Sealed forcible trigger gap

A technology of triggering gap and sealing unit, which is applied to emergency protection circuit devices, electrical components, circuit devices and other directions for limiting overcurrent/overvoltage, which can solve the limitation of trigger gap adjustment range, inaccurate concentricity, and inability to adjust distance. and other problems, to achieve the effect of large gap adjustment range, long service life and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

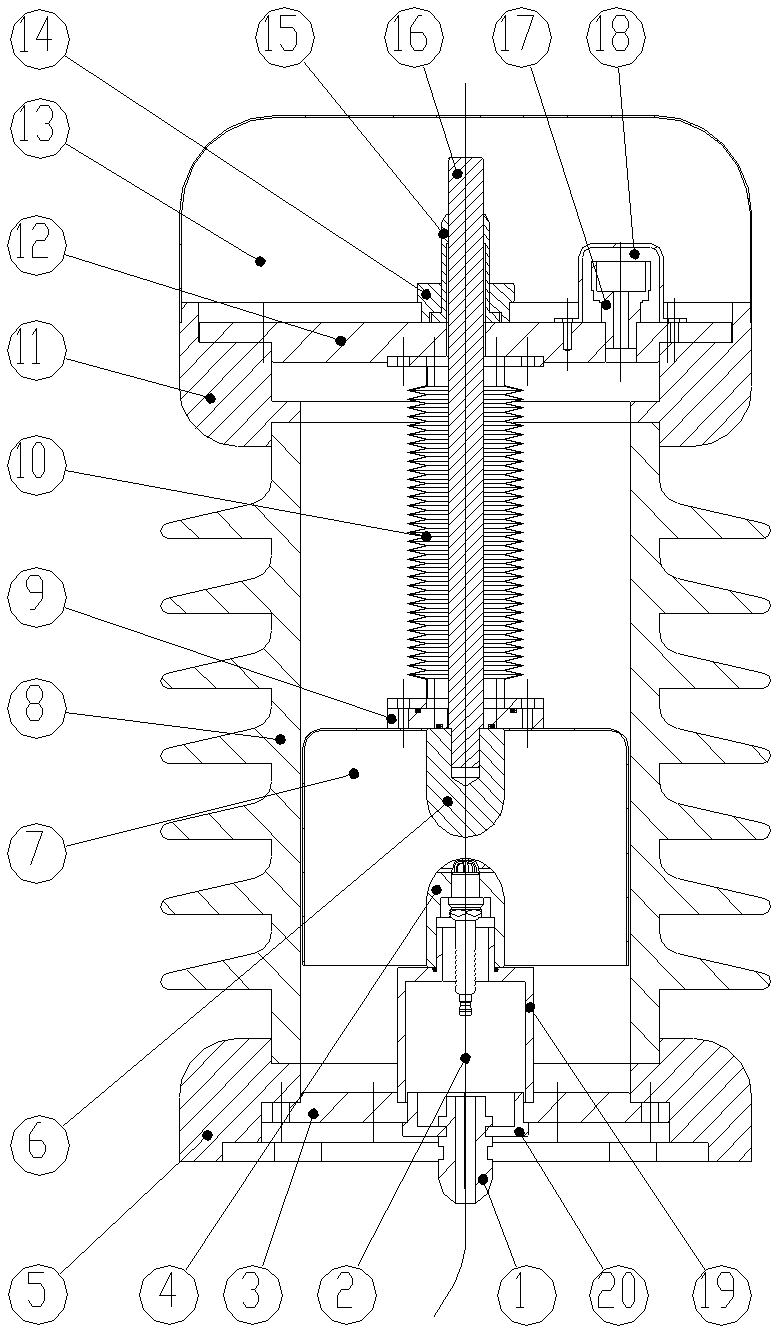

[0018] The technical content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

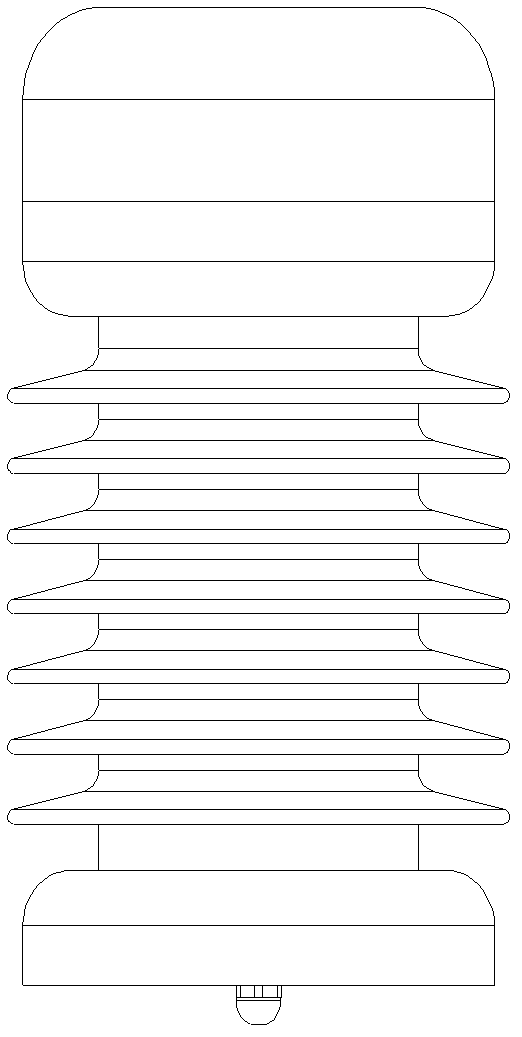

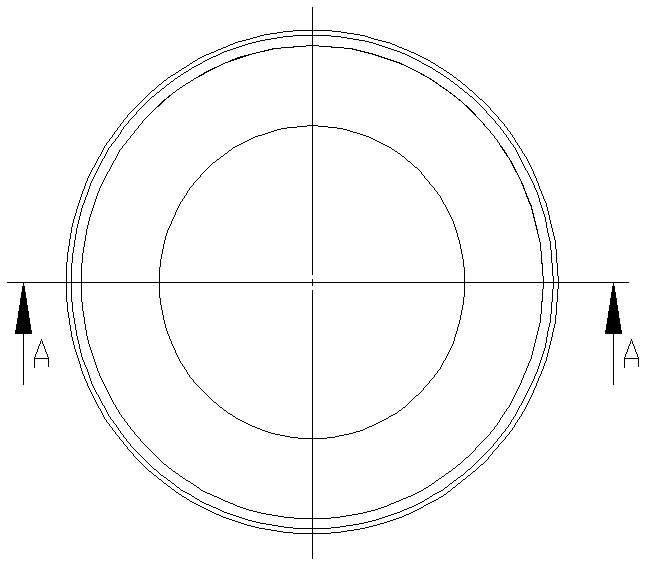

[0019] See Figure 1-Figure 4 , Seal the forced trigger gap, the trigger gap adopts a closed structure in a cylinder, including a sealing unit, an arc strike unit, a discharge unit, a gas injection unit, and an electrode adjustment unit.

[0020] The sealing unit is composed of an upper cover 12, a lower cover 3, a ceramic umbrella skirt 8, a rain cover 13, a lower fixing seat 5 and an upper fixing seat 11. The rain cover 13 is located outside the upper end cover 12 and the guide rod 16. The upper end cover 12 and the lower end cover 3 are fixedly connected with the ceramic umbrella skirt 8 through the upper end holder 11 and the lower end holder 5 respectively. Vacuum and fill with inert gas.

[0021] The arc striking unit is composed of a three-head spark plug 2, a cable jacket 1, and a jacket lock cover 20. The three-head spark p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com