Preparation process of dry-particle tile with strong tile surface stereoscopic sensation

A technology of preparation technology and three-dimensional effect, which is applied in the field of dry granule brick preparation technology, can solve problems such as single three-dimensional effect, lower three-dimensional effect, and insufficient texture, and achieve a structure with strong three-dimensional effect, rich convex effect and brick surface stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

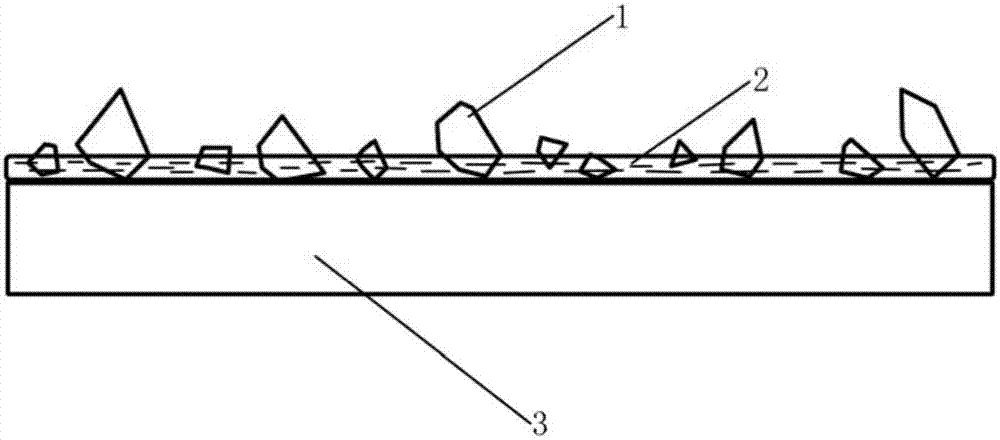

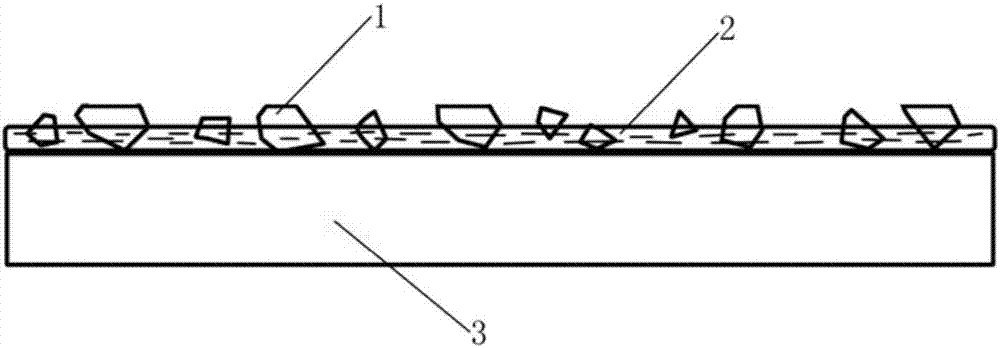

Image

Examples

Embodiment 1

[0031] 1. Preparation of ceramic glue:

[0032] (1) CMC is dissolved in ethylene glycol solvent, and CMC is dissolved completely, obtains CMC solution;

[0033] (2) Pour the CMC solution into water, stir evenly, and leave it to stand until it solidifies into a transparent jelly shape to obtain a CMC hydrogel, and observe with the naked eye that there are no CMC solid particles;

[0034] (3) Mix selected kaolin, water and CMC hydrogel according to the ratio of 7:2:100, and ball mill for 2 hours to form a uniform ceramic glue. The specific gravity of the ceramic glue is 1.05, and the flow rate is 35-35m / s, the measuring tool is LND-1 coated with 4 viscosity cups.

[0035] It should be noted that the dissolving ratio of CMC and ethylene glycol in step (1) is CMC: ethylene glycol=1:4, and the actual operation is based on the complete dissolution of CMC; the CMC solution and water in step (2) The mixing ratio is CMC solution: water = 1:50. In fact, the amount of water added can be...

Embodiment 2

[0060] 1. Preparation of ceramic glue:

[0061] (1) CMC is dissolved in ethylene glycol solvent, and CMC is dissolved completely, obtains CMC solution;

[0062] (2) Pour the CMC solution into water, stir evenly, and leave it to stand until it solidifies into a transparent jelly shape to obtain a CMC hydrogel, and observe with the naked eye that there are no CMC solid particles;

[0063] (3) Mix selected kaolin, water and CMC hydrogel at a ratio of 8:1.5:100, and ball mill for 2.5 hours to form a uniform ceramic glue. The specific gravity of the ceramic glue is 1.15, and the flow rate is 55m / s.

[0064] 2. Preparation of dry bricks:

[0065] (1) Adopt known ceramic powder to press to form the adobe of 600 specifications, wherein powder comprises following chemical composition according to mass percentage:

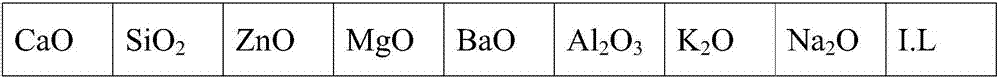

[0066] CaO

[0067] And dry the adobe with hot air at 150°C for 30 minutes to obtain a dry adobe with a moisture content of <0.5%;

[0068] (2) Mix high-tempera...

Embodiment 3

[0077] 1. Preparation of ceramic glue:

[0078] (1) CMC is dissolved in ethylene glycol solvent, and CMC is dissolved completely, obtains CMC solution,

[0079] (2) Pour the CMC solution into water, stir evenly, and leave it to stand until it solidifies into a transparent jelly shape to obtain a CMC hydrogel, and observe with the naked eye that there are no CMC solid particles;

[0080] (3) Mix selected kaolin, water and CMC hydrogel at a ratio of 8:1.5:100, and ball mill for 2 hours to form a uniform ceramic glue. The specific gravity of the ceramic glue is 1.5, and the flow rate is 40m / s.

[0081] 2. Preparation of dry bricks:

[0082] (1) Adopt known ceramic powder to press to form the adobe of 600 specifications, wherein powder comprises following chemical composition according to mass percentage:

[0083] CaO

[0084] And dry the adobe with hot air at 150°C for 30 minutes to obtain a dry adobe with a moisture content of <0.5%;

[0085] (2) Mix high-temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com