Dyeing method of acid dyes for cotton textiles

An acid dye, cotton textile technology, applied in the field of textile printing and dyeing, can solve the problems of fiber moisture absorption, air permeability and hand feeling, and achieve the effect of improving the dyeing rate, strong operability and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

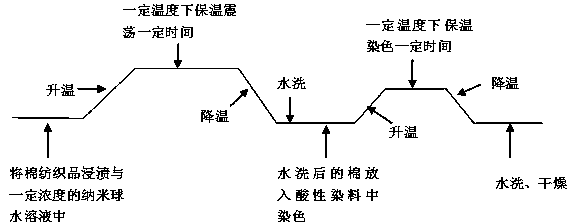

Method used

Image

Examples

Embodiment 1

[0020] Configure a solution of cationic polystyrene nanospheres with a weight of 0.1% for pure cotton knitted fabrics, and place the cotton fabrics in an impregnation solution with a liquor ratio of 1:50, a pH of 7.2, and a sodium chloride concentration of 0mol / L at a temperature of 30 At ℃, soak for 1min, 2min, 5min, 10min, 15min, 20min, 25min, 30min, 40min, 50min, 60min, 70min, 80min, 90min, 100min, 110min, 120min. After the treatment, take out the sample and wash it with water; For Acid Yellow 1 dye with a weight of 0.35% of the fabric, dye for 30 minutes at a bath ratio of 1:30, dye bath pH 6.0, sodium chloride concentration of 0 g / L, and a dyeing temperature of 25°C, and wash with water after dyeing Allow to dry at room temperature.

Embodiment 2

[0022] Configuration is respectively 0.01%-1.0% cationic polystyrene-methyl acrylate nanosphere solution to the weight of pure cotton woven fabric, and the cotton fabric is 1:50 in bath ratio, and pH is 7.2, and sodium chloride concentration is 0mol / L In the soaking solution, at a temperature of 30°C, soak for 120 minutes. After the treatment, take out the sample and wash it with water; then use acid orange 7 with a weight of 0.35% of the fabric, at a liquor ratio of 1:30, and a pH of 6.0 in the dyeing bath. , the concentration of sodium chloride is 0g / L, and the dyeing temperature is 25°C, dyeing for 30min, after dyeing, wash with water and dry at room temperature.

[0023] The color depth of the dyed fabric is measured by the American X-Rite computer color measuring and matching instrument, as shown in Table 1.

Embodiment 3

[0025] Configure a cationic polystyrene-butyl acrylate-methacryloyloxyethyltrimethylammonium chloride nanosphere solution with a weight of 0.1% for cotton / sky bamboo fiber blended fabrics, and make the fabric in a bath ratio of 1:50, pH 7.2, the concentration of sodium chloride is 0mol / L, 0.0001mol / L, 0.001mol / L, 0.01mol / L, 0.1mol / L impregnation solution, at a temperature of 30 ℃, immersion treatment for 120min, the treatment is completed Finally, take the sample out and wash it with water; then use acid red 3 with a weight of 0.35% to the fabric, under the conditions of a bath ratio of 1:30, a pH of the dyeing bath of 6.0, a concentration of sodium chloride of 0g / L, and a dyeing temperature of 25°C. , dyed for 30min, washed with water and dried at room temperature after dyeing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com