Anti-fatigue high speed data cable for mechanical arm

A high-speed data, fatigue-resistant technology, applied in cables, insulated cables, cables with double-stranded/quad-stranded, etc., can solve the problems of decreased anti-interference performance, easy generation of static electricity, signal interference, etc. Improve performance reliability and safety, reduce the generation of static electricity, and reduce the impact of structural changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

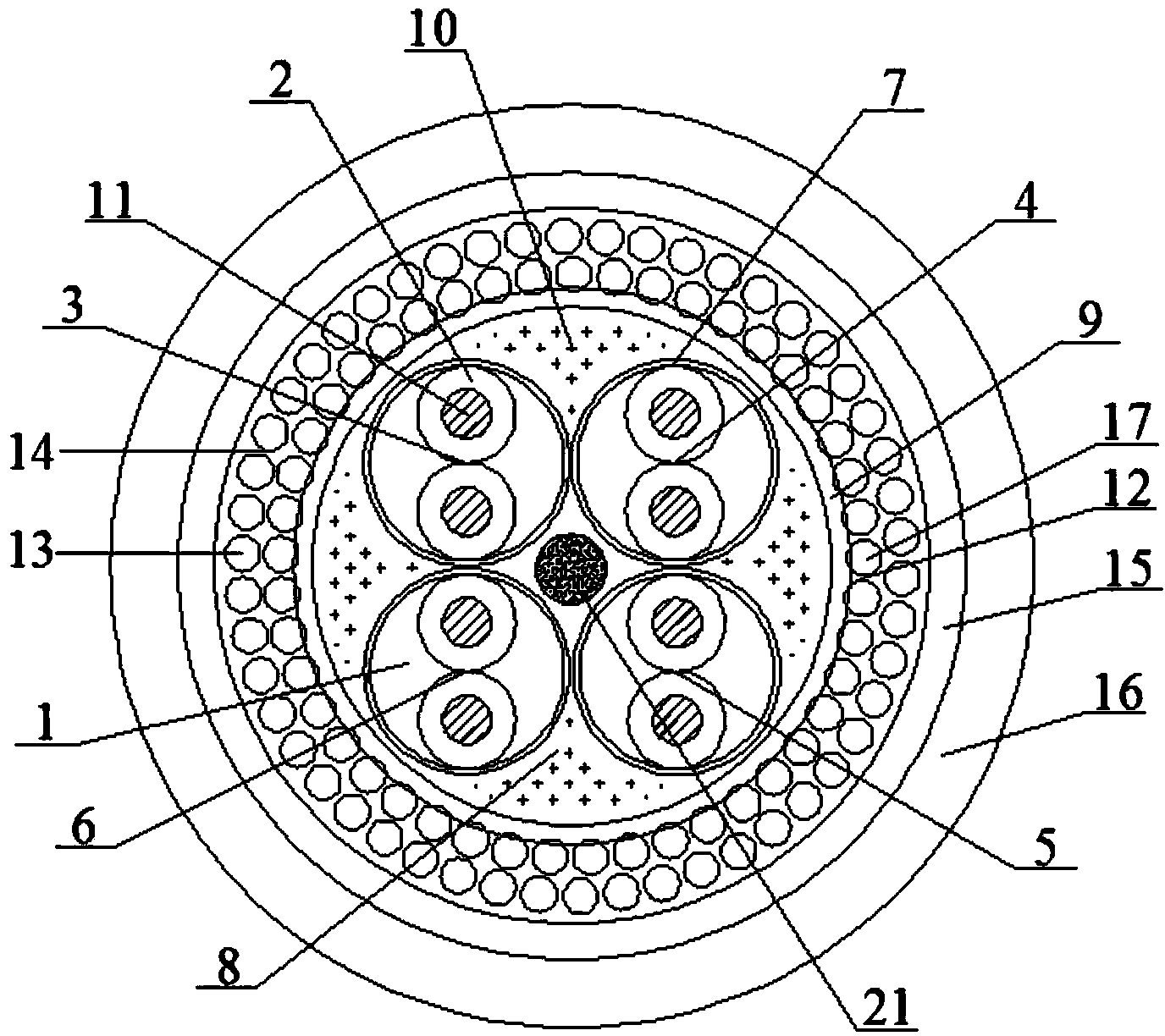

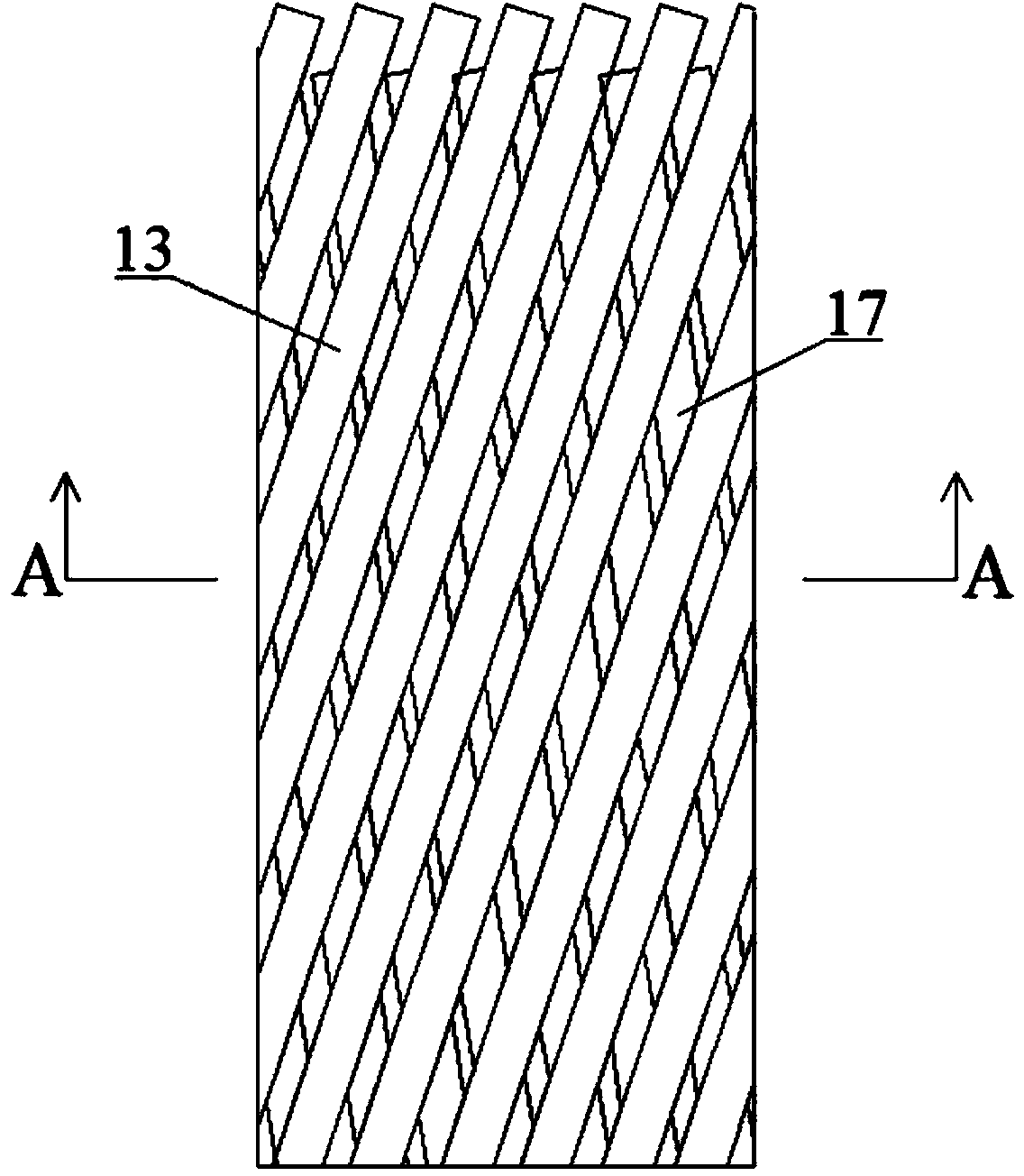

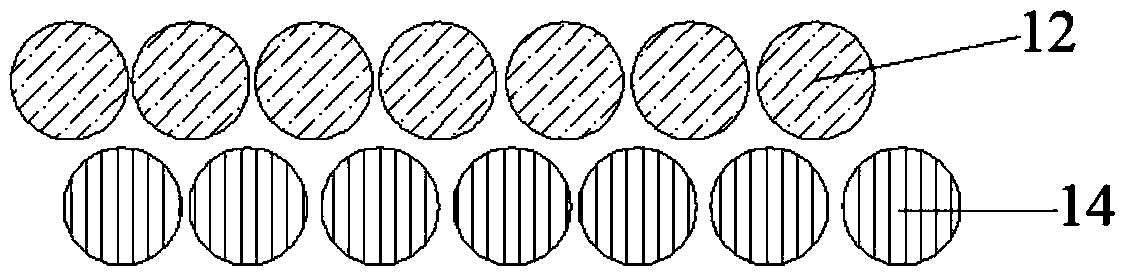

[0027]Example: A fatigue-resistant high-speed data cable for a robotic arm, comprising: eight metal conductor units 1 and an aramid reinforcement 21, the outer surface of the metal conductor unit 1 is covered with an insulating polypropylene layer 2, and the metal conductor The unit 1 includes an aramid fiber 20 in the center, an inner conductive layer composed of a plurality of first tin-copper alloy conductors 22 stranded on the outer surface of the aramid fiber 20, a first oxygen-free copper conductor 23, and a plurality of second conductors. The tin-copper alloy conductor 24 and the second oxygen-free copper conductor 25 are twisted on the outer surface of the inner conductive layer to form an outer conductor layer, the first tin-copper alloy conductor 22 and the first oxygen-free copper conductor 23 have the same diameter, and the second The diameters of the tin-copper alloy conductors 24 and the second oxygen-free copper conductors 25 are equal, and the diameters of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com