Sinking method and device for water well pipe

A technology of water well pipes and sinking, which is applied in construction, infrastructure engineering, etc., can solve the problems of lack of standardized equipment, and achieve the effects of saving manpower, light weight, and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

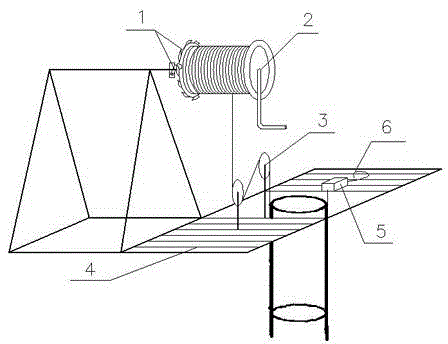

[0029] Such as figure 1 As shown, a wheel shaft device for well pipe sinking according to the present invention includes a bracket 7, a ratchet positioning device 1, a wheel shaft rotation mechanism 2, a guide pulley block 3, an operating platform 4, a locking switch 5 and a wire rope 6.

[0030] Described operating platform 4 is arranged on the top of well opening and described operating platform 4 has a hole to match with well opening; Described support 7 is arranged on the side of one end of operating platform 4, and described axle rotation mechanism 2 is installed on On the bracket 7, the ratchet positioning device 1 is installed on the wheel shaft rotating mechanism 2 and the ratchet positioning device 1 is positioned through the bracket 7; the guide pulley block 3 is longitudinally installed on the operating platform; one end of the steel wire rope 6 is wound around the wheel shaft to rotate On the mechanism 2, the other end is fixed on the operating platform 4 away from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com