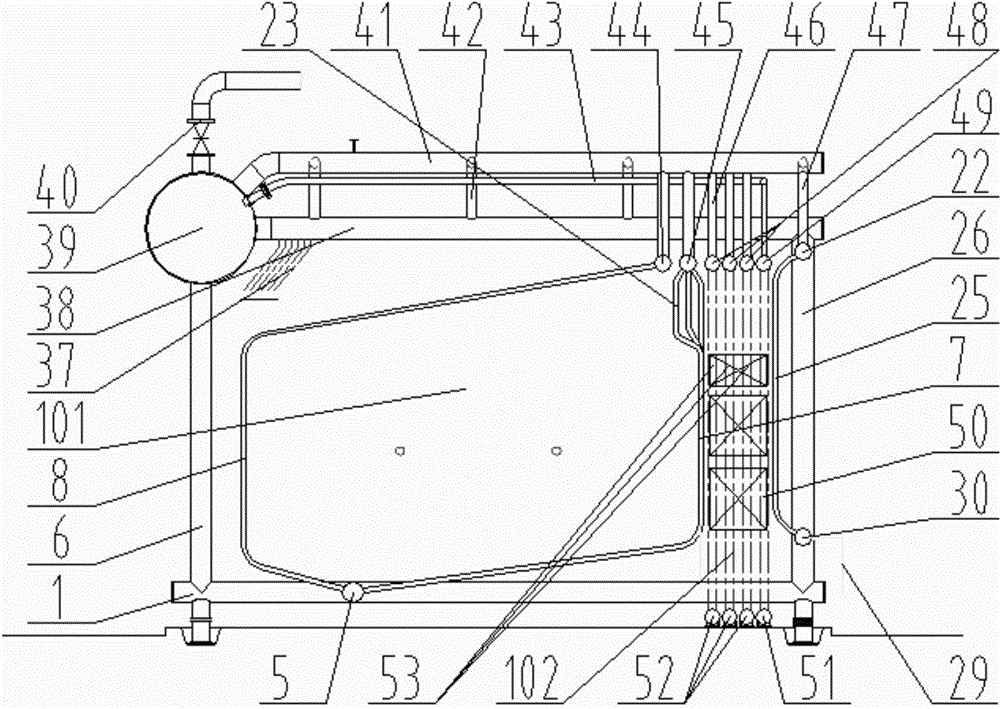

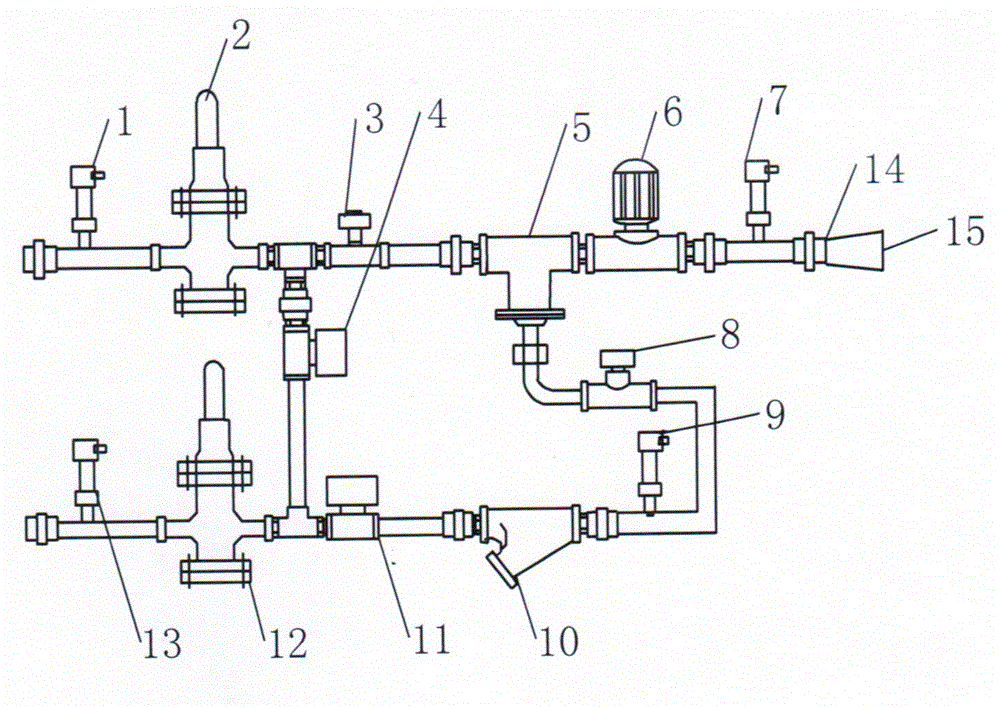

Intelligent self-cleaning dry fog de-dusting equipment

InactiveCN104623998ARealize self-cleaningAchieve anti-cloggingUsing liquid separation agentSeparation devicesProcess engineeringInlet pressure

The invention provides intelligent self-cleaning dry fog de-dusting equipment. A water supply pipe and an gas supply pipe are connected respectively with a water gas mixer; a water inlet pressure sensor, a water supply adjusting valve and a water control electromagnetic valve are connected to the water supply pipe; a gas inlet pressure sensor, a gas supply adjusting valve, a gas storage tank filter and a gas outlet pressure sensor are connected sequentially to the gas supply pipe; the gas supply pipe is connected with the water gas mixer by the gas pressure adjusting valve; an fog spraying box, an outlet pressure sensor and a sprayer are arranged on the pipe of the rear part of the water gas mixer; a spraying vibrator is arranged on the sprayer. A connecting pipe is arranged between the gas supply adjusting valve pipe on the gas supply pipe and the water supply adjusting valve pipe, and a back blow valve is arranged on the connecting pipe. The equipment is controlled by a PLC. By utilizing the equipment, the water gas mixed vibrating fog spraying can be realized, the self-cleaning and blockage prevention of pipelines and sprayer can also be realized. The equipment has the advantages of good de-dusting effect and high reliability. And the equipment is suitable for being used as the dry fog de-dusting equipment.

Owner:SUIZHONG ZHONGWEI TECH

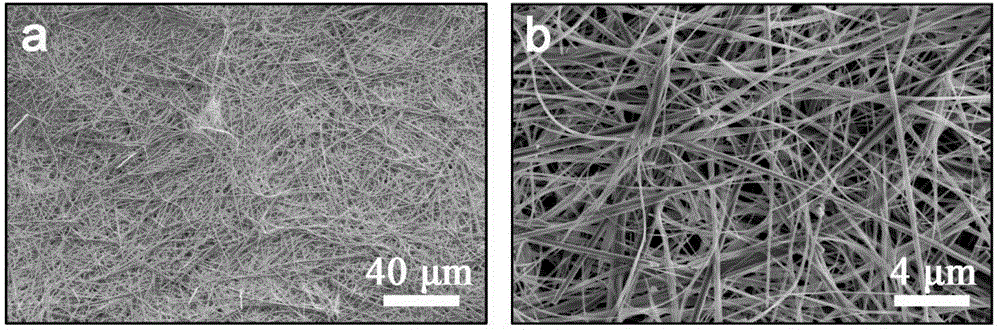

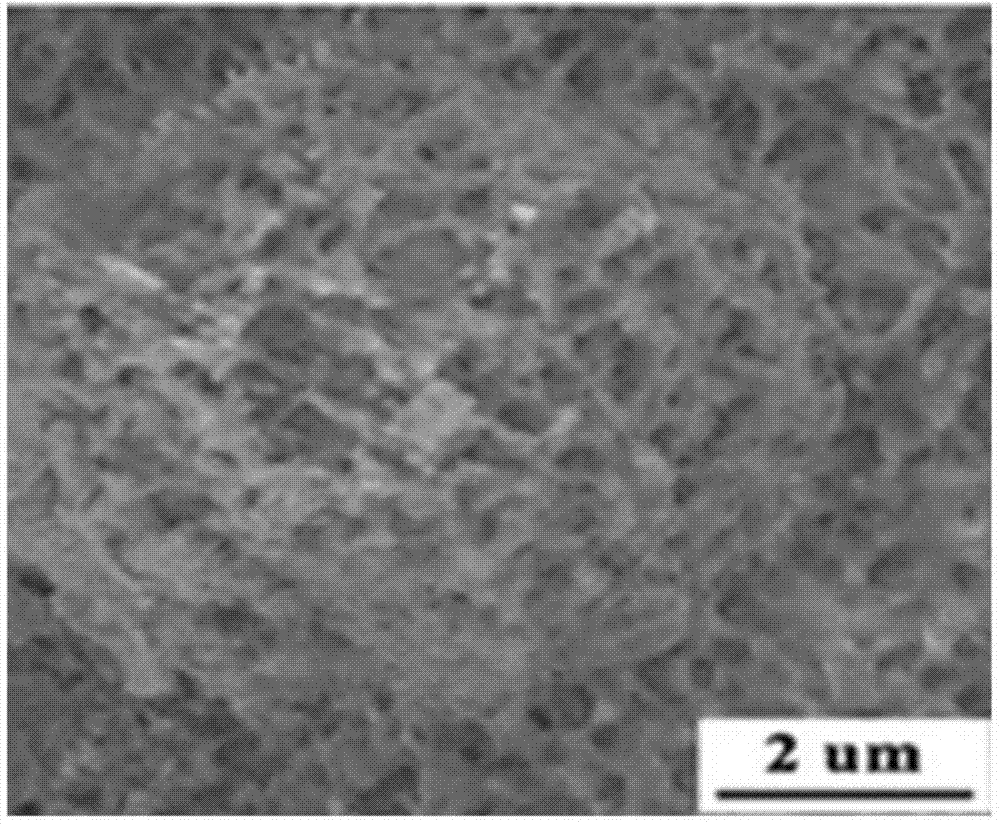

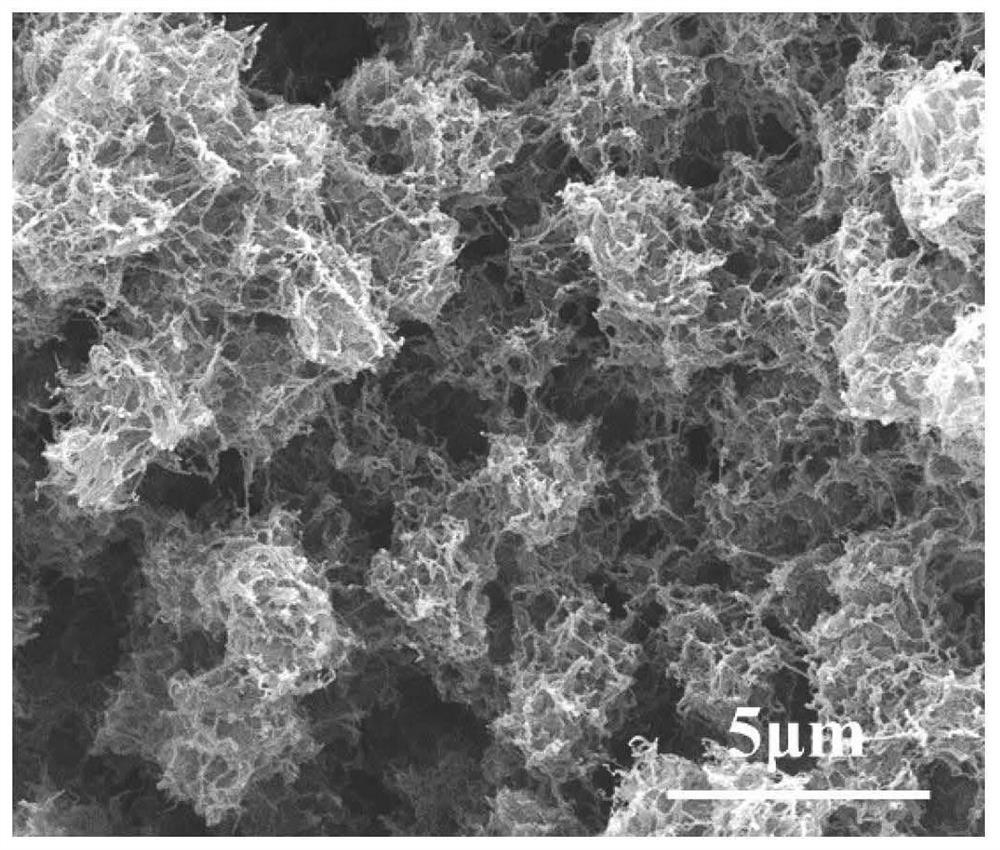

In-situ hydrophobic modified aramid nano aerogel fiber as well as preparation method and application thereof

ActiveCN113463375AUnique three-dimensional porous network structureLow thermal conductivityAdditive manufacturing apparatusPhysical treatmentPolymer scienceSpinning

The invention discloses in-situ hydrophobic modified aramid nano aerogel fiber as well as a preparation method and application thereof. The preparation method comprises the following steps of providing an aramid nano spinning solution; preparing hydrophobic modified aramid nano gel fiber by adopting a spinning technology, wherein a coagulating bath adopted by the spinning technology comprises a first organic solvent and a halogenating reagent, and the halogenating reagent comprises monobromoalkane, monochloroalkane, dibromoalkane, dichloroalkane, trichloroalkane and the like; and then carrying out drying treatment to obtain the in-situ hydrophobic modified aramid nano aerogel fiber. The in-situ hydrophobic modified aramid nano aerogel fiber prepared by the method has a unique three-dimensional porous network structure, lower heat conductivity, higher porosity, higher tensile strength and elongation at break and certain spinnability and structural stability, and can be applied to the field of spinning; a fabric woven from the hydrophobic fiber has self-cleaning ability; hydrophobic aramid nano aerogel fiber flocculus can also be prepared; and good hydrophobic performance is showed.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

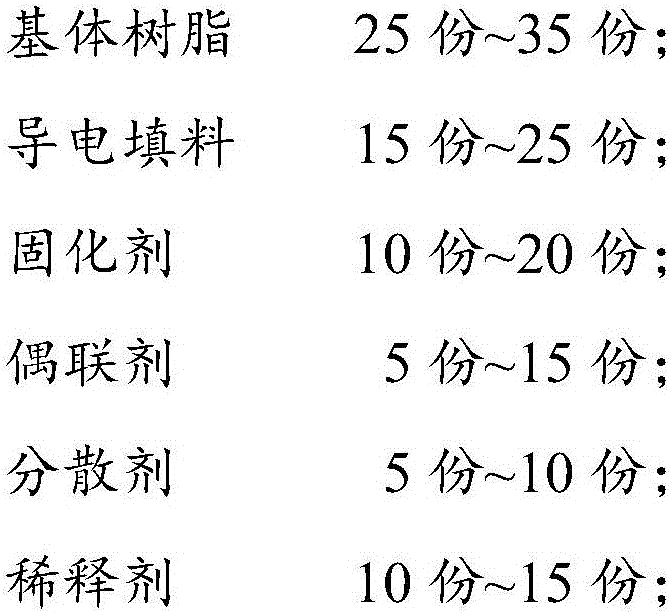

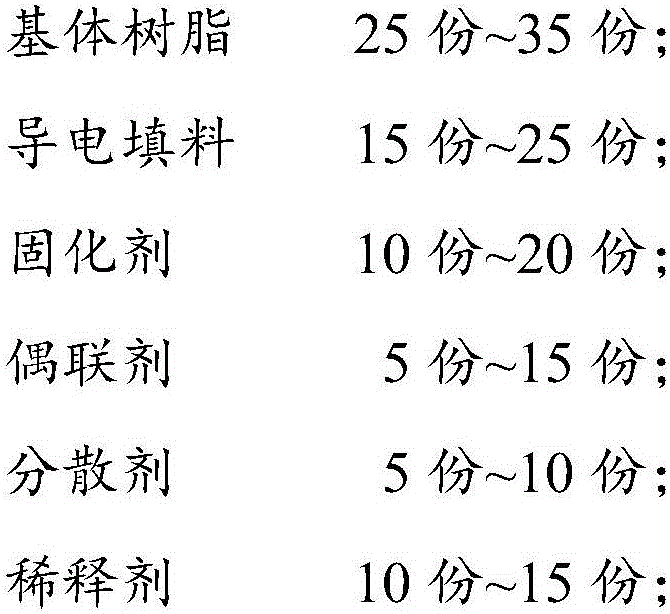

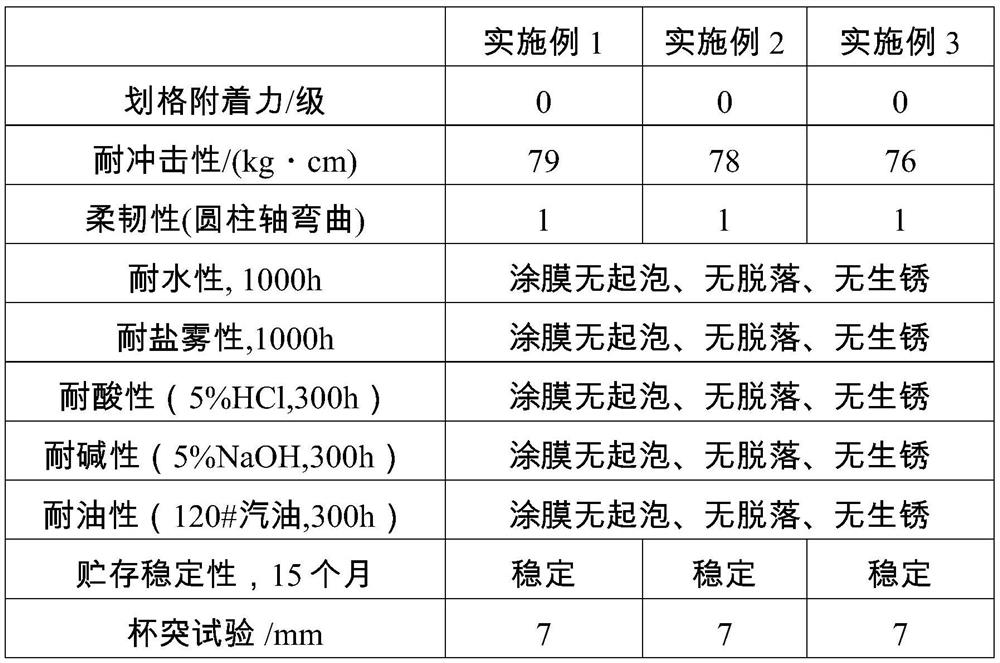

Conductive anticorrosive paint for power grounding grid and preparation method thereof

ActiveCN105907243ALarge specific surface areaImprove adsorption capacityAnti-corrosive paintsEpoxy resin coatingsGrounding gridPower grid

The invention belongs to the field of paint for the power grid, relates to the grounding grid, and particularly relates to conductive anticorrosive paint for the power grounding grid and a preparation method thereof. The paint is prepared from the following effective ingredients in parts by weight: 25-35 parts of matrix resin, 15-25 parts of conductive filler, 10-20 parts of a curing agent, 5-15 parts of a coupling agent, 5-10 parts of a dispersing agent and 10-15 parts of a diluting agent, wherein the conductive paint comprises carbon nano-tube, modified graphene and nano-grade titanium dioxide in a mass ratio of 1:2:1. According to the anticorrosive paint, corrosive medium can be effectively isolated by utilizing the characteristics of graphene and carbon nanotube, and the corrosion resistance of anticorrosive paint can be finally improved; the conductive performance of paint can be improved by utilizing the excellent conductive property of graphene, and the surface resistance of the paint is 103-105 omega; furthermore, the paint has certain self-cleaning capability due to addition of the nano-grade titanium dioxide, and the corrosion resistance of the paint can be improved.

Owner:GAOTANG COUNTRY POWER SUPPLY BUREAU OF STATE GRID SHANDONG ELECTRIC POWER CO

Superhydrophobic coating and preparation method thereof

InactiveCN105507061AWide range of usesWith self-cleaning abilityWater-repelling agents additionNon-macromolecular organic additionSurface energyMicro nano

The invention belongs to the field of material surface and inorganic porous material and specifically relates to a superhydrophobic coating and its preparation method. The preparation method comprises the following steps: a, adding 1-5 parts by weight of natural zeolite into 50-100 parts by weight of ethanol, carrying out ultrasonic dispersion for 10-30 min, adding 0.15-0.85 part by weight of perfluorodecyltrichlorosilane, and continuously carrying out ultrasonic dispersion for 10-30 min to obtain a dispersion liquid; b, immersing a base material into the dispersion liquid obtained in the step a for 3-5 min, taking out the base material and drying the base material at 50-70 DEG C for more than 30 min; and c, repeating the step b for two to three times so as to form the superhydrophobic coating on the surface of the base material. Natural zeolite belongs to an inorganic porous material and is easy to form a micro-nano structure in the coating. Meanwhile, there exist many hydroxide radicals on the surface of zeolite, and its surface energy is reduced after condensation between perfluorodecyltrichlorosilane and hydroxide radicals. Thus, the superhydrophobic effect is achieved. The natural zeolite is cheap and easily available. The preparation method is simple and easy for industrialization. The coating of the invention has a self-cleaning ability, is applicable to many base materials and is widely applied.

Owner:HUBEI UNIV

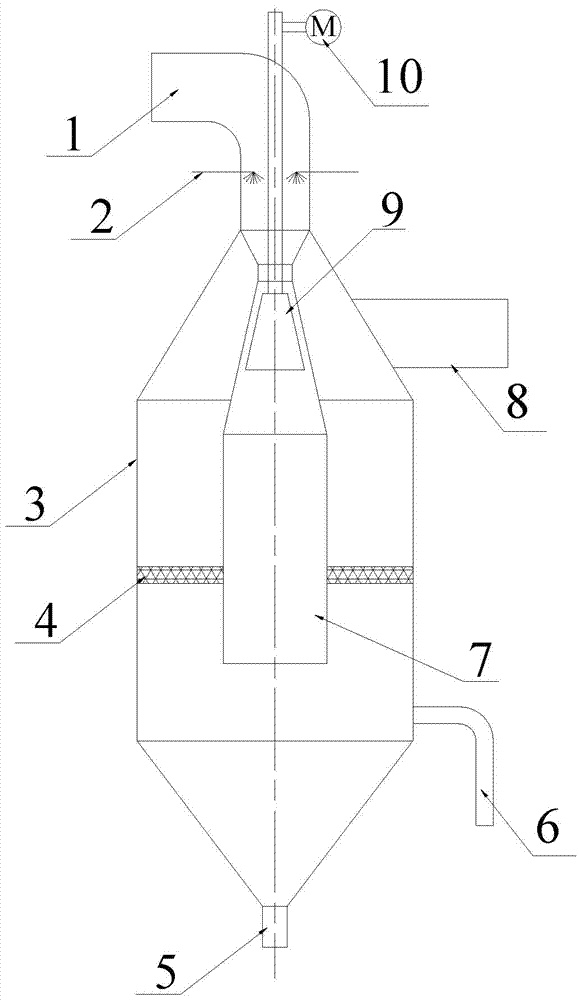

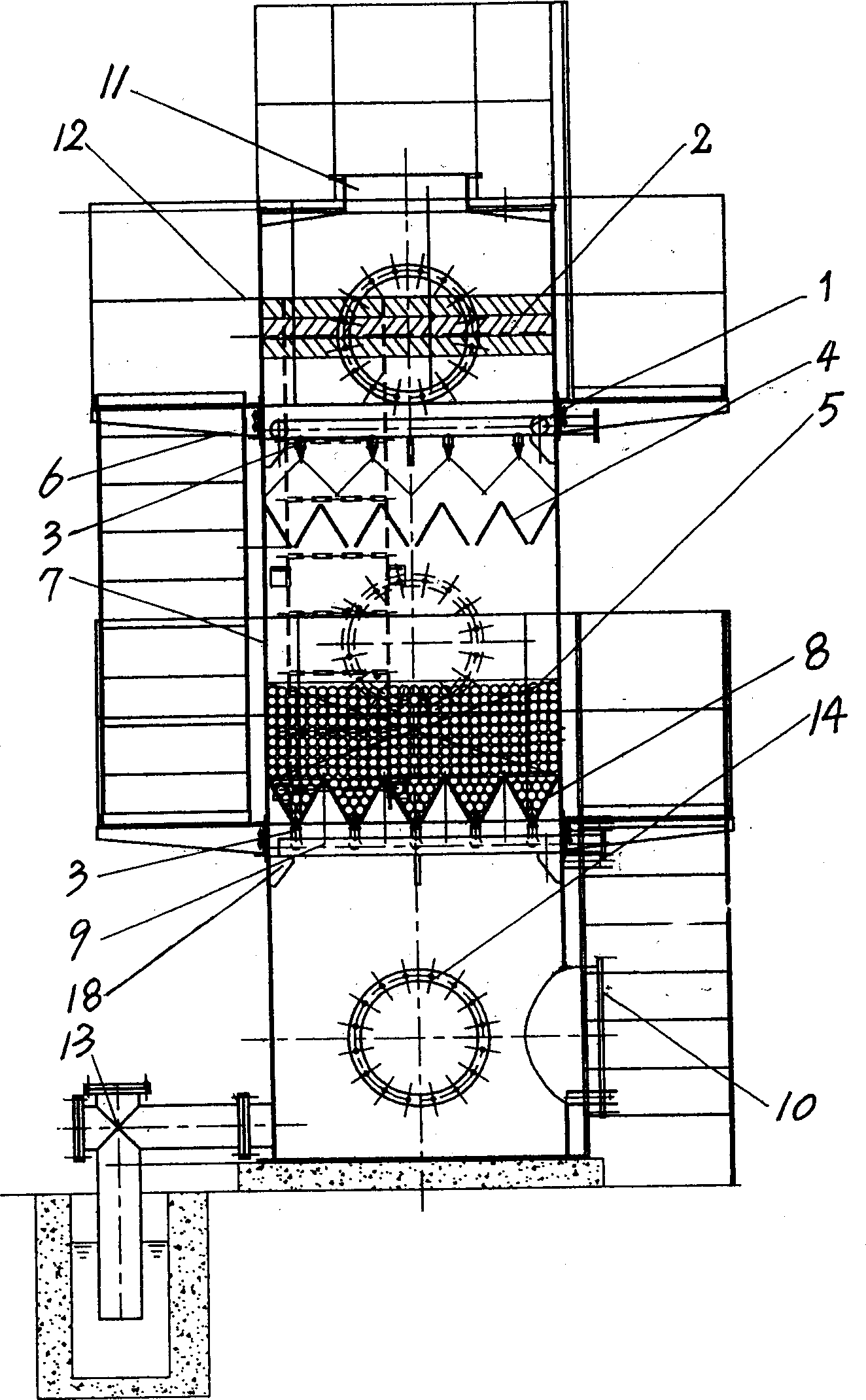

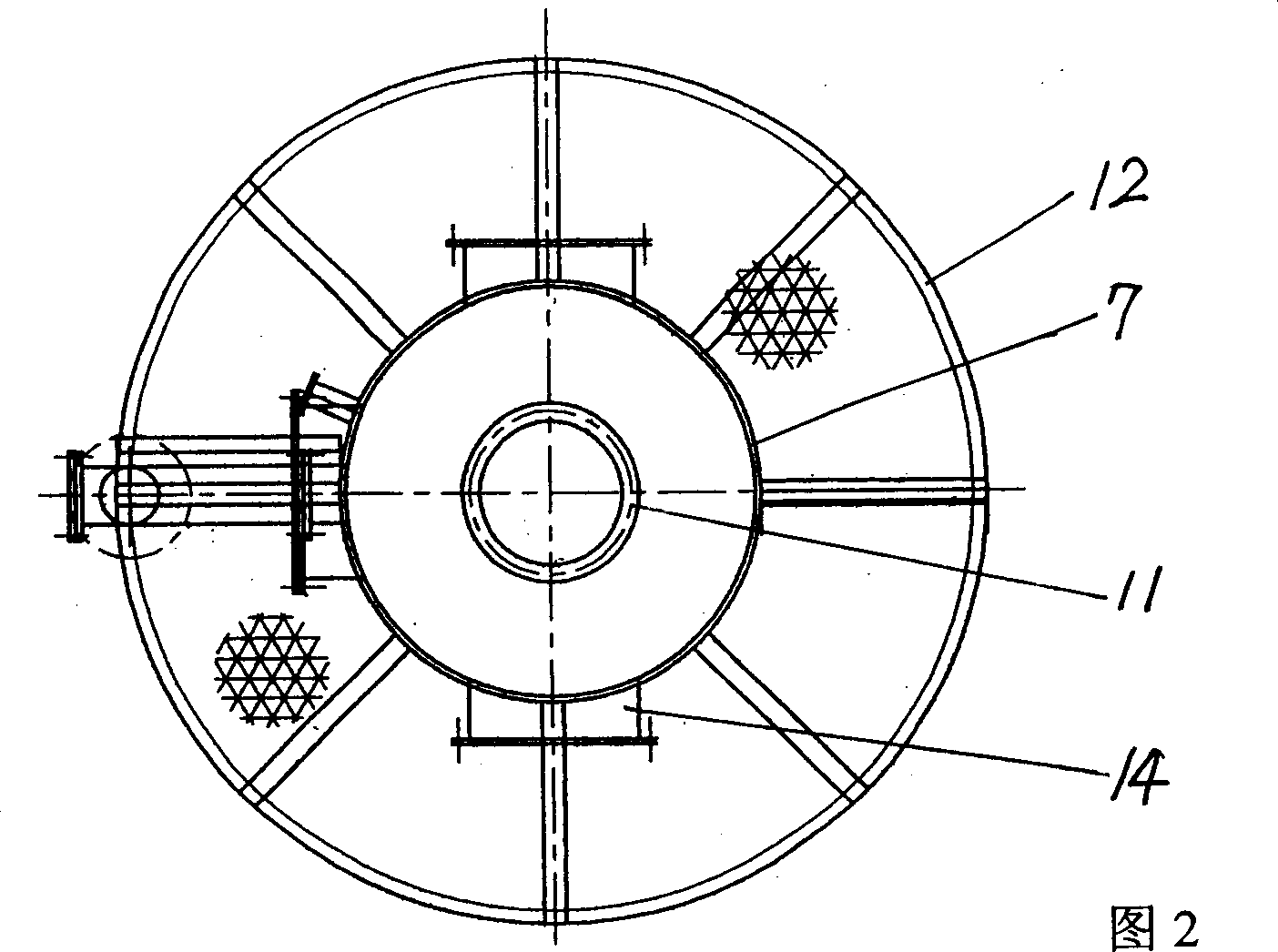

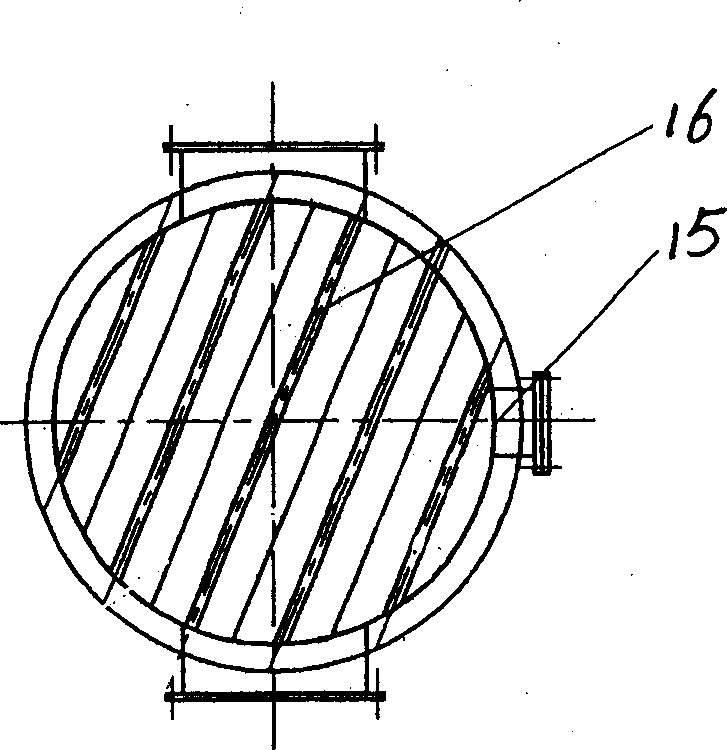

Three-phasefluidized turbulent ball gas washing tower

This invention relates to a device for processing resultants of burning gas especially to a three-phase fluidized turbulent ball gas washing tower including a shell set with an air intake at the bottom and a vent at the top, ladder and an operation platform fixed on the shell and an annealing pipe connected at the bottom of the shell, a baffle water-collector, an upper wind plate, an upper water spraying system with shower nozzles at the bottom, a turbulent ball filling layer, a lower wind plate and a lower spraying system with nozzles at the top, in which, the wind plate is porous and wave, slots are set between two adjacent wind plates at the trough, several isolated guide plates are set between the slots and the nozzles of the lower spraying system are set at the isolation place between the guide plates of the lower wind plate.

Owner:SHANXI KWONG FUK ENG

High-performance waterborne epoxy anticorrosive coating

InactiveCN111876052AIncrease the degree of cross-linkingImprove toughnessAntifouling/underwater paintsPaints with biocidesEpoxyPolymer science

The invention provides high-performance water-based epoxy anticorrosive coating. The coating comprises a component A and a component B. The component A is prepared from the following components in parts by weight: 60-70 parts of waterborne epoxy resin emulsion, 5-8.5 parts of styrene-acrylic emulsion, 2-3.5 parts of a zinc oxide / graphene oxide composite material, 0.5-1.2 parts of cerium-doped nanotitanium dioxide, 1-2 parts of nano attapulgite, 3-5 parts of organic bentonite, 0.2-3 part of pigment, 0.3-0.5 part of a silane coupling agent, 2-3 parts of n-butyl alcohol, 0.3-0.6 part of a dispersing agent, 0.3-0.5 part of a defoamer, 0.2-0.4 part of a leveling agent and 18-25 part of deionized water. The component B is prepared from the following components in parts by weight: 30-35 parts ofpolyether amine, 3-5 parts of diethylenetriamine, 25-32 parts of wet sericite powder and 8-12 parts of talcum powder. The anticorrosive coating is environmentally friendly, all the raw materials arematched with one another, and the prepared coating is good in anticorrosive effect, excellent in mechanical property and high in adhesive force.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Preparation method of multifunctional water treatment ceramisite filter material

InactiveCN108654207AWith self-cleaning abilitySuitable for pollution control processWater/sewage treatment by irradiationFiltration separationChemistryGlycerol

The invention discloses a preparation method of a multifunctional water treatment ceramisite filter material, and belongs to the field of environmental purification functional materials. The preparation method comprises the following technological steps: putting ceramisite into a hydrochloric acid solution with the concentration of 0.5 mol / L, carrying out constant temperature treatment on the solution and reaming ceramisites; preparing a titanium alkoxide and ceramisite mixture from ethanol, n-propanol, tetrabutyl titanate, glycerol and the ceramsites; adding a copper chloride aqueous solutionwith the solution of 0.3 mol / L into the titanium alkoxide and ceramisite mixture, stirring and filtering to obtain biofilm culturing ceramisites; drying the biofilm culturing ceramisites at 80 DEG Cfor 24 hours, calcining at the calcining temperature of 620 to 870 DEG C for 3 hours and naturally cooling to obtain the multifunctional water treatment ceramisite filter material. The filter materialcan utilize adsorption and biodegradation to purify sewage and also has self-cleaning ability under illumination, so that the multifunctional water treatment ceramisite filter material is suitable for water pollution treatment process with various forms.

Owner:SHENYANG LIGONG UNIV

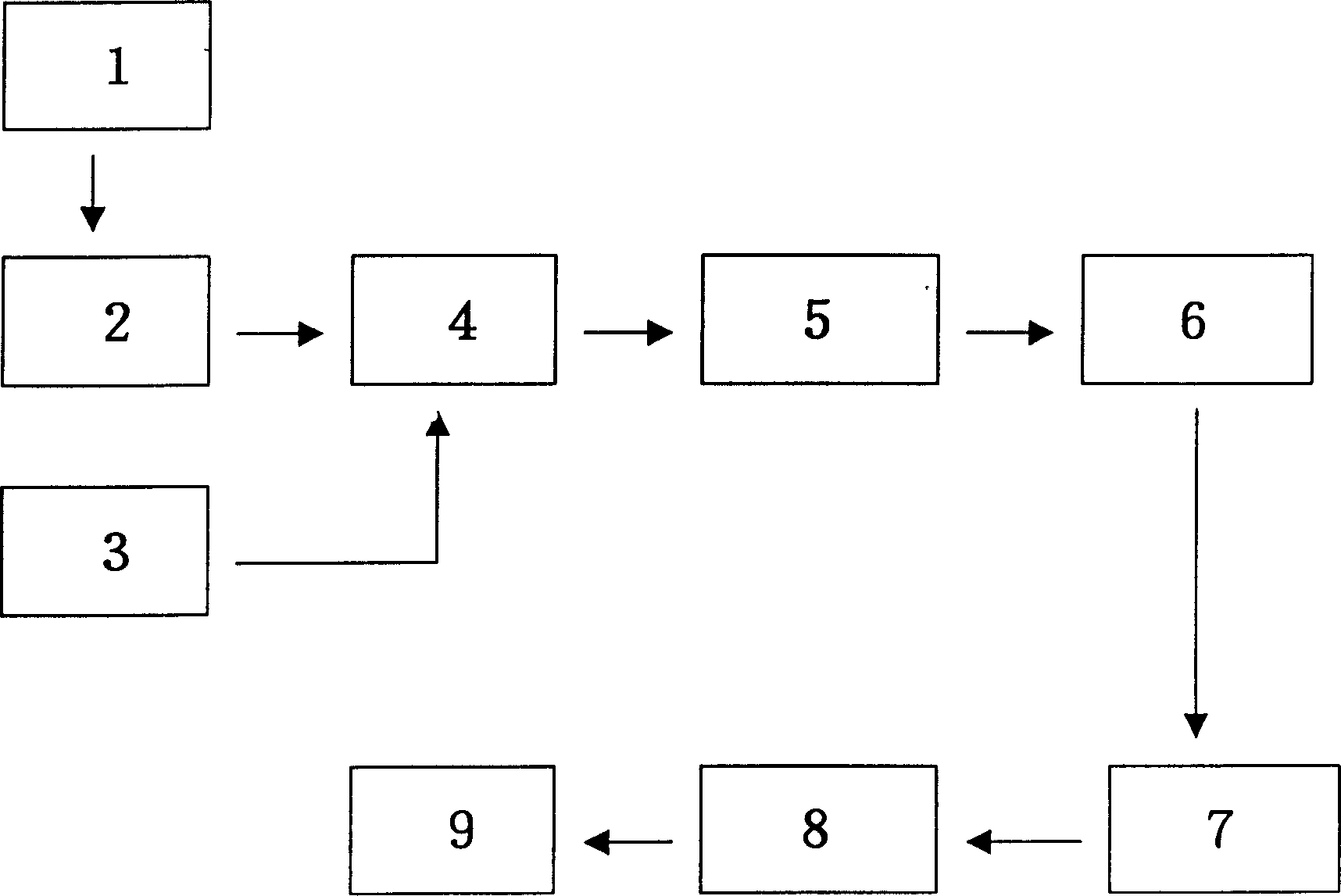

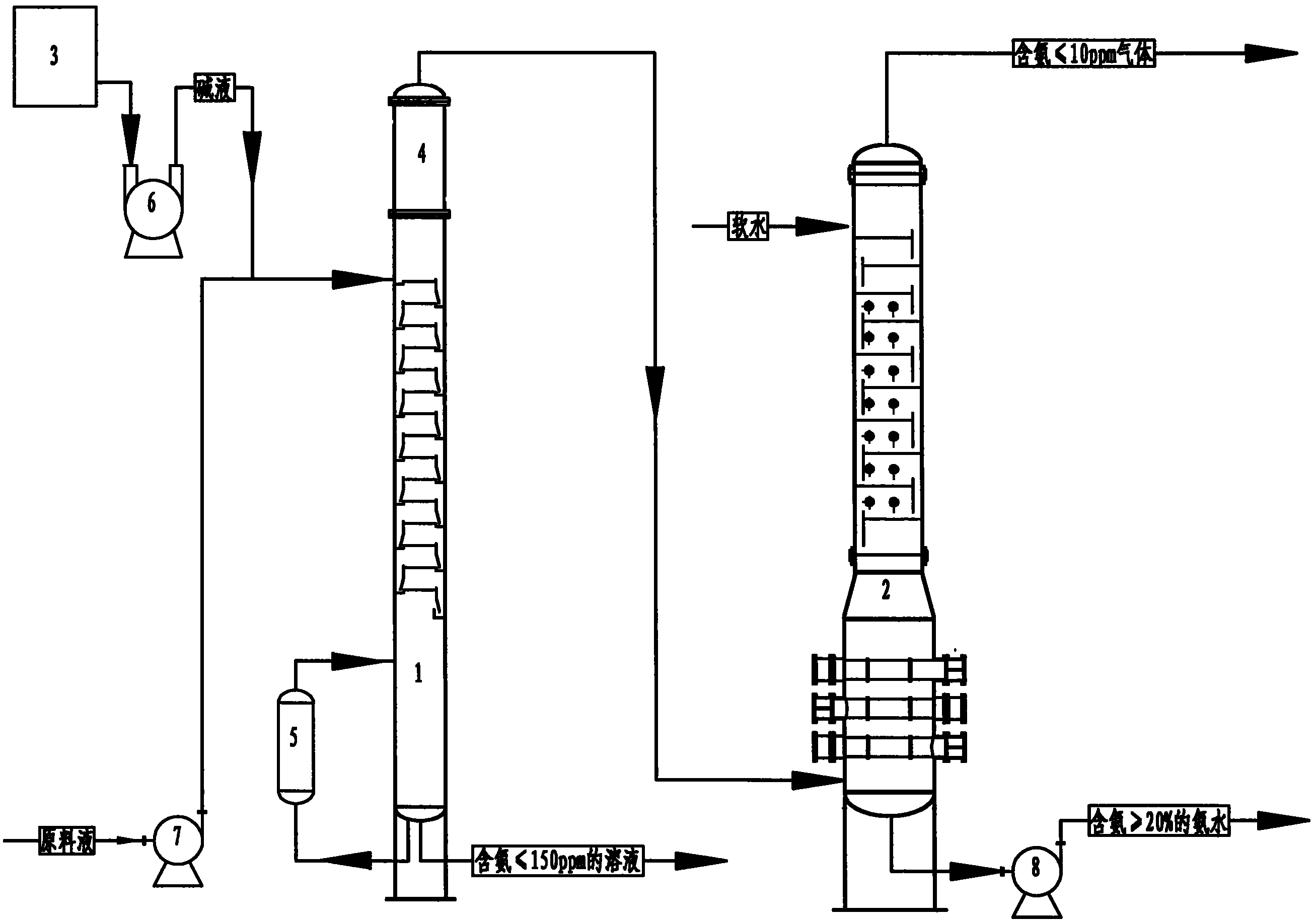

Ammonia recovery process and equipment for non-ferrous metal metallurgical industry

InactiveCN102303873AImprove efficiencyImprove distillation efficiencyAmmonia preparation/separationReboilerChemistry

The invention discloses an ammonia recovery process and equipment for a non-ferrous metal metallurgical industry. The process comprises the following steps: mixing a base liquid with a raw material liquid in a pipeline and then feeding a mixed liquid to the upper part of an ammonia still, and carrying out steam stripping to remove ammonia in the raw material liquid; feeding a low-ammonia aqueous solution obtained at the bottom of the ammonia still to the next process; condensing gas-phase ammonia on the top of the ammonia still in an ammonia dephlegmator so as to obtain high-concentration ammonia gas; feeding the high-concentration ammonia gas into the bottom of an ammonia recovery tower to be absorbed by soft water; and recovering and recycling the high-mass-concentration ammonia water obtained at the bottom of the ammonia recovery tower, and evacuating trace fixed gas at the top of the ammonia recovery tower. The equipment is suitable for the ammonia recovery process disclosed by the invention and mainly comprises the ammonia still and the ammonia recovery tower, wherein the upper part of the ammonia still is in pipe connection with an alkali formulating tank through an alkali liquid pump and in pipe connection with a raw material liquid through a raw material pump; the ammonia dephlegmator is arranged inside the upper part of the ammonia still, and the lower part of the ammonia still is externally connected with a reboiler and is in pipe connection with the upper part of the ammonia still; and the kettle bottom of the ammonia recovery tower is in pipe connection with an ammonia water pump, the upper part of the ammonia recovery tower is in pipe connection with a soft water pipe, and the top of the ammonia recovery tower is provided with a discharge pipe.

Owner:TIANJIN CHUANGJU TECHNOLGOY +1

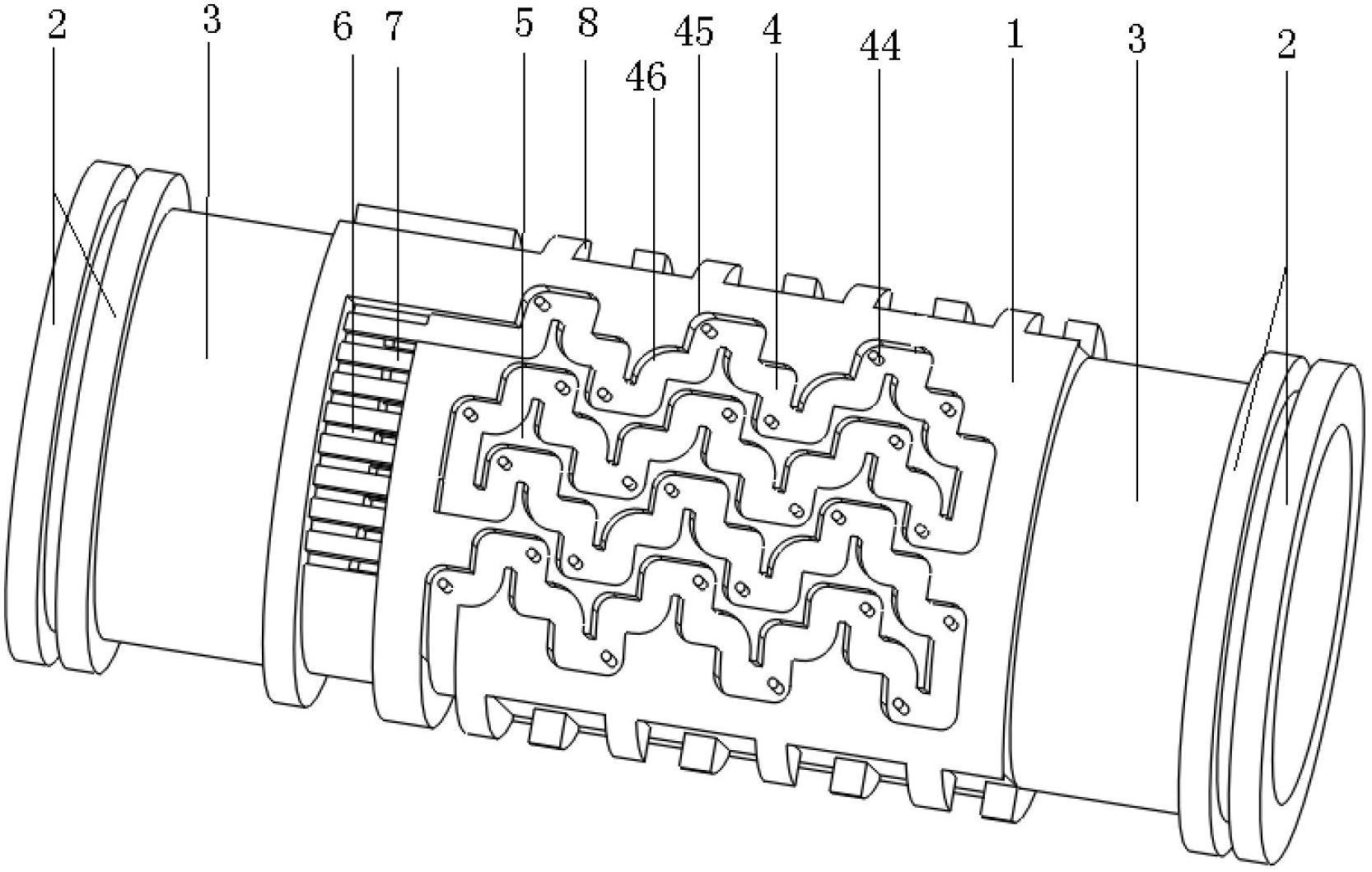

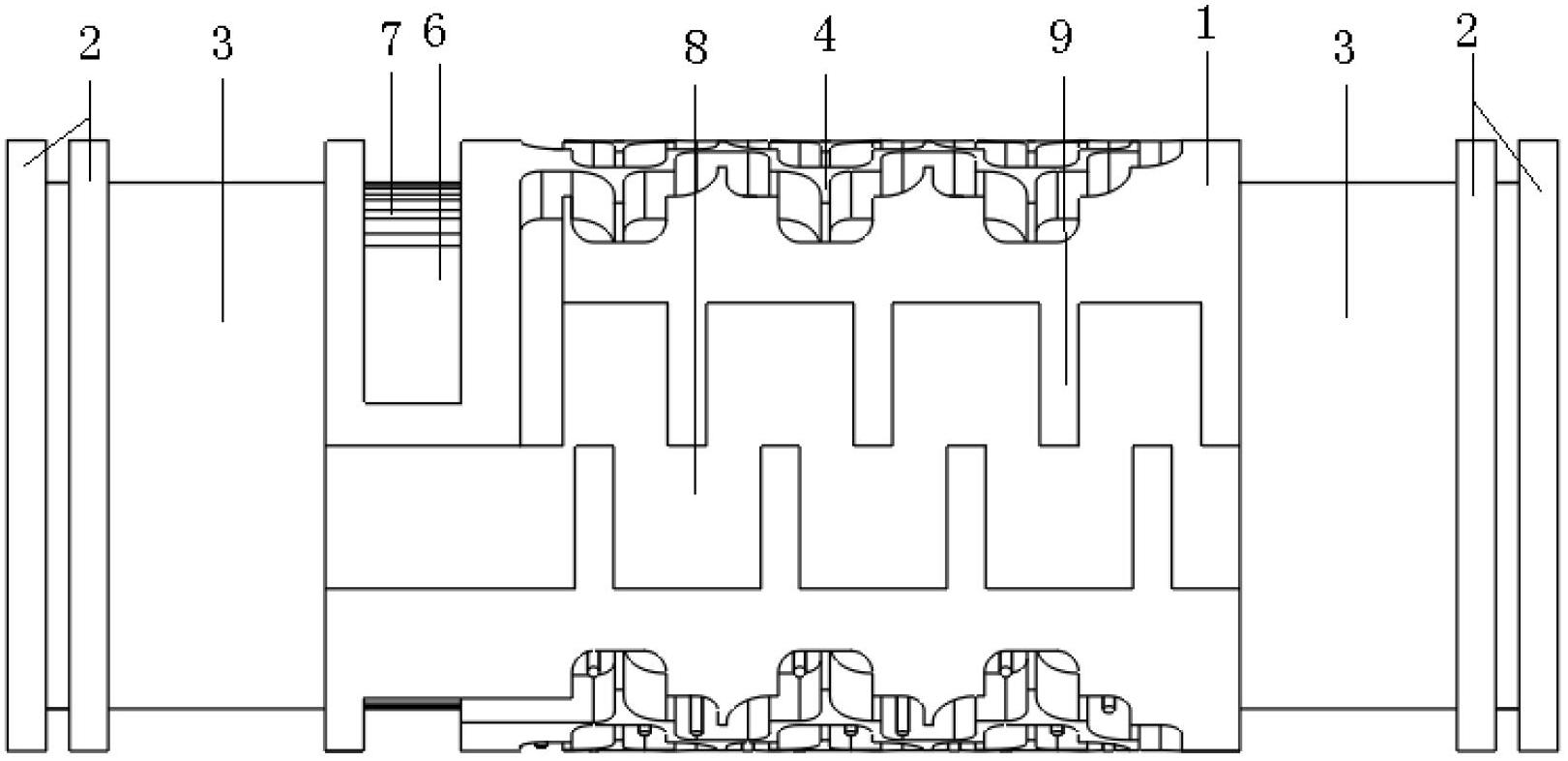

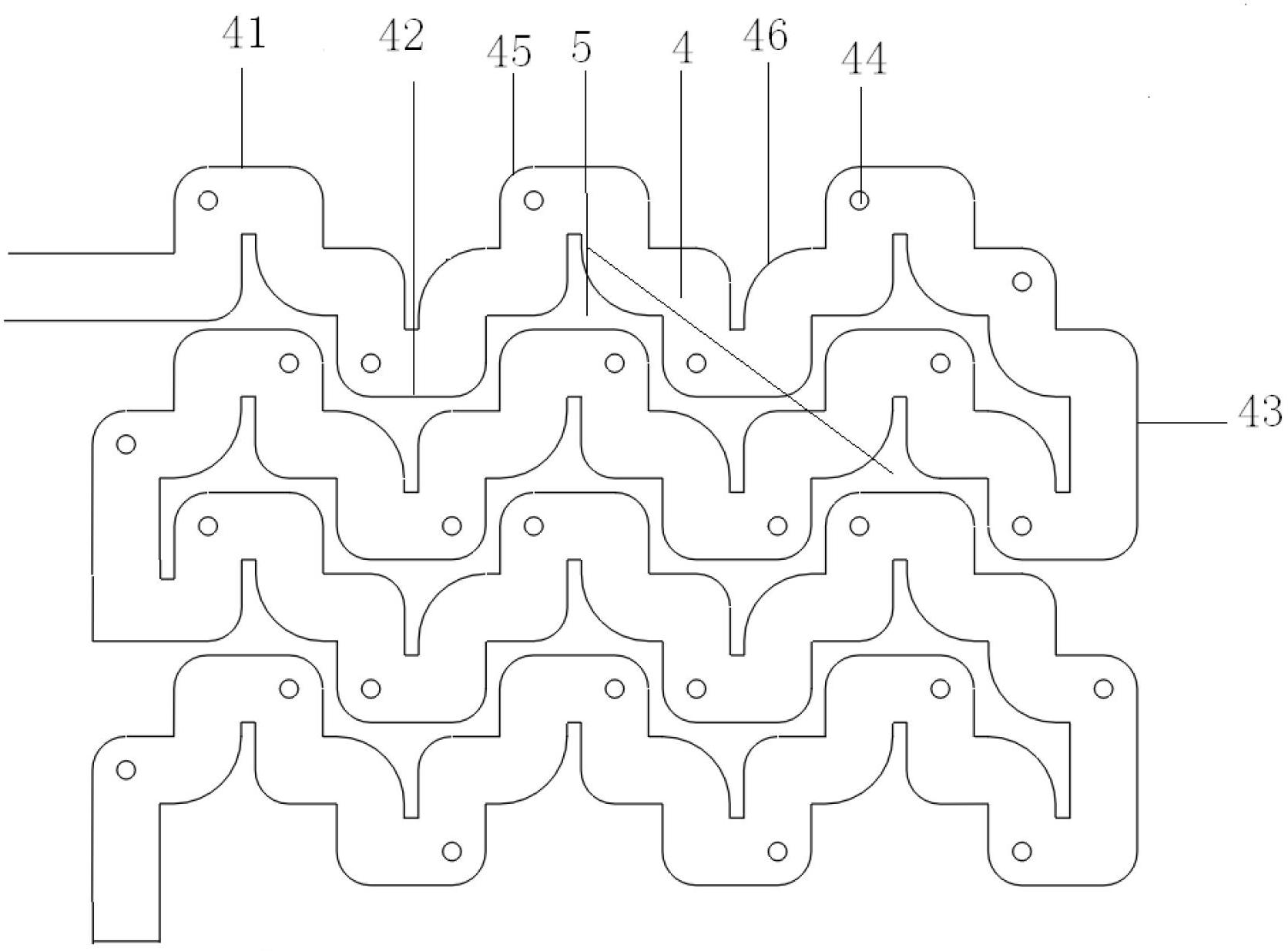

Special surface drip irrigation emitter capable of automatically cleaning blocking antibiotic membranes

ActiveCN102658246AIncreased turbulenceIncrease carrying capacitySpray nozzlesDrip irrigationEngineering

The invention relates to a special surface drip irrigation emitter capable of automatically cleaning blocking antibiotic membranes. The special surface drip irrigation emitter is characterized by comprising a dripper body disposed in a drip irrigation tube, two end adhesion surfaces are disposed at the outermost ends of two axial sides of the dripper body, two water outlets are arranged on the dripper body and positioned on inner sides of the two end adhesion surfaces, two groups of flow channels are radially arranged on the dripper main body at intervals and positioned between the two water outlets, each group of flow channels consists of a plurality of flow channels axially disposed and communicated with each other, two water inlets are arranged at one end of the dripper body and positioned among the two groups of flow channels and the corresponding water outlet at intervals, a trash rack is arranged on each water inlet, each group of flow channels is connected with the corresponding water inlet, two flow buffering areas are axially arranged on the surface of the dripper body and between the two groups of flow channels, a plurality of water retaining components are arranged inside each flow buffering area in a staggered manner, a radial side of each flow buffering area is correspondingly communicated with one group of flow channels, and two axial ends of the two flow buffering areas are correspondingly communicated with the water outlets at the corresponding ends.

Owner:CHINA AGRI UNIV

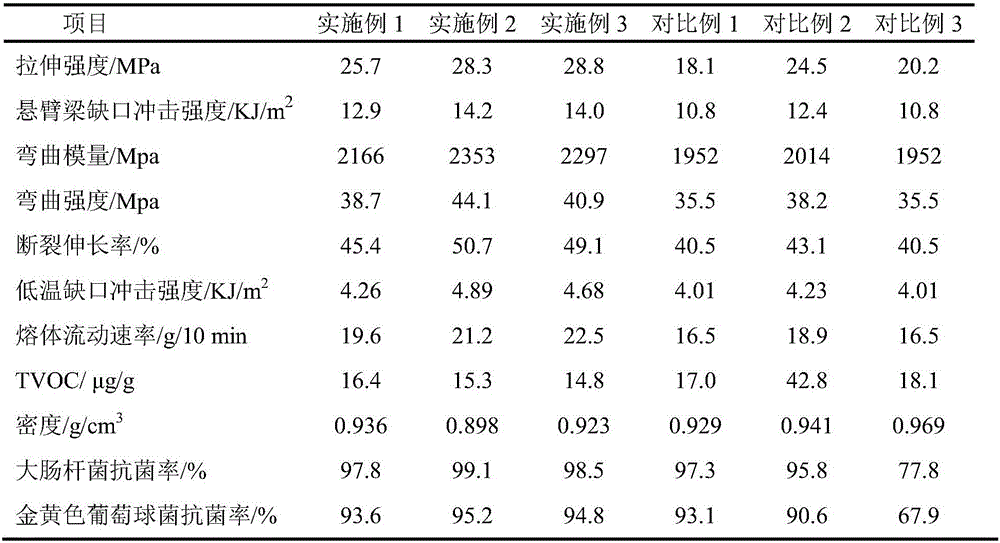

Preparation method of low-VOC (volatile organic compound) antimicrobial glass-fiber-reinforced polypropylene (PP) composite material

InactiveCN106046544AEfficient catalytic degradationEnergy-saving catalytic degradationPolypropylene compositesGlass fiber

The invention discloses a preparation method of a low-VOC (volatile organic compound) antimicrobial glass-fiber-reinforced polypropylene (PP) composite material. The preparation method comprises the following steps: drying raw materials; respectively carrying out melt blending by a double screw extruder to prepare a glass-fiber-reinforced PP master batch and a hollow glass microsphere master batch; and mixing the glass-fiber-reinforced PP master batch and hollow glass microsphere master batch, and carrying out injection molding by a single-screw injection molding machine to obtain the low-VOC antimicrobial glass-fiber-reinforced PP composite material. The composite material obtained by the preparation method can catalytically degrade VOCs in the vehicles in a high-efficiency energy-saving environment-friendly way without the aid of any external ultraviolet light source or facility. The added compatilizer-coated hollow glass microspheres have favorable compatibility with the glass-fiber-reinforced PP on the premise of not lowering the strength of the composite material, and can effectively lower the density; and the addition of a small amount of the silver-carried antimicrobial agent greatly enhances the antimicrobial property. The preparation method disclosed by the invention is simple and reliable.

Owner:SUZHOU RONGCHANG COMPOUND MATERIAL

Self-cleaning high-crack-resistance self-leveling veneer mortar and preparation method

The invention discloses a self-cleaning high-crack-resistance self-leveling veneer mortar. The mortar is prepared from, by weight, 25-35% of white cement, 0.5-1.0% of a water reducing agent, 1-2% of an expanding agent, 0.2-0.5% of nano titanium dioxide, 2-6% of alkali activation pulverized fuel ash and 10-13% of water. The sum of the weight percentage of all the raw materials is 100%. The invention further discloses a preparation method of the self-cleaning high-crack-resistance self-leveling veneer mortar. The method comprises the following steps that after the titanium dioxide and the alkaliactivation pulverized fuel ash are mixed and stirred, the mixture, white Portland cement, metakaolin, redispersible emulsion powder and the expanding agent are added into a stirrer according to a proportion, white sand is added for stirring for one minute, and finally fibers are added for stirring for 3-5 minutes. The self-cleaning high-crack-resistance self-leveling veneer mortar has better crack resistance, fluidity and self-cleaning performance and can be widely applied to large-size outer wall face layers of assembly-type buildings, and the social and economic benefits are obvious.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Anti-pollution flashover coating for electrical device and preparation method thereof

InactiveCN107652885ABoth hydrophobicHydrophobicAntifouling/underwater paintsPaints with biocidesSilanesSolvent

The invention relates to the field of coatings, and specifically relates to an anti-pollution flashover coating for an electrical device and a preparation method thereof. The coating is hydrophobic, insulated and self-cleaning coating developed based on pollution flashover occurring principle and is applicable to the surface treatment of an outdoor electrical device, in particular an insulator. The anti-pollution flashover coating comprises 5-20 parts of organic silicon resin, 2-12 parts of fluoridized titanium dioxide powder, 1-10 parts of fumed silica powder, 0.1-0.5 part of silane couplingagent, 0.2-3 parts of auxiliary, 0.3-2 parts of carbon black, 50-80 parts of mixed solvent, and 8-15 parts of a curing agent. The anti-pollution flashover coating has the beneficial effects of being hydrophobic, anti-pollution, self-cleaning, and insulated, and is applicable to an outer coating layer of the outdoor electrical device; nano silica and the silane coupling agent are compounded, so that the superficiality of the coating layer is greatly reduced, and the hydrophobic and oleophobic performances of the coating layer are improved; nano fluoridized titanium dioxide is added, so that thecoating is capable of self-cleaning; the coating has a good adhering performance relative to a base material, and is high in weather resistance, resistant to high- and low-temperature, resistance toillumination, and resistance to radiativity.

Owner:湖南创研工业技术研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com