Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Guaranteed arc" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

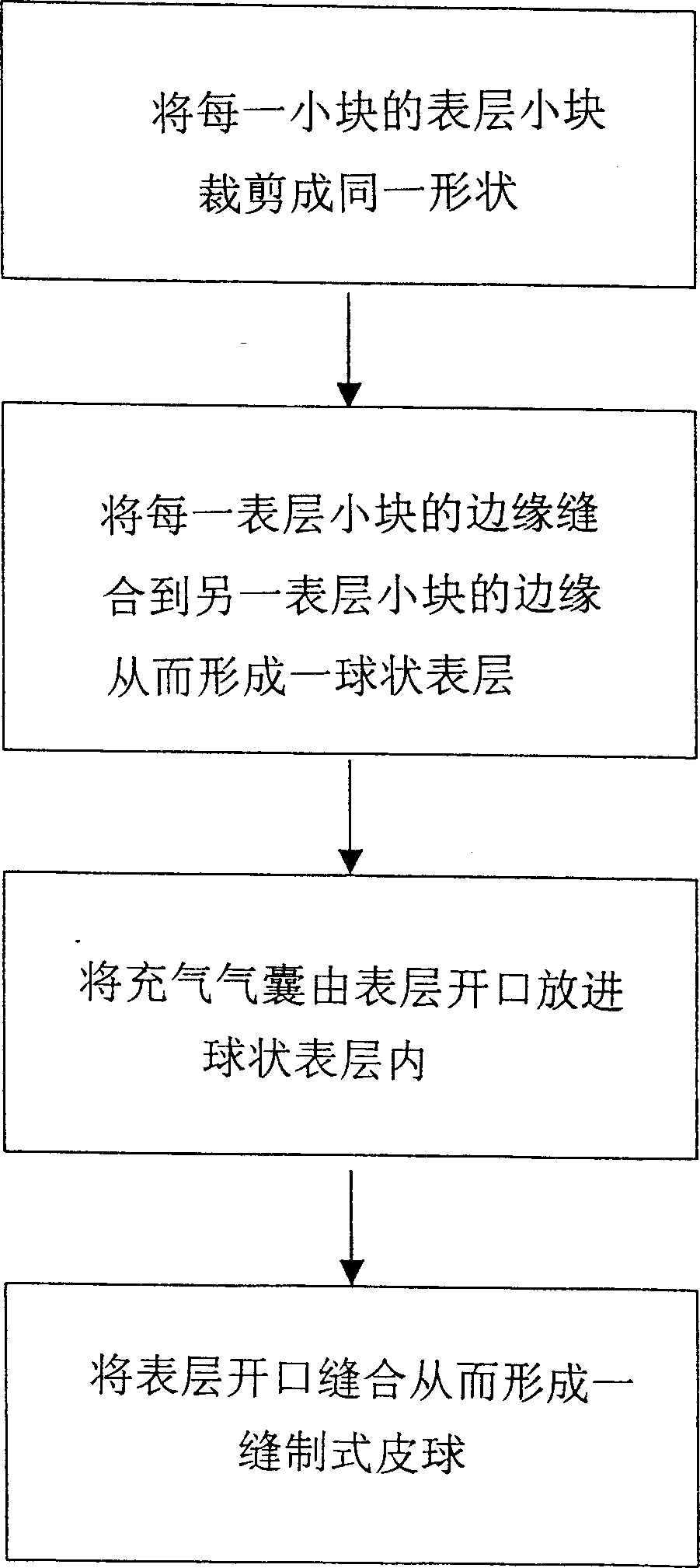

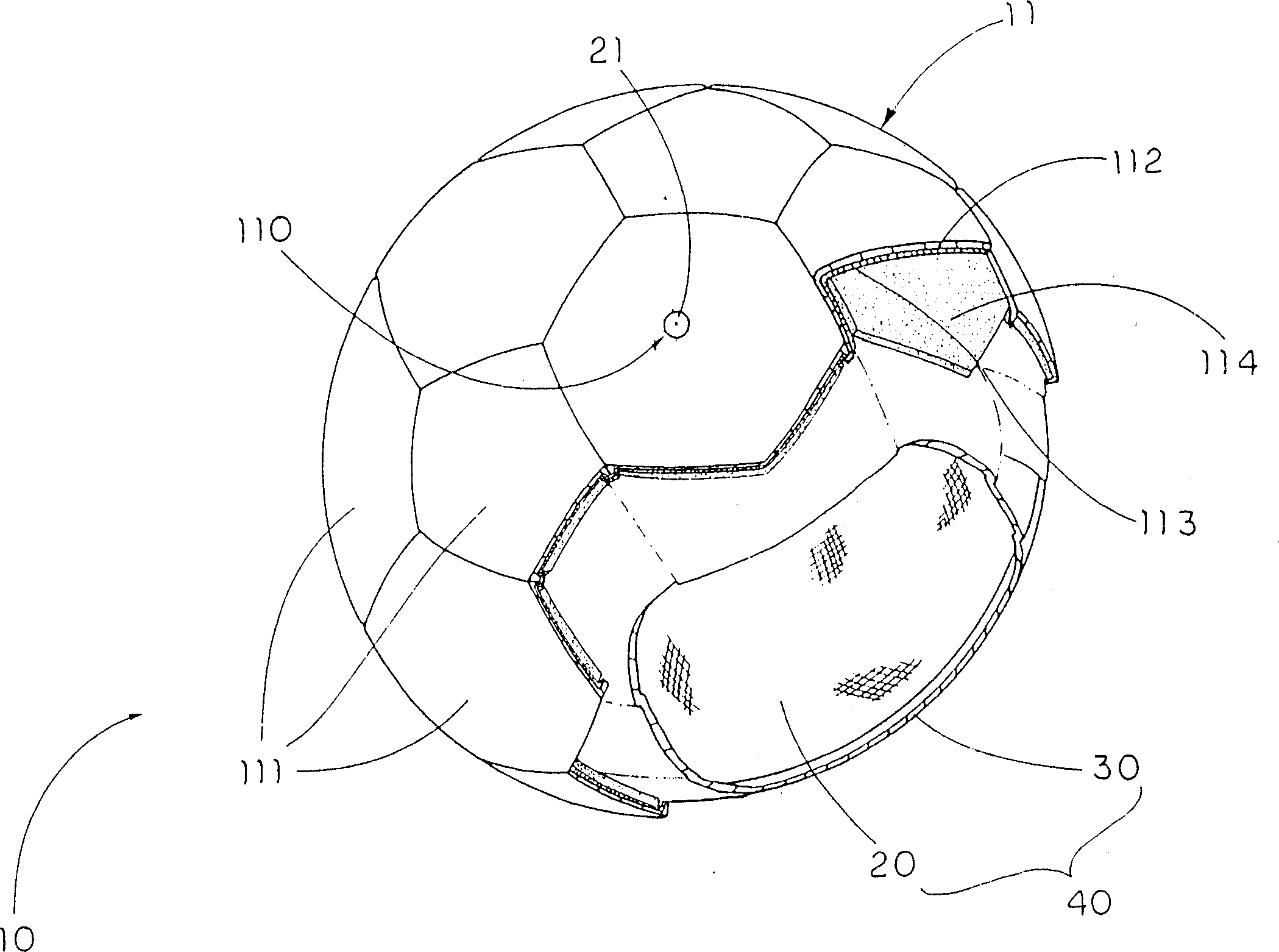

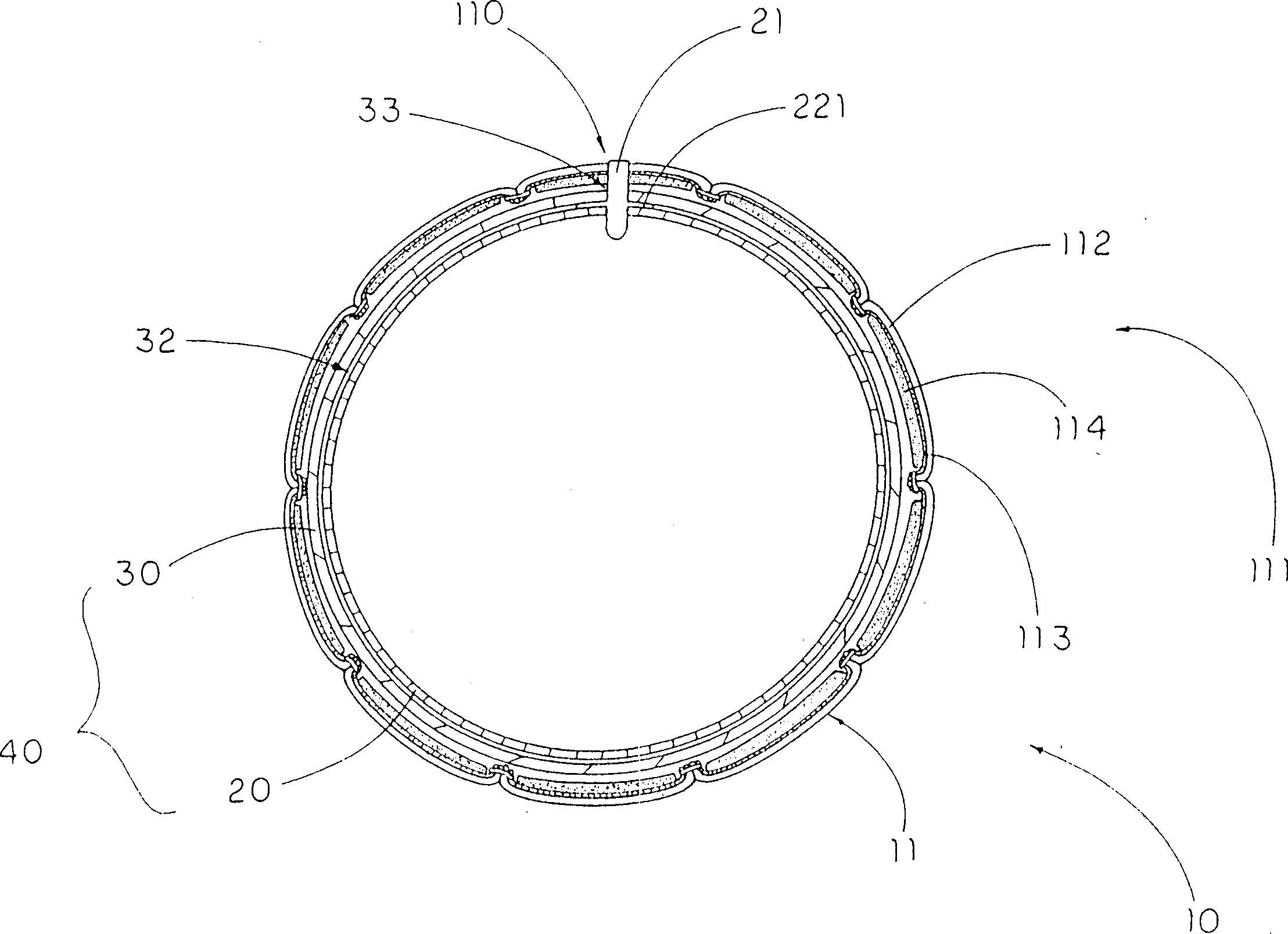

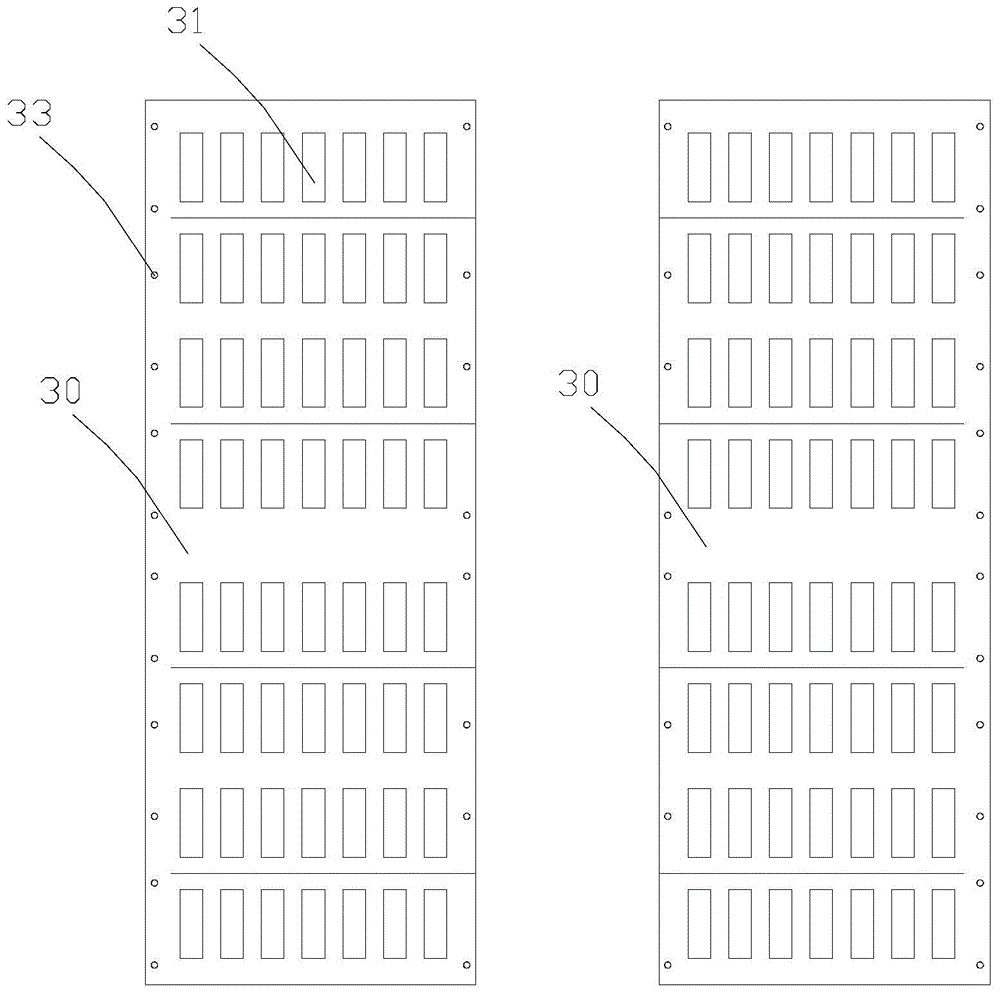

Ball bag built-in sewn ball

The present invention relates to a sewed ball with built-in ball bag. Said ball is formed from a ball surface layer and a ball bag internal bladder placed in the interior of ball surface layer. Said ball bag internal bladder includes an inflatable air bag with an inflatable hole, a built-in ball bag which has a receiving space for receiving said inflatable air bag and a movable air hole from which the inflatable hole can be passed through and extended outward. Said ball surface layer can be used for receiving said ball bag internal bladder, after said ball bag internal bladder is inflated, said ball surface layer can be expanded and formed into a ball with a certain radian and flexibility. Said invention also provides its sewing method.

Owner:欧陈丽卿

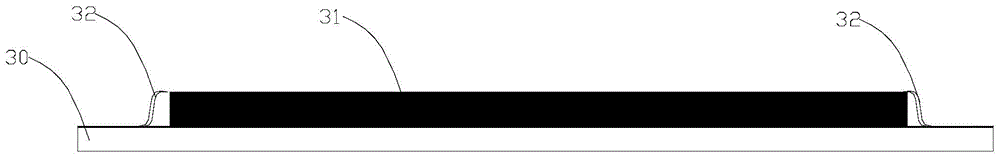

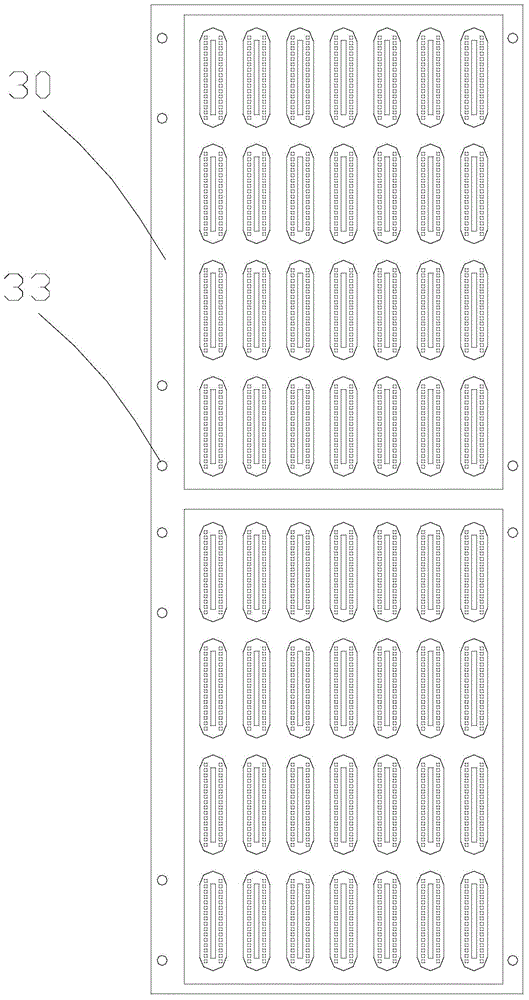

Packaging equipment possessing arc edge fingerprint identification chip and packaging and cutting method

ActiveCN104916549AGuaranteed sizeGuaranteed thicknessSemiconductor/solid-state device manufacturingHot runnerInjection port

The invention provides packaging equipment possessing an arc edge fingerprint identification chip. The equipment comprises a pair of dies. The dies are divided into an upper die and a lower die. A slot position which can accommodate a PCB is arranged in the lower die. The PCB is an entire PCB on which multiple groups of fingerprint identification devices are welded. The upper die is provided with circular or oval or flat oval cavities which can accommodate the identification devices, have a consistent shape with the fingerprint chip and possess arc edges. The cavity and the fingerprint identification devices on the PCB are correspondingly arranged. The cavities are connected to a packaging material injection port through a hot runner. The hot runner is divided into a main runner and a branch runner. The main runner is connected to the injection port. The branch runner is connected to side edges of the cavities. A distance between an inner surface of the upper die and a slot position bottom surface is equal to a thickness of the PCB. A depth of the cavities is greater than a height from the PCB surface to an upper surface of the identification devices.

Owner:深圳市东方聚成科技有限公司

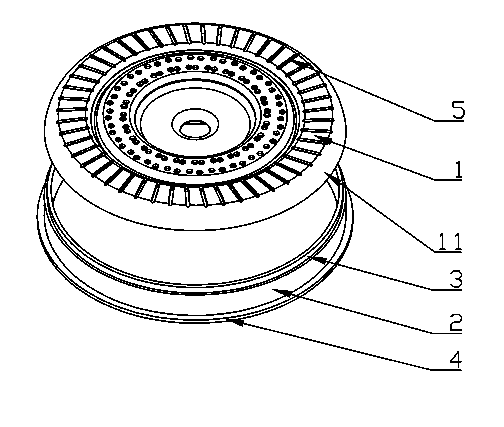

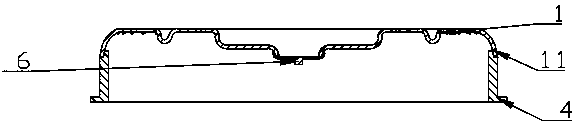

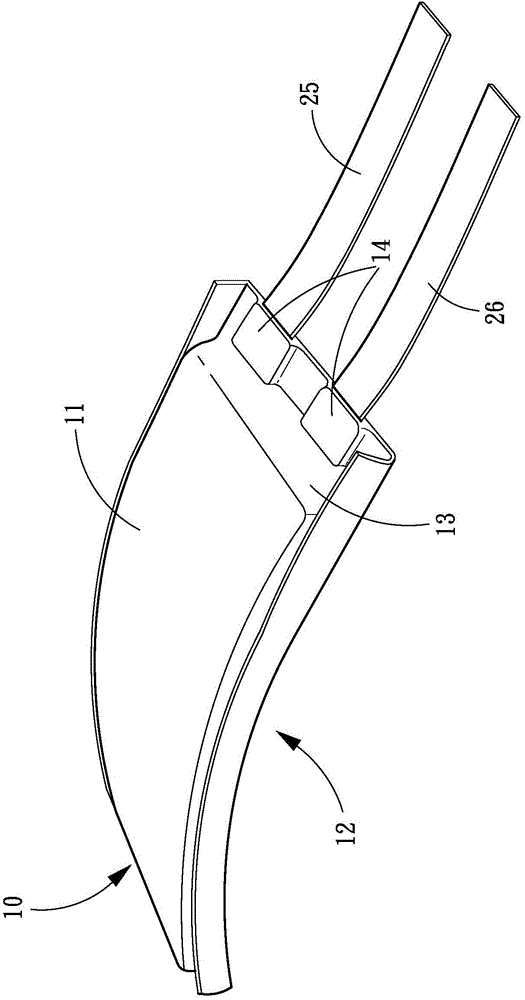

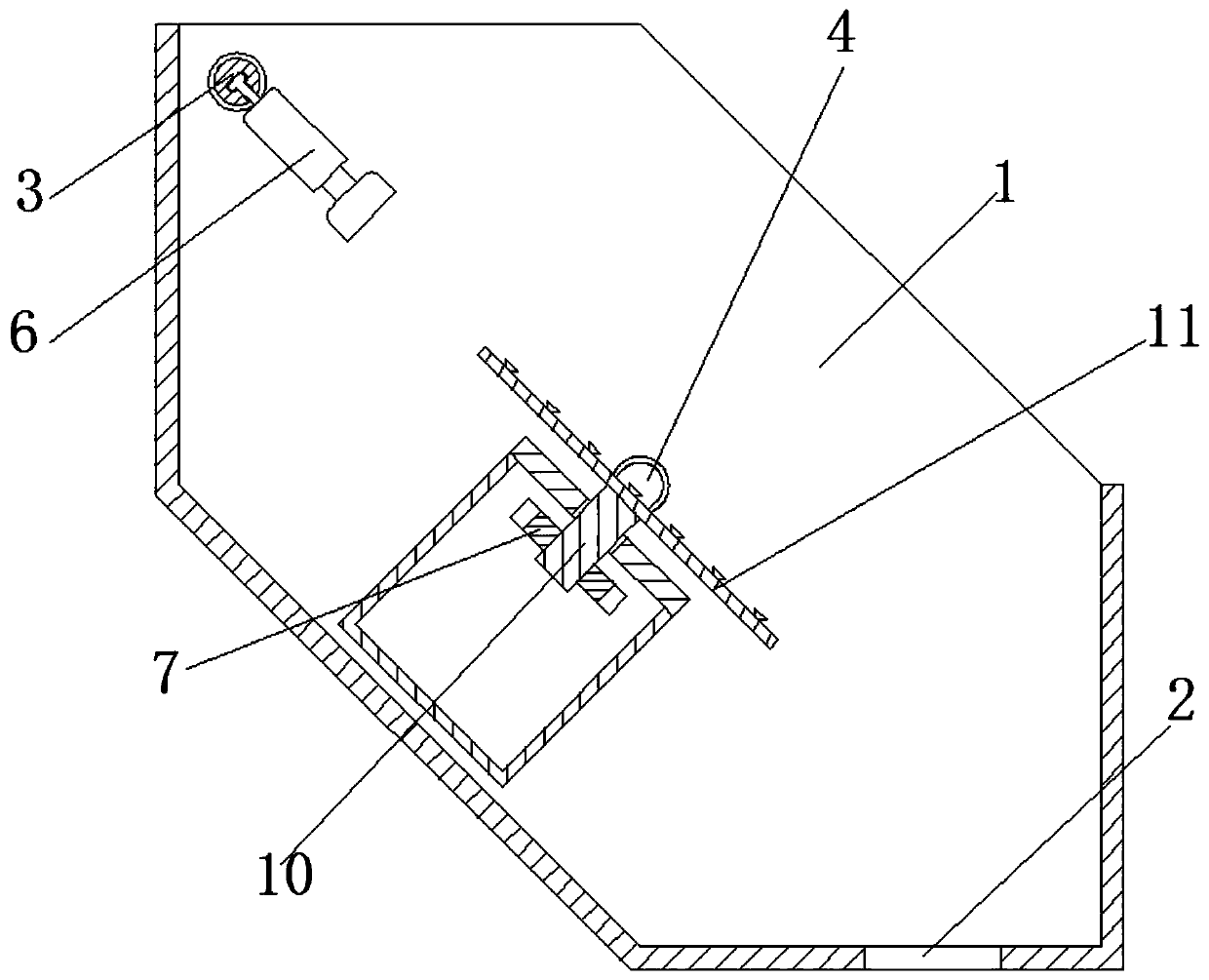

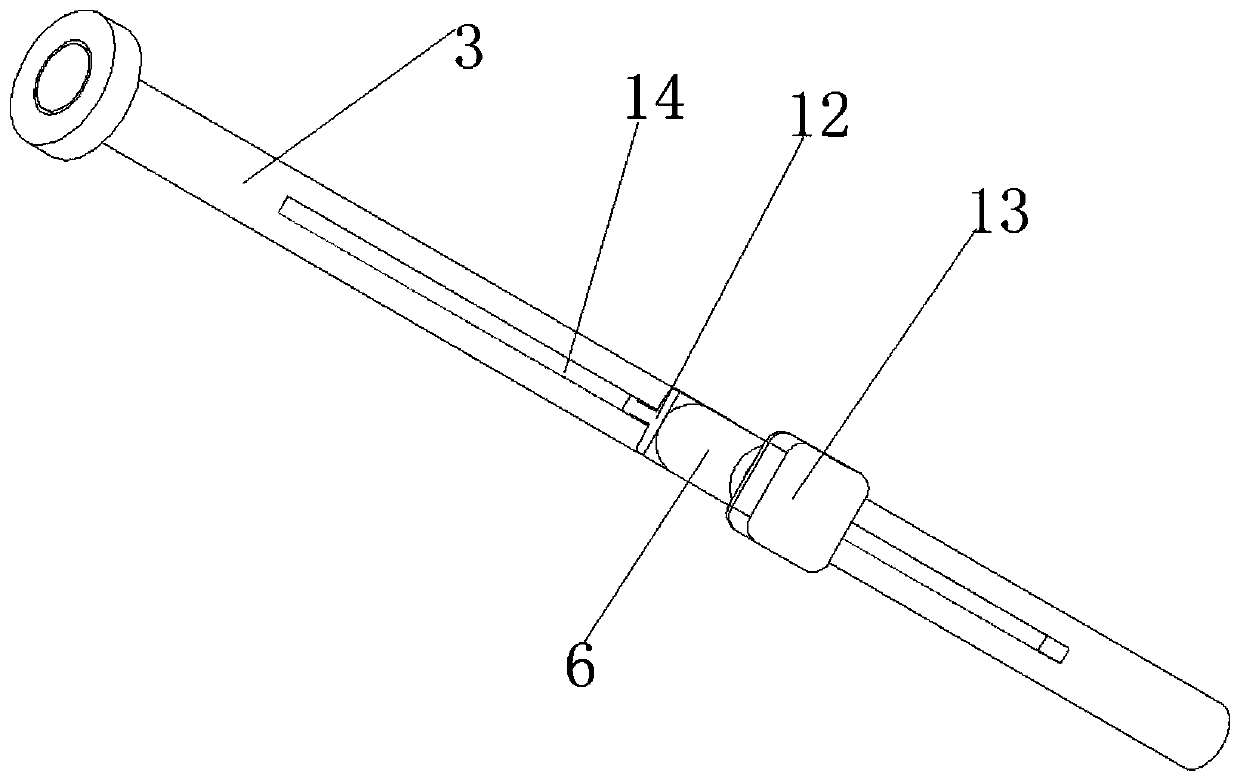

Shaver, shaver foil and manufacturing process of shaver foil

ActiveCN103753608AImprove uniformityGuaranteed StrengthMetal working apparatusRazor stropMetal sheet

Owner:WENZHOU RUNWE ELECTRICAL APPLIANCE

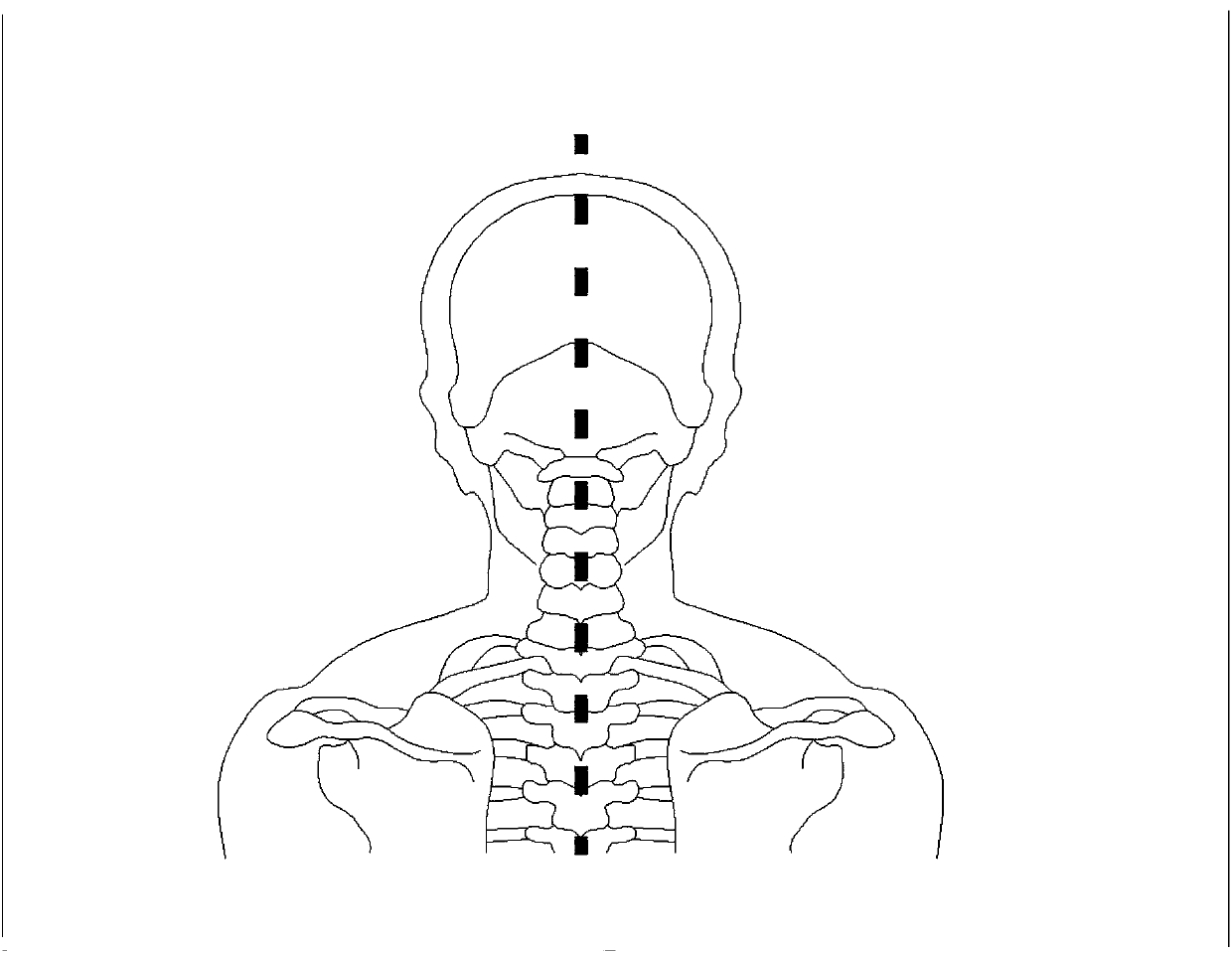

Pillow and making method

PendingCN107752620AImprove comfortStable and not easy to deformPillowsHuman bodyPhysical medicine and rehabilitation

The invention discloses a pillow suitable for physiological size of the human body and a making method. For achieving the purpose of making a pillow suitable for corresponding specific individual according to the difference of a head shape, a neck shape and a shoulder shape of the human body, customized design and pillow production are achieved. In addition, the pillow is divided into a hard baselayer special for shaping and a soft cushion layer special for improving the comfort level, wherein the base layer is located under the cushion layer, the base layer can be produced in a modular mode,splicing and adjustment are performed according to the demand, the base layer can be also directly formed through 3d printing, and the requirements for all dimensions including arc-alignment degree,perpendicularity and horizontal width of the pillow can be met in the two ways.

Owner:劳海睿

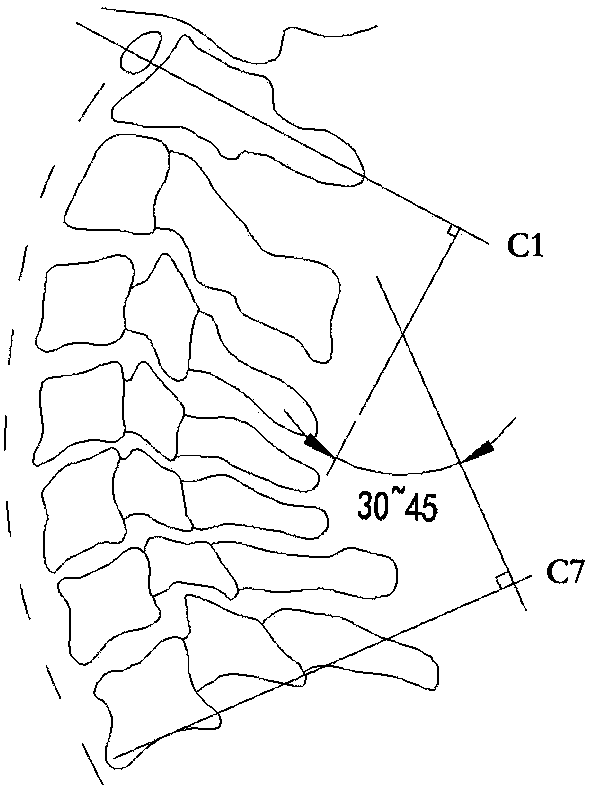

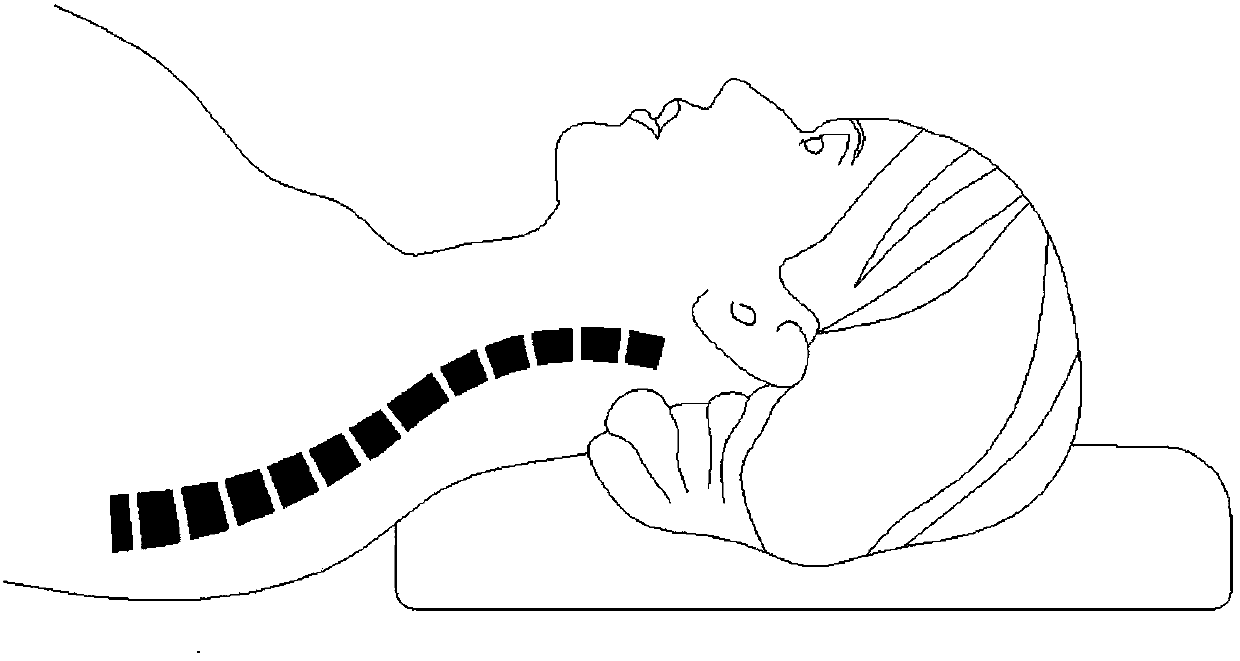

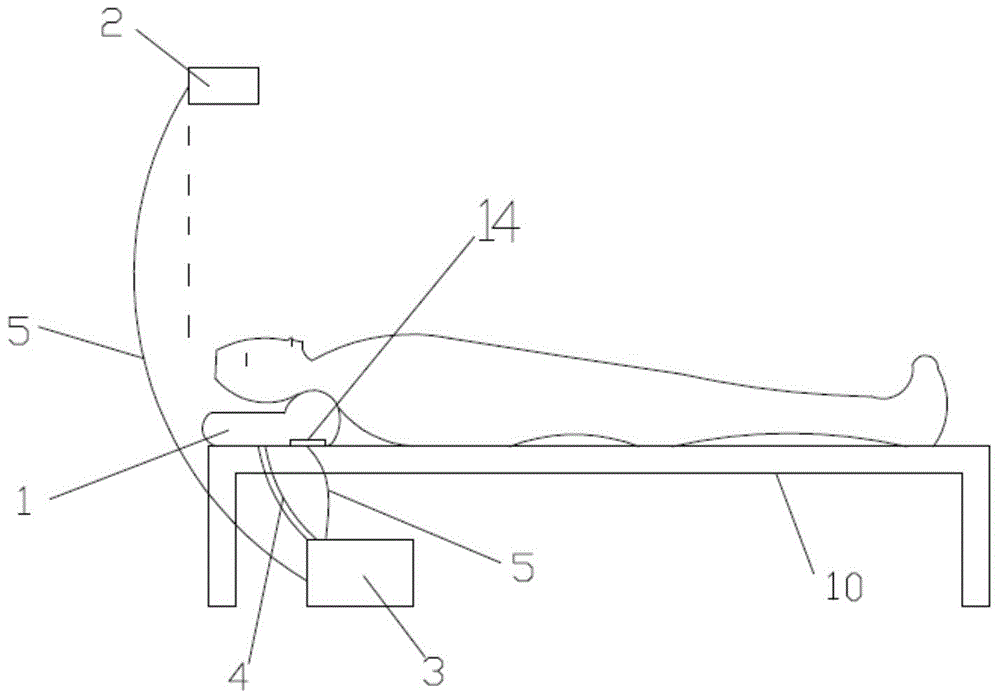

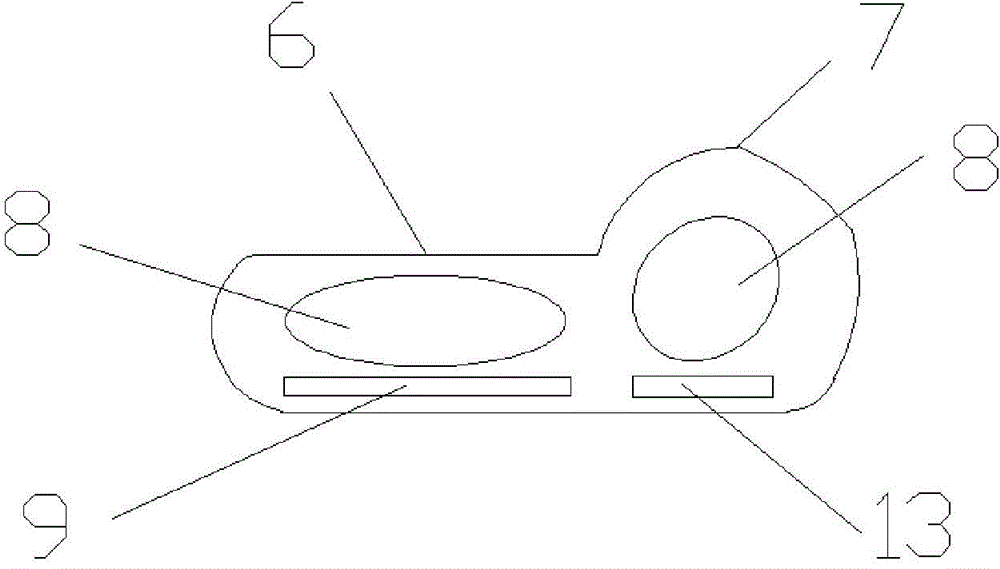

Sleep device with function of automatic cervical vertebrae balance

InactiveCN104305792AGuaranteed arcHelp sleep qualityPillowsDwelling equipmentEmergency medicineCervical vertebral body

The invention relates to the field of sleep healthcare articles and discloses a sleep device with a function of automatic cervical vertebrae balance. The sleep device comprises a balancer, a sensor and a central processing unit. The central processing unit comprises a central information processor and an air pressure processor, the central information processor is connected with the air pressure processor through an information wire, and the sensor is used for collecting information of a sleeper and feeding back timely. The air pressure processor comprises a silent motor, an air pressure venturi and a 'valve' system, the silent motor is connected with the balancer through the air pressure venturi, and the 'valve' system is arranged at an access port of the air pressure venturi. The sleep device is capable of detecting sleeping postures of the sleeper by the aid of the sensor and feeding back to the central information process, the balancer is adjusted by the air pressure processor to enable the sleeper to be in a posture that the head and the cervical vertebrae are most balanced, under the lowest pressure, lowest in torsion and best accordant to human physiological curvature for a long time, the relation between the head and the cervical vertebrae can be kept beneficial to sleeping so as to realize deeper and longer sleep.

Owner:何世华

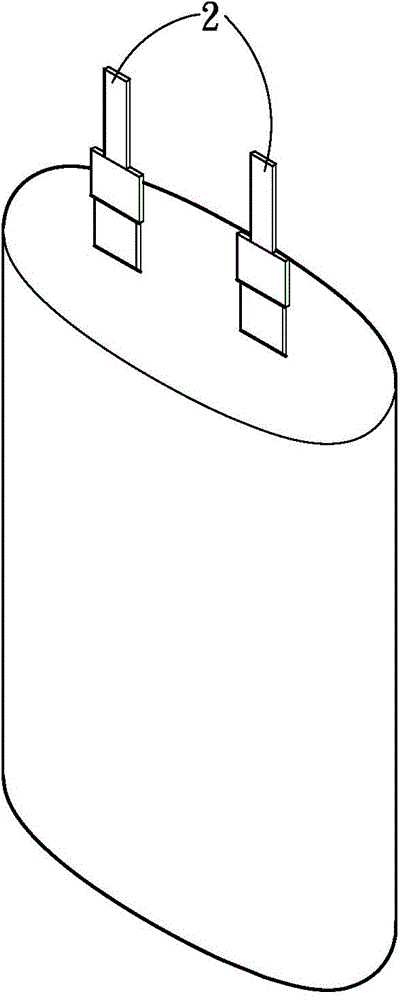

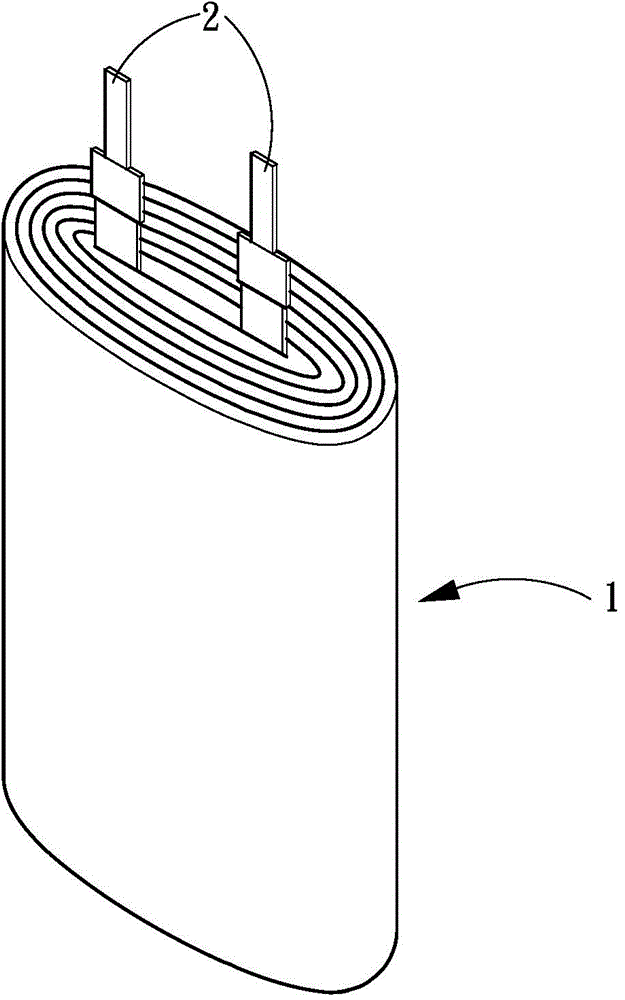

Curved battery and manufacturing method thereof

InactiveCN105098222AAvoid damageWell formedFinal product manufactureCell electrodesIsolation layerEngineering

A curved battery includes a protection member, a battery unit and a conductive material. The battery unit is disposed in the protection member and has a shape corresponding to the protection member. The battery unit includes a first electrode layer, a second electrode layer, a first conductive handle, a second conductive handle, a first isolation layer and a second isolation layer. The first conductive handle and the second conductive handle point to directions perpendicular to an axial direction of the battery unit and extend out of the protection member via two openings of the protection member. Thus, the curved battery is allowed with a large curvature that is less likely to cause damages of the battery unit.

Owner:SYNERGY SCIENTECH CORP

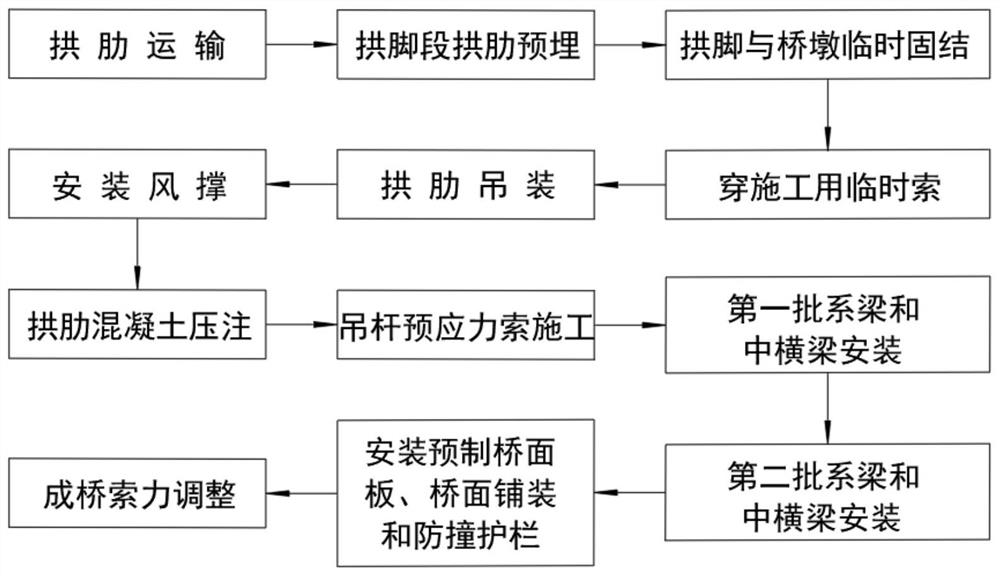

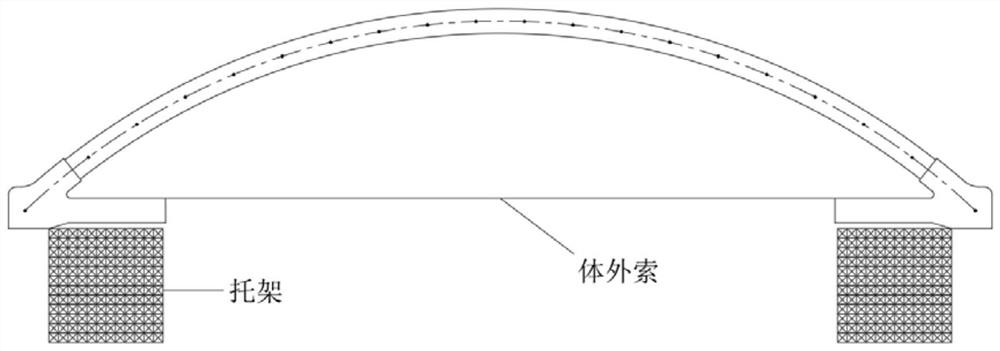

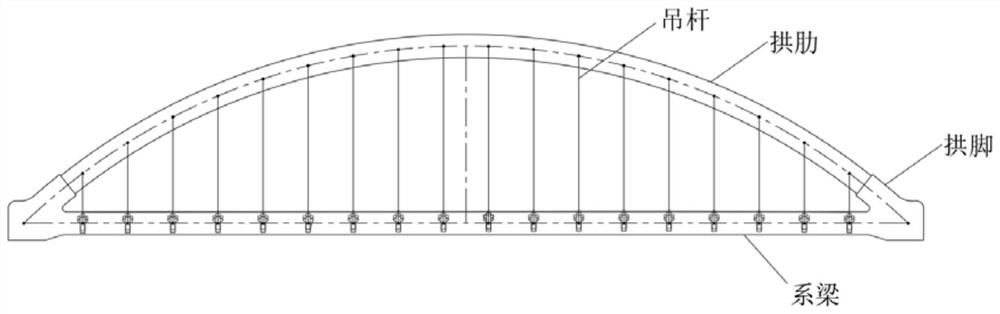

Arch-first and beam-second construction method for bracket-free tied arch

InactiveCN112554067AReduce labor intensityGuaranteed to be unbiasedBridge erection/assemblyPre stressArchitectural engineering

The invention discloses an arch-first and beam-second construction method for a bracket-free tied arch, and belongs to the technical field of building construction. The method comprises the followingsteps: 1, transporting arch ribs; 2, pre-burying arch ribs of arch foot sections; 3, temporarily solidifying the arch feet and the bridge piers; 4, penetrating a temporary cable for construction: pulling the temporary cable to the cross beam at the mounting end, fixing the temporary cable through an anchorage device, and circularly constructing and penetrating the cable until the end; 5, hoistingarch ribs; 6, mounting a wind brace; 7, performing pressure injection on arch rib concrete; 8, performing suspender prestressed cable construction; 9, mounting a tie beam and a middle cross beam; 10,installing prefabricated bridge decks, bridge deck pavement and anti-collision guardrails; and 11, adjusting the cable force of the finished bridge suspender. By the adoption of the construction method, the construction period is shortened, and the labor intensity of workers is reduced; and the navigation requirement is guaranteed during construction, the balance of stress changes in arch structure construction is effectively guaranteed, the safety of bridge construction and later operation is guaranteed, the ecological environment is protected, and wide application and popularization value and reference significance are achieved.

Owner:浙江省建投交通基础建设集团有限公司

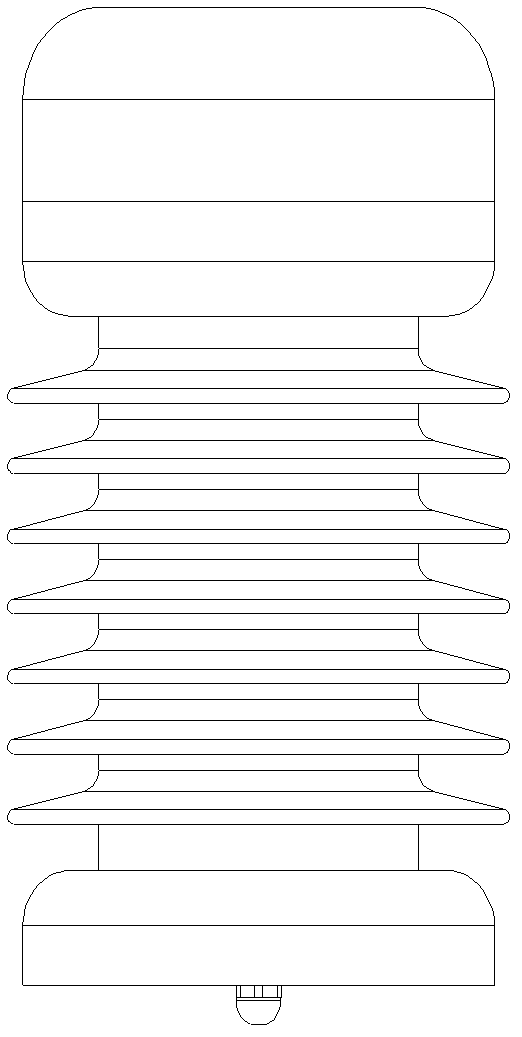

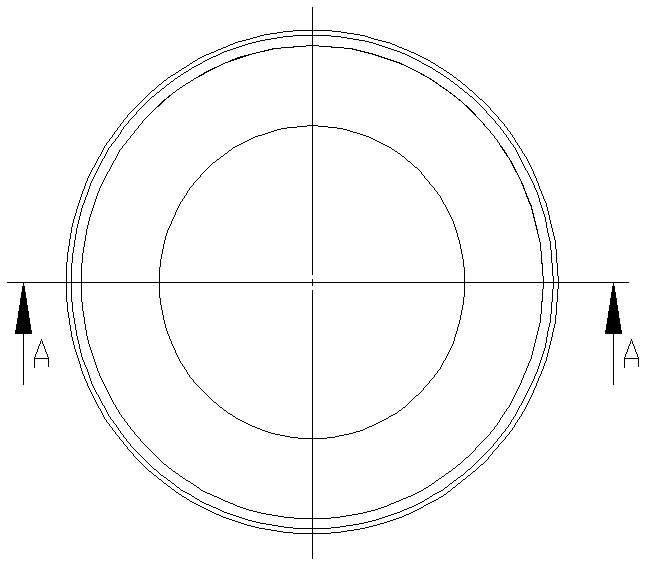

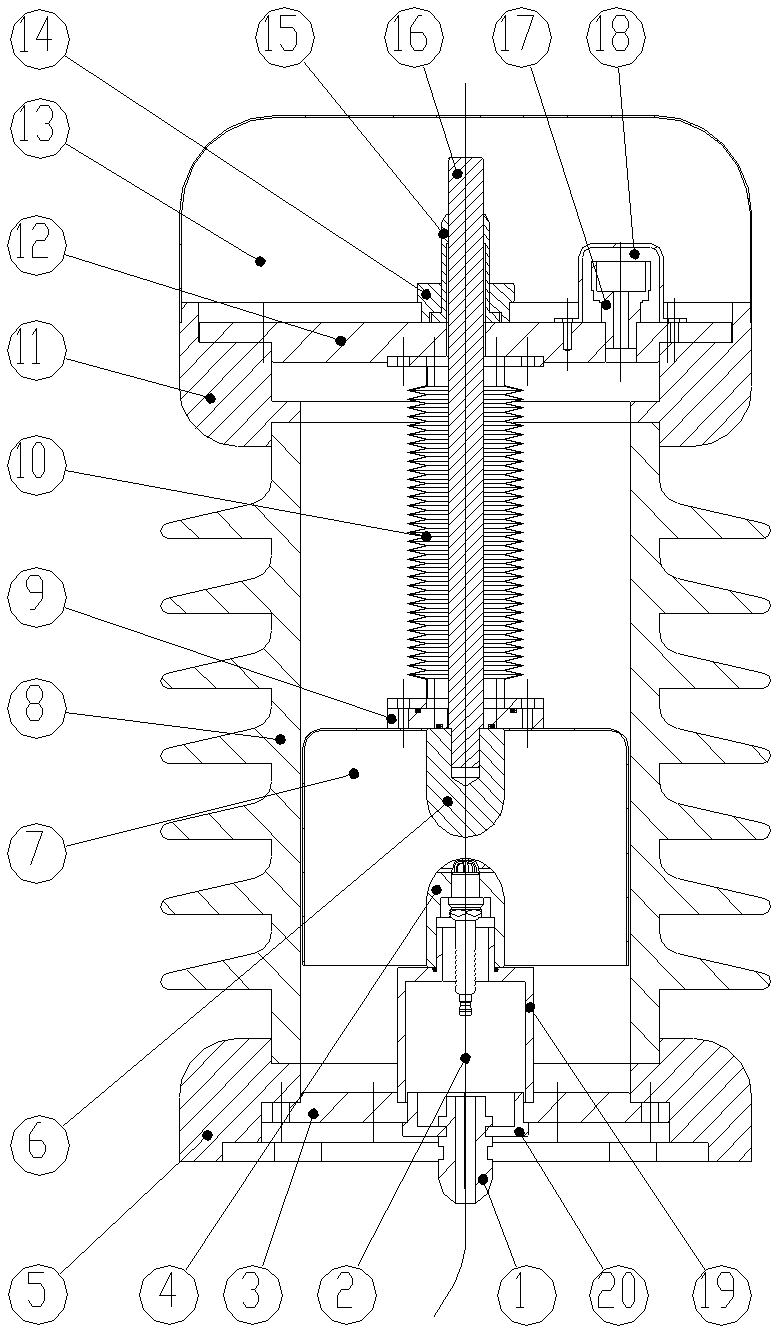

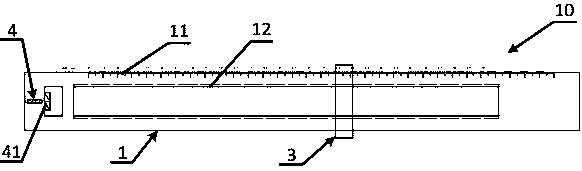

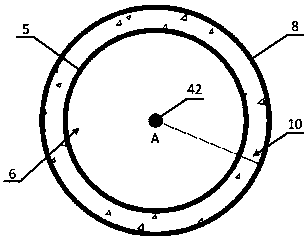

Sealed forcible trigger gap

InactiveCN102496922AImprove consistencyGuaranteed concentricityEmergency protective arrangements for limiting excess voltage/currentEngineeringVoltage

The invention relates to a sealed forcible trigger gap comprising an arc ignition unit, a sealing unit, a discharging unit, and a gas injection unit. The trigger gap has a cylindrical enclosed structure. Besides, the trigger gap is characterized in that: an electrode adjusting unit is also arranged and is composed of a vacuum bellows, an adjusting nut, a locking nut, and a guide rod having an adjusting scale; the guide rod is connected with an upper electrode of the discharging unit; the vacuum bellows is at an external portion of the guide rod; the top of the guide rod penetrates an upper end enclosing cover and the guide rod is fixed with the upper end enclosing cover by the adjusting nut and the locking nut; on the basis of adjustment of the adjusting nut, the upper electrode makes up-and-down lifting movements with the guide rod under the guiding effects of an arc shield and an inner wall of a ceramic umbrella skirt; and the upper electrode is locked by the locking nut; therefore, it can be ensured that a gap between the upper electrode and a lower electrode can be accurately adjusted. According to the sealed forcible trigger gap provided by the invention, good consistency of triggered voltages can be ensured; spacing between two electrodes can be adjusted; and three-point arc ignition is employed, so that reliability of electrode triggering for discharging can be improved.

Owner:RONGXIN POWER ELECTRONICS

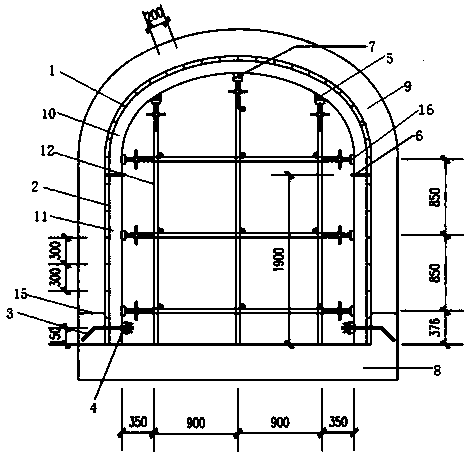

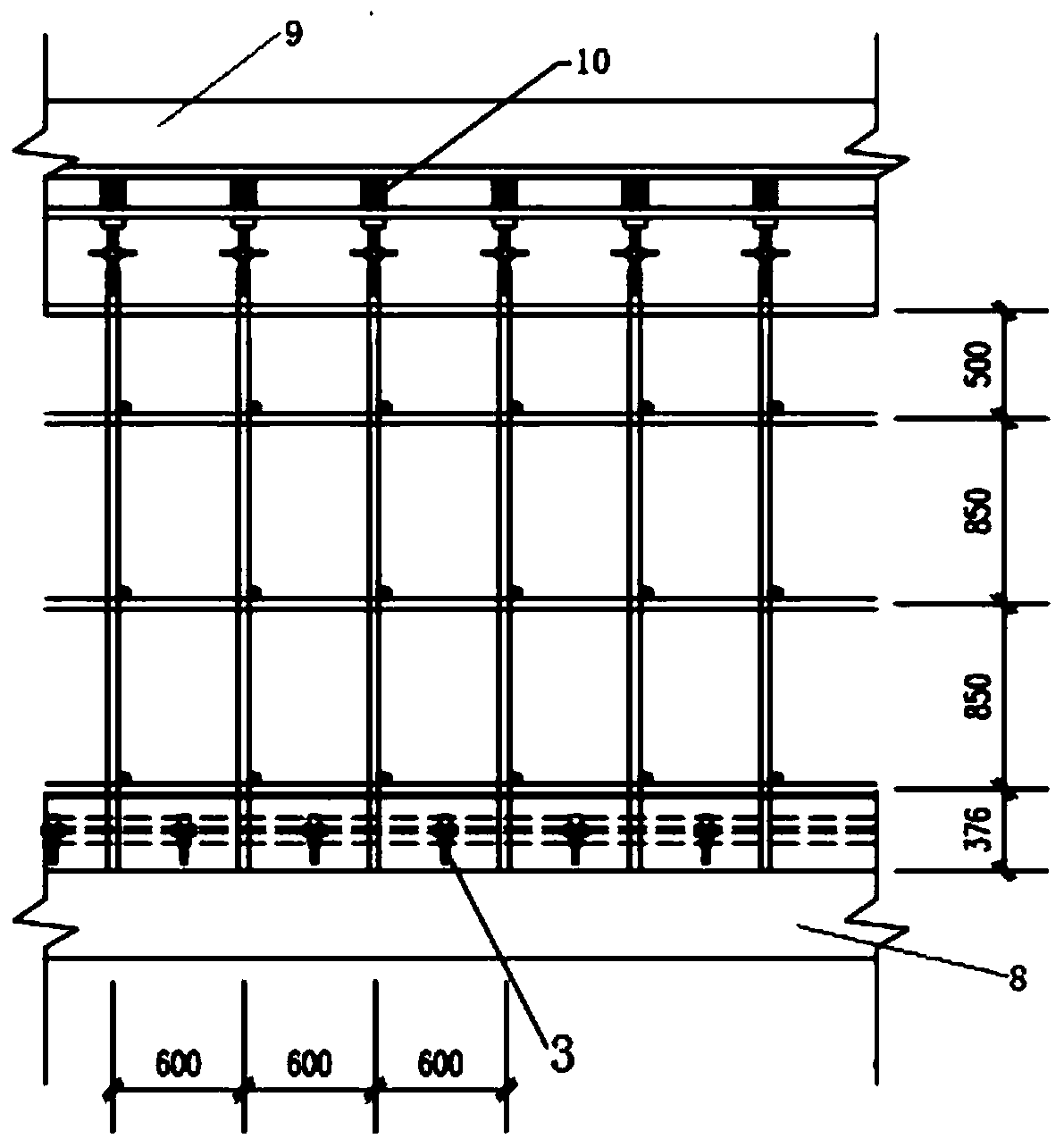

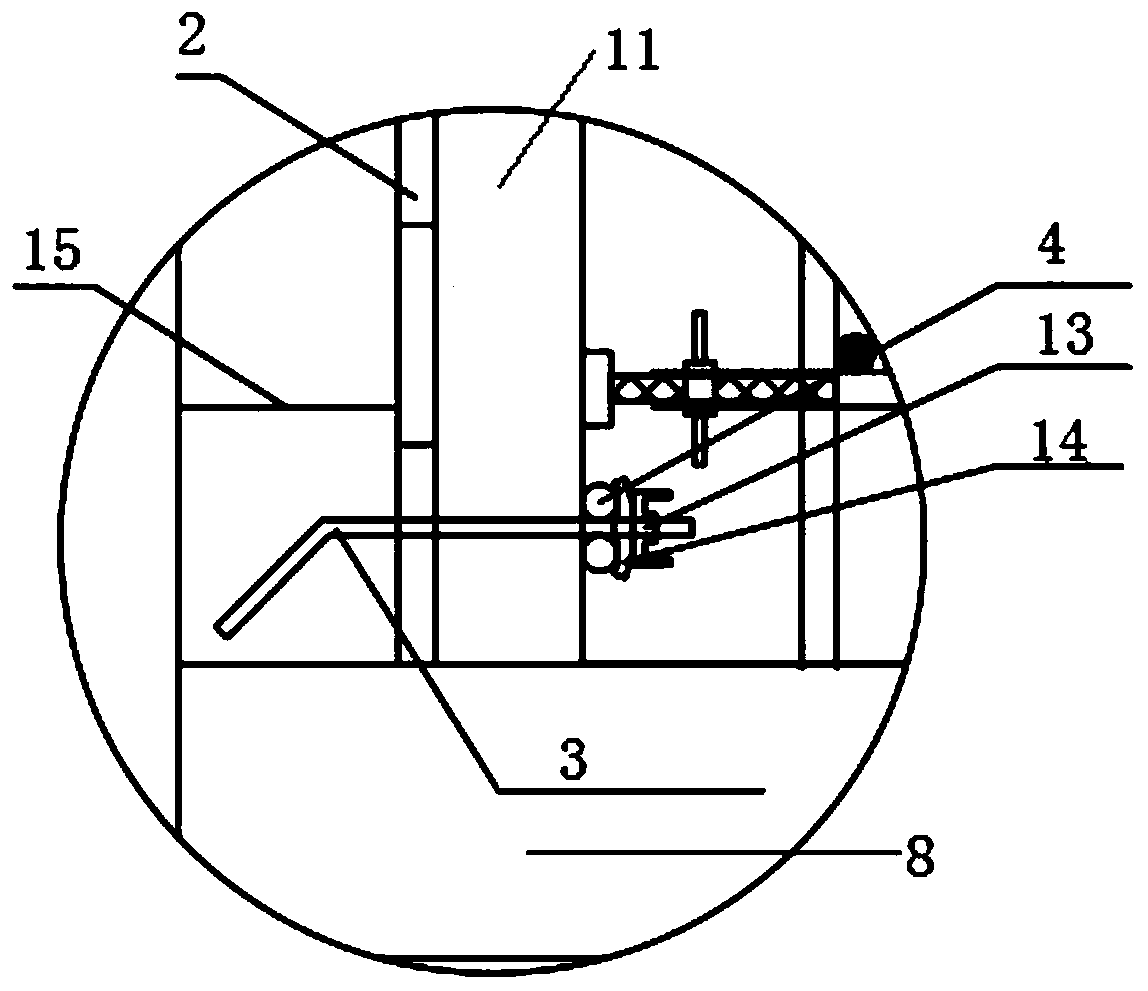

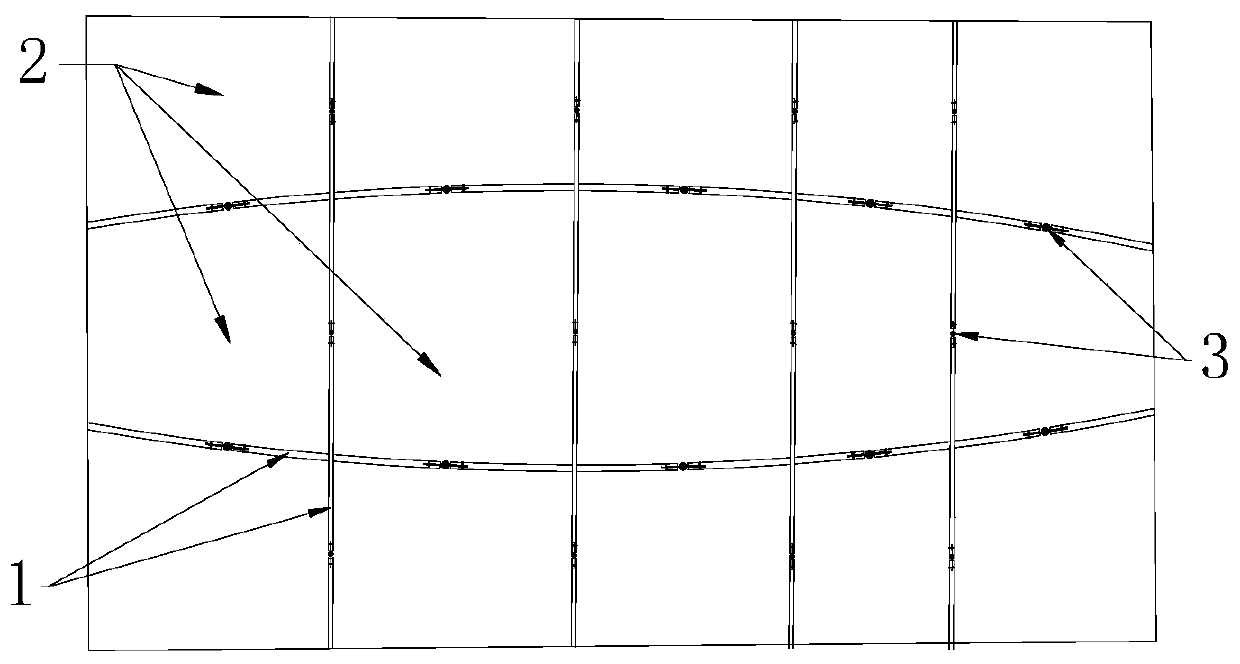

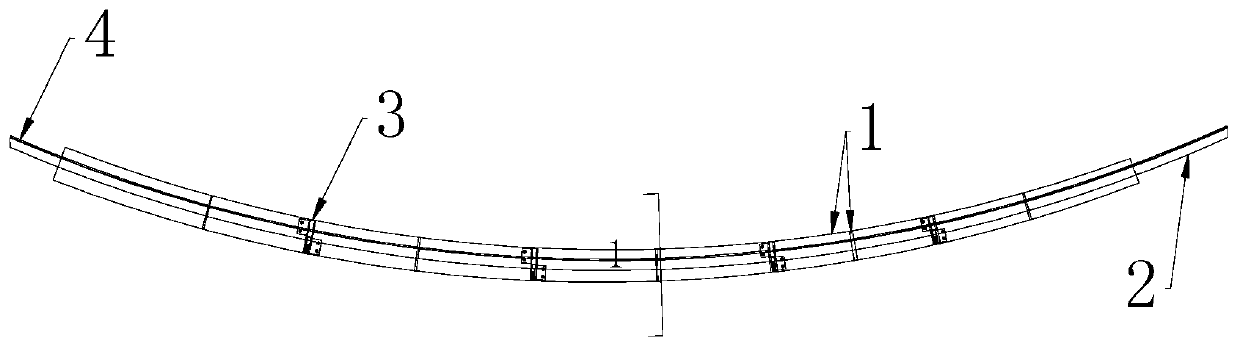

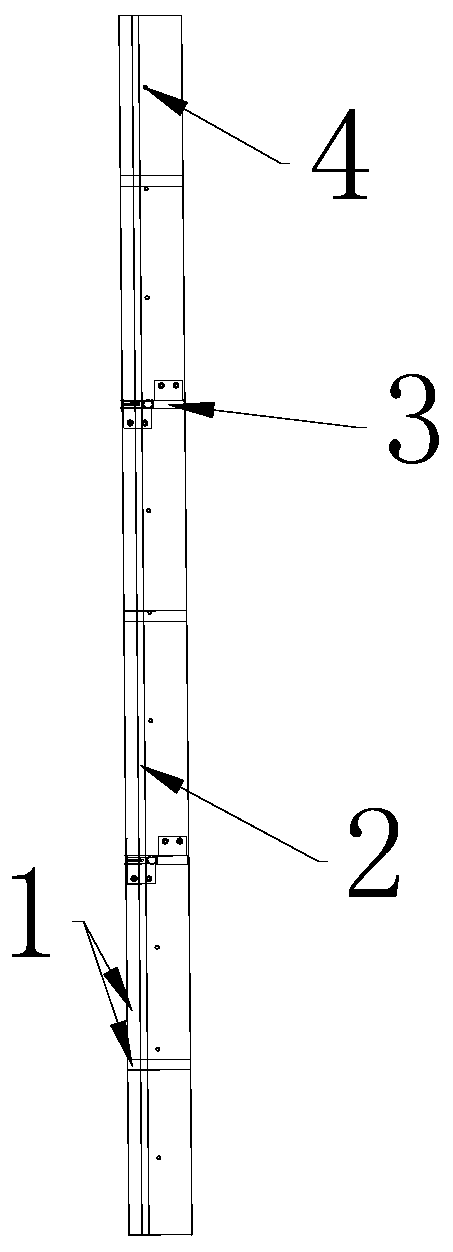

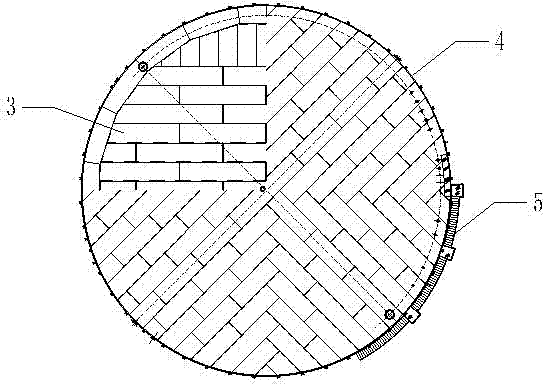

Self-anchored template bracket system for connecting channel and construction method

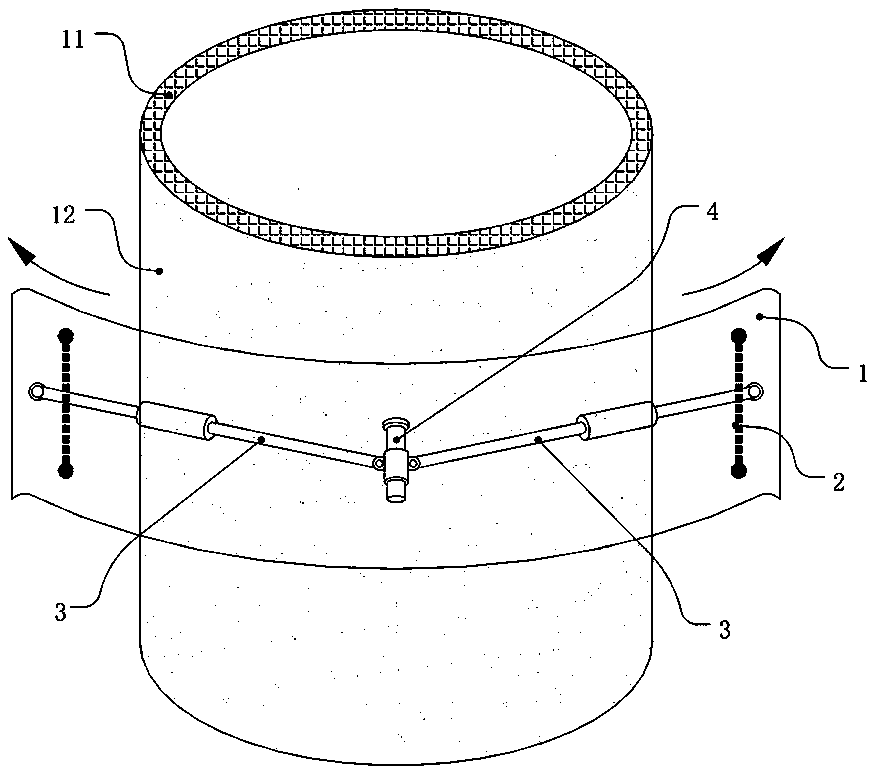

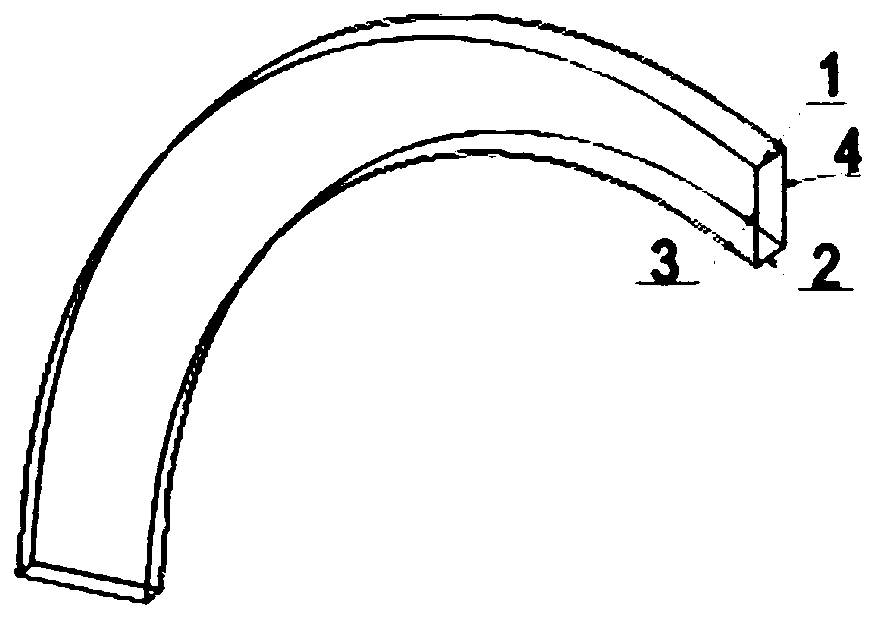

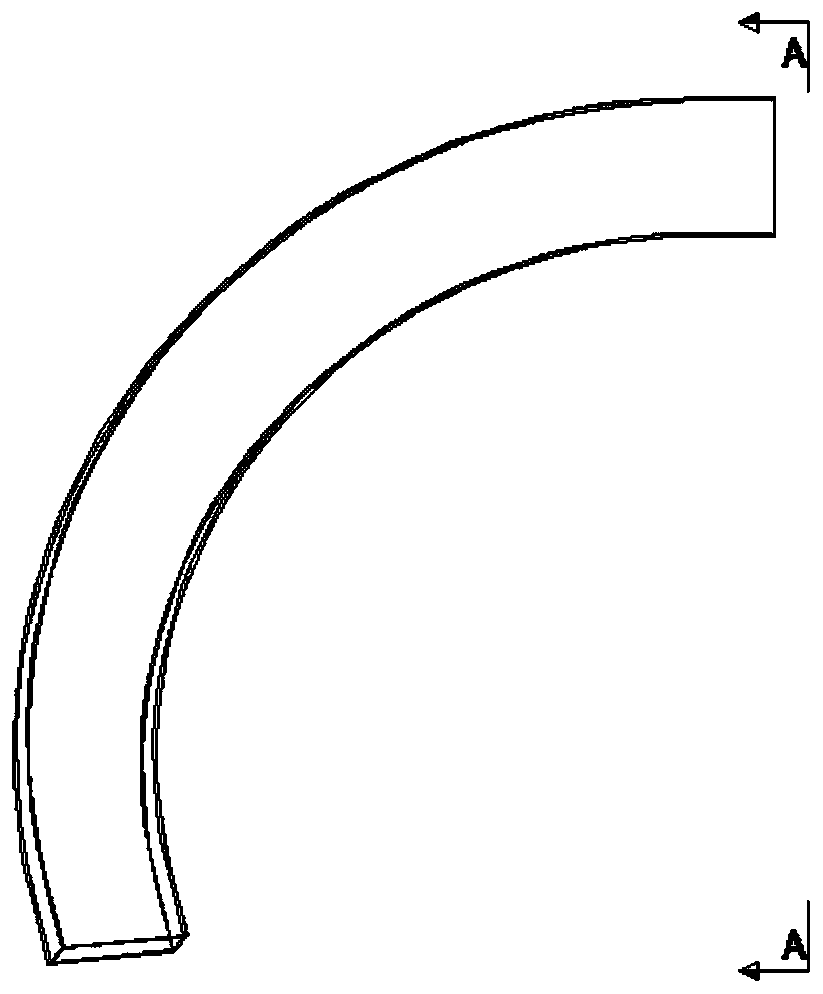

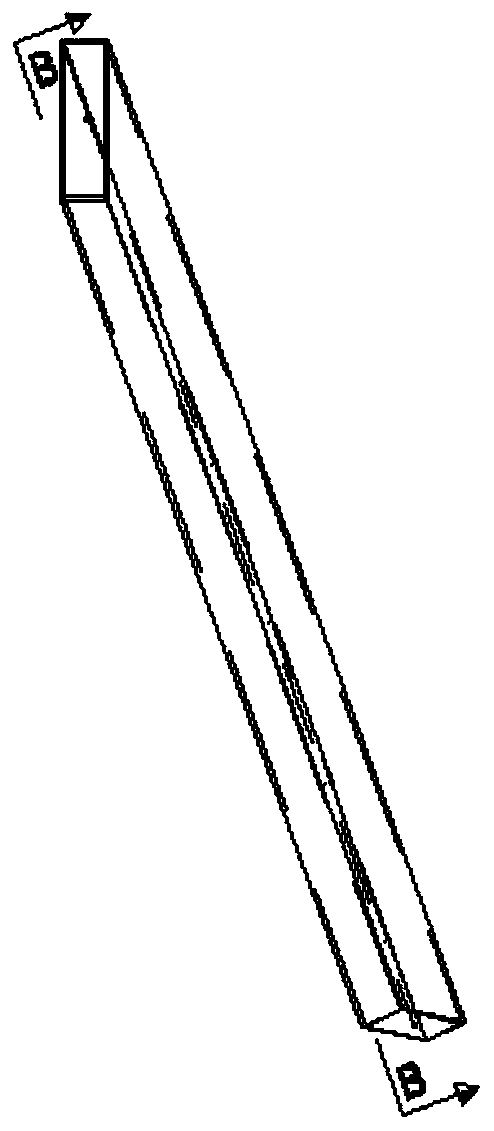

InactiveCN110645022AGuaranteed arcEasy to pourUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention belongs to the technical field of metro construction and relates to a self-anchored template bracket system for a connecting channel and a construction method. A first steel template anda second steel template are spliced by small steel templates which can be repeatedly used, and meanwhile, the radian of a structural arch wall can be also guaranteed and the rigidity also can meet the demand fully. By taking pre-bended I-shaped steel as a main keel and reserving a self-anchoring bar to fix the I-shaped steel when a structural bottom plate is poured, so that the system is stressedwell, a relatively large operation space is released and second lining concrete is poured conveniently. The I-shaped steel is reinforced assisted by a simple bracket and is served as an operating platform of pouring the second lining concrete, the passing condition of operators is good, and meanwhile, the stability of the whole template bracket system is also improved.

Owner:中建八局轨道交通建设有限公司

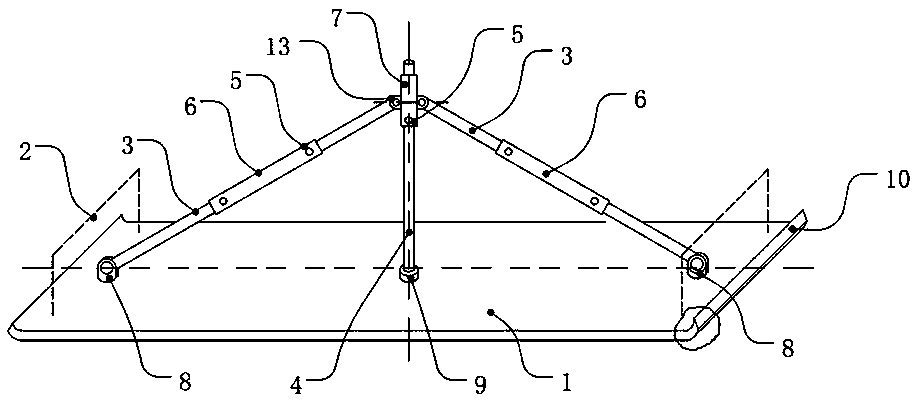

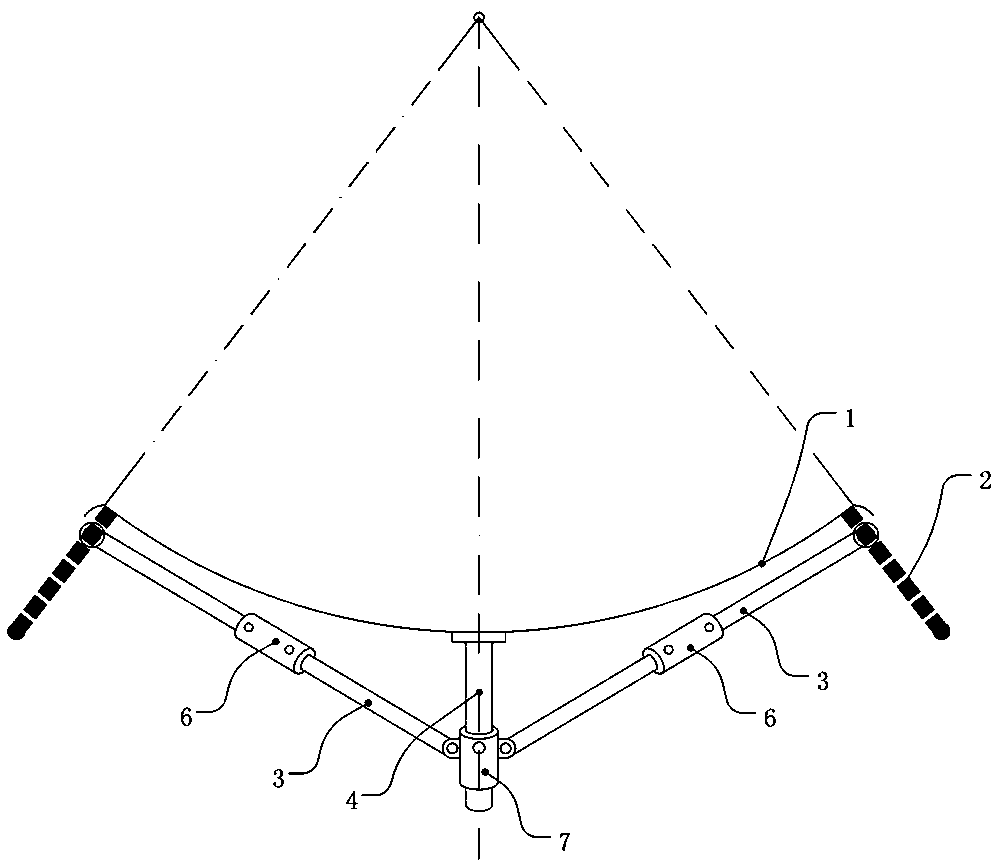

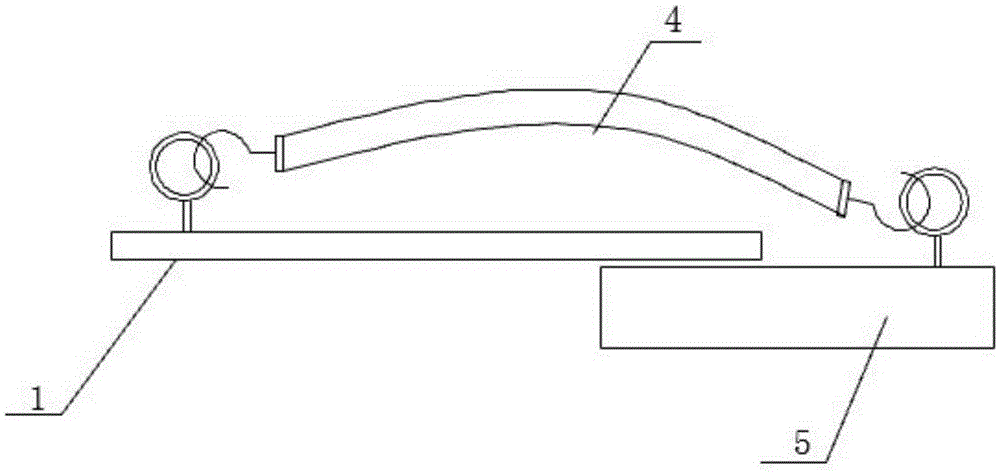

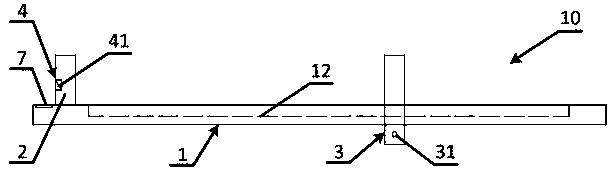

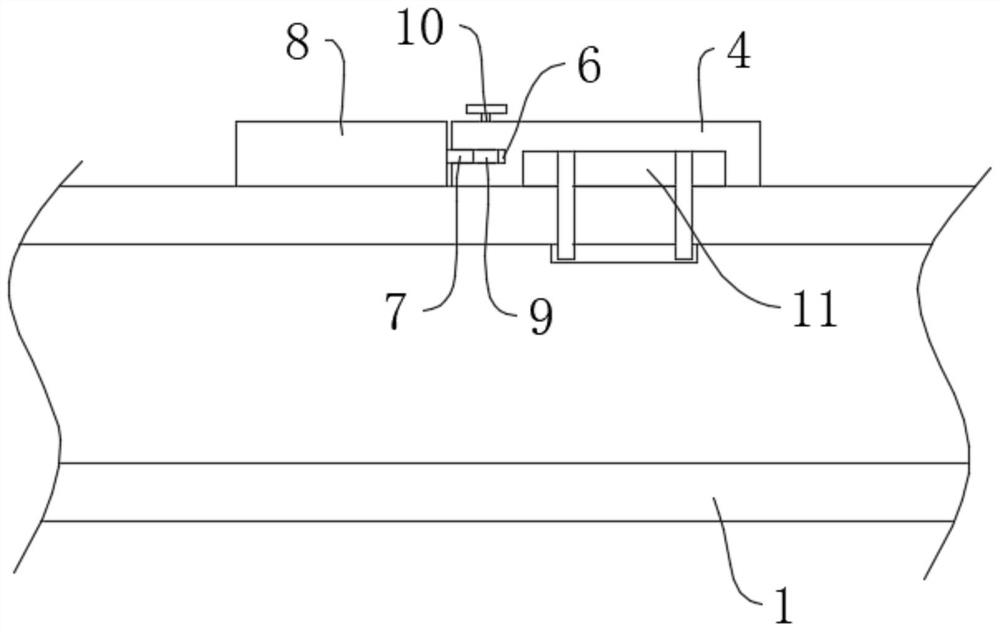

Thick-coated fire-resistant coating surface fine leveling device suitable for steel cylinder

InactiveCN108104435AReasonable structureLow skill level requiredBuilding constructionsEngineeringSteel cylinder

The invention discloses a thick-coated fire-resistant coating surface fine leveling device suitable for a steel cylinder. The thick-coated fire-resistant coating surface fine leveling device comprisesa base plate, a pair of support rods, a pull rod, and handles; the support rods, the pull rod and the handles are arranged at a single side of the base plate; the handles are symmetrically distributed on two sides in a longer direction of the base plate; one ends of the support rods are connected with the base plate in a hinged mode through support rod hinged joints, and the other ends are connected with a pull rod sleeve in a hinged mode; the pull rod passes through the pull rod sleeve and is connected with the base plate in a hinged mode through a pull rod hinged joint; the pull rod hingedjoint is arranged at the center position of the base plate; and the support rod hinged joints are symmetrically distributed on two sides of the pull rod hinged joint. The thick-coated fire-resistant coating surface fine leveling device is suitable for leveling the steel cylinder surface coating, the structure is reasonable, the requirements for the technical level of workers are not high; throughthe thick-coated fire-resistant coating surface fine leveling device, the surface compaction and rounding of coated fireproof coating are carried out, and the arc degree, the compactness, the straightening degree of the upper and lower surface of the coating surface and the flatness of the surface are ensured; and labor costs and repair costs are reduced, and the construction efficiency is improved.

Owner:TIANYUAN CONSTR GROUP +2

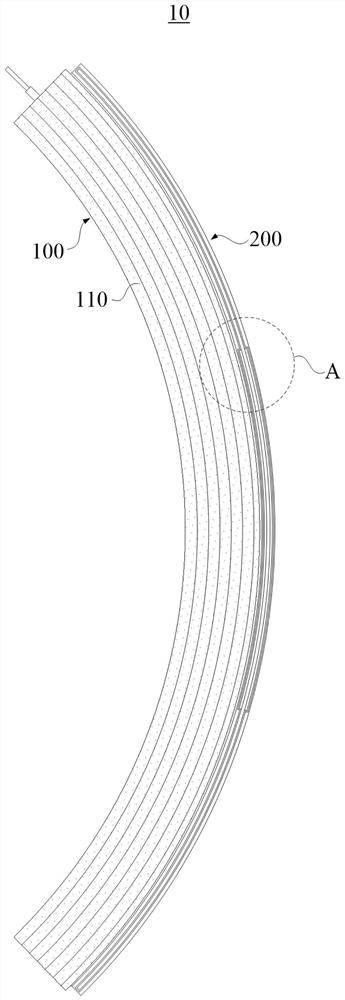

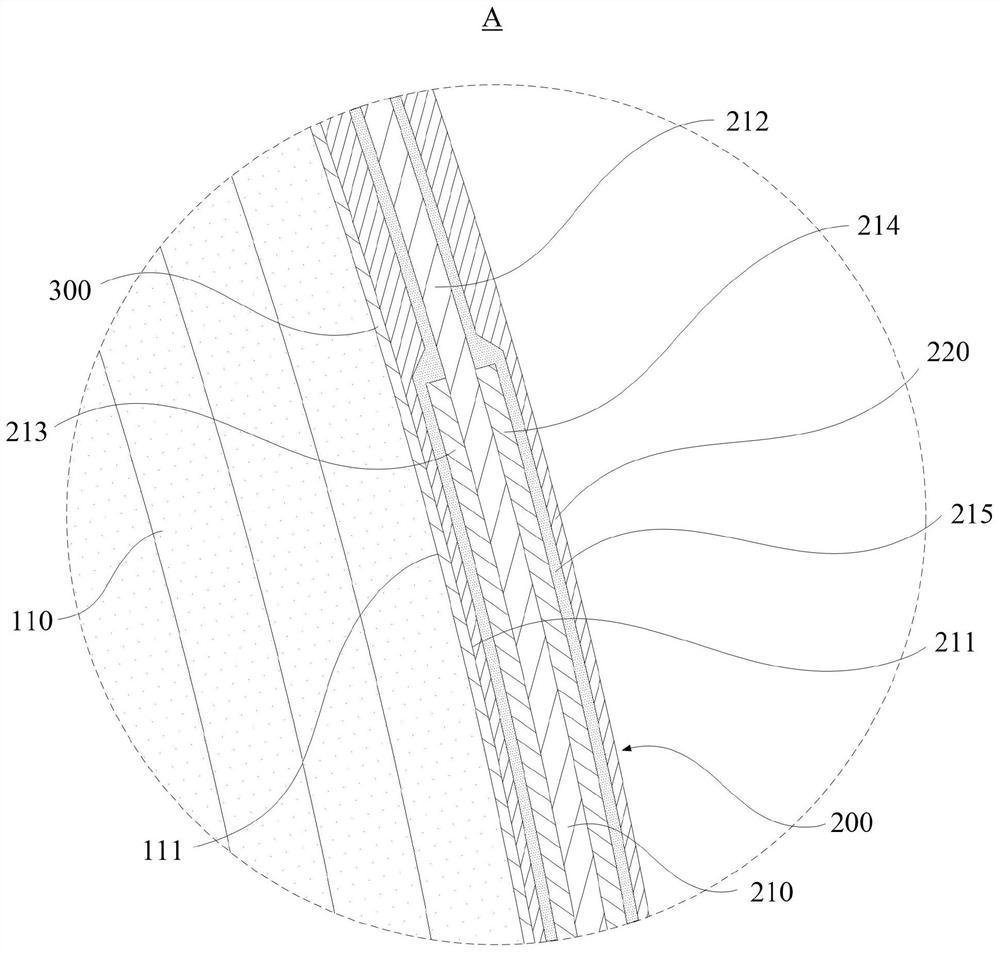

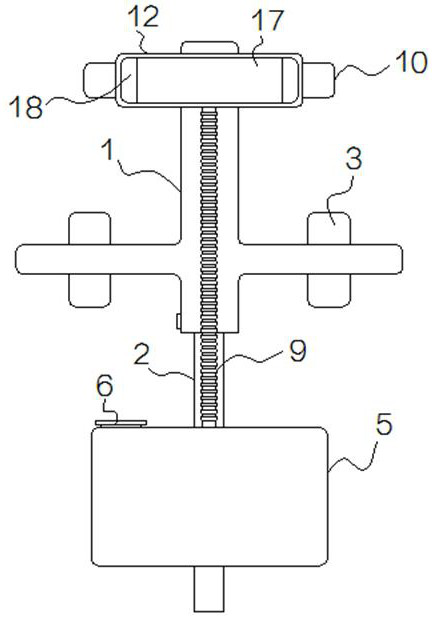

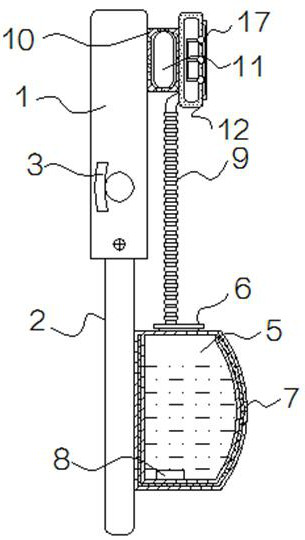

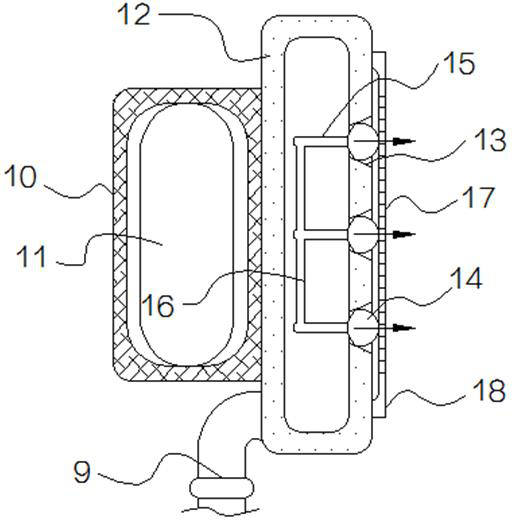

Arc-shaped battery shaping structure and arc-shaped soft package battery

PendingCN113140777AAct as a solid supportHigh mechanical strengthFinal product manufactureSmall-sized flat cells/batteriesEngineeringMechanical engineering

The invention provides an arc-shaped battery shaping structure and an arc-shaped soft package battery. The arc-shaped battery shaping structure comprises an arc-shaped battery cell and a battery cell shaping piece. The arc-shaped battery cell comprises a battery cell body and a first connecting part, and the first connecting part is arranged on the convex arc surface of the battery cell body. The battery cell shaping piece comprises an arc-shaped fixing piece and a second connecting part, the second connecting part is arranged on the concave arc surface of the arc-shaped fixing piece, and the first connecting part is connected with the second connecting part. Due to the fact that the concave cambered surface of the arc-shaped fixing piece abuts against the convex cambered surface of the battery cell body, and the arc-shaped fixing piece has good mechanical strength, the arc-shaped fixing piece can play a role in supporting and fixing the battery cell body, that is, reset deformation of the battery cell body is prevented, and the radian of the arc-shaped battery can be well kept in the transportation and circulation process.

Owner:HUIZHOU HENGTAI TECH

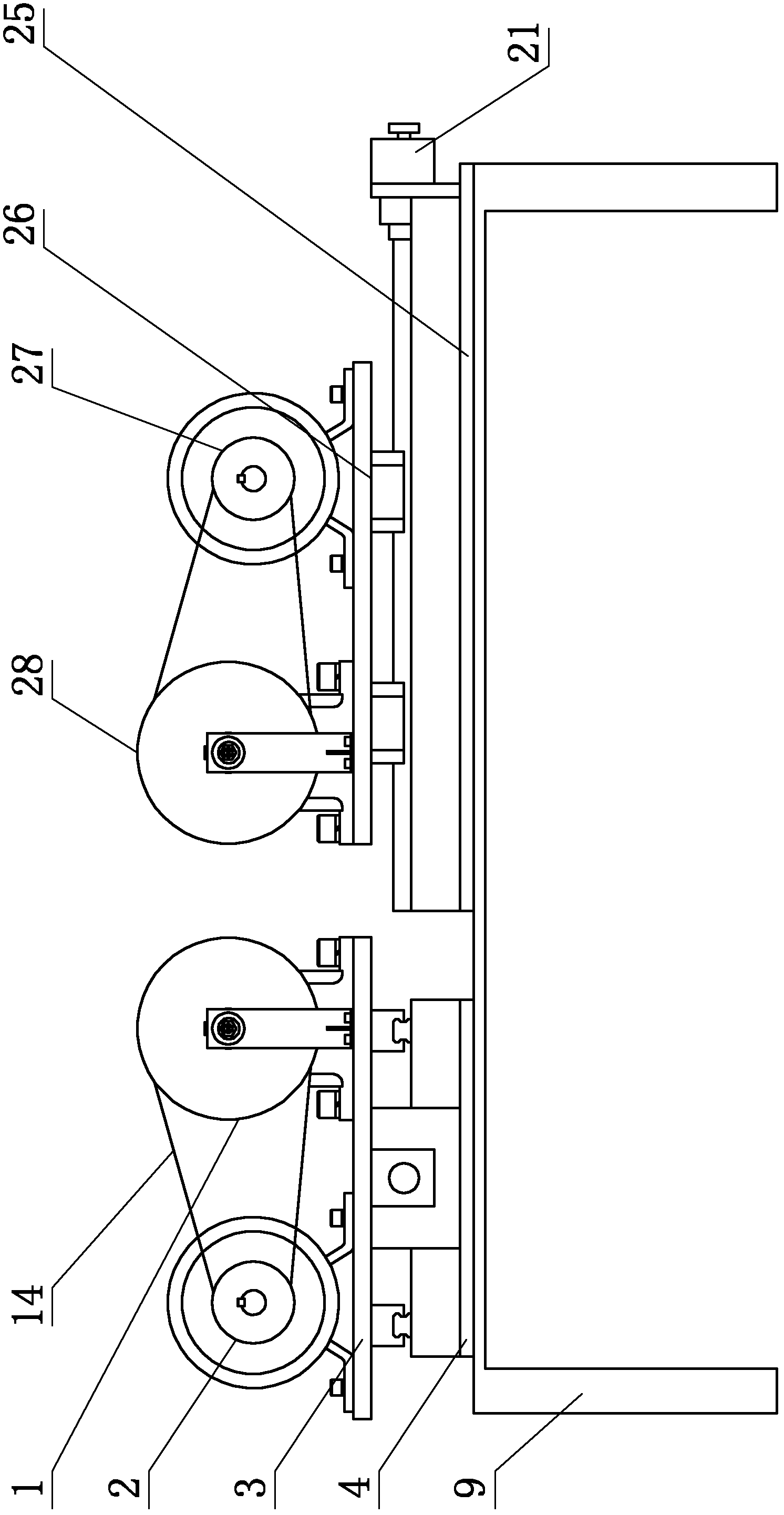

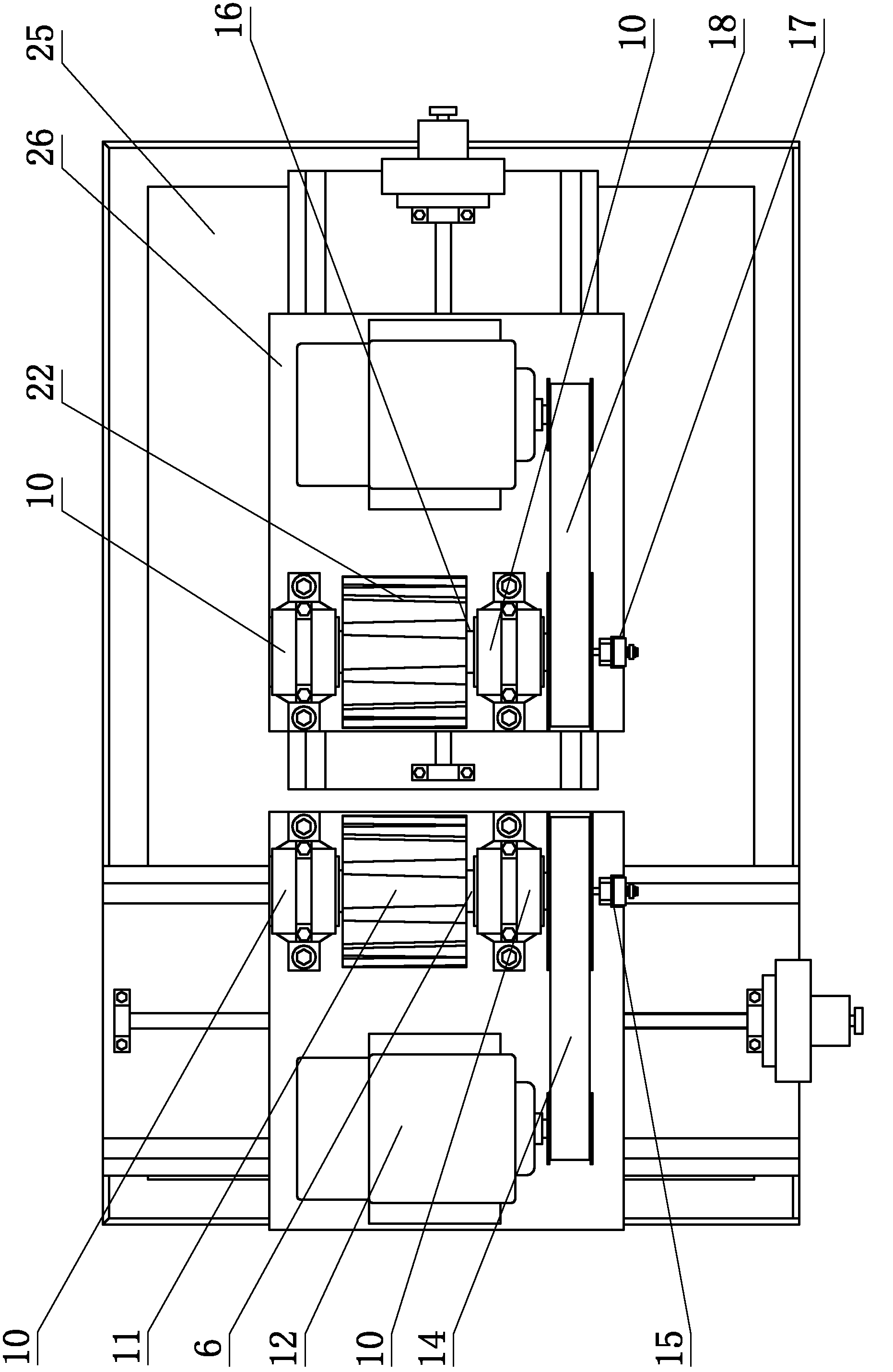

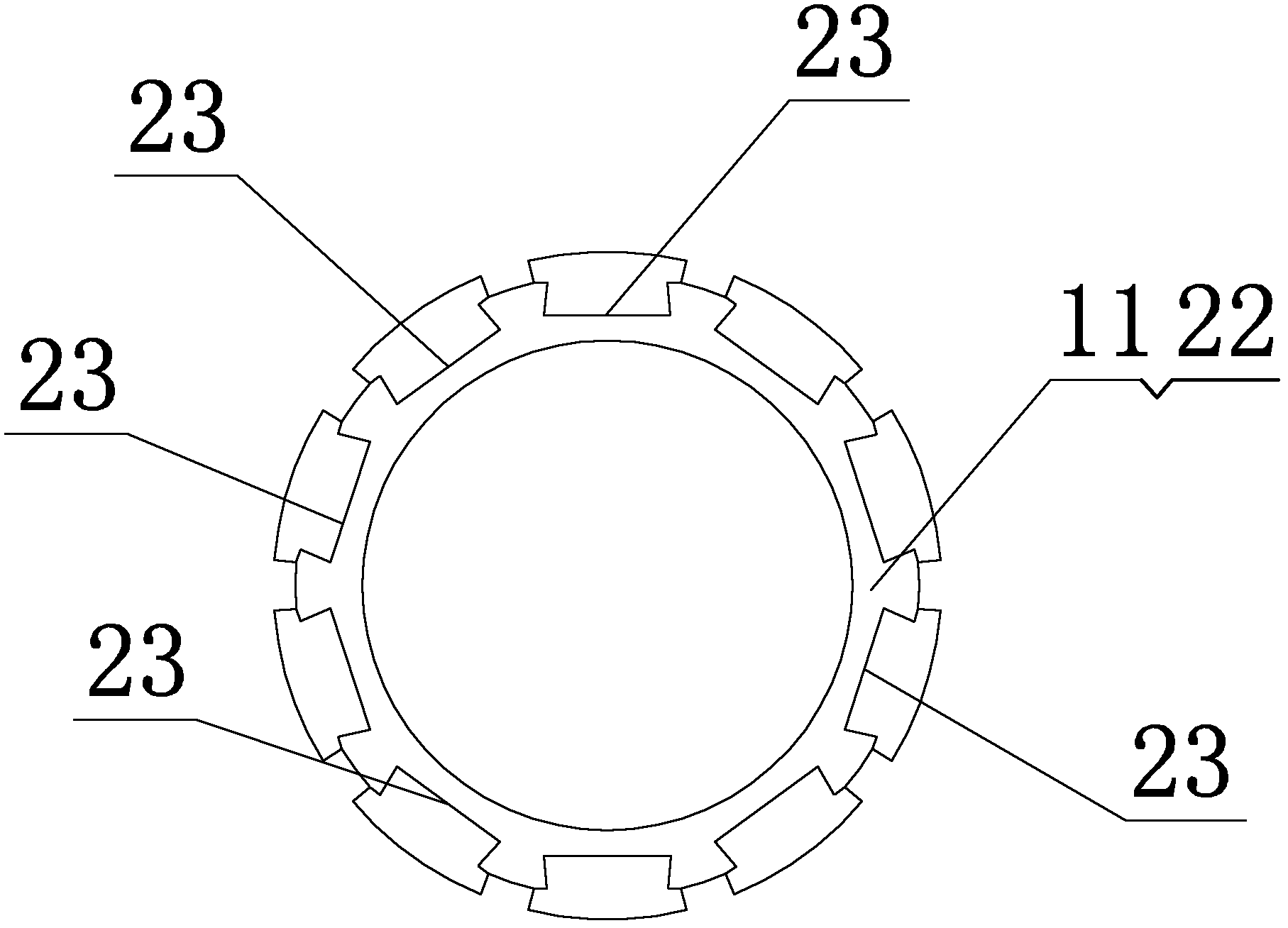

Diamond grinding block dressing device for polished tile

InactiveCN102554787ALoading and unloadingUniform dressingAbrasive surface conditioning devicesGrinding work supportsDrive shaftLinearity

The invention discloses a diamond grinding block dressing device for a polished tile, relates to a diamond grinding block dressing device and aims to solve the problems that the dressing efficiency is low and the dressed grinding block has low linearity in the conventional diamond grinding block dressing method. A guide rail of a first lead screw guide rail worktable and a guide rail of a second lead screw guide rail worktable are arranged in a T shape; a first large belt pulley is fixedly sleeved at one end of a first transmission shaft; a first electrode is fixedly arranged at one end of the first transmission shaft; a first small belt pulley is in transmission connection with the first large belt pulley through a first synchronous belt; a first grinding block clamp is fixedly sleeved in the middle of the first transmission shaft; a second electrode is fixedly arranged at one end of a second transmission shaft; a second small belt pulley is in transmission connection with a second large belt pulley through a second synchronous belt; a second grinding block clamp is fixedly sleeved in the middle of the second transmission shaft; and a plurality of grooves are uniformly formed on the first grinding block clamp and the second grinding block clamp along a circumferential direction. The device is used for dressing the diamond grinding block.

Owner:HARBIN INST OF TECH

Full-automatic double-sided polishing device for glass

PendingCN111037405AGuaranteed arcGuaranteed grinding qualityEdge grinding machinesGrinding carriagesPolishingCrank

The invention discloses a full-automatic double-sided polishing device for glass, and relates to the technical field of glass polishing. The full-automatic double-sided polishing device for glass comprises a polishing frame; the polishing frame comprises a driven rod, a fixing frame and an adjusting mechanism, the driven rod is rotationally matched with the top in the polishing frame, a polishingmechanism is slidably arranged in the driven rod, and the fixing frame is rotationally matched with the middle of the polishing frame; and the driven rod is linked with the fixing frame through a belt, the adjusting mechanism comprises a sheave mechanism, a motor and a crank mechanism, a driving rod is rotationally matched in the fixing frame, the two ends of the driving rod are respectively connected with a fixing plate and the sheave mechanism, and the motor is connected with the fixing frame through the crank mechanism. According to the full-automatic double-sided polishing device for glass, the driven rod and the fixing frame are controlled to be in a reverse rotation direction through the adjusting mechanism, so that the upper edge and the lower edge of the glass can be respectively polished by a polishing head, the peripheral side surfaces of the glass can be sequentially polished through intermittent rotation controlled by the sheave mechanism, and the working efficiency is improved.

Owner:CHANGZHOU INST OF LIGHT IND TECH

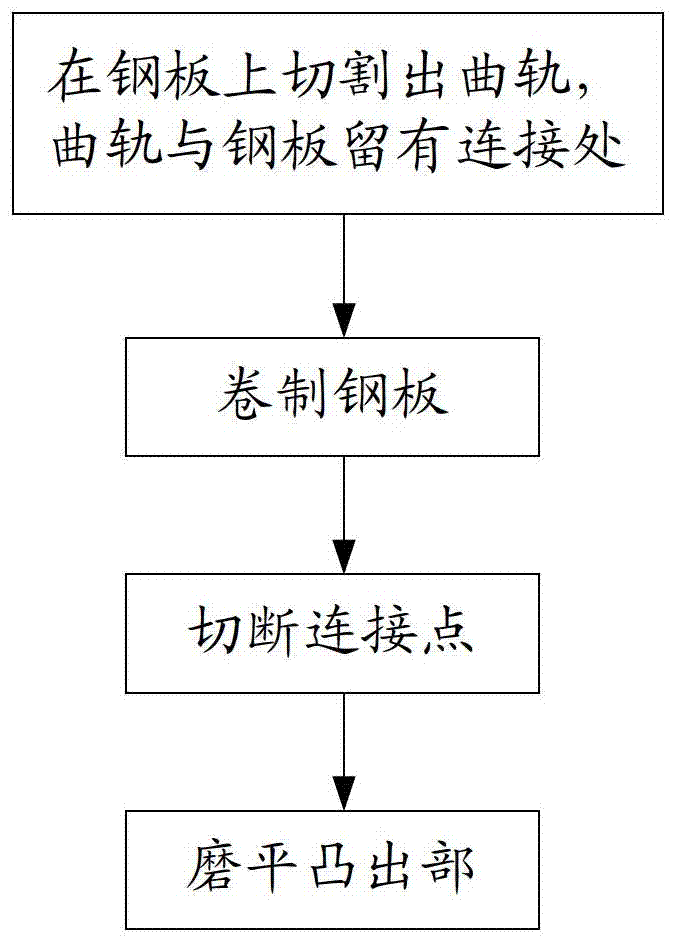

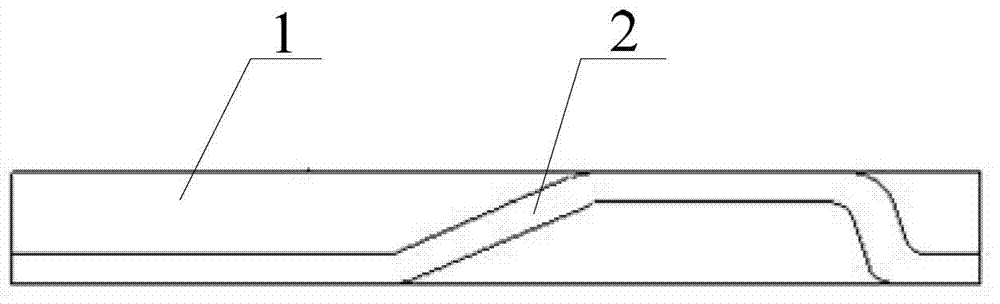

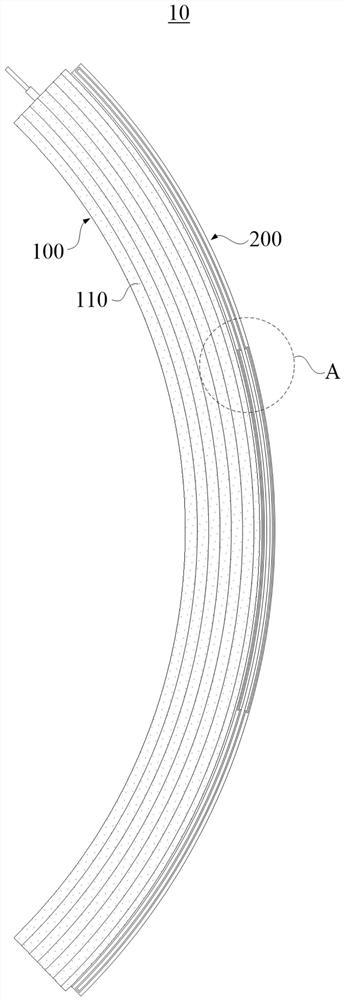

Method for manufacturing curved rail

The invention discloses a method for manufacturing a curved rail. The method comprises the following steps of: (1) cutting out the curved rail on a steel plate, wherein connection points are reserved between the curved rail and the steel plate; (2) rolling up the steel plate; and (3) cutting off the connection points. According to the method for manufacturing the curved rail, disclosed by the invention, a method of steel plate rolling up is adopted, and then, flaws, such as air holes, sand adhering and sand swelling, cannot occur during casting, so that the phenomenon of fracture difficultly occurs; and when the curved rail is cut on the steel plate, the connection points are reserved between the curved rail and the steel plate, the curved rail is still connected with the steel plate integrally, the steel plate is integrally rolled up, the curvature of the curved rail can be excellently ensured due to the spatial limitation of the surrounding steel plate while the curved rail is also rolled up, and thus, the accuracy of the curvature of the curved rail is ensured. In summary, the method for manufacturing the curved rail, disclosed by the invention, has the advantages that the accuracy of the curvature of the curved rail is ensured, and the phenomenon of fracture difficultly occurs.

Owner:江苏宏大特种钢机械厂有限公司

Support adjustment structure for side skin of passenger car

The invention discloses a support adjustment structure for a side skin of a passenger car. The support adjustment structure for the side skin of the passenger car comprises a framework and the side skin. Fixed brackets are arranged on the framework through welding and formed by welding nuts and angle bars, a small rectangular tube is arranged on the side skin, the framework is fixedly connected with the small rectangular tube in a manner that bolts penetrate through the nuts, and sound insulation cotton is arranged between the framework and the side skin. The support adjustment structure for the side skin of the passenger car is simple in structure, lower in cost and convenient to install, as the support adjustment structure is additionally arranged, the side skin can be guaranteed to be tensioned, and thus the flatness of the side skin is guaranteed; and the support adjustment structure can adjust the space between the side skin and the framework, the radian of the skin is guaranteed, the sound insulation cotton can absorb part of noise, and the practicability is higher.

Owner:SHENZHEN GREENWHEEL ELECTRIC VEHICLE CO LTD

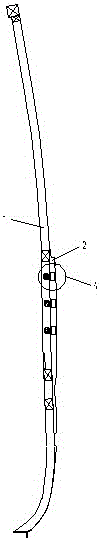

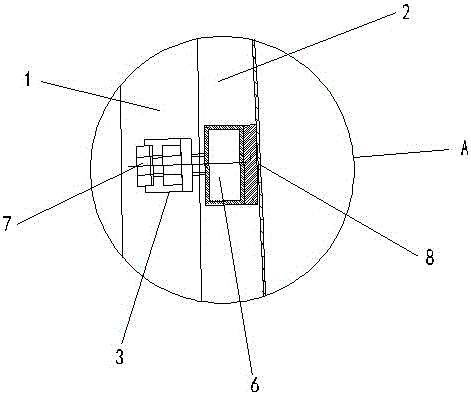

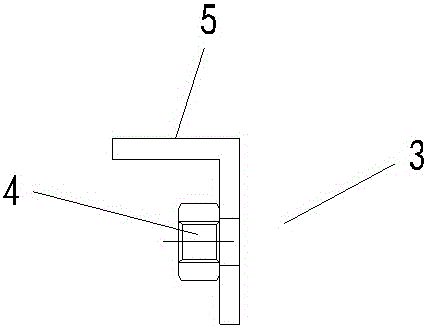

Flexible hook spanner

The invention discloses a flexible hook spanner. The flexible hook spanner is applicable to mounting and dismounting of machine tool spindle connecting rod nuts with different sizes and comprises a handle and a working part arranged at the front end of the handle, wherein the working part comprises a chain, a hook head, a chain wheel and a limiting block, the chain wheel is meshed with the chain and used for increasing / decreasing the length of the chain, and the limiting block is used for limiting rotation of the chain wheel. The flexible hook spanner can realize mounting and dismounting of connecting nuts with different diameter specifications by the aid of the flexible characteristic of the chain, and in combination with the replaceable characteristic of a clamping hook of the hook spanner, the spanner can be adapted to aperture sizes of nut unthreaded holes with different diameters.

Owner:WUHAN TIANHE TECH

Manufacturing method of large-section small-radius hyperbolic box beam

The invention relates to a manufacturing method of a large-section small-radius hyperbolic box beam. The manufacturing method is characterized in that the large-section small-radius hyperbolic box beam is designed and disassembled into four blocks of a long flange slab, a short flange slab, a long web plate and a short web plate correspondingly, the long flange slab, the short flange slab, the long web plate and the short web plate are prepared by blanking and bending correspondingly, and then the long flange slab, the short flange slab, the long web plate and the short web plate are assembledand welded to form the large-section small-radius hyperbolic box beam. The manufacturing method has the beneficial effects that by adopting the scheme for manufacturing the large-section small-radiushyperbolic box beam, the error is reduced and the radian of the hyperbola is guaranteed, the appearance of the whole component is ensured, and the processing progress of the component is improved toa greater extent; and the radian of the box beam is guaranteed to be formed at one time, and the phenomenon of folding marks and bumps is further avoided.

Owner:MCC TIANGONG GROUP +1

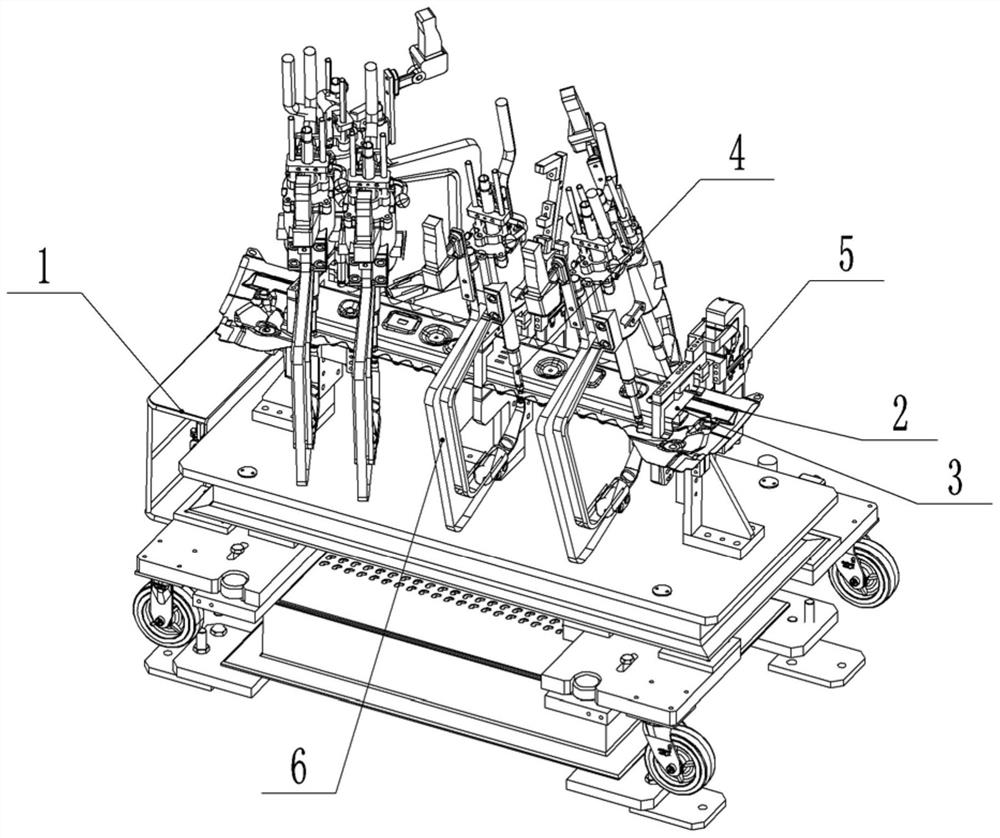

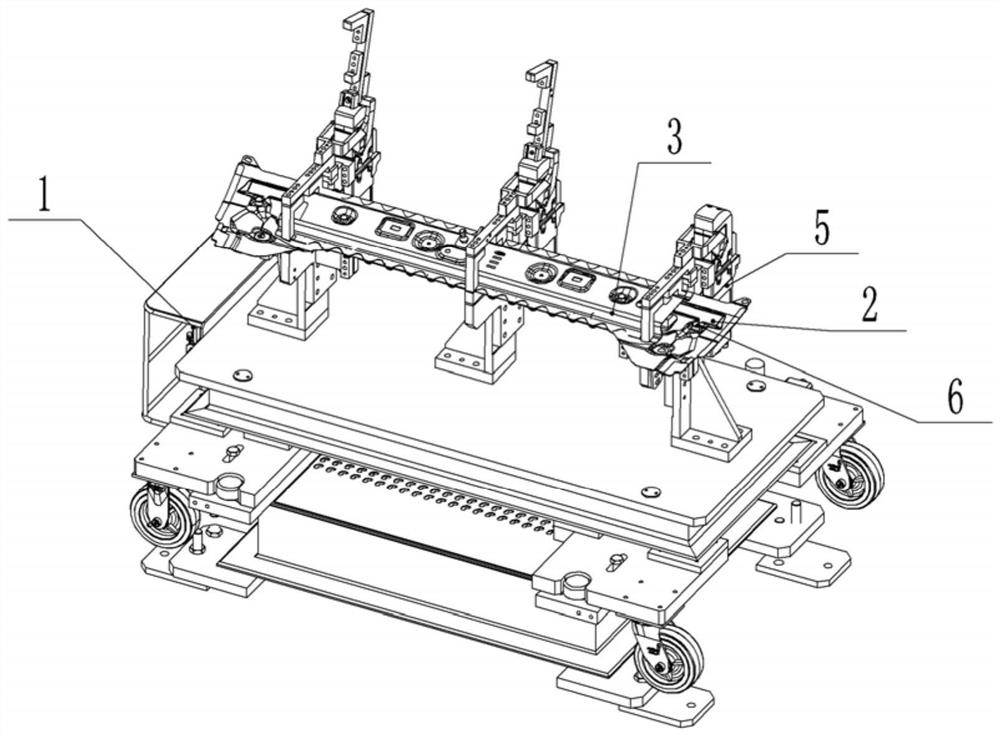

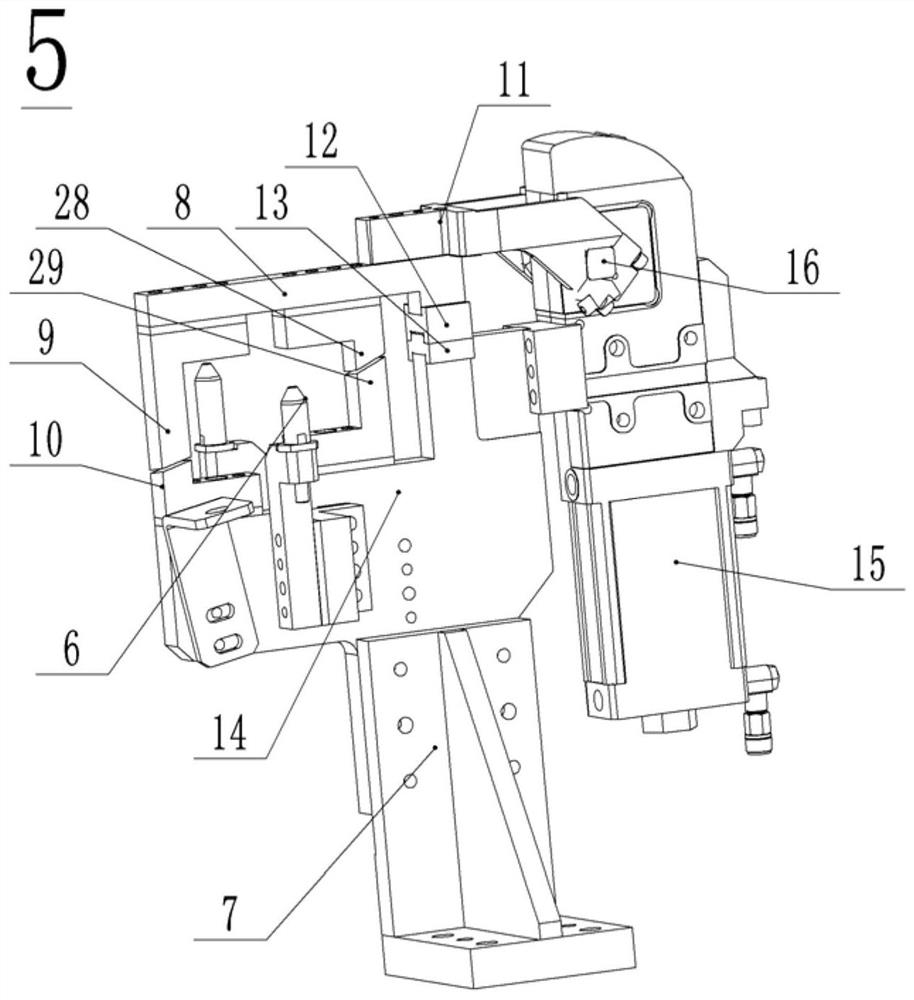

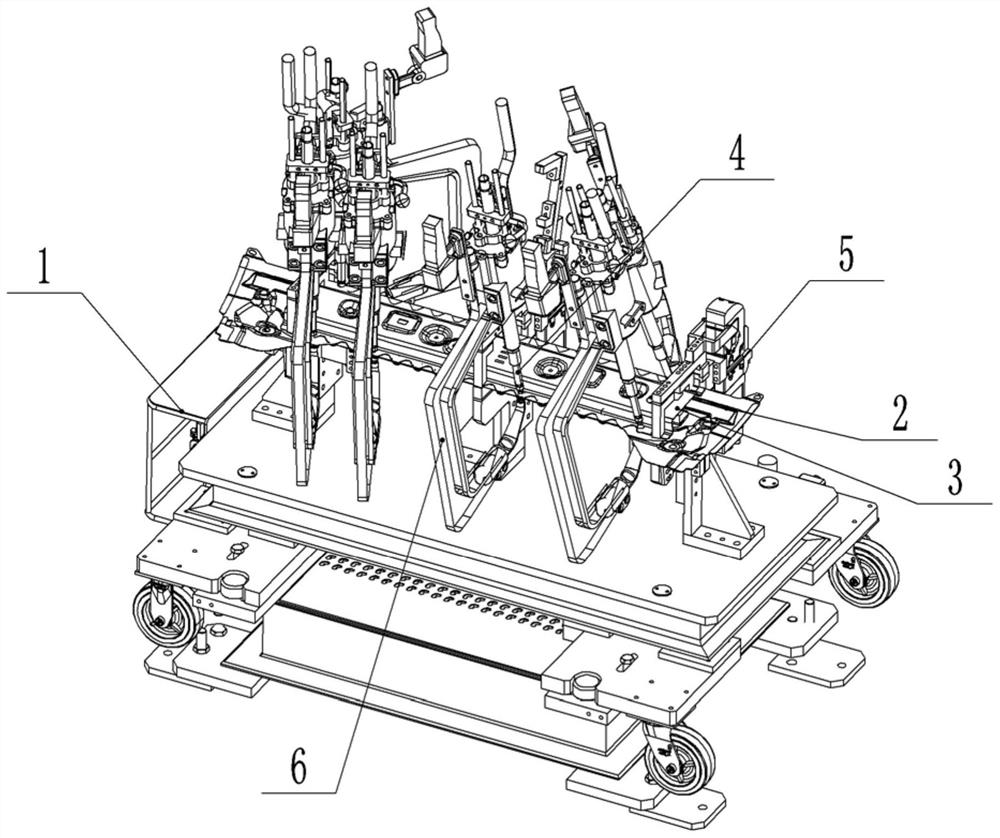

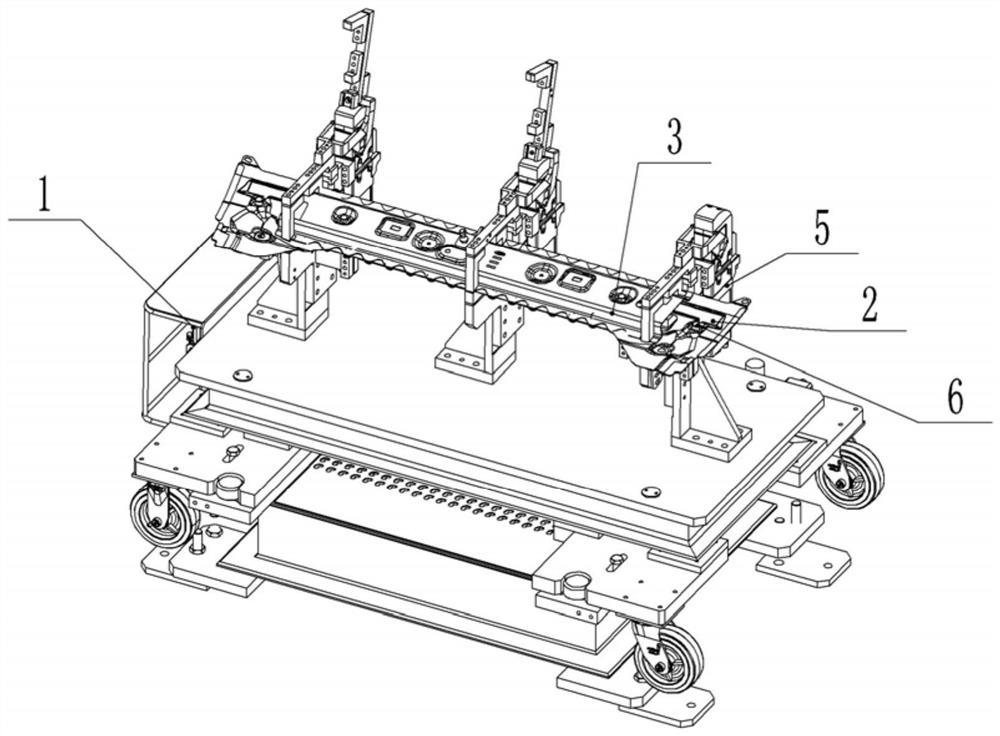

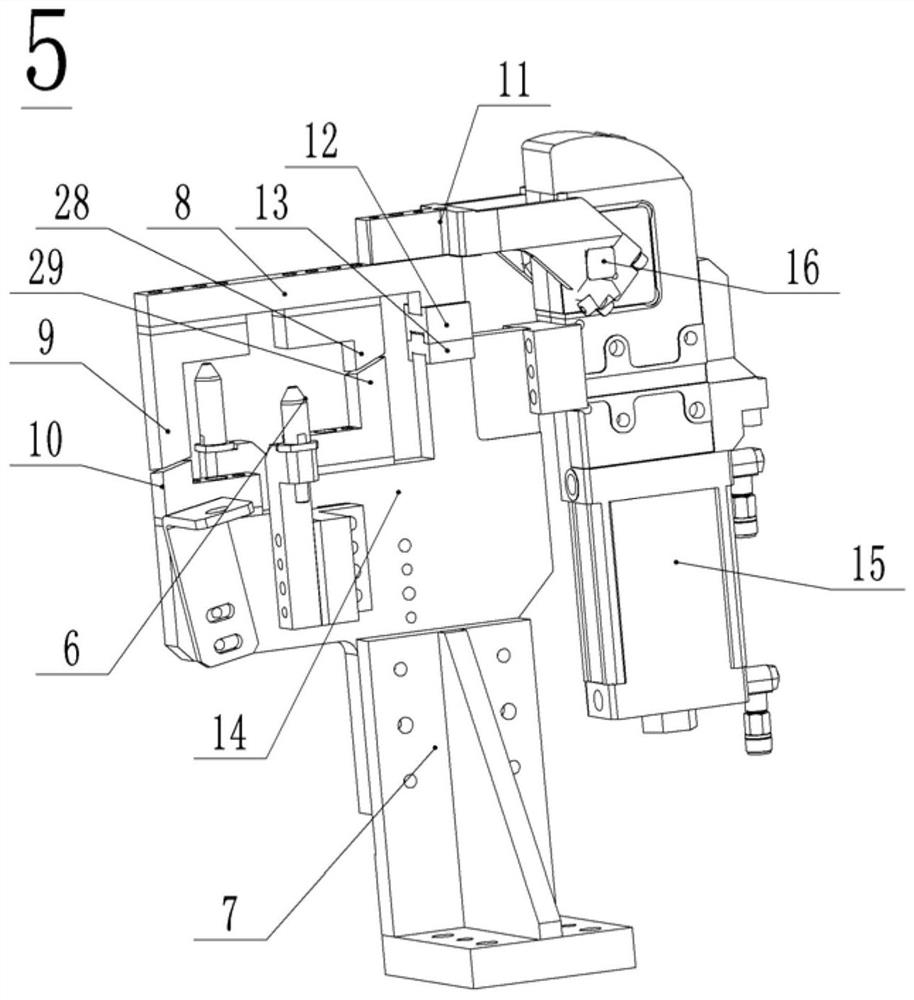

Machining process and device for front roof panel assembly

ActiveCN112692460AImprove processing and production pass rateHigh resilienceWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsStructural engineering

The invention relates to the field of automobile part machining, in particular to a machining device for a front roof panel assembly. The machining device for the front roof panel assembly comprises a rack, a welding mechanism and a clamping mechanism, wherein the clamping mechanism comprises a base, an oscillating rod and an air cylinder; the oscillating rod and the air cylinder are rotatably connected onto the base; a first clamping group and a second clamping group are arranged on the clamping mechanism; the first clamping group comprises a first lower clamping jaw located on the base and a first upper clamping jaw located on the oscillating rod; and the second clamping group comprises a second lower clamping jaw located on the base and a second upper clamping jaw located on the oscillating rod. The invention further provides a machining process for the front roof panel assembly. The machining process comprises the following steps of 1, preparing a front roof panel outer plate and a front roof panel inner plate; 2, using the clamping mechanism for clamping the front roof panel outer plate and the front roof panel inner plate, and adjusting the clamping force of the clamping mechanism; and 3, welding the front roof panel outer plate and the front roof panel inner plate by using the welding mechanism. According to the machining process and device for the front roof panel assembly provided by the invention, the processing and production qualification rate of the front roof panel assembly is improved.

Owner:CHONGQING ZHIXIN IND

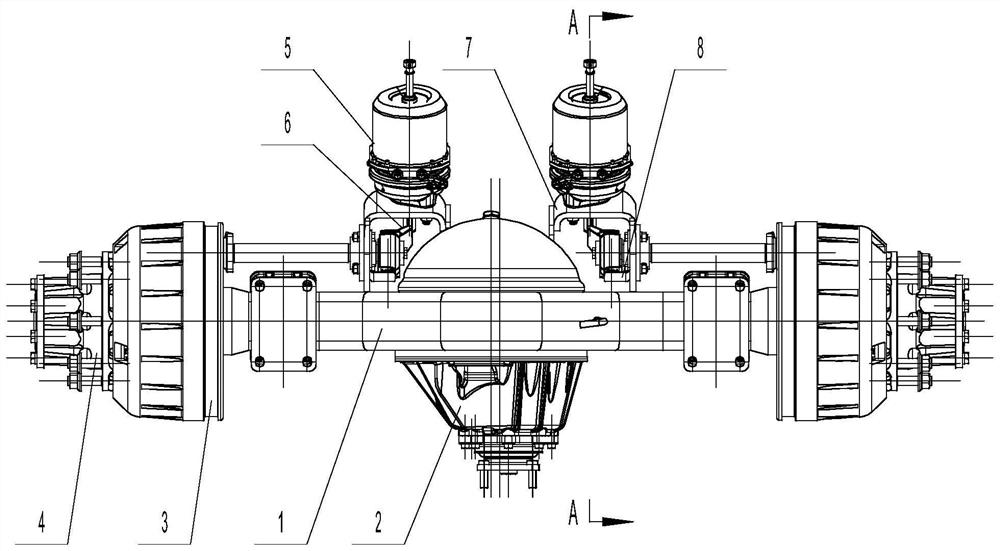

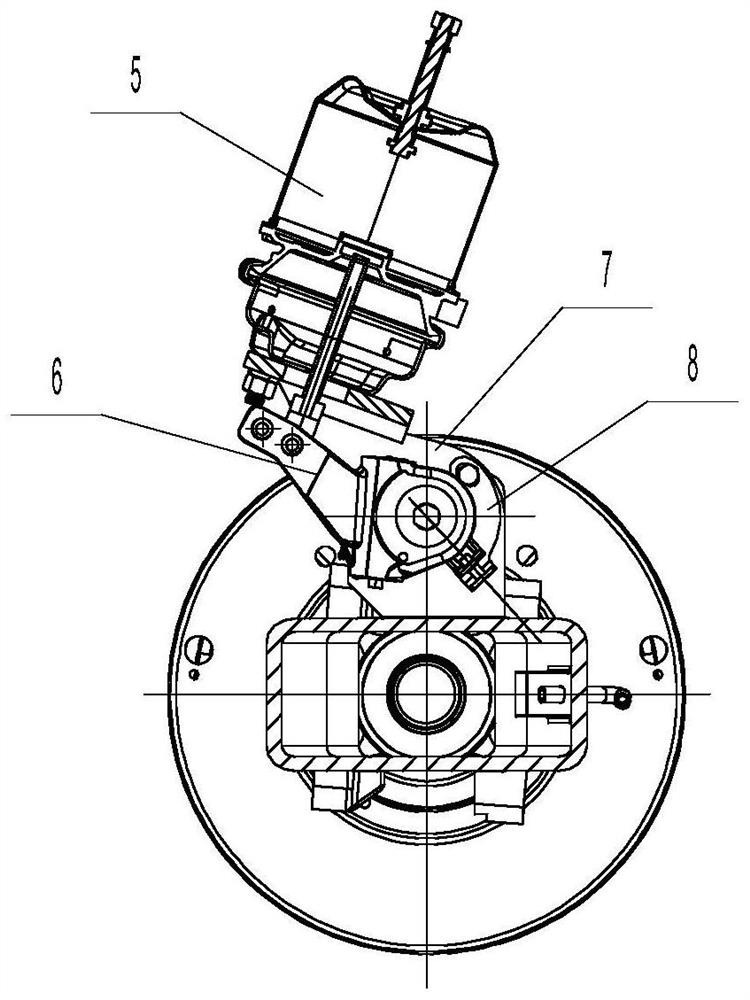

Automobile rear axle assembly with adjusting arm convenient to disassemble, assemble and adjust

ActiveCN111731245AMeet the requirementsLarge adjustment rangeBraking action transmissionReservoir arrangementsControl armFastener

The invention discloses an automobile rear axle assembly with an adjusting arm convenient to disassemble, assemble and adjust, which relates to an automobile rear axle assembly. The automobile rear axle assembly comprises a rear axle shell assembly, a main reducing assembly, a brake assembly, a hub assembly, a brake air chamber, the adjusting arm and a half-moon-shaped adjusting support. An arc-shaped adjusting groove is formed in the half-moon-shaped adjusting support, and the half-moon-shaped adjusting support is directly fixed to the air chamber support through the arc-shaped adjusting groove by means of a fastener. A stop pin is further installed on the half-moon-shaped adjusting support and penetrates into a pin hole of the control arm control support of the adjusting arm. The installation clearance angle of the adjusting arm can be adjusted at different positions of the arc groove through the fastener, and the assembly can be suitable for installation clearance angles of variousadjusting arms; the half-moon-shaped adjusting support is directly fixed on the air chamber support, so that a bracket fixing seat does not need to be additionally arranged; and the stop pin directlypenetrates into the pin hole of the control arm control bracket of the adjusting arm, so that the installation is simple, the disassembly is easy, the operation process and the production cost can bereduced, the after-sales maintenance cost is reduced, and the popularization and the use are easy.

Owner:FANGSHENG AXLE LIUZHOU

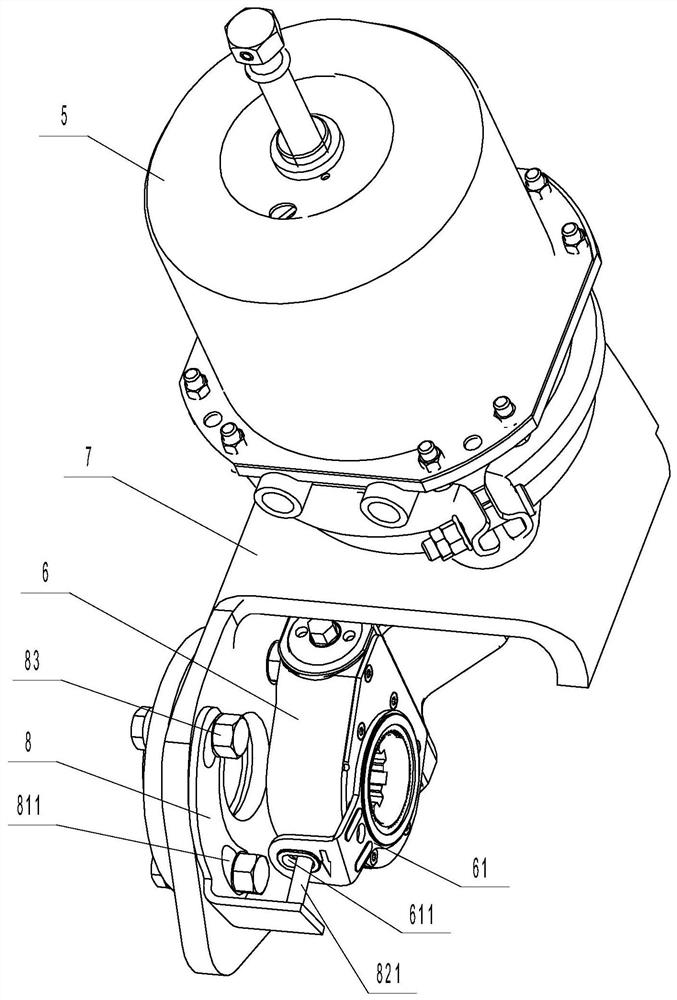

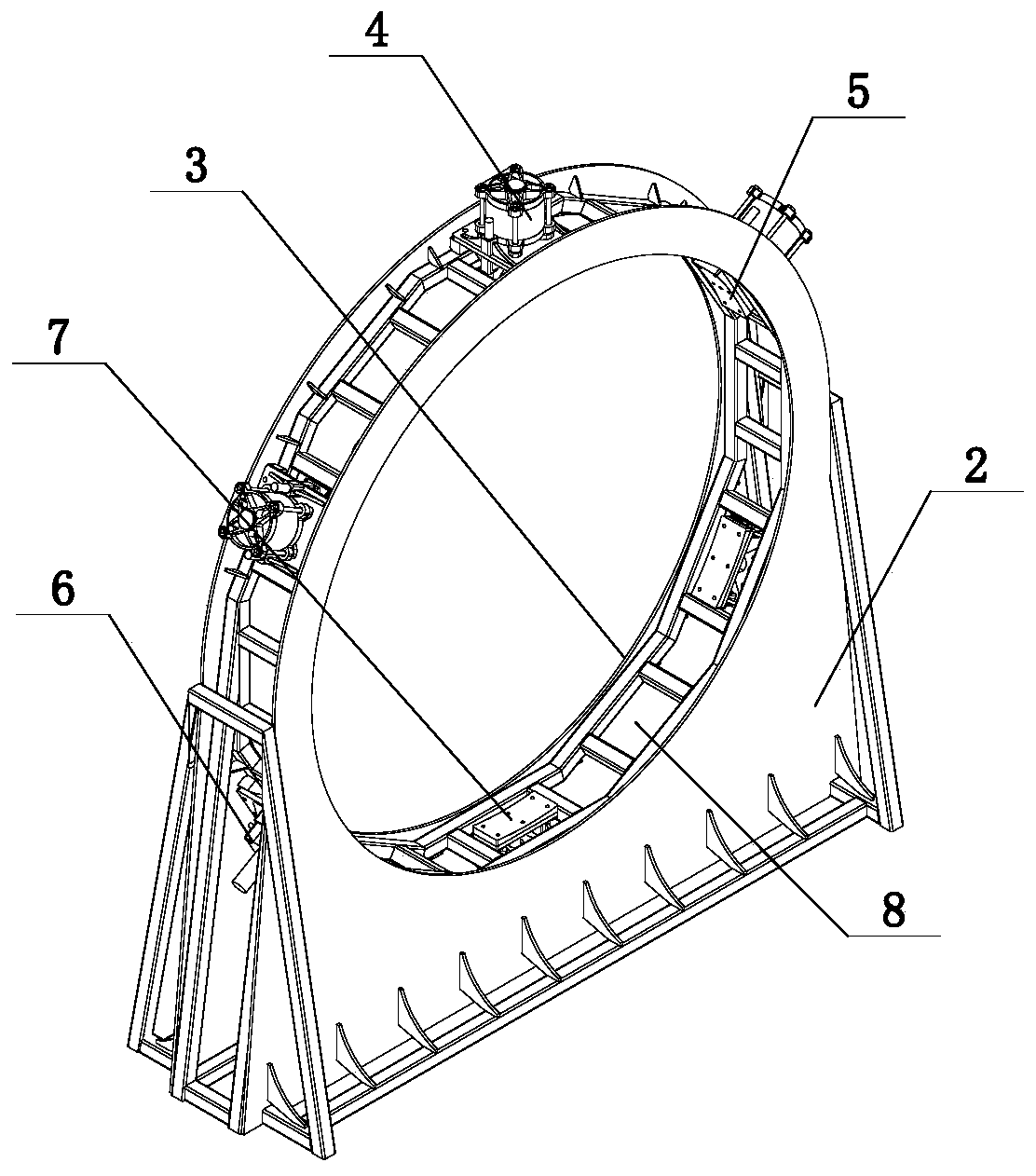

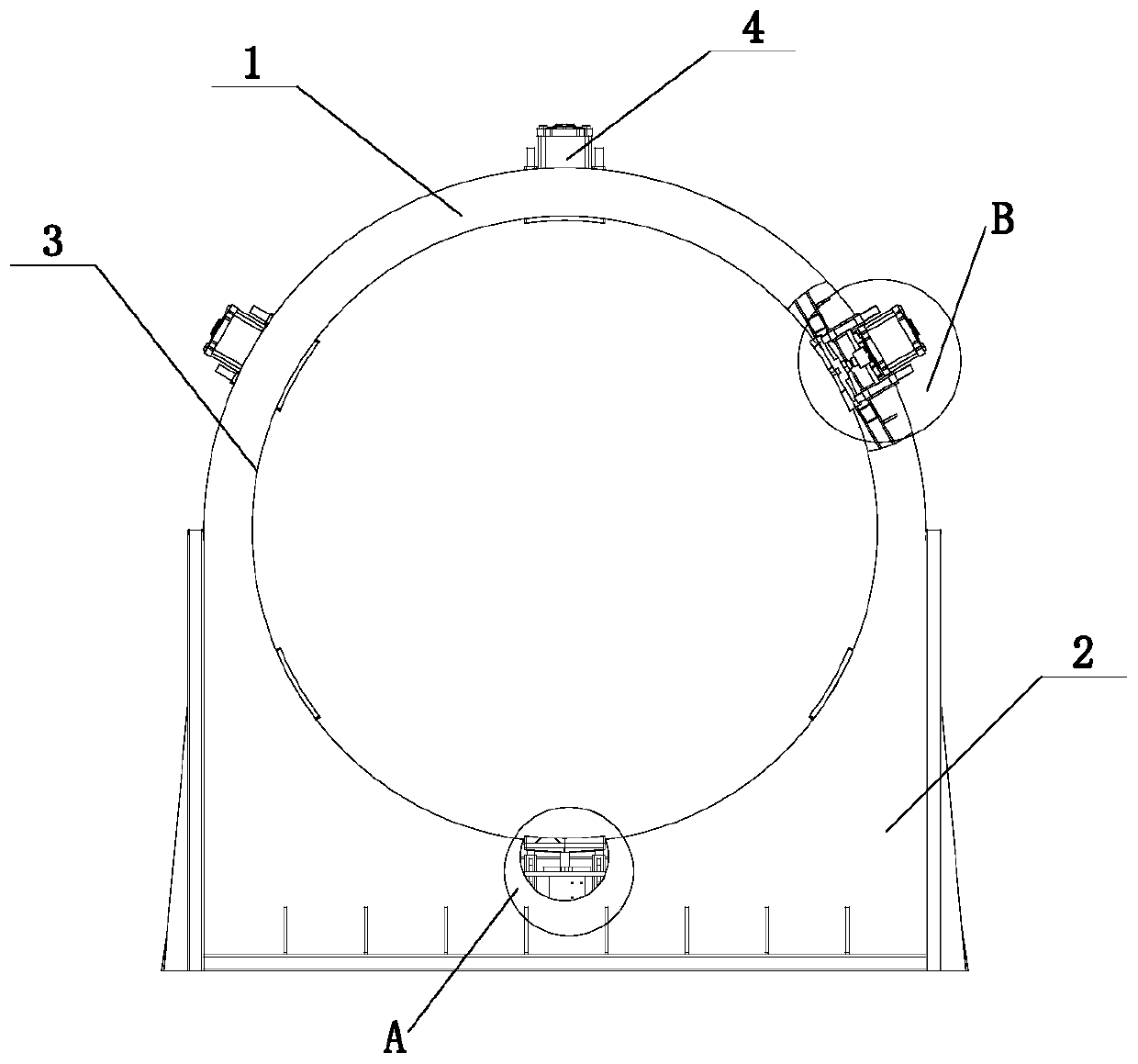

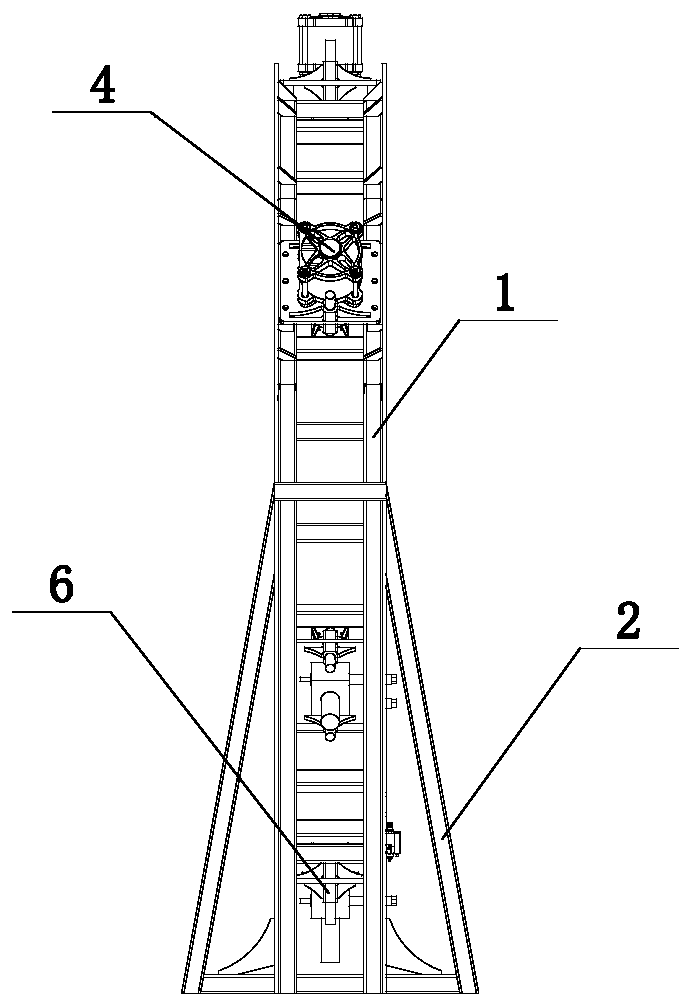

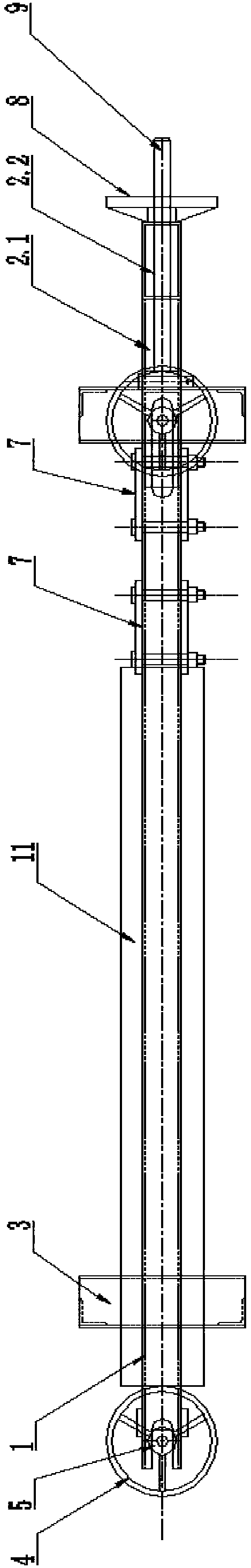

Clamping ring for root end of composite material blade

The invention discloses a clamping ring for a root end of a composite material blade. The clamping ring comprises a clamping ring main body with a circular cross section and a clamping bracket arranged below the clamping ring main body and integrally formed with the clamping ring main body; an annular installation through groove is formed in the clamping ring main body; a plurality of indexing installation grooves are uniformly arranged in the annular installation through groove; a plurality of upper clamping plates matched with the outer diameter of the blade root end are arranged in the indexing installation grooves closing to a top position in the annular through groove by an upper adjusting device; and a plurality of lower clamping plates matched with the outer diameter of the blade root end are arranged in the indexing installation grooves closing to a bottom position of the annular through groove by a lower adjusting device. The clamping ring for the root end of the composite material blade provided by the invention can achieve better clamping to the root end of the blade by adjusting the upper adjusting device and the lower adjusting device; and the root end of the blade isprevented from shaking and displacing during the swaying and displacement of the root end of the blade during the processing, so that the root end can ensure the completed arc degree.

Owner:海尼肯智能技术成都有限公司

Processing technology and device for front roof panel assembly

ActiveCN112692460BImprove processing and production pass rateIncrease elasticityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining process

The invention relates to the field of auto parts processing, in particular to a processing device for a front roof panel assembly, including a frame, a welding mechanism and a clamping mechanism. Rod and cylinder, the clamping mechanism is provided with a first clamping group and a second clamping group, the first clamping group includes a first lower jaw on the base and a first upper jaw on the swing rod, The second clamping group includes a second lower jaw on the base and a second upper jaw on the swing rod. The present invention also provides a processing technology for the front roof panel assembly, including the following steps: 1. Prepare the front roof panel outer panel and the front roof panel inner panel; Clamp the panel and the inner panel of the front roof panel, and adjust the clamping force of the clamping mechanism; 3. Use the welding mechanism to weld the outer panel of the front roof panel and the inner panel of the front roof panel. The invention improves the pass rate of processing and production of the front roof plate assembly.

Owner:CHONGQING ZHIXIN IND CO LTD

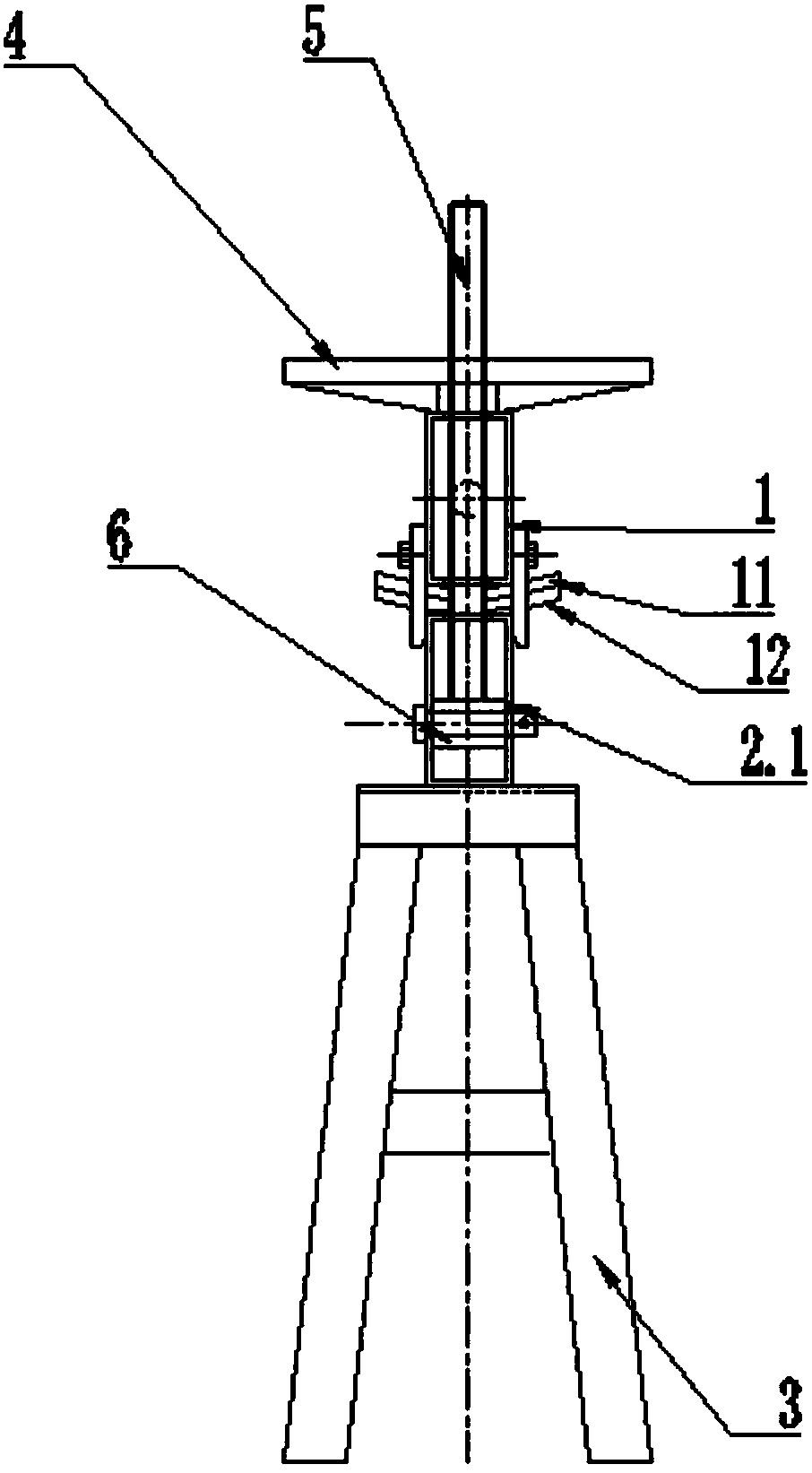

Arc template positioning and adjusting device and method for positioning template by using same

ActiveCN110080587ASimplify planningGuaranteed accuracyForms/shuttering/falseworksBulk storage containerEngineeringRotational flow

The invention provides an arc template positioning and adjusting device and a method for positioning a template by using the same. The device comprises a supporting frame, a fixed baffle and a movablebaffle, the fixed baffle is arranged and connected to the supporting frame, and a distance measuring device is arranged on the fixed baffle and used for measuring the distance between the fixed baffle and a preset position, so as to position an inner side arc template; a preset position is the central position of a liquid purifying tank or a rotational flow tank, the movable baffle is connected to the supporting frame in the length direction of the supporting frame in a position-adjustable mode and used for adjusting the distance between the fixed baffle and the movable baffle, so as to position an outer side arc template. According to the invention, the distance between the fixed baffle and the central position of the liquid purifying tank or the rotational flow tank is measured throughthe distance measuring device, so that the inner side arc template is positioned, measured and adjusted through the fixed baffle; and the movable baffle moves along the supporting frame, so that the distance between the fixed baffle and the movable baffle is adjusted according to the design sizes of the liquid purifying tank and the rotational flow tank.

Owner:CHINA FIRST METALLURGICAL GROUP

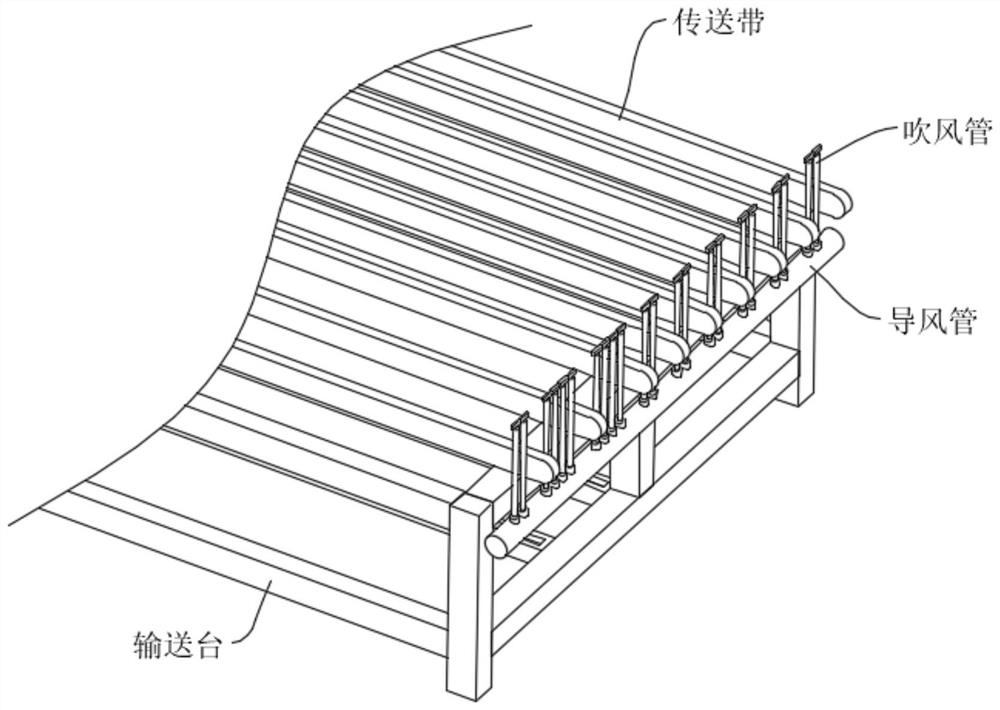

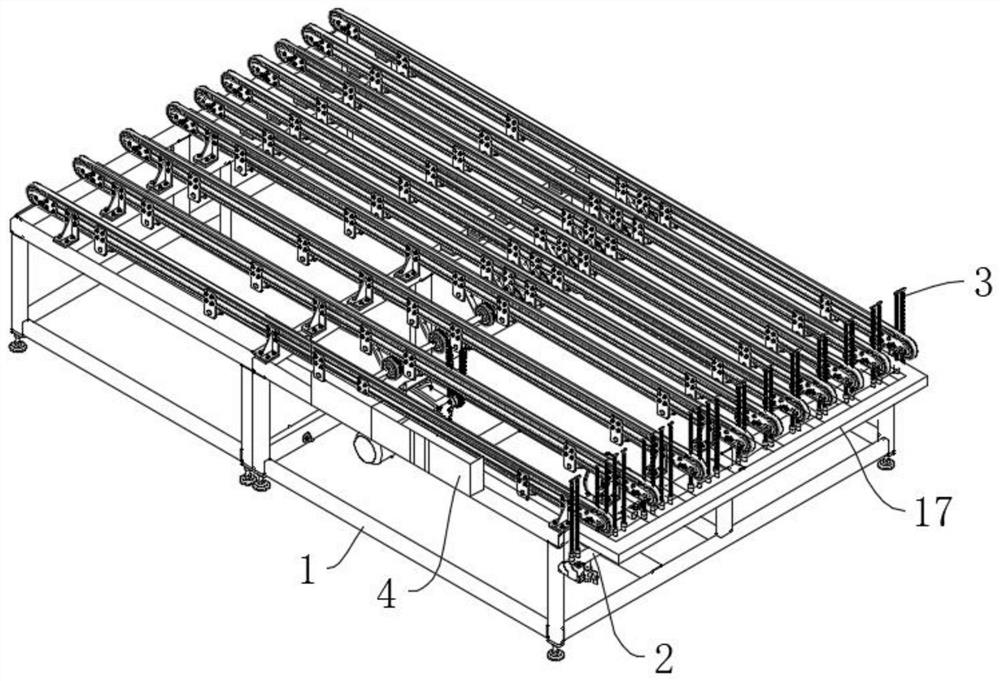

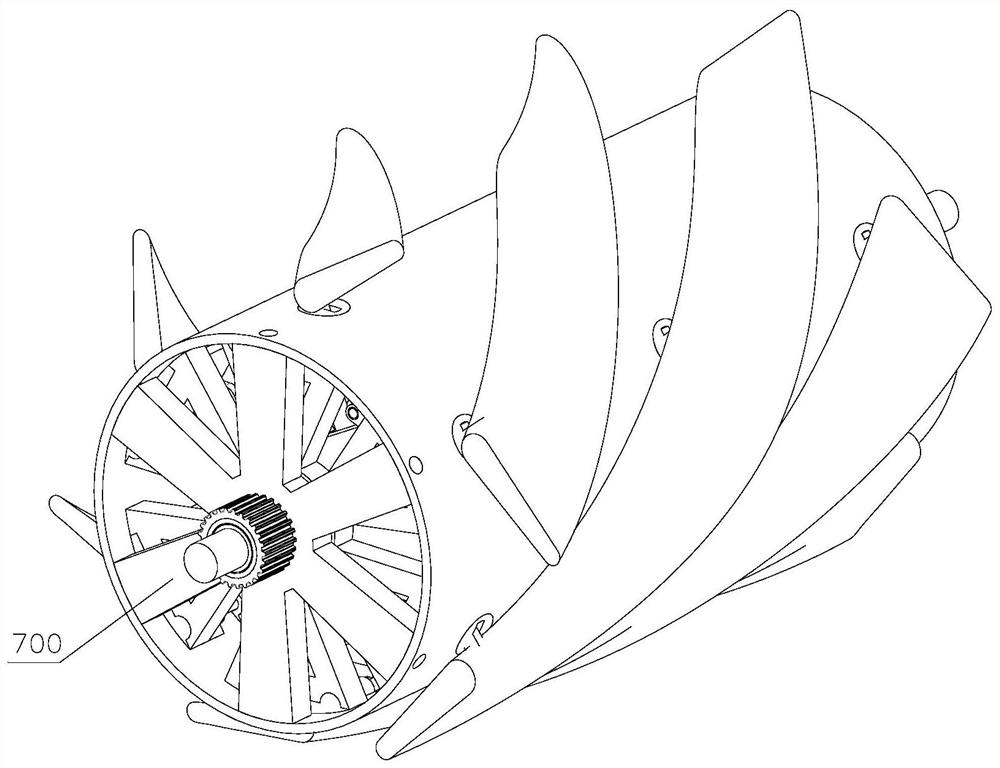

Automatic film blowing device of laminated glass conveying table

ActiveCN114425904APlay the role of clamping and fixingEasy to assemble and disassembleLamination ancillary operationsLaminationGear wheelEngineering

The automatic film blowing device comprises the conveying table, an air guide pipe is fixed to one side of the conveying table, a plurality of universal bamboo joint blowpipes are arranged on the air guide pipe in a penetrating mode, two sets of first side plates are arranged on the upper surface of the conveying table, and first through grooves are formed in the ends, away from the air guide pipe, of each set of first side plates; a first gear disc is rotationally arranged in the first through groove, a second side plate is fixed to the outer side wall of the first gear disc, a second gear disc is further rotationally arranged in the first through groove, and the second gear disc is connected with the first gear disc in an engaged mode. Through cooperation of a second side plate, a first gear disc and a second gear disc, an operator can adjust and rotate a rotating disc and correspondingly adjust the position of the first side plate according to site conditions, so that the first side plate is located at the optimal air guide position, air blown out of the universal bamboo joint air blowing pipe is guided, and the air blowing efficiency is improved. And wind blown by the universal bamboo joint blowpipes located on the outer side is prevented from diffusing to the outer side, and the use effect is not affected.

Owner:蚌埠朝阳玻璃机械有限公司

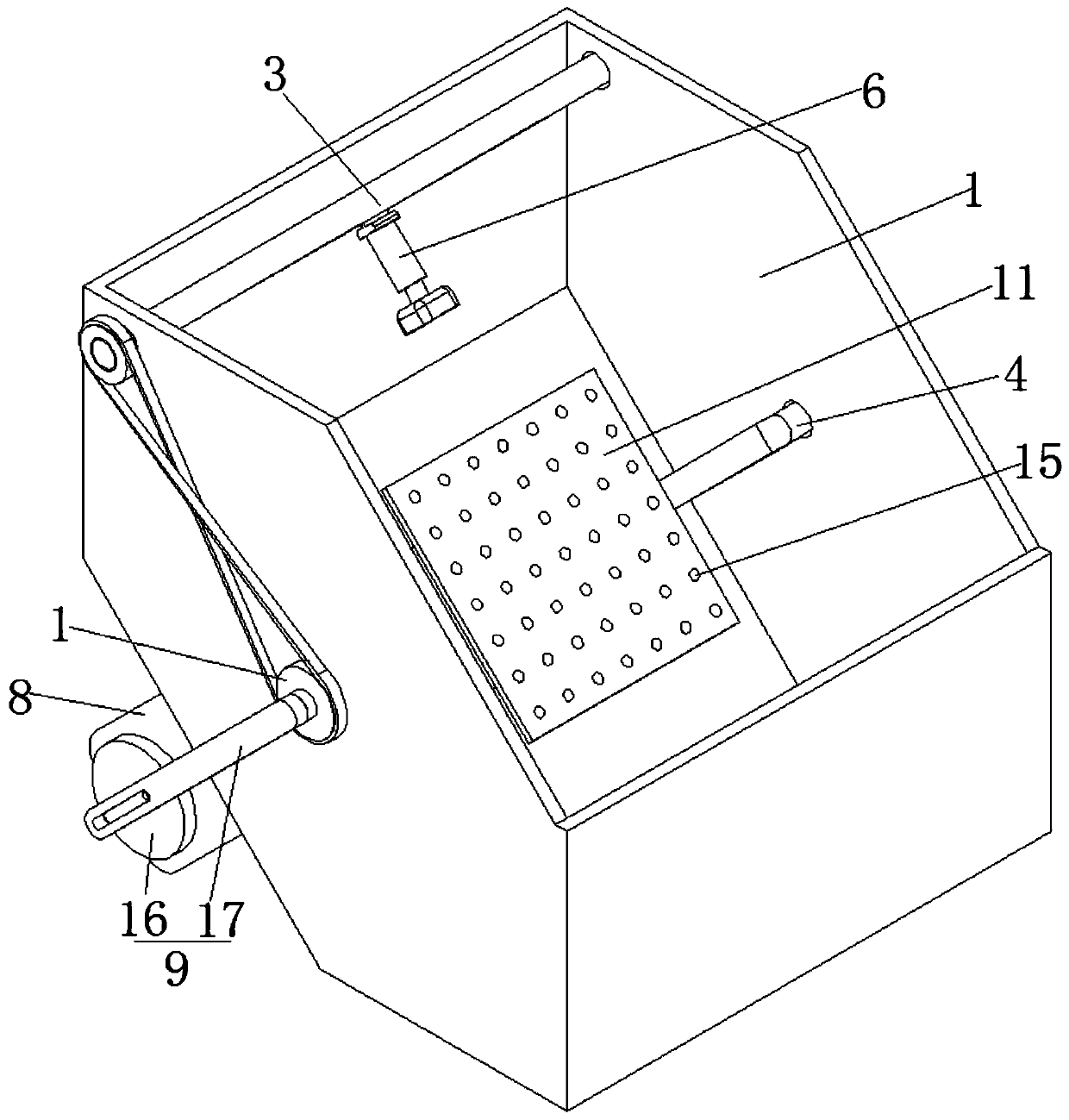

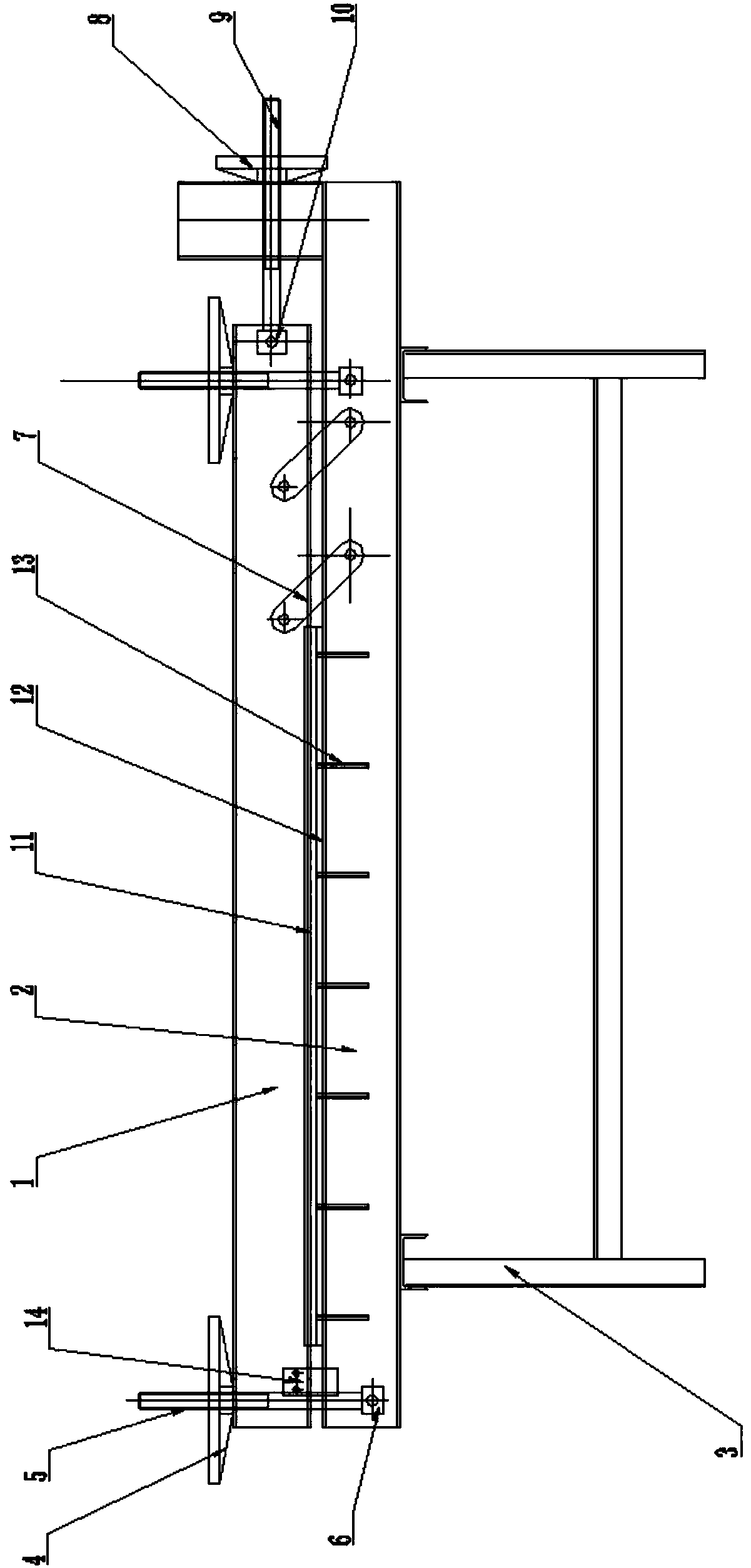

Transformer paper tube bonding device

PendingCN108242339AEasy accessEven by forcePaper/cardboard wound articlesCoils manufactureTransformerEngineering

The invention discloses a transformer paper tube bonding device. An upper press plate is a rectangular frame; a lower support plate comprises a cross beam and a vertical support seat; the cross beam and the vertical support seat are both a rectangular frame; the vertical support seat is fixed at the upper end on one side of the cross beam; the length of the upper press plate is less than the length of the cross beam; a compaction device is arranged at the left and right ends of the upper press plate respectively; a screw I is fixed at the upper end of a fixing block I and sequentially passes through an oblong hole in the cross beam and an oblong hole in the upper press plate; a hand wheel I is mounted at a threaded end on the upper side of the screw I; a connecting rod is articulated between the upper press plate and the cross beam; when the left end surface of the upper press plate is level with the left end surface of the cross beam, the center line of the articulation hole in the upper press plate does not stay on the same vertical line with the center line of the articulation hole in the cross beam; and a stretching device is arranged on the vertical support seat. In the invention, the structure is simple, the transformer paper tube bonding side is under uniform stress, the finished product can be taken out easily without auxiliary equipment, and thus the device has high efficiency and is convenient to use.

Owner:JIANGSU HUACHEN TRANSFORMER

Pain relieving device for pain department

InactiveCN114767354AAdjustable distanceRelief the painPneumatic massageMedical devicesPhysical medicine and rehabilitationPhysical therapy

The pain relieving device for the pain department comprises a main support, an auxiliary support is slidably connected to the interior of the main support, side supports are installed on the rear sides of the left end and the right end of the main support, and fixing belts are connected to the rear sides of the side supports; the lower supporting box body is installed on the front side of the lower portion of the auxiliary support, a heating pipe is installed on the bottom side face in the lower supporting box body, and a feeding port is connected to the upper left side of the lower supporting box body; and the heat insulation cotton is mounted in the side wall of the lower supporting box body. According to the pain relieving device for the pain department, the lower supporting box body and the relieving pillow are arranged, the distance between the lower supporting box body and the relieving pillow can be adjusted through the main support and the auxiliary support which are connected in a sliding mode, it is guaranteed that the lower supporting box body and the relieving pillow correspond to the waist and the neck of a patient respectively, and the waist of the patient is supported and pushed through the lower supporting box body; the waist of the patient can be guaranteed to have a certain radian, and waist pain of the patient is relieved through pressing force of the lower supporting box body.

Owner:安阳市第六人民医院

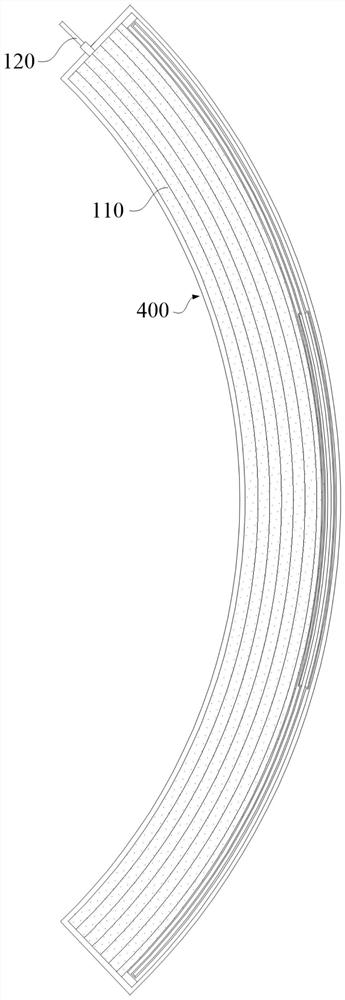

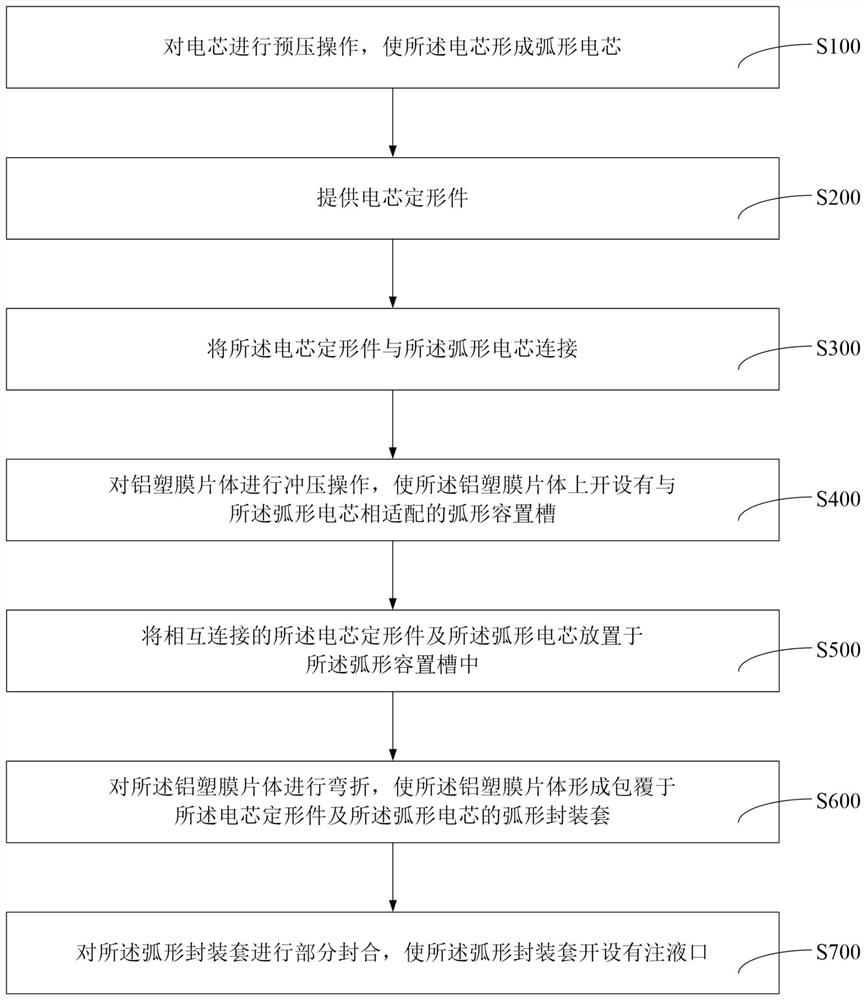

Shaping processing method for arc-shaped battery, and arc-shaped battery

ActiveCN113258122AReduce bending timeImprove processing efficiencyFinal product manufactureSecondary cells manufactureStructural engineeringPlastic film

The invention provides a shaping processing method for an arc-shaped battery, and the arc-shaped battery. The shaping processing method for the arc-shaped battery comprises the following steps: carrying out pre-pressing operation on a battery cell so as to allow the battery cell to form an arc-shaped battery cell; providing a shaped battery cell; connecting the shaped battery cell with the arc-shaped battery cell; performing stamping operation on an aluminum-plastic film sheet body so as to allow an arc-shaped accommodating groove matched with the arc-shaped battery cell to be formed in the aluminum-plastic film sheet body; placing the shaped battery cell and the arc-shaped battery cell which are connected with each other in the arc-shaped accommodating groove; and bending the aluminum-plastic film sheet body to allow the aluminum-plastic film sheet body to form an arc-shaped packaging sleeve covering the shaped battery cell and the arc-shaped battery cell. According to the invention, the flat battery cell is quickly bent and pressed into an arc-shaped structure through pre-pressing operation, so the processing time of bending and pressing is favorably shortened; the arc-shaped battery cell is fixed through the shaped battery cell, so the arc-shaped battery keeps self radian in the processes of transportation and circulation; and as bending operation does not need to be carried out on an packaged aluminum-plastic film, wrinkles caused by bending operation can be effectively avoided.

Owner:HUIZHOU HENGTAI TECH

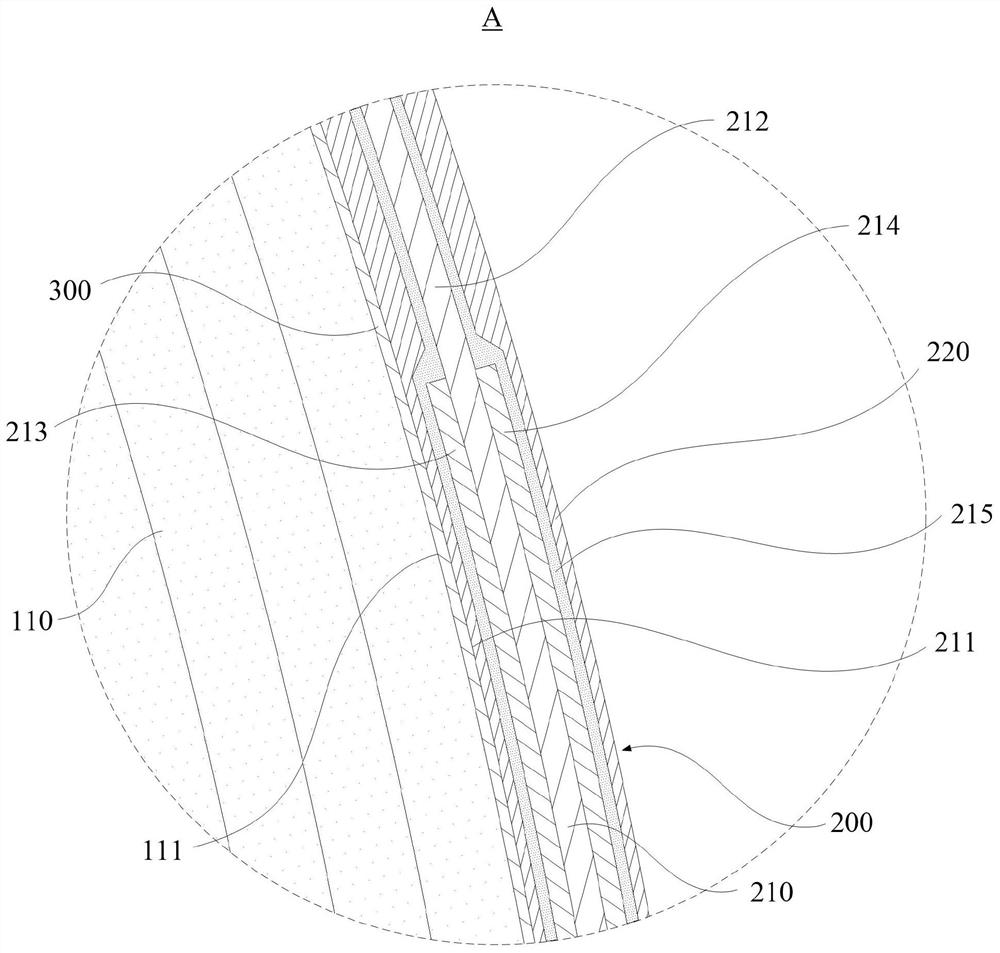

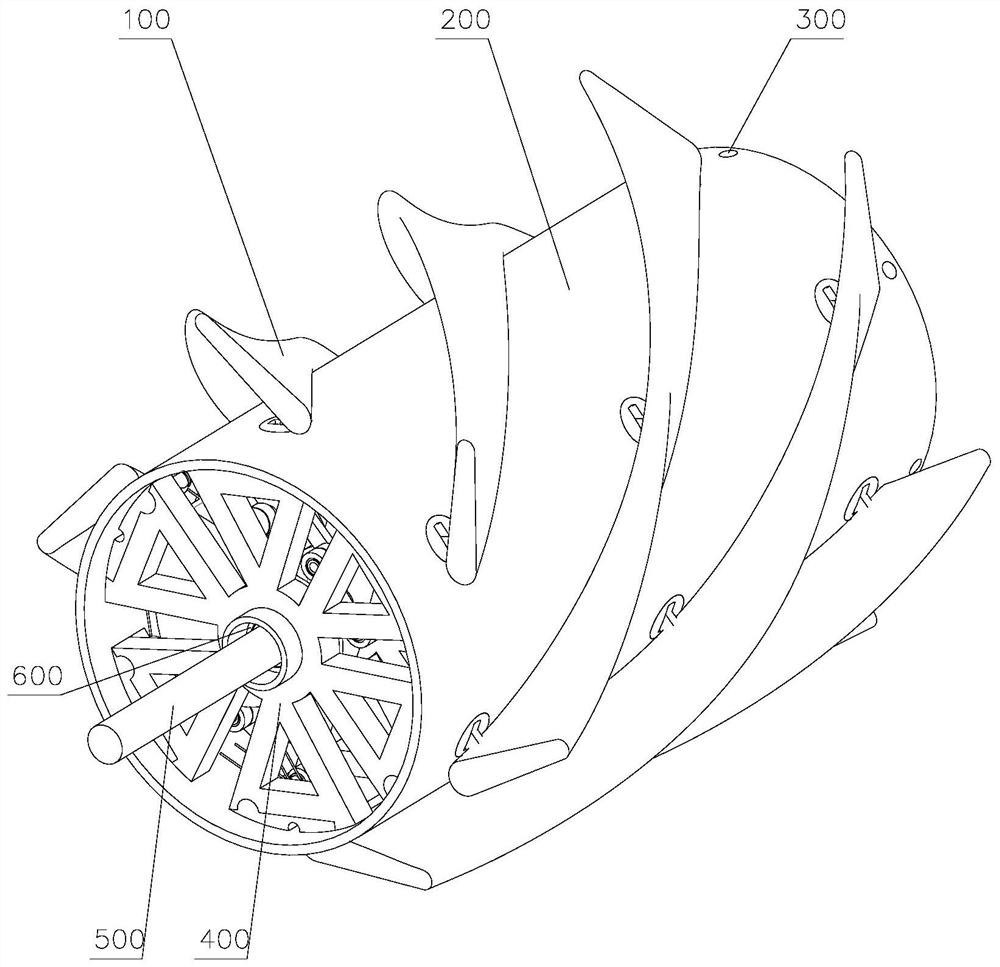

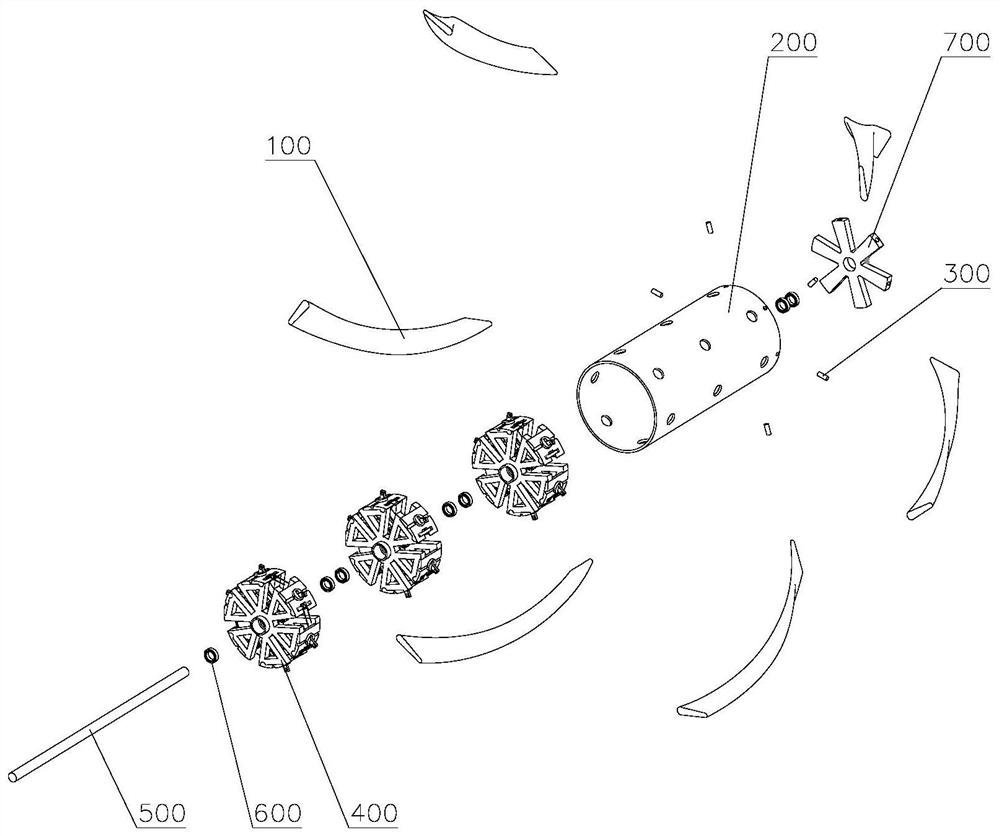

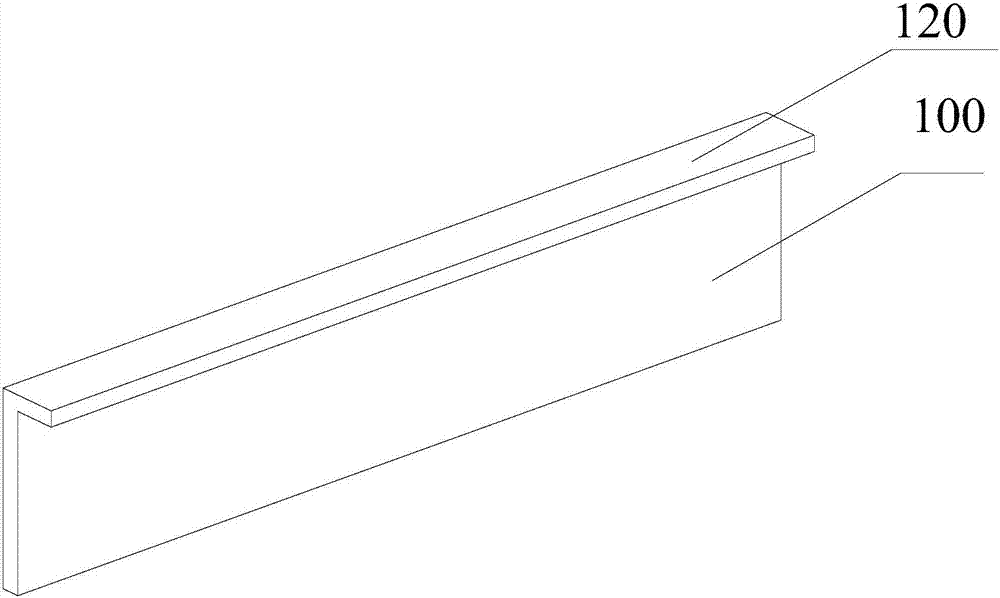

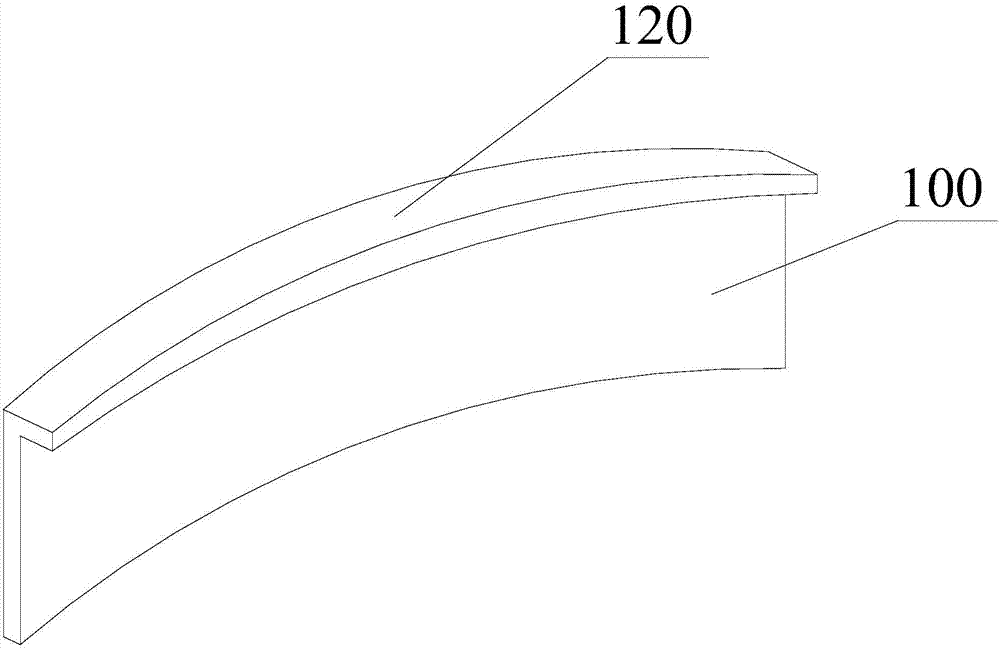

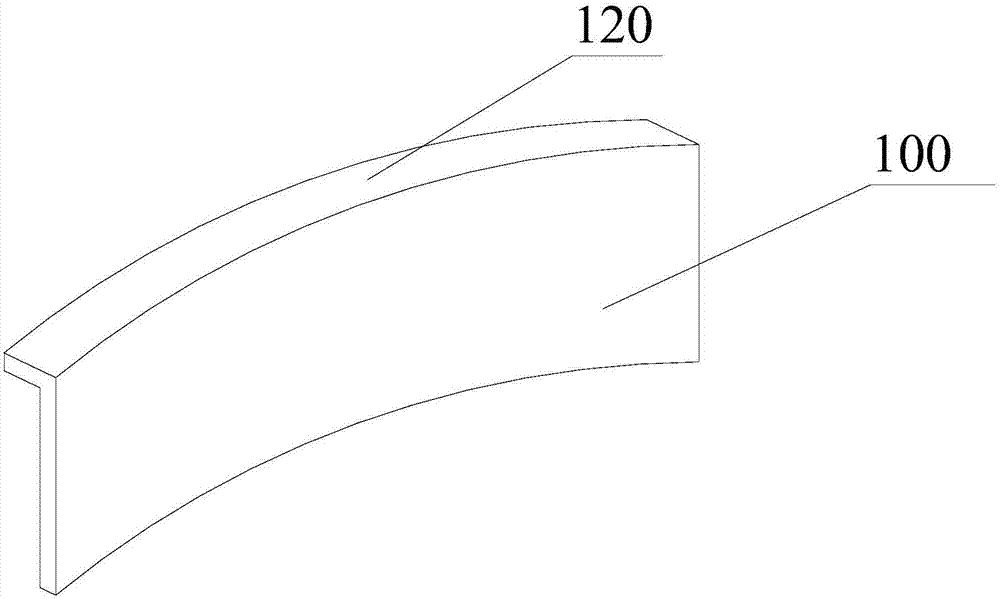

Strawberry picking device and assembly method thereof

The invention relates to the technical field of agricultural automation, in particular to a strawberry pickup device and an assembly method thereof. The strawberry pickup device comprises a roller anda supporting shaft, a pickup roller transmission module and a plurality of front-end contact blocks, wherein the central line of the supporting shaft coincides with the central line of the roller, the pickup roller transmission module penetrates through the supporting shaft to be fixed to one end of the inner side of the roller, the diameter of the pickup roller transmission module is identical to the inner diameter of the roller, the front-end contact blocks are arranged on the outer side of the roller at preset angles in the form that the front-end outer contact blocks are higher the front-end inner contact blocks. By adopting the form that the front-end outer contact blocks are higher the front-end inner contact blocks, the pull forces of fruit stems to strawberries can be ingeniouslyapplied in a spiral pickup mode. Under the effects of the pull forces, the supporting forces of the front-end outer contact blocks and the gravity of the strawberries, strawberries are picked up through the front-end outer contact blocks by applying spiral motion, so that the pickup process is smoother, strawberry skin damage in the strawberry pickup process is decreased, and the losses of orchardists are decreased.

Owner:苏州屹润保鲜设备有限公司

Bending device for circular arc coaming plate of radiator air guide cover

Owner:安徽汇展热交换系统股份有限公司

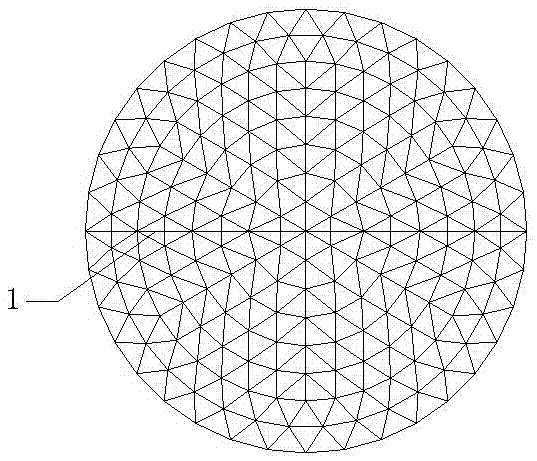

A design method of grg control template and grg control template

ActiveCN107023158BGuaranteed accuracyReduce construction errorsDesign optimisation/simulationAuxillary members of forms/shuttering/falseworksTemplate designDesign methods

The invention discloses a design method for a GRG control template and the GRG control template. A three-dimensional model is constructed according to a GRG special-shaped curved face; then, the three-dimensional model is partitioned into GRG unit modules; then the GRG unit modules are partitioned to form a grid unit, and the GRG control template is designed according to the boundary line of the grid unit; and finally, the GRG control template is installed on a GRG special-shaped curved face frame, and the GRG unit modules are installed according to the GRG control template. The special-shaped GRG control template designed according to the method includes the GRG control template which comprises a transverse frame and a longitudinal frame, each of the transverse frame and the longitudinal frame comprises multiple GRG control template unit blocks, and an arc GRG control template frame is composed of the multiple GRG control template unit blocks. By means of the method, special-shaped GRG panels in any shape can be accurately installed, the installation precision is ensured, and the construction errors are reduced.

Owner:MCC5 GROUP CORP SHANGHAI

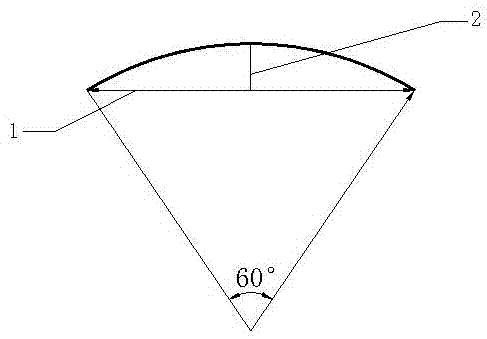

Manufacturing method of tank top steel skin plate of large-scale stainless steel tank

The invention discloses a manufacturing method of a tank top steel skin plate of a large-scale stainless steel tank. The manufacturing method is characterized by comprising the following steps: a, drawing an arrangement drawing of the tank top steel skin plate according to the design working drawing of the large-scale stainless steel tank; b, conducting blanking according to the arrangement drawing of the tank top steel skin plate, cutting steel plates and carrying out weld preparation, conducting machining or carrying out automatic and semi-automatic flame cutting machining, and carrying out manual flame cutting machining on the circular arc edge of the tank top steel skin plate; c, designing an arc sample plate of the tank top steel skin plate according to the 60-degree central angle of the spherical arched top of the construction drawing of the large-scale stainless steel tank; inspecting by the arc sample plate after the arc component of the tank top steel skin plate is machined and molded; and inspecting warpage of the tank top steel skin plate on a platform. The manufacturing method of the tank top steel skin plate of the large-scale stainless steel tank has the advantages of good formation degree of the tank top steel skin plate, capability of effectively ensuring the radian of the arched top plate and preventing the deformation and attractive appearance of the spherical spherical arched top.

Owner:MCC5 GROUP CORP SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com