Composition dispersion liquid used for water repellent treatment

A technology of water repellent treatment and composition, which is applied in the direction of fiber treatment, liquid-repellent fibers, improved hand-feeling fibers, etc., and can solve the problems of fabrics such as astringent hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

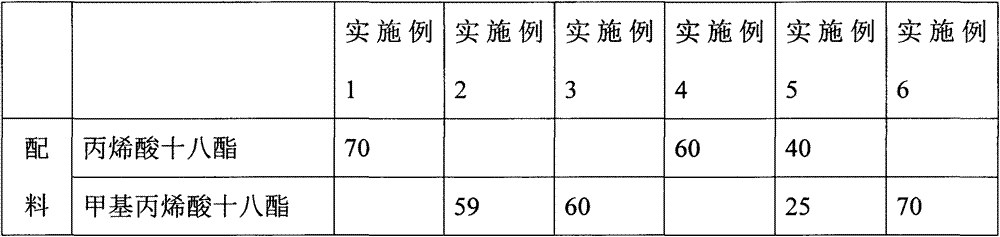

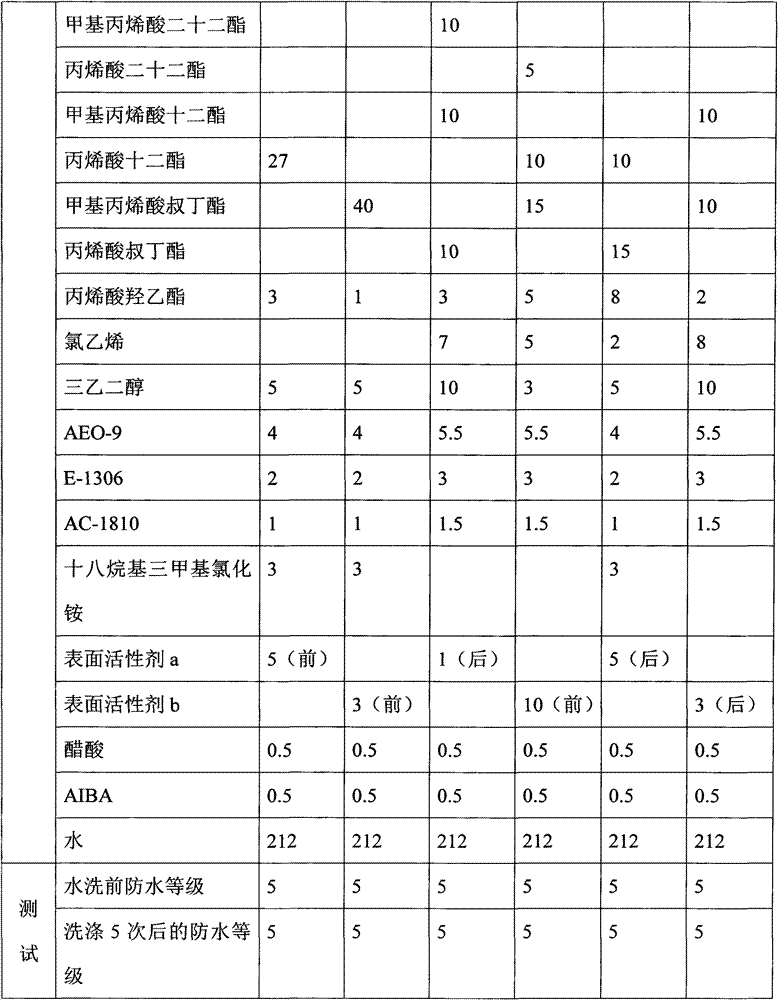

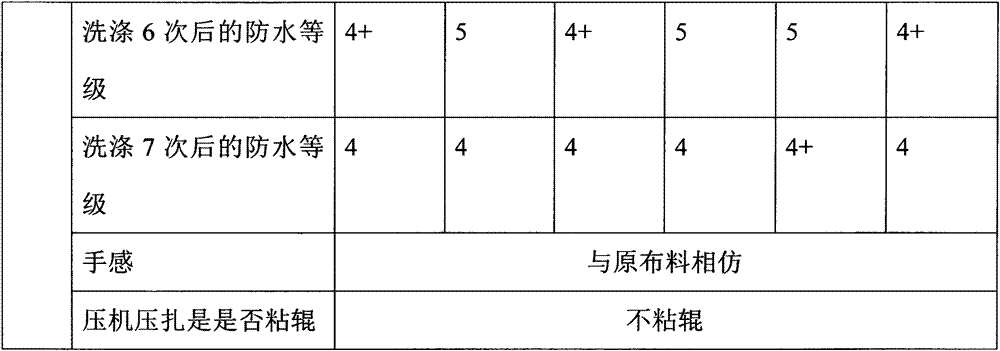

Embodiment 1

[0062] 70 parts by mass of stearyl acrylate, 27 parts by mass of dodecyl acrylate, 3 parts by mass of hydroxyethyl acrylate, 5 parts by mass of triethylene glycol, 4 parts by mass of AEO-9, 2 parts by mass of E-1306, 1 Add parts by mass of AC-1810, 3 parts by mass of octadecyltrimethylammonium chloride, 5 parts by mass of surfactant a, 0.5 parts by mass of acetic acid and 210 parts by mass of water into the reactor, and heat up to 40-45°C for pre-emulsification . Then homogenize under high pressure for 30 minutes at a pressure of 30 MPa, transfer the homogenized solution to the reaction kettle, and start stirring. 0.5 parts by mass of the initiator AIBA was dissolved in 2 parts by mass of water to form a homogeneous solution, which was added to the reaction kettle. Then the temperature was raised to 70-75° C. for 5 hours to obtain the dispersion liquid of the composition for water repellent treatment of the present invention.

Embodiment 2

[0064] Using the same process as in Example 1, the specific formula is shown in Table 2.

Embodiment 3

[0066] 60 parts by mass of stearyl methacrylate, 10 parts by mass of behenyl methacrylate, 10 parts by mass of dodecyl methacrylate, 10 parts by mass of tert-butyl methacrylate, 3 parts by mass of hydroxyethyl acrylate , 10 parts by mass of triethylene glycol, 5.5 parts by mass of AEO-9, 3 parts by mass of E-1306, 1.5 parts by mass of AC-1810, 0.5 parts by mass of acetic acid and 210 parts by mass of water were added to the reaction kettle, and the temperature was raised to 40-45°C. pre-emulsified. Then homogenize under high pressure for 30 minutes at a pressure of 30 MPa, transfer the homogenized solution to the reaction kettle, and start stirring. 0.5 parts by mass of the initiator AIBA was dissolved in 2 parts by mass of water to form a homogeneous solution, which was added to the reaction kettle. Then the temperature was raised to 70° C. to start the timing reaction, and 7 parts by mass of vinyl chloride was introduced within 1 hour after the reaction started. Continue t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com