Anti-skid glaze and anti-skid ceramic tile

A technology of anti-slip and surface glaze, applied in the field of ceramics, can solve the problems of rough product surface, easy to hide dirt, impact on production continuity, etc., achieve the effect of delicate hand feeling and increase anti-slip performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

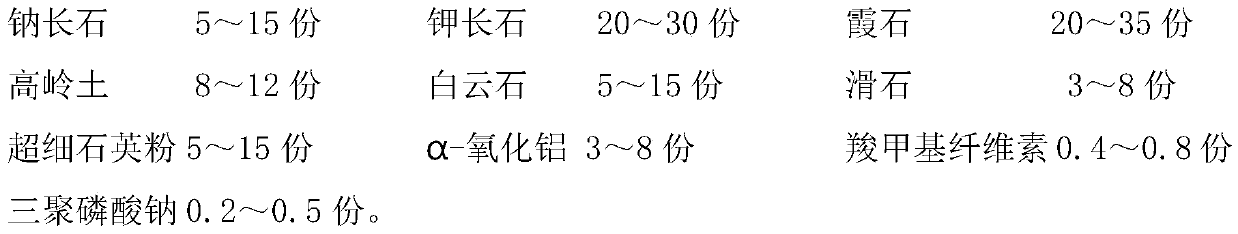

Method used

Image

Examples

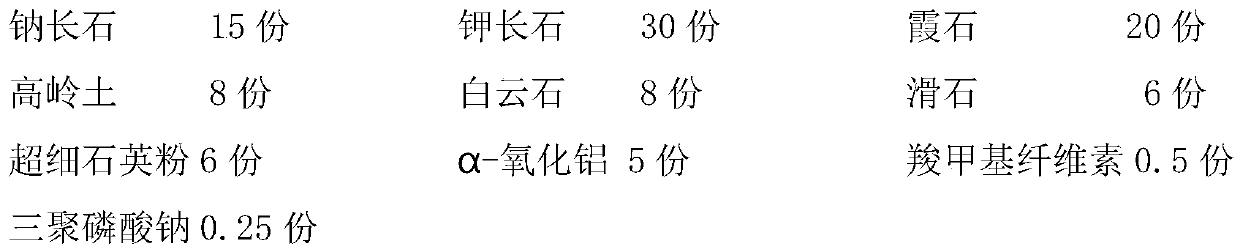

Embodiment 1

[0037] The basic technological process is: green body pressing → surface glaze application → inkjet printing → anti-slip glaze spraying → firing → edge grinding → packaging.

[0038] The weight composition of the anti-skid glaze is: 15 parts of albite, 30 parts of potassium feldspar, 20 parts of nepheline, 8 parts of kaolin, 8 parts of dolomite, 8 parts of talc, 6 parts of ultrafine quartz powder, α-alumina 5 parts, carboxymethyl cellulose 0.5 parts, sodium tripolyphosphate 0.25 parts.

[0039] The particle diameter of the ultrafine quartz powder is 200-300nm, and the particle diameter of α-alumina is 100-200nm.

[0040] The glazing parameters of the anti-skid glaze are: specific gravity 1.21±0.01, glaze amount 130g / m 2 , Engel's viscosity 12 ~ 15s.

[0041] The weight composition of the surface glaze is: 3 parts of calcined zinc oxide, 15 parts of albite, 20 parts of potassium feldspar, 20 parts of nepheline, 8 parts of kaolin, 8 parts of calcined talc, 5 parts of calcined ...

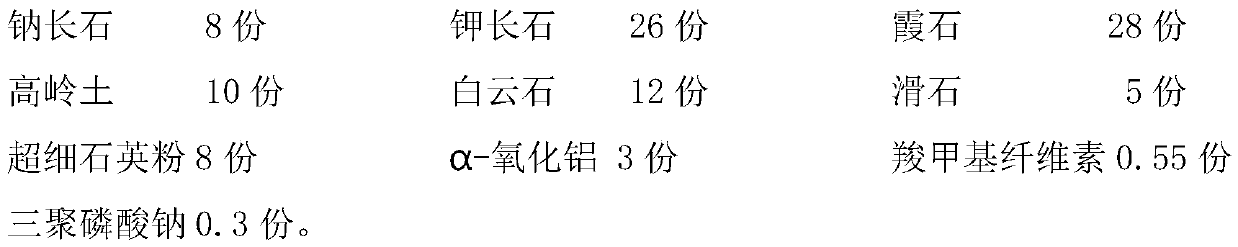

Embodiment 2

[0047] The basic technological process is: green body pressing → surface glaze application → inkjet printing → anti-slip glaze spraying → firing → edge grinding → packing.

[0048] The weight composition of the antiskid glaze is: 8 parts of albite, 26 parts of potassium feldspar, 28 parts of nepheline, 10 parts of kaolin, 12 parts of dolomite, 5 parts of talc, 8 parts of ultrafine quartz powder, α-alumina 3 parts, 0.55 parts of carboxymethyl cellulose, 0.3 parts of sodium tripolyphosphate.

[0049] The particle diameter of the ultrafine quartz powder is 100-200nm, and the particle diameter of α-alumina is 50-100nm.

[0050] The glazing parameters of the anti-skid glaze are: specific gravity 1.23±0.01, glaze amount 180g / m 2 , Engel's viscosity 12 ~ 15s.

[0051] The weight composition of the surface glaze is: 2 parts of calcined zinc oxide, 12 parts of albite, 18 parts of potassium feldspar, 20 parts of nepheline, 10 parts of kaolin, 6 parts of calcined talc, 8 parts of calci...

Embodiment 3

[0057] The basic technological process is: green body pressing → surface glaze application → inkjet printing → anti-slip glaze spraying → firing → edge grinding → packaging.

[0058] The weight composition of the anti-skid glaze is: 5 parts of albite, 20 parts of potassium feldspar, 32 parts of nepheline, 10 parts of kaolin, 5 parts of dolomite, 6 parts of talc, 14 parts of ultrafine quartz powder, α-alumina 8 parts, carboxymethyl cellulose 0.55 parts, sodium tripolyphosphate 0.3 parts.

[0059] The particle diameter of the ultrafine quartz powder is 100-200nm, and the particle diameter of α-alumina is 50-100nm.

[0060] The glazing parameters of the anti-skid glaze are: specific gravity 1.21±0.01, glaze amount 100g / m 2 , Engel's viscosity 12 ~ 15s.

[0061] The weight composition of the surface glaze is: 1 part of calcined zinc oxide, 10 parts of albite, 18 parts of potassium feldspar, 23 parts of nepheline, 10 parts of kaolin, 5 parts of calcined talc, 10 parts of calcined...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com