Processing technology and device for front roof panel assembly

A processing device and processing technology, applied in auxiliary devices, metal processing equipment, manufacturing tools, etc., can solve the problem that the qualification rate of the front roof panel assembly fails to meet the requirements, and the front roof panel assembly cannot be delivered to customers. The qualification rate of the outer panel of the front roof panel fails to meet the requirements, so as to achieve the effect of improving the qualification rate of processing and production and improving the precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

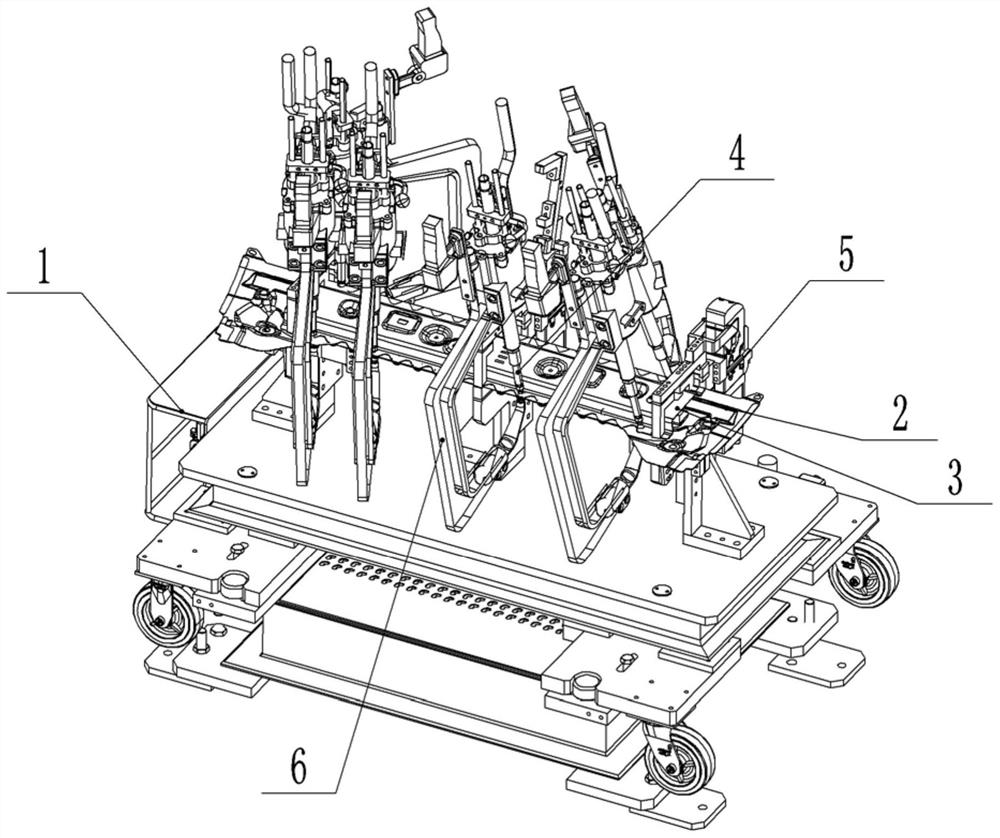

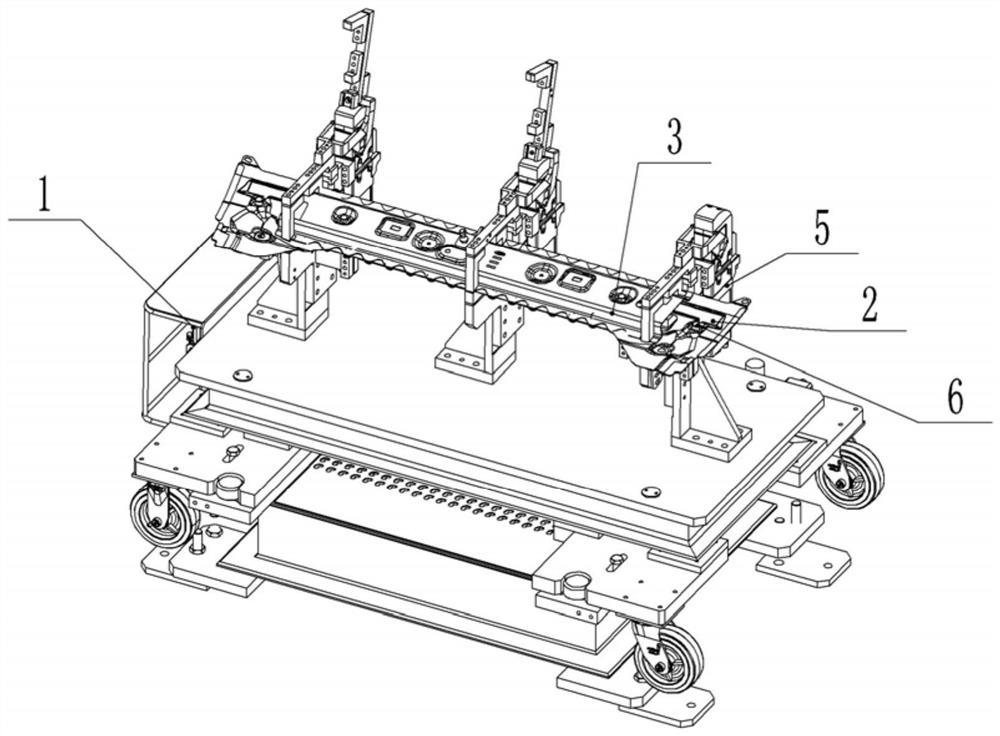

[0031] basically as attached Figure 1-Figure 4 Shown: a processing device for a front roof panel assembly, including a frame 1, a plurality of welding mechanisms and a plurality of clamping mechanisms 5, and the number of clamping mechanisms 5 and welding mechanisms can be specifically set according to actual conditions. Wheels are provided on the bottom of the frame 1 to facilitate the movement of the whole frame 1 .

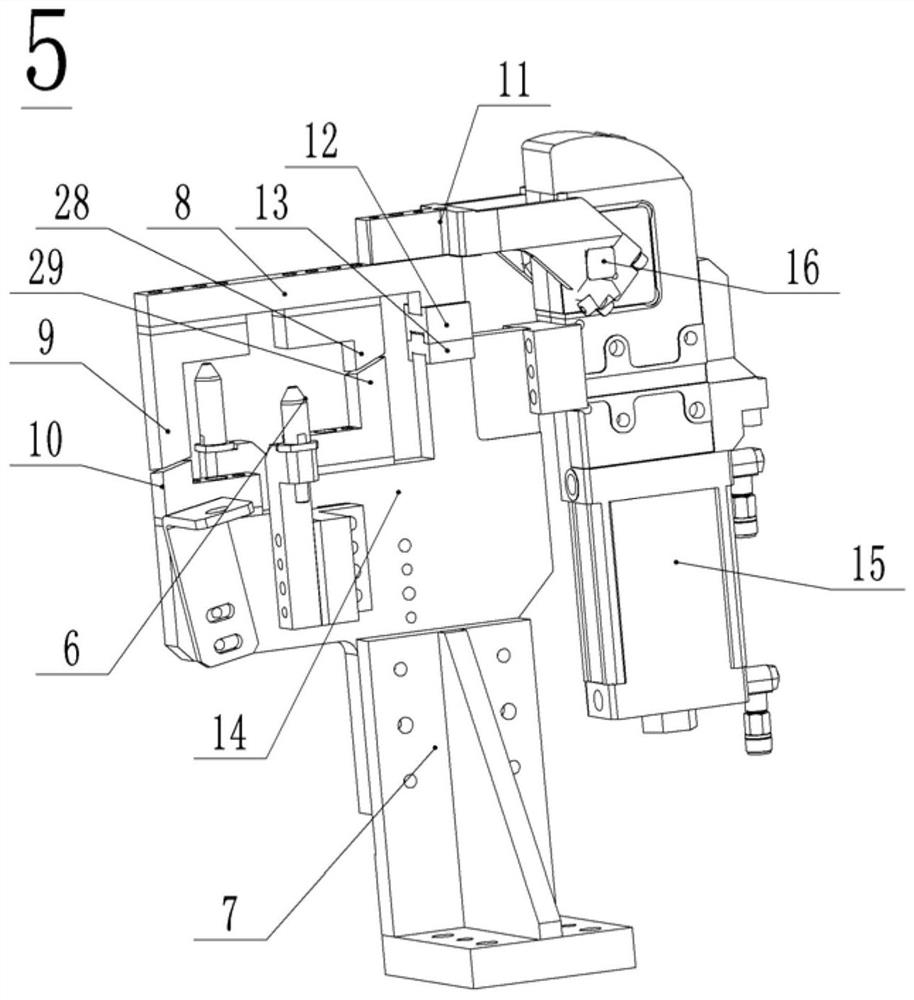

[0032] combine Figure 3-Figure 4As shown, the clamping mechanism 5 includes a base 14, a swing rod 8 on the rotary connection base 14, and a cylinder 15 for driving the swing rod 8 to rotate. The bottom of the base 14 is fixed with a support 7 by screws, and the support 7 is fixed on the frame 1 by screws, and a triangular reinforcing rib is welded on the support 7. The swing rod 8 is rotatably connected to the base 14, and the specific rotational connection method is as follows: a turret 11 is welded on the right end of the swing rod 8, a rotating shaft 16...

Embodiment 2

[0042] combine Figure 5 As shown, this embodiment further improves the clamping mechanism 5. In this embodiment, the first upper clamping jaw 9, the second upper clamping jaw 28, the first lower clamping jaw 10 and the second lower clamping jaw 29 can all be telescopic. The structure and principle of telescoping are the same. Specifically, taking the first clamping group as an example, the swing rod 8 and the base 14 are both provided with a sliding cavity, and the first upper clamping jaw 9 is located in the sliding cavity on the swing rod 8 and can be moved. Sliding on the sliding cavity, the first lower clamping jaw 10 is located in the sliding cavity on the base 14 and can slide in the sliding cavity, between the top end of the first upper clamping jaw 9 and the swing rod 8, the first lower clamping jaw 10 A tension spring 17 is connected between its bottom end and the base 14 . Both sliding chambers are filled with hydraulic oil. The apparatus for processing the front ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com