Method for heating special steel with low-heat-value blast furnace coal gas

A blast furnace gas and special steel technology, applied in blast furnaces, heat treatment furnaces, blast furnace details, etc., to reduce the exhaust gas temperature, improve the heating quality, and stabilize the combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

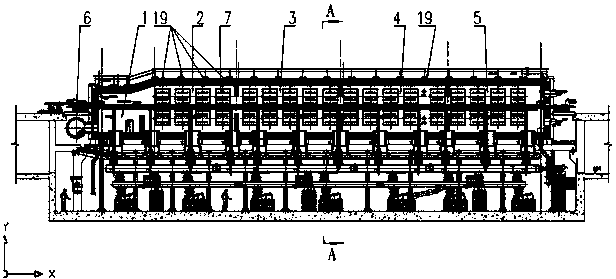

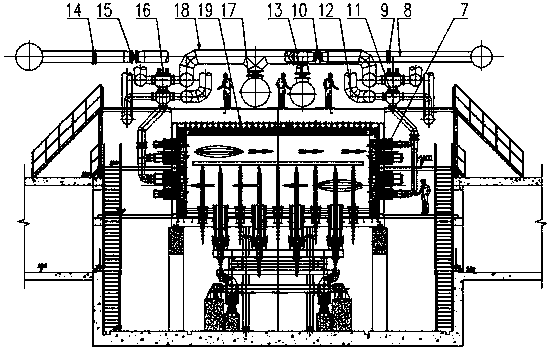

[0022] Taking the 140t / h special steel heating furnace of Jiangsu Zhongtian Iron and Steel Group as an example, the heating furnace adopts 5-stage furnace temperature control. Section 1, the first heating section 2, the second heating section 3, the third heating section 4 and the soaking section 5 control the heating temperature of each heating section according to the heating process requirements of each steel type, and the implementation method is as follows:

[0023] (1) On the heating furnace, air and gas double regenerative combustion control mode is adopted, and a tail flue 6, a chimney and a 5m-long preheating section 1 without burners are left at the end of the furnace. By adjusting the first heating section 2 The section air-smoke regulating valve 13 and the section soot regulating valve 17 reduce the amount of flue gas entering the air and gas double regenerative storage type regenerative burner 7 from 100% to 50%, and the remaining 50% of the flue gas It flows long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com