Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

149results about How to "Does not affect the feel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

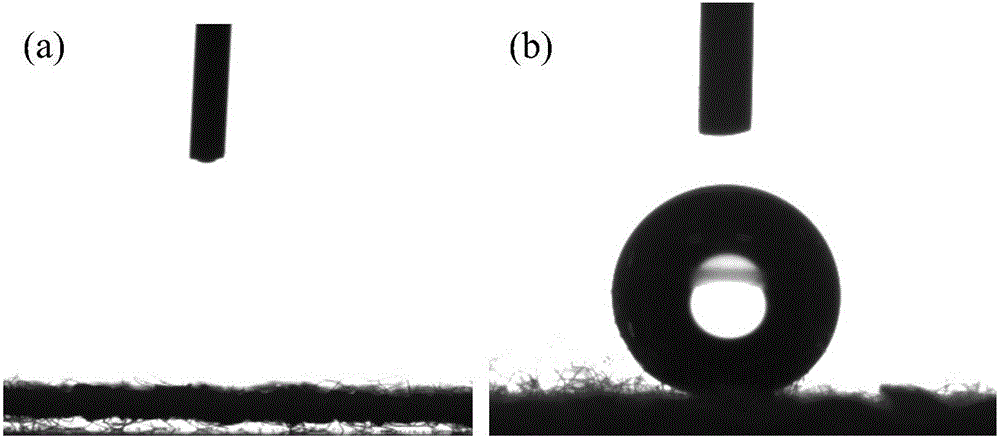

Method for preparing super-hydrophobic textile from thiol-ene click chemistry-modified fiber

InactiveCN105696306AWashableWear-resistantLiquid repellent fibresAbrasion resistant fibresFiberPolyester

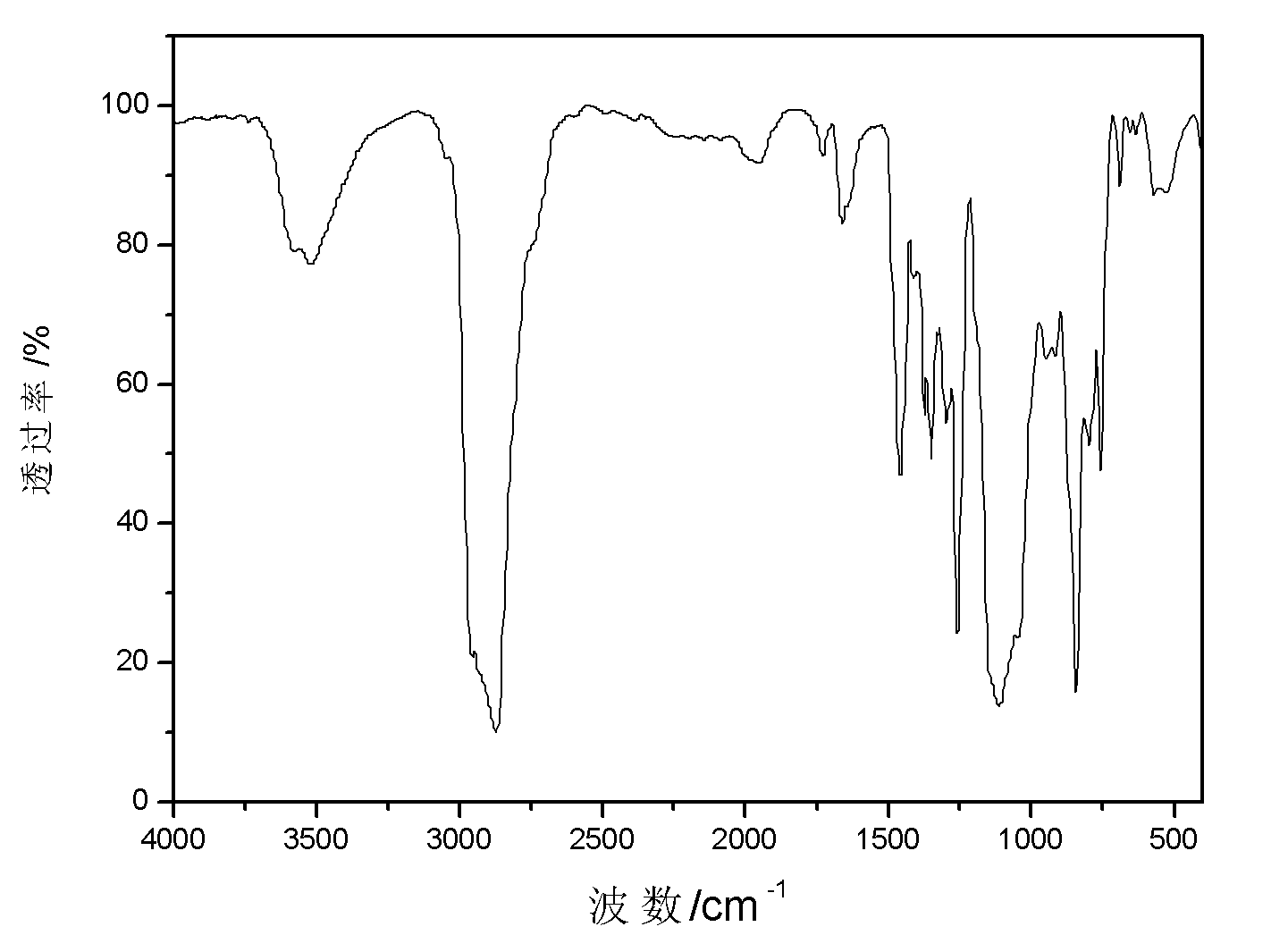

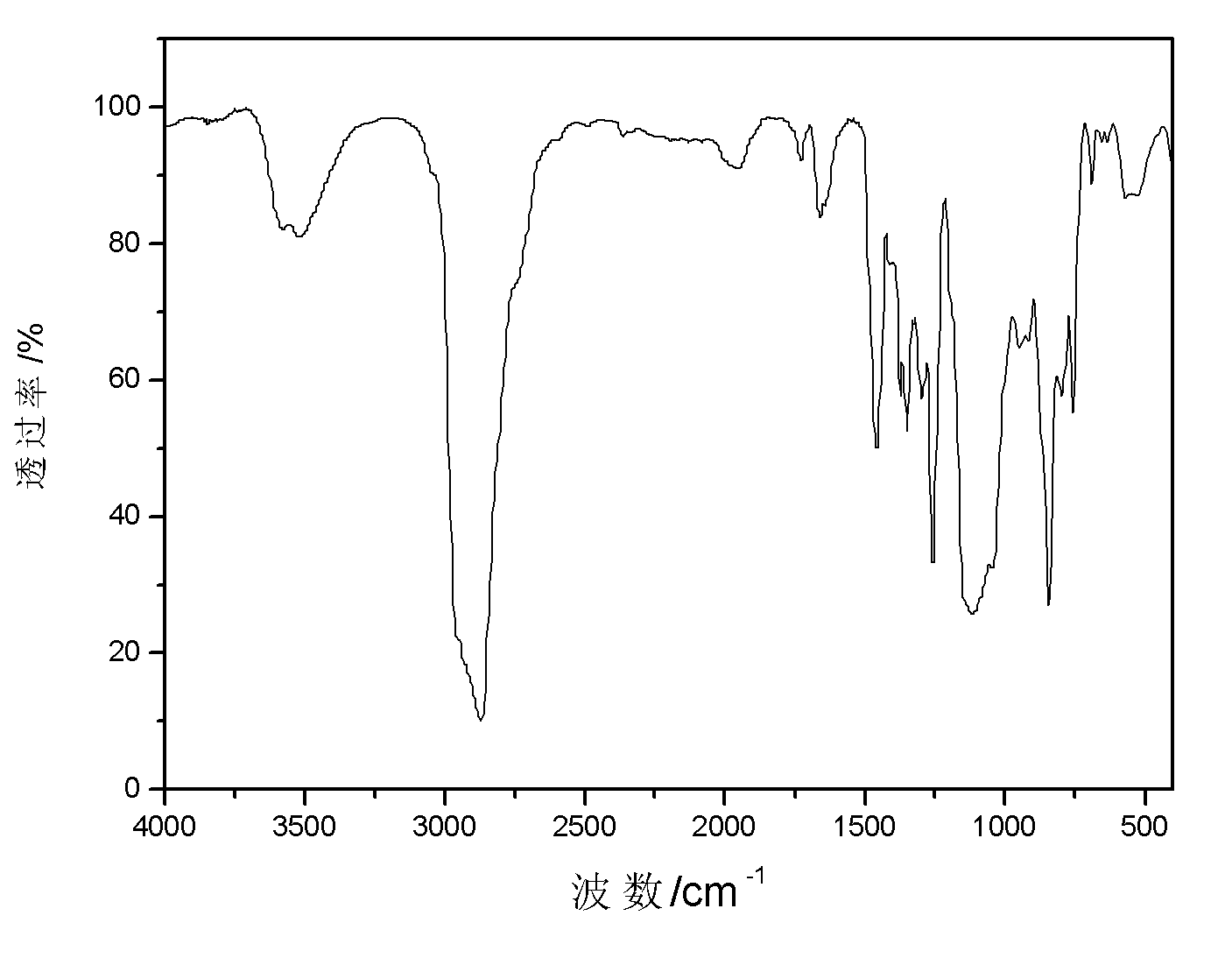

The invention relates to a preparation method of a functional textile, and belongs to the field of textile surface grafting modification. The method for preparing a super-hydrophobic textile from a thiol-ene click chemistry-modified fiber is characterized by comprising the steps that alkali liquor steaming treatment is performed on a polyester fiber, then mercaptosilane is fixed to the surface of the polyester fiber, finally a methacrylate monomer is grafted to the surface of the polyester through a thiol-ene click chemistry reaction to reduce the surface tension of the fiber, and then the super-hydrophobic polyester textile is obtained. The contact angle between the polyester textile prepared through the method and water drops is larger than 150 degrees, and the polyester textile is stable to acid, alkali, salt and solvent and capable of resisting friction and washing and has the very good hydrophobic stability.

Owner:SHAANXI UNIV OF SCI & TECH

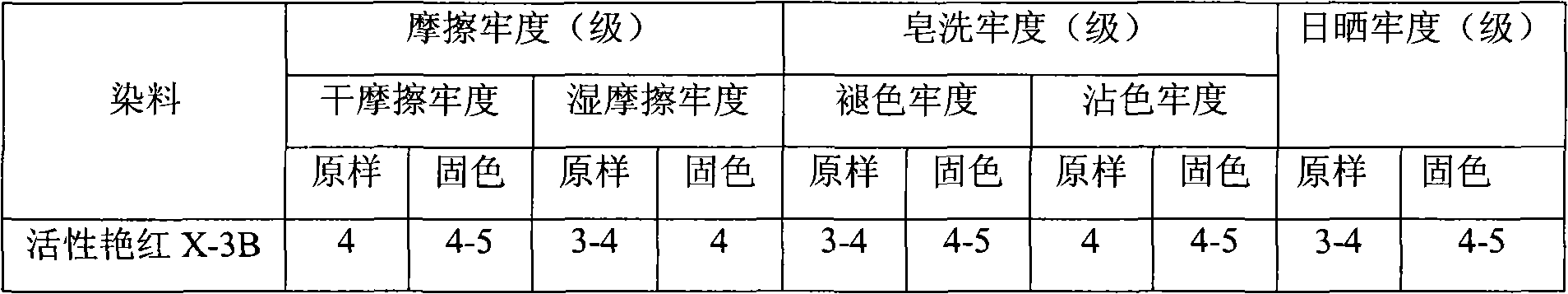

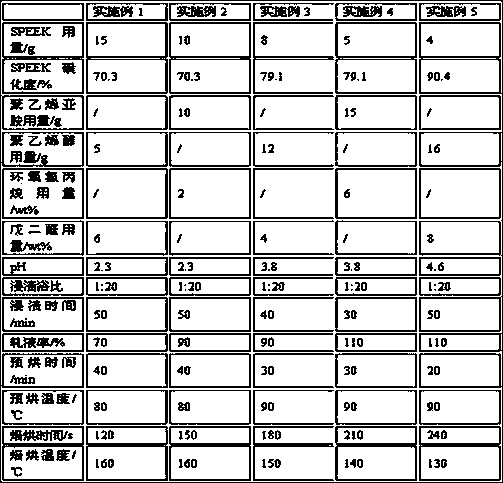

Preparation method of formaldehyde-free active dye fixing agent

InactiveCN101768883AImprove rubbing fastnessImprove washing fastnessDyeing processUltrasound - actionTetramine

The invention relates to a preparation method of a formaldehyde-free active dye fixing agent. The compound prescription of the active dye fixing agent consists of two components, component 1 is chitosan quaternary ammonium salt produced by 3-chlorine-2-hydroxypropyl trimethyl ammonium chloride grafted with chitosan under ultrasonic, and component 2 is reactive fixing agent produced after reaction of one weight part of triethylene tetramine and three weight parts of epoxy chloropropane; the mass ratio of the component 1 and the component 2 is 1:3. The method of the invention can be applied to fixing treatment of cotton fabric dyed by active dye, can improve rubbing fastness, washing fastness and light fastness of the fabric without influence on the chromatic light and the fabric hand feel; the prepared fixing agent which is free from formaldehyde, nontoxic and environment-friendly is a novel printing and dyeing assistant.

Owner:QINGDAO UNIV

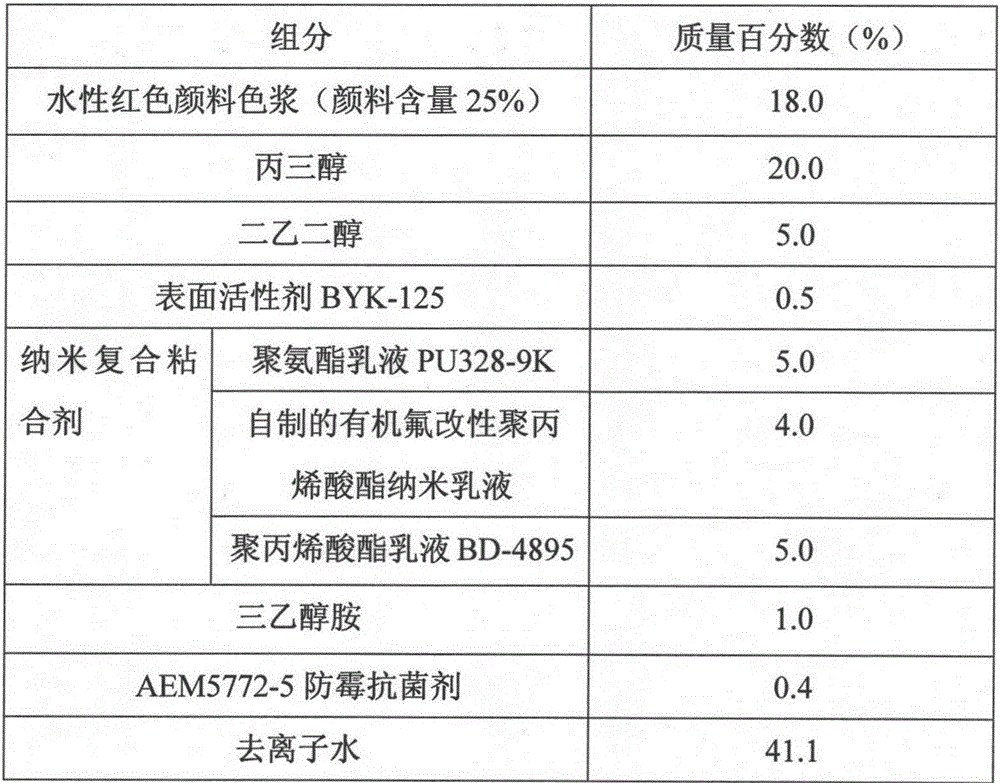

Environment friendly non-halogen reacting fire-retardant aqueous polyurethane and preparation method thereof

The invention provides an environmental-protection halogen free reaction type fire retardant waterborne polyurethane and a method for preparing the same, which belongs to the technical field of chemical industry. The fire retardant waterborne polyurethane consists of diisocyanate, non-fire retardant polyhydric alcohol, organic phosphorus polyhydric alcohol, organosilicon polyhydric alcohol, a hydrophilic chain extender, a neutralizer and a catalyst. The preparation method comprises the following steps: at certain temperature, the diisocyanate, the non-fire retardant polyhydric alcohol, the hydrophilic chain extender, the organic phosphorus polyhydric alcohol and the organosilicon polyhydric alcohol are orderly added in a reaction kettle, and are subjected to pre-polymerization under the action of the catalyst and the protection of N2 and by stirring; and a pre-polymer is cooled down, added with neutralizer water solution and then put in high-speed emulsifying equipment for emulsifying neutralization, and a target product is obtained. The product has the characteristics of no halogen and low-release volatile solvent; and when the waterborne polyurethane is used to clean up textile fabrics, the coating is transparent and adhesiveness-free, the touch feeling of the textile fabrics is not affected, and the fire retardant effect is obvious.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

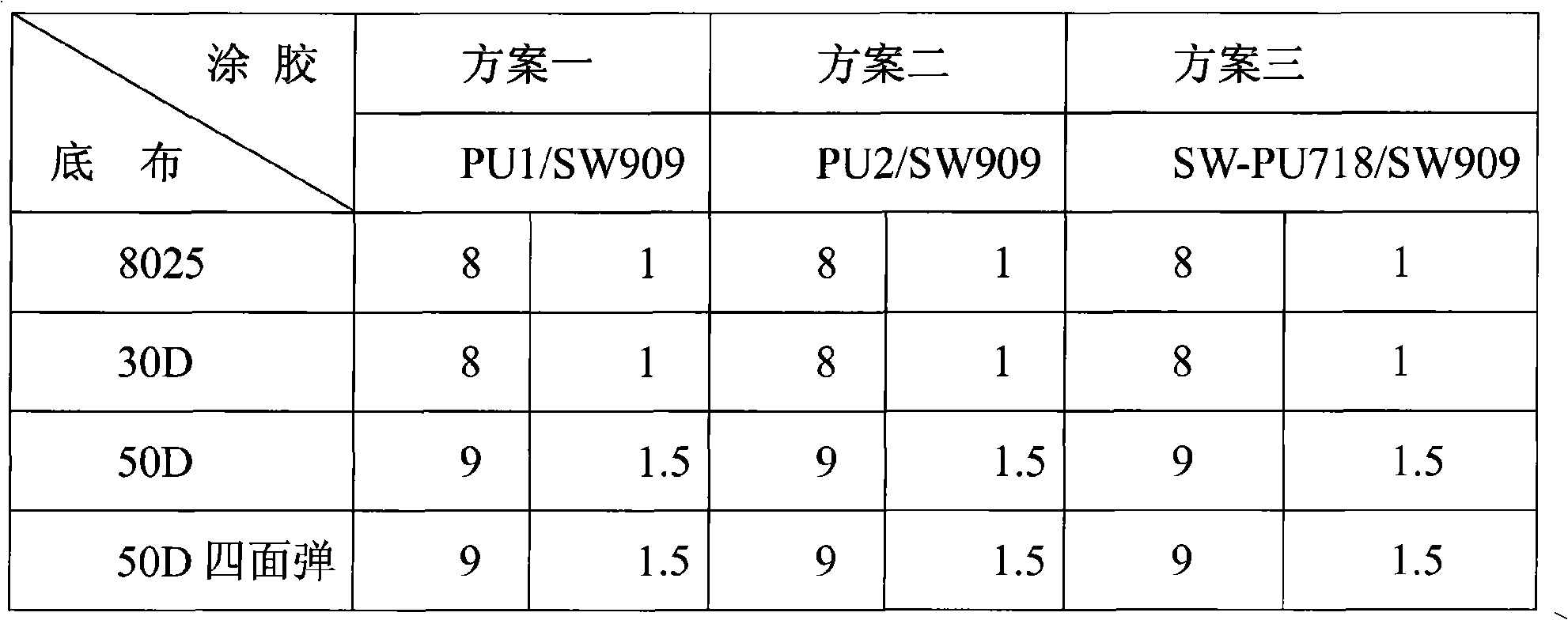

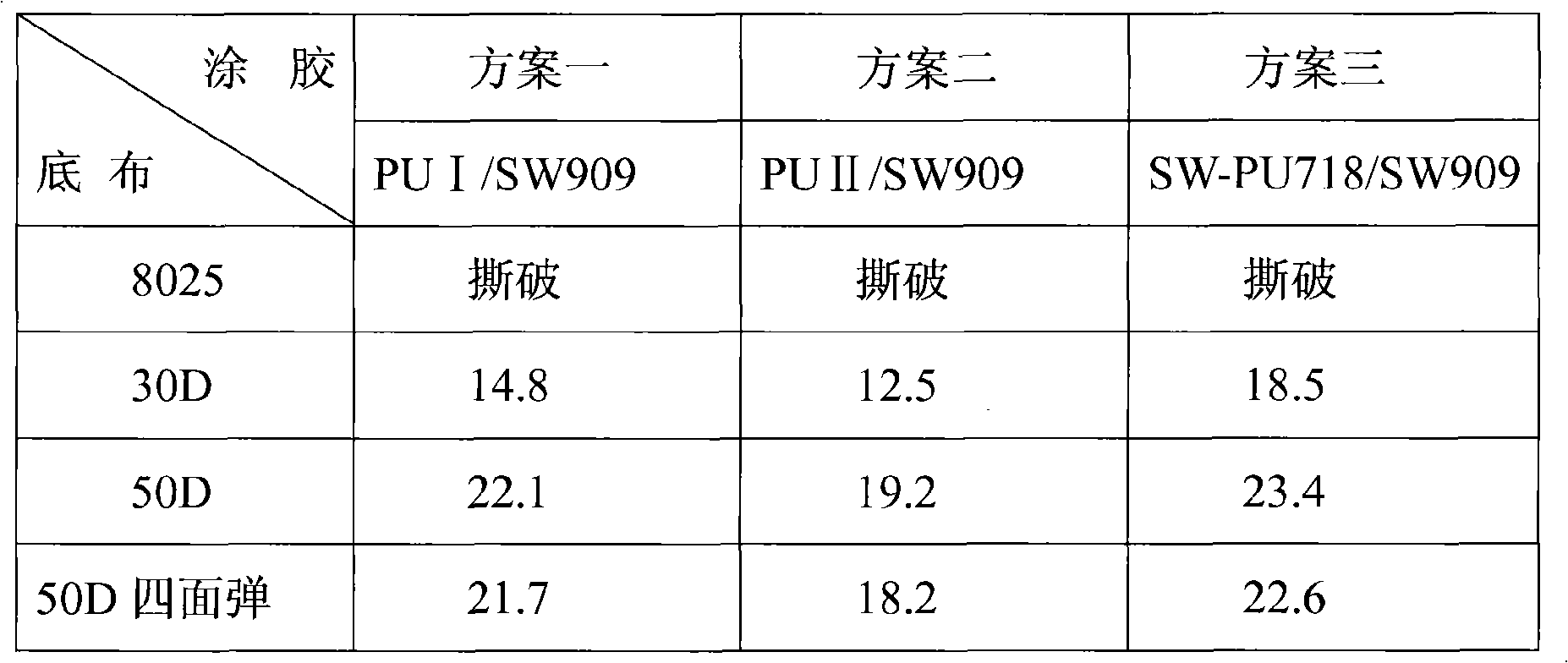

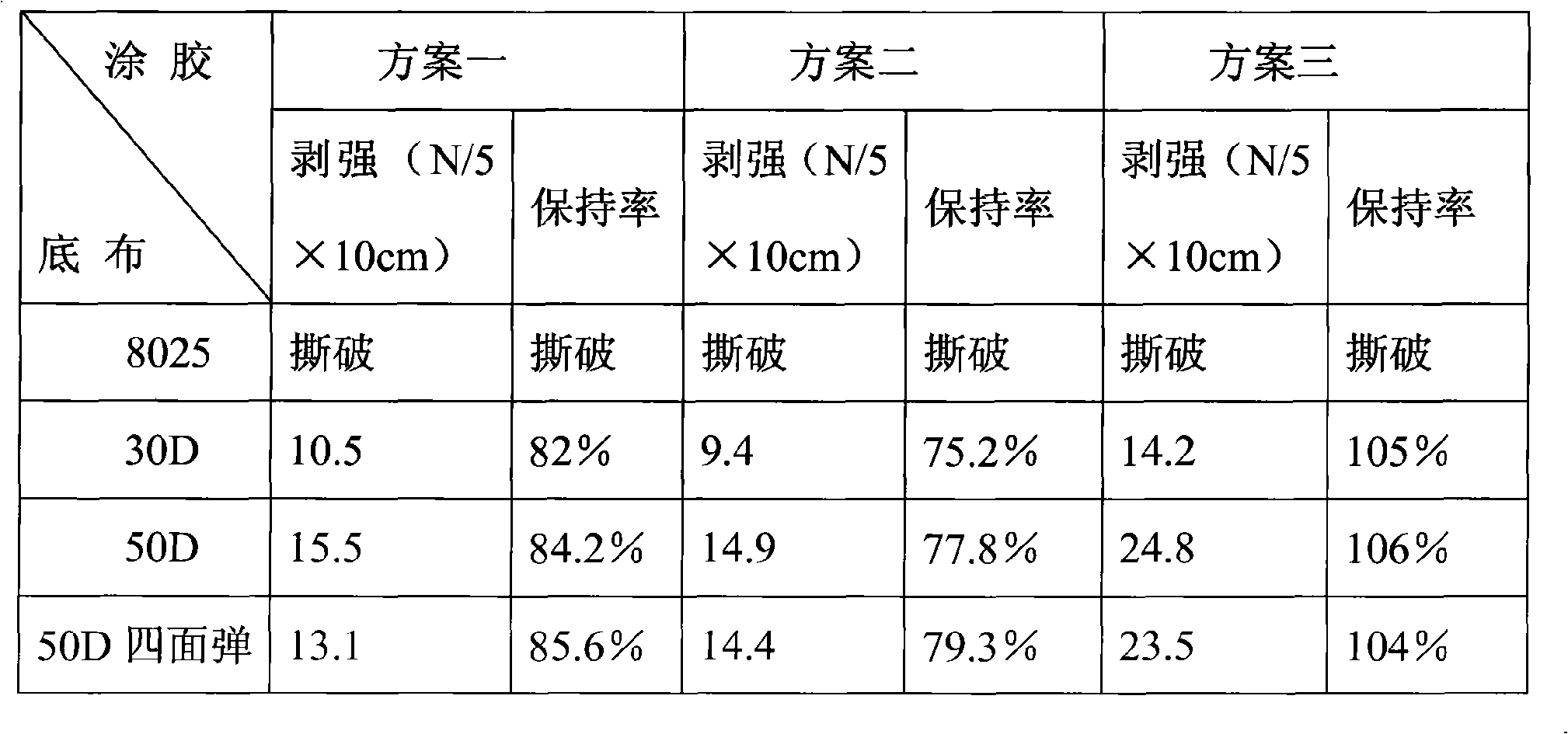

Polyurethane hot melt adhesive for high-grade lining cloth and preparation method thereof

InactiveCN101570676AOvercome difficult bonding problemsDoes not affect damagePolyureas/polyurethane adhesivesPolyesterToluene diisocyanate

The invention discloses the polyurethane hot melt adhesive for high-grade lining cloth, which is obtained through the reaction among polyester polyols with the relative molecular weight thereof being 2,000 to 2,200, 4,4-diphenylmethane diisocyanate (MDI), toluene diisocyanate (TDI), 1,4-butanediol (1,4-BDO) and aromatic diamine extender, wherein, the molecular weight of the polyurethane hot melt adhesive is 85,000 to 95,000. The polyurethane hot melt adhesive has the advantages of low thermal-bonding temperature and rapid crystallization, thereby facilitating the machining operations, preventing the polyurethane hot melt adhesive from being stuck to cloth and further preventing the polyurethane hot melt adhesive from penetrating and bleeding on ultra-thin loose base cloth; furthermore, the polyurethane hot melt adhesive has outstanding resistance to dry-cleaning and washing as well as washing under various caustic conditions. The invention further discloses a method for preparing the polyurethane hot melt adhesive for high-grade lining cloth.

Owner:长兴三伟热熔胶有限公司

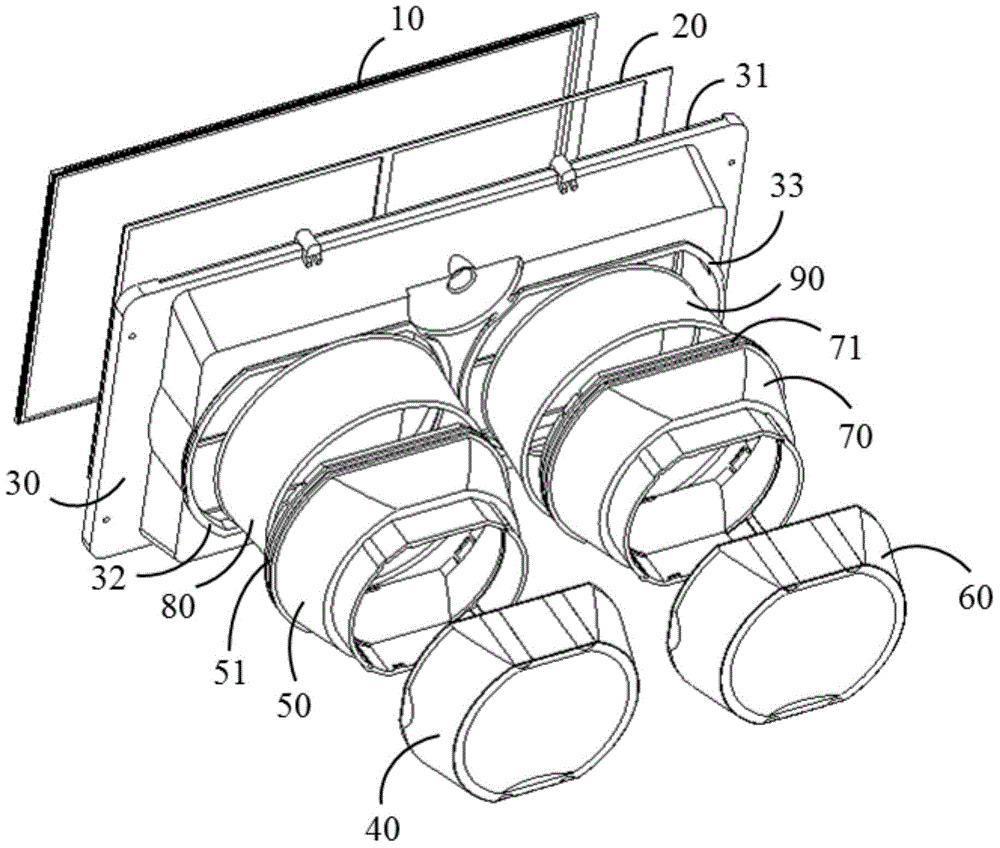

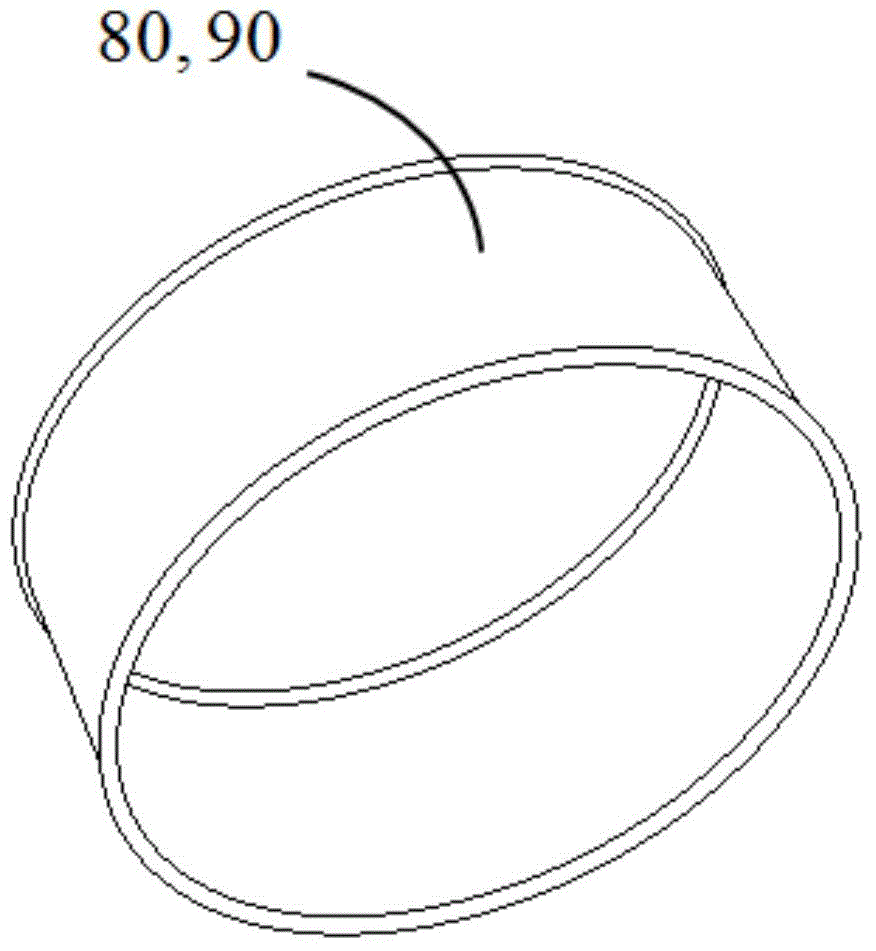

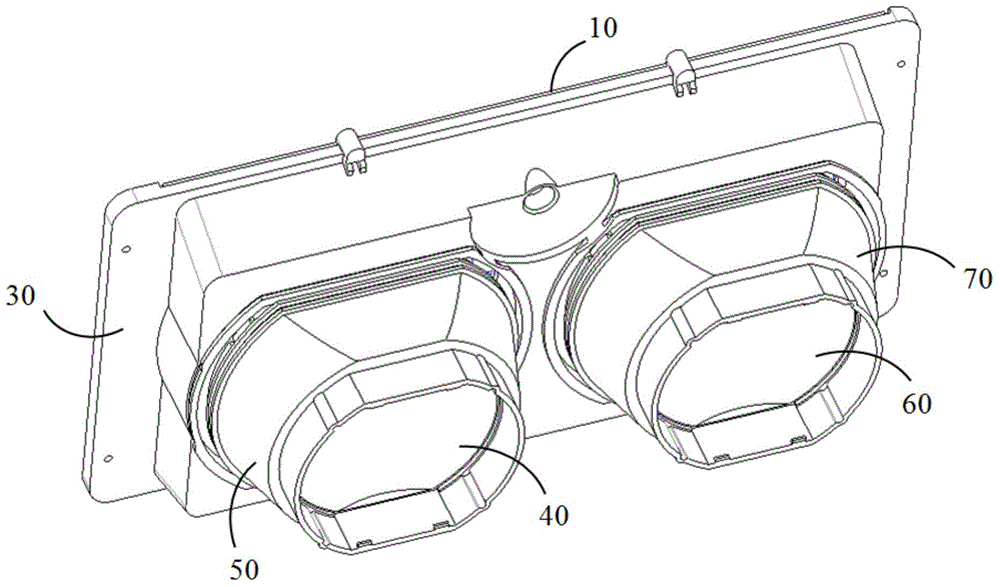

Head-mounted display and dustproof method applied to head-mounted display

ActiveCN104914579ARealize interpupillary distance adjustmentRealize dustproofOptical elementsDisplay devicePupil

The invention discloses a head-mounted display and a dustproof method applied to the head-mounted display. The head-mounted display comprises a display screen, a display screen support, left and right eye lens groups, left and right eye lens group supports and left and right eye annular sealing soft rubber sleeves; and the display screen is fixed to the display screen support, the left and right eye lens groups are respectively fixed to the left and right eye lens group supports, the left and right eye lens group supports are installed on the display screen support and can slide left and right relative to the display screen support, and the left and right eye annular sealing soft rubber sleeves are disposed at installation connection portions between the lens group supports and the display screen support. The technical scheme provided by the invention achieves dust prevention between the display screen and the lens groups of the head-mounted display in the pupil distance adjustment process; and because the annular sealing soft rubber sleeves are thin and have large elasticity, borne resistance forces when the lens group supports slide relative to the display screen support are small, and hand feeling of the pupil distance adjustment is not influenced.

Owner:BEIJING PICO TECH

Fabric gold stamping technological method

InactiveCN101457492AHigh fastnessDoes not affect the feelDecorative surface effectsTextile decorationMaterials scienceNanotechnology

The invention discloses a gold stamping method of a surface fabric, comprising the following steps: 1: gold stamping film rubberizing; 2: compound of the gold stamping film and the surface fabric; 3: heat preservation; 4: parting; the gold stamping surface fabric produced by the invention retains previous feel after gold stamping, as heat preservation provides the gold stamping surface fabric produced by the method with very good fastness and the gold stamping surface fabric does not fade or deform after going through washing or high temperature, therefore, seen from any angle, the gold stamping surface fabric reflects different colors and has colorful and diverse designs and patterns.

Owner:WUJIANG LINGTONG TEXTILE FINISHING

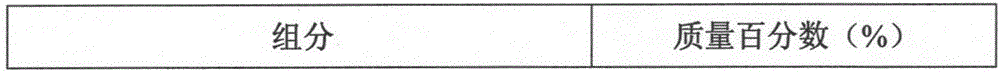

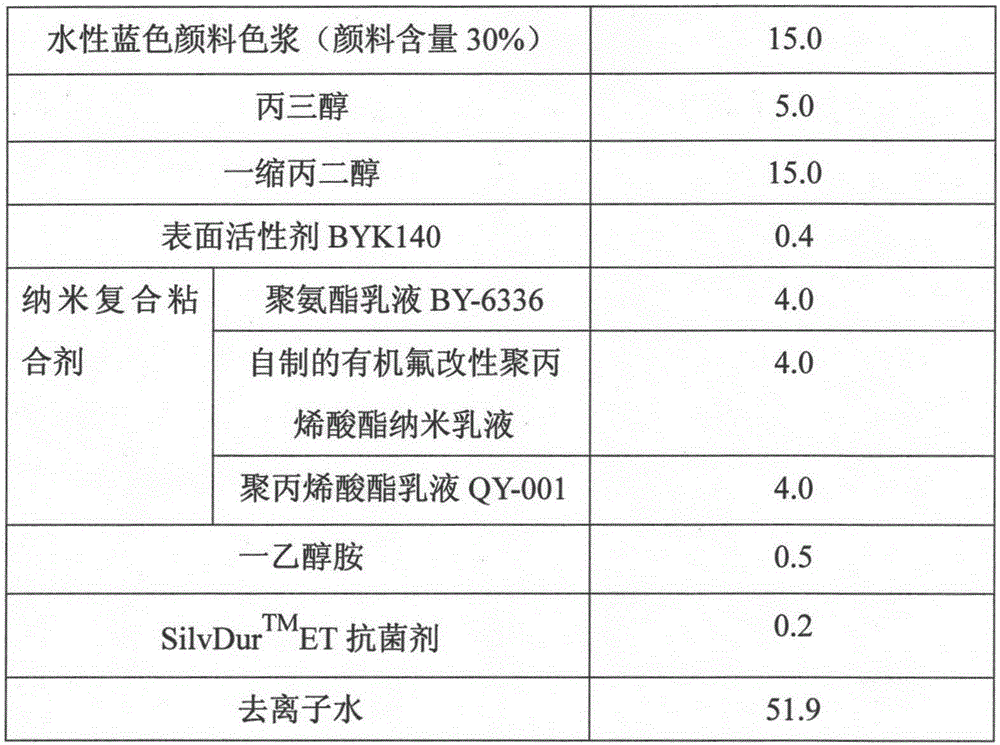

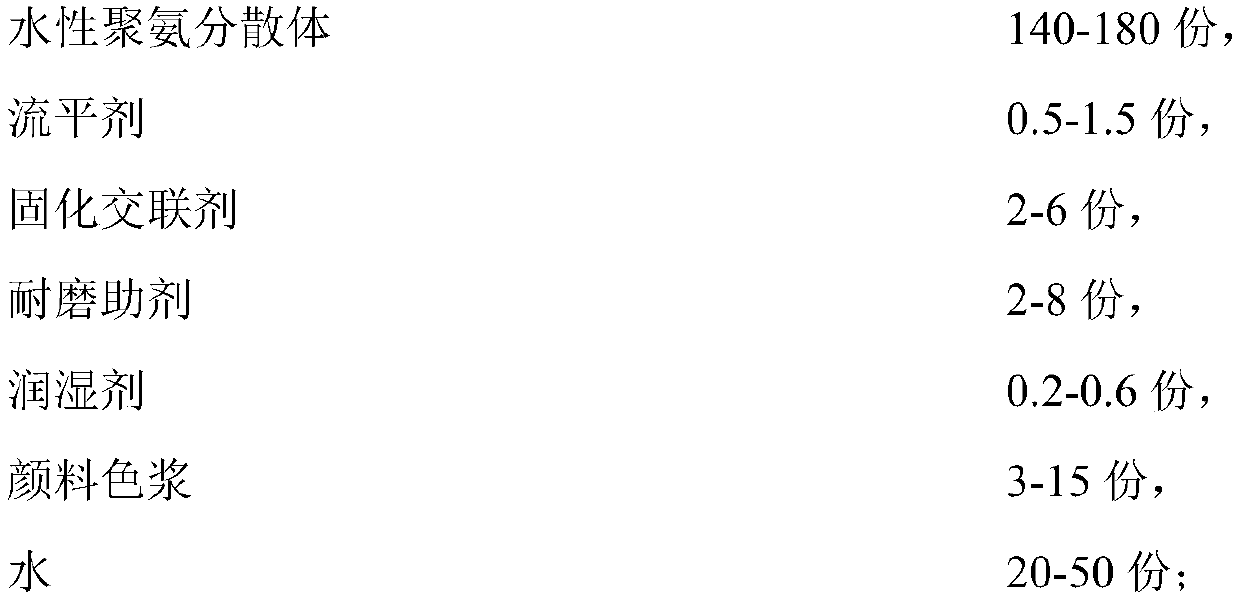

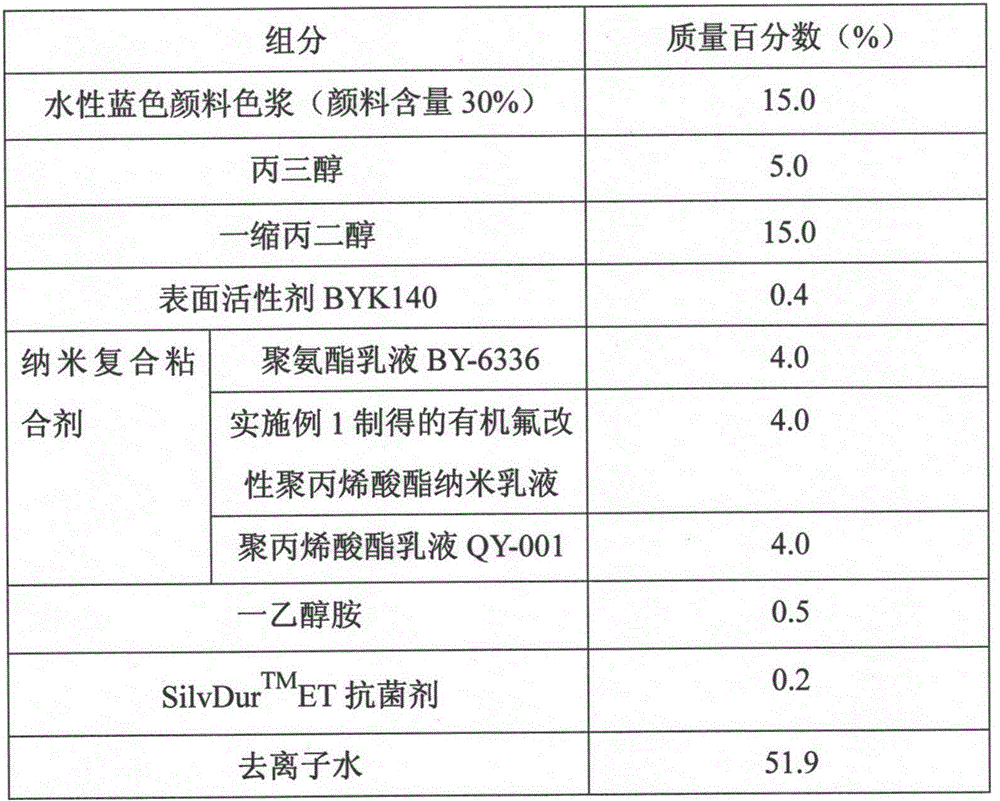

Water-based pigment digital ink-jet textile printing ink and preparation and use methods thereof

ActiveCN106567267AImprove washing fastnessImprove hydrophobicityDuplicating/marking methodsInksWater basedTextile printer

The invention provides a water-based pigment digital ink-jet textile printing ink and preparation and use methods thereof. The water-based pigment digital ink-jet textile printing ink is characterized by containing a pigment color paste, a nano composite adhesive and deionized water, wherein the nano composite adhesive comprises a polyurethane emulsion, an organic fluorine modified polyacrylate nano emulsion and another polyacrylate emulsion. With use of the nano composite adhesive, the problem of low water washing fastness of a water-based pigment ink-jet printing ink on a printing fabric is solved emphatically, and a new solution is provided for industrialized application of the water-based pigment ink-jet printing ink in the field of fabric digital ink-jet printing.

Owner:上海英威喷墨科技有限公司

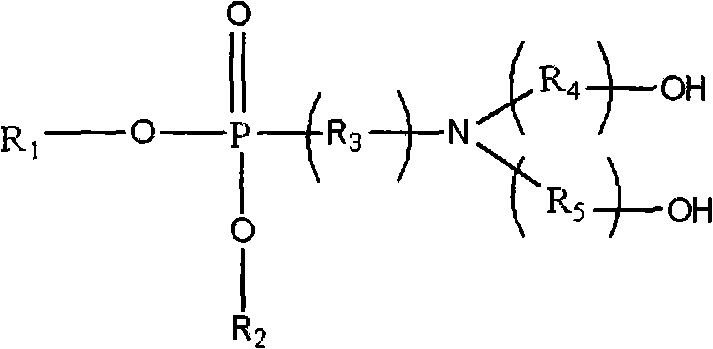

Halogen free phosphorous-nitrogen synergic antiflaming water-soluble polyurethane fabric coating agent and preparation method thereof

The invention relates to halogen free phosphorous-nitrogen synergic antiflaming water-soluble polyurethane fabric coating agent and a preparation method thereof, belonging to the technical field of light industry. The coating agent comprises diisocyanate, non-antiflaming polyalcohol, reactive type phosphorous-nitrogen series polyalcohol, hydrophilic chain extender and neutralizing agent. The diisocyanate, non-antiflaming polyalcohol, reactive type phosphorous-nitrogen series polyalcohol and hydrophilic chain extender are added into a kettle, and reaction is carried out, thus obtaining prepolymer; then the prepolymer is added into aqueous solution containing neutralizing agent, emulsification neutralization is carried out in high speed emulsification equipment, and then rotary evaporation is carried out to remove solvent, thus obtaining target product. The invention has the characteristics of environmental protection, no toxicity, low smoke, phosphorous-nitrogen synergic antiflaming and obvious antiflaming effect; the antiflaming water-soluble polyurethane fabric coating agent is adopted for finishing fabric, coating is transparent and unsticky, handfeel of fabric is not influenced, and soaping resistance can be realized, thus passing level B1 in GB / T5455-1997 textile-burning behaviour-vertical method.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

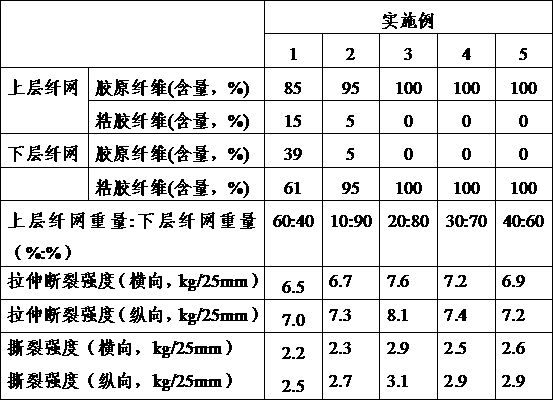

Collagenous fiber regenerated leather low in production cost and manufacturing method thereof

The invention relates to a collagenous fiber regenerated leather low in production cost and a manufacturing method thereof. The regenerated leather is composed of double-layer fiber nets, wherein the double-layer fiber nets on one side contain low-cost viscose fibers which achieve 100% in weight, and the double-layer fiber nets on the other side are collagenous fibers. During recombination, one side, containing a large number of the viscose fibers, of the regenerated leather and other cloth layers or leather layers are recombined, and therefore adulteration of the viscose fibers does not affect hand feeling of the regenerated leather. Meanwhile, as the regenerated leather contains a large number of the viscose fibers, the production cost of the regenerated leather is greatly reduced. The double-layer fiber nets on one side can contain the low-cost viscose fibers, besides, the viscose fibers achieving 15% to the maximum in weight can be adulterated in the double-layer fiber nets on the other side, and the cost of the regenerated leather is further reduced. According to the method of the collagenous fiber regenerated leather, effective winding between the upper fiber nets and the lower fiber nets is formed in a puncture fixing mode, and the strength of the regenerated leather is guaranteed. In addition, the species and the number of net laying devices of the collagenous fiber regenerated leather can be regulated according to the ratio of the upper fiber nets and the lower fiber nets so that high cloth passing speed and high production efficiency can be achieved.

Owner:JIANGYIN JUNHUA TEXTILE TECH

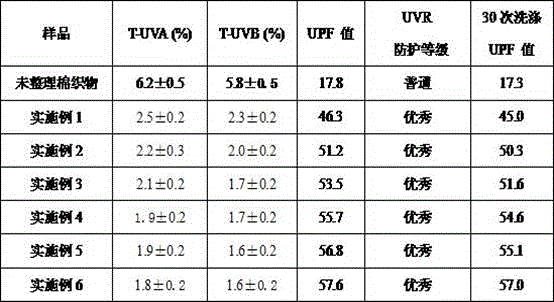

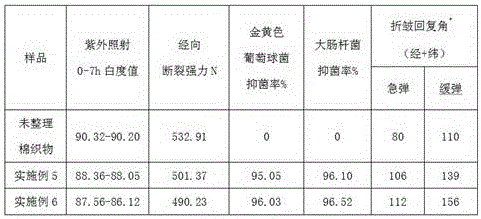

Modified-chitosan-containing anti-ultraviolet finishing agent for cotton fabric and anti-ultraviolet cotton fabric obtained by aid of anti-ultraviolet finishing agent

The invention provides a modified-chitosan-containing anti-ultraviolet finishing agent for cotton fabric and anti-ultraviolet cotton fabric obtained by aid of the anti-ultraviolet finishing agent. The modified-chitosan-containing anti-ultraviolet finishing agent for the cotton fabric is a uniformly mixed solution of 3,4,5-trimethoxybenzoyl chitosan, a crosslinking agent, a penetrant and an acetic acid or lactic acid solution, wherein the crosslinking agent is organic polycarboxylic acid or amino-modified silicone oil emulsion; the penetrant is either JFC or peregal O. The anti-ultraviolet cotton fabric with anti-ultraviolet, anti-bacterial and anti-crease finishing functions is obtained through double-dip double-nip, water washing and drying, the anti-ultraviolet, anti-bacterial and anti-crease finishing functions are high in durability, the cotton fabric still maintains the original style of the fabric after finishing, the hand feel, the strength, the whiteness and the color of the cotton fabric are not affected, and the original human body affinity is maintained; the finishing agent is simple in composition and easy to prepare, and a finishing process is simple and environment-friendly.

Owner:EASTERN LIAONING UNIV

Semen Cassiae Composite Antibacterial Finishing Agent, Preparation Method, Fiber Treatment Method and Application

The invention discloses a cassia seed composite antibacterial finishing agent which is prepared from a cassia seed extract or nano-cassia seed, a finishing agent and TW-80 (Tween-80). The cassia seed composite antibacterial finishing agent is convenient to use and stable; by adopting the technology of applying the cassia seed composite antibacterial finishing agent on fiber, a product has high-efficient, lasting and safe antibacterial performance; the natural cassia seed is introduced into the traditional home textile industry, thereby avoiding the safety problem during the application of an organic antibacterial agent; and the problems of dispersion, uniformity, firm combination and the like between the antibacterial agent and the fiber can be solved, and the high-efficient lasting antibacterial effect can be achieved in the real sense. The invention further discloses a preparation method of the cassia seed composite antibacterial finishing agent, a method for processing the fiber byutilizing the cassia seed composite antibacterial finishing agent and an application of the cassia seed composite antibacterial finishing agent in home textile products.

Owner:SHANGHAI SHUIXING HOME TEXTILE

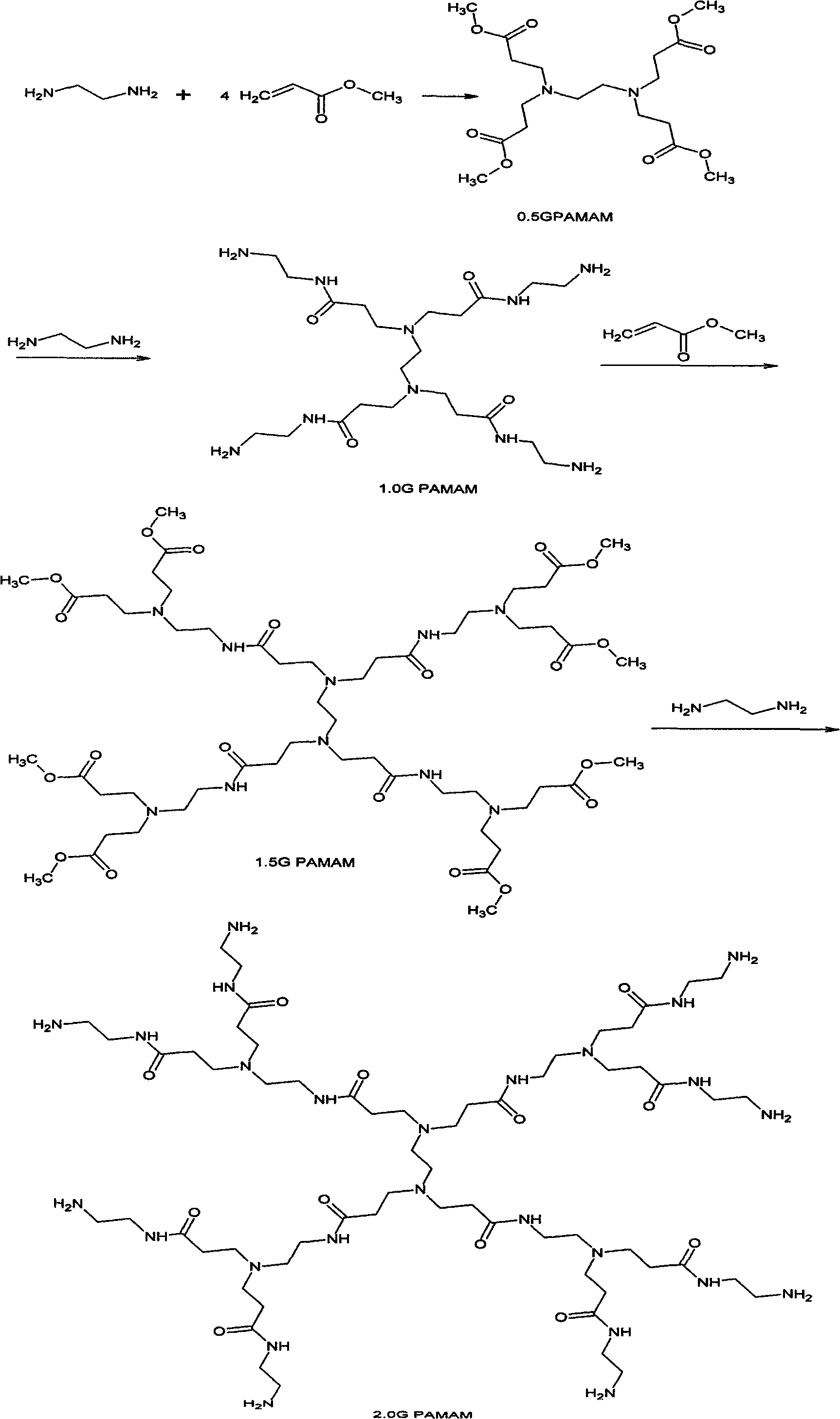

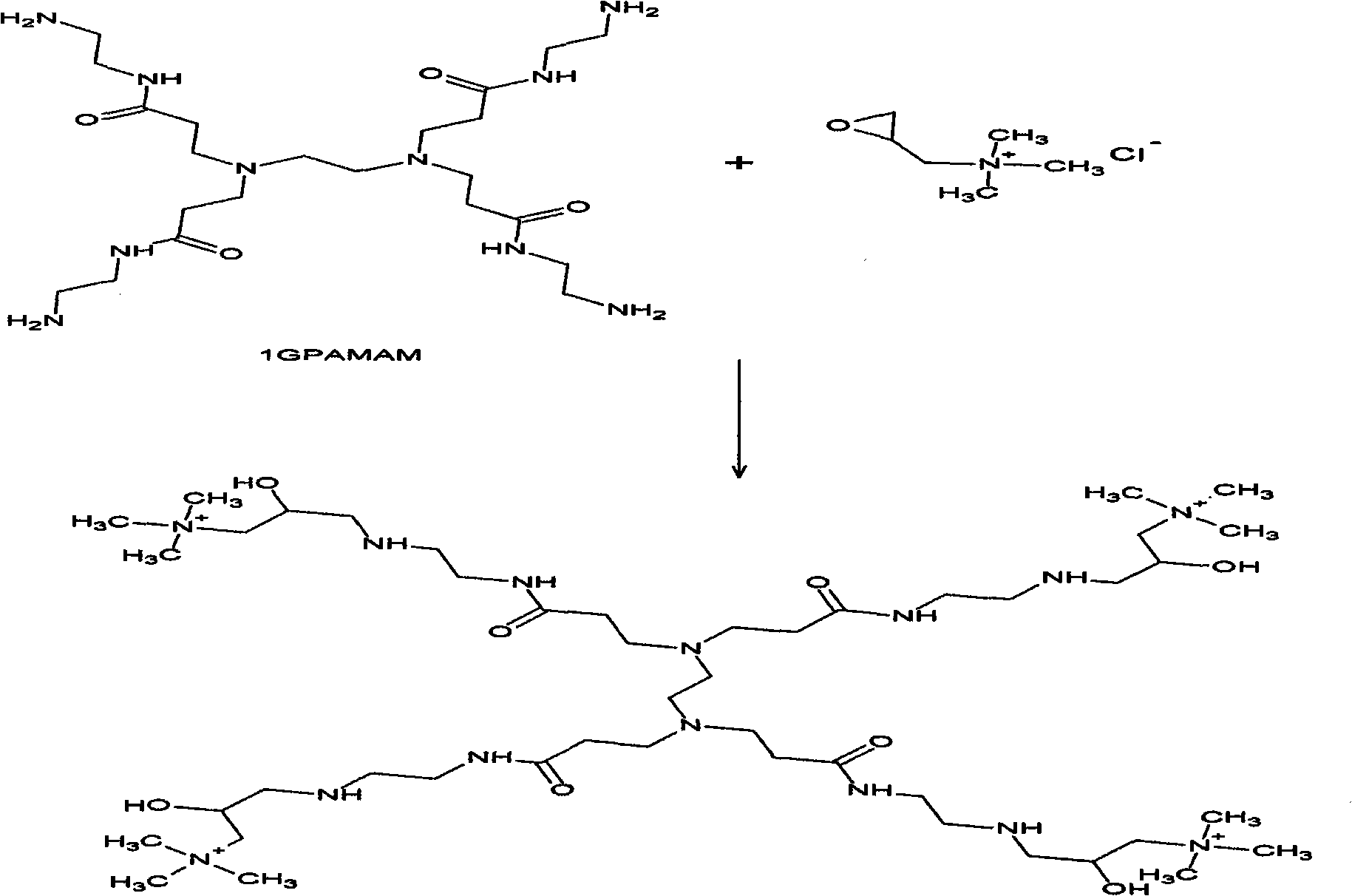

Dendriform cationic leather fixing agent and preparation method thereof

The invention relates to a method for preparing a leather fixing agent, in particular to a dendriform cationic leather fixing agent and a preparation method thereof. To overcome the defects of low activity, high consumption and easily caused grain leather existing in the prior art, the invention adopts a technical scheme that: the method for preparing the dendriform cationic leather fixing agent comprises the following steps: (1) mixing organic amine and acrylic ester, adding a reaction solvent, stirring to react, vacuumizing, distilling by rotating, and removing the solvent and excessive acrylic ester to prepare dendriform PAMAM; and (2) mixing the dendriform PAMAM prepared in the step (1) with a cationic etherifying agent, adding a solvent, adding an extracting agent after reaction, andextracting for multiple times to prepare graft modified dendriform cationic leather fixing agent. Compared with the prior art, the method has the advantages of reducing the hydrolysis effect of dye, improving fastness of leather to wet rubbing, reducing the consumption of the dye, not influencing the hand feeling of the leather, and making the fixing agent biologically degraded easily.

Owner:SHAANXI UNIV OF SCI & TECH

Finishing method of multifunctional textile

InactiveCN106480741AHas wash fastnessGood hydrophobic and oleophobic self-cleaning functionLiquid repellent fibresVegetal fibresCooking & bakingCross-link

The invention discloses a finishing method of a multifunctional textile. One surface of the textile has a water-and-oil-repellent antifouling function, and the other surface of the textile has oleophilic and hydrophilic moisture absorption and sweat releasing functions. The method comprises steps as follows: dip-coating of the textile in a cross-linking agent solution, spraying of oleophilic and hydrophilic components, spraying for the other surface of the textile by the oleophilic and hydrophilic components as well as pre-drying and baking for the textile after finishing. The single surface of the textile after finished with the method has a self-cleaning function, the other surface can be worn next to the skin and has the comfortable moisture absorption and sweat releasing functions, two surfaces with different functions both have certain water resistance, raw materials are widely sourced, a technology is simple and easy, the raw materials have certain compatibility with other textile finishing auxiliaries, and the method can be applied to the functional afterfinish field of the textile.

Owner:GUANGZHOU UNIVERSITY

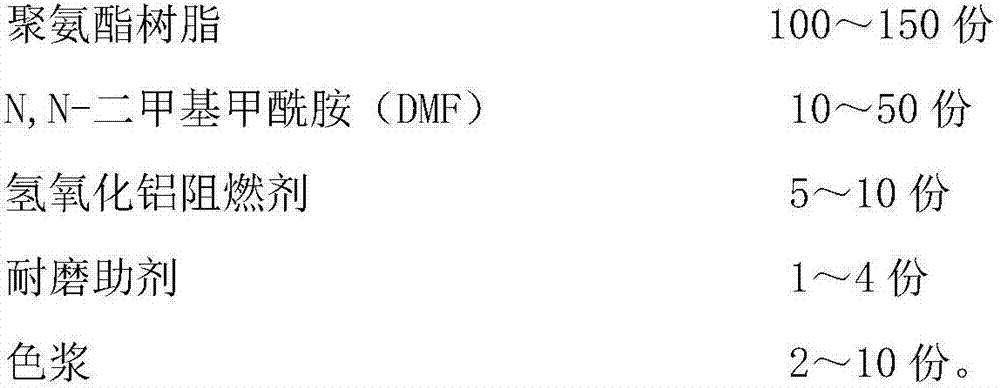

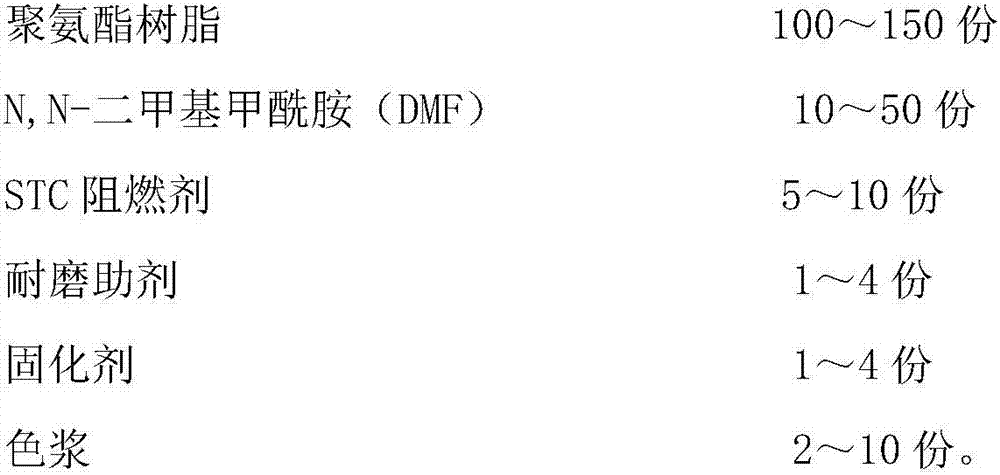

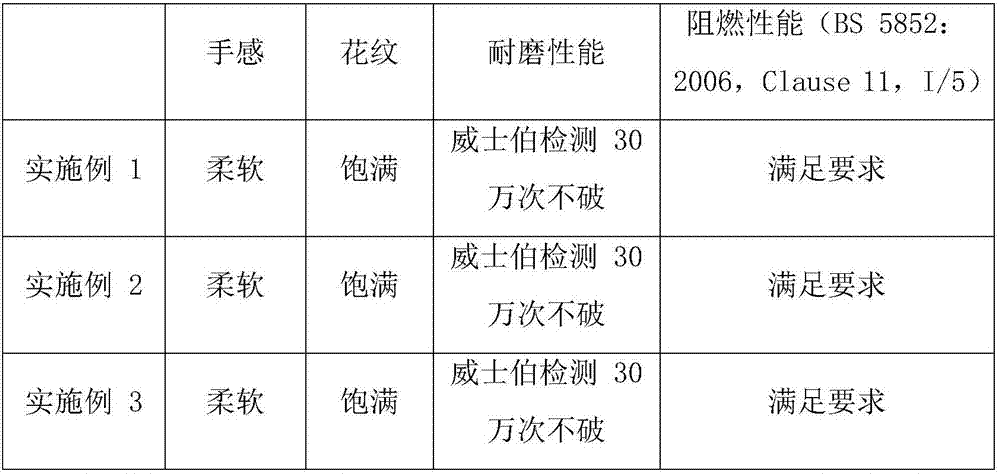

High-flame retardant property solvent-free polyurethane synthetic leather and preparation method thereof

InactiveCN107503168AImprove flame retardant performanceImprove wear resistanceTextiles and paperSurface layerAlcohol

The invention relates to high-flame retardant property solvent-free polyurethane synthetic leather and a preparation method thereof. The polyurethane synthetic leather is composed of a surface layer, an intermediate layer and a base fabric, wherein a solvent-free layer is arranged between the intermediate layer and the base fabric; the solvent-free layer is formed by mixing a component A and a component B according to a mass ratio of 100:(40-50); the component A is composed of the following components in parts by mass: 100-120 parts of polyhydric alcohol component material CC 6945-100C-A, 20-40 parts of a compound flame retardant and 0.05-0.1 part of a catalyst; and the component B is an isocyanate prepolymer CC 6945-100C-B. According to the polyurethane synthetic leather disclosed by the invention, the flame retardant property of the synthetic leather can meet the requirements of 'BS 5852:2006, Clause 11, I / 5' on the premise of not influencing the mechanical property and hand feeling of the synthetic leather.

Owner:ANHUI ANLI MATERIAL TECH

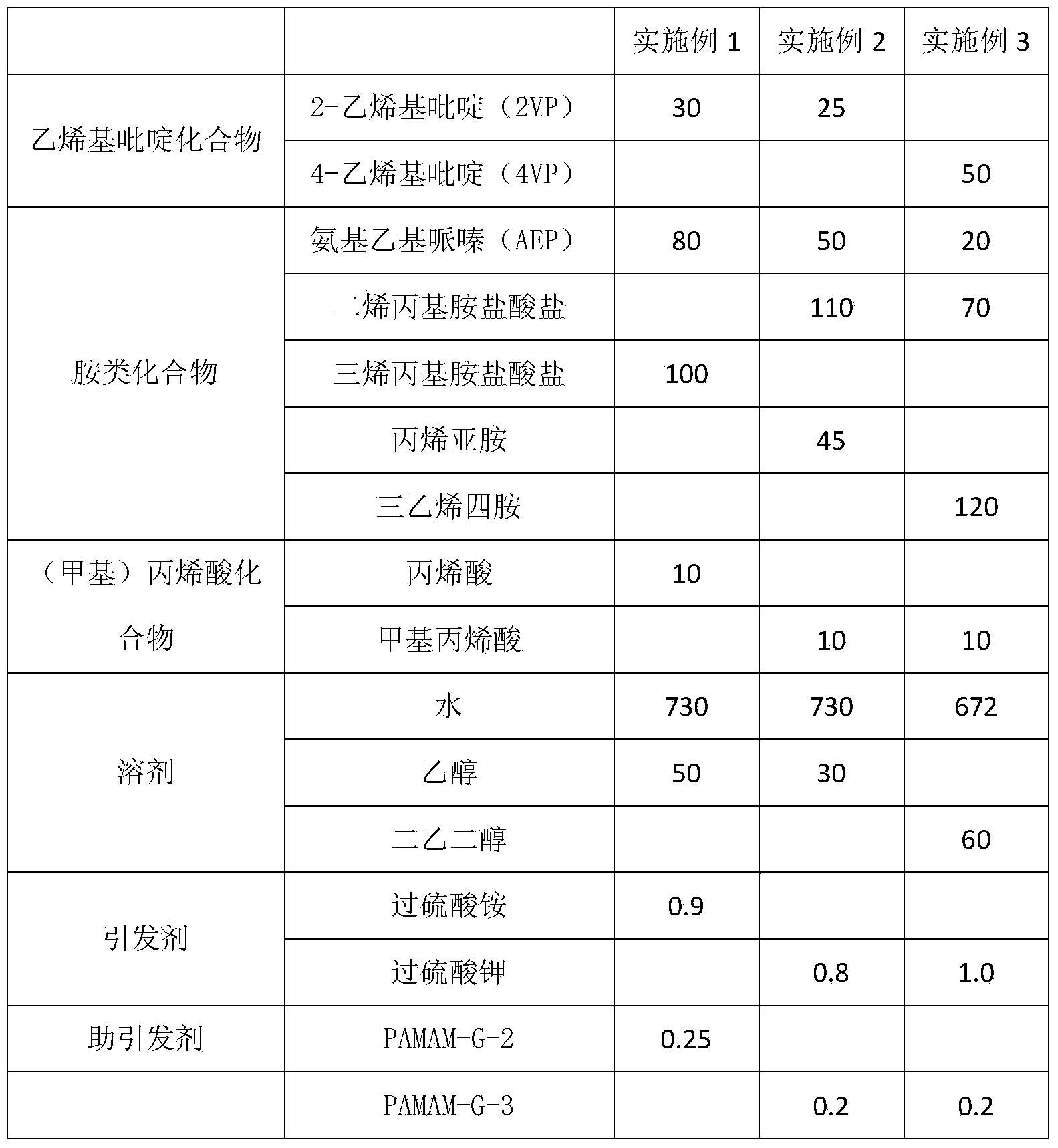

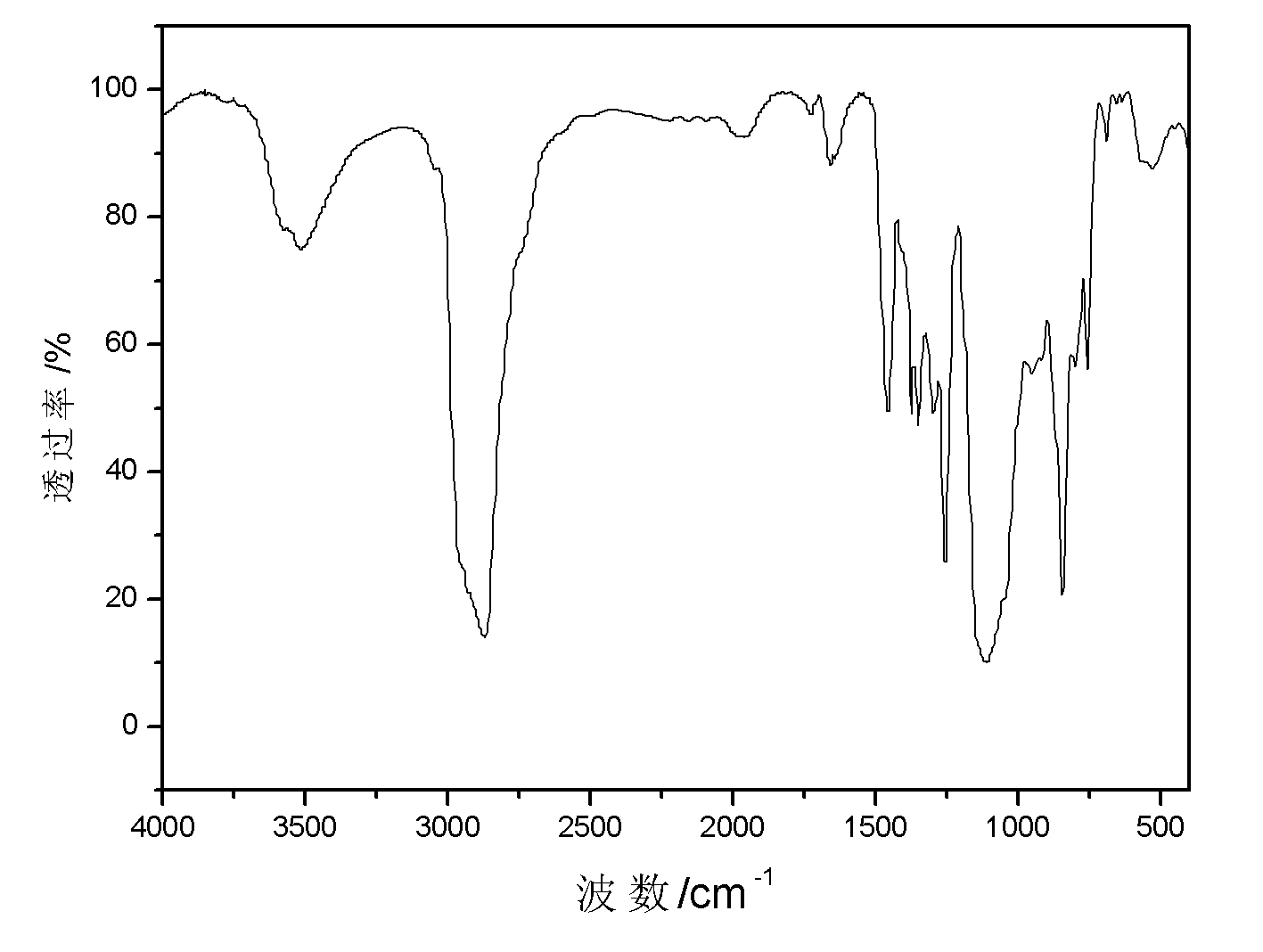

Preparation method for hydrophilic dye-fixing agent for reactive dyeing

ActiveCN104313926ADoes not affect hydrophilicityDoes not affect the feelDyeing processRadical initiatorDyeing

The invention relates to a preparation method for a hydrophilic dye-fixing agent for reactive dyeing. According to the method, vinylpyridine, amine monomers and acrylate monomers have a polymerization reaction when radical initiators and assisting initiators exist, and the hydrophilic dye-fixing agent is obtained. The hydrophilic dye-fixing agent prepared with the method has an excellent dye-fixing effect, meanwhile, the hygroscopicity and the hydrophilia of cotton fabric are not affected, and a good hand feeling is achieved.

Owner:SHANGHAI ARGUS NEW MATERIAL CO LTD

Aminosilicone durable hydrophilic potentiating agent, and preparation method and application thereof

InactiveCN102505496APreparation reaction conditions are mildImprove responseGroup 4/14 element organic compoundsFibre treatmentEpoxyEmulsion

The invention discloses aminosilicone durable hydrophilic potentiating agent, and a preparation method and the application thereof. The preparation method is that methyl silicone oil containing hydrogen, allyl-terminated epoxy-terminated compound and allyl polyether are reacted under the effect of platinum catalyst in oxygen-free condition, so that the aminosilicone durable hydrophilic potentiating agent is obtained. The method has the advantages that the reaction step is simple, the reaction condition is mild, and the method is simple and easy. The aminosilicone durable hydrophilic potentiating agent not only can be independently used before and after the softening finish of traditional aminosilicone, but also can be co-bathed with traditional aminosilicone emulsion; as the agent has good penetrability, wettability and reactivity, the agent can not only keep the soft and smooth feel of the traditional aminosilicone, but also give good hydrophilicity to fabrics in the condition that the use level is low, and also has durability; and the difference between the fabric finished by the aminosilicone durable hydrophilic potentiating agent and the fabric finished by the independently used traditional traditional aminosilicone emulsion is that fabric treated by the aminosilicone durable hydrophilic potentiating agent can be directly repaired without treatment.

Owner:东莞市中纺化工有限公司

Fabric containing Tencel A200 and cotton and processing method thereof

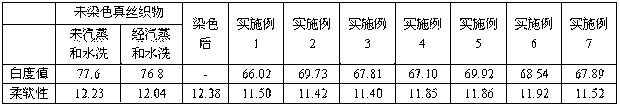

InactiveCN105063852ACombined softness and smoothnessDoes not affect the feelSucessive textile treatmentsDyeing processFiberYarn

The invention provides fabric containing Tencel A200 and cotton and a processing method thereof. The fabric is formed by interweaving of warps and wefts. The warps and the wefts are made of cotton yarn or cotton / Tencel A200 blended yarn, and the cotton / Tencel A200 blended yarn is adopted for at least one direction of the warps and the wefts. The processing method comprises the steps of blending cotton fiber and Tencel A200 fiber firstly to obtain the blended yarn, and then conducting beaming, dressing, weaving, singeing, desizing, boiling off, bleaching, mercerizing, printing or dyeing, steam-washing, tentering and softening, calendaring and preshrinking in sequence. The obtained fabric not only has the skin-friendly and comfort hand feeling of pure cotton, but also has the softness and smoothness of Tencel products. Furthermore, the surface of the fabric is smooth, and the fabric is highly stiff and smooth.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Anti-skid glaze and anti-skid ceramic tile

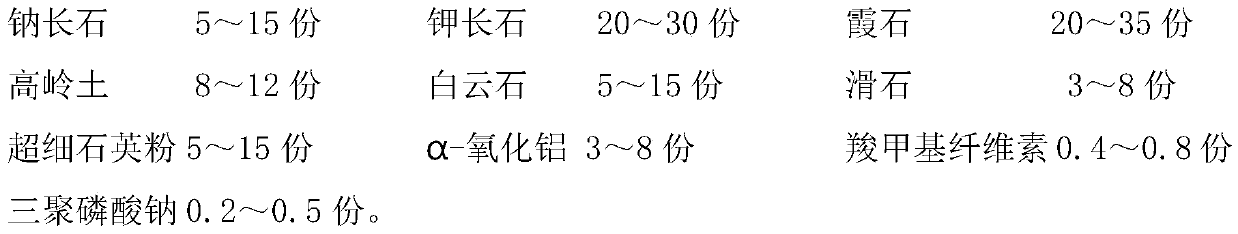

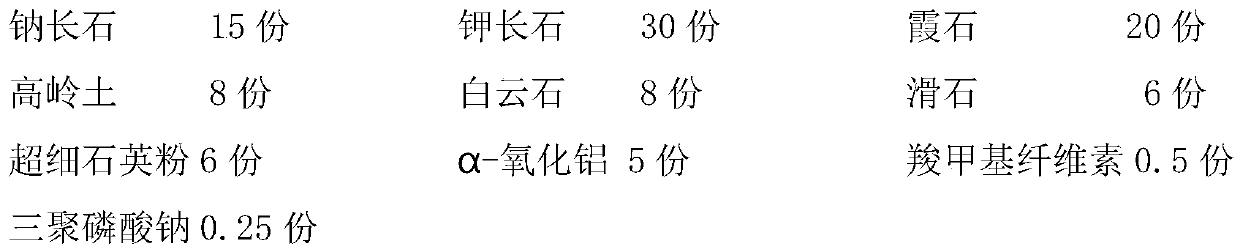

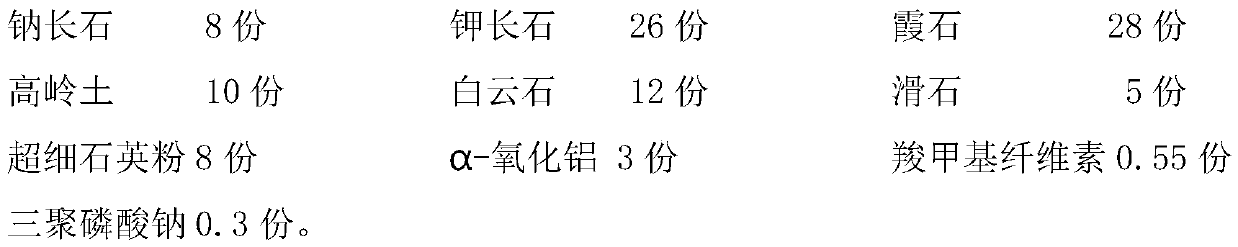

The invention relates to an anti-skid glaze and an anti-skid ceramic tile, wherein the anti-skid ceramic tile consists of a blank layer, a surface glaze layer, an ink jet layer and an anti-skid glazelayer. The anti-skid glaze comprises 5 to 15 parts of albite, 20 to 30 parts of potash feldspar, 20 to 35 parts of nepheline, 8 to 12 parts of kaolin, 5 to 15 parts of dolomite, 3 to 8 parts of talc,5 to 15 parts of superfine quartz powder, 3 to 8 parts of alpha alumina, 0.4 to 0.8 part of carboxymethyl cellulose and 0.2 to 0.5 part of sodium tripolyphosphate.

Owner:JIANGXI HEMEI CERAMICS +3

Environment-friendly paste discharge agent for textile printing and preparation method thereof

ActiveCN102704292ANon-oxidizingNon-reducibleTransportation and packagingMixingSolubilityTextile printer

The invention discloses an environment-friendly paste discharge agent for textile printing and a preparation method thereof. The environment-friendly paste discharge agent comprises the following components in parts by weight: 30-60 parts of decamethyl cyclopentasiloxane, 40-70 parts of thiourea dioxide, 1-3 parts of surfactant and 3-6 parts of glycerin. The preparation method comprises the steps: putting the decamethyl cyclopentasiloxane into a ball grinder container; adding the surfactant to be uniformly dispersed or dissolved and uniformly agitated; and then adding the thiourea dioxide into the ball grinder container to blend and grind for 1-3 hours. Specific liquid compound decamethyl cyclopentasiloxane as a disperse medium and the thiourea dioxide are not subjected to chemical reaction; With the environment-friendly paste discharge agent provided by the invention, contact of the thiourea dioxide with the external water and air is isolated; the stability of the thiourea dioxide is improved; the discharge effect is excellent; and the problems of low solubility, poor dispersible uniformity in discharge pulp, poor net permeability and insufficient development of the discharge action caused by common thiourea dioxide used as the discharge agent are overcome.

Owner:HAINING GREEN SHIELD TEXTILE TECH CO LTD

Soaping-free active digital ink-jet ink and preparation method thereof, and active ink-jet printing soaping-free printing and dyeing process used for fabrics

The invention provides a soaping-free active digital ink-jet ink and a preparation method thereof, and an active ink-jet printing soaping-free printing and dyeing process used for fabrics. In the existing active ink-jet printing technology, the price of the ink is high, the soaping is required after steaming, and the process can produce a large amount of printing and dyeing sewage. A purpose of the present invention is to solve the problems in the prior art. The soaping-free active digital ink-jet ink contains the following raw materials by weight: 5-20% of an active mixing dye, 0.01-2.0% of asurfactant, 15-30% of a moisturizing agent, 0.05-0.5% of a bactericide, 0.03-2% of a pH value adjuster, 2-10% of a viscosity modifier, 0.01-0.05% of a defoamer, and the balance of deionized water. According to the present invention, the problems of the sewage discharge generated during soaping, water washing and other washing processes after the ink-jet printing aging of the active ink-adapted fabric, and the high cost of the existing active ink are effectively solved so as to achieve the purposes of energy saving and emission reducing.

Owner:浙江海印数码科技有限公司

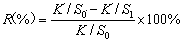

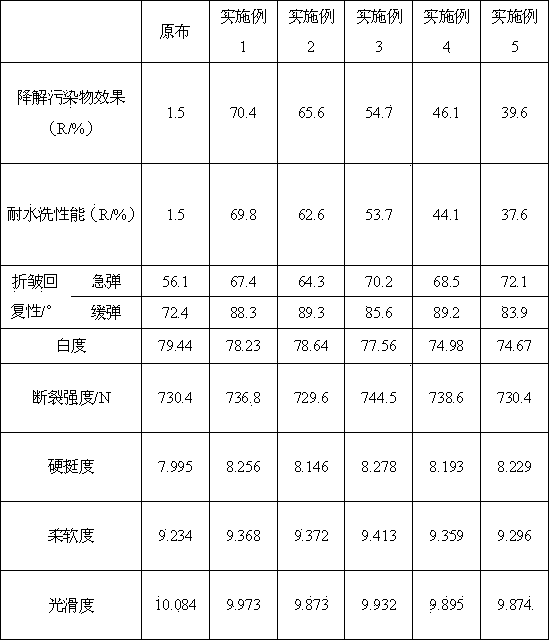

Preparation method of self-cleaning cotton fabric based on light-induced polymer free radicals for degrading pollutants

InactiveCN103410001AImprove mechanical propertiesImprove heat resistanceVegetal fibresCross-linkPolymer science

The invention discloses a manufacturing method of cotton fabric based on light-induced polymer free radicals for degrading pollutants, which belongs to the technical field of functional textiles. According to the manufacturing method, an appropriate H donor agent and a crosslinking agent are selected by utilizing the characteristic that sulfonated polyether ether ketone has high activities to H atoms in organic substances under light induction, so as to cross-link and form a film on the cotton fabric rich in hydroxyl to prepare the self-cleaning fabric which can generate the polymer free radicals by lighting and has an elimination effect on the pollutants. The manufacturing method mainly comprises the following steps: (1) preparing a composite finishing liquid of light-induced free-radical polymer, wherein the finishing liquid contains the sulfonated polyether ether ketone, H donor polymer, the crosslinking agent, HCL (hydrogen chloride) and the like; and (2) padding and baking the cotton fabric in the finishing liquid. The cotton fabric which is prepared by using the preparation method and has a function of degrading the pollutants by the light induction has the effects of antibiosis, pesticide degradation, pigment degradation and the like, can be used for common clothing, medical fabric, household fabric and the like, and has a wide application prospect.

Owner:ZHEJIANG SCI-TECH UNIV

Textile pre-treatment solution as well as preparation technology and application thereof

InactiveCN108193524AReduce penetrationImprove color expressionDyeing processPolymer sciencePre treatment

The invention discloses a textile pre-treatment solution as well as a preparation technology and application thereof. According to the textile pre-treatment solution provided by the invention, cationic mixed liquid is prepared by mixing a cationic modifier, resin and the like; the permeation of coating ink on a fabric can be reduced and a better color expressive force is realized; the color yieldand the brightness can be effectively improved and the wet rubbing fastness is improved; meanwhile, the textile pre-treatment solution has the advantages that the textile pre-treatment solution does not become yellow at high temperature and the hand feeling is not influenced.

Owner:深圳市墨库图文技术有限公司

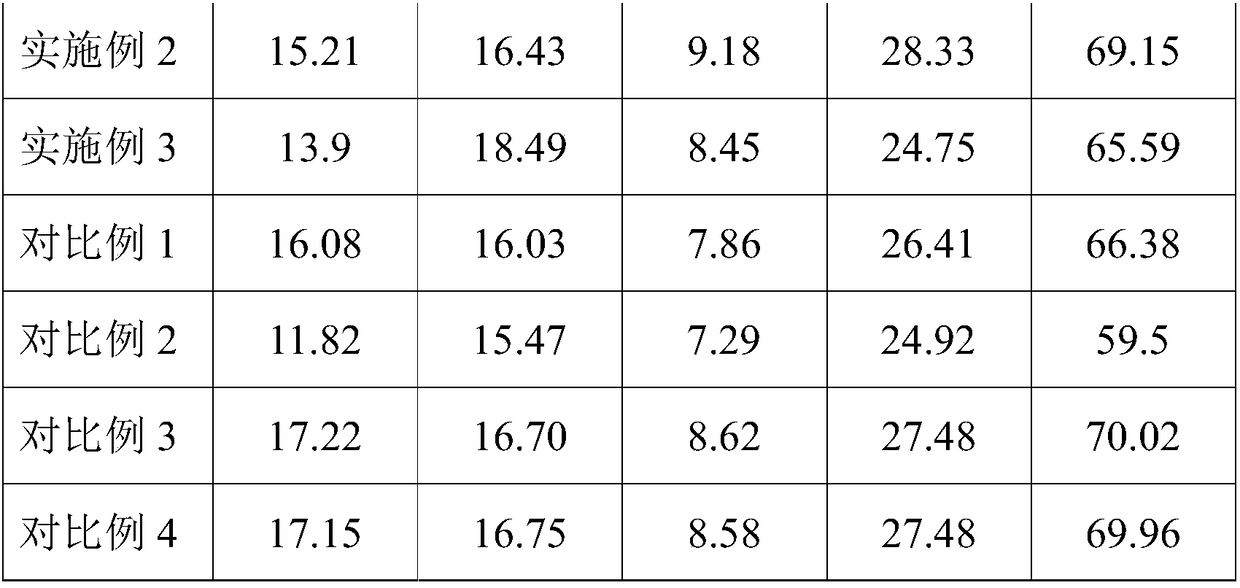

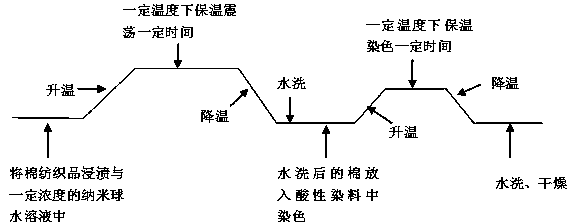

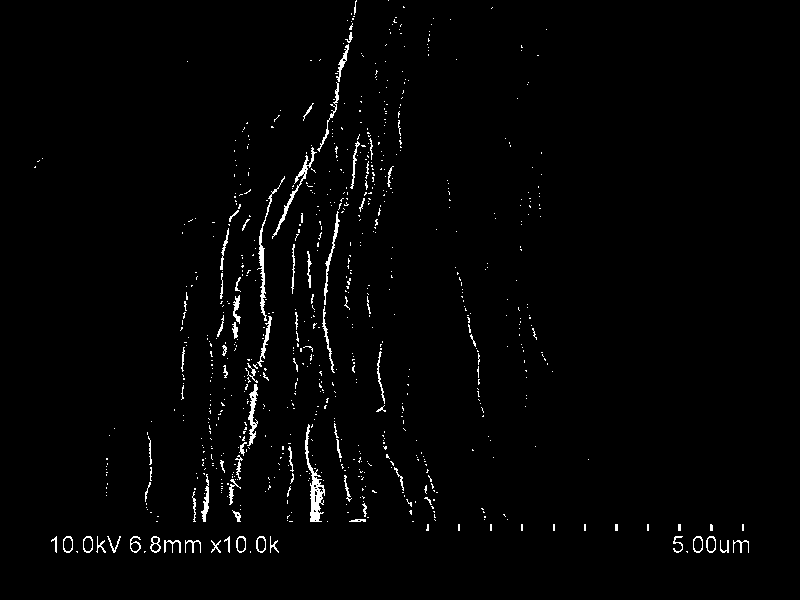

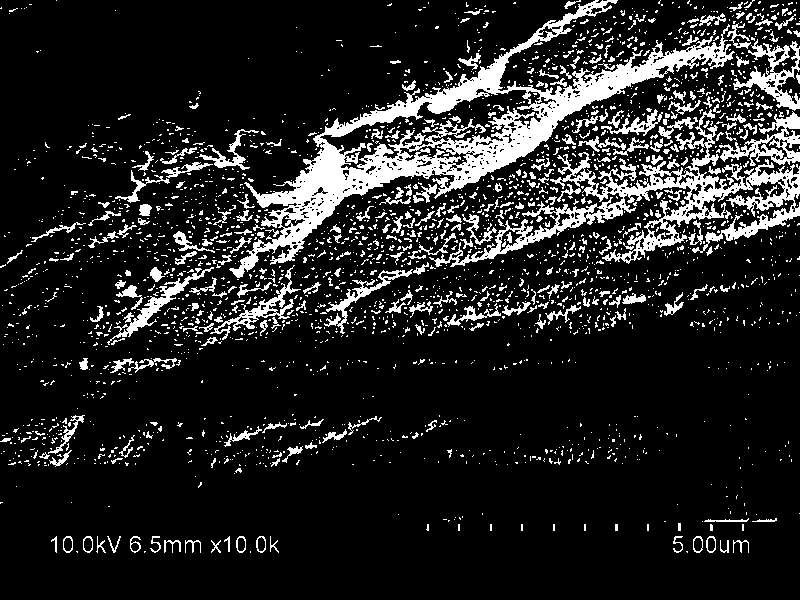

Dyeing method of acid dyes for cotton textiles

ActiveCN103790016AImprove dye uptakeDoes not affect moisture absorptionDyeing processVegetal fibresFiberSalt free

The invention relates to a dyeing method of acid dyes for cotton textiles. The dyeing method comprises the steps of carrying out dipping or padding treatment on the cotton textiles by use of a cationic polymer nanosphere solution and dyeing with the acid dyes. The cotton is modified by cationic polymer nanospheres to enable the modified fibers to be positively charged, and the binding force between the acid dyes and the cotton is improved and the dyeing performance of the acid dyes to the cotton is improved in the presence of Coulomb attraction. The method can dye the cotton textiles with the acid dyes, has high dye take-up rate and short dyeing time and achieves salt-poor and salt-free dyeing; the method has simple process and strong operability; the air permeability and the hand feeling of cotton are not influenced after modified treatment.

Owner:YUYUE HOME TEXTILE

Ecological antimicrobial fabric and method for producing the same

InactiveCN101153460ANo growthGuaranteed antimicrobial propertiesFibre treatmentLiquid/gas/vapor textile treatmentAntibacterial agentChemistry

The invention discloses a preparation method of biological antibacterial fabric. The invention is characterized in that an antibacterial processing technology is provided based on the prior fabric preparation technology, and the antibacterial processing technology orderly comprises the following steps, the fabric is dipped in nano-silver ions antibacterial agent solution, stentered, preliminarily dried and baked. The method in the invention can be used to produce a biology antibacterial fabric.

Owner:上海龙头家纺有限公司

Method for darkening finishing of wool fabric

InactiveCN103643528AIncreased apparent color depthDoes not affect the feelAnimal fibresChemistryWool

The invention provides a method for darkening finishing of a wool fabric, and the method at least comprises the following steps: (1) preparation of fluoroalkyl modified amino silicone oil; (2) emulsifying of the fluoroalkyl modified amino silicone oil; (3) padding; (4) preliminary drying; and (5) baking. Compared with the prior art, the method for darkening finishing uses the fluoroalkyl modified amino silicone oil as a finishing agent, the apparent color depth (K / S) of the wool fabric after the finishing can be increased by more than 20%, and the hand feeling, the flexibility and the serviceability of the fabric may not be affected.

Owner:TONGXIANG PUYUAN WOOLEN KNITTING TECH SERVICE CENT

Reactive dye ink jet printing sizing agent for cotton fabric

ActiveCN104790236ADoes not affect the feelImprove printing color yieldDyeing processVegetal fibresSodium carboxymethylcelluloseReactive dye

The invention discloses a reactive dye ink jet printing sizing agent for cotton fabric and belongs to the technical field of ink jet printing. The reactive dye ink jet printing sizing agent for the cotton fabric comprises sodium alginate, sodium carboxymethyl cellulose, hydroxypropyl guar gum, a dispersing agent and a migration inhibitor. The sizing agent can increase the reactive dye ink jet printing color yield without affecting the hand feeling of the cotton fabric after printing.

Owner:SHANDONG HUANGHE DELTA INST OF TEXTILE SCI & TECH RES INST

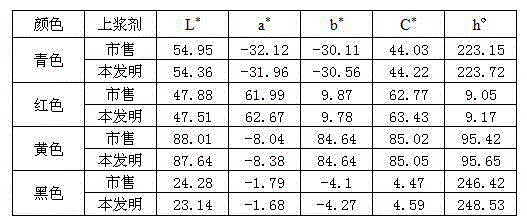

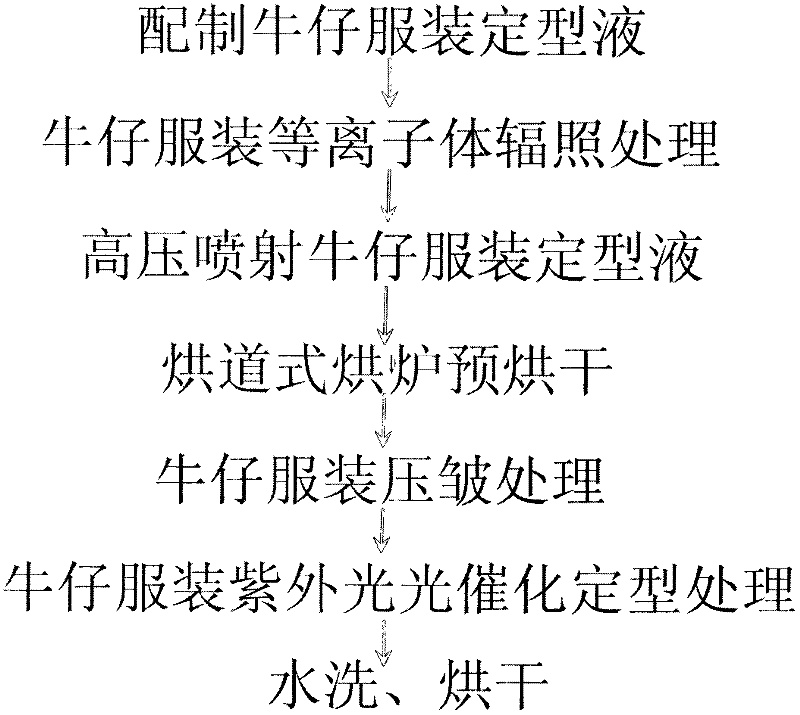

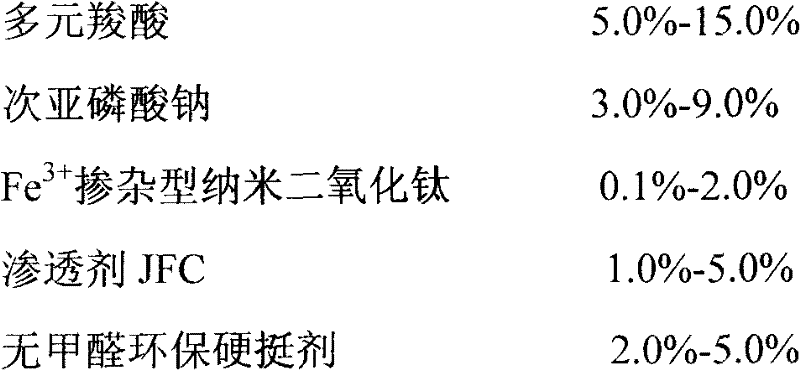

Jeans garment shaping liquid as well as preparation method and application thereof in ultraviolet light photocatalytic shaping and finishing method

InactiveCN102517893AGood shaping effectSolve the release problemPhysical treatmentSodium Hypophosphite MonohydrateUltraviolet lights

The invention provides a jeans garment shaping liquid as well as a preparation method and an application thereof in an ultraviolet light photocatalytic shaping and finishing method and relates to a jeans garment shaping liquid. The jeans garment shaping liquid comprises the following components in percentage by weight: 5.0-15.0 percent of polycarboxylic acid, 3.0-9.0 percent of sodium hypophosphite, 0.1-2.0 percent of Fe<3+>doped nanometer titanium dioxide, 1.0-5.0 percent of penetrating agents, 2.0-5.0 percent of formaldehyde-free environmentally-friendly stiffening agents, 3.0-5.0 percent of smooth brighteners and 59.0-85.9 percent of water. The invention also relates to the jeans garment ultraviolet light photocatalytic shaping and finishing method by adopting the shaping liquid, which comprises the following steps of: carrying out plasma radiation treatment on a part of a jeans garment required to be shaped, spraying the shaping liquid onto the treated part of the jeans garment, pre-drying on a drying tunnel-type drying oven and crinkling the treated part of the jeans garment; then carrying out photocatalytic shaping on the treated parts; and finally washing and drying. The method is high in catalytic efficiency, is environmental-friendly and energy-saving and is high in production efficiency. The finished jeans garment is durable, is good in shaping effect and good in handfeel and gloss, is environmental-friendly and generates no formaldehyde emission.

Owner:GUANGDONG JUNAN JEANS RES INST +1

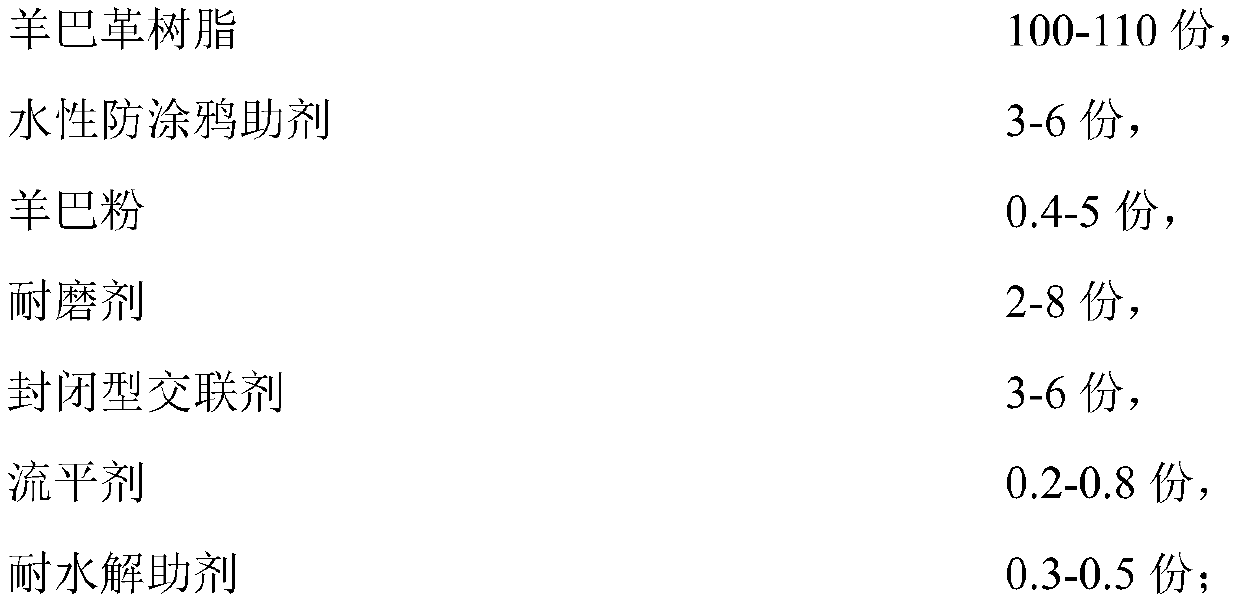

Waterborne foamed velvet solvent-free compound polyurethane synthetic leather for sofas and preparation method of waterborne foamed velvet solvent-free compound polyurethane synthetic leather

ActiveCN110644255AGood wear resistanceGood hydrolysis resistanceTextiles and paperEnvironmentally friendlyPolymer chemistry

The invention discloses waterborne foamed velvet solvent-free compound polyurethane synthetic leather for sofas and a preparation method of the waterborne foamed velvet solvent-free compound polyurethane synthetic leather. The compound polyurethane synthetic leather comprises a wear-proof foamed velvet layer, a waterproof surface layer, a waterborne middle layer, an environment-friendly solvent-free compound adhesive layer and base cloth sequentially from top to bottom. The compound polyurethane synthetic leather has durable soft velvet hand feel, delicate genuine leather texture and excellentwear resistance and durability, hydrolysis resistance lasts for 8-12 years, Wyzenbeek wear resistance is 900,000-1,500,000 times, and Martindale wear resistance is 200,000-300,000 times. In addition,a production process is simple, convenient and environmentally friendly.

Owner:ANHUI ANLI MATERIAL TECH

Fragrant detergent for household textiles

InactiveCN104845758AEfficient and durable antibacterialGood cleanlinessAnionic-cationic-non-ionic surface-active compoundsDetergent perfumesChemistryActive agent

The invention discloses a fragrant detergent for household textiles. The fragrant detergent for the household textiles is prepared from the following raw materials in parts by weight: 2-4 parts of rose essence, 7-14 parts of zinc sulfate, 8-16 parts of methyl acrylate, 1.2-2 parts of essence, 6-12 parts of fatty alcohol-polyoxyethylene ether, 10-16 parts of a petroleum emulsion, 7-10 parts of cetyltrimethylammonium chloride, 8-13 parts of lauryl polyoxyethylene ether sodium sulfate, 2.4-4.6 parts of honeysuckle essential oil, 1-2.1 parts of sodium sulfate, 6-9 parts of a compound surfactant, 8-13 parts of ethyl alcohol and 2-5 parts of hydroxyethyl cellulose. The fragrant detergent for the household textiles is efficient and durable in antibacterial property, excellent in cleaning property, free of influence on the hand feeling of textiles, free of toxicity and harm to the human body and free of pollution to the environment, and is capable of durably scenting fragrant smell.

Owner:青岛千帆高新技术有限公司

Organic fluorine modified polyacrylate nanometer emulsion and nanometer composite adhesive

ActiveCN106565891AIncrease the degree of cross-linkingDoes not affect the feelPolyureas/polyurethane adhesivesInksMethacrylateEmulsion

The invention provides an organic fluorine modified polyacrylate nanometer emulsion and a nanometer composite adhesive. The organic fluorine modified polyacrylate nanometer emulsion is characterized by being synthesized through the method comprising the steps that 10-15 parts by weight of methyl methacrylate, 2-4 parts by weight of hexafluorobutyl methacrylate, 0-1 part by weight of emulgator and 0-1 part by weight of ethylene glycol dimethacrylate are added into 15-25 parts by weight of water, stirring is carried out, pre-emulsification is carried out for 25-35 min, and a monomer pre-emulsion is obtained; then, 25-35 parts by weight of the monomer pre-emulsion is added into a reaction container, the temperature is increased to 75-85 DEG C, 2-5 parts by weight of the initiator potassium peroxodisulfate water solution with the concentration being 0.7-0.9% is added, a reaction is carried out for 25-35 min, 4-8 parts by weight of the initiator potassium peroxodisulfate water solution with the concentration being 0.7-0.9% and residual monomer pre-emulsion are dropwise added into the reaction container at the same time, a reaction is carried out for 1-3 h, and therefore the needed organic fluorine modified polyacrylate nanometer emulsion is obtained. The washing color fastness of textiles can be improved by means of the organic fluorine modified polyacrylate nanometer emulsion.

Owner:上海英威喷墨科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com