Packaging equipment possessing arc edge fingerprint identification chip and packaging and cutting method

A technology for fingerprint identification and packaging equipment, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of uneven thickness of the chip surface coating, low yield rate, etc., to ensure smoothness, smooth and tidy arc edges Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

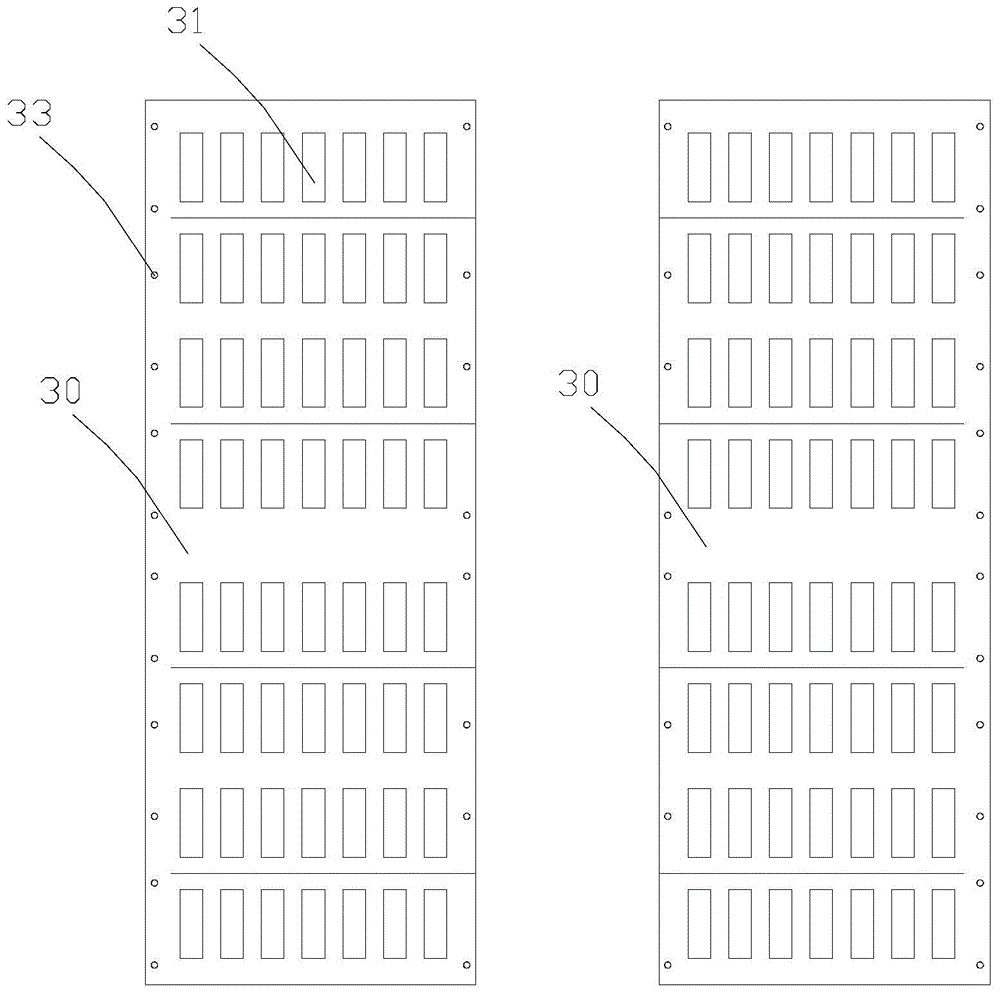

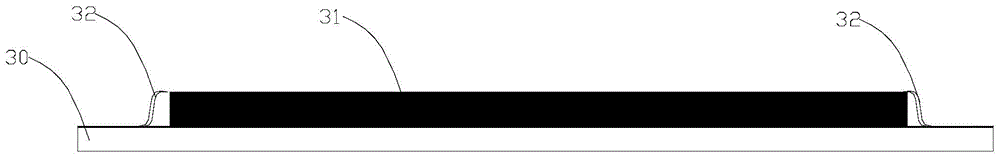

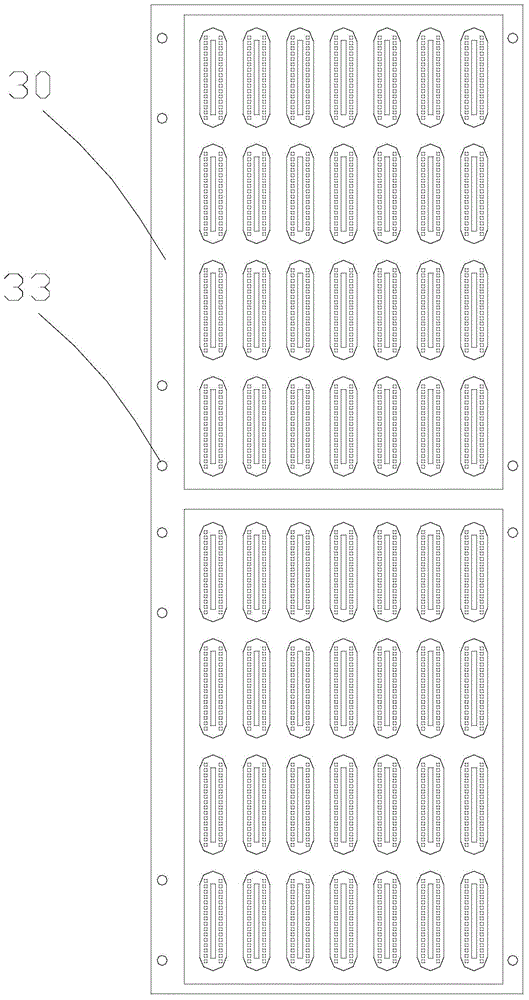

[0034] Embodiment one, with reference to Figure 1-9As shown, the embodiment of the present invention provides a packaging device with an arc-edge fingerprint identification chip, including a pair of molds, the mold is divided into an upper mold 20 and a lower mold 10, and the lower mold 10 is provided with a PCB board that can accommodate slot 11, the PCB board 30 is a whole PCB board with multiple groups of fingerprint identification devices 31 welded, and the upper mold 20 is provided with a circle that can accommodate the identification devices 31 and is consistent with the shape of the fingerprint chip. Shaped or elliptical or flat elliptical cavity 21 with arc edges, the cavity 21 is set corresponding to the fingerprint identification device 31 on the PCB 30, and the cavity 21 is connected to the package through the hot runner 40 The material injection port 50 is connected, the hot runner 40 is divided into a main channel 41 and a branch channel 42, the main channel 41 c...

Embodiment 2

[0036] Embodiment two, refer to Figure 1-9 As shown, this embodiment also provides a packaging and cutting method for fingerprint identification chips with arc edges, using the packaging equipment described in the first embodiment above, the specific steps are as follows:

[0037] Step 1, placing the PCB board 30 into the slot 11 of the lower mold 10, and positioning the PCB board 30 after passing the positioning column 13 through the positioning hole 33;

[0038] Step 2, fastening the upper mold 20 to the lower mold 10 through the positioning pin 22;

[0039] Step 3: vacuumize the mold, heat the mold and keep it at a certain temperature, and then inject packaging material from the injection port 50, and the packaging material enters the injection port 50 in a high-temperature liquid state Enter the main flow channel 41 and the branch flow channel 42 in sequence, gradually reduce the injection pressure and inject into the gap between the cavity 21 and the identification devi...

Embodiment 3

[0047] Embodiment 3, this embodiment also provides a method for encapsulating and cutting a circular fingerprint identification chip, using the encapsulation equipment described in the above-mentioned embodiment 1, the difference from the above-mentioned embodiment is that the identification chip that needs to be produced is Circular, so it is necessary to set a plurality of said branch channels 42 to communicate with the side of the cavity, and it is necessary to keep the flow channels at the communication places relatively thin, so as to make it easier to leave a small gap when laser cutting is used in the cutting process. Burnt surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com