Environment-friendly paste discharge agent for textile printing and preparation method thereof

一种环保型、拔染剂的技术,应用在纺织品和造纸、染色法、化学仪器和方法等方向,能够解决涂料印花削弱、稳定性不高、限制推广和应用等问题,达到改善分散性和颗粒细度、提高研磨效率、解决溶解度低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

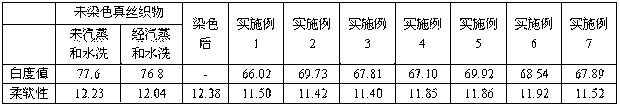

Examples

Embodiment 1

[0032] Adopt the raw material composition paste dye discharge agent of following parts by weight:

[0033] Decamethylcyclopentasiloxane 30 parts

[0034] Thiourea dioxide 70 parts

[0035] oleic acid 2 parts

[0036] Glycerin 6 parts

[0037] And prepare as follows:

[0038] 1) Under normal temperature conditions, put 30 parts of decamethylcyclopentasiloxane as a dispersion medium in a ball mill;

[0039] 2) Add 6 parts of glycerin and 2 parts of oleic acid at the same time, stir to make them evenly dispersed;

[0040] 3) After adding 70 parts of thiourea dioxide and stirring, carry out blending and grinding at a speed of 600 rpm for 1 hour, and undergo mechanical grinding and physical modification until it is made into a white paste containing fine particles of thiourea dioxide.

Embodiment 2

[0042] Adopt the raw material composition paste dye discharge agent of following parts by weight:

[0043] Decamethylcyclopentasiloxane 40 parts

[0044] Thiourea dioxide 60 parts

[0045] Polyoxyethylene sorbitan fatty acid ester (Tween20) 1 part

[0046] Glycerin 5 parts

[0047] And prepare as follows:

[0048] 1) Under normal temperature conditions, place 40 parts of decamethylcyclopentasiloxane as a dispersion medium in a ball mill;

[0049]2) Add 5 parts of glycerin and 1 part of polyoxyethylene sorbitan fatty acid ester (Tween20) at the same time, stir to make them evenly dispersed;

[0050] 3) After adding 60 parts of thiourea dioxide and stirring, carry out blending and grinding at a speed of 500 rpm for 2 hours, and undergo mechanical grinding and physical modification until it is made into a white paste containing fine particles of thiourea dioxide.

Embodiment 3

[0052] Adopt the raw material composition paste dye discharge agent of following parts by weight:

[0053] Decamethylcyclopentasiloxane 50 parts

[0054] Thiourea dioxide 50 parts

[0055] Simethicone 100cs 1.5 parts

[0056] 4 parts glycerin

[0057] And prepare as follows:

[0058] 1) Under normal temperature conditions, put 50 parts of decamethylcyclopentasiloxane as a dispersion medium in a ball mill;

[0059] 2) Add 4 parts of glycerin and 1.5 parts of simethicone 100cs at the same time, stir to make them evenly dispersed;

[0060] 3) After adding 50 parts of thiourea dioxide and stirring, carry out blending and grinding at a speed of 400 rpm for 3 hours, mechanical grinding and physical modification until it is made into a white paste containing fine particles of thiourea dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com