Treatment method of zinc-bearing dust for steel works

A processing method and technology of iron and steel plants, applied in the metallurgical field, can solve the problems such as the failure of the rotary hearth furnace, the failure of the waste heat boiler or the heat exchanger, and the influence of the operation rate of the rotary hearth furnace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

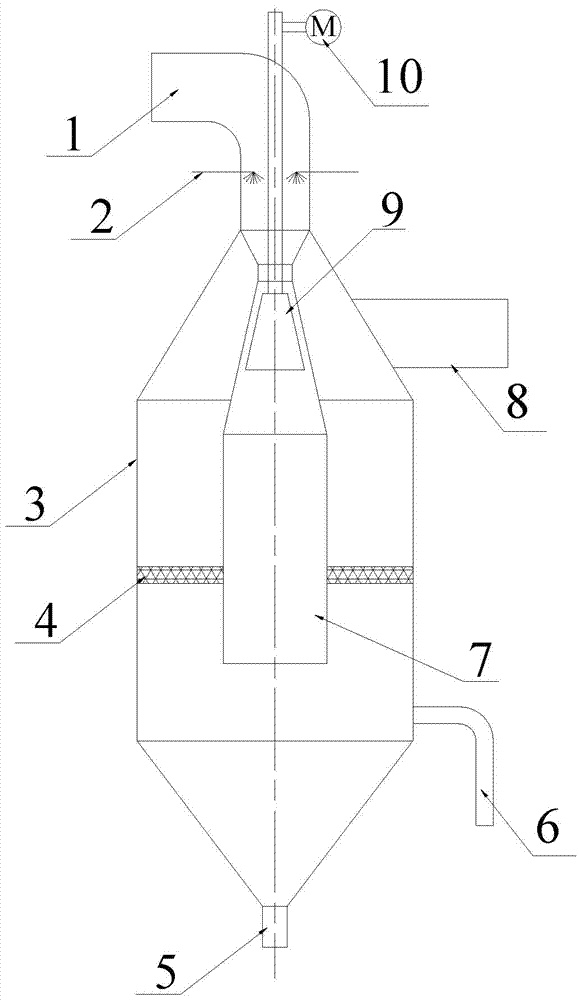

[0020] The present invention will be further described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention and implement it.

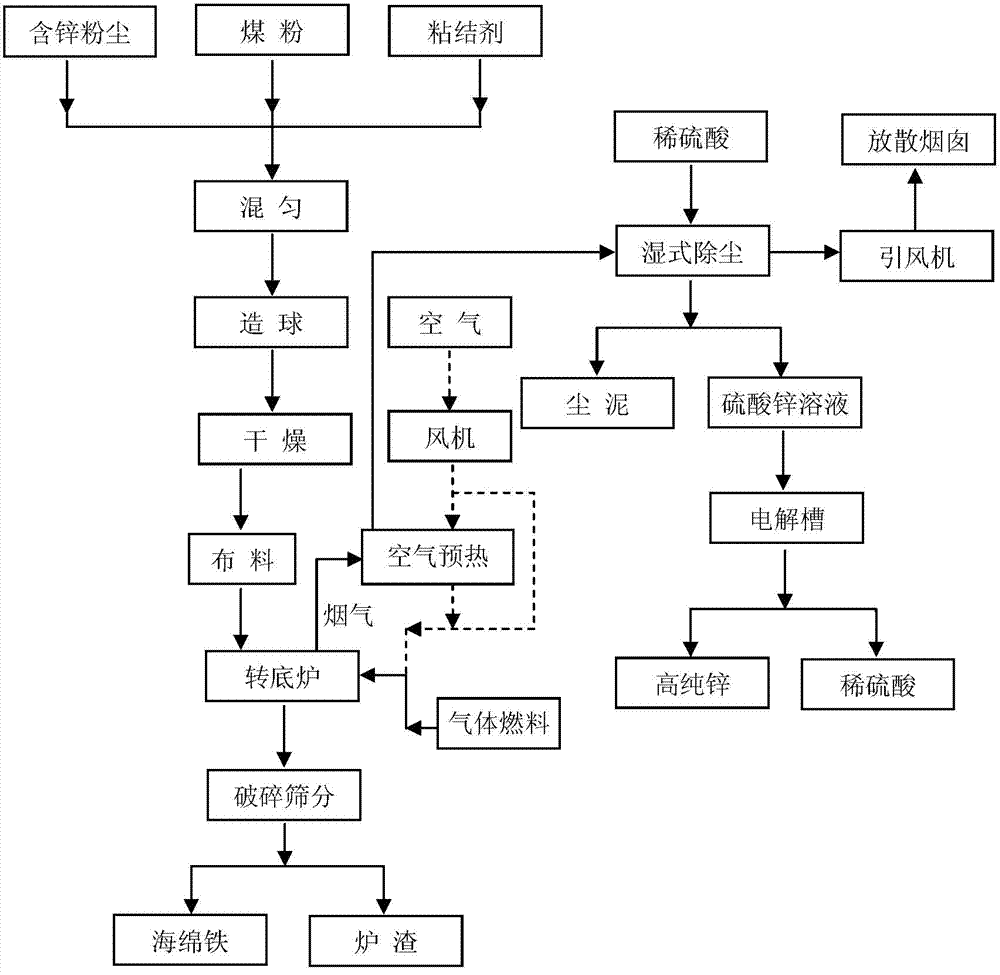

[0021] The present invention proposes a treatment method for zinc-containing dust in iron and steel plants, such as figure 1 shown, including the following steps:

[0022] Step 1: Mix the iron and steel plant zinc dust, coal powder and binder in proportion to make green balls. The particle size of the green balls is 7 mm to 13 mm; the mass of the zinc dust, coal powder and binder mixed The ratio is 1:(0.27~0.33):(0.04~0.08).

[0023] The zinc-containing dust of the iron and steel plant includes sintering dust, blast furnace dust, blast furnace gas ash, blast furnace gas mud, converter dust, converter gas ash and steel rolling scale, etc., and its main components are iron oxide, zinc oxide , silicon dioxide, and a small amount of alkali metal oxides such as potassium and sod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com