Modified-chitosan-containing anti-ultraviolet finishing agent for cotton fabric and anti-ultraviolet cotton fabric obtained by aid of anti-ultraviolet finishing agent

A finishing agent and cotton fabric technology, which is applied in fiber treatment, plant fiber, textiles and papermaking, etc., can solve the problems of cumbersome preparation of nano-scale composite dispersion finishing liquid, complex composition of composite nano-composites, and high requirements for the stability of the dispersion system. Achieve the effects of maintaining human affinity, easy preparation, and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

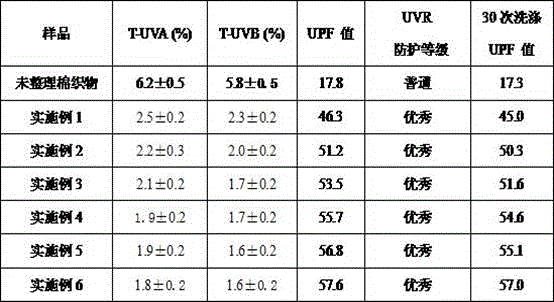

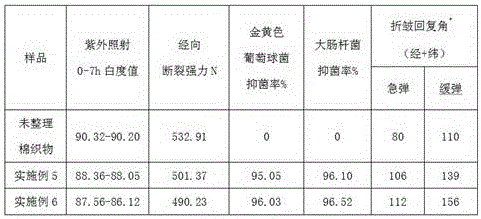

Examples

Embodiment 1

[0017] This finishing agent is a homogeneous mixture of 3,4,5-trimethoxybenzoyl chitosan, crosslinking agent, penetrating agent and acetic acid or lactic acid solution, measured per 100 ml of final finishing agent solution, 3,4 , The amount of 5-trimethoxybenzoyl chitosan is 2.0g, dissolved in acetic acid or lactic acid solution containing 2 grams of acetic acid or lactic acid per 100 ml of finishing agent solution, adding 0.5 g of crosslinking agent citric acid, penetrating agent JFC 0.05g and citric acid reaction catalyst sodium hypophosphite 0.5g were prepared to obtain 100ml finishing agent solution;

[0018] Finished cotton fabrics are prepared by the following finishing process: immerse an appropriate amount of cotton fabrics in the above finishing agent solution at room temperature for 0.5 to 1 minute, after two dips and two rollings, the liquid retention rate is 90%, pre-baked at 70°C for 8 minutes, 150 Bake at ℃ for 2 minutes, wash in warm water at 40 ℃, wash in cold ...

Embodiment 2

[0020] This finishing agent is a homogeneous mixture of 3,4,5-trimethoxybenzoyl chitosan, crosslinking agent, penetrating agent and acetic acid or lactic acid solution, measured per 100 ml of final finishing agent solution, 3,4 , The amount of 5-trimethoxybenzoyl chitosan is 2.5g, dissolved in acetic acid or lactic acid solution containing 2 grams of acetic acid or lactic acid per 100 ml of finishing agent solution, and 0.5 g of cross-linking agent butane tetracarboxylic acid is added 1. Penetrant JFC 0.05g, butane tetracarboxylic acid reaction catalyst sodium hypophosphite 0.5g, prepare 100ml finishing agent solution;

[0021] Finished cotton fabrics are prepared by the following finishing process: soak an appropriate amount of cotton fabrics in the above finishing agent solution at room temperature for 0.5-1min, double dipping and rolling, the liquid retention rate is 90%, pre-baking at 85°C for 5 minutes, and baking at 130°C 3min, wash in warm water at 40°C, wash in cold wa...

Embodiment 3

[0023] This finishing agent is a homogeneous mixture of 3,4,5-trimethoxybenzoyl chitosan, crosslinking agent, penetrating agent and acetic acid or lactic acid solution, measured per 100 ml of final finishing agent solution, 3,4 , The amount of 5-trimethoxybenzoyl chitosan is 3.0g, dissolved in acetic acid or lactic acid solution containing 2 grams of acetic acid or lactic acid per 100 ml of finishing agent solution, adding 0.5 g of crosslinking agent citric acid, penetrating agent Pingpingjia O 0.05g, citric acid reaction catalyst sodium hypophosphite 0.5g, prepare 100ml finishing agent solution;

[0024] Finished cotton fabrics are prepared by the following finishing process: soak an appropriate amount of cotton fabrics in the above finishing agent solution at room temperature for 0.5-1min, double dipping and rolling, the liquid retention rate is 90%, pre-baking at 85°C for 5 minutes, and baking at 150°C 2min, wash in warm water at 40°C, wash in cold water, and dry to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com