Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73 results about "Gravitational effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The one effect is gravity. That is, the gravitational force is one way of explaining the phenomenon that we call gravity. Since it is a force, the effect is the same as any force: a contribution to the acceleration in the direction of the force.

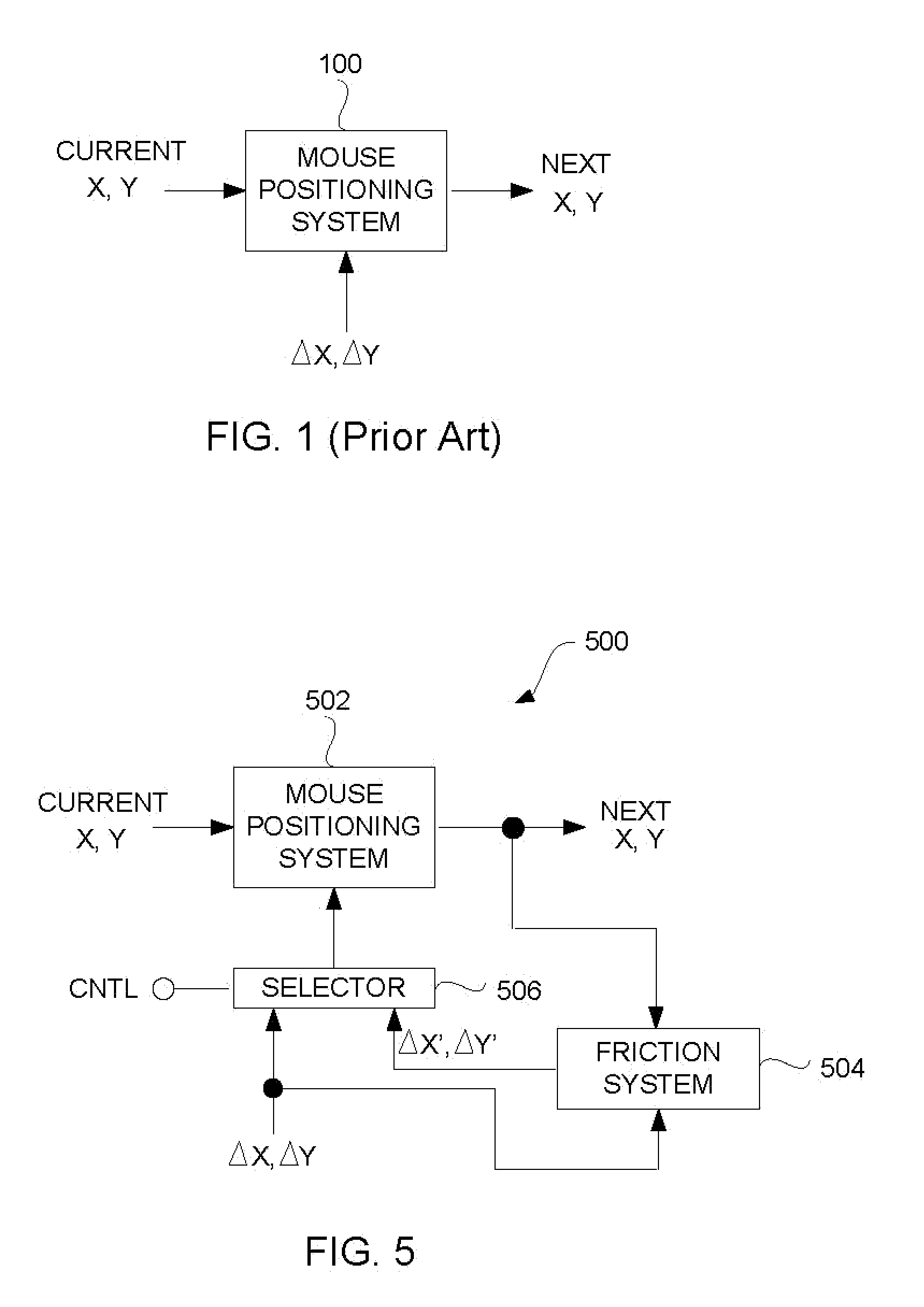

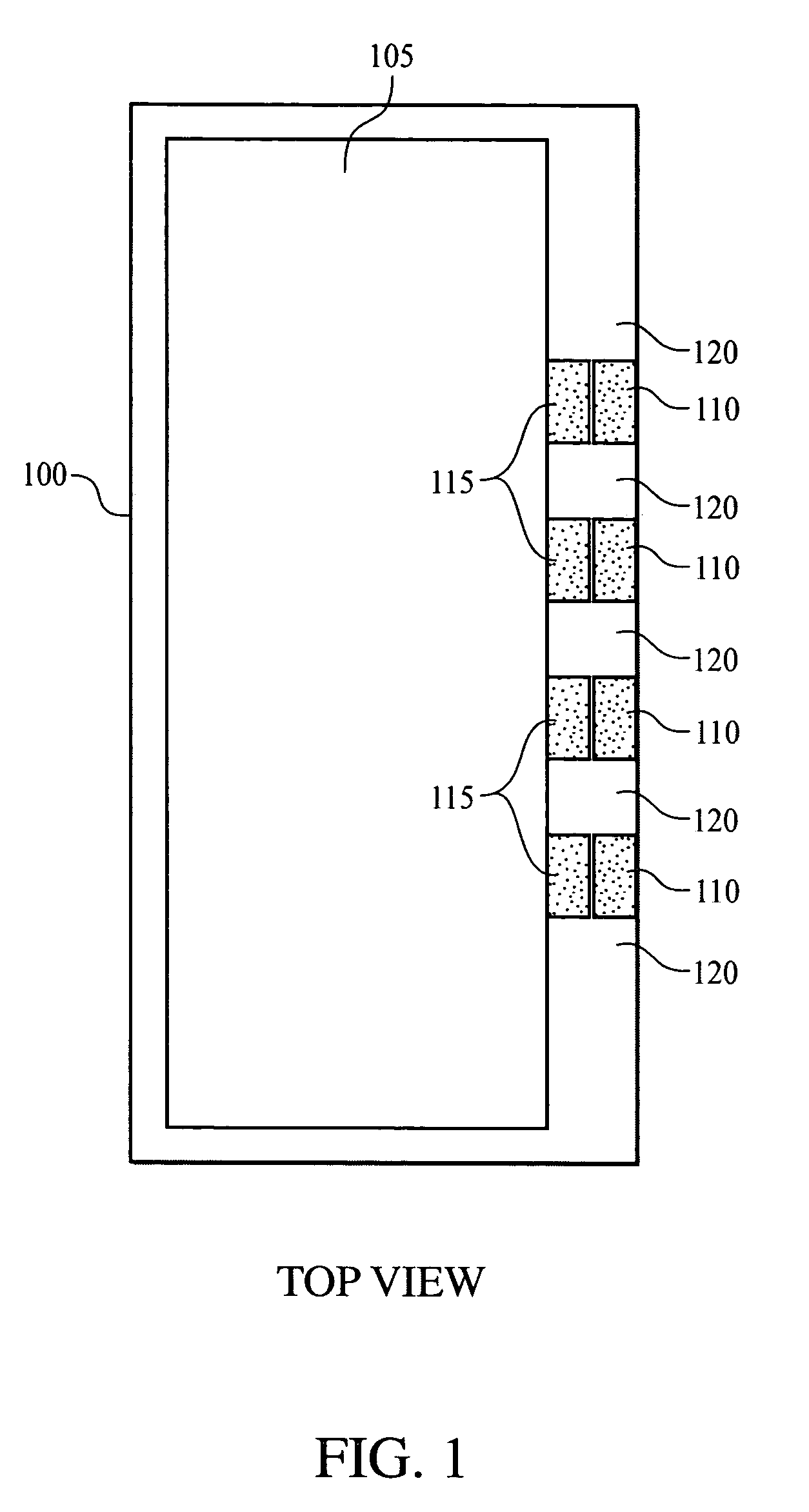

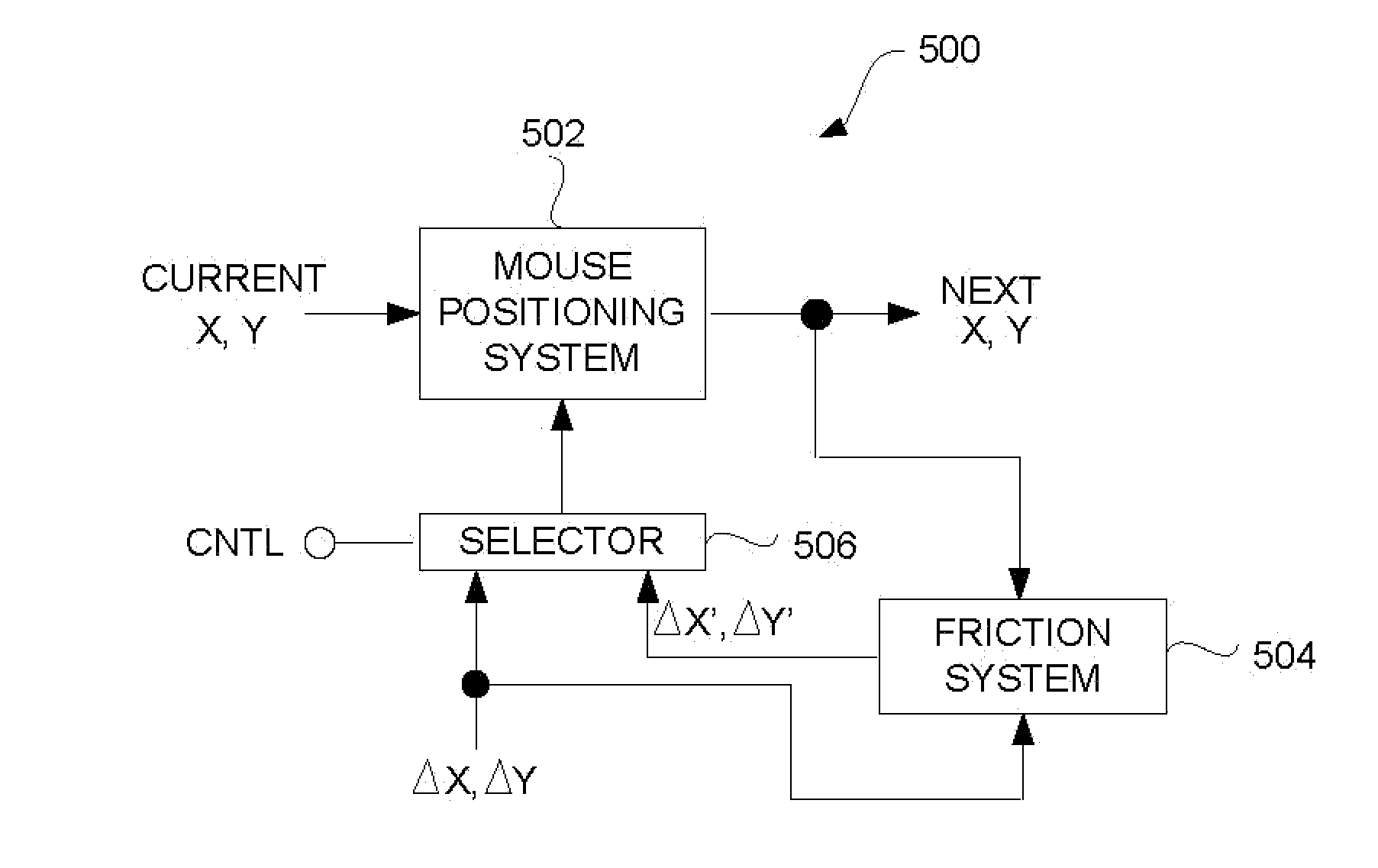

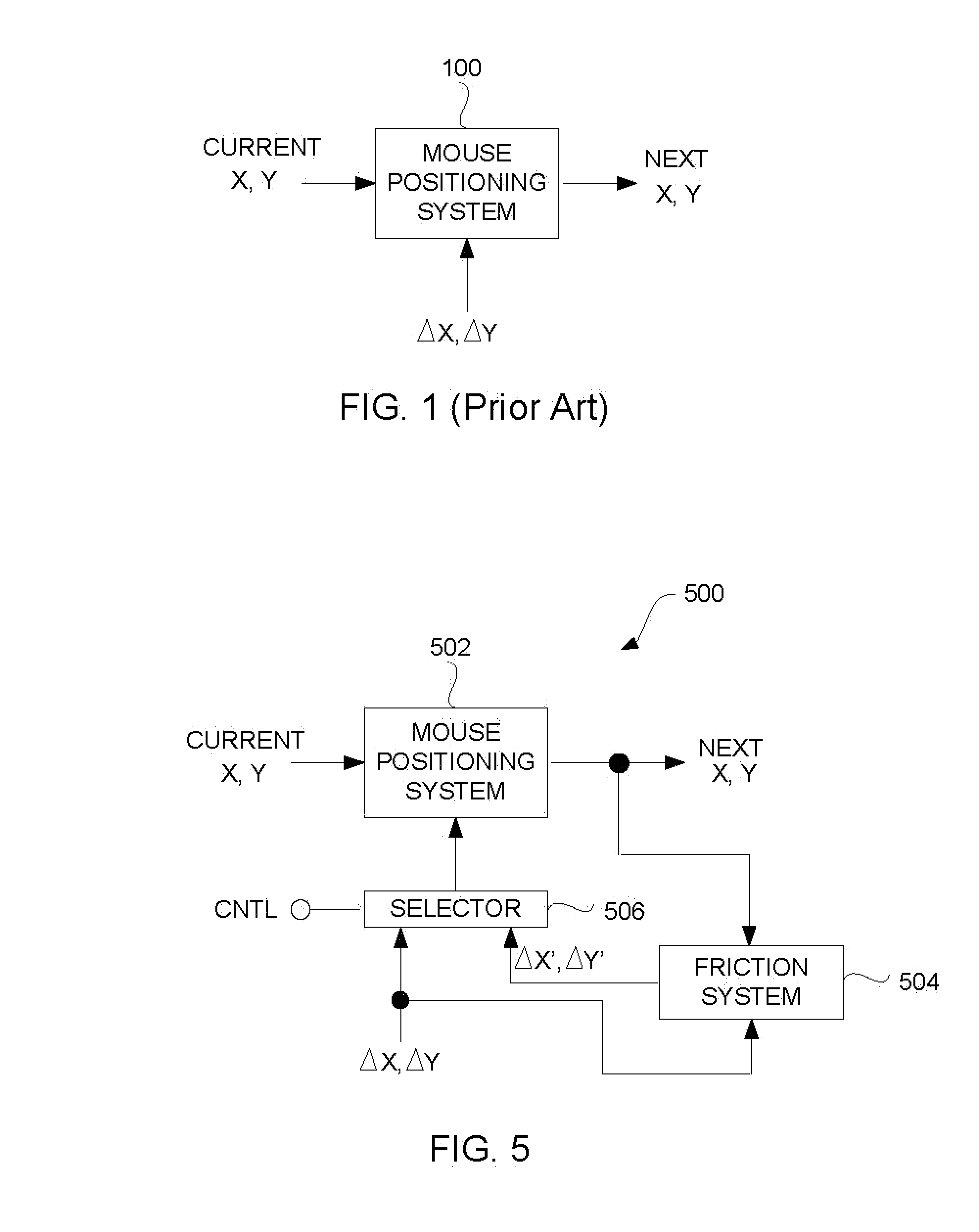

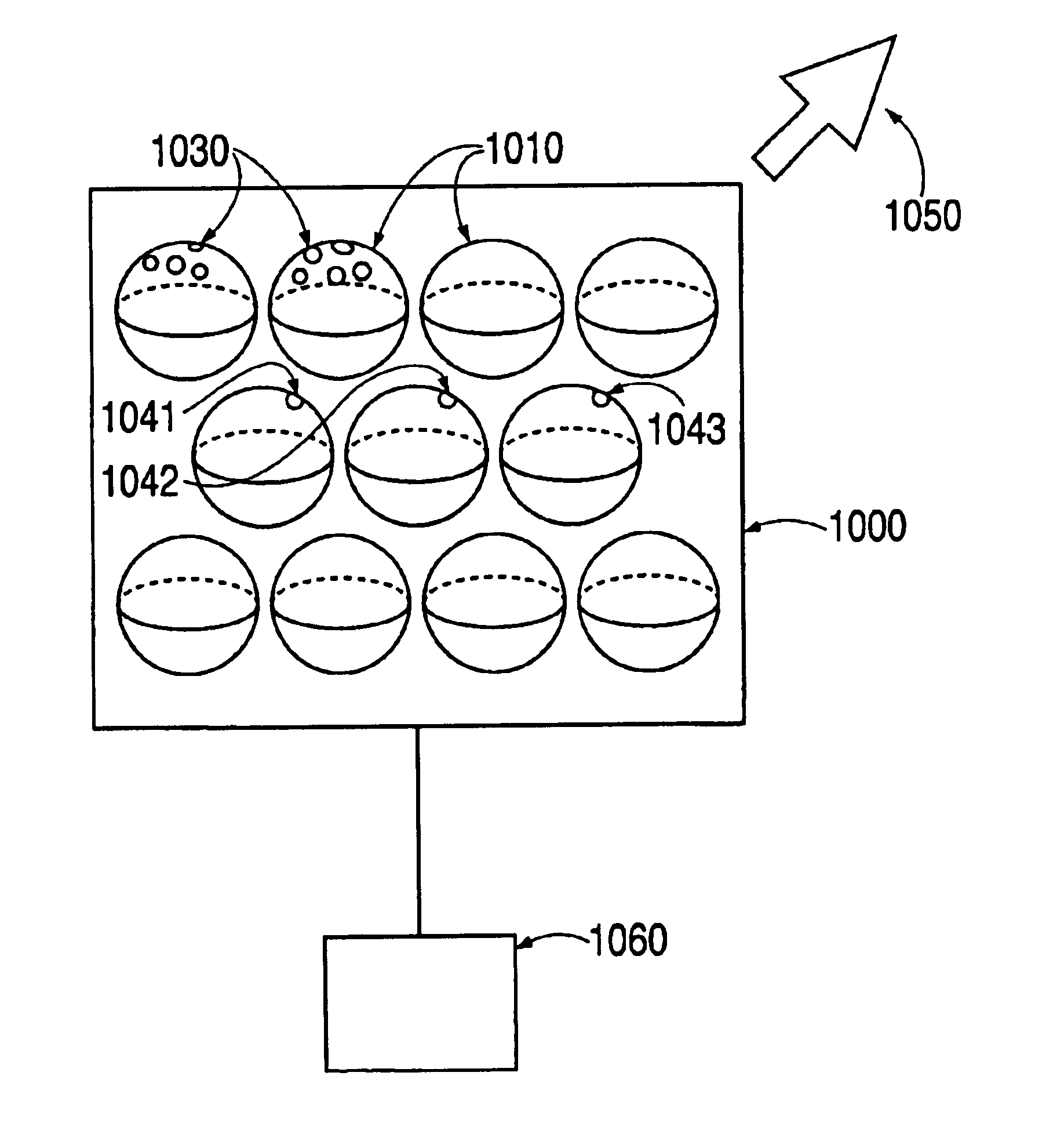

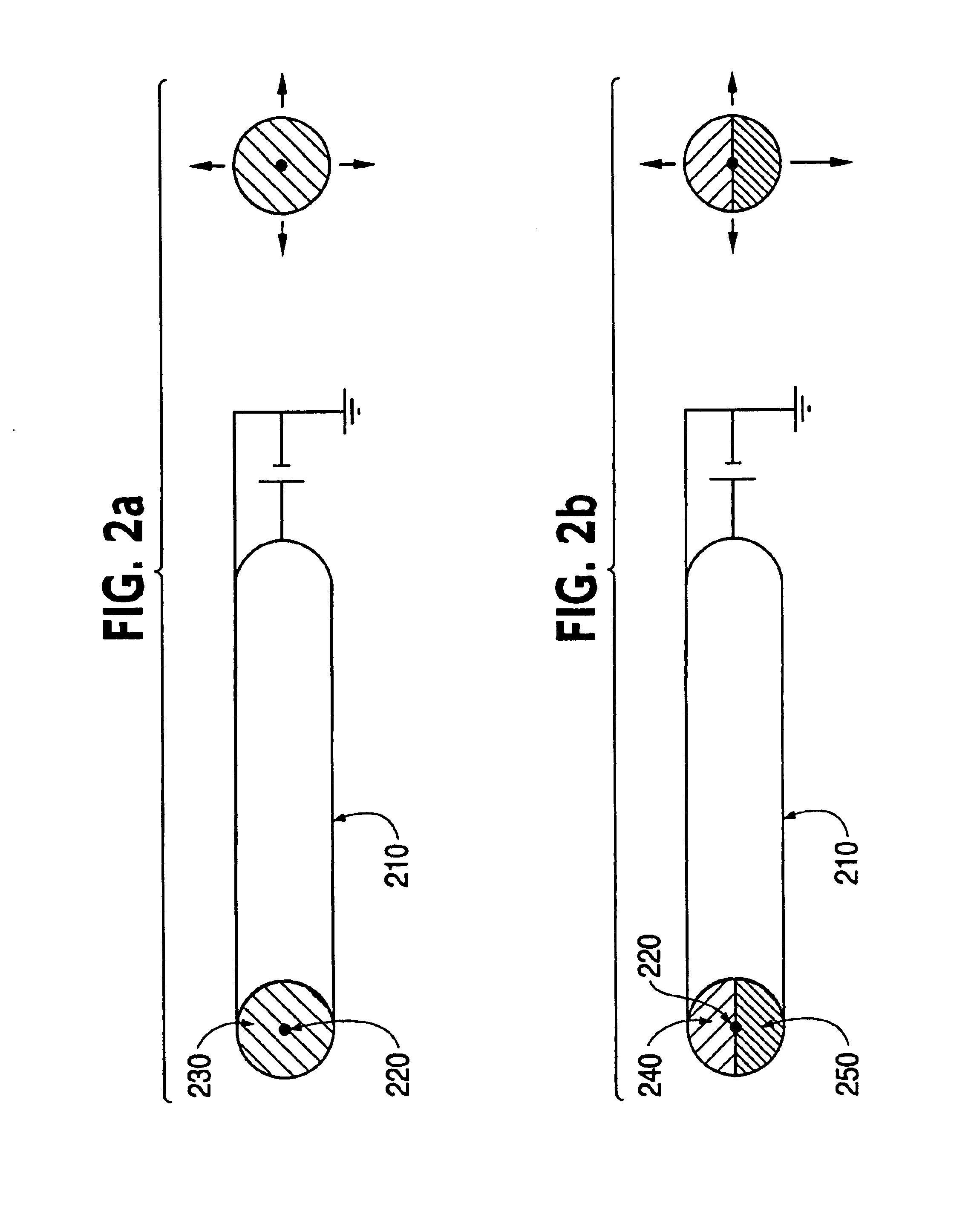

Responsiveness Control System for Pointing Device Movement with Respect to a Graphical User Interface

InactiveUS20090015550A1Improve user interactionEasy to navigateCathode-ray tube indicatorsInput/output processes for data processingGraphicsGraphical user interface

Improved techniques that enable control of responsiveness to user movement of a pointing device with respect to a graphical user interface are disclosed. According to one embodiment, by controlling responsiveness, a friction effect can be imposed at predetermined regions of the graphical user interface. According to another embodiment, by controlling responsiveness, a gravitational effect can be imposed at predetermined regions of the graphical user interface. According to still another embodiment, by controlling responsiveness, frictional and gravitational effects can be imposed at predetermined regions of the graphical user interface. The responsiveness control, e.g., frictional effect and / or gravitational effect, can be used to enhance user interaction with the graphical user interface. For example, user controls, such as buttons, boxes, borders, boundaries, etc., can be more easily navigated and selected by users when the regions associated with such user controls are provided with modified responsiveness control (e.g., frictional effect and / or gravitational effect).

Owner:APPLE INC

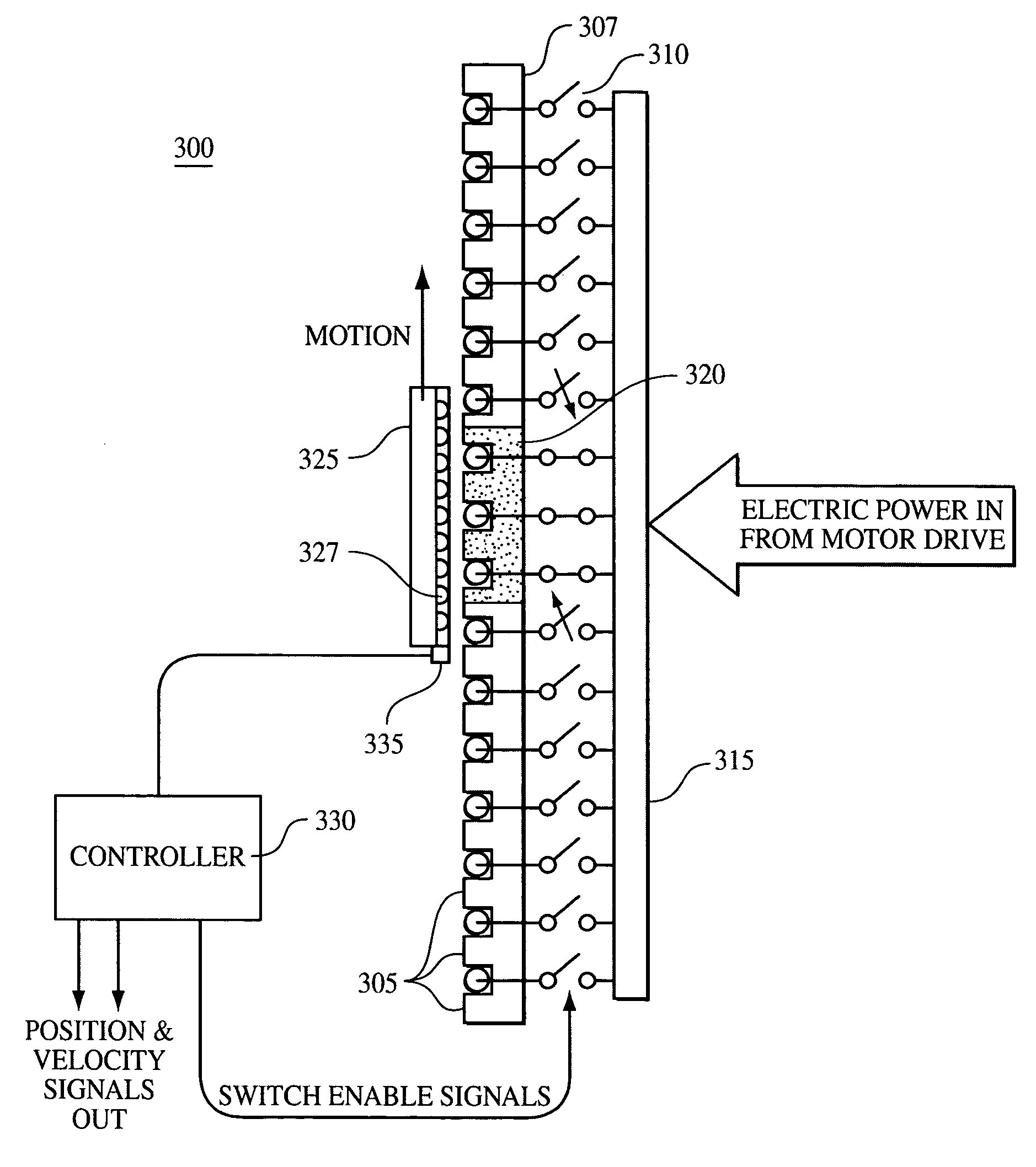

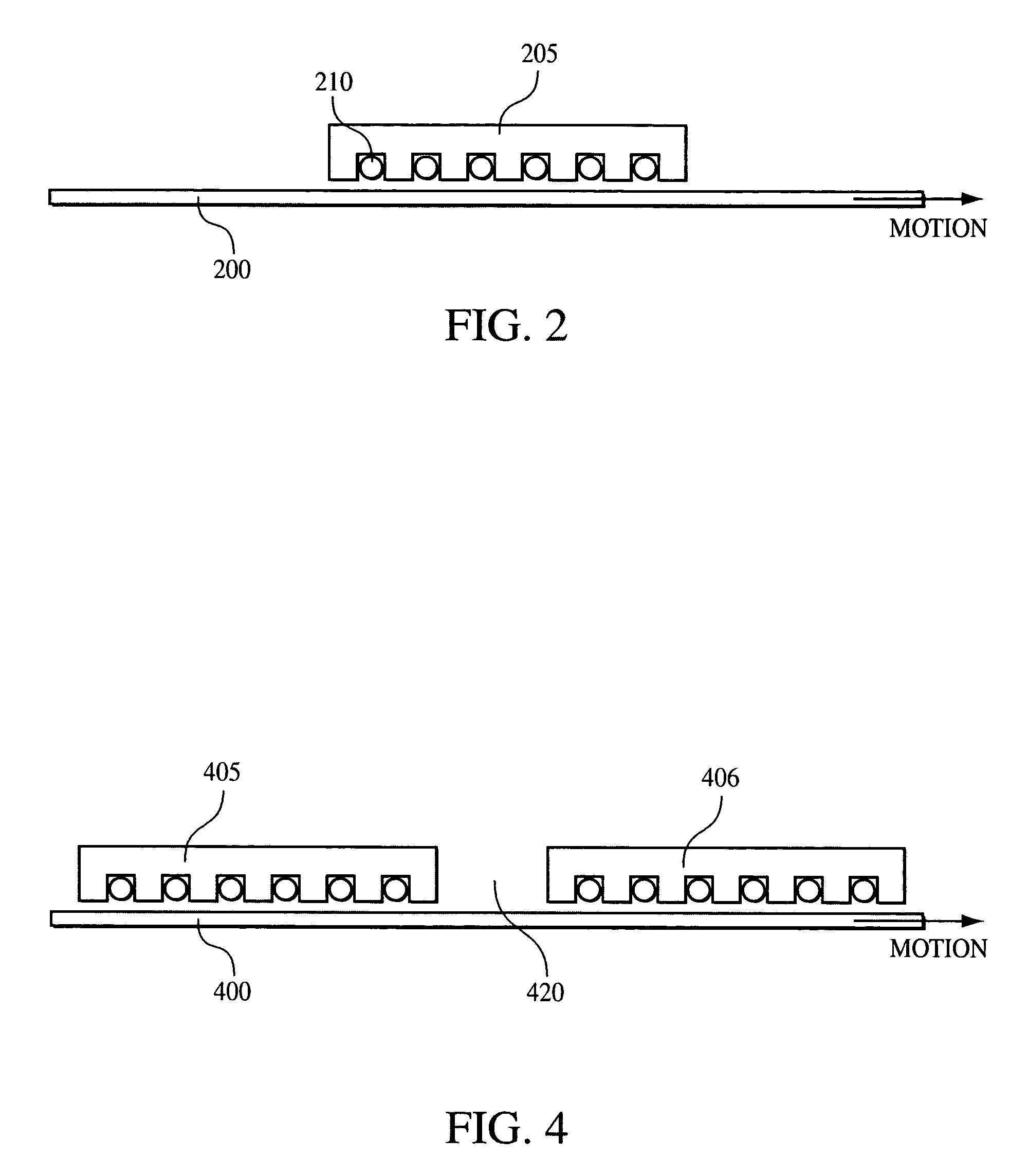

Modular linear electric motor with limited stator excitation zone and stator gap compensation

A linear motor system including compartmentalized stator sections provides an interchangeable and serviceable alternative to other linear motors. The stator sections may be individually-energized so that power is only sent to stator sections adjacent to the thrust plate or rotor of the linear motor. A sufficiently long thrust plate is used to cover any gaps in the linear stator, and additional compensation stator sections are used to provide additional motor force to the thrust plate adjacent to these gap sections. If utilized onboard a ship, additional compensation stator sections may be incorporated into the face of deck hatches. The linear motor system can also be used to counteract gravitational effects in a large hanging door system implementation.

Owner:CURTISS WRIGHT ELECTRO MECHANICAL

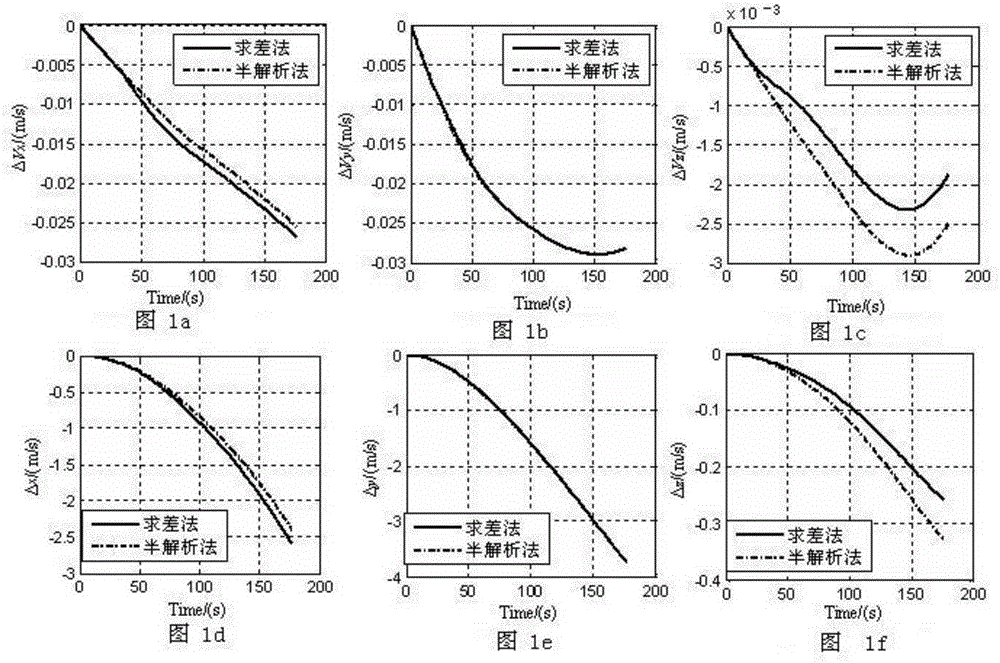

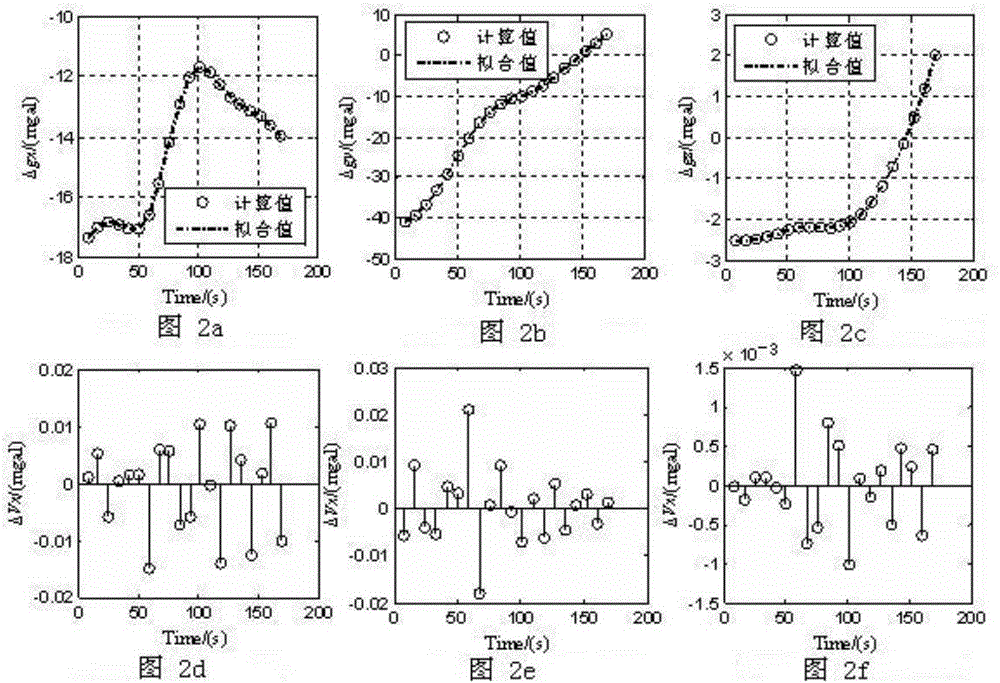

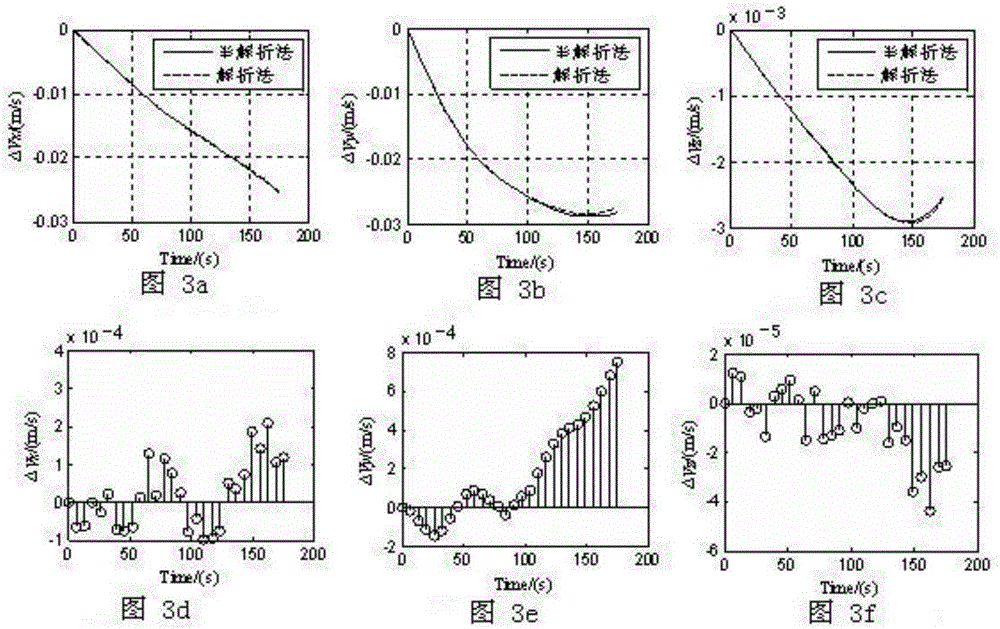

Trajectory boosting segment state deviation parsing and calculating method under action of disturbance gravitation

ActiveCN105184109ACalculation speedAdapt to a wide areaSpecial data processing applicationsMassive gravityResearch Object

The invention provides a trajectory boosting segment state deviation parsing and calculating method under the action of disturbance gravitation. In particular, a ballistic missile serves as a research object, and the problem of rapidly working out the ballistic missile boosting segment state deviation is solved. The method includes the specific steps that firstly, a standard trajectory is designed and generated according to a launch mission; secondly, the state deviation of each point of the boosting segment is worked out through a state deviation parsing method induced by the perturbation thought; then, the apparent acceleration deviation of the corresponding point is calculated based on the state deviation of each point of the boosting trajectory, the deviation is regarded as a high-order item of disturbance gravitation, and meanwhile compensation is conducted; finally, the state deviation result is amended through a Newton iteration method. By means of the method, fast calculation of the state deviation of the boosting segment of any flight trajectory can be achieved, the calculation accuracy can meet the requirement for trajectory calculation, the calculation method is far superior to that of an existing method, and a foundation is laid for achieving fast mobile lunching of the trajectory.

Owner:NAT UNIV OF DEFENSE TECH

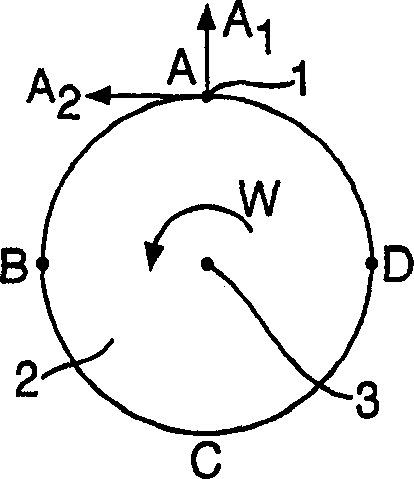

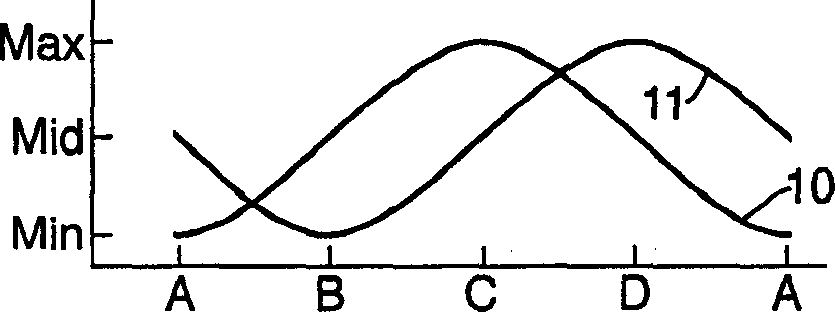

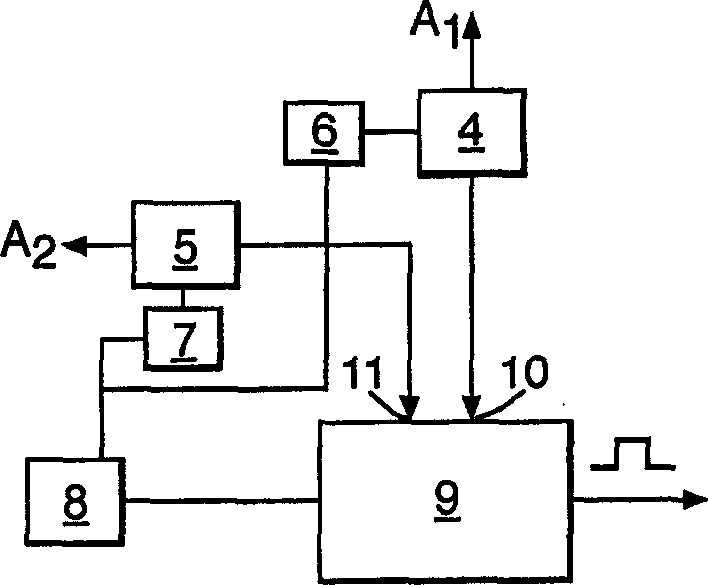

Detection of rotating direction

InactiveCN1334464ATotal circuit system simplificationAcceleration measurementIndication/recording movementAccelerometerPhase difference

A sensor for sensing a direction of rotation of a body. The sensor comprises a first accelerometer arranged, in use, on the body, and having a first sensing direction; and a second accelerometer arranged, in use, on the body and having a second sensing direction. The two accelerometers are arranged such that the first and second sensing directions are not parallel to one another and are not parallel to the axis of rotation of the body, such that there is a phase difference due to gravitational effects between the outputs of the accelerometers when the body rotates in use. Means receives the acceleration indicative output signals from the first and second accelerometers and determines the phase relationship between the two signals to thereby determine the direction of rotation of the body.

Owner:INFINEON TECH AG

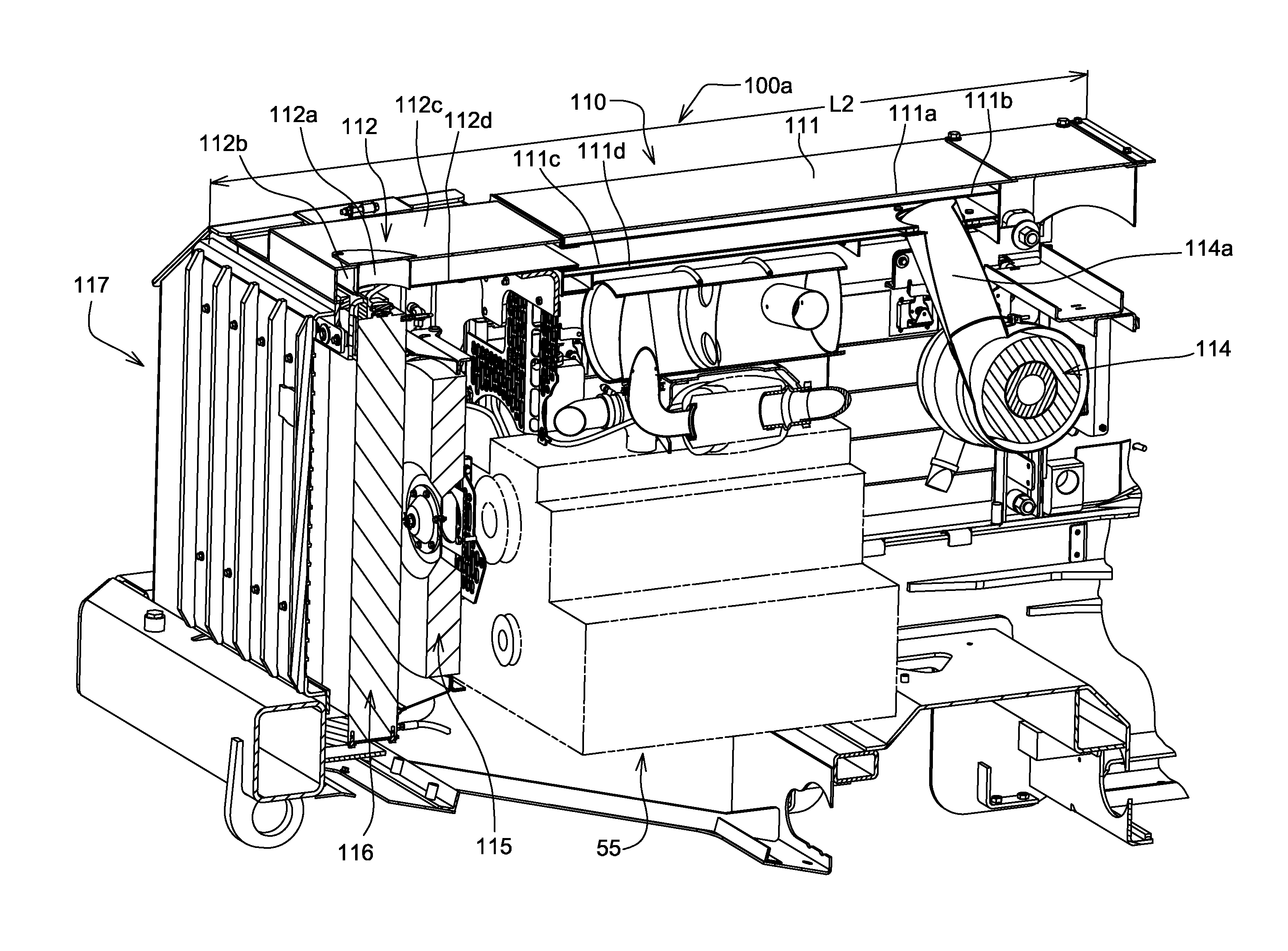

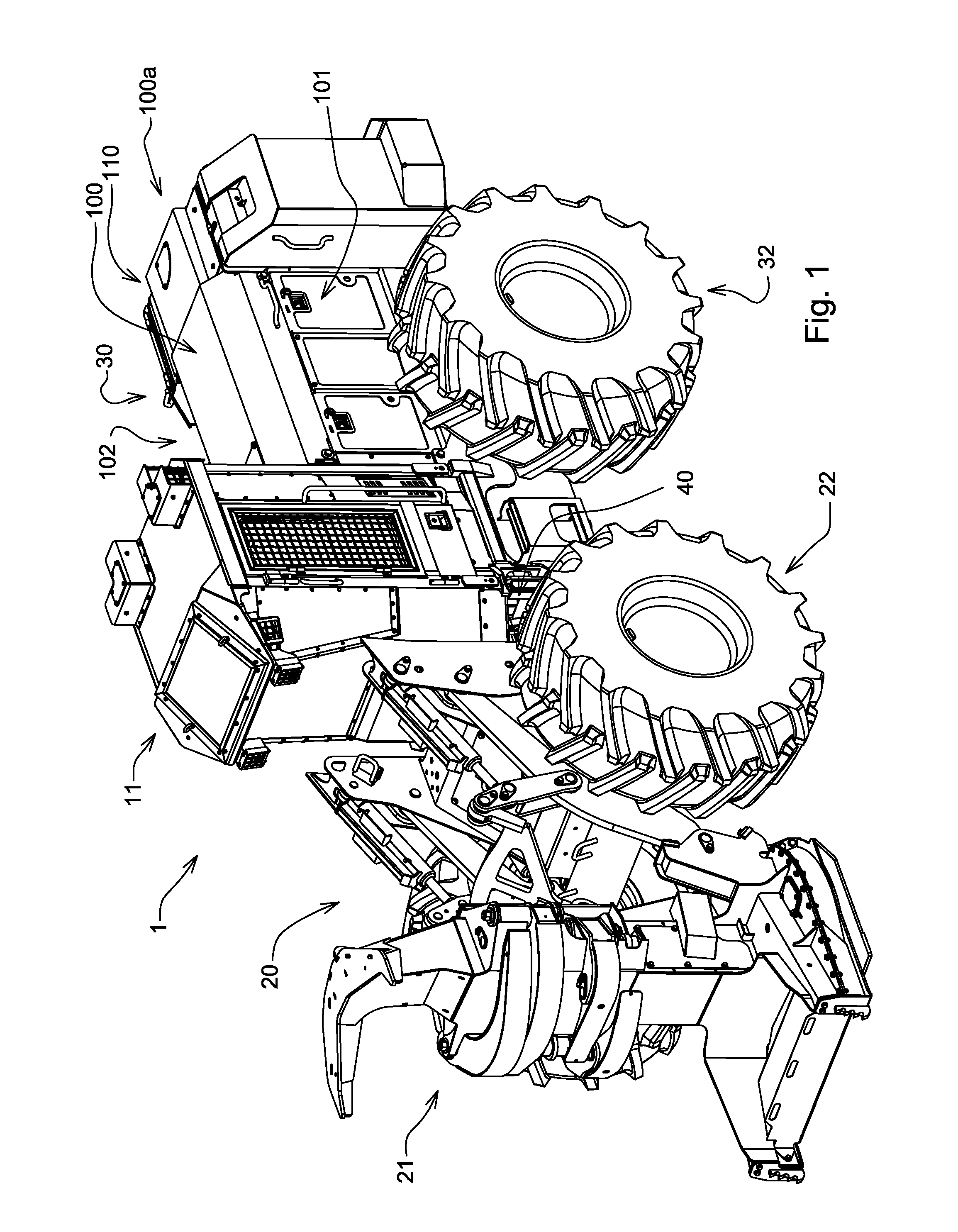

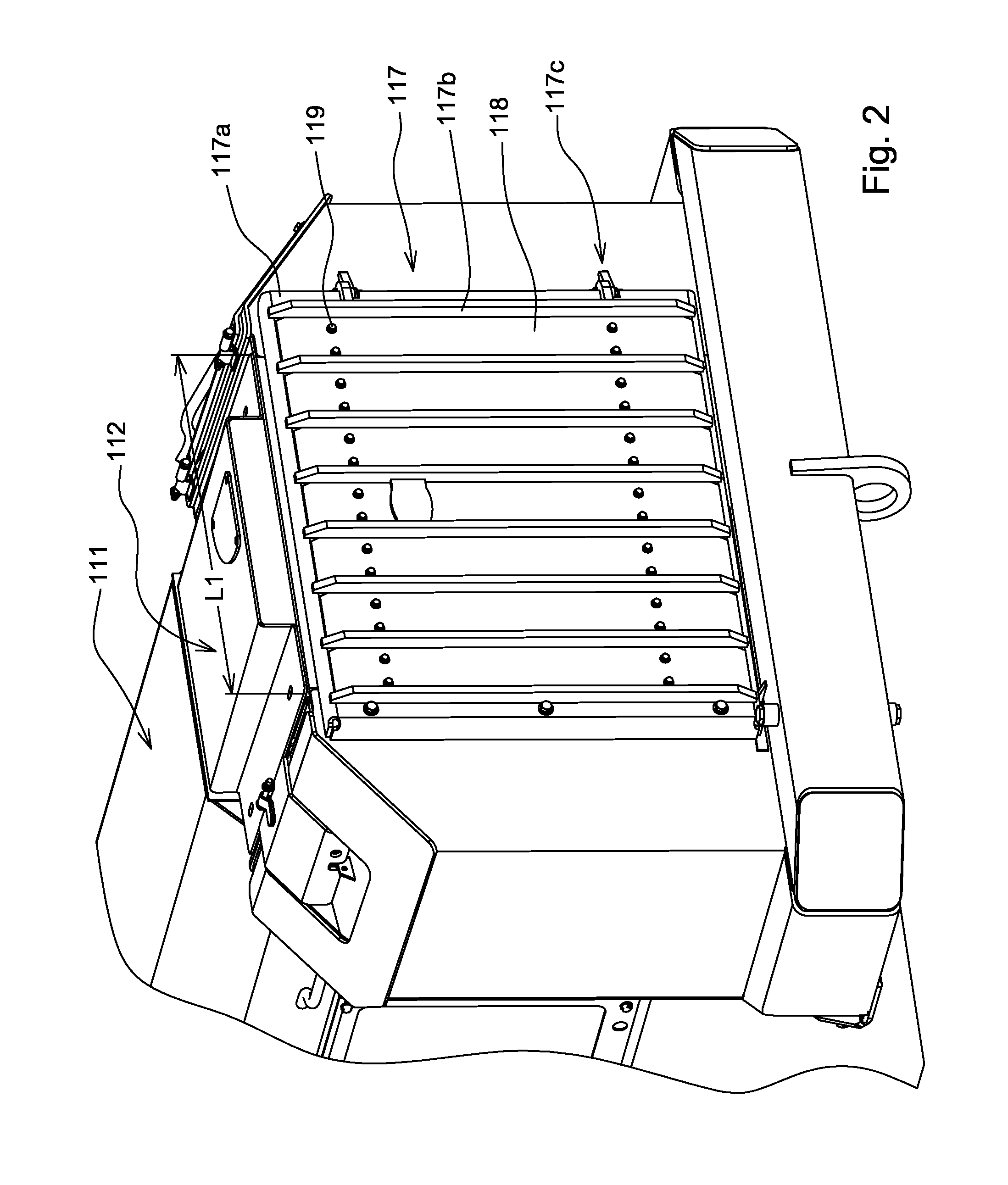

Integrated Air Intake System

InactiveUS20100301638A1Overcome disadvantagesVehicle seatsCombustion-air/fuel-air treatmentAir filterGravitational effect

An engine air intake system is provided which is formed by an engine compartment. A fan and a grille screen are used to remove a portion of debris from air external to the vehicle. After the air is partially cleaned via the grille screen, it moves toward a heat exchanger carrying a portion of the remaining debris with it. A portion of the debris may fall out of the air via gravitational effects. A portion of the air then moves up and into an entrance passage for an air intake duct that is integrated with the hood of the engine enclosure, this portion having been further cleaned via debris passage to and through the heat exchanger as well as gravitational effects. The air then travels through the air intake duct and passes through an air filter where a portion of the remaining debris is removed prior to the air being supplied to the engine intake.

Owner:DEERE & CO

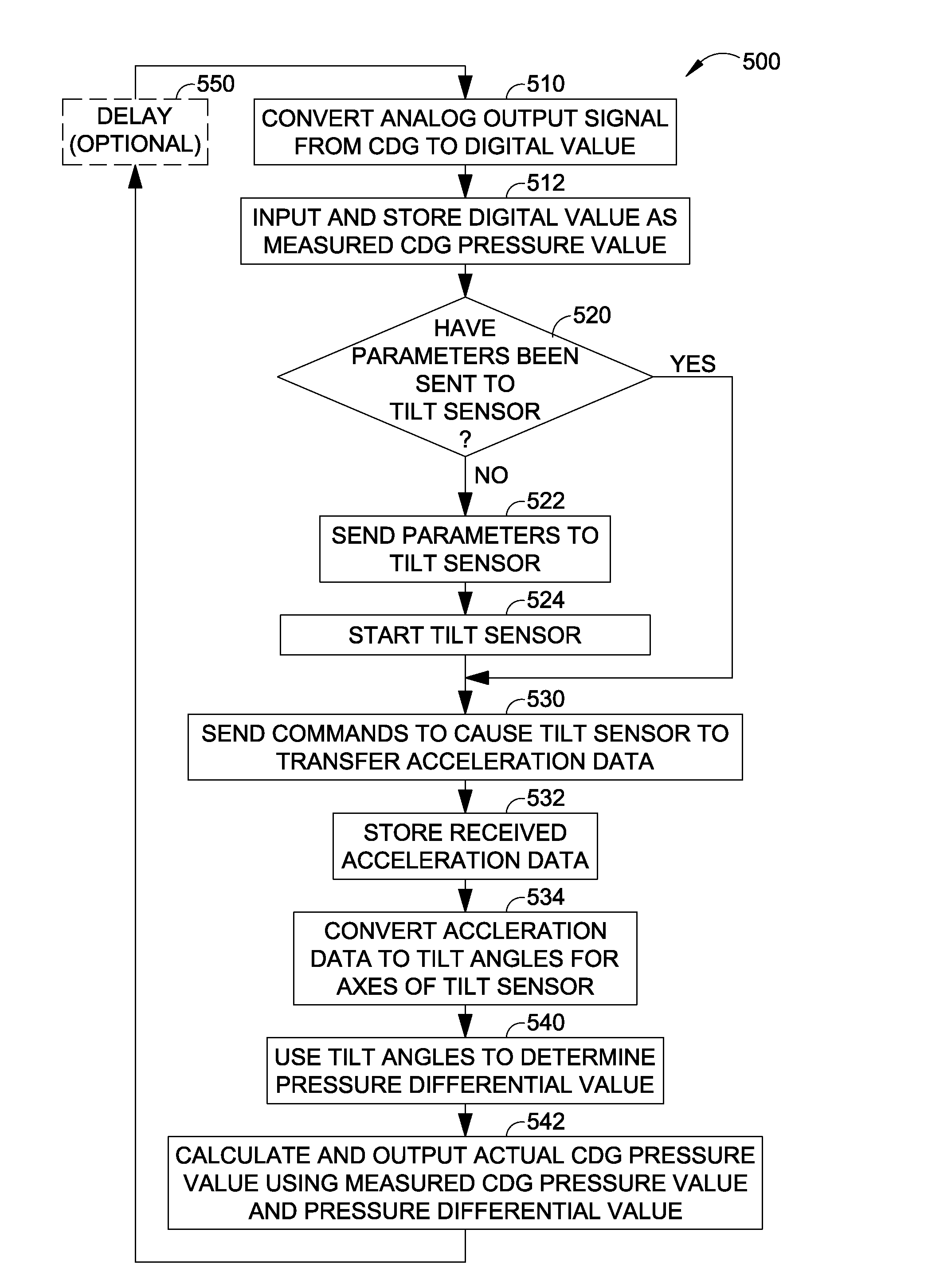

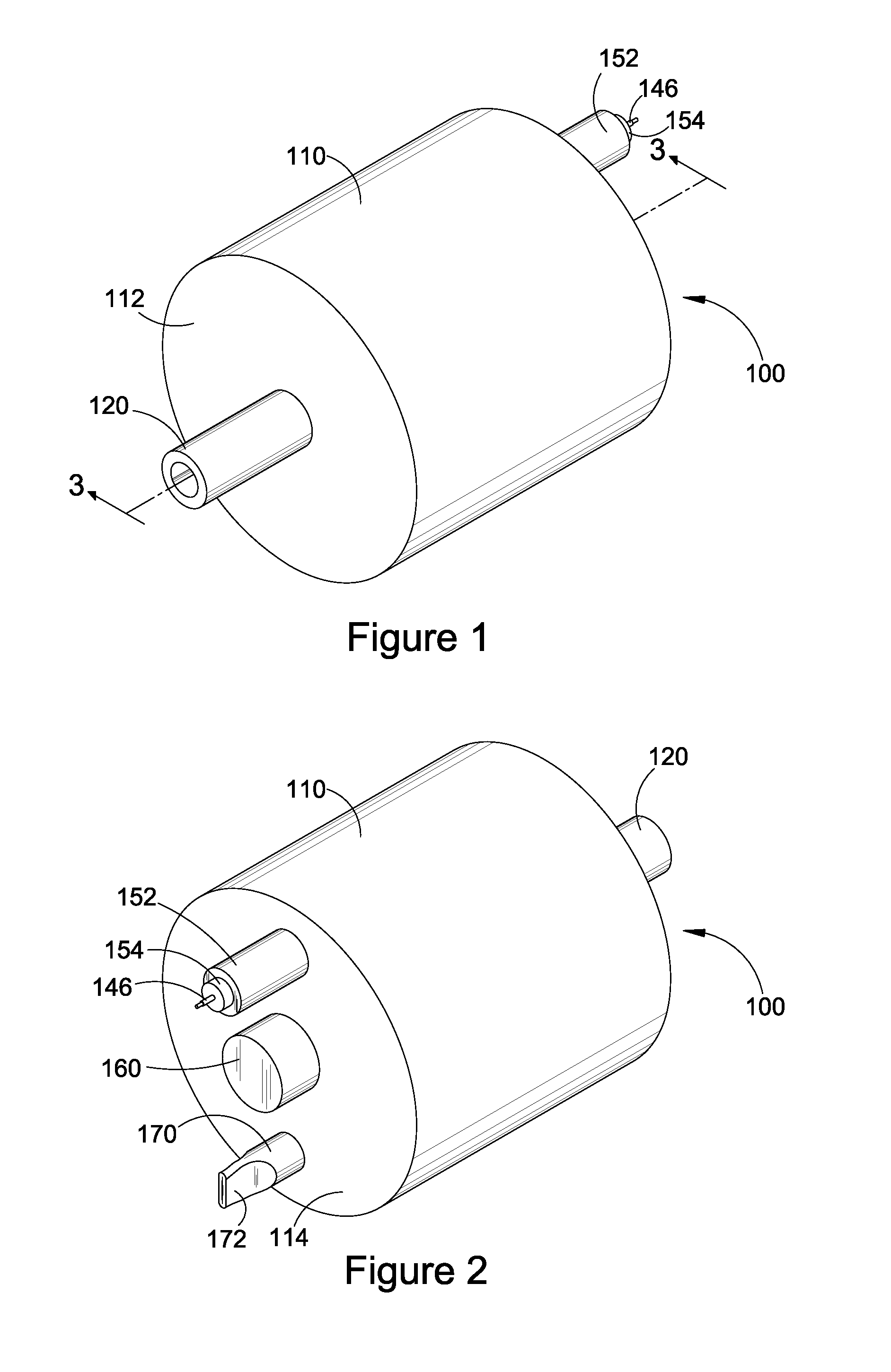

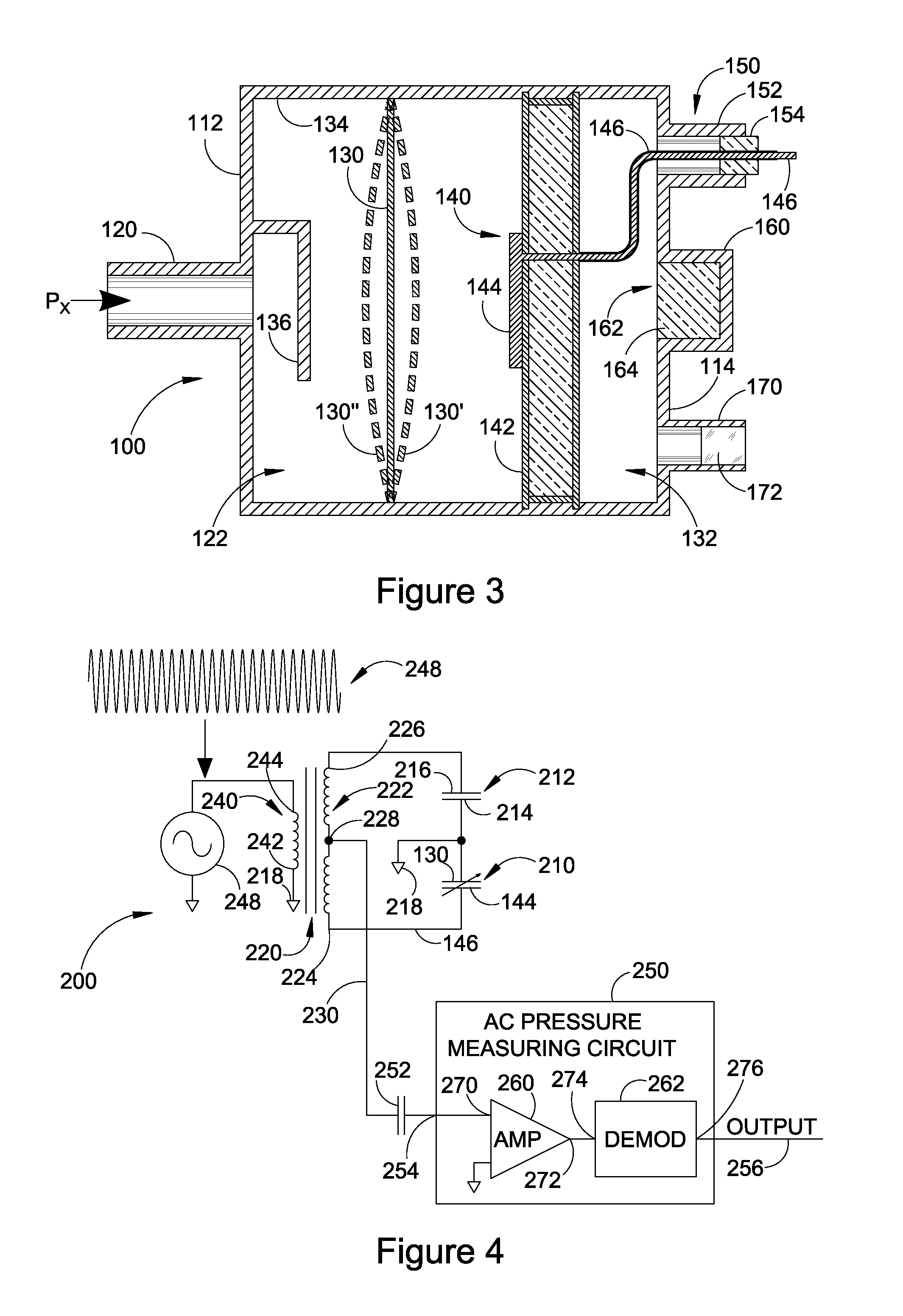

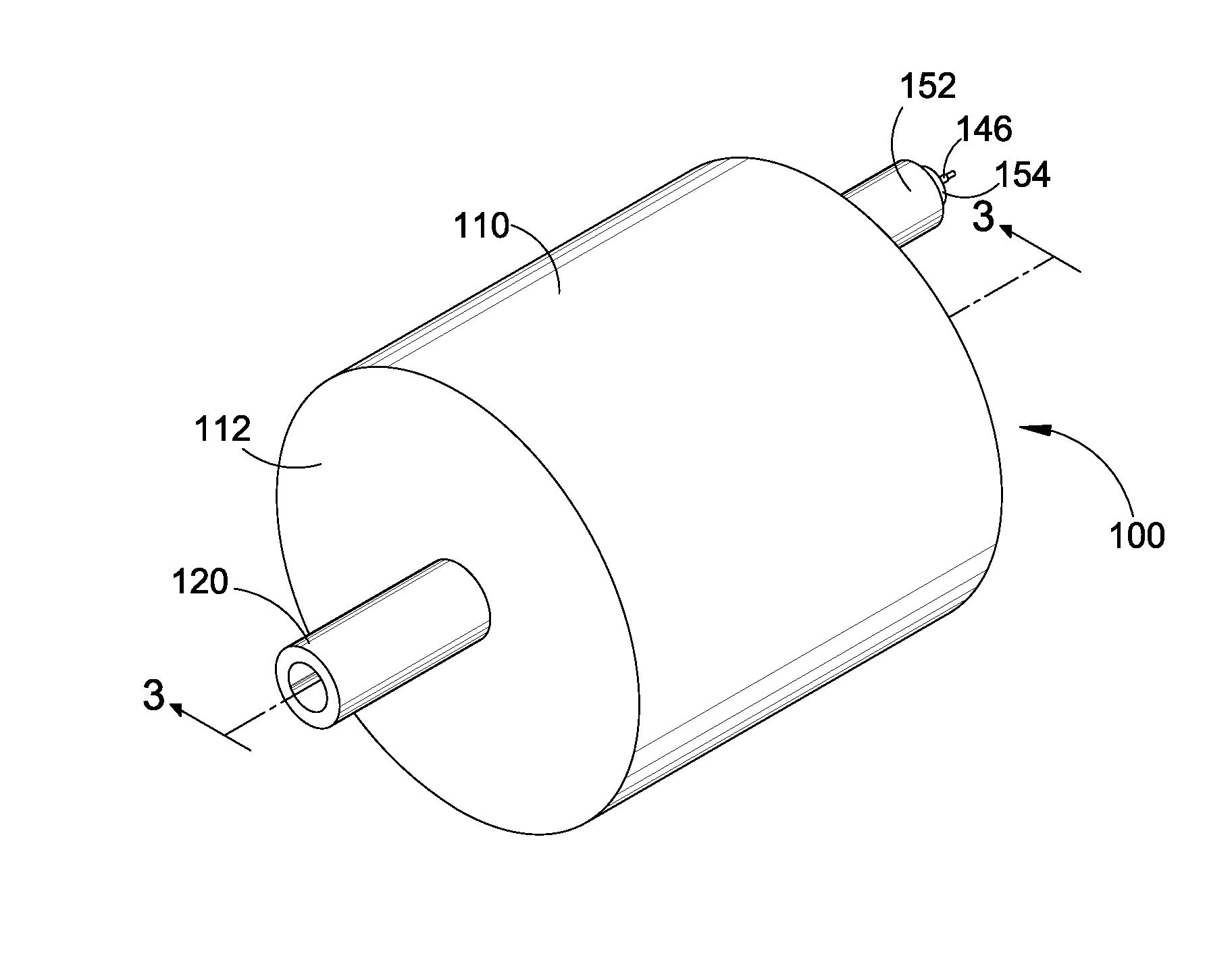

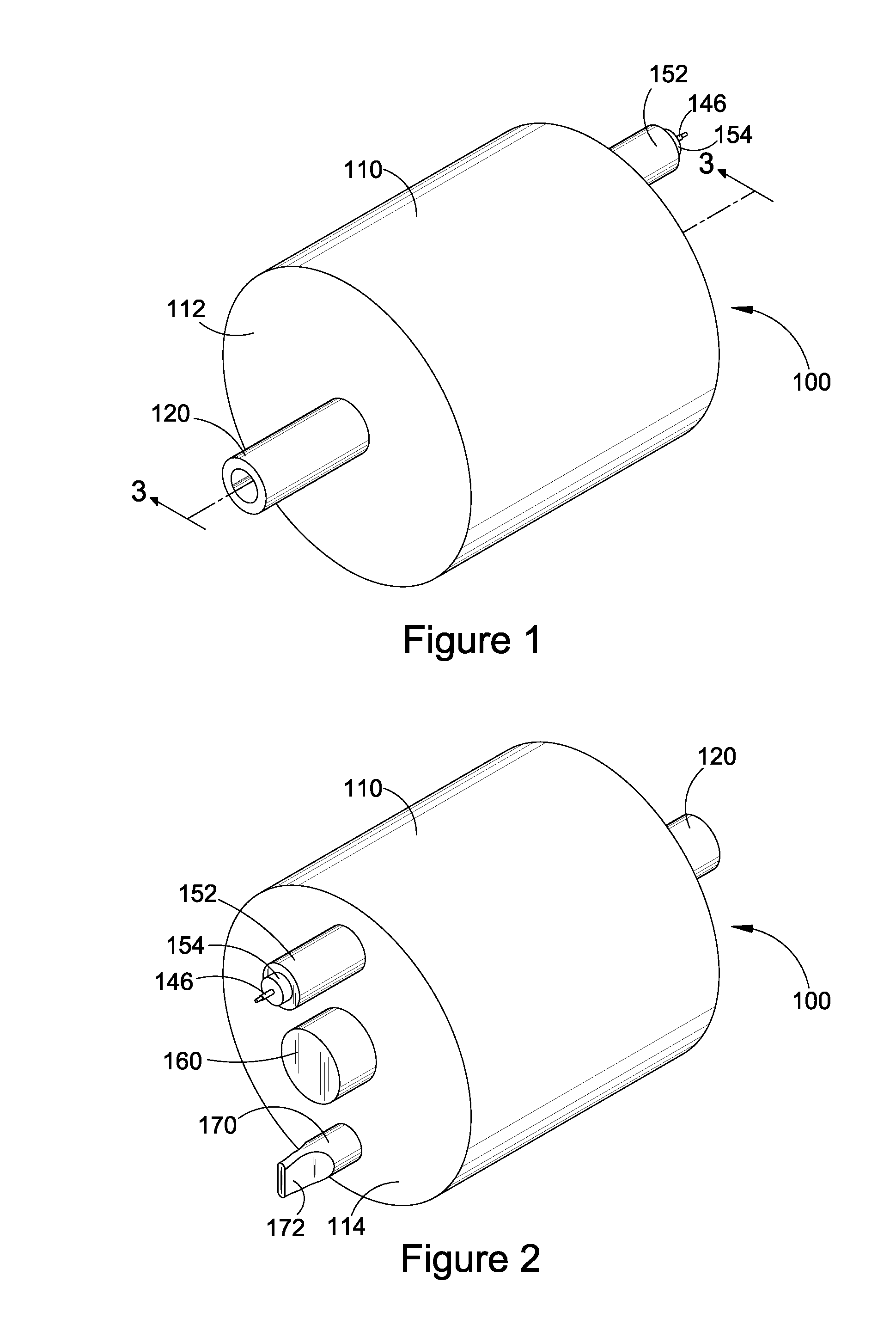

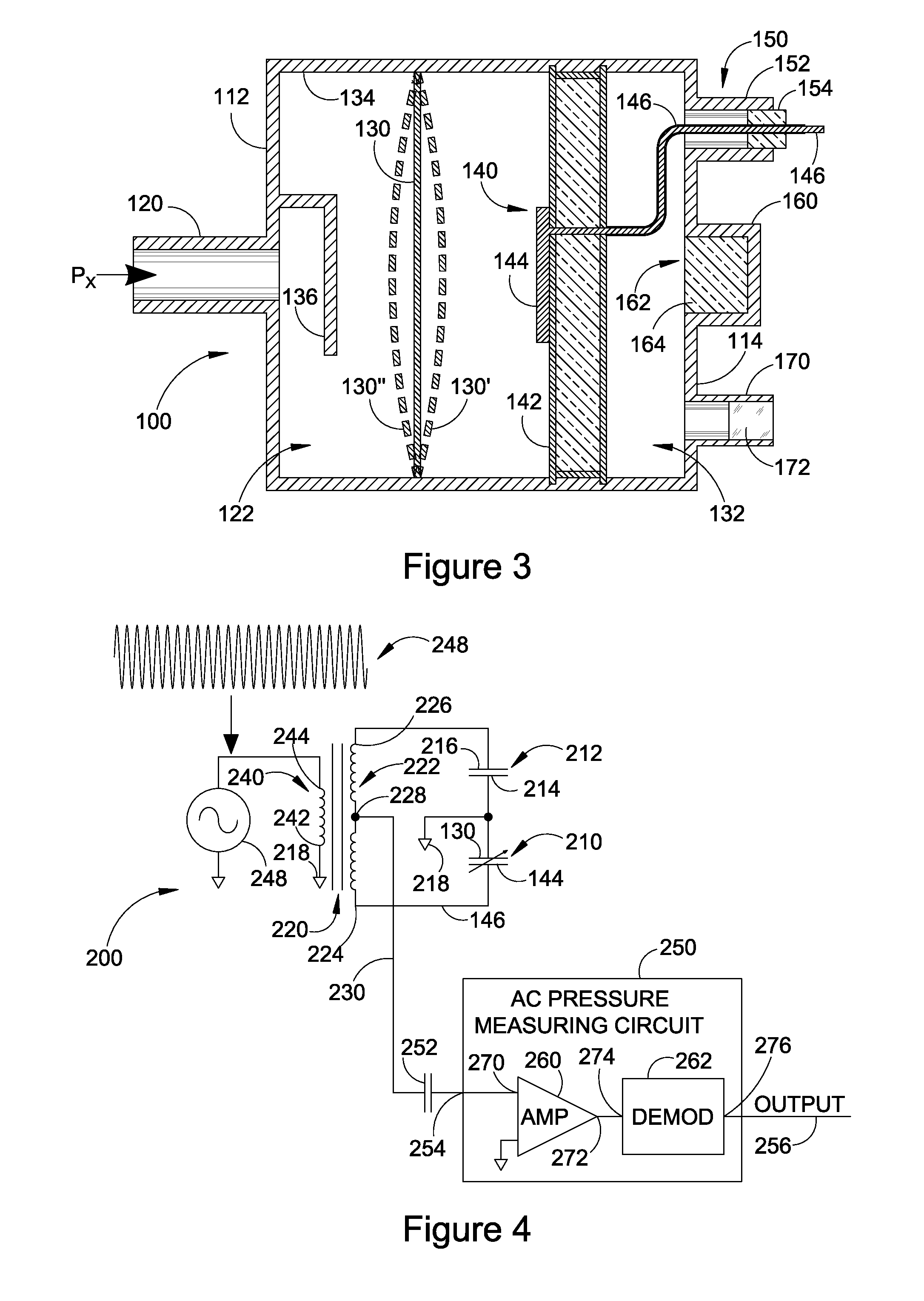

Multi-axis tilt sensor for correcting gravitational effects on the measurement of pressure by a capacitance diaphragm gauge

ActiveUS8862420B2Fluid pressure measurement by electric/magnetic elementsSpecial data processing applicationsCapacitanceGravitational force

A system and method compensate for effects of gravity on the diaphragm of a capacitance diaphragm gauge (CDG). The CDG generates a measured absolute pressure value in response to an applied absolute pressure on an input of the CDG. The CDG is subjected to a variable orientation of the CDG with respect to the earth's surface that can cause inaccurate pressure measurements. A pressure measuring circuit generates a measured value of an applied absolute pressure provided to an input of the CDG. A tilt sensor generates at least one tilt sensor output value that is responsive to an orientation of the CDG with respect to the earth's surface. A processing system adjusts the measured absolute pressure value by a calibration factor to generate a calibrated absolute pressure value representing the applied absolute pressure, wherein the calibration factor is selected in response to the at least one tilt sensor output value.

Owner:SUMITOMO SHI CRYOGENICS OF AMERICA

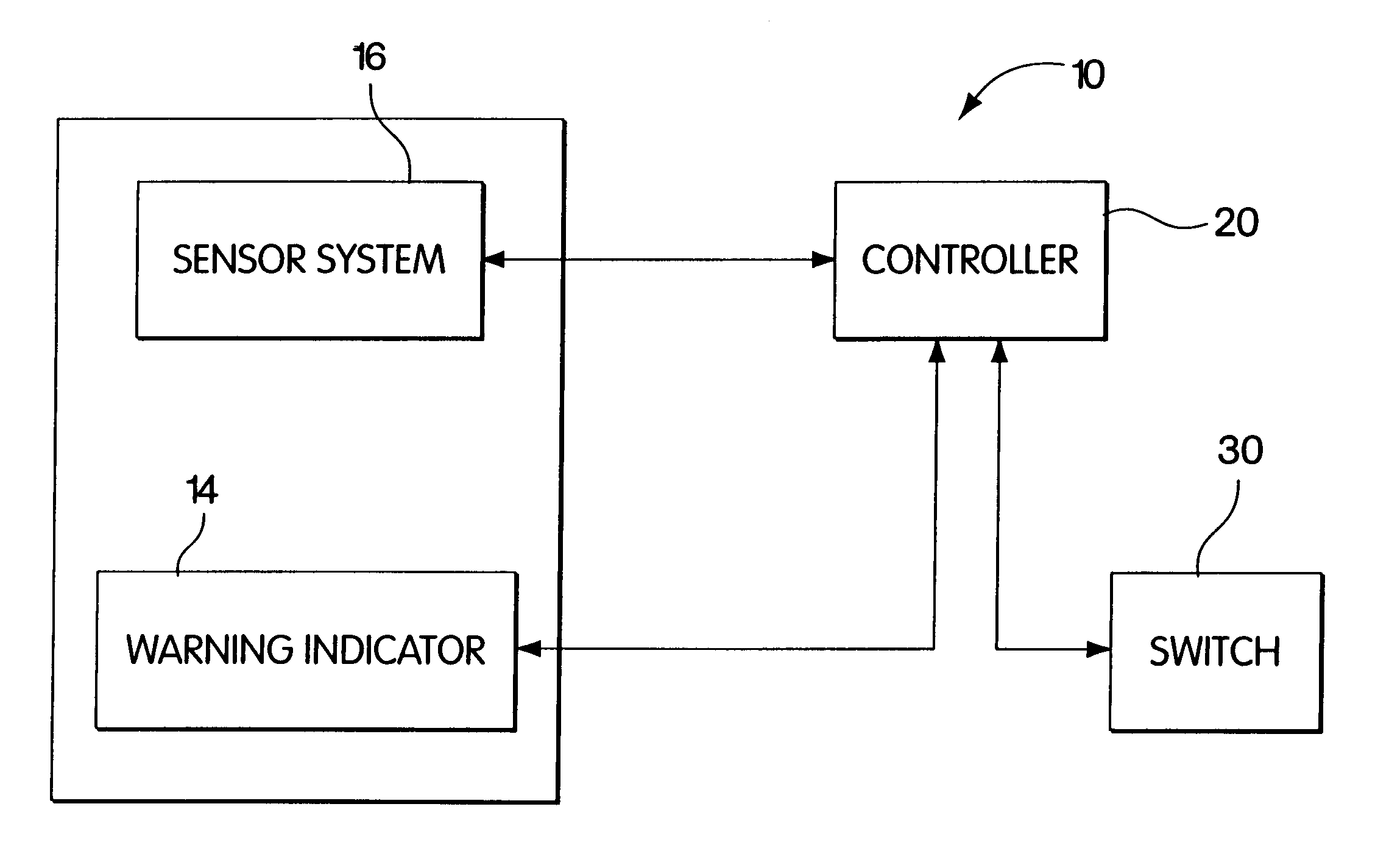

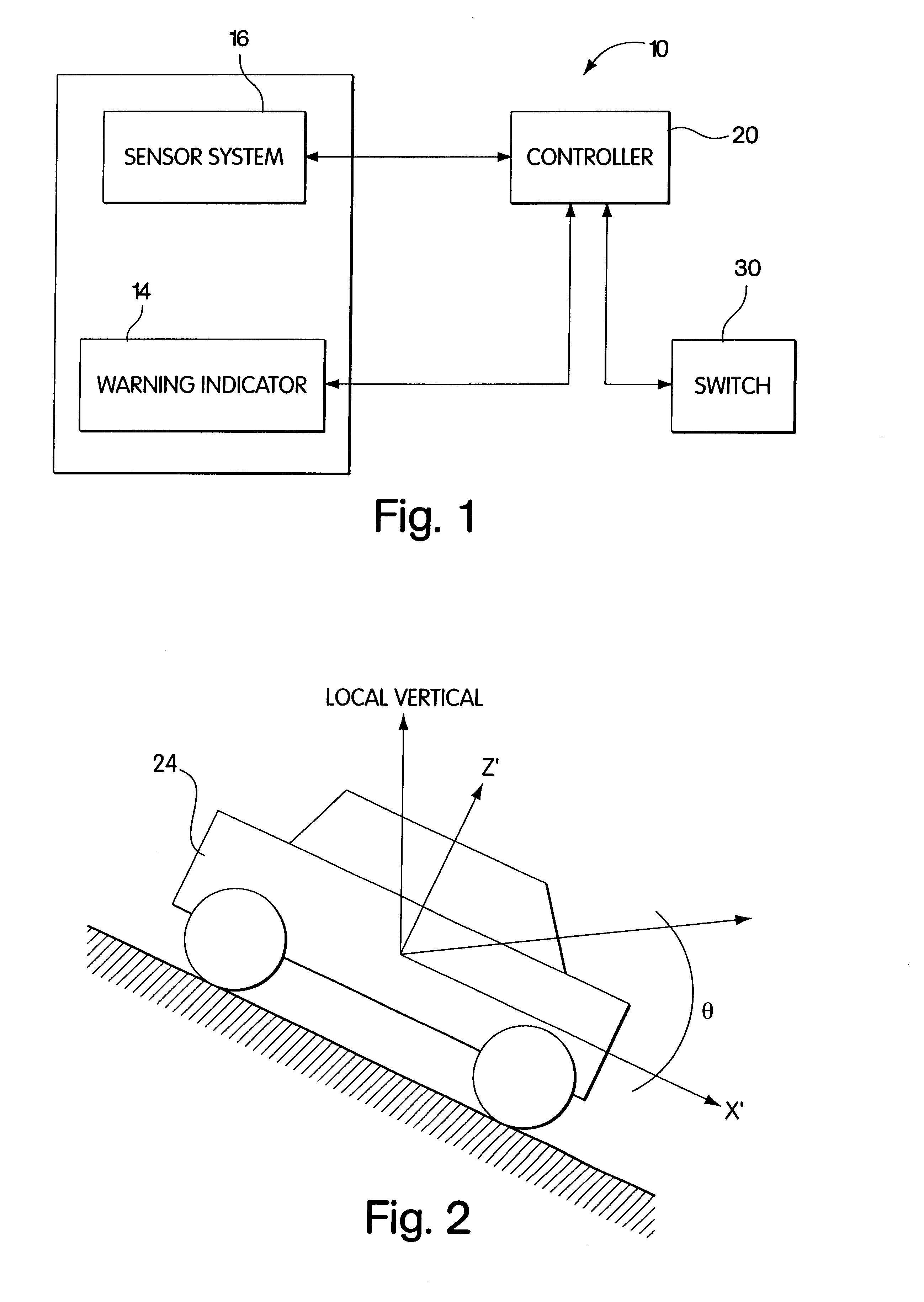

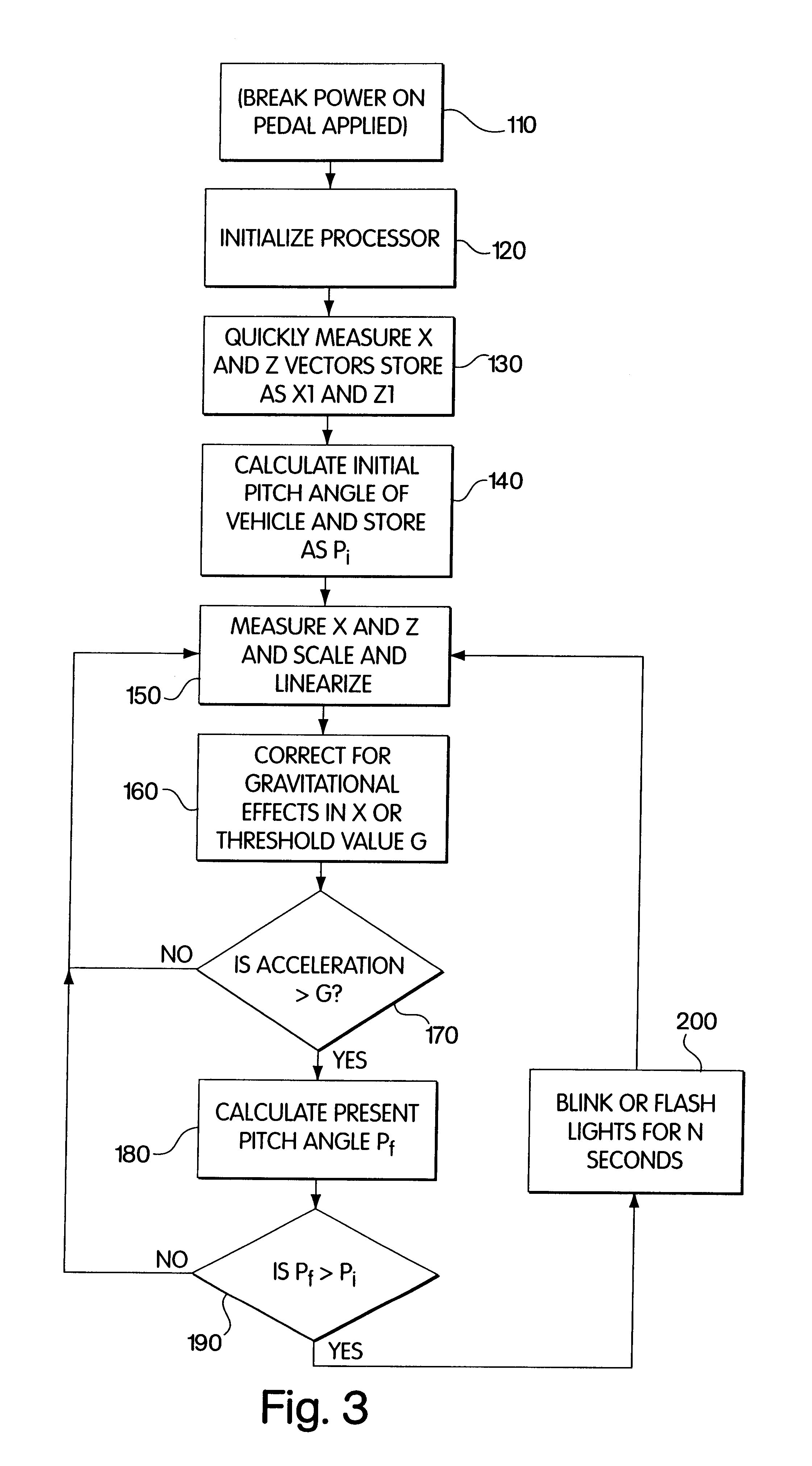

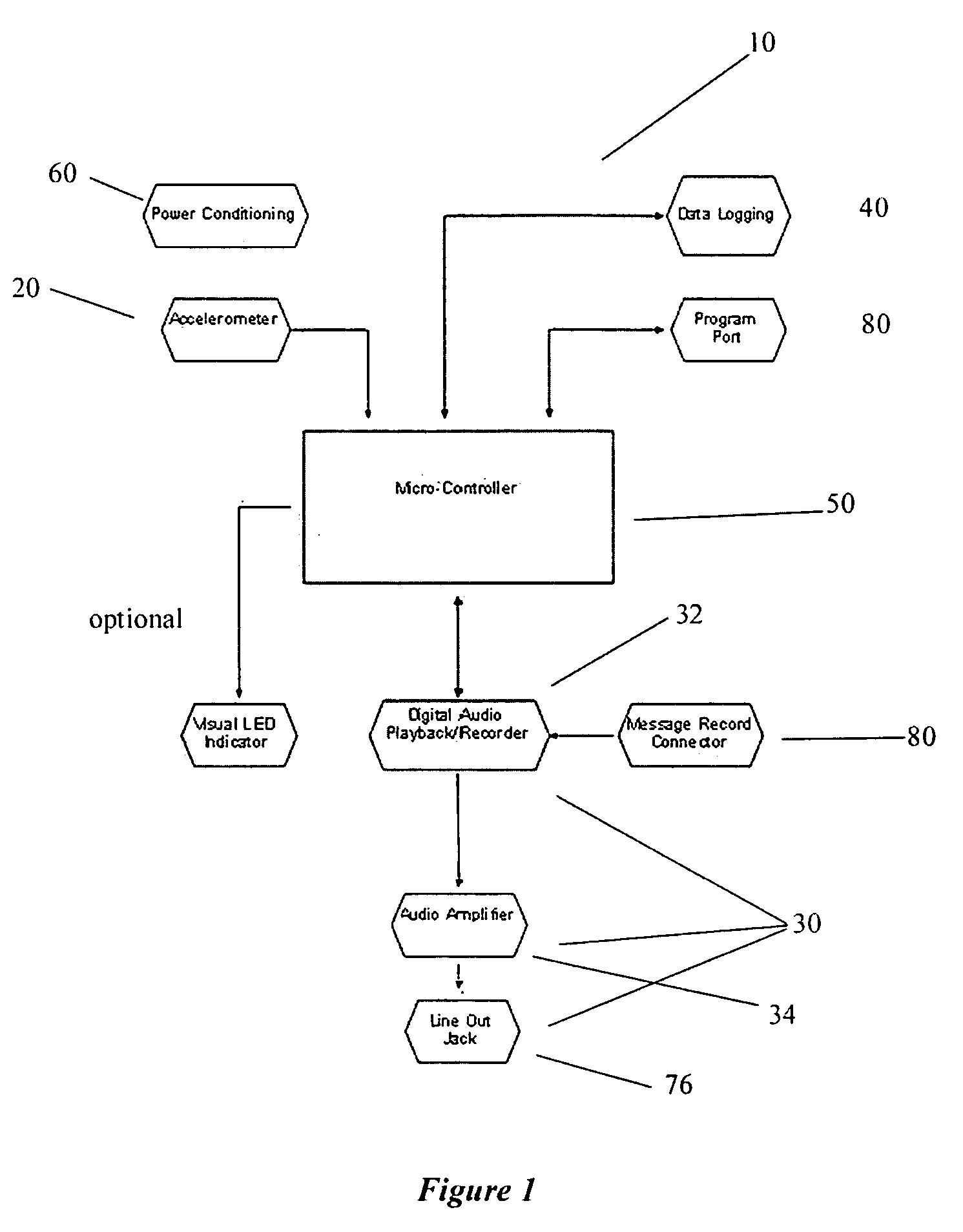

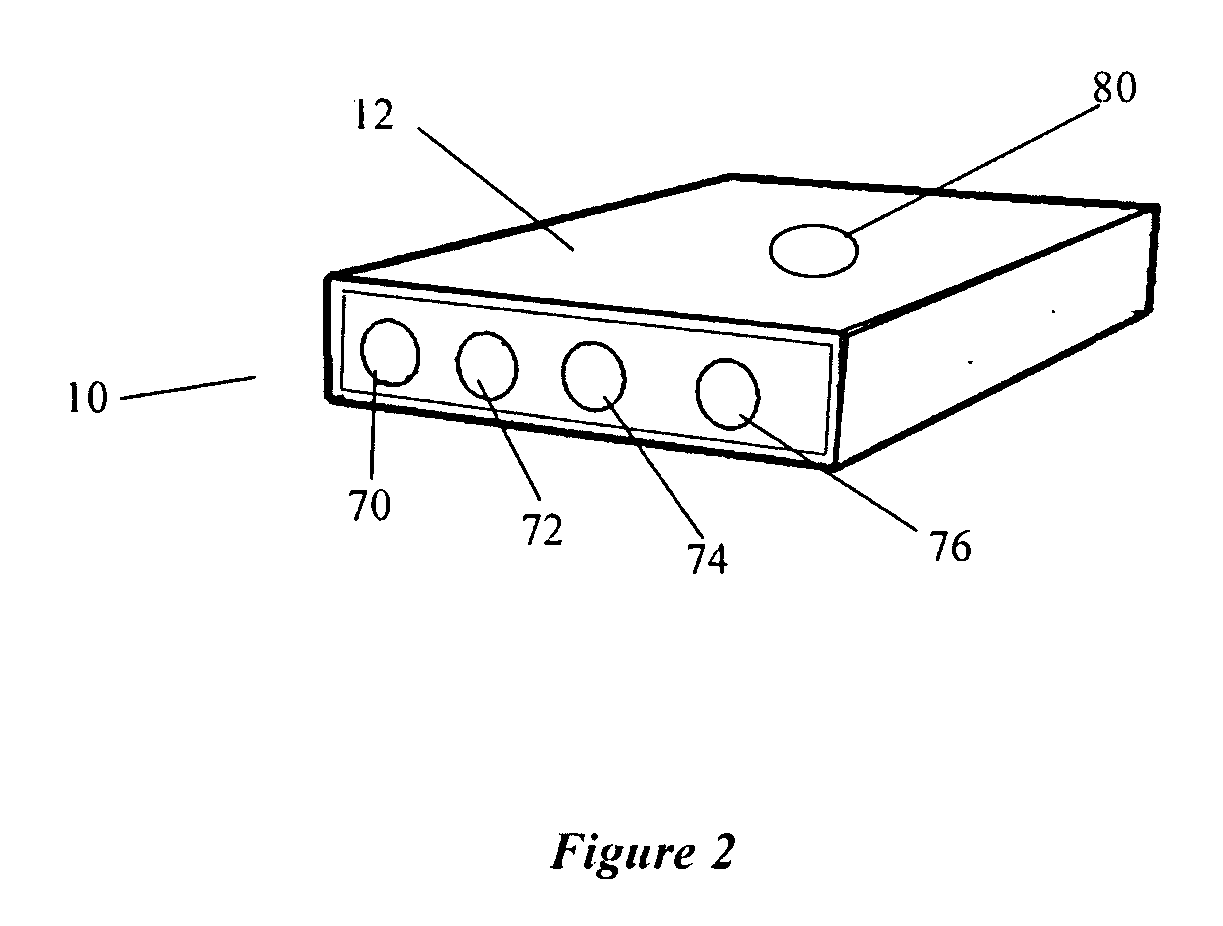

Device and system for indicating rapid deceleration in vehicles

InactiveUS6911905B2False failureReduce failureArrangements for variable traffic instructionsOptical signallingIn vehicleControl theory

A device and system for indicating rapid deceleration to warn the operator and / or others of an urgent deceleration condition is provided. The device includes one or more sensors that are responsive to acceleration in the primary direction of vehicle motion. The controller communicates with the one or more sensors, corrects for gravitational effects, and initiates at least one warning indicator when the sensed acceleration exceeds a threshold value and thereby indicates an urgent deceleration condition.

Owner:CARLSON CRAIG

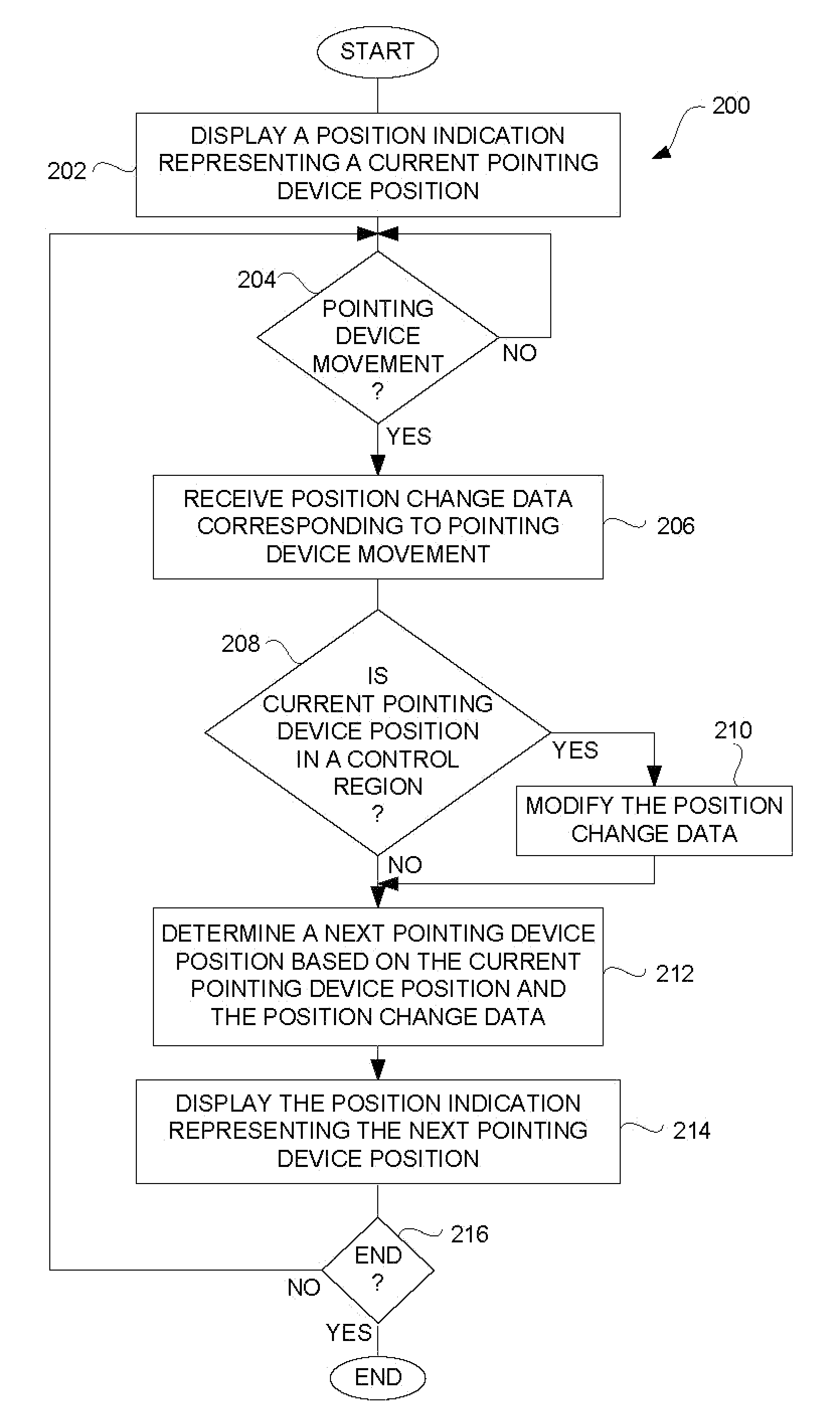

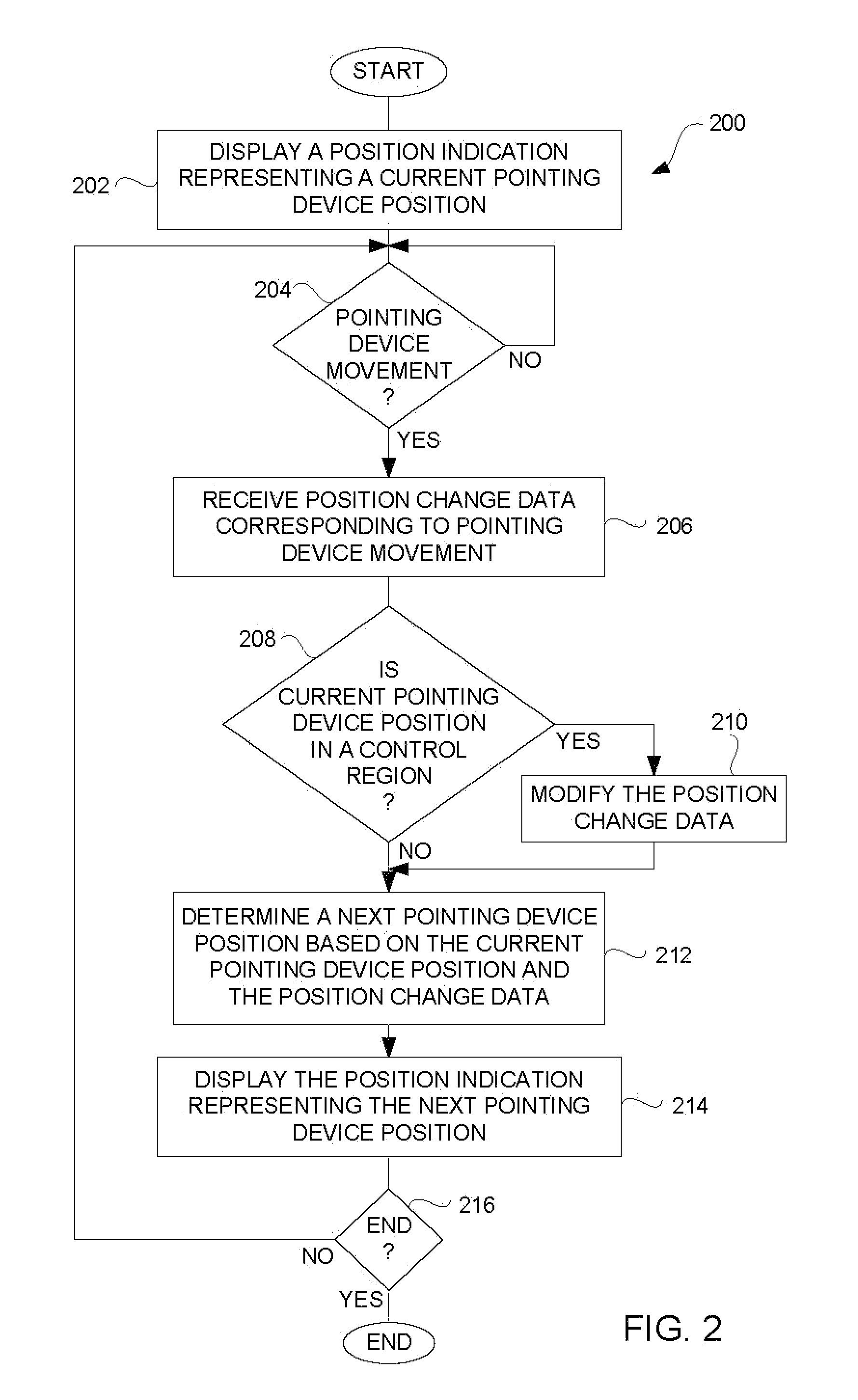

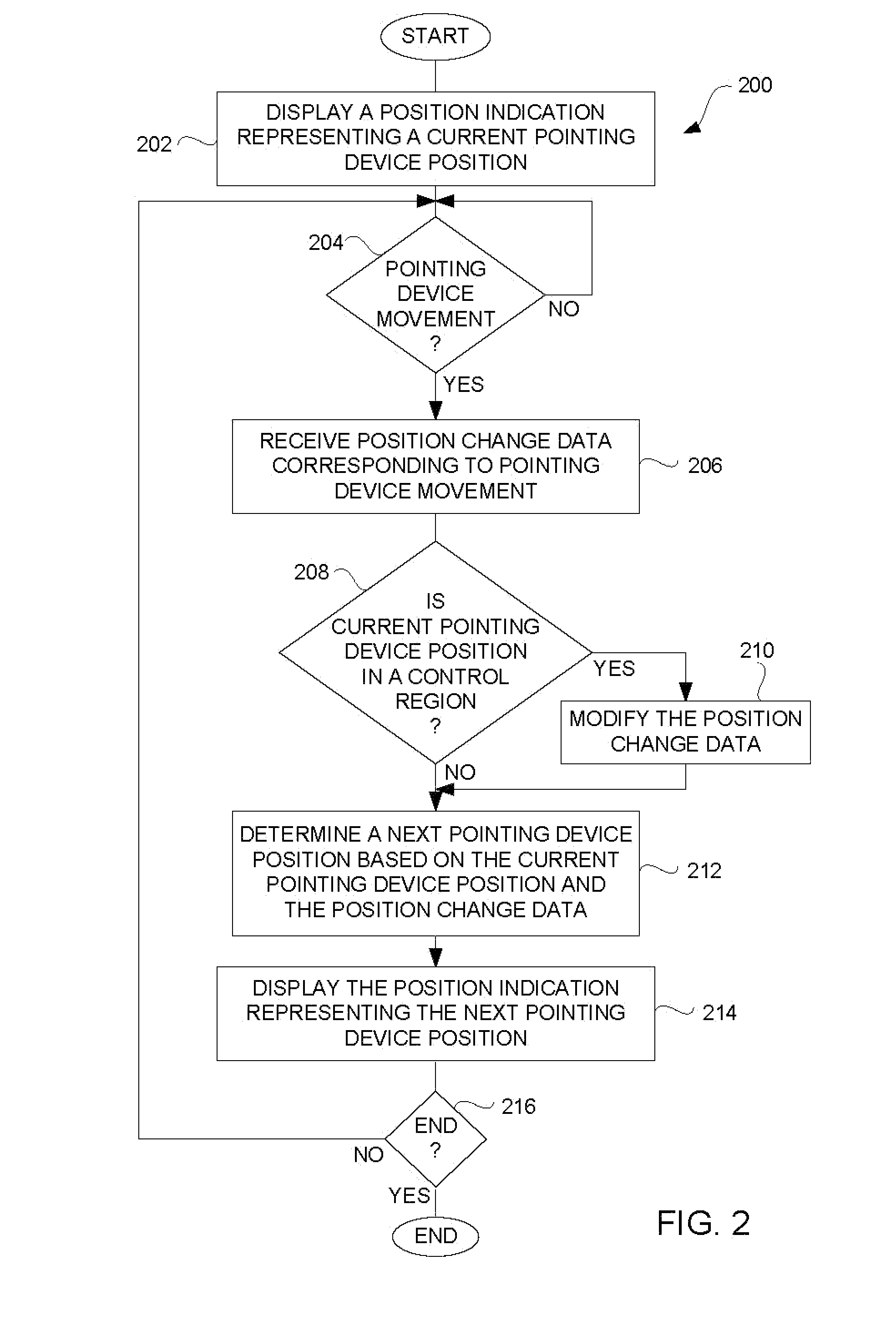

Responsiveness Control Method for Pointing Device Movement With Respect to a Graphical User Interface

InactiveUS20090015557A1Improve user interactionEasy to navigateCathode-ray tube indicatorsInput/output processes for data processingGraphicsFriction effect

Improved techniques that enable control of responsiveness to user movement of a pointing device with respect to a graphical user interface are disclosed. According to one embodiment, by controlling responsiveness, a friction effect can be imposed at predetermined regions of the graphical user interface. According to another embodiment, by controlling responsiveness, a gravitational effect can be imposed at predetermined regions of the graphical user interface. According to still another embodiment, by controlling responsiveness, frictional and gravitational effects can be imposed at predetermined regions of the graphical user interface. The responsiveness control, e.g., frictional effect and / or gravitational effect, can be used to enhance user interaction with the graphical user interface. For example, user controls, such as buttons, boxes, borders, boundaries, etc., can be more easily navigated and selected by users when the regions associated with such user controls are provided with modified responsiveness control (e.g., frictional effect and / or gravitational effect).

Owner:APPLE INC

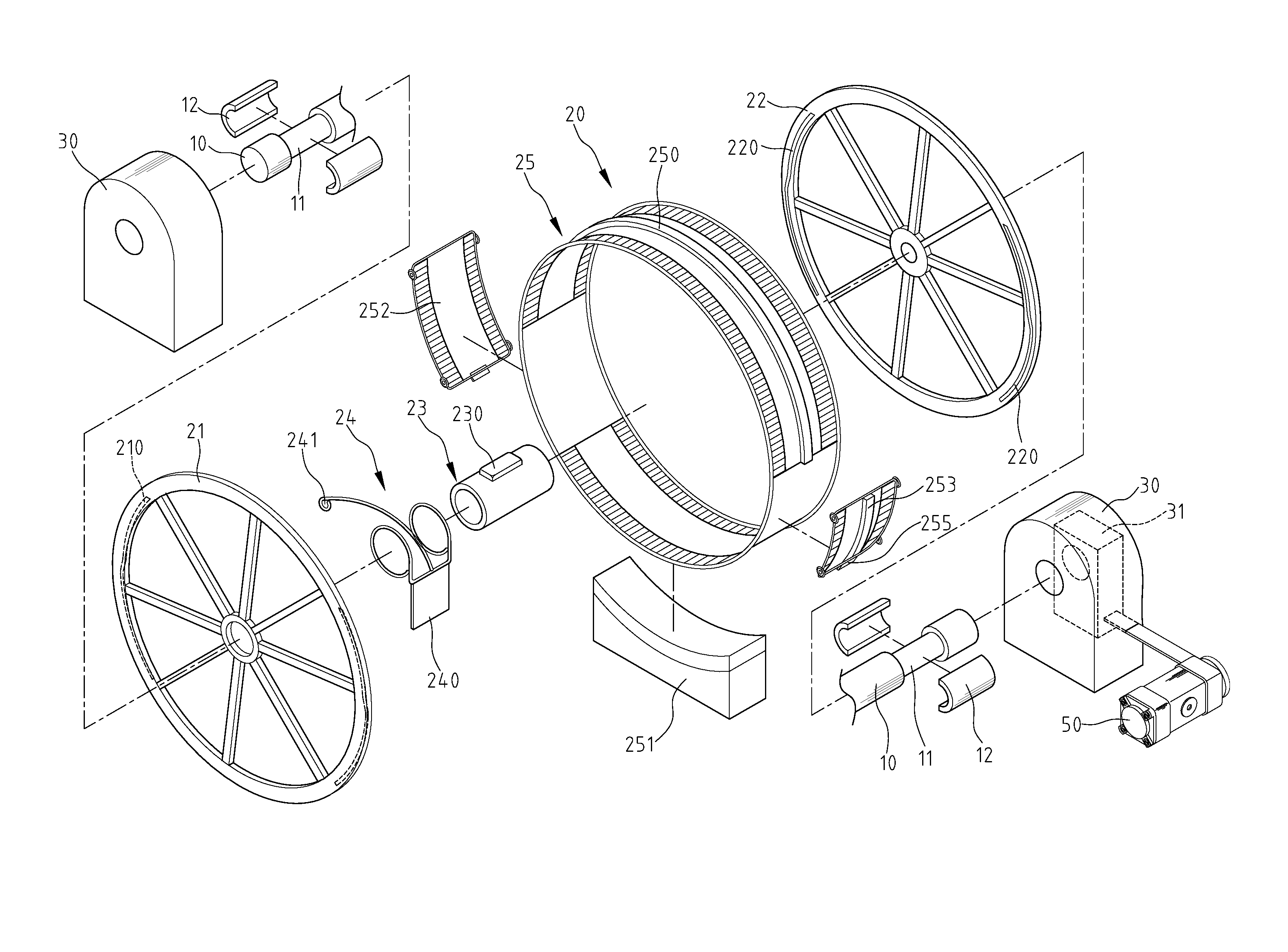

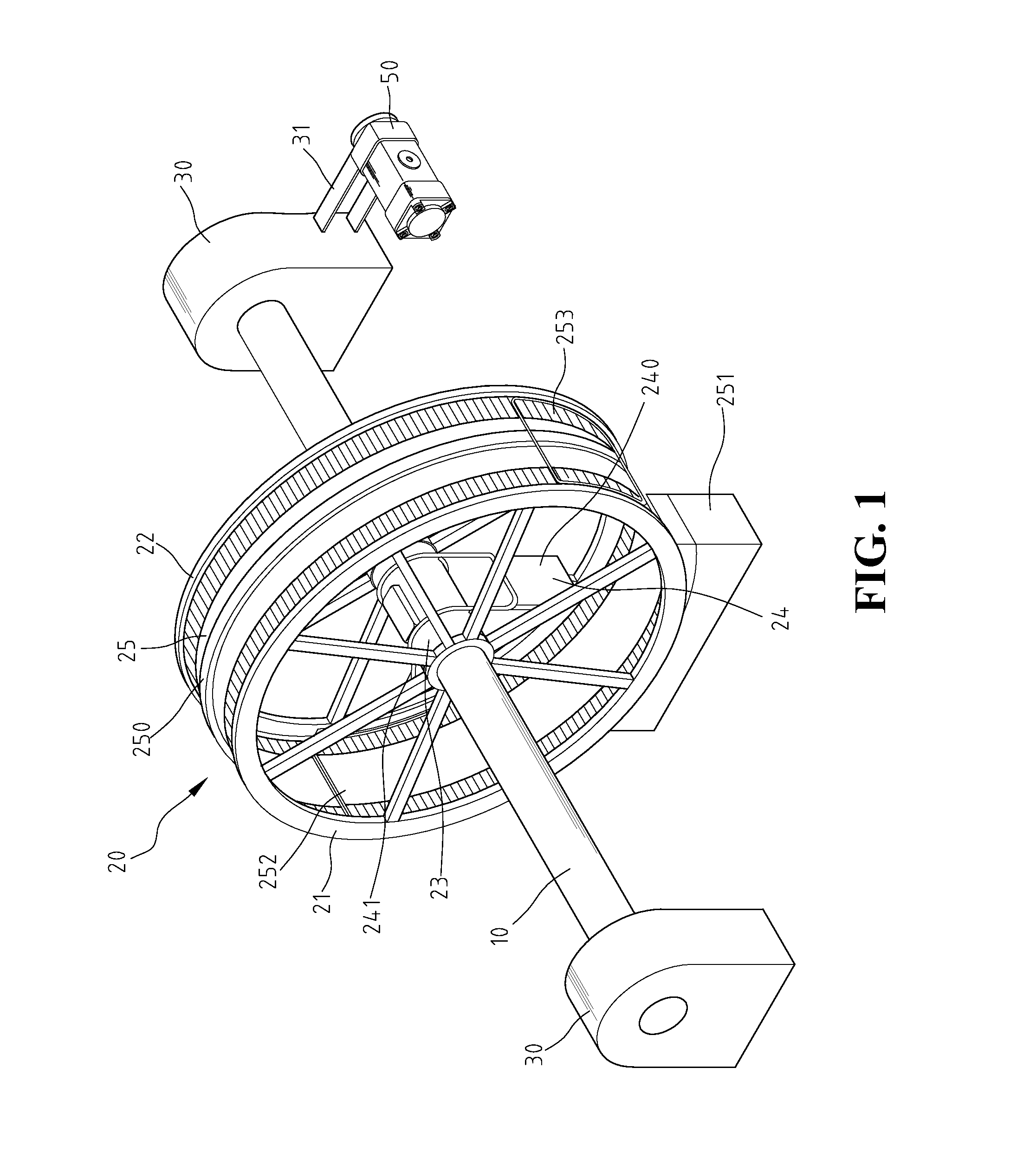

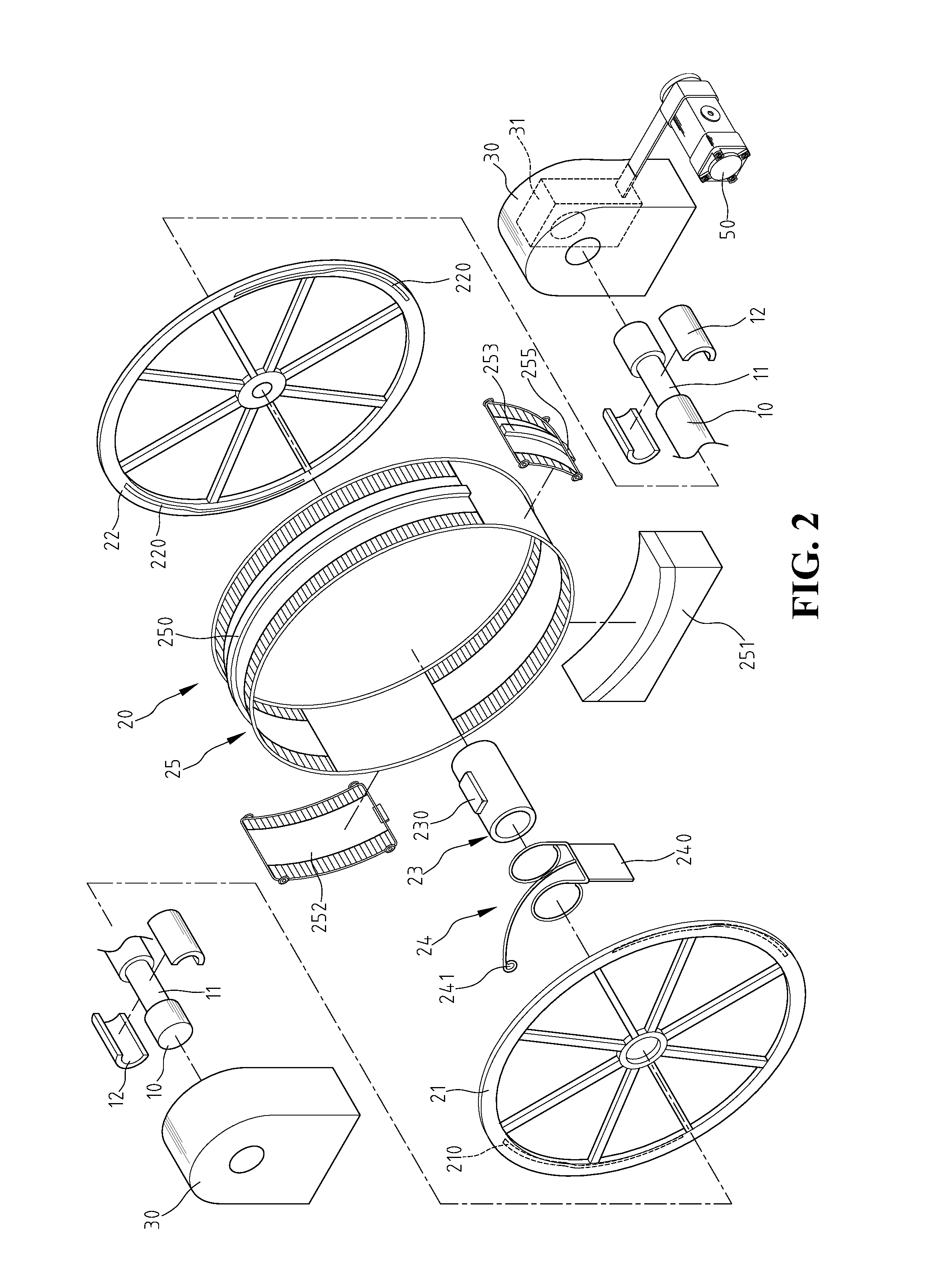

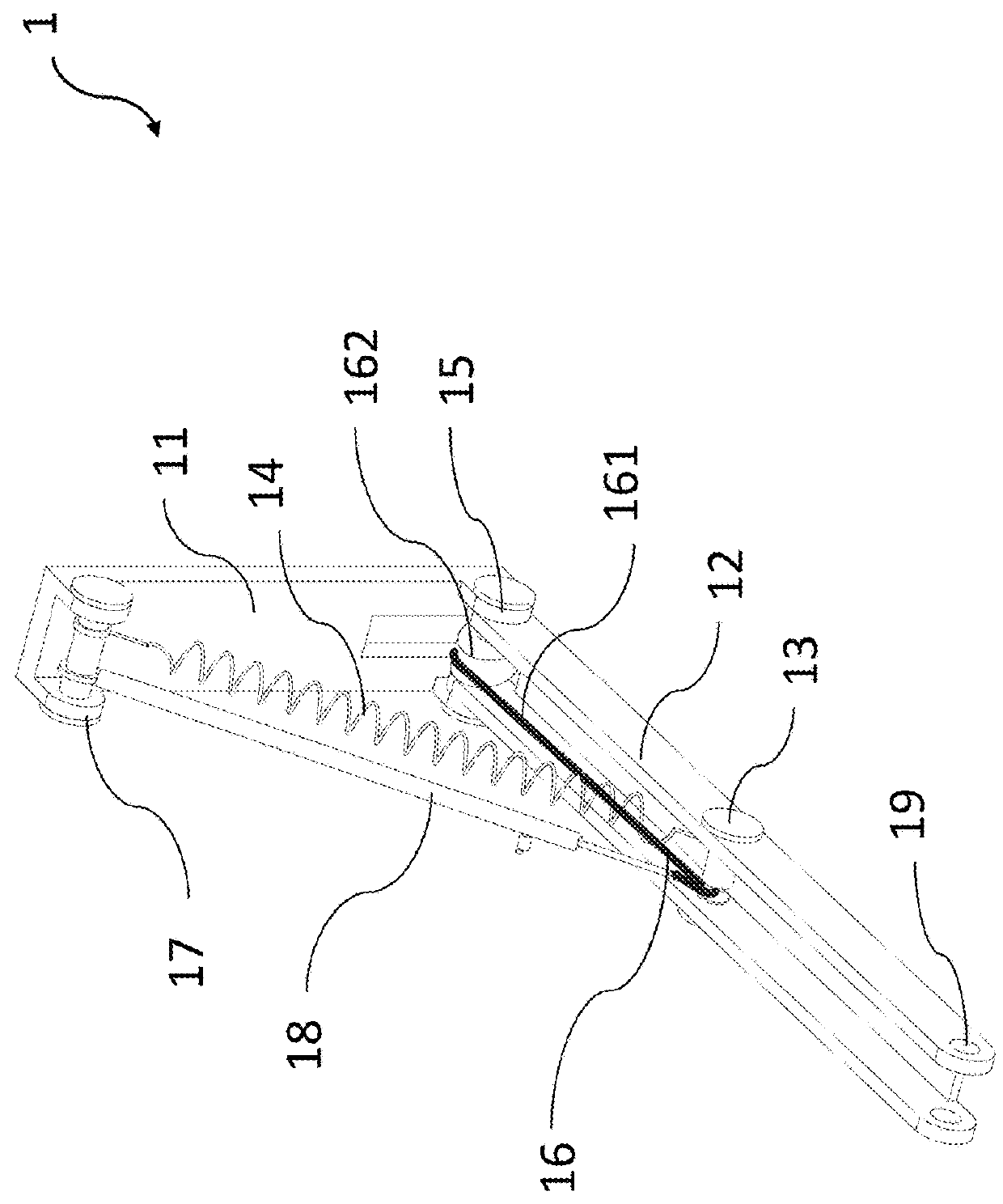

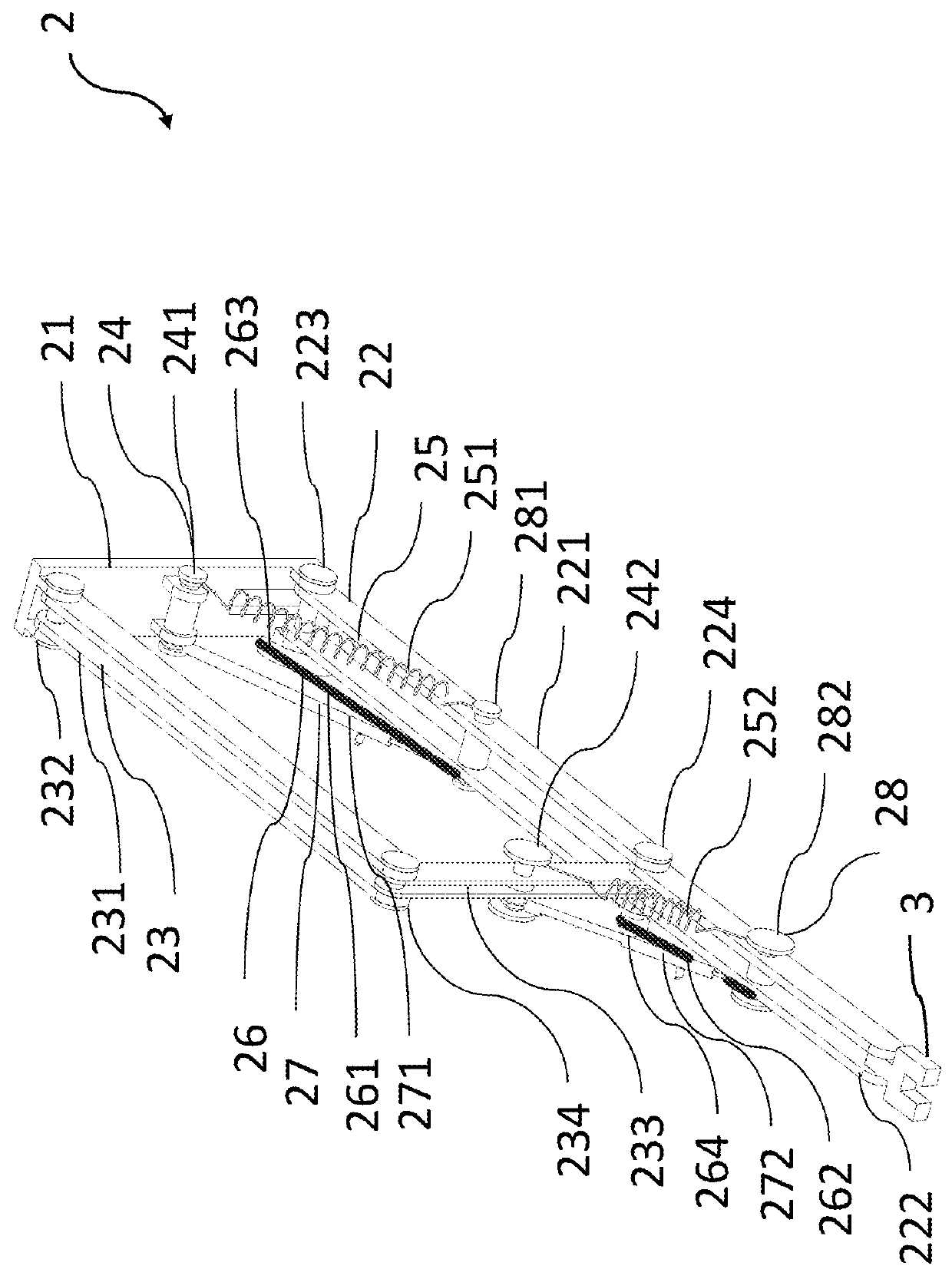

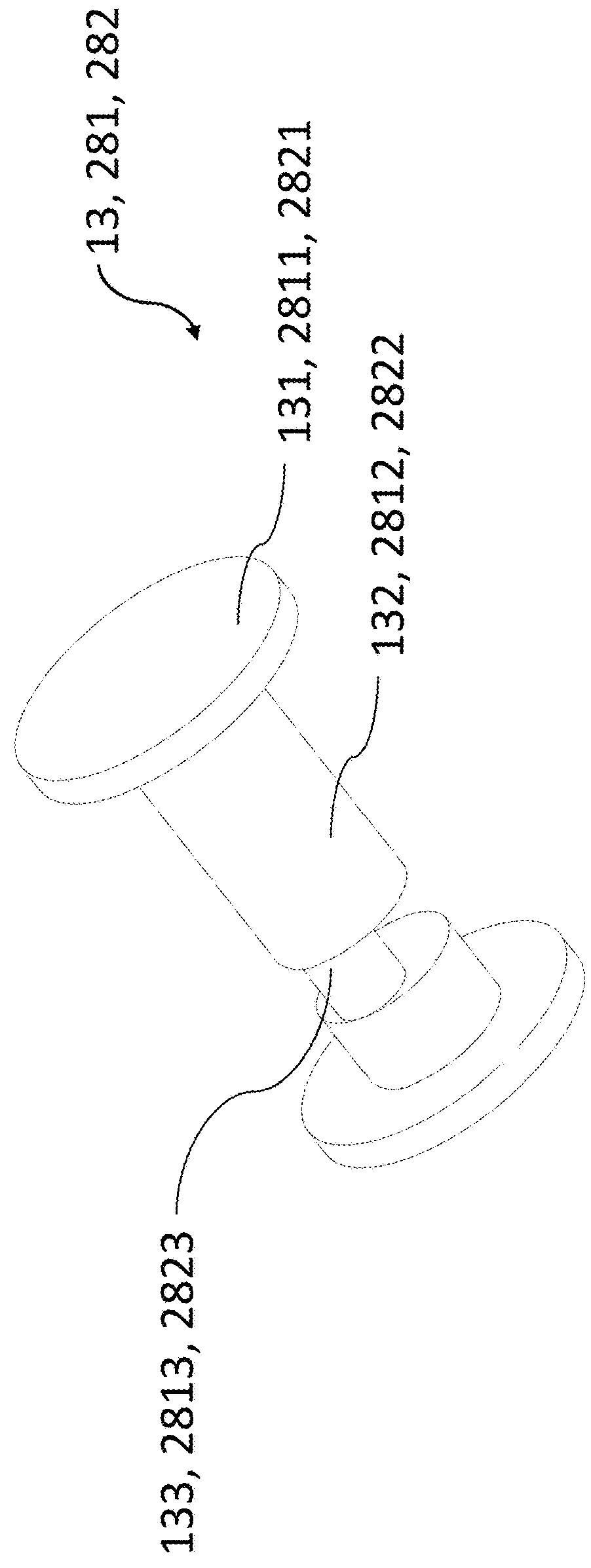

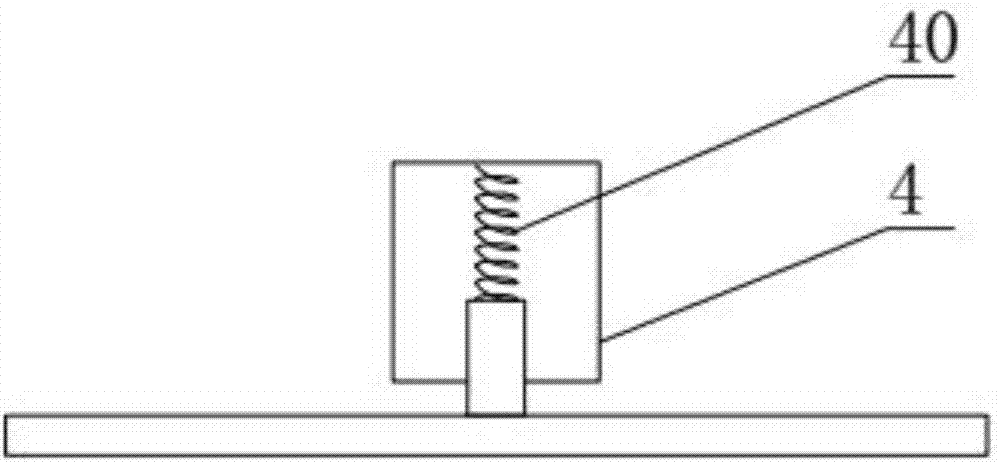

Gravitational electric power generating device

InactiveUS7288849B1Low costIncrease power generationFrom muscle energyMachines/enginesDrive shaftMoment of inertia

A gravitational electric power generating device includes a driving shaft, at least a spinning wheel, and two mount assemblies, in which each of the spinning wheels includes a first spoke rim, a second spoke rim, a wheel hub, and at least a tread-wheel. The two mount assemblies are erected at the two ends of the driving shaft, respectively, and can support both the driving shaft and the spinning wheel on the driving shaft. Using a moving object to move in the tread-wheel, and making use of the gravitational effect of the moving object, the spinning wheel is able to drive the driving shaft to rotate. The mount assemblies have a power conversion module, which is connected to an electric generator. The rotational inertia of the driving shaft is transmitted to the electric generator to generate the electric power using the power conversion module.

Owner:CHIANG CHIN HUI +1

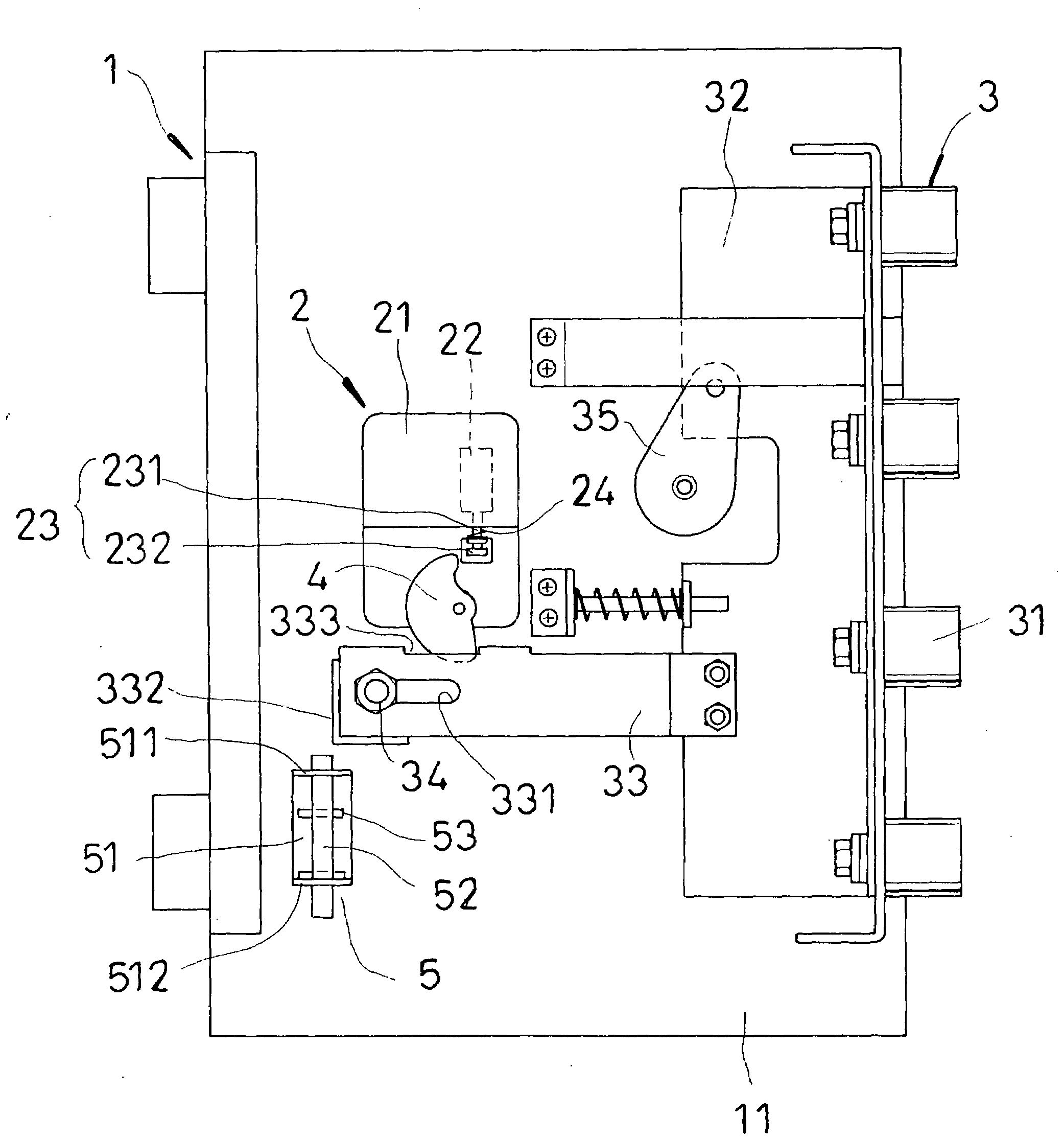

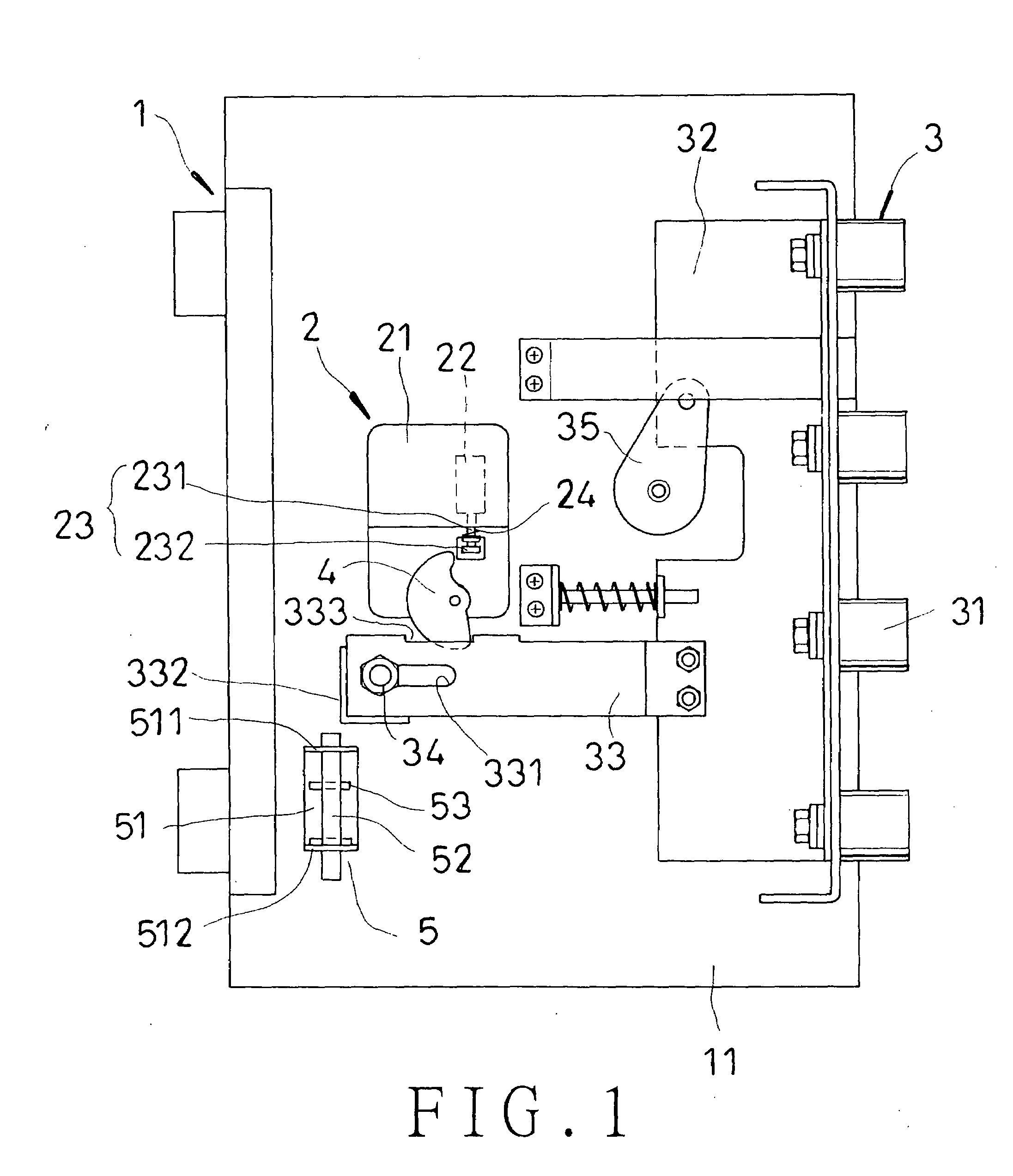

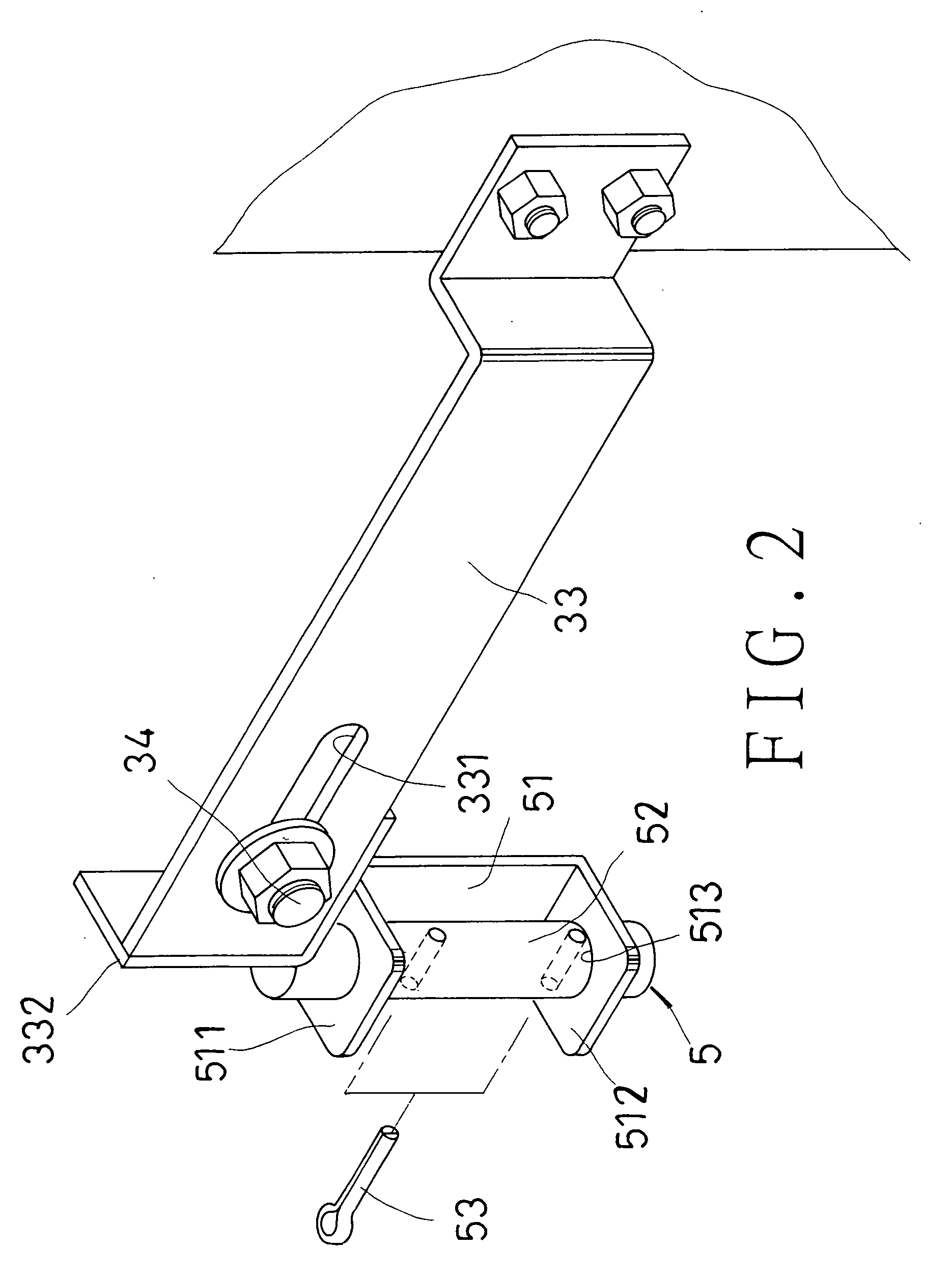

Electronic-controlled magnetic lock anti-theft unit for coffer

InactiveUS20100281934A1Hinder propertyNon-mechanical controlsElectric permutation locksGravitational effectElectrical and Electronics engineering

This invention relates to an electronic-controlled magnetic lock anti-theft unit for coffer in which a magnetic lock and a latch unit are assembled on the door panel of a coffer, a pivoting plate being provided between the magnetic lock and the latch unit, and an anti-theft unit at the lateral side of the latch unit. When a thief begins to turn the coffer upside down to steal, a stop post of the anti-theft unit falls down to engage in the latch unit by gravitational effect. In this manner, even if the engaging plate is disengaged from the magnetic lock, the latch unit is unable to be wrenched for unlocking. Therefore, the purpose of anti-theft can be achieved.

Owner:JIAN SHUN KING TRADING

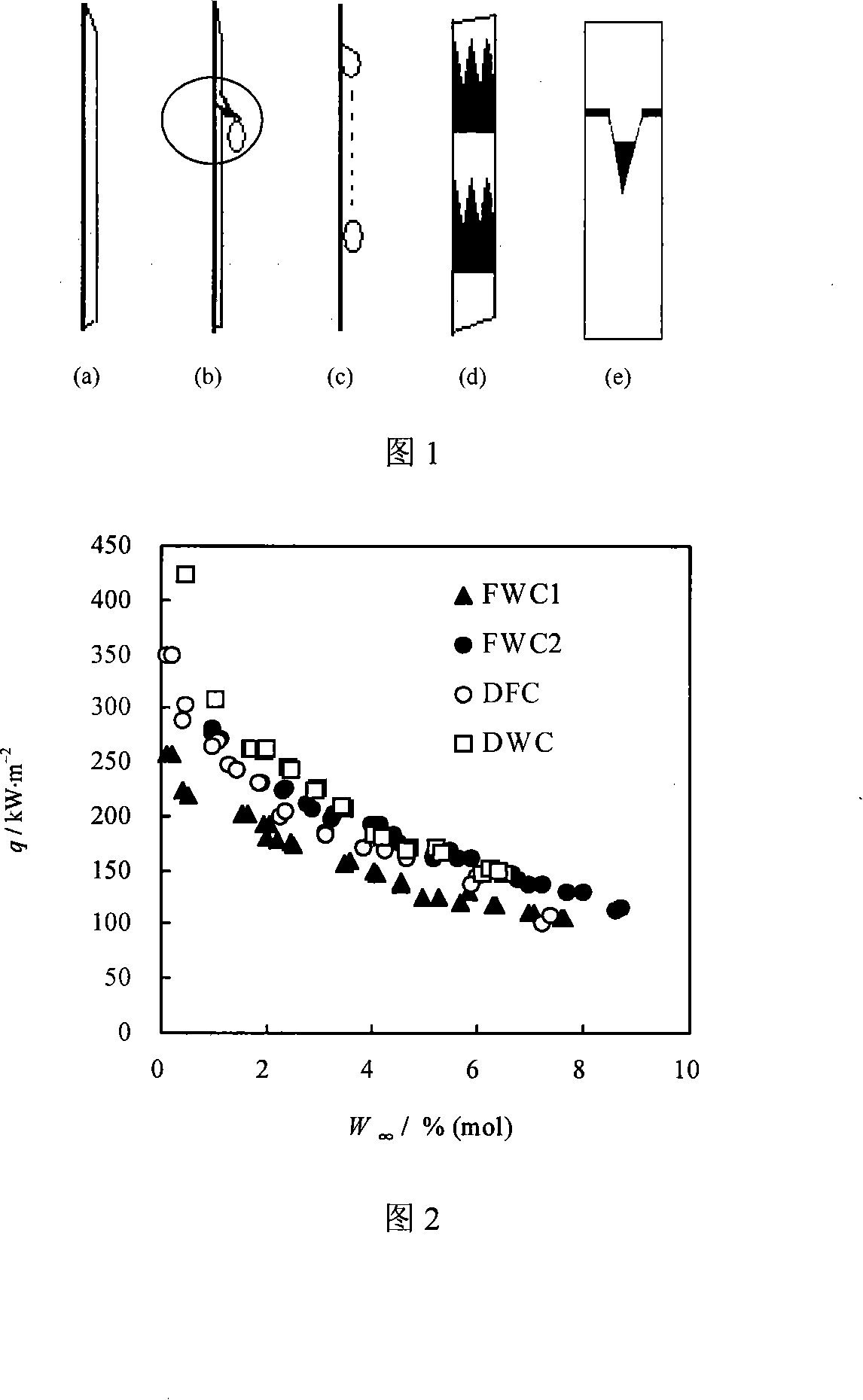

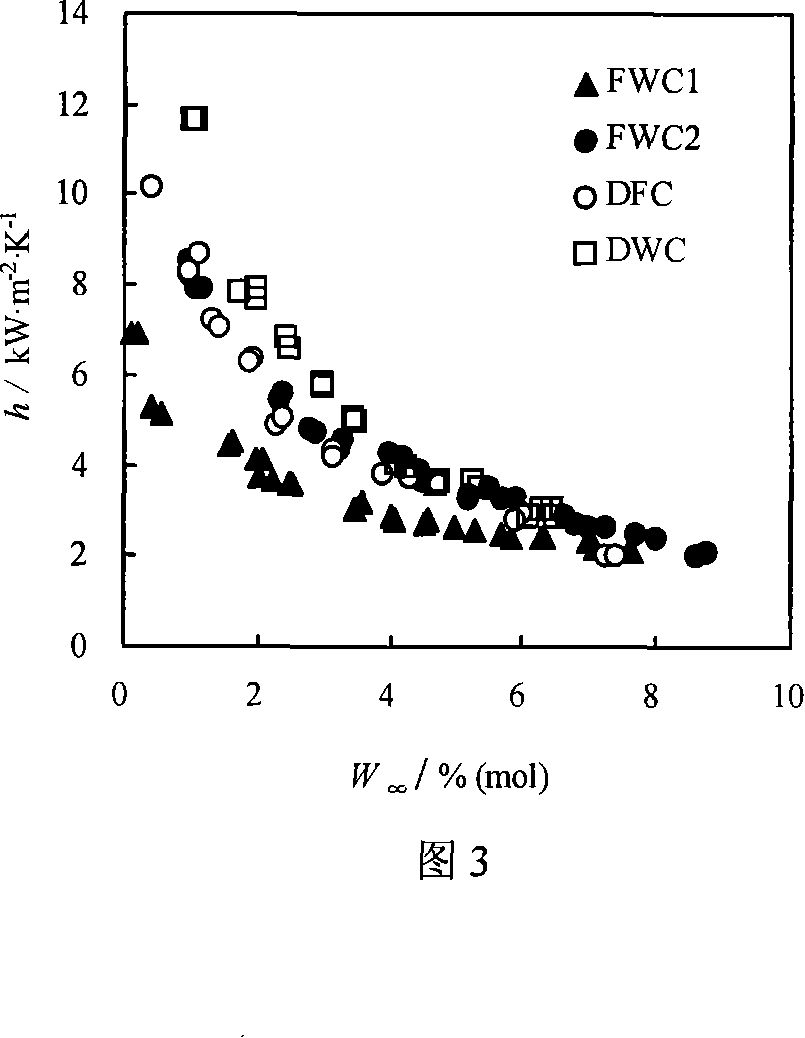

Mixed vapour condensation intensify heat transmission method

ActiveCN101082471AEnhance heat and mass transferAchieve synergyHeat transfer modificationGas phaseHeat transmission

There is a sort of heat transfer method of condensation aggrandizement type which mixes the steam, and it belongs to the area of aggrandizement heat transfer and energy-saving technique. It relates concretely to the modified character or the dispose course, and it applies to the set which has incondensable gas or the condensation-heat exchange set which mixes the steam in order to realize the aggrandizement of the condensation-heat exchange character. By changing the flowing form of the condensation liquid and the reciprocity between the dynamic and the boundary layer of the gas phase it makes the condensate which is in the groovy reliable membranous flow method to shell in the form of big dripping, the dripping can slide in the surface or shell along the boundary layer of the gas phase, it decreases the thermal resistance of the film of the condensate, at the same time for the intrusive action of the shell of the dripping, it is propitious to decrease the boundary layer of the heat transfer and the matter transfer, and it consolidates the whole heat transfer character of condensation aggrandizement type which mixes the steam. This invention can be used in the condenser which mixes the industrial material or has the incondensable gas. Its effect and benefit is that: in this instance that not using any additive power consumption, it only use the autologous gravitational effect of the condensate, and it makes the mixed steam heat transfer character of the mixed steam to obtain obvious melioration.

Owner:DALIAN UNIV OF TECH

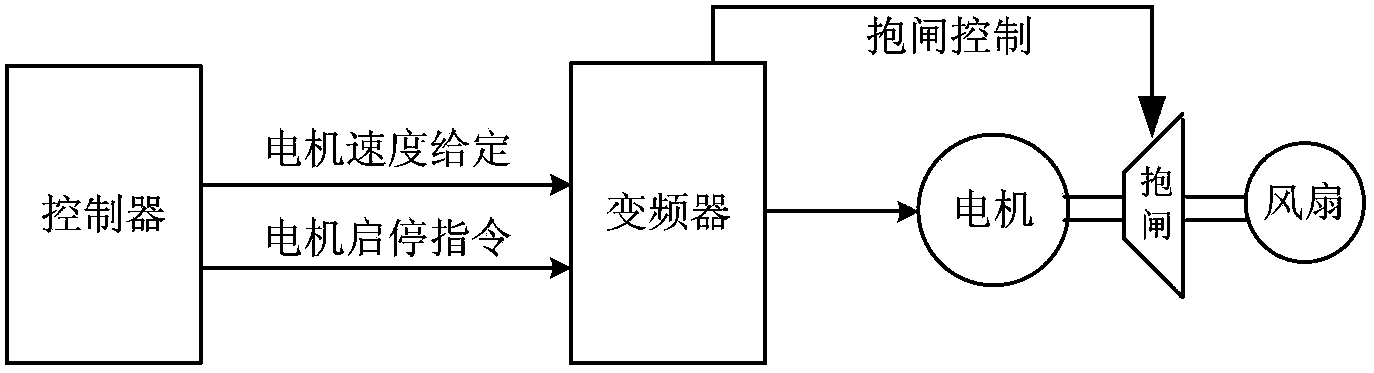

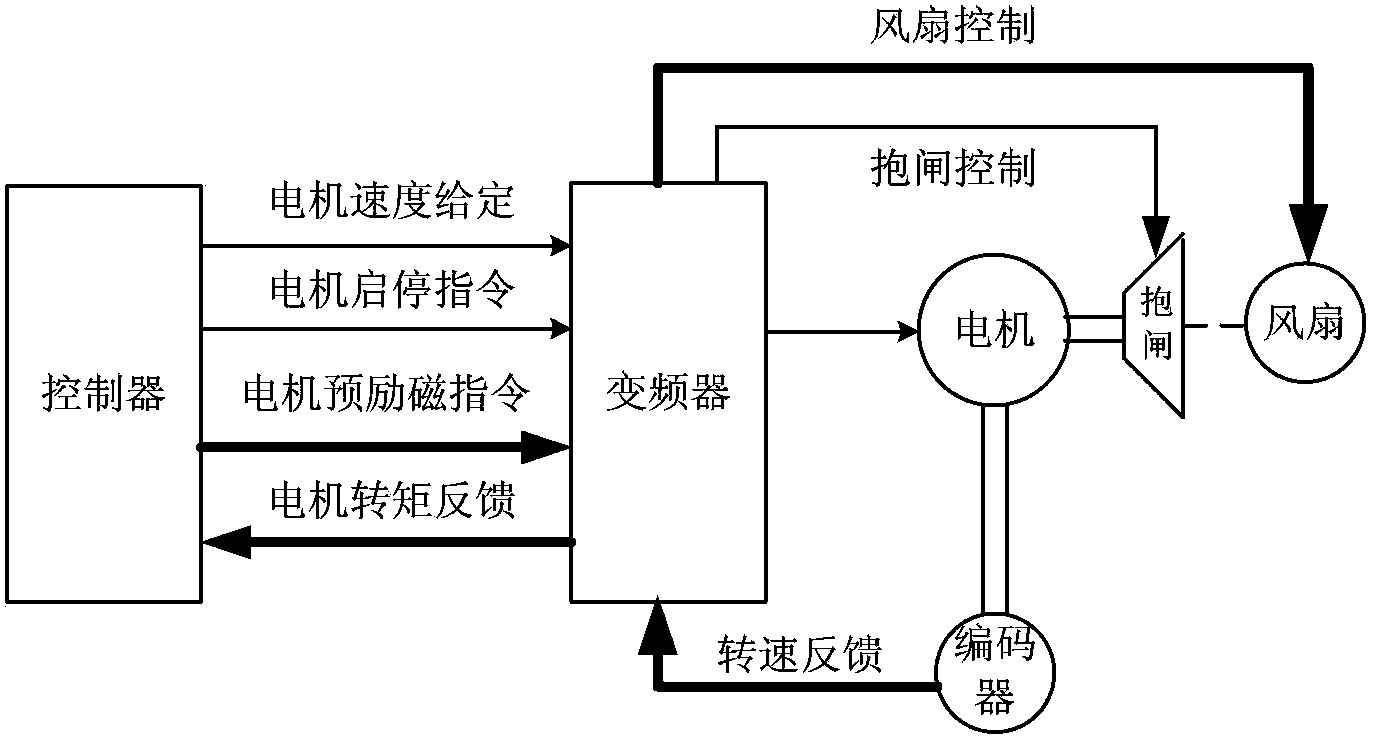

Control method for keeping insertion position of dummy bar

The invention discloses a control method for keeping the insertion position of a dummy bar. By exciting the pre-excitation effect of an inverter of a motor of a driving roller of a withdrawal and straightening unit, the control method utilizes the zero-speed electromagnetic braking torque provided for the motor by the closed-loop speed control inverter after pre-excitation to counteract the opposite drag force applied on the driving roller of the withdrawal and straightening unit by the gravitational effect of the dummy bar, so that the dummy bar can be kept in a zero-speed still state at the insertion position, and at the same time, an encoder is utilized to monitor and judge the actual torque of the motor in real time, playing a role in remotely monitoring the braking state and giving the alarm for abnormalities.

Owner:BAOSHAN IRON & STEEL CO LTD

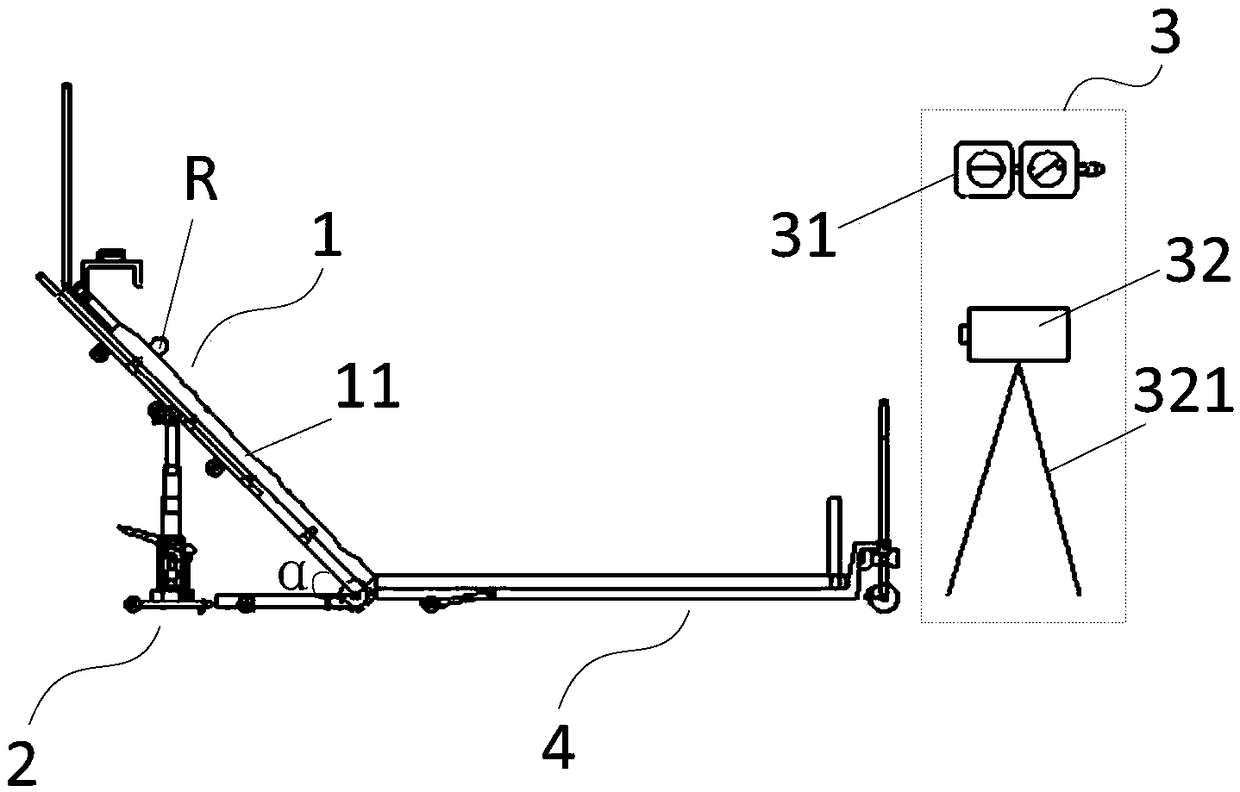

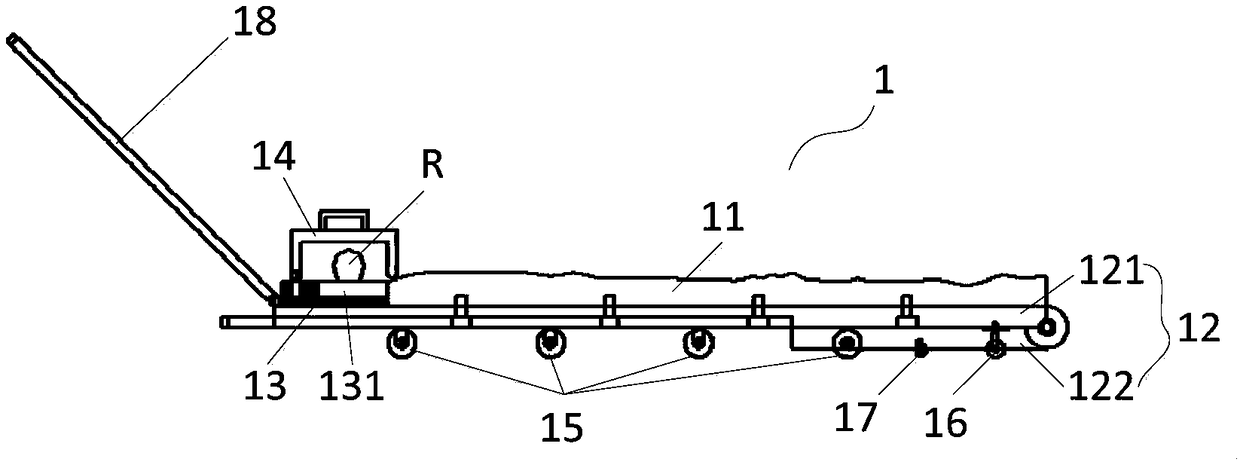

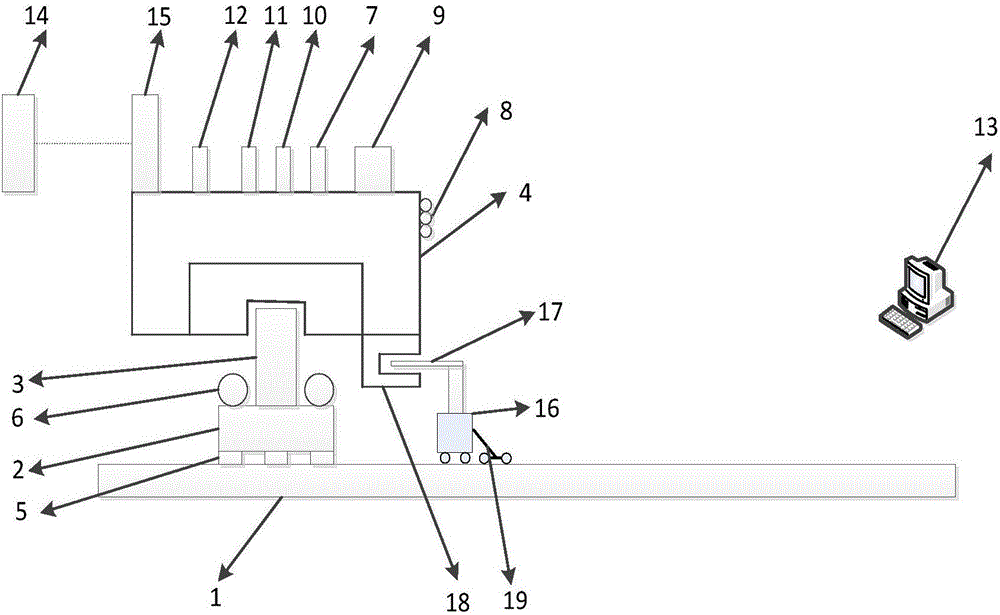

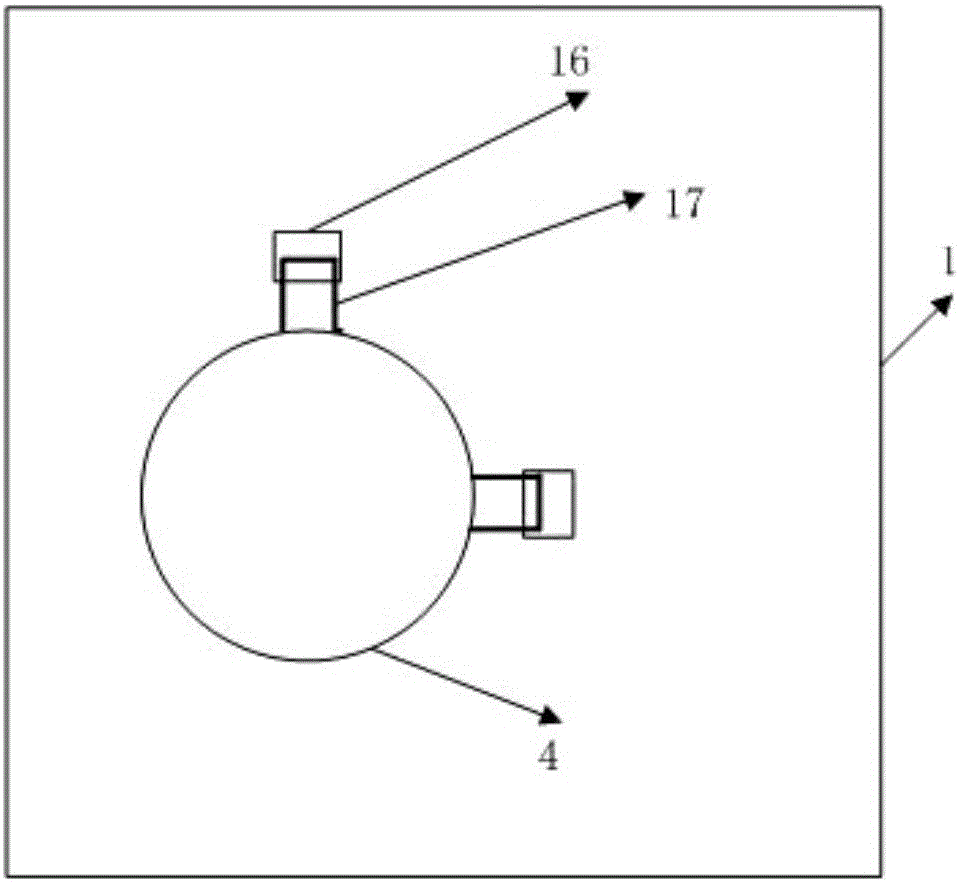

Test equipment for simulating collapse of rock mass

The invention belongs to the field of rock mass dynamics indoor tests, and particularly relates to test equipment for simulating collapse of rock mass. The test equipment aims to bring convenience formeasuring the collapse failure critical slope gradient of the rock mass or further measuring the horizontal movement distances of the rock mass with different degrees of roughness. The test equipmentcomprises a rock mass collapse simulation device, a slope gradient adjustment device and a rock mass collapse monitoring device. The rock mass collapse simulation device at least comprises a slope surface roughness simulation plate, and the rock mass can slide on the slope surface roughness simulation plate after collapsing; the slope gradient adjustment device is used for adjusting the slope gradient alpha of the slope surface roughness simulation plate relative to horizontal planes; the rock mass collapse monitoring device is at least used for measuring values of the slope gradient alpha when the rock mass starts to slide along the slope surface roughness simulation plate under the gravitational effects. The test equipment has the advantages that the collapse failure critical slope gradient of the rock mass can be conveniently measured by the test equipment; the test equipment in certain examples further can be provided with different types of slope surface roughness simulation plates, accordingly, collapse procedures of the rock mass R with the different degrees of roughness can be simulated, and relations between the horizontal movement distances of the rock mass R and the roughness of slopes can be obtained.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

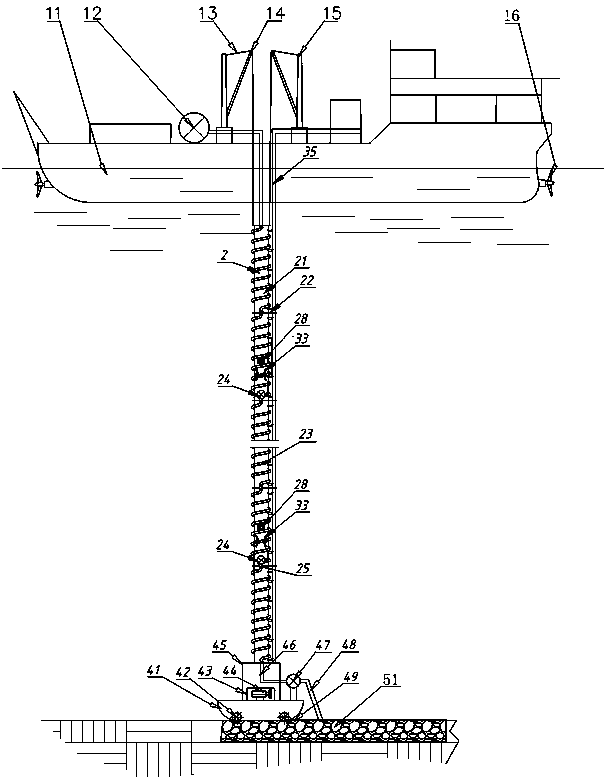

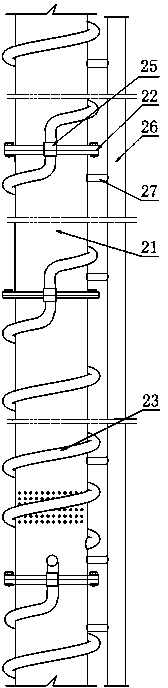

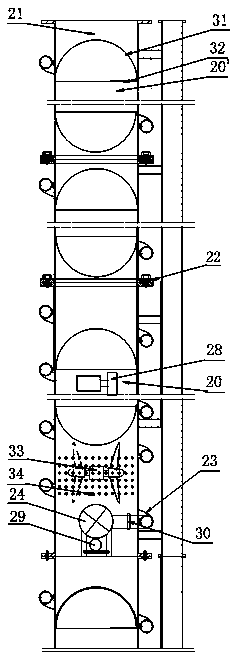

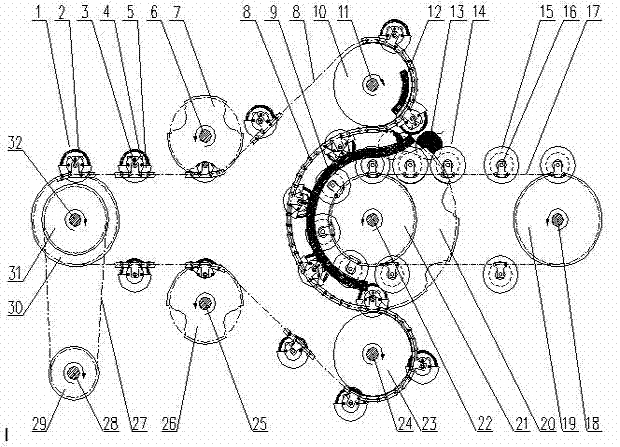

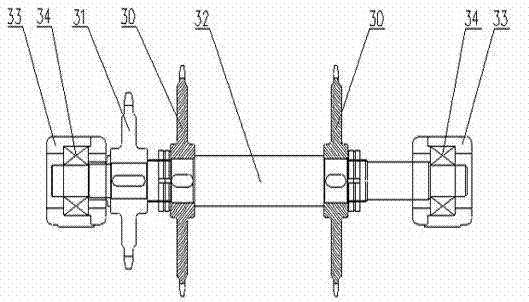

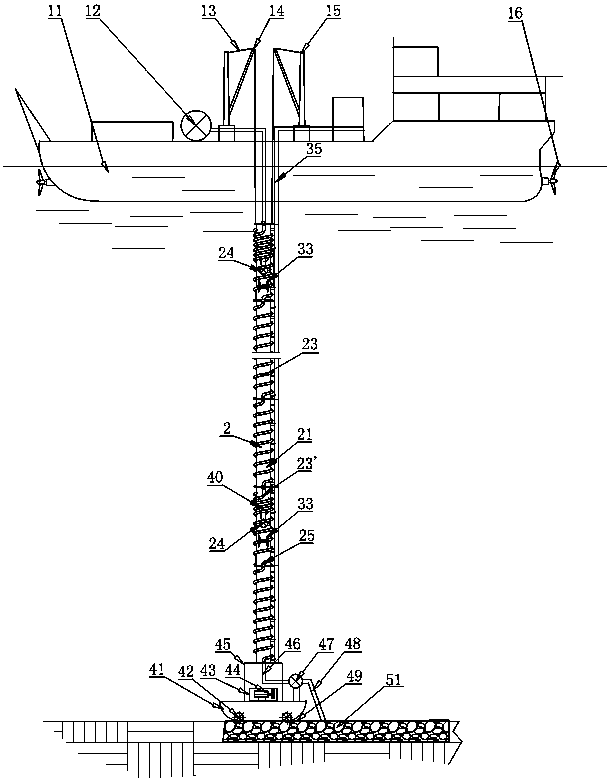

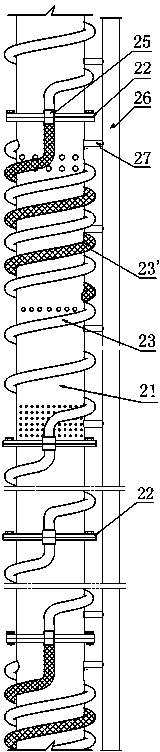

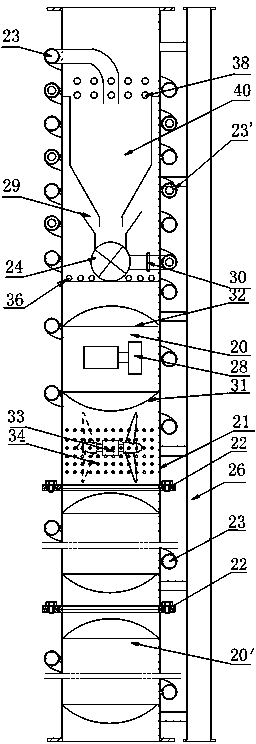

Deepwater mining annular pipeline lifting and conveying device

InactiveCN103587955ANo gravity effectImprove delivery efficiencyBulk conveyorsLoading/unloadingFree fallingHydraulic pump

The invention discloses a deepwater mining annular pipeline lifting and conveying device. A main supporting pipe is integrally formed by fixing at least two segments of supporting pipes through connecting pieces. A buoyancy air cabin with an electric hydraulic pump station, a buoyancy air cabin and a middle boost pump are arranged in the supporting pipes and an electric power control cable is arranged in a cable groove in the outer sides of the supporting pipes. The upper end and the lower end of the main supporting pipe are connected with a mining vessel lifting device and a traction steel wire rope respectively. A lifting and conveying pipe is an annular spiral pipeline which is fixed on the supporting pipes in a surrounding mode. The upper end and the lower end of the lifting and conveying pipe are connected with an ore sand output pump and a flexible conveying pipe respectively. The lifting and conveying pipe performs lifting and conveying in a spiral mode, the gravitational effect due to mineral substance free fall in the pipeline is avoided, and therefore the lifting and conveying distance is longer. Due to the fact that the electric hydraulic pump station is arranged in the buoyancy air cabin in the supporting pipes, the underwater weight of the whole device is reduced, in addition, working power is provided for the middle boost pump and an all-direction propeller, and the deepwater mining annular pipeline lifting and conveying device is safer and more reliable in use. Deepwater is led in through the all-direction propeller and a diversion hole to generate reacting force to prevent the supporting pipes from being twisted and deformed.

Owner:裘尧云

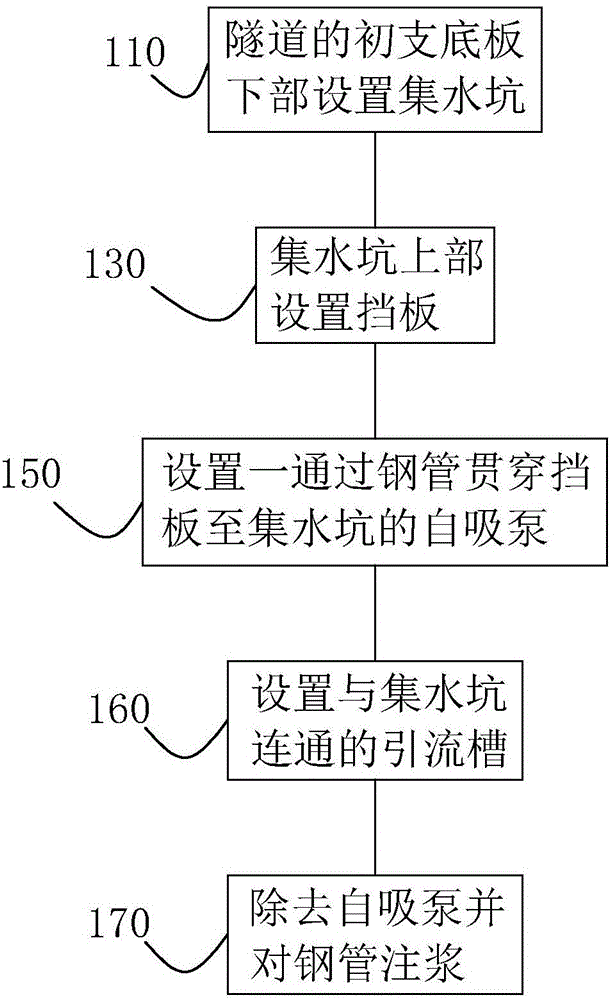

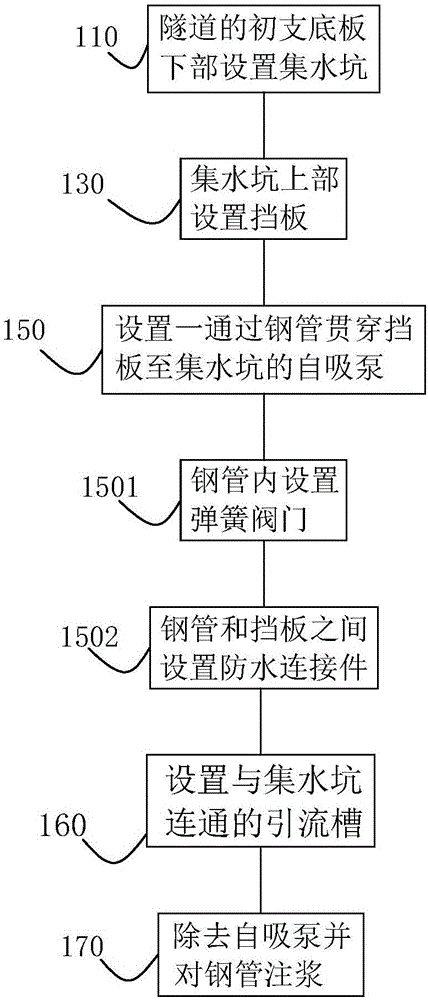

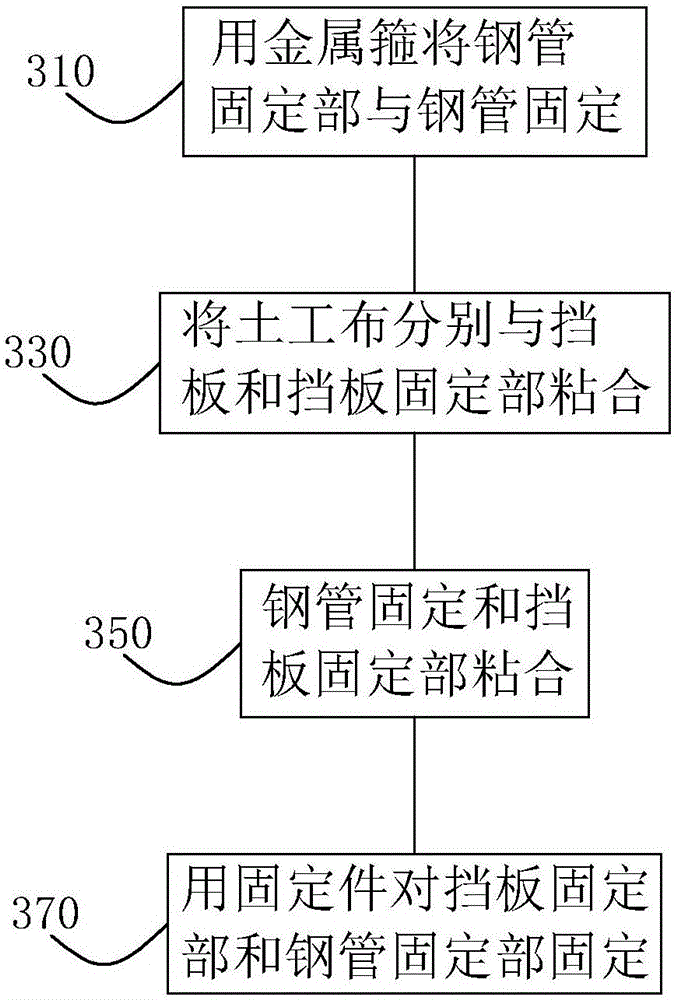

Concealed tunnel base plate water draining treatment method and structure thereof

A concealed tunnel base plate water draining treatment method comprises the steps that a water collecting pit is formed in the lower portion of a preliminary supporting concrete layer of a tunnel, and seepage water at a preliminary supporting bottom is drained to the water collecting pit; a baffle located at the upper portion of the water collecting pit and provided with a through hole is laid on the surface of the preliminary supporting concrete layer; a steel pipe penetrating through the through hole is arranged, one end of the steel pipe extends into the water collecting pit, and the other end of the steel pipe is connected with a self-priming pump for water pumping; after concealed tunnel construction is completed, the self-priming pump is removed, the steel pipe is grouted to seal the hole of the steel pipe, the water collecting pit can collect seepage water and underground accumulated water at the preliminary supporting bottom, a negative pressure is produced at a steel pipe port extending into the water collecting pit through the self-priming pump, the seepage water and the underground accumulated water flows out of the water collecting pit through the steel pipe, and the problem that a water body in the water collecting pit can be led out under the gravitational effect and accordingly water accumulation is caused is solved.

Owner:THE 5TH CONSTR COMPANY LTD OF CHINA RAILWAY 15TH BUREAU GRP

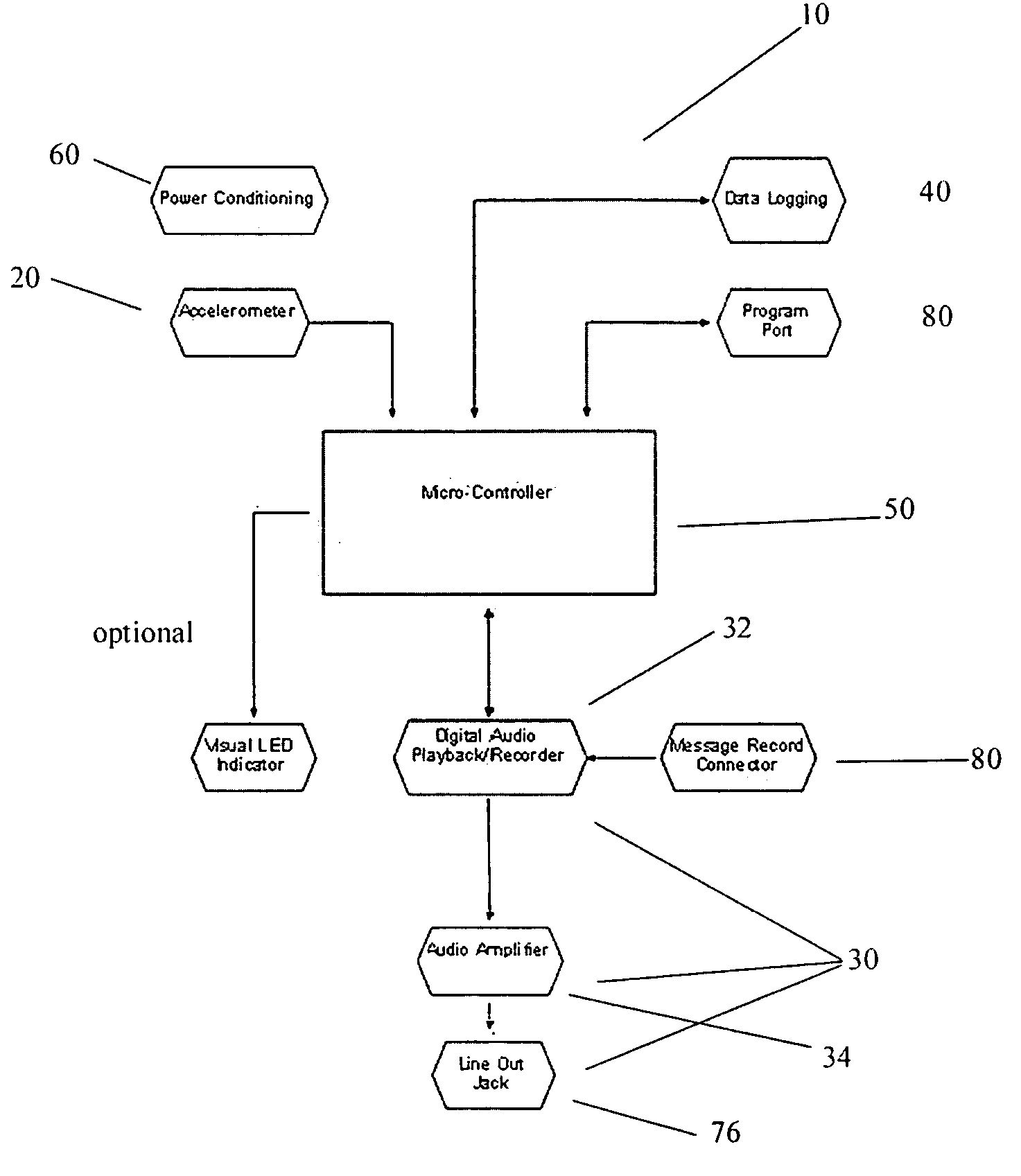

System for Measuring Lateral Gravitational Effect of Vehicles

InactiveUS20090248240A1Maintain speedEasy to installVehicle testingRegistering/indicating working of vehiclesDriver/operatorAccelerometer

A system for measuring the lateral acceleration of a vehicle. The system includes an accelerometer that measures the lateral gravitational forces, an annunciator that announces the changes in the lateral gravitation forces, a data logging for storing the measured changes and the relative times and a controller. This system is particularly useful for training for performance driving such as racecar drivers and law enforcement drivers.

Owner:OLSEN STEVEN C +1

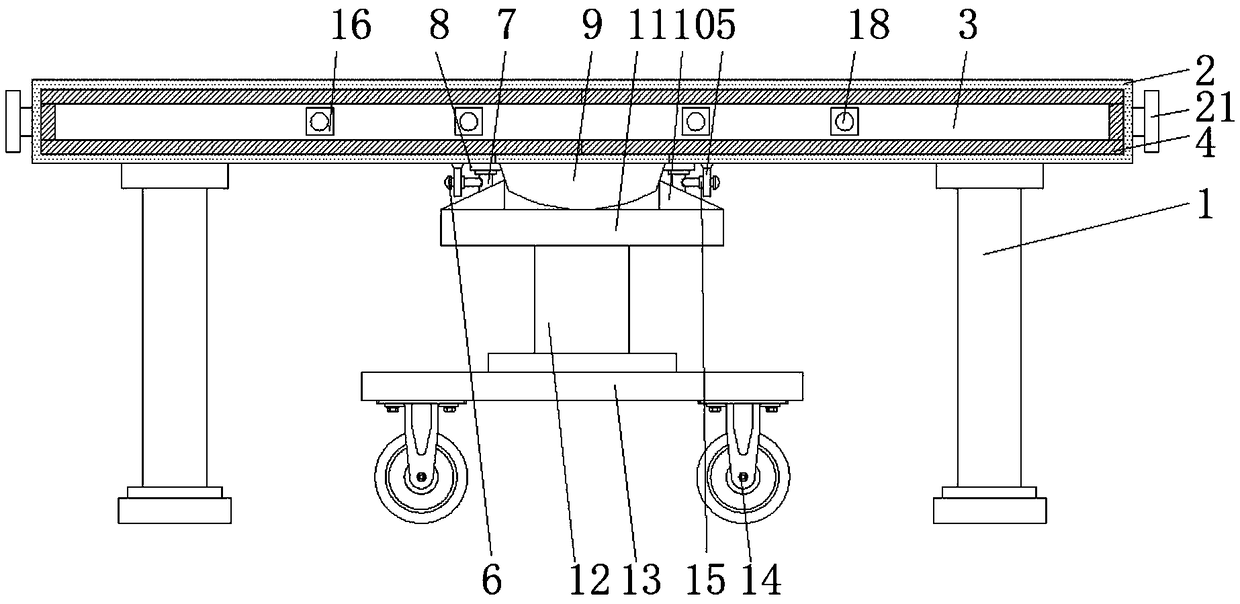

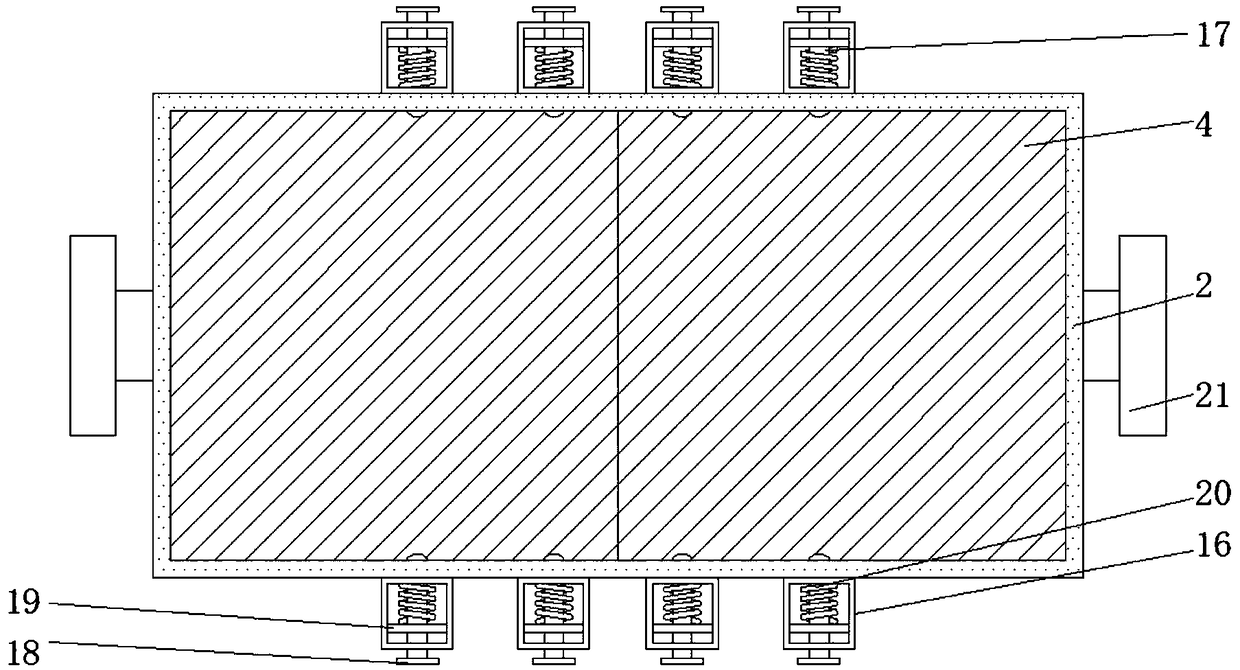

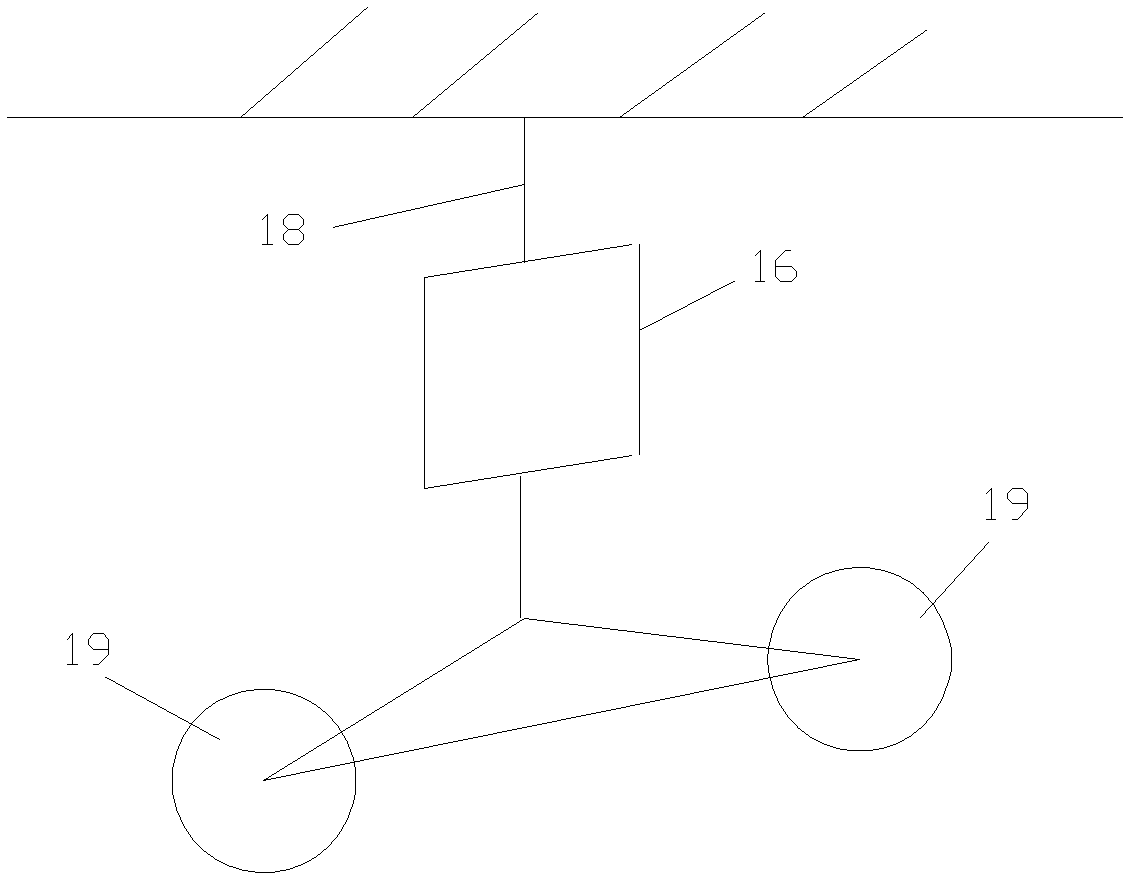

Mars gravity ground-based simulation device and simulation method thereof

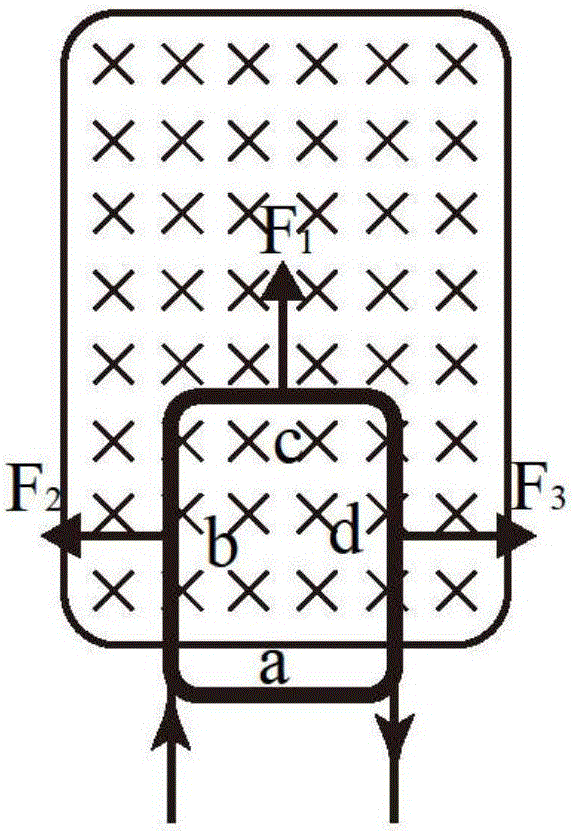

ActiveCN106354030ASimple structureEasy to controlSimulator controlResultant forceGravitational effect

The invention relates to a Mars gravity ground-based simulation device and a simulation method thereof. The device and method which are provided by the invention are mainly used for simulating Mars gravity with both magnitude and direction changed in a simulated test, a gravitational field does not need to be produced on the whole test system, and only a motion simulator needs to be always under the action of the gravity in the whole testing stage. By virtue of coordination of equipment such as a gravity applying device and a position measuring device, Mars gravity action with both the magnitude and direction changed at the same time is simulated by a resultant force received by the motion simulator, and a practical process of orbit control is truly simulated. The device provided by the invention is simple in structure, the control method is simple and easy, and cost is low.

Owner:HARBIN INST OF TECH

Multi-Axis Tilt Sensor for Correcting Gravitational Effects on the Measurement of Pressure by a Capacitance Diaphragm Gauge

ActiveUS20140222363A1Compensation effectFluid pressure measurement by electric/magnetic elementsSpecial data processing applicationsCapacitanceMulti axis

A system and method compensate for effects of gravity on the diaphragm of a capacitance diaphragm gauge (CDG). The CDG generates a measured absolute pressure value in response to an applied absolute pressure on an input of the CDG. The CDG is subjected to a variable orientation of the CDG with respect to the earth's surface that can cause inaccurate pressure measurements. A pressure measuring circuit generates a measured value of an applied absolute pressure provided to an input of the CDG. A tilt sensor generates at least one tilt sensor output value that is responsive to an orientation of the CDG with respect to the earth's surface. A processing system adjusts the measured absolute pressure value by a calibration factor to generate a calibrated absolute pressure value representing the applied absolute pressure, wherein the calibration factor is selected in response to the at least one tilt sensor output value.

Owner:SUMITOMO SHI CRYOGENICS OF AMERICA

Adjustable passive gravity compensation apparatus

Owner:INST NUCLEAR ENERGY RES ROCAEC

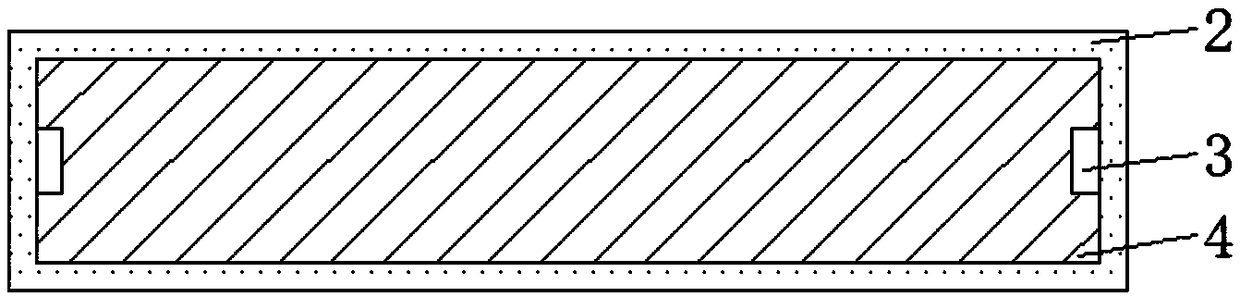

Immunomagnetic experimental device with test strip

ActiveCN106970211ASimple structureBiological testingConverting sensor output electrically/magneticallyFiberAcoustics

The invention relates to the field of immunomagnetic tests, in particular to an immunomagnetic experimental device with a test strip. The immunomagnetic experimental device with the test strip comprises the test strip and a magnetic sensor device. The test strip comprises a first coated layer, a second coated layer and a nitro fiber film layer, the nitro fiber film layer is arranged between the first coated layer and the second coated layer, and a sample injection hole is formed in the first coated layer; the magnetic sensor device comprises magnetic sensors and is configured in such a manner that the magnetic sensors of the magnetic sensor device can closely cling to the surface of the test strip under the gravitational effects when the magnetic sensor device is arranged above the test strip, and magnetic lines generated by the magnetic sensors can be cut when the test strip moves. The immunomagnetic experimental device has the advantages that the immunomagnetic experimental device is simple in structure, and the magnetic sensors can closely cling to the surfaces of the test strip.

Owner:佳贺斯(浙江)生物医药科技有限公司

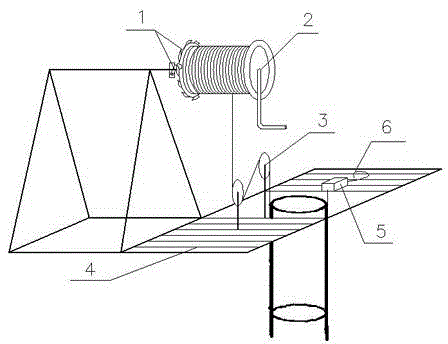

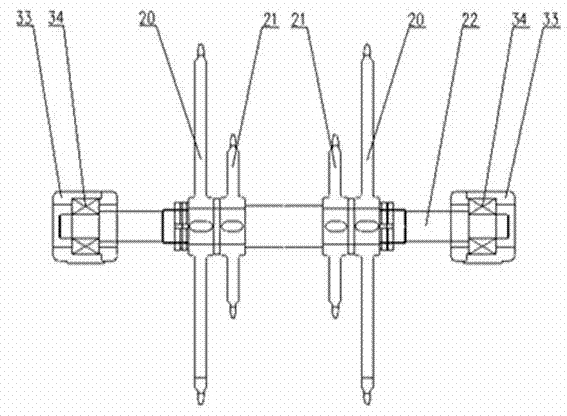

Sinking method and device for water well pipe

InactiveCN104963343AOperational securityPrecise positioningFoundation engineeringEngineeringWater well

Provided is a sinking device for a water well pipe. The sinking device comprises a ratchet positioning device, a wheel shaft power mechanism, a guide pulley block, an operation platform and a steel wire rope. The operation platform is arranged right above a well hole and has an opening matching the well hole. A support is arranged on one side surface at one end of the operation platform. The wheel shaft power mechanism is arranged on the support. The ratchet positioning device is arranged on the wheel shaft power mechanism and positioned by means of the support. The sinking device for the water well pipe has following beneficial effects: due to the fact that the wheel shaft device is low in weight and gravitational effect and a lever principle are completely utilized, energy is saved and convenience and safety of construction are enhanced; due to application of the ratchet positioning device, the well pipe can be conveniently and stably positioned at any position so that safety, reliability and convenience are achieved; the wheel shaft power mechanism can easily draw the steel wire rope without mechanical coordinating operation such that construction flexibility is improved and construction cost is decreased; and the wheel shaft power mechanism is conveniently operated and helps to save manual power and decrease cost.

Owner:CHINA AEROSPACE CONSTR GROUP +1

Field converter

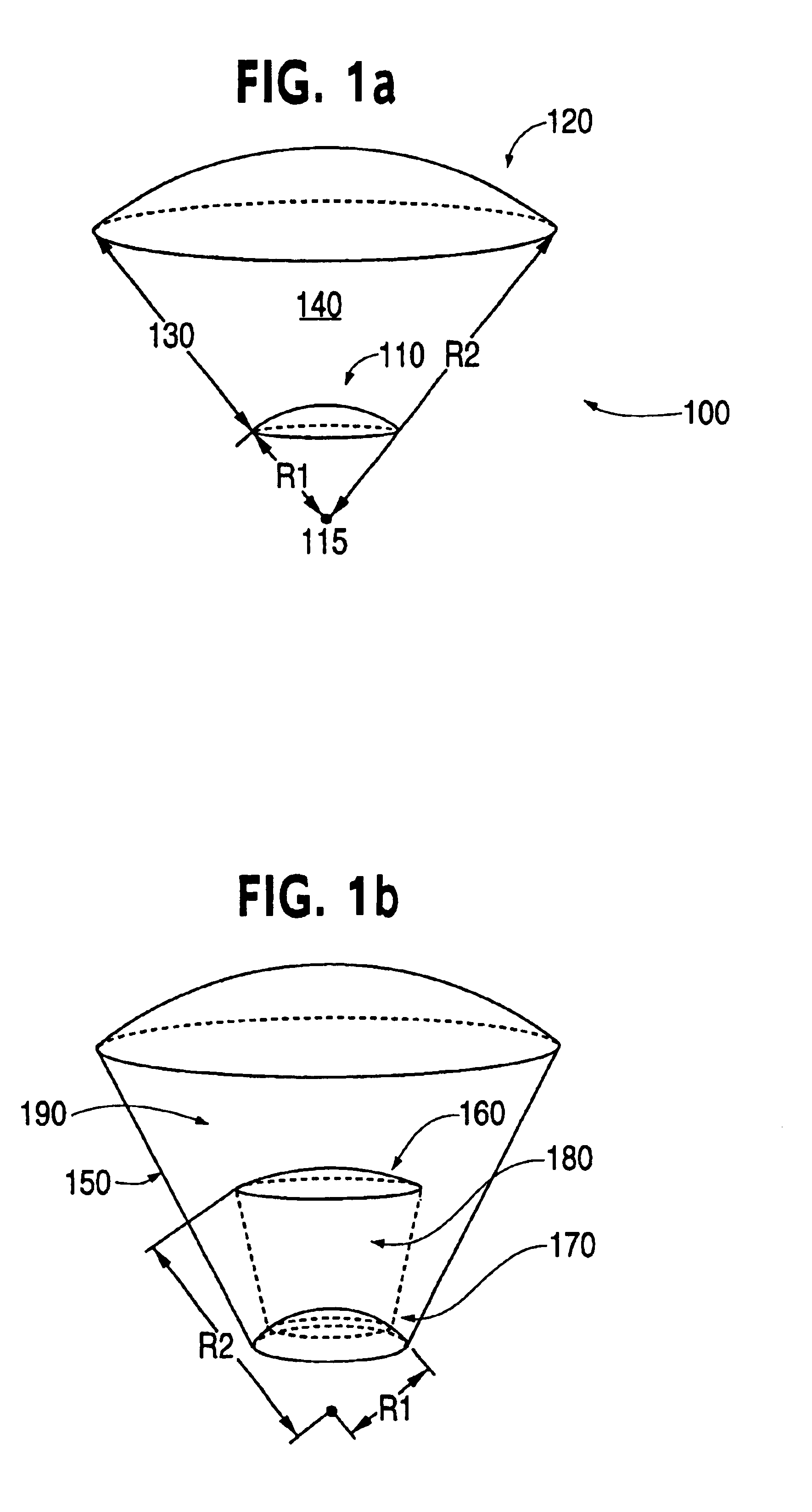

A device for generating an inhomogeneous electrical field includes first and second electrodes. The first electrode may be a portion of a sphere, a cone, a paraboloid, a cylinder; a hollow sphere, a hollow cone, a hollow paraboloid, or a hollow cylinder. The second electrode may be a portion of a sphere, a cone, a paraboloid, a cylinder, a hollow sphere, a hollow cone, a hollow paraboloid or a hollow cylinder. The first and second electrodes are aligned to produce an inhomogeneous electric field when charged with a voltage potential and generate a gravitational effect. The second electrode may be at least partially concentric with said first electrode.

Owner:PST ASSOC LLC

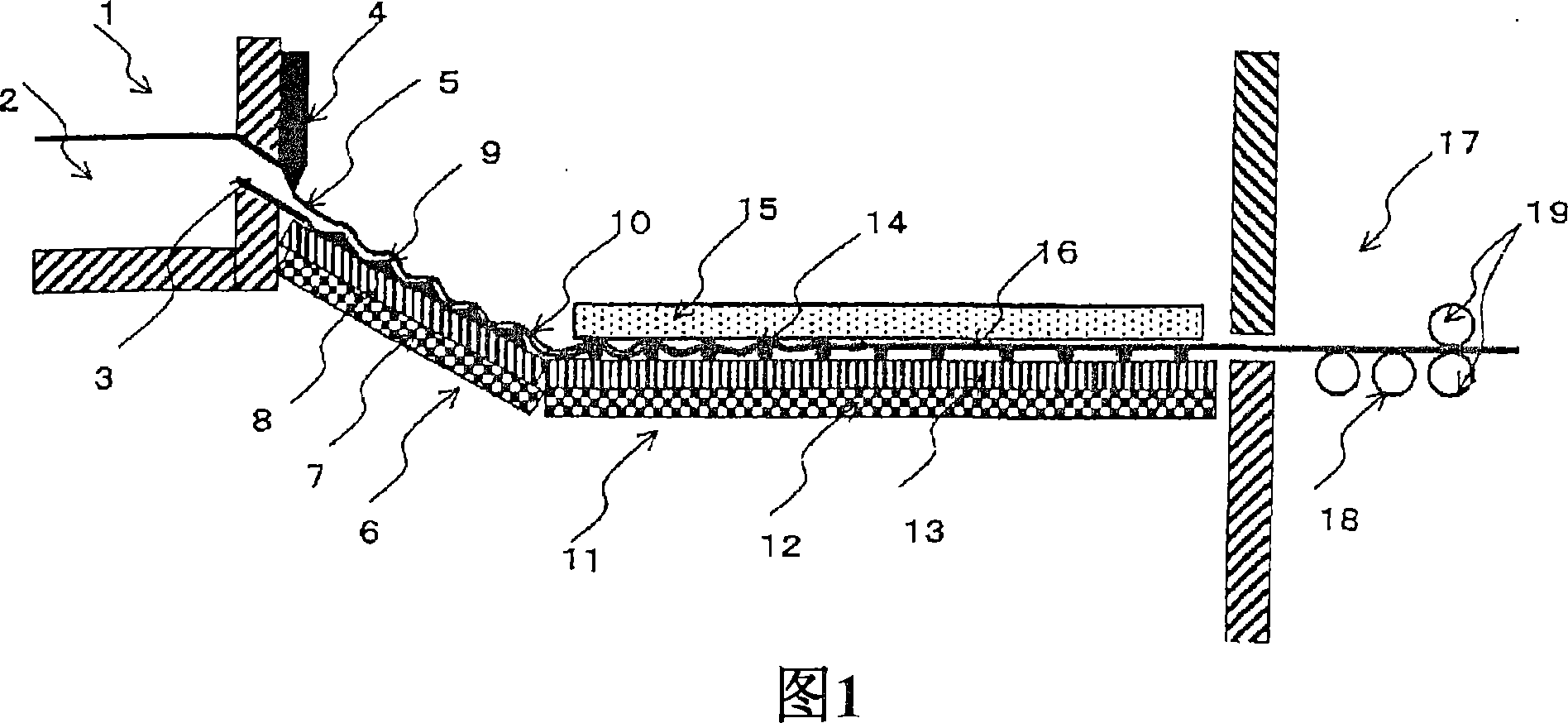

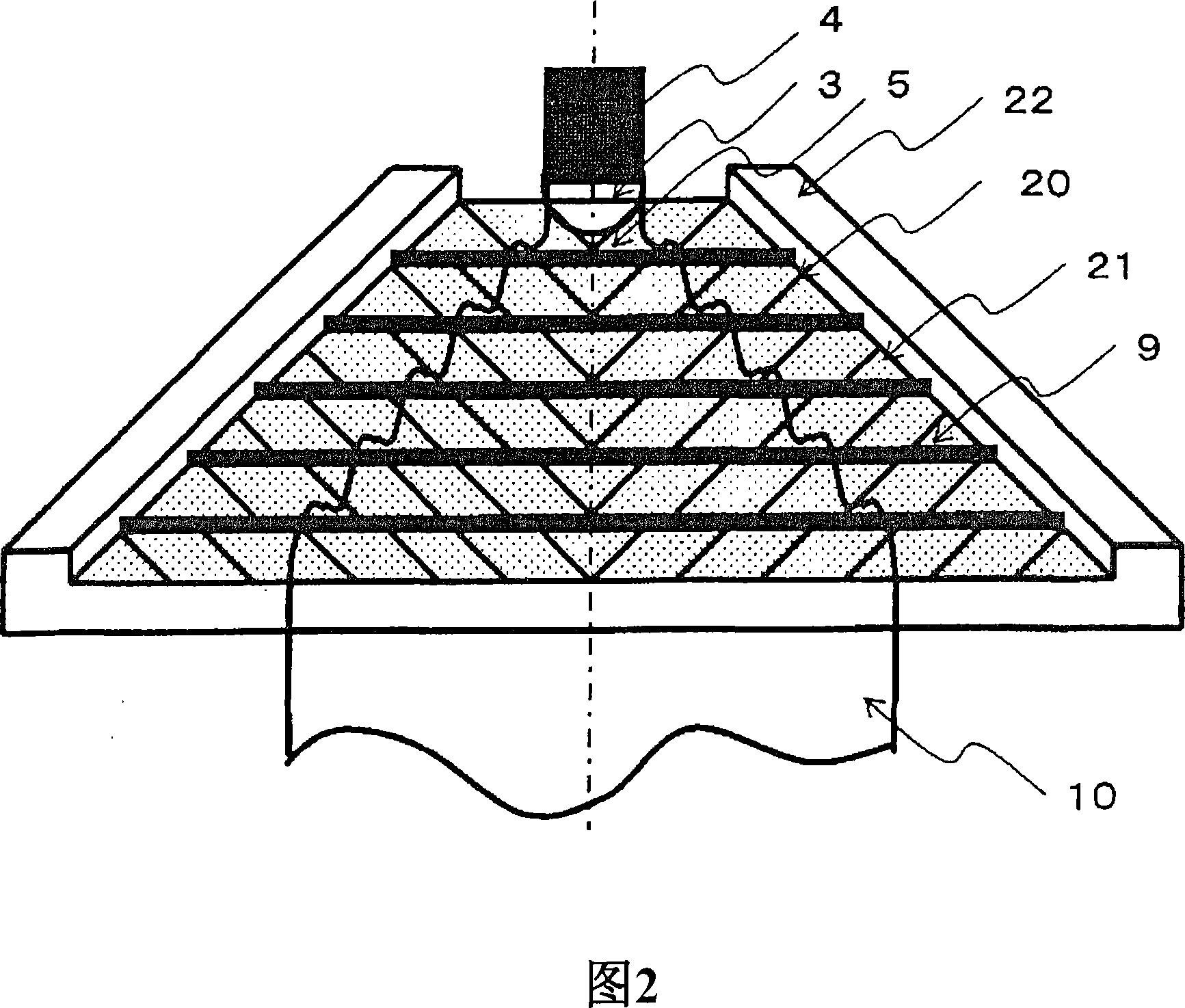

Method of manufacturing panel glass

InactiveCN101080367AImprove flatnessCheap and easy to produceGlass forming apparatusGlass productionEngineeringProduct gas

A process for producing a plate glass, characterized in that in the method of continuously forming of glass into a plate, continuously traveling glass before solidification on at least its underside is supported by a gas emitted from a support member and with any gravitational effect on the glass controlled, partial displacement and deformation while shifting the position thereof are repeatedly exerted on the glass so as to achieve propagation over the entirety of the glass and expansion thereof. Thus, there is provided a technology that attains resolution or improvement as to the drawbacks, restraints, etc. of the prior art, being simple and easy, and that markedly alleviates the problems of energy, resources and environment, and that produces a high-quality plate glass with flawless surface. Furthermore, there is provided a new technology that through clarification of important technical aspects and factors in principle and fundamentally lacking in the method making use of vapor films, produces a high-quality plate glass excelling in not only microscopic smoothness but also macroscopic thickness uniformity and planarity, etc. throughout plate glass forming processes utilizing an increased variety of gases.

Owner:NAT INST OF ADVANCED IND SCI & TECH

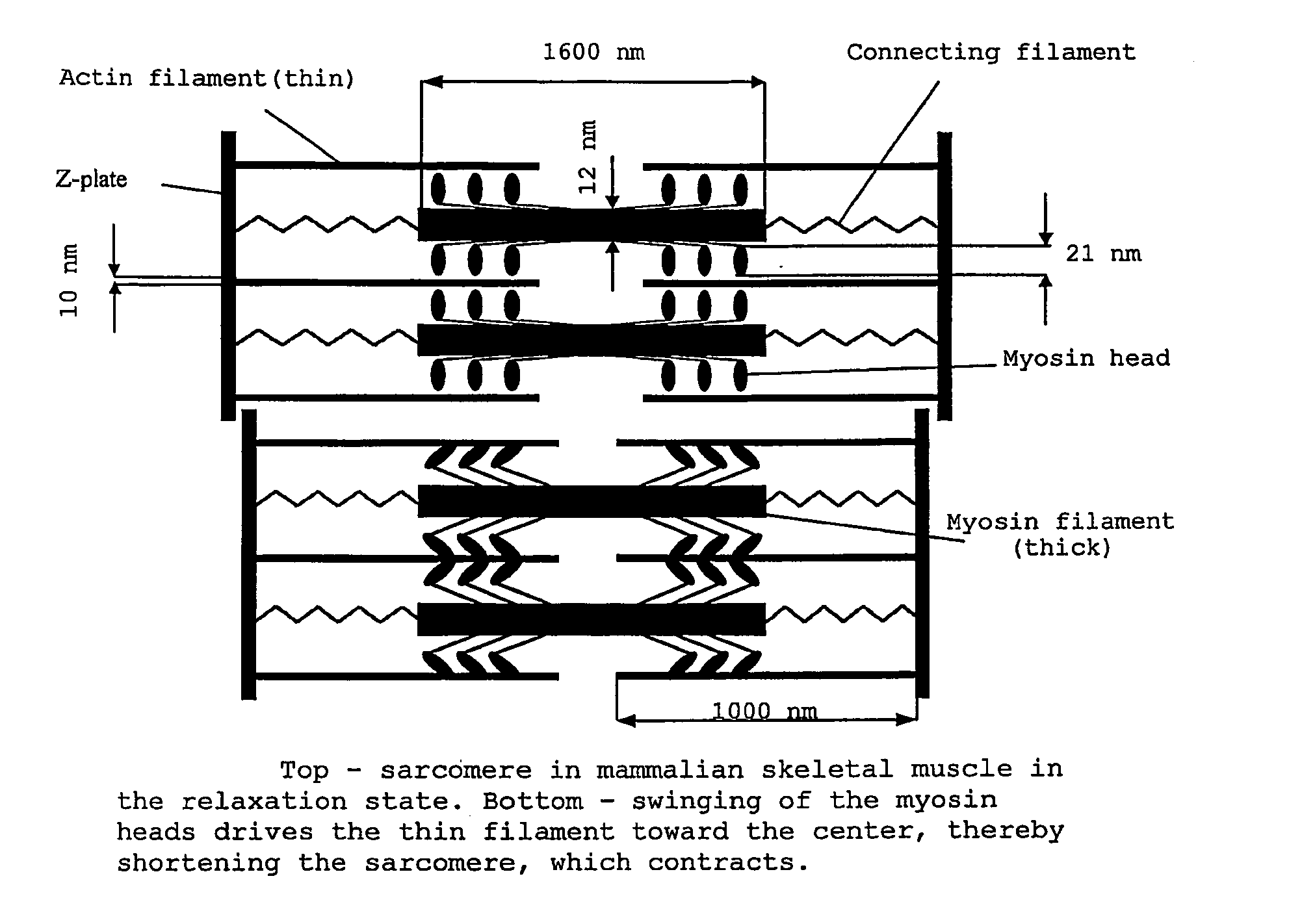

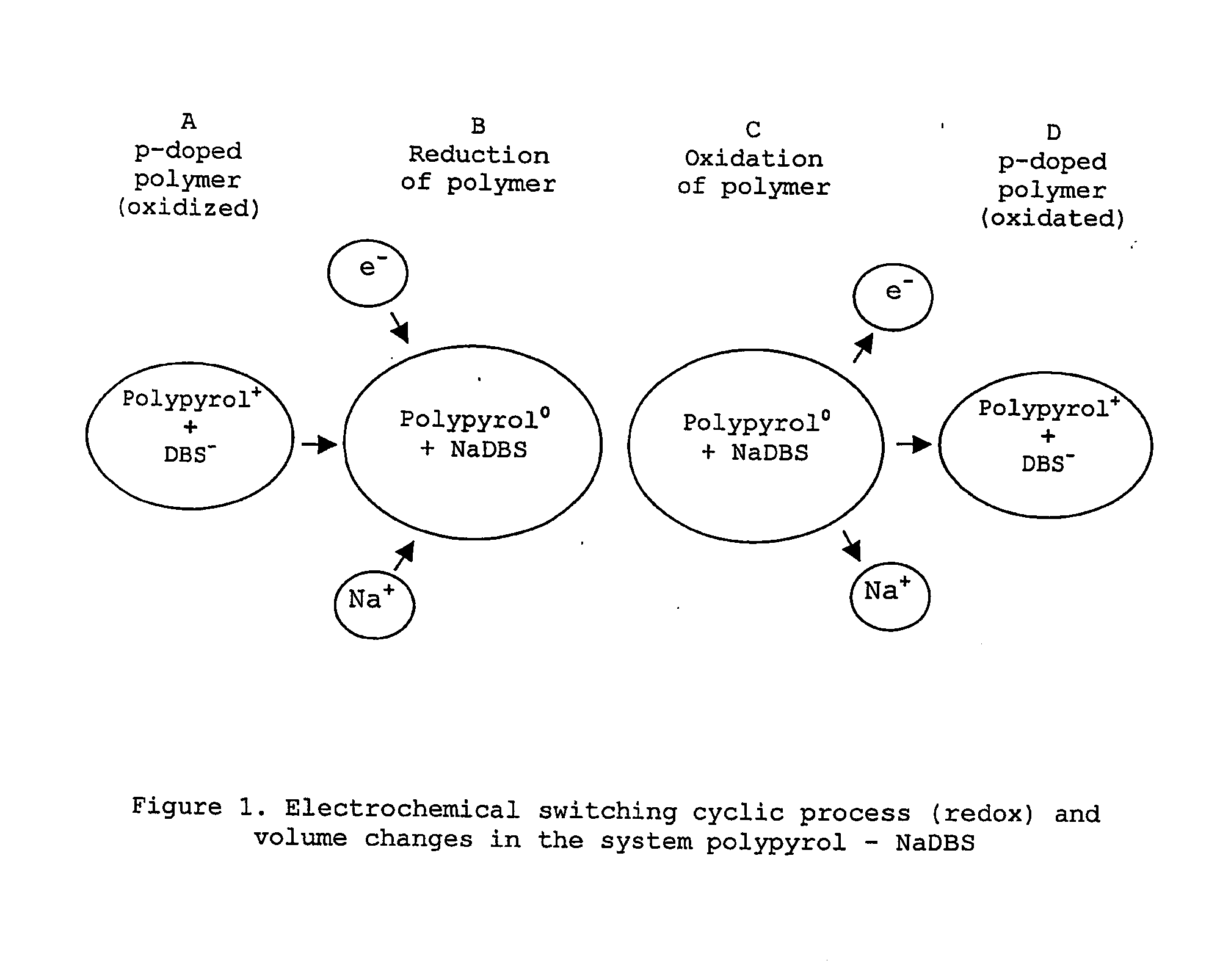

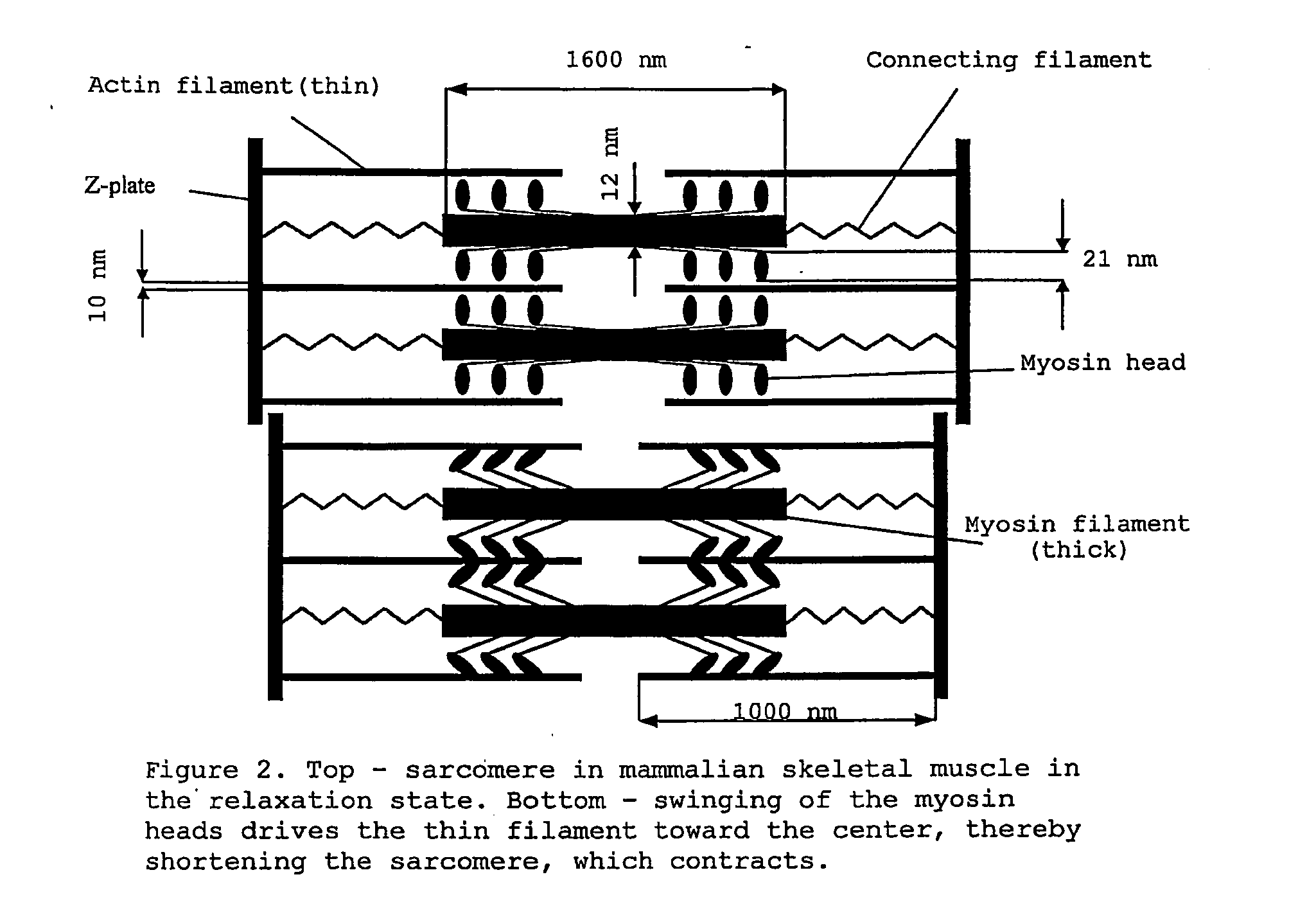

Electromechanical Transducer

InactiveUS20090179520A1Maximize change densityMachines/enginesMechanical power devicesModular designModularity

The function of the key element of the SMA, is based on a mutual alternating slipping of two systems of filaments. Its contraction is caused by the attractive effect of van der Waal's forces between the functional particles among the filaments. The relaxation is attained through the repulsive effect of the electrostatic repulsive forces between the functional particles. The alternating change of ionic concentration in the area of the particles results in the alternating function of van der Waal's attraction and repulsive electrostatic forces. The size and material of the particles, their configuration and working temperature must be specifically optimized. The total contraction of the key element results from the summation of its partial contractions. The total force and contraction of the SNA result from the summation of the key elements in the parallel (collateral) and / or serial (linear ranked) arrangements, respectively. Large compound actuators with high performance can be built from key elements using the modular design.

Owner:CZECH TECH UNIV IN PRAGUE

Device for filtering cutting fluid of grinding lathe

InactiveCN106621511ASpeed up filteringReduce filter timeMembrane filtersLubricant compositionHydraulic cylinderLiquid storage tank

The invention discloses a device for filtering a cutting fluid of a grinding lathe. The device comprises a hydraulic cylinder, a filtering device, a liquid storage tank and a pipeline, wherein the liquid storage tank is located under the filtering device; the liquid storage tank is used for storing the liquid filtered by the filtering device; the filtering device comprises a filtering component and a filtering cylinder; an opening is formed at the bottom of the filtering cylinder; the filtering component is arranged at the bottom of the filtering cylinder; a free end of a piston rod of the hydraulic cylinder is penetrated through the top of the filtering cylinder and is located in an inner chamber of the filtering cylinder; a piston is arranged at the free end of the piston rod; the size of a cross section of the piston is matched with the size of the cross section of the inner chamber of the filtering cylinder; the inner chamber of the filtering cylinder is divided into upper and lower filtering chambers under the sealed state by the piston. In the filtering device, the cutting fluid passes through a filter paper under a gravitational effect; the arranged hydraulic cylinder and piston can accelerate the filtering speed of the cutting fluid; the filtering time of the cutting fluid is shortened; the time cost is lowered.

Owner:成都欧珀琅精密工具有限公司

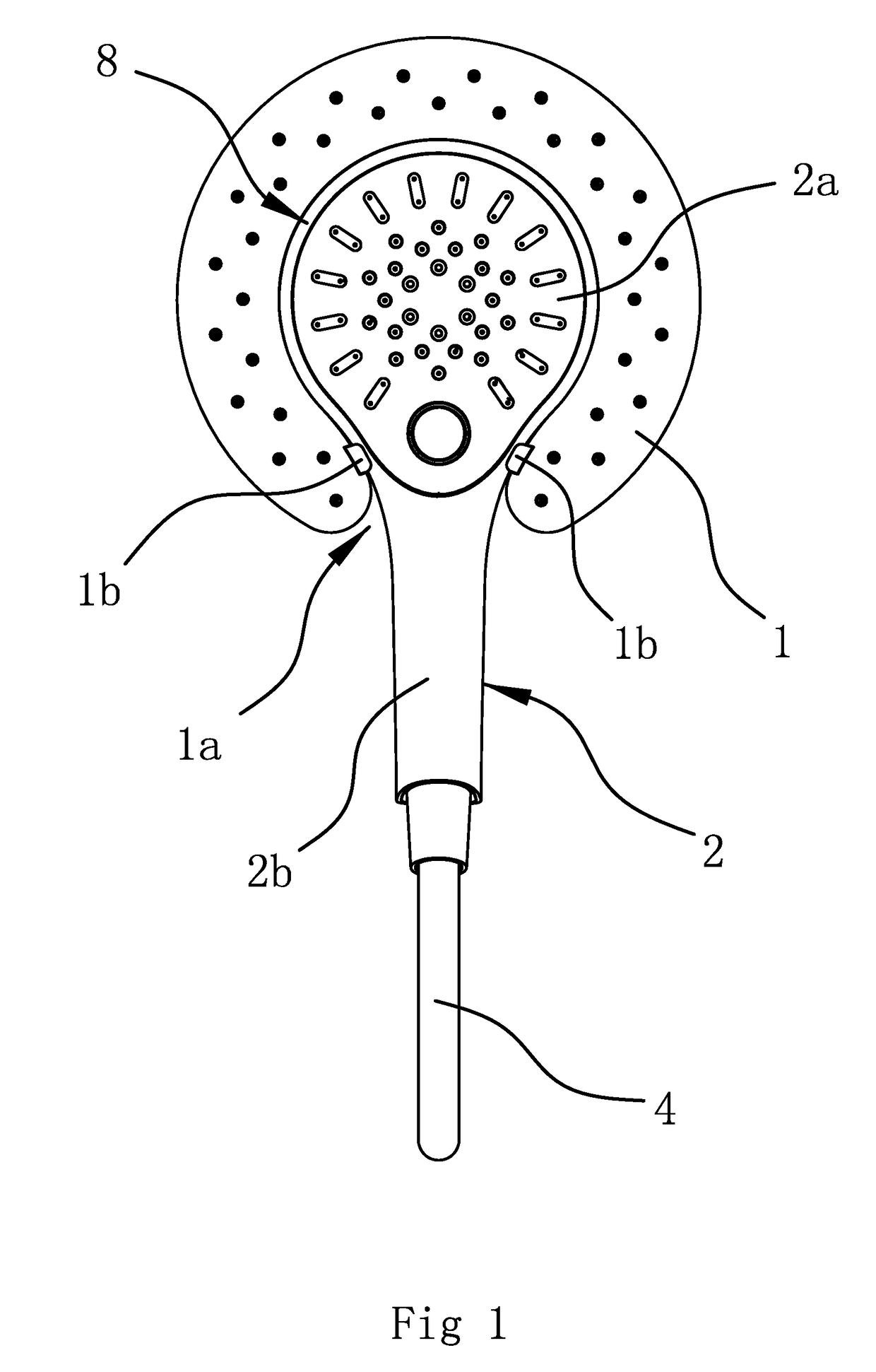

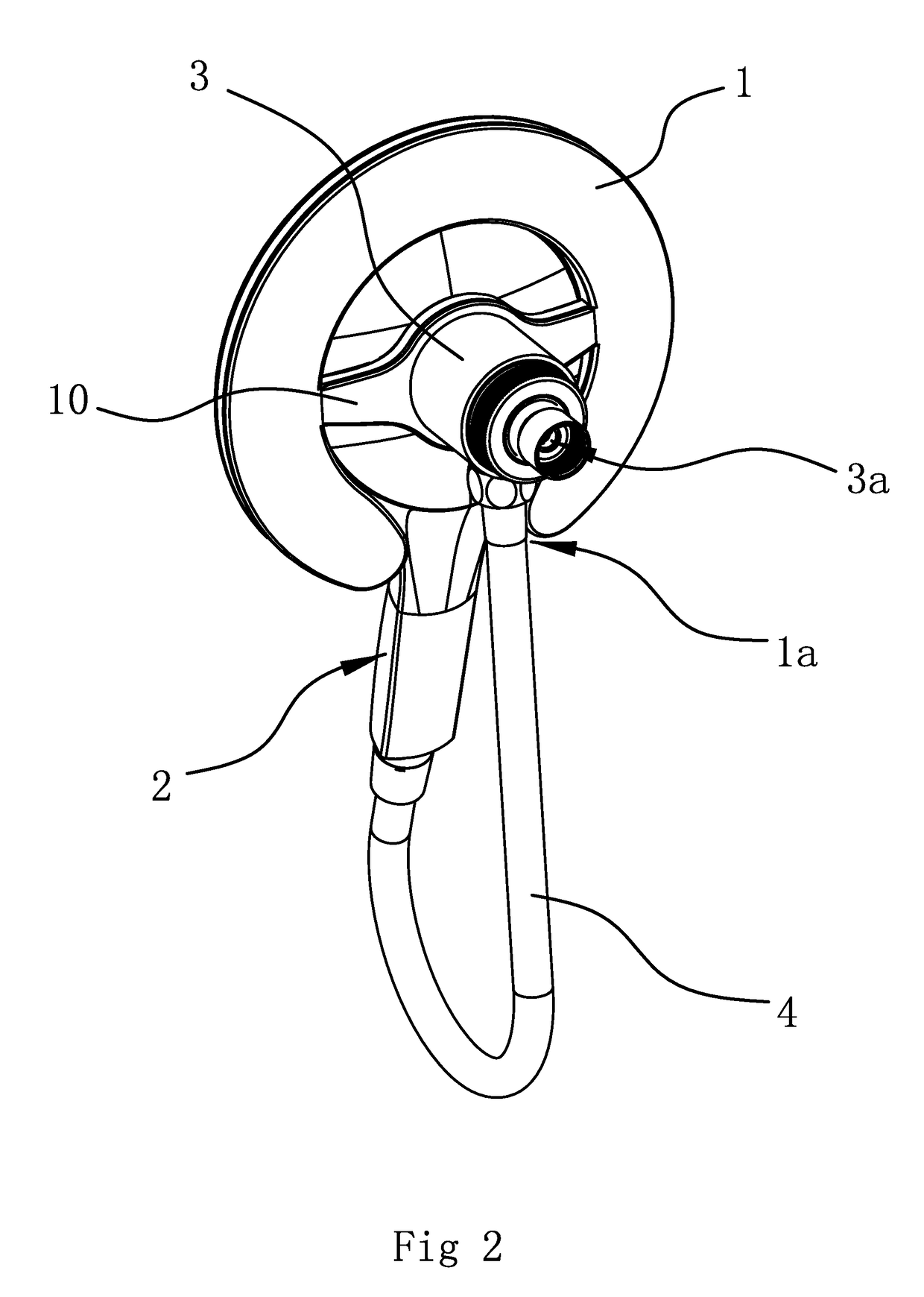

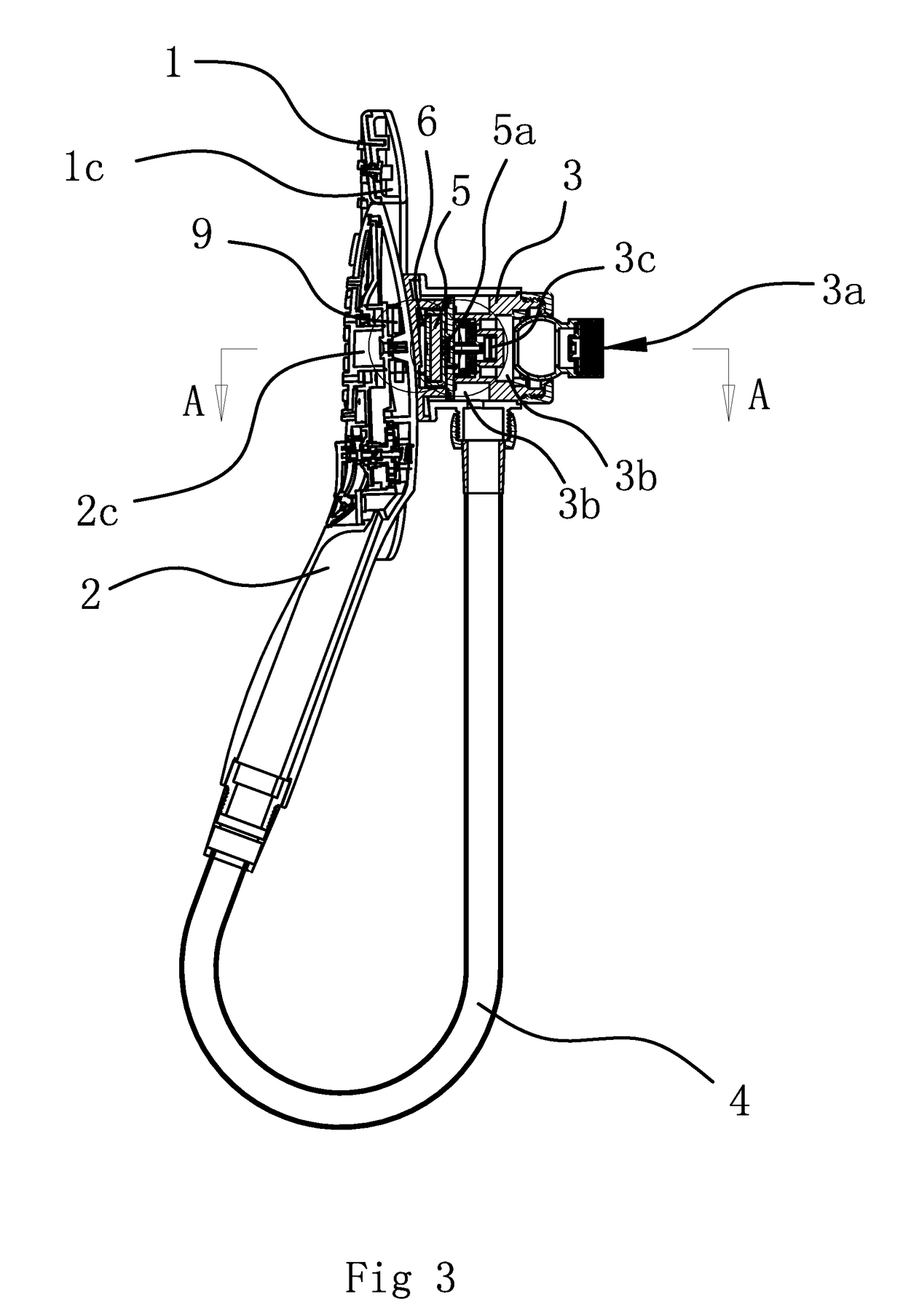

Combined shower

ActiveUS10150121B2Improve stability and convenienceReduce space consumptionOperating means/releasing devices for valvesSpray nozzlesEngineeringGravitational effect

A combined shower comprising a top shower head and a handheld shower head, a first magnetic piece, an elastic piece and a sealing structure is inside an assembly hub of the top shower head. The first magnetic piece can move under the action of the elastic force from the elastic piece and then makes the sealing structure shut off the outflow cavity of the top shower head. The second magnetic piece is fixed on the handheld shower head and the second magnetic piece is arranged magnetically opposite and facing the first magnetic piece. Under the action of the attraction force from the second magnetic piece, the first magnetic piece can overcome the elastic force from the elastic piece, moves in the opposite direction, and makes the sealing structure connect the outflow cavity of the top shower head to the water inlet cavity.

Owner:ZHEJIANG HUALE TECH CO LTD

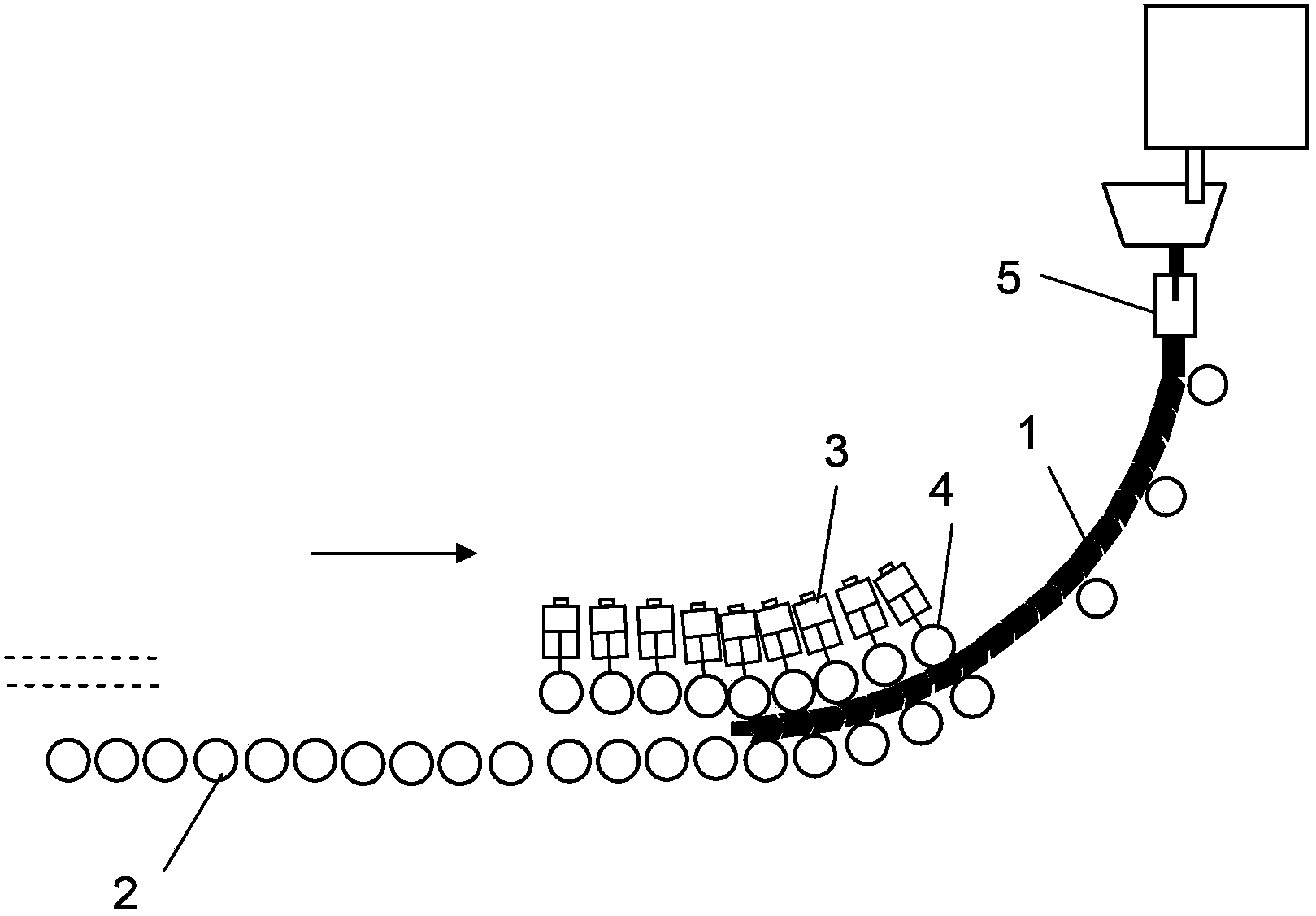

Enveloping-reversion type fruit transfer device and method

ActiveCN102488299ANo mechanical damageSmooth transitionConveyor partsFood treatmentSprocketRelative motion

The invention discloses an enveloping-shifting type fruit transfer device and a method. The enveloping-shifting type fruit transfer device comprises a detection table and a discharge table, which are connected in an end-to-end stacked manner. The detection table is provided with rolls for conveying fruits. The discharge table is provided with fruit carriers for conveying fruits. In the fruit transfer section, discharge conveying chain sprockets and detection conveying chain sprockets are coaxial, the discharge conveying chain sprockets are externally meshed with discharge conveying chains, and fruit carriers envelope outside the rolls. The fruit carriers and the rolls convey fruits with respective chains from bottom to top in an arc form, and the fruit carriers constantly face the fruits between each two adjacent rolls. With increase of the arc conveying angle, position relation between the fruit carriers and the rolls is changed gradually till vertical reversion is complete, the fruits gradually leave the rolls and enter the fruit carriers under inertial and gravitational effects of the fruits so as to be transferred, transferring is stable, transferring phases are accurate, the rolls and the fruit carriers are in no relative motion during transferring, the fruits cannot be mechanically injured, and the enveloping-shifting type fruit transfer device and the method are widely applicable to classified transferring of torispherical fruits such as apples, oranges and the like.

Owner:JIANGSU UNIV

Segmented lifting and conveying device of deep-sea mining annular pipelines

InactiveCN103587956AExtend the conveying distanceNo gravity effectBulk conveyorsLoading/unloadingDeep sea miningFree falling

The invention discloses a segmented lifting and conveying device of deep-sea mining annular pipelines. A main supporting pipe is formed by fixing at least two segments of supporting pipes through flanges. An electric hydraulic pump station, a buoyancy air cabin, a boost pump and a hopper are arranged in the main supporting pipe, and an electric power control cable is arranged in a cable groove outside the supporting pipes. The upper end and the lower end of the main supporting pipe are connected with a mining vessel lifting device and a traction steel wire. Conveying pipes are annular pipelines, the front conveying pipes and the rear conveying pipes are arranged on the supporting pipes in a surrounding mode, wherein the front conveying pipes and the rear conveying pipes are disconnected in a front-and-rear mode. The rear conveying pipe and the front conveying pipe of the uppermost segment of the supporting pipe and the lowermost segment of the supporting pipe are connected with an ore sand output pump and a flexible conveying pipe. The upper ends of the rear conveying pipes which are sequentially connected through the supporting pipes are connected with the upper end of the front conveying pipe of the front segment, and the lower ends of the rear conveying pipes are matched with the hopper. An inlet and an outlet of the boost pump are connected with the hopper and the rear conveying pipes. Due to segmented lifting and conveying, the mineral substance free fall gravitational effect is avoided. The lifting distance is longer, the hydraulic pump station reduces the weight of the device under the water and provides power for the boost pump and an all-direction propeller, the supporting pipes are prevented from being twisted and deformed, if blocking occurs, the boost pump reverses to dredge, and the segmented lifting and conveying device of the deep-sea mining annular pipelines is suitable for conveying large-particle mineral substances.

Owner:裘尧云

Feces receiving device applied to nursing bed

The invention relates to the technical field of medical equipment and discloses a feces receiving device applied to a nursing bed. The device includes support legs, a bed frame is fixedly connected tothe tops of the support legs, two sliding rails are fixedly mounted on the inner surface of the bed frame, and bed boards are slidably connected to the inner wall of the bed frame; a support plate isfixedly connected to the bottom of each support leg, a support rod is movably connected to the side face of each support plate, and a support block is slidably connected to one end of each support rod. According to the feces receiving device applied to the nursing bed, under the action of the bed frame, the stability of the bed boards during movement is improved, and the bed boards are preventedfrom directly falling down under the gravitational effect; under the action of the sliding rails, the situation that the bed boards get stuck during movement and cannot continue moving is avoided. Thetwo bed boards cannot be separated from each other, and usage of the feces receiving device is not influenced; under the action of the support plates, the stability of the support rods is improved, and the situation is avoided that the support rods swing back and forth during movement and cannot move into the support blocks.

Owner:JIAMUSI UNIVERSITY

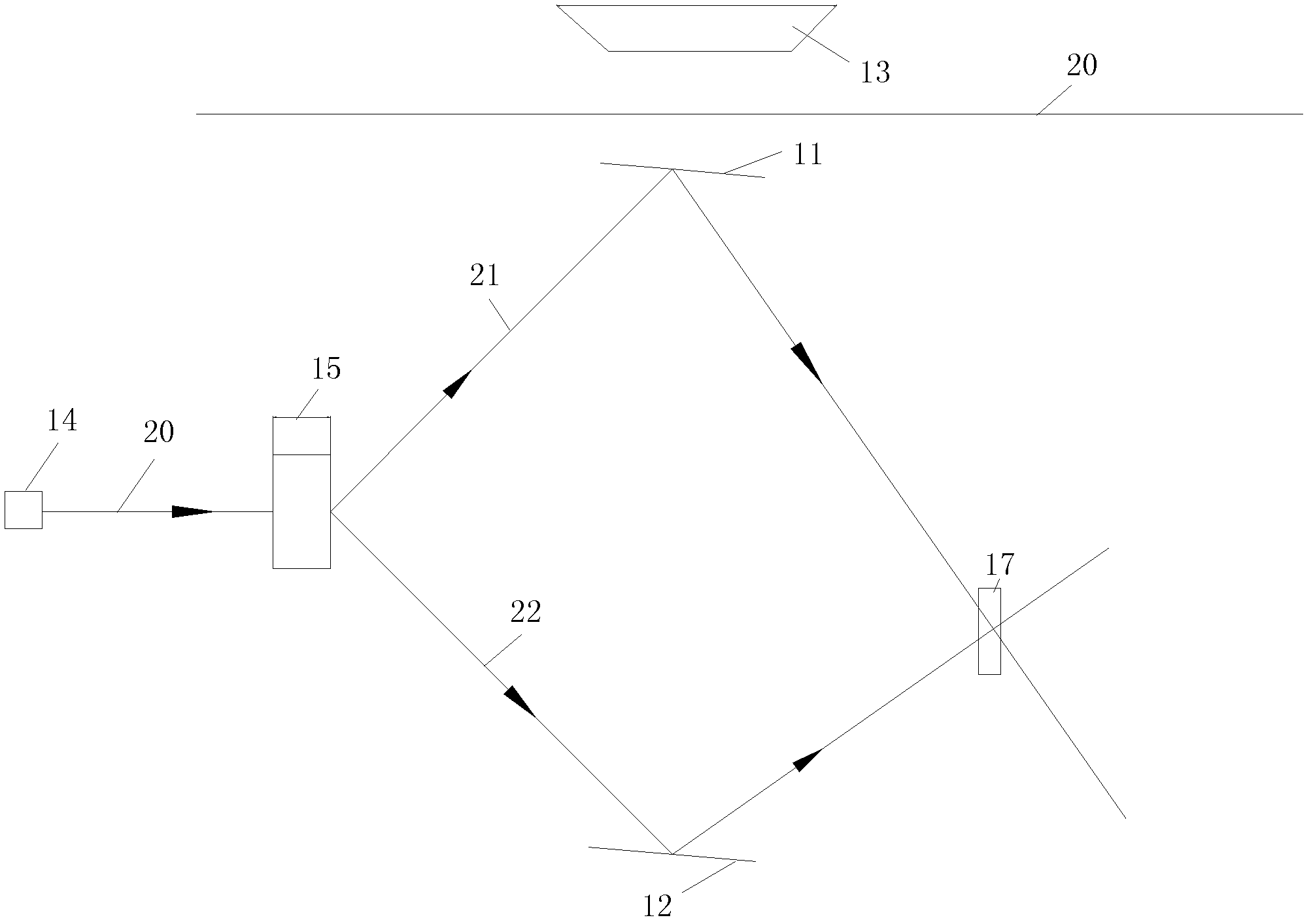

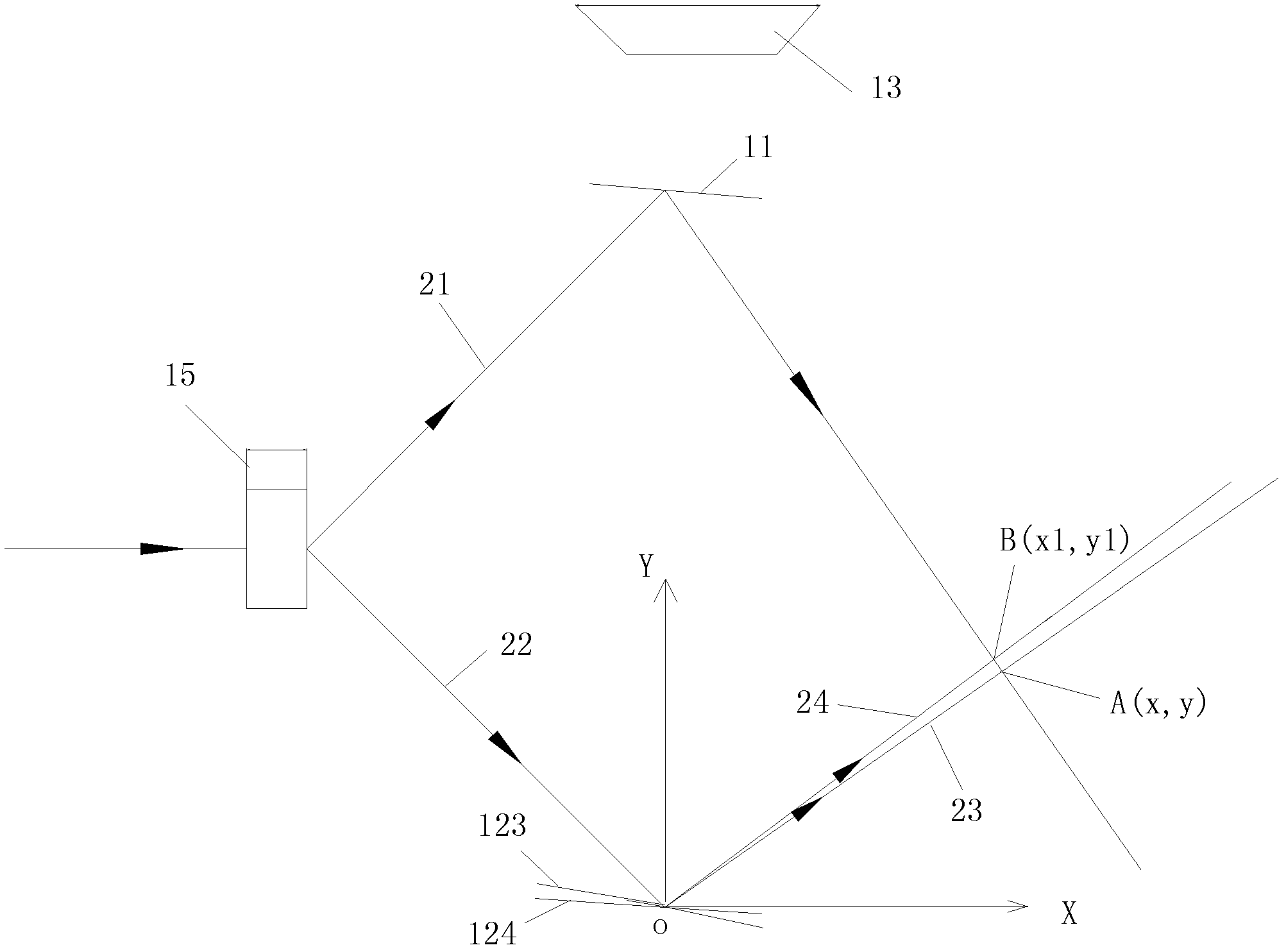

Measuring device for propagation speed of gravitational field and method of measuring device

The invention discloses a measuring device for the propagation speed of a gravitational field and a method of the measuring device. The measuring device comprises two enlarged Cavendish torsion balances, a megaton oil tanker, a laser source, a spectrometer, a reflector and an optical screen. A principle of a Cavendish experimental device is utilized, the megaton oil tanker is used as a signal source to reciprocate, the effect of gravitational force of the signal source reaches the two Cavendish torsion balances via the alternating gravitational field at different moments, the phase difference between movement of one Cavendish torsion balance and movement of the other Cavendish torsion balance is measured by laser interferometry, time difference is computed, and finally the propagation speed of the alternating gravitational field can be computed by the aid of the known distance between the two Cavendish torsion balances. Whether the propagation speed of the gravitational force is faster than the light speed or not can be judged by means of measuring the propagation speed of the gravitational force by the aid of the measuring device and the method.

Owner:SHANGHAI NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com