Rotor expander

A rotor expansion and male rotor technology, applied in the field of rotor expanders, can solve the problems of shortening the service life of the blades, increasing the use cost, reducing the work efficiency, etc., and achieve the effect of improving the overall efficiency, increasing the efficiency, and reducing the use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

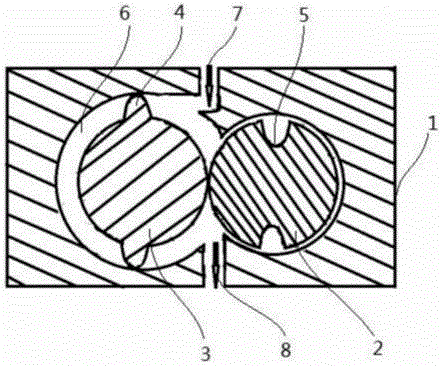

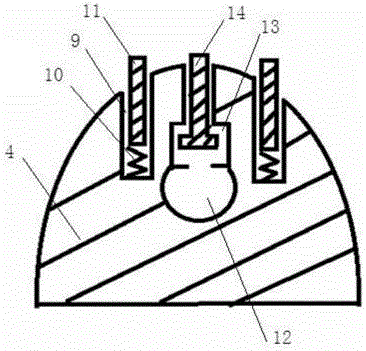

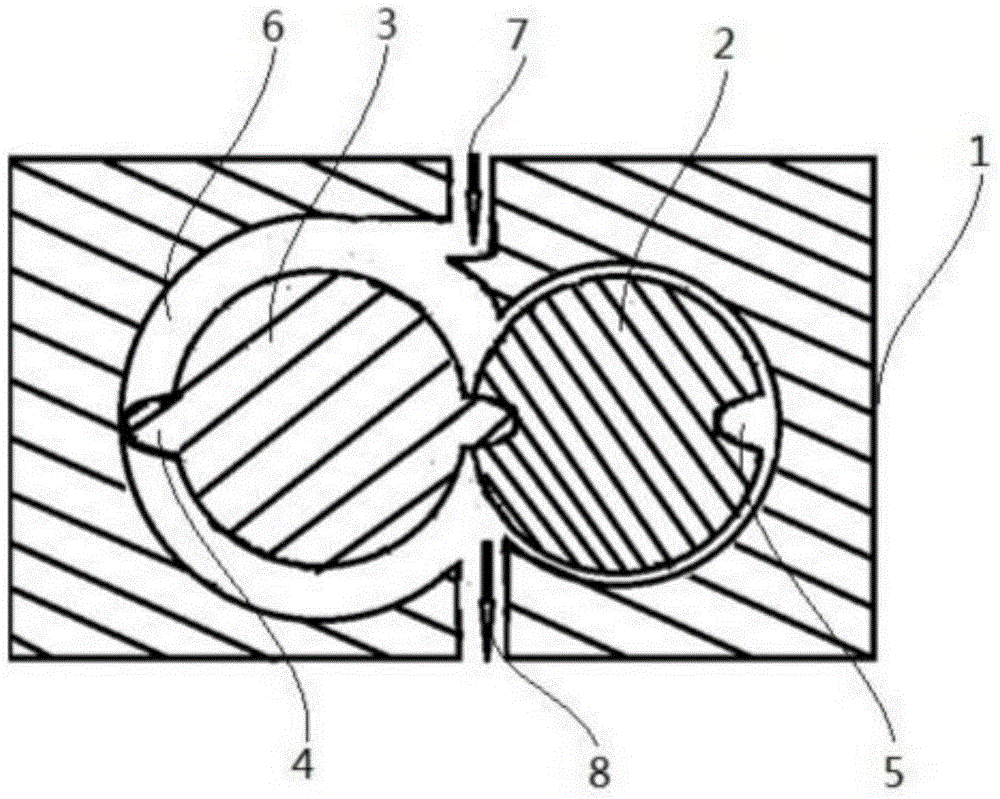

[0035] Such as figure 1 and image 3 As shown, the present invention discloses a rotor expander, which includes a cylinder body 1 , a female rotor 2 and a male rotor 3 inside the cylinder body 1 . The male rotor 3 and the female rotor 2 are cylinders with tangential outer diameters and the same diameter. The cylinder body 1 is provided with a synchronous gear that drives the male rotor 3 and the female rotor 2 to rotate synchronously and reversely. The synchronous gear is an existing A common structure in the technology will not be repeated here. The male rotor 3 is provided with protruding vanes 4 extending radially outward from its outer circumference, and the female rotor 2 is provided with grooves 5 that cooperate with the protruding vanes 4 on the male rotor 3 When the male rotor 3 and the female rotor 2 rotate synchronously in reverse to the meshing position, the protruding blades 4 fit into the grooves 5 . An annular gas channel 6 is provided inside the cylinder body...

Embodiment 2

[0041] Such as Figure 4 and Figure 5 As shown, the principle and structure of this embodiment and Embodiment 1 are basically the same, the difference is that there are two male rotors, and the two male rotors are symmetrically arranged on both sides of the female rotor, and a total of Two grooves corresponding to the male rotor. Said gas channel surrounds the outer surface of each male rotor successively from the air inlet to the air outlet.

Embodiment 3

[0043] Such as Figure 6 and Figure 7 , the principle and structure of this embodiment and Embodiment 1 are basically the same, the difference is that there are four male rotors, and the four male rotors are evenly distributed along the circumferential direction of the female rotor, and there are four The corresponding groove of the male rotor. When the four male rotors are in a series structure, the gas channel surrounds the outer surface of each male rotor in turn from the air inlet to the air outlet. The four male rotors can also be connected in parallel, and the principle is the same.

[0044] In addition, it can also be designed as a structure of 6 male rotors and 1 female rotor, 6 male rotors are evenly distributed along the circumference of the female rotor, and 6 grooves are evenly distributed on the female rotor to match the blades of each male rotor. Blade and groove also can be other shapes such as rectangle.

[0045] The present invention does not have sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com