Control method for keeping insertion position of dummy bar

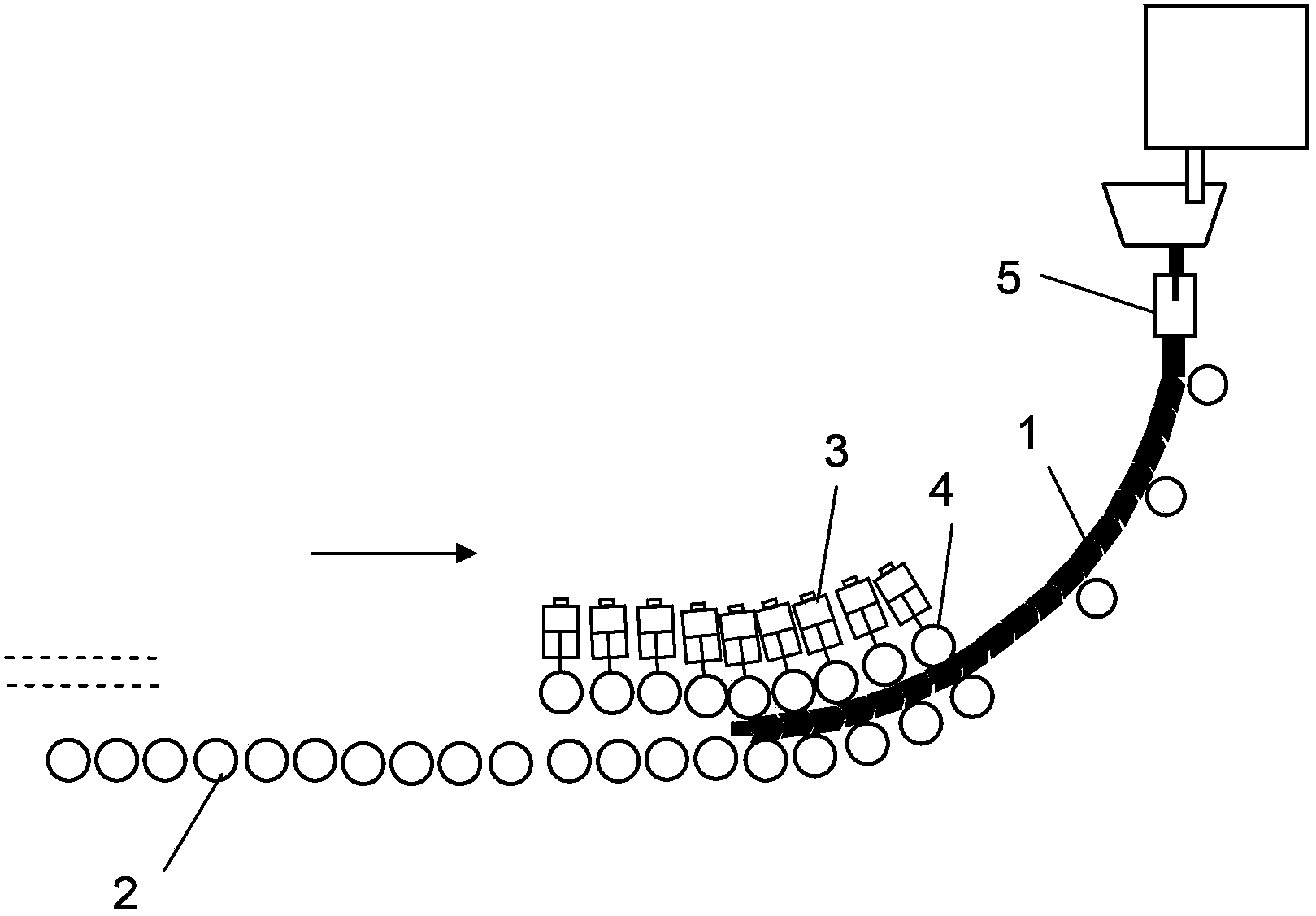

A technology for maintaining control and inserting position, which is applied in the field of continuous casting control, and can solve problems such as production interruption, failure of dummy bar falling down, high risk of dummy bar falling down, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

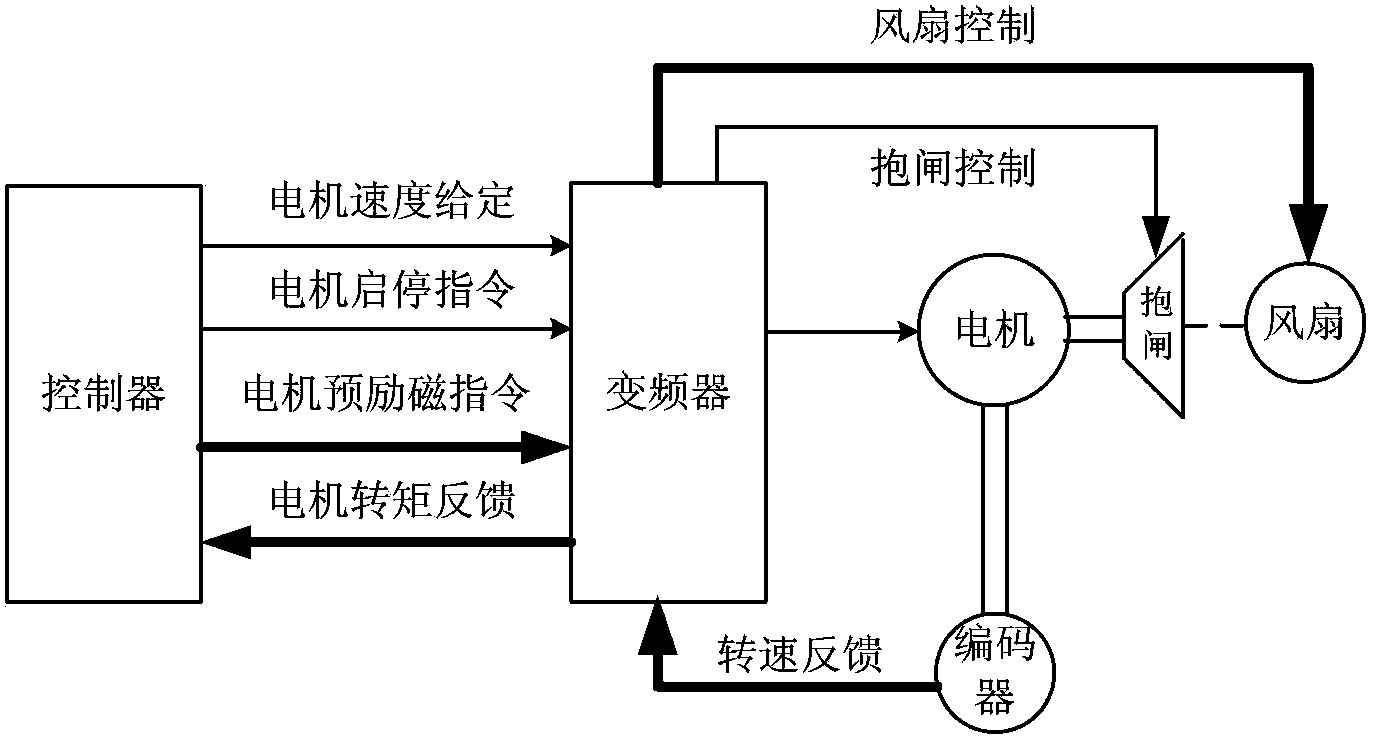

[0032] Please combine Figure 3 ~ Figure 4 As shown, the invented dummy bar insertion position maintenance control method specifically includes the following steps:

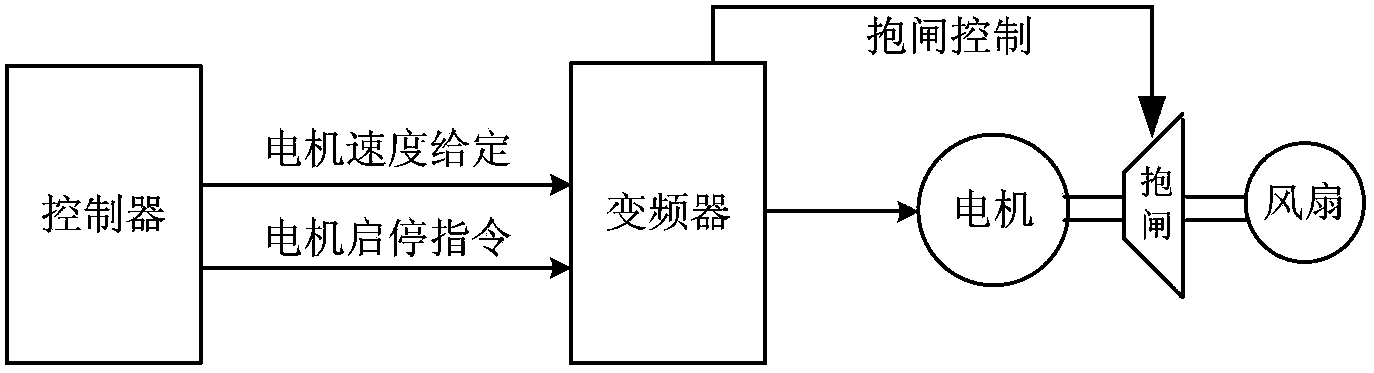

[0033] First, configure relevant hardware equipment on the drive roller motors of each tension leveling machine that require zero-speed electromagnetic braking torque (that is, press on the dummy bar during the holding phase):

[0034] a) A speed measuring encoder is installed on the driving roller motor of each tensioning and straightening machine, and the encoder signal is sent to the frequency converter, and the signal is used as the motor speed feedback value for the closed-loop speed control of the frequency converter;

[0035] There are many control methods for frequency converters, such as V / F control, frequency control, torque control, speed control, etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com