Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Consistent arc" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

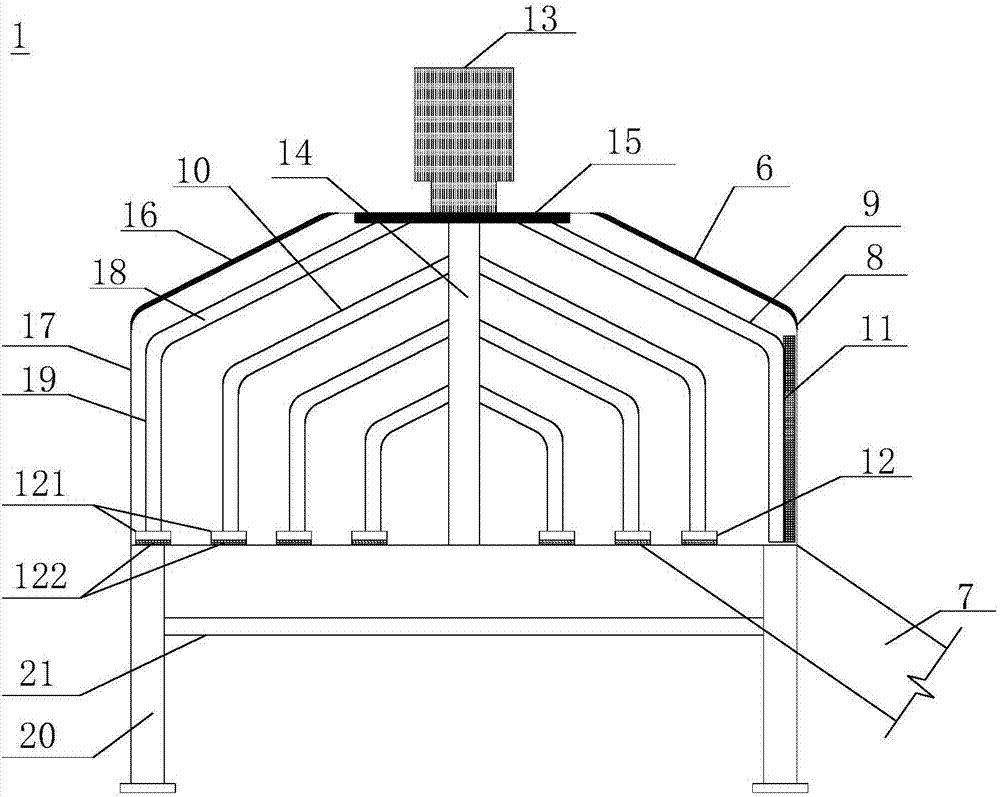

Split type water jacket with diversion water tank and assembly method

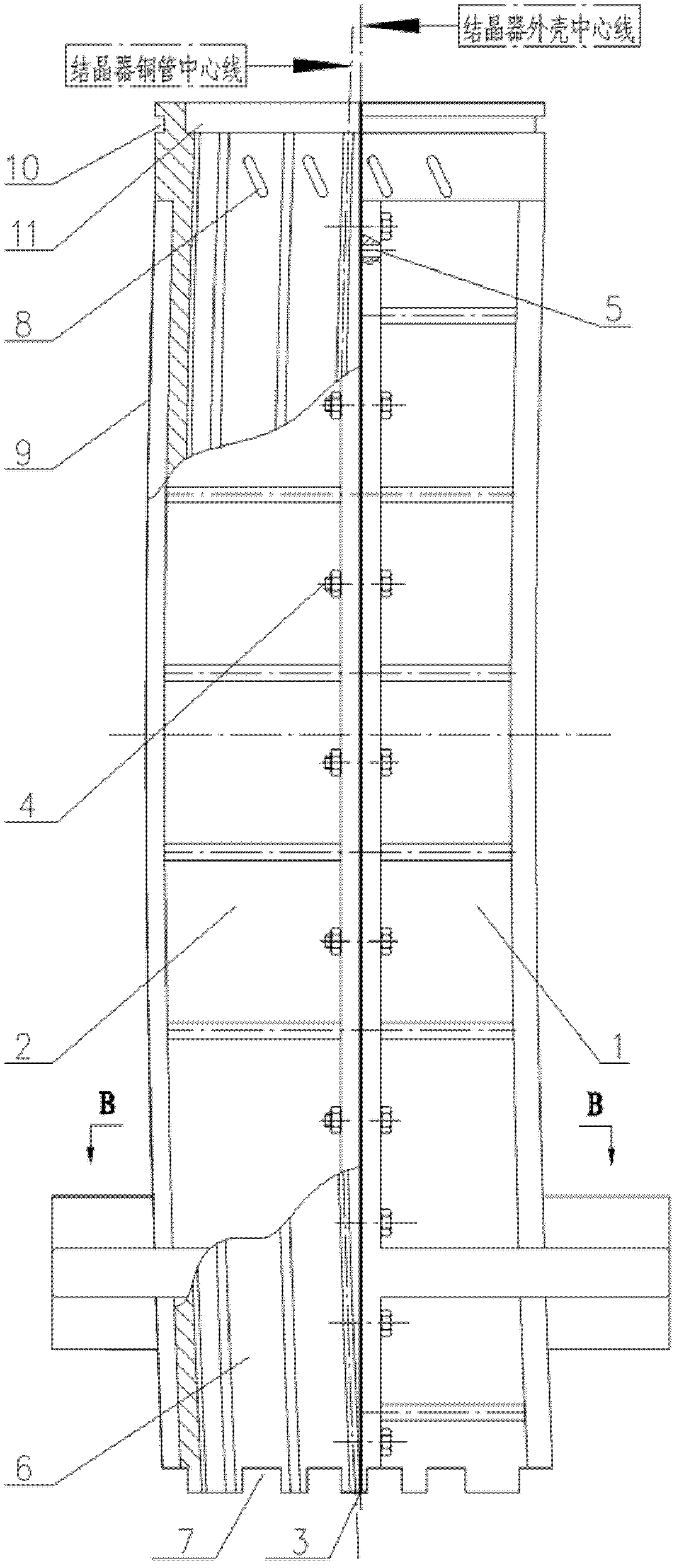

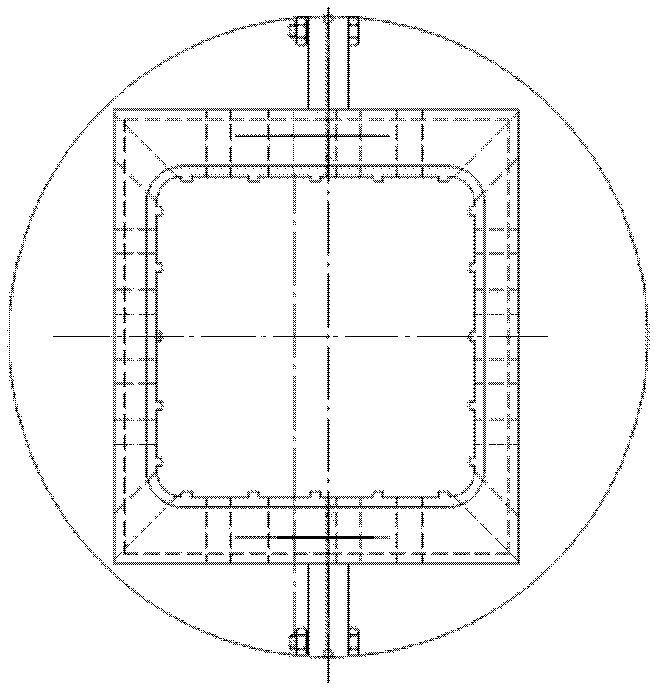

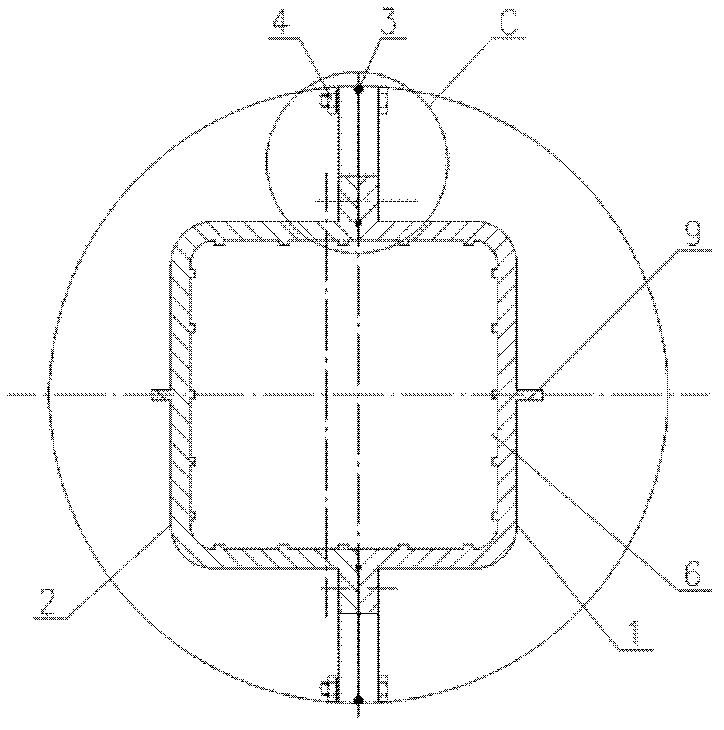

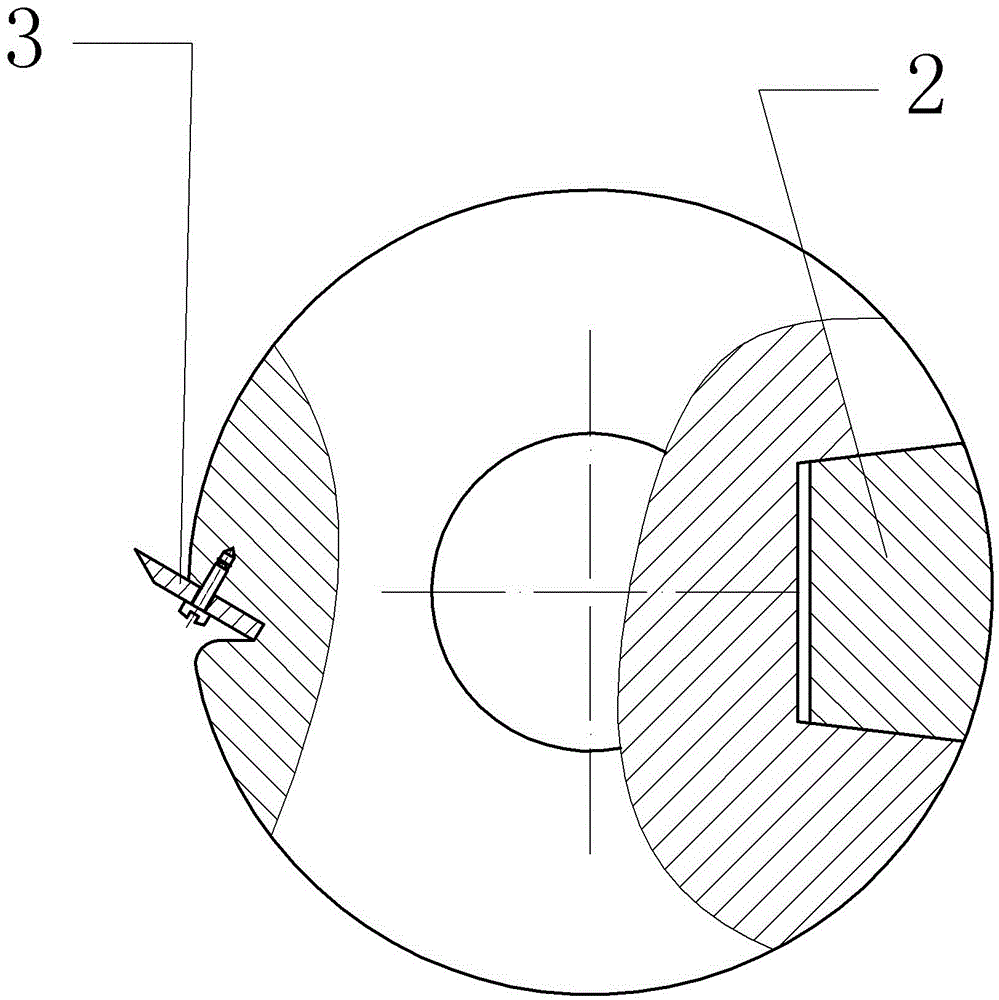

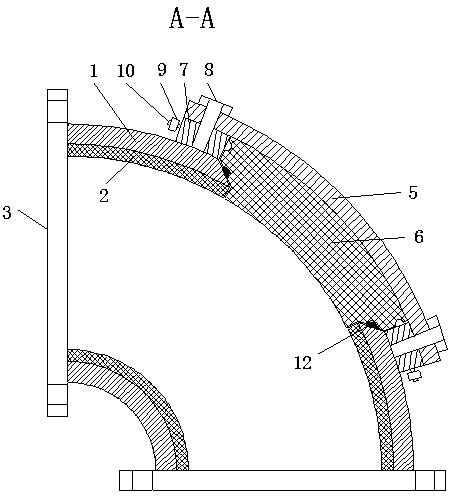

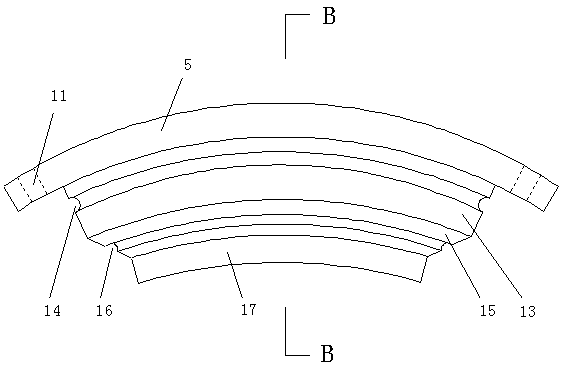

The invention provides a split type water jacket with a diversion water tank and an assembly method. The split type water jacket with the diversion water tank comprises an inner arc half water jacket, an outer arc half water jacket, a sealing element, a fastening element and a positioning pin group; wherein the water jacket are two separated bodies by using the centerline of a crystallizer cylinder as a dividing line; an angular water path, a side surface water path and an arc surface water path are arranged in each separated body; an inner cavity of each water jacket is provided with ribs; a diversion water tank is formed between every two adjacent ribs; and crisscross rib plates are distributed at the outer side of the water jackets. When the water sleeves are assembled, the inner arc half water jacket, an outer arc half water jacket are combined according to design dimensions firstly and then are integrally processed; after being processed, the inner arc half water jacket, an outer arc half water jacket are assembled in a crystallizer; combining surfaces are sealed; positioning pins are arranged between the combining surfaces for positioning; and bolts are arranged between the combining surfaces for fastening. According to the split type water jacket, the controllability of cooling water joints is structurally ensured; the deviation between the center of a circle of a copper pipe circular arc and the center of a casting machine can be avoided; the heat exchange effect of the water joints is beneficial for improving; and the production and operation cost is reduced.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

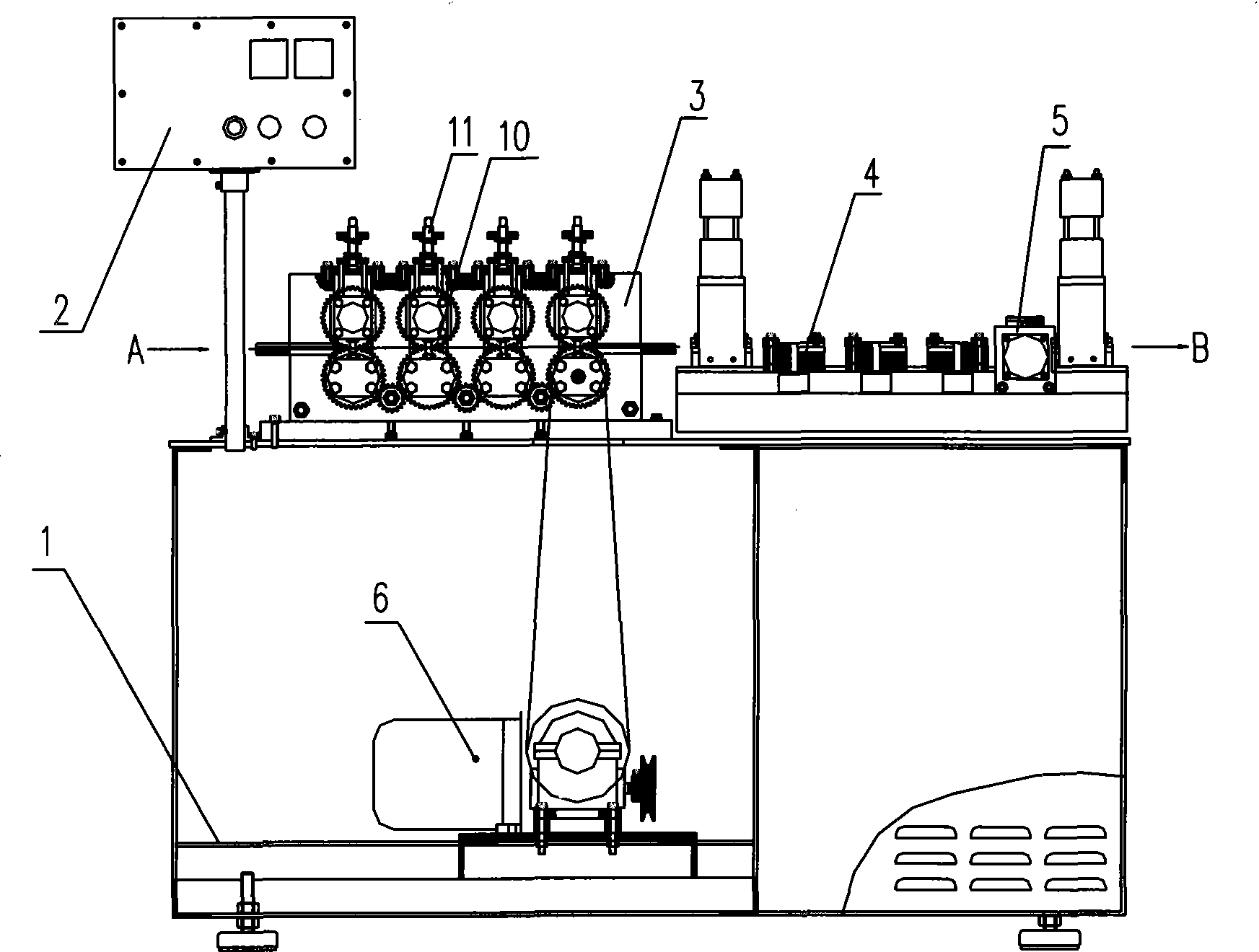

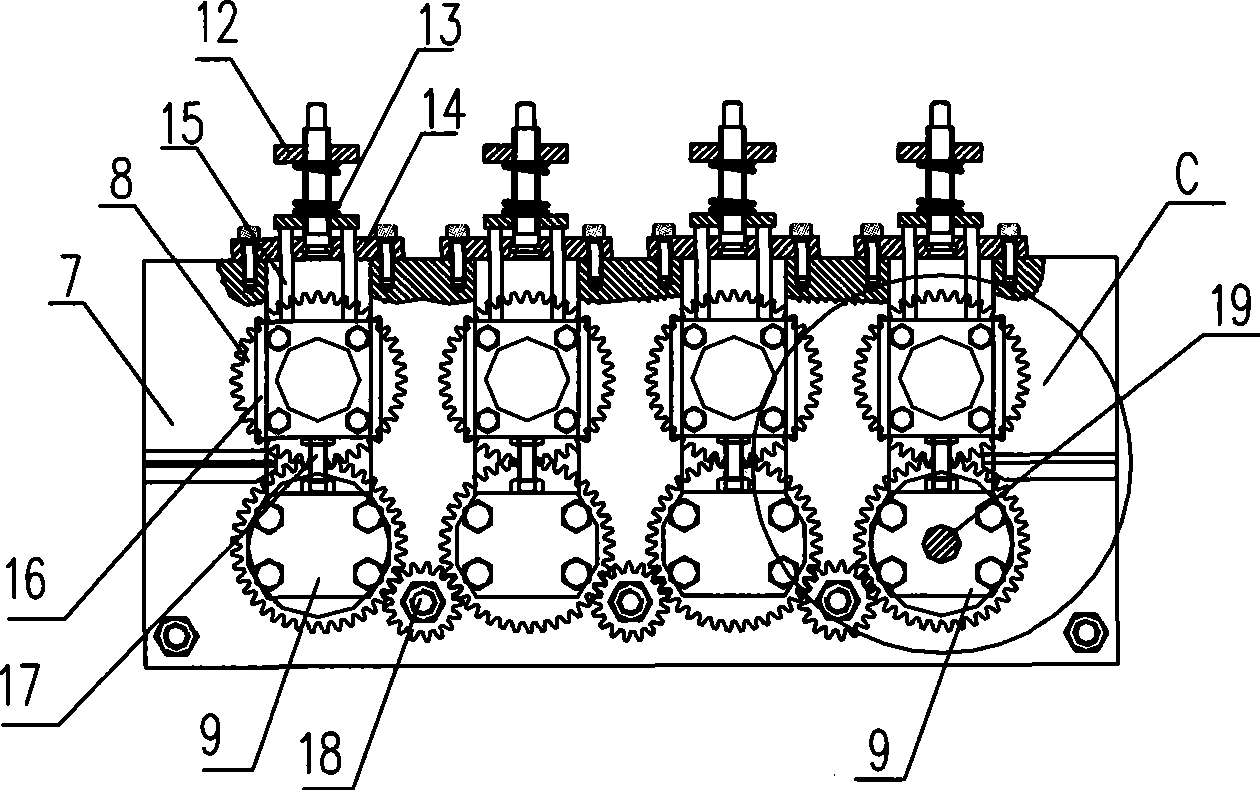

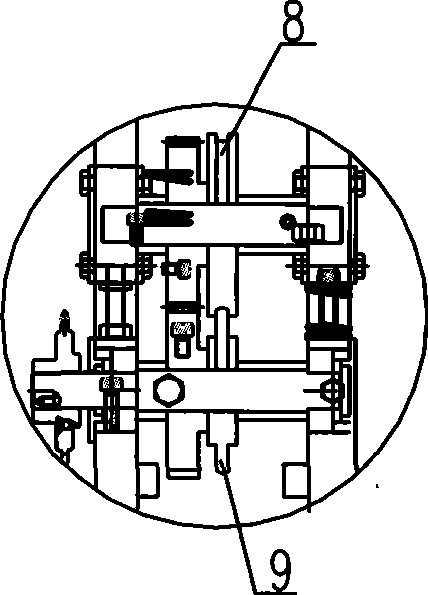

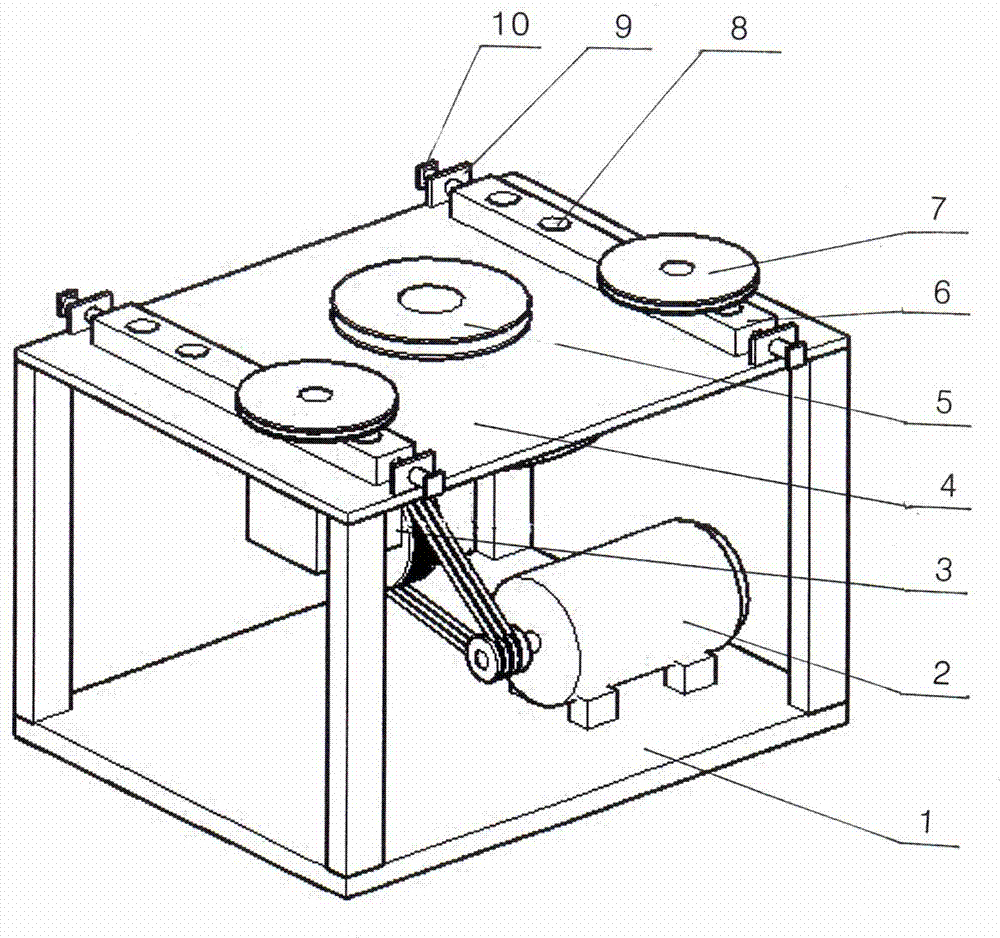

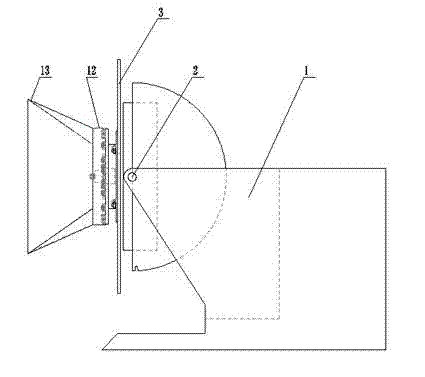

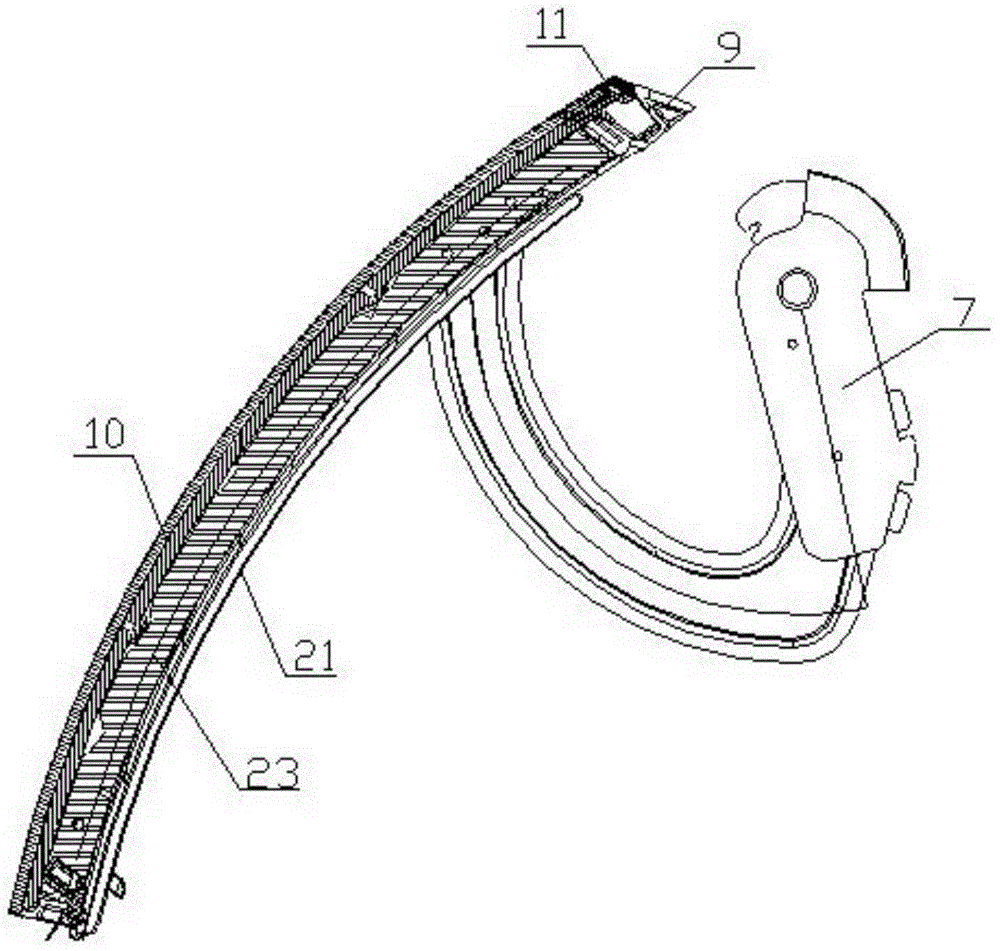

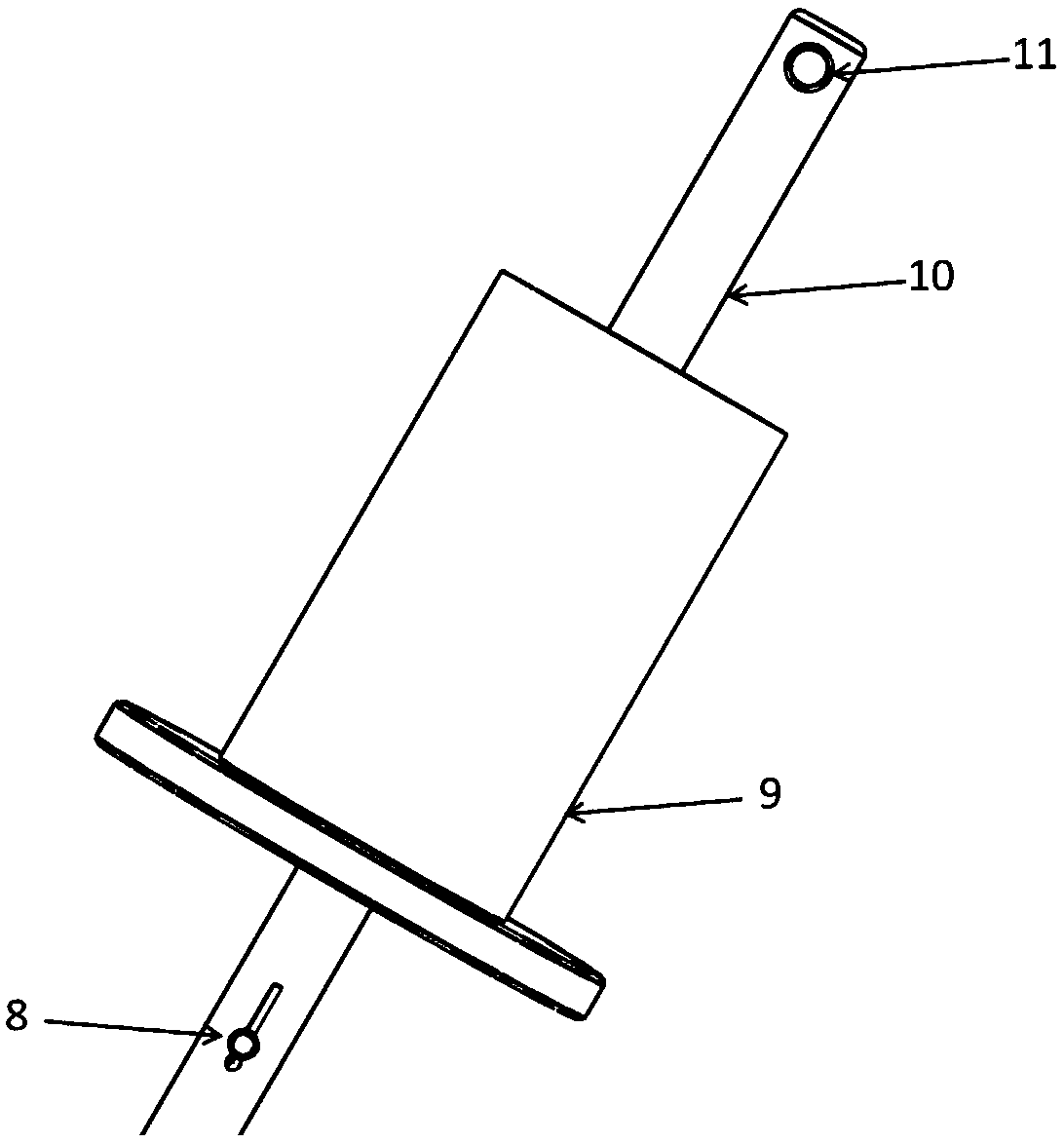

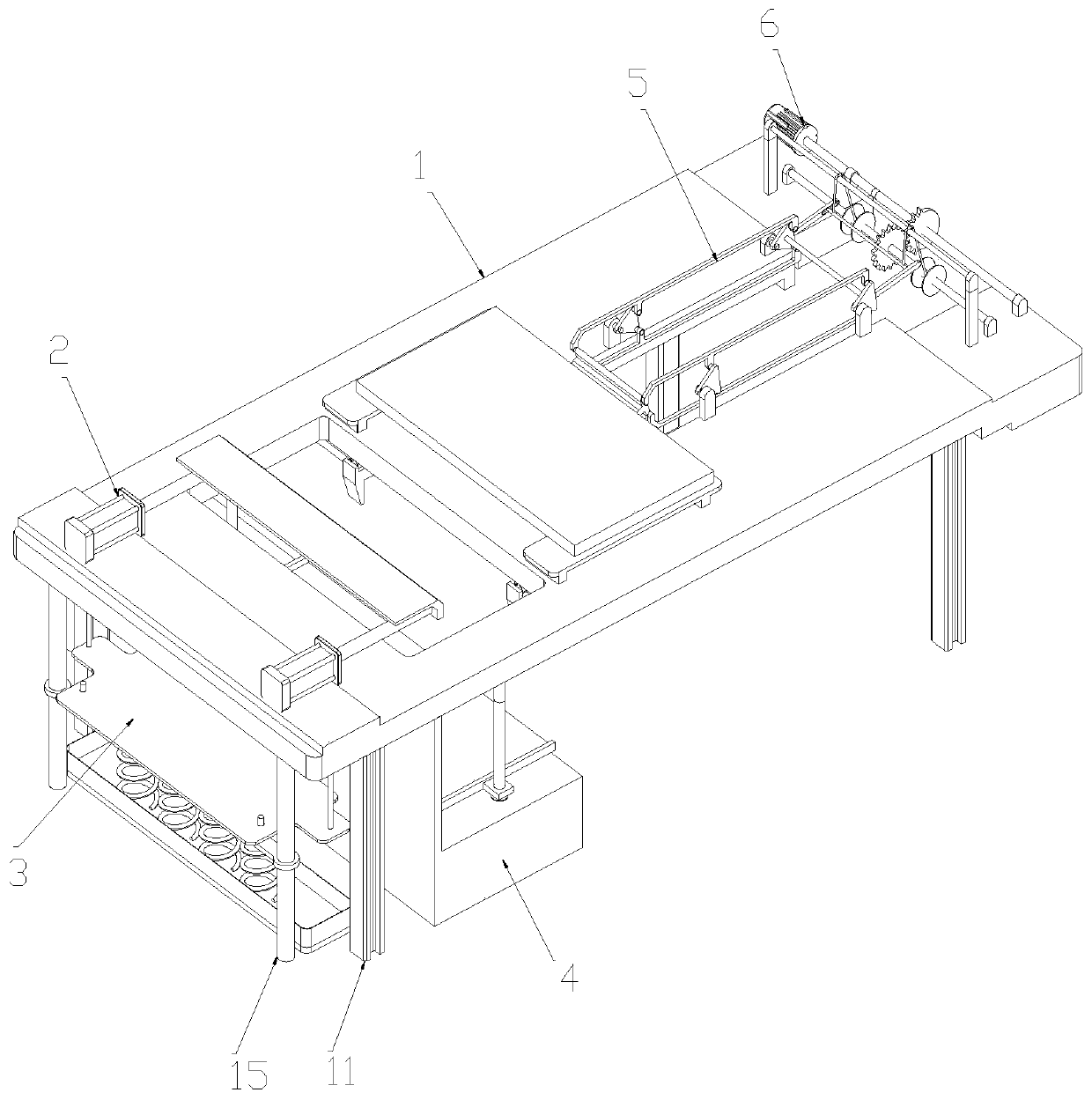

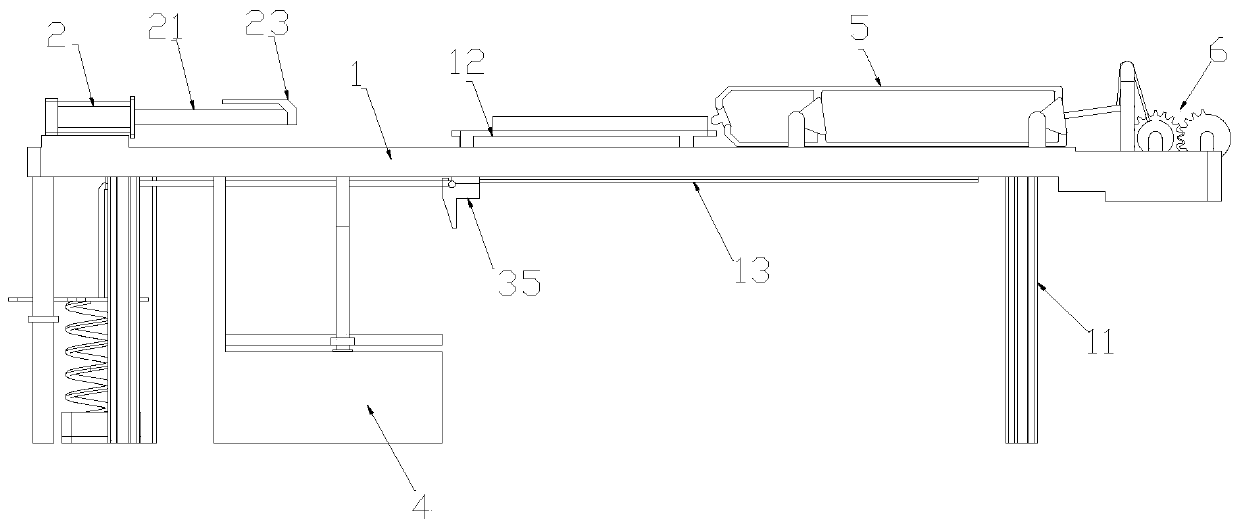

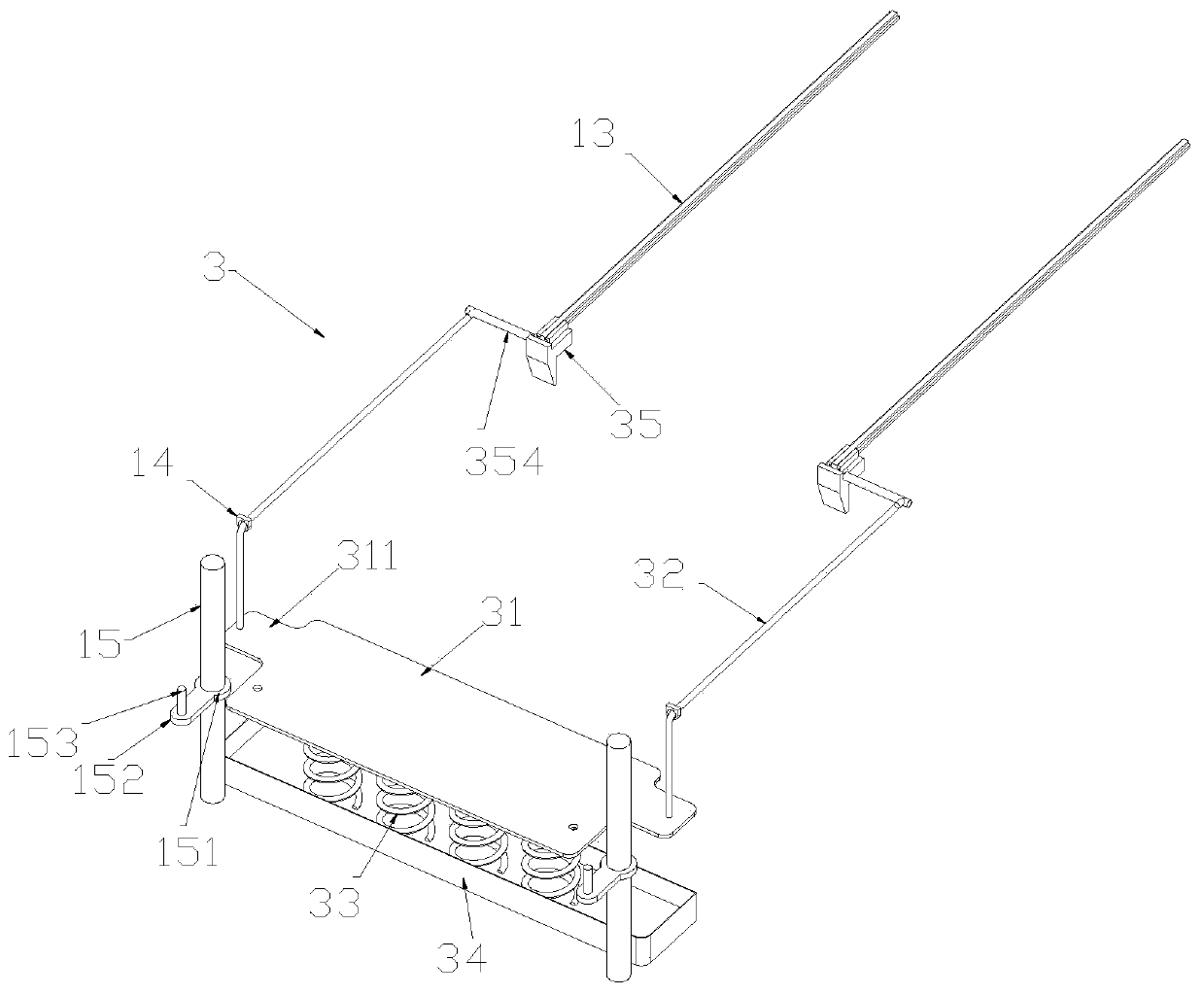

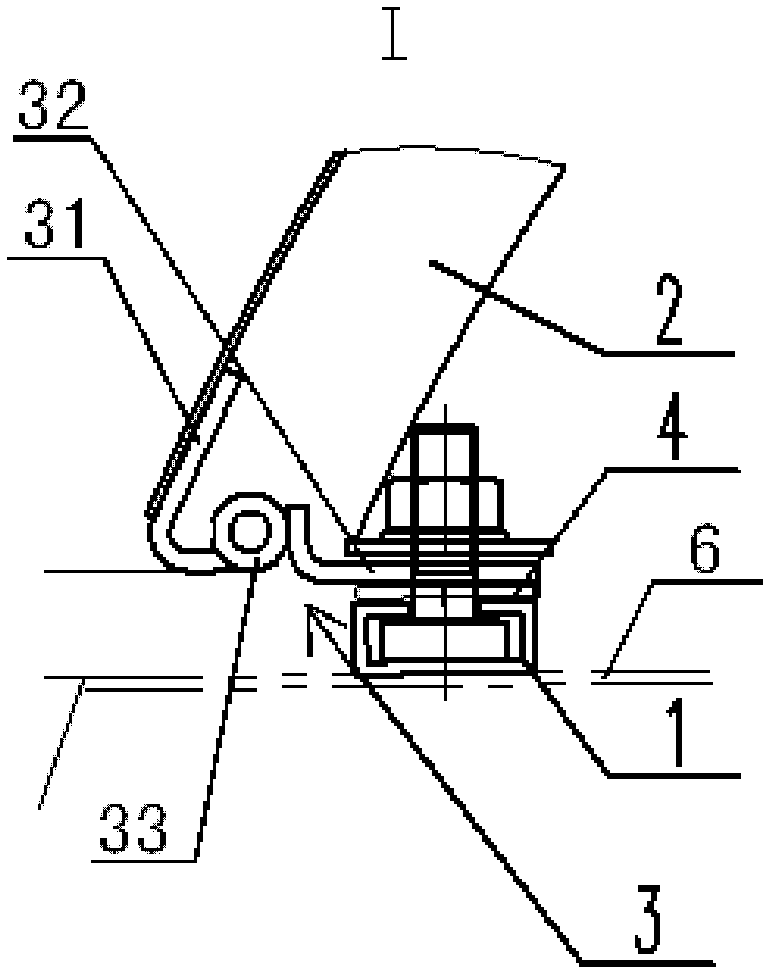

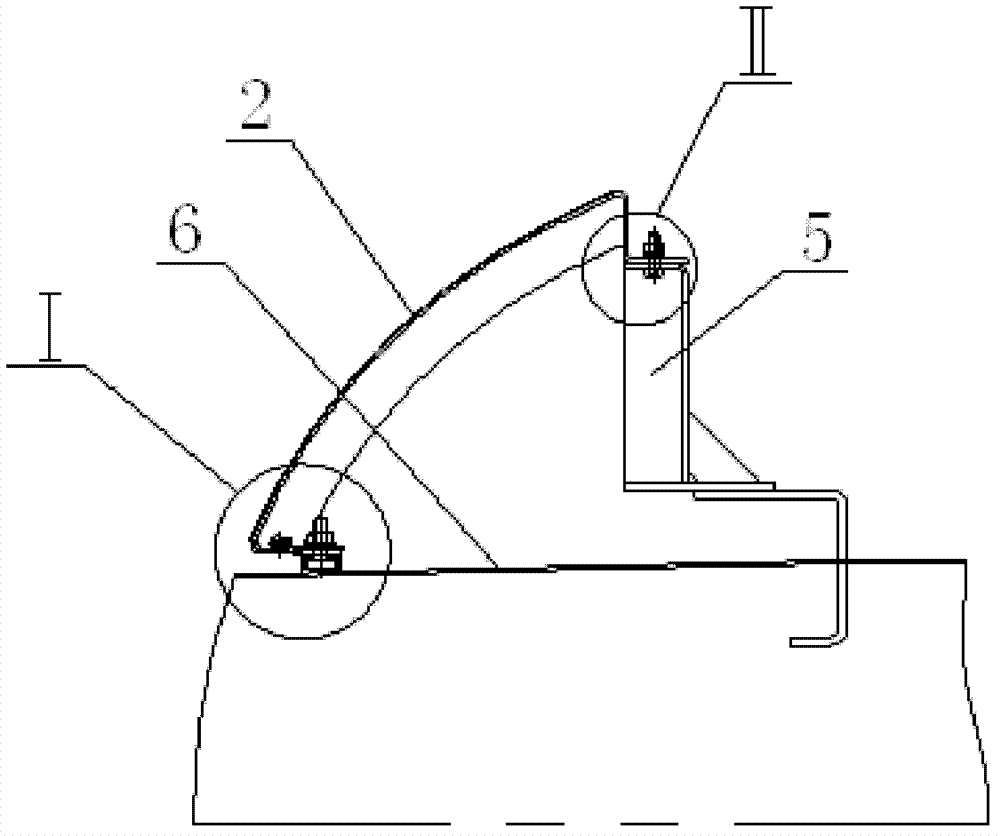

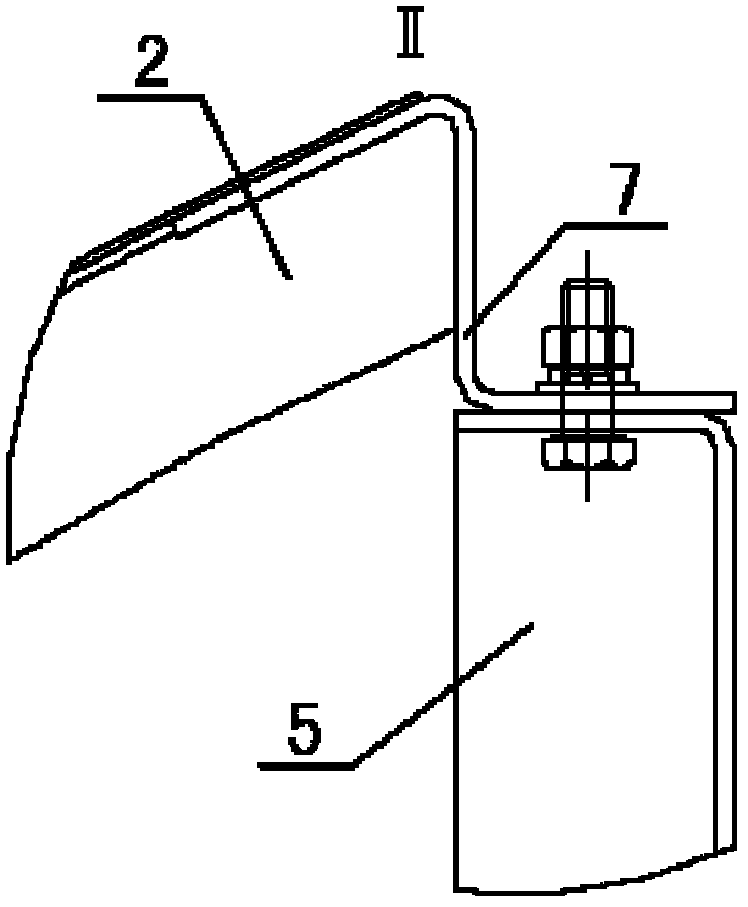

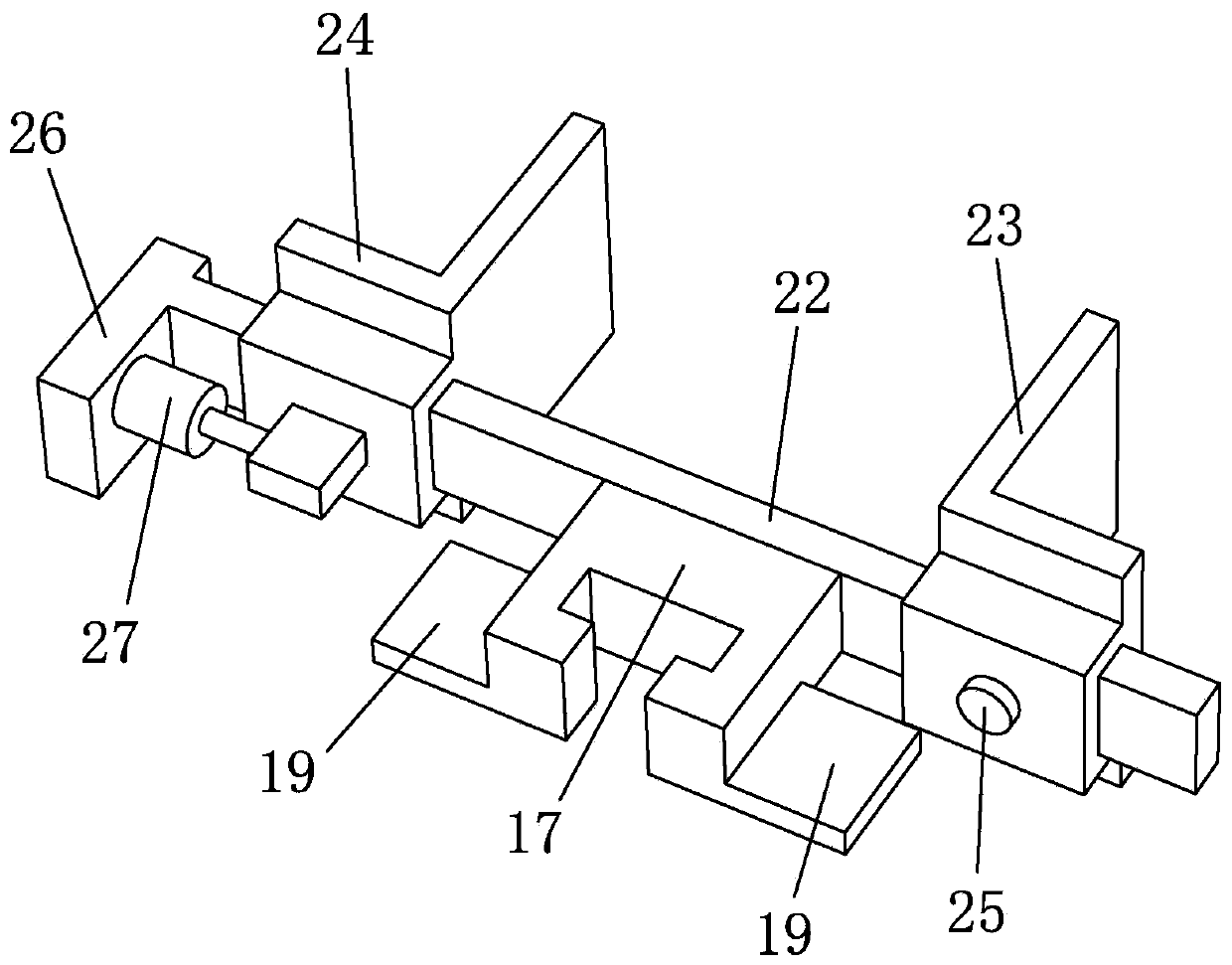

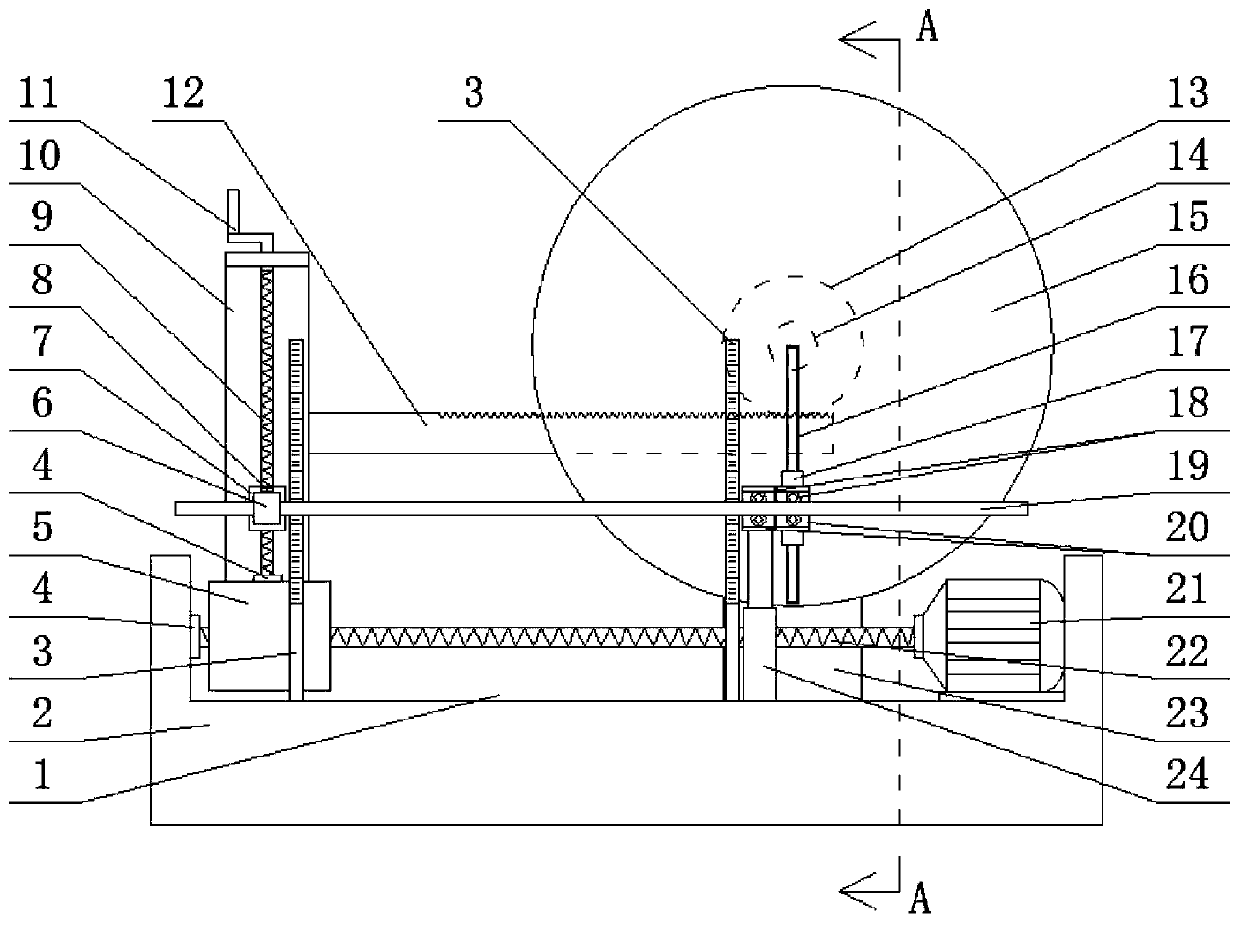

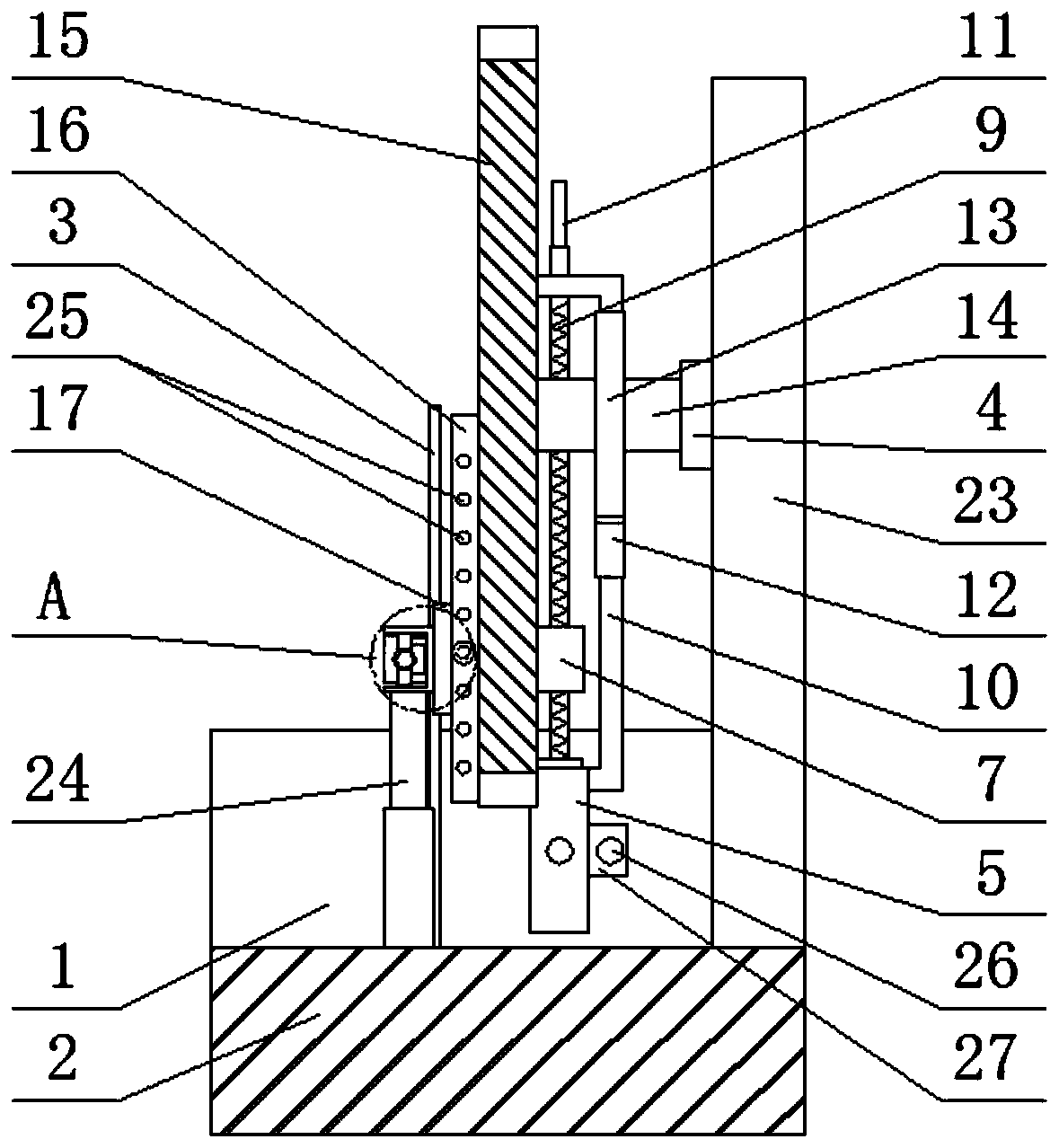

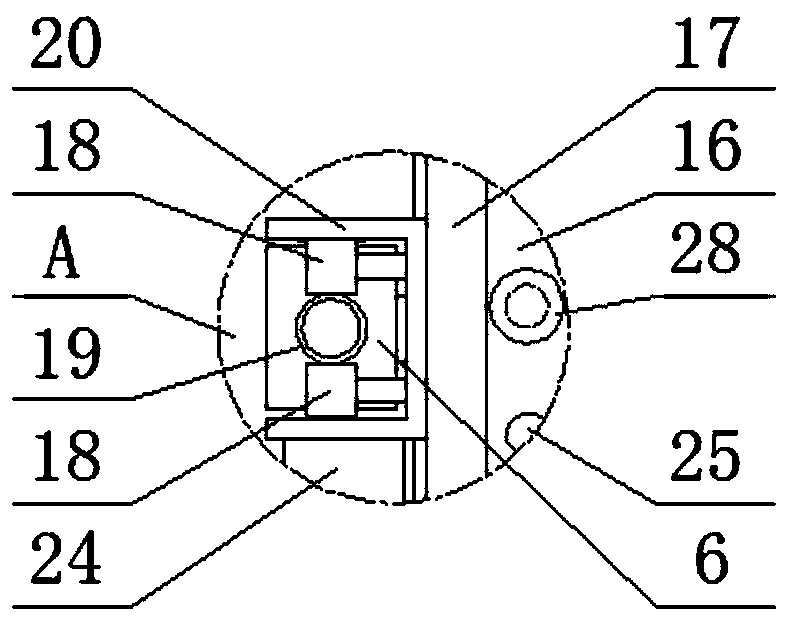

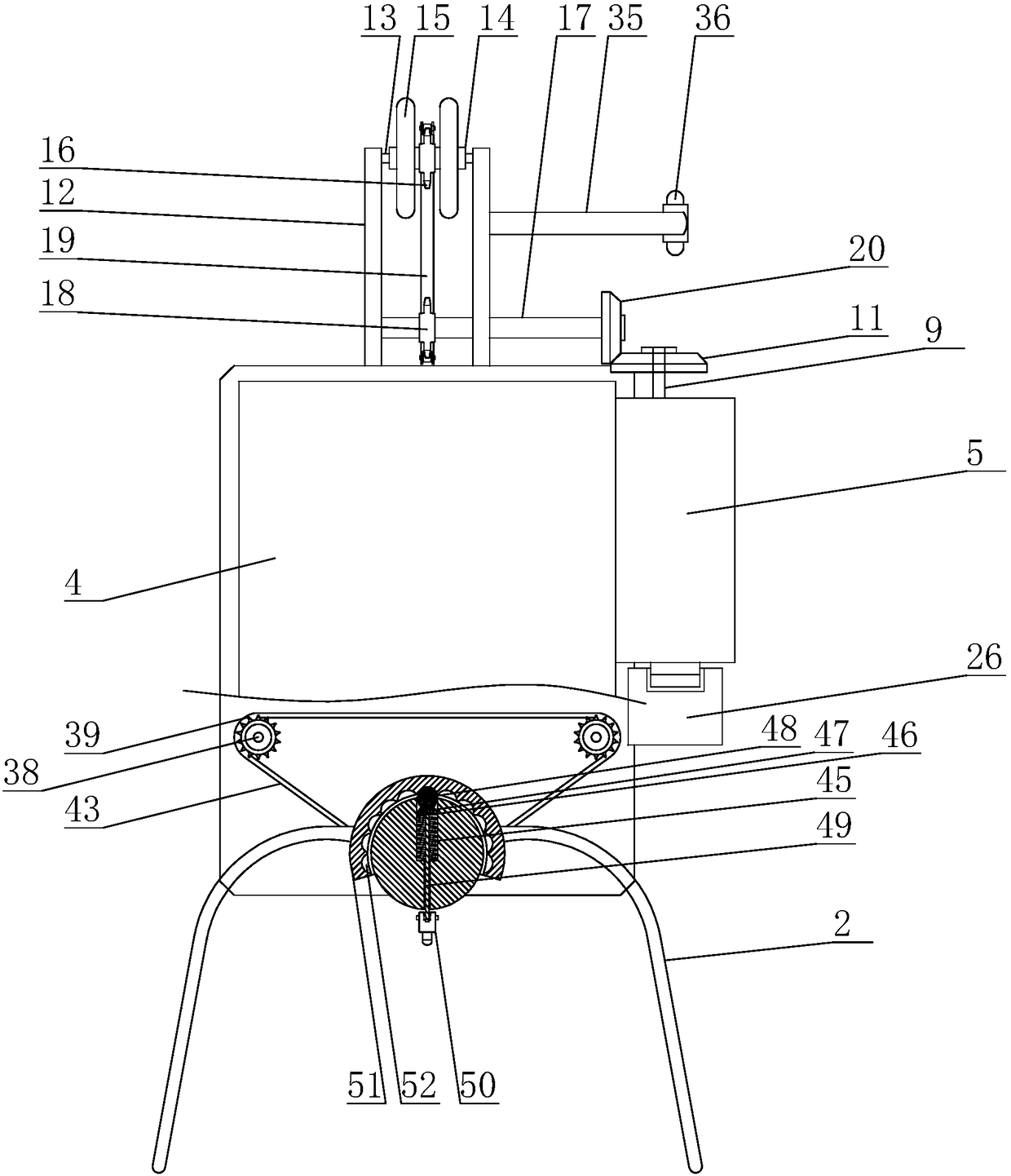

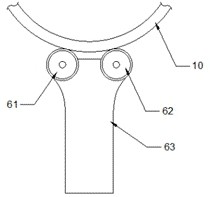

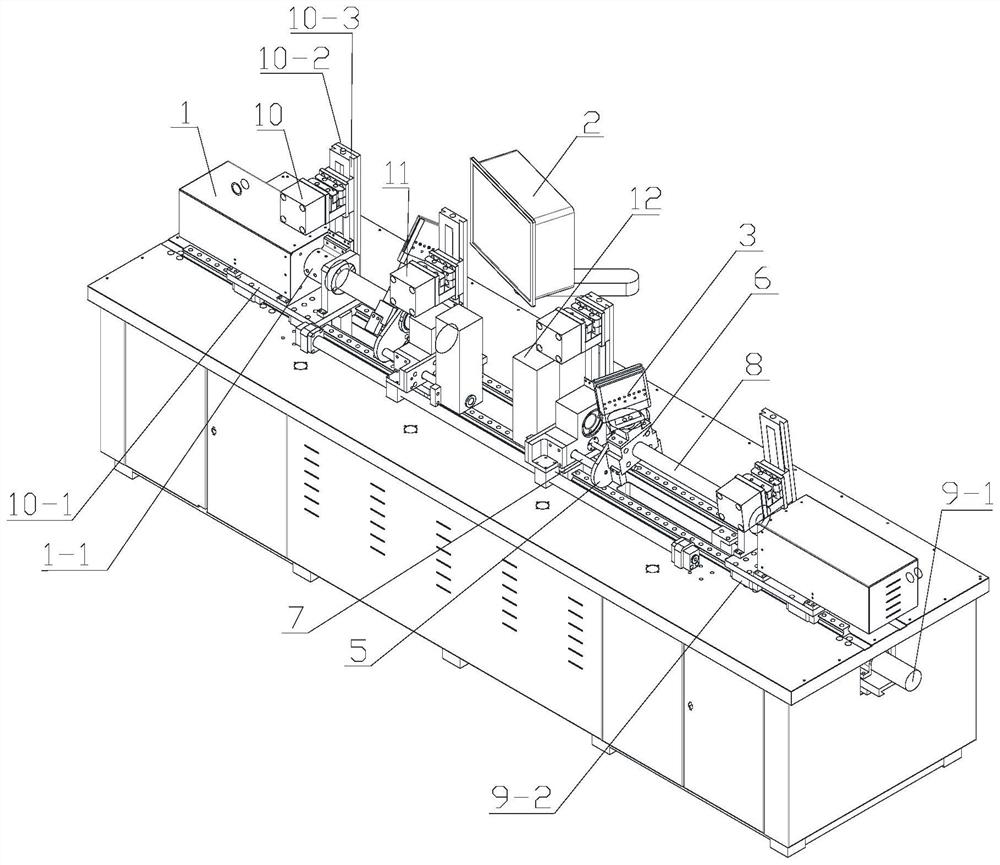

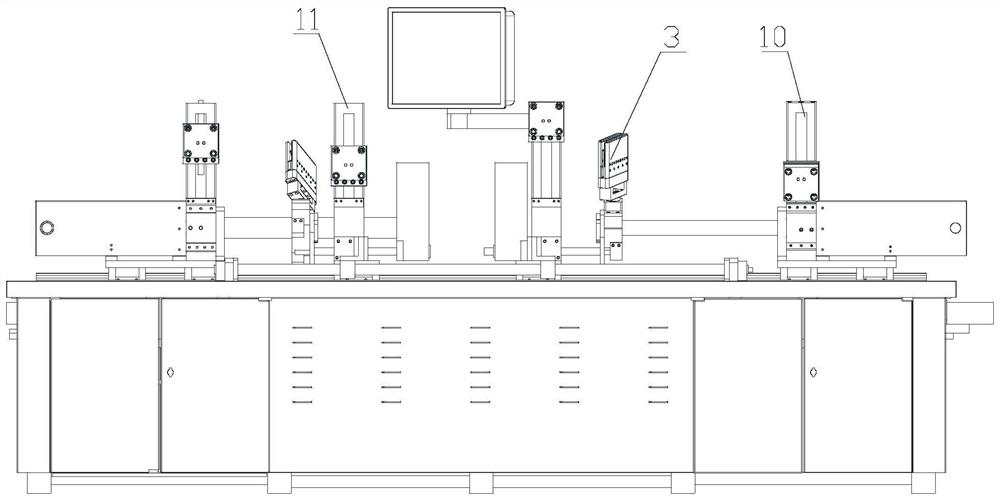

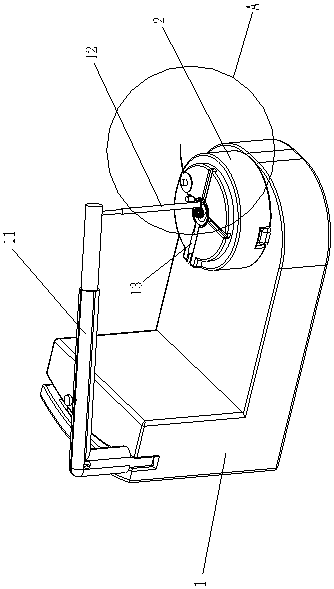

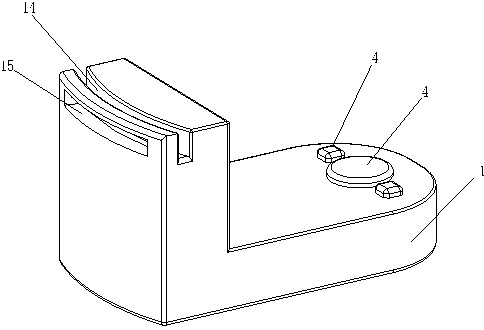

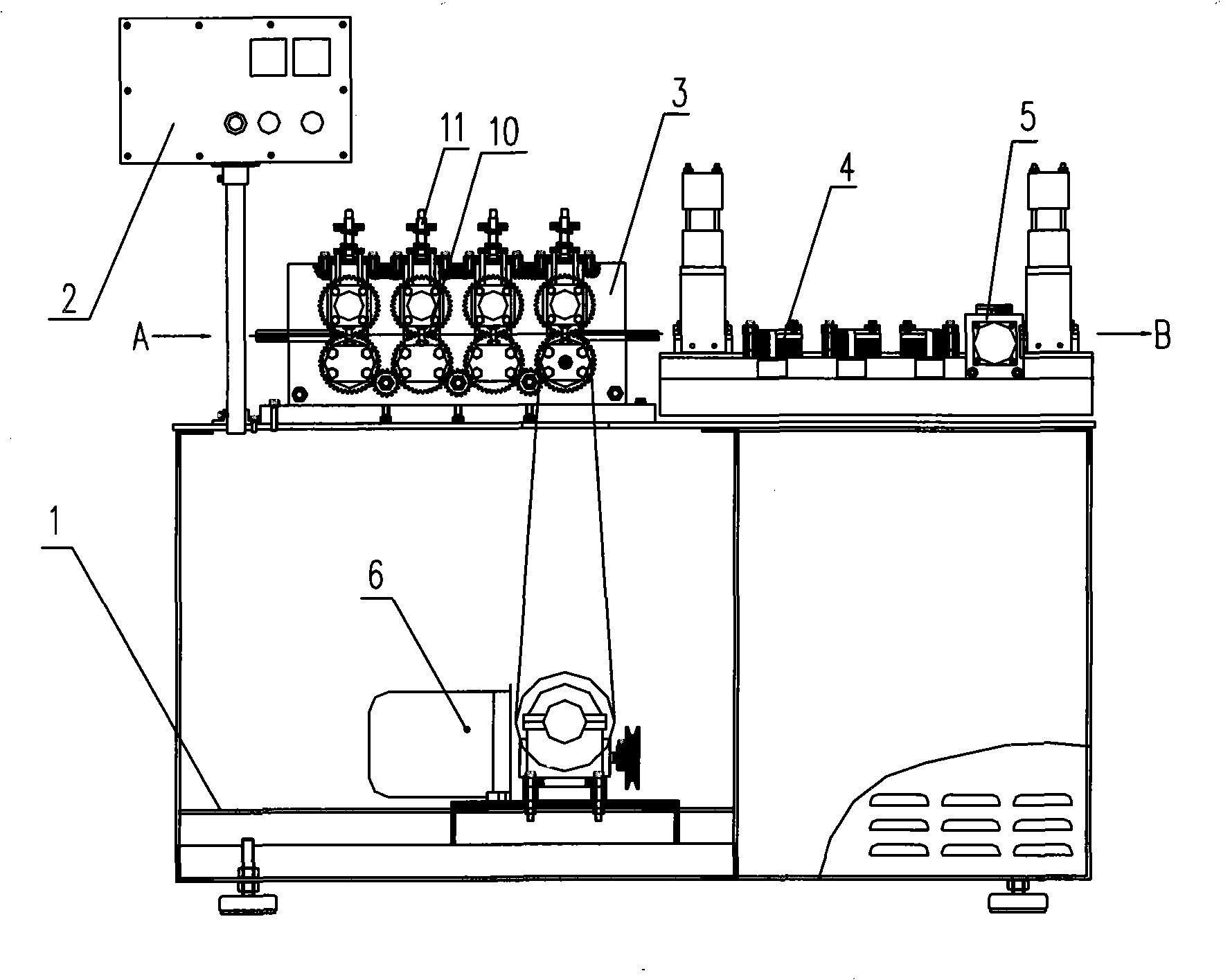

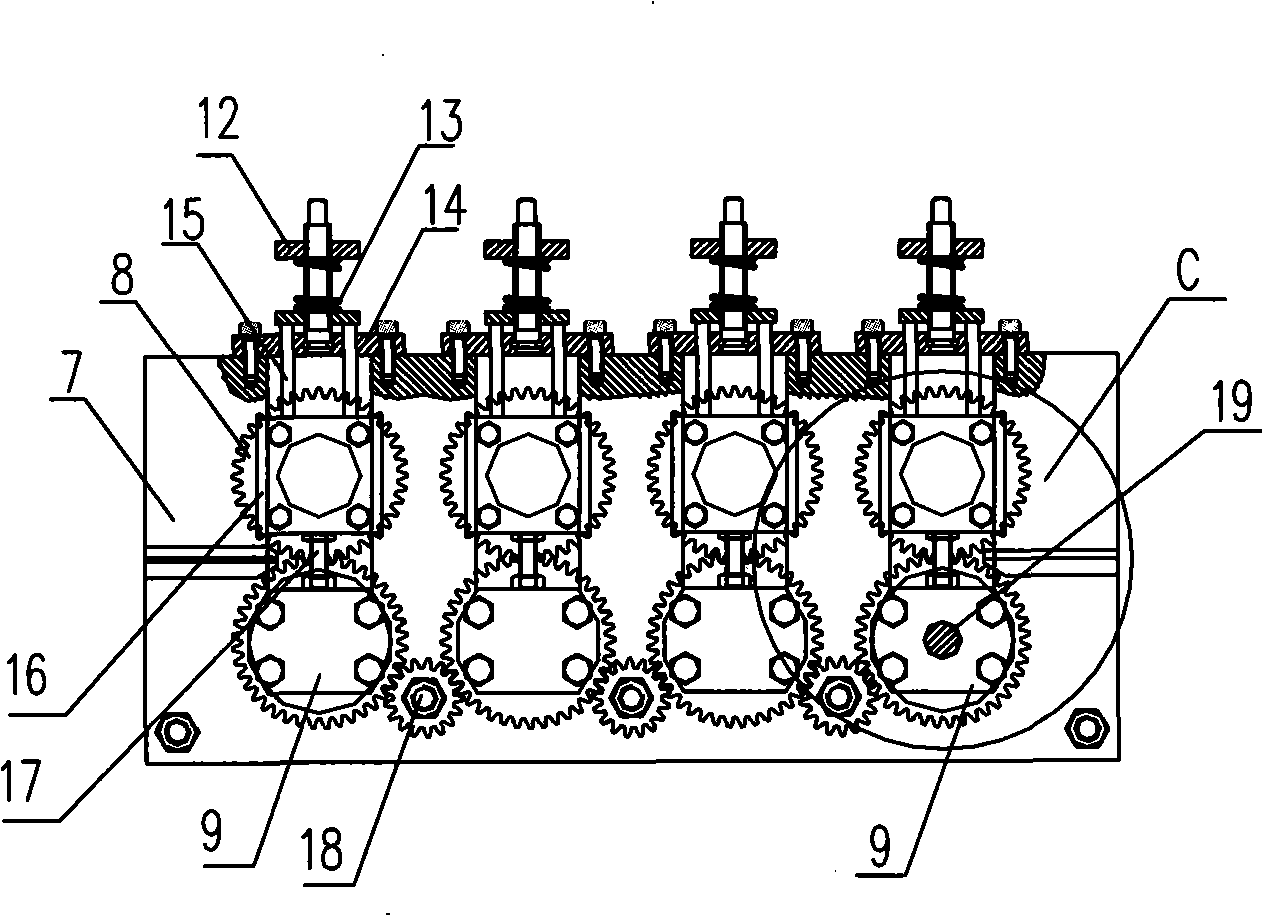

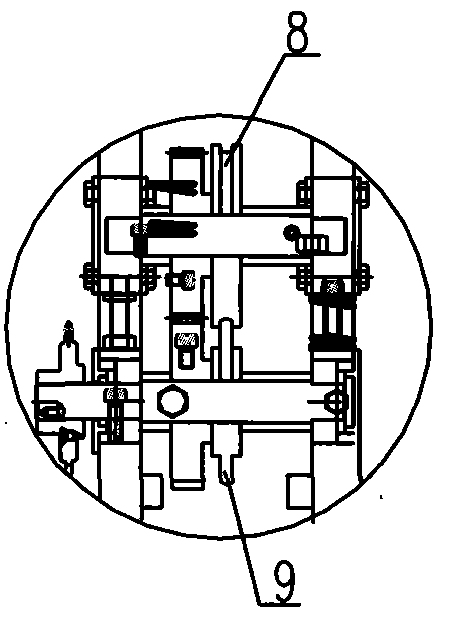

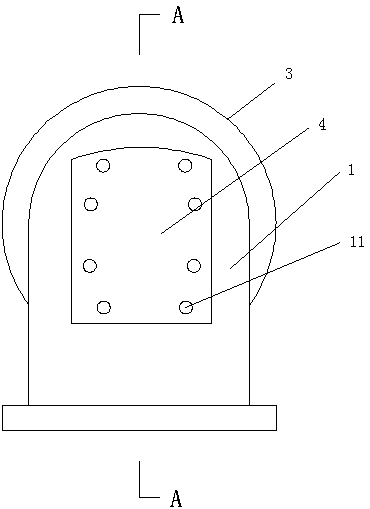

Metal blade forming machine

ActiveCN101444813AConsistent arcNot easy to bendMetal-working feeding devicesPositioning devicesMolding machineFully automatic

The invention relates to a metal blade forming equipment used for processing heating and ventilating equipment. A metal blade forming machine comprises a frame (1), a motor (6) and a rolling forming mechanism (3), a material cutting mechanism (4) and a material throwing mechanism (5) which are arranged on the frame. The blade forming machine adopts fully-automatic operation and has high processing efficiency; the rolling forming mechanism ensures that the radians of a profiled blade are consistent, and the whole blade does not flex easily; the material cutting mechanism ensures the standard of the cut blade length and size; and the material throwing mechanism ensures the consistency and the high speed for outputting the formed blade.

Owner:宁波朗迪智能机电有限公司

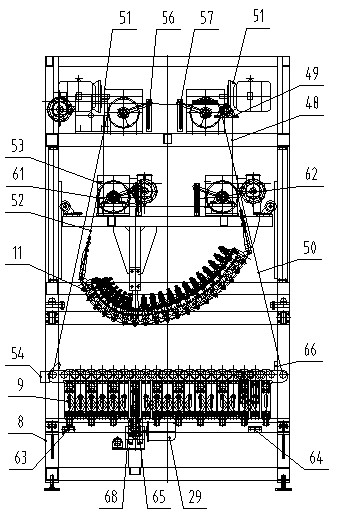

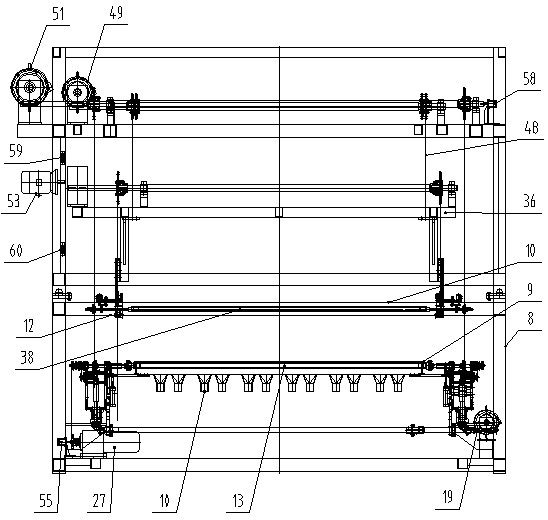

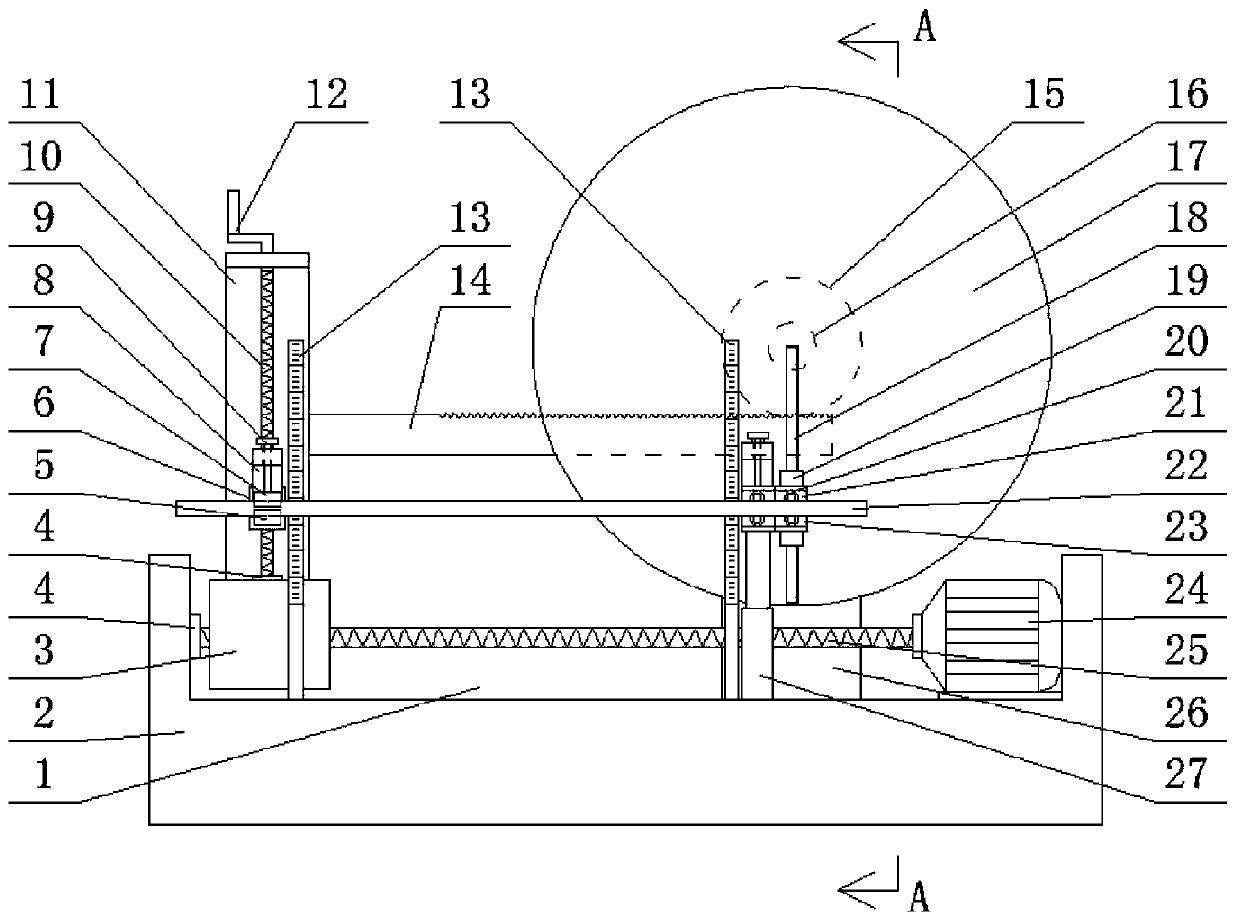

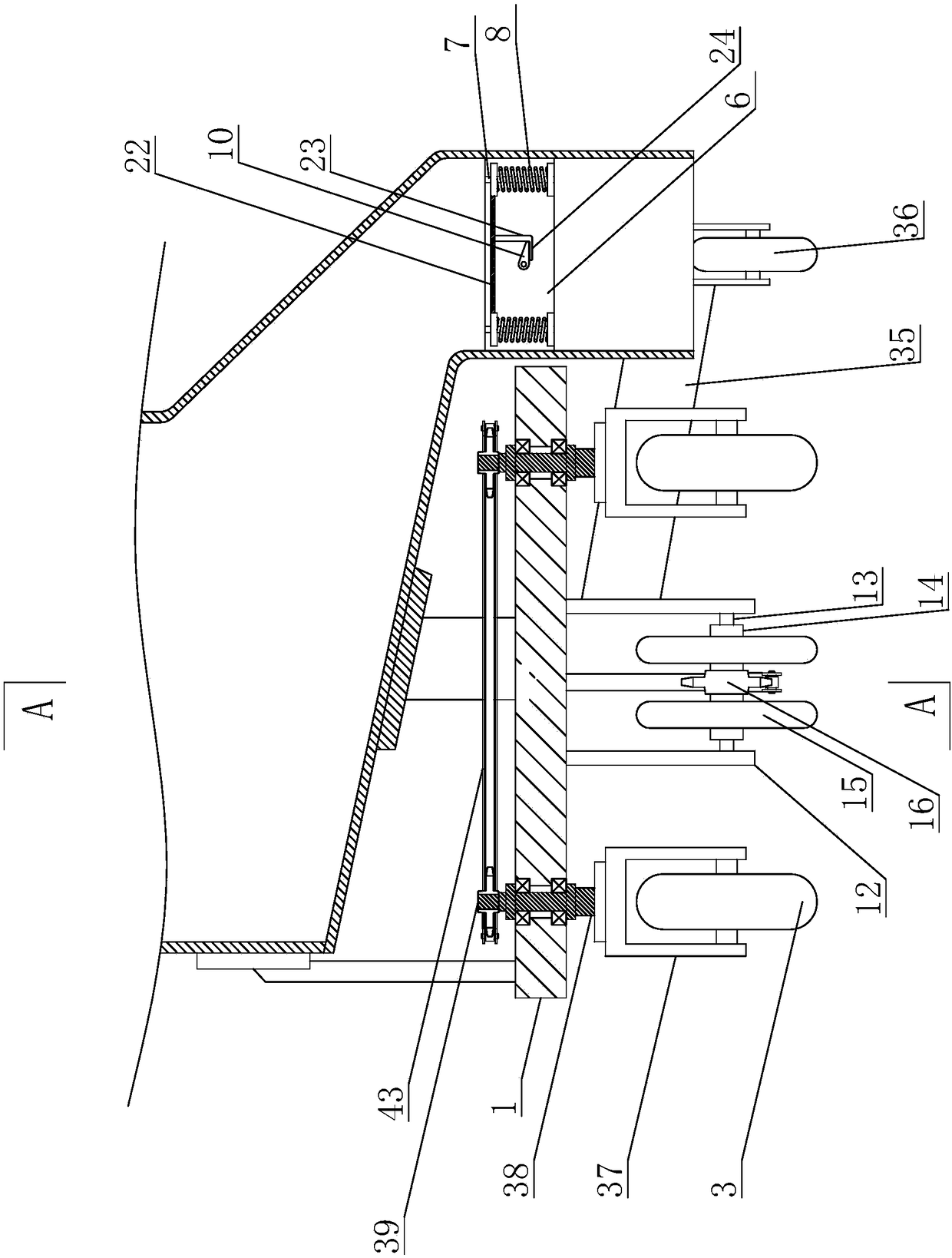

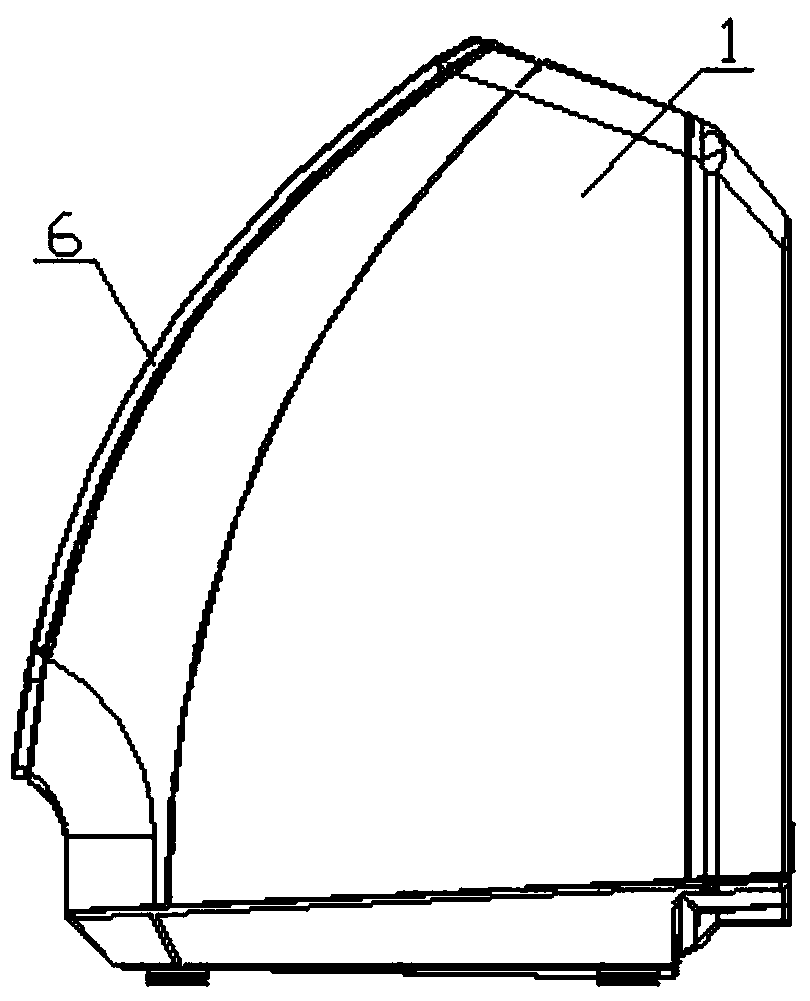

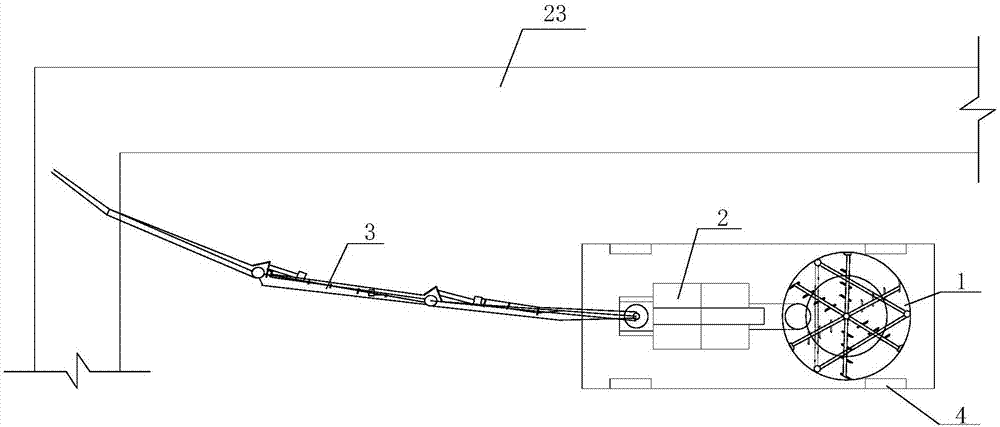

Abnormal-shape single-bent toughened glass processing equipment

ActiveCN102690043AGuaranteed accuracyConsistent arcGlass reforming apparatusGlass tempering apparatusAbnormal shapedEngineering

The invention discloses a piece of abnormal-shape single-bent toughened glass processing equipment which comprises a sheet glass feed table, a multistation furnace body, a moulding section, a sheet glass discharge table with a cooling device, a fan, a wind path system connected with the fan, and a control system, wherein the moulding section comprises a stand on which a lower arc-changing mechanism, a lower wind gate assembly, an upper arc-changing mechanism, an upper wind gate assembly, an arc-regulating mechanism and a lifting mechanism are arranged, wherein the lower wind gate assembly is arranged on the lower arc-changing mechanism, the upper arc-changing mechanism is positioned above the lower arc-changing mechanism and can slide up and down along the stand, the upper wind gate assembly is arranged on the upper arc-changing mechanism, and the arc-regulating mechanism is positioned under the lower arc-changing mechanism and in transmission connection with the lower arc-changing mechanism; the upper wind gate assembly and the lower wind gate assembly are respectively connected with the wind path system, and the lifting mechanism is respectively in transmission connection with the upper arc-changing mechanism and the lower arc-changing mechanism. The abnormal-shape single-bent toughened glass processing equipment has the advantages of convenience and rapidness in use, high glass production efficiency, energy saving and environmental protection, the radian accuracy of the finished toughened glass is guaranteed, and any two piece of glass can be completely matched, and the product quality is improved.

Owner:LUOYANG GANGXIN GLASS TECH

Steel tube bending machine

The invention discloses a steel tube bending machine. A table top is arranged at the upper part of a rack; a horizontal driving wheel is arranged in the middle part of the table top through a wheel axle in a supporting manner; a speed reducing box is fixed at the lower side of the table top; an output shaft of the speed reducing box is connected with wheel and axle power of the driving wheel; the rack is provided with an electromotor; the output shaft of the electromotor is connected with power of an input shaft of the speed reducing box; the two sides of the driving wheel on the table top are respectively provided with a driven wheel; the outer peripheries of the driving wheel and the driven wheels are provided with semicircular grooves; slideways at the two sides of the driving wheel on the table top are respectively provided with a sliding plate; the two ends of the table top corresponding to the sliding plates are fixedly provided with a top plate; an adjustment bolt is arranged on the top plate; the front end of the adjustment bolt presses against the front parts of the sliding plates; a plurality of support holes are distributed on the sliding plates; and support shafts of the driven wheels are inserted into the support holes on the sliding plates. The steel tube bending machine is used for the working procedure of bending hollow steel tubes; the working procedure can be independently finished only by one person; the radian of the bent steel tubes is consistent, and the time and labor are saved, so that the construction progress is accelerated.

Owner:CHINA COAL NO 68 ENG COMPANY

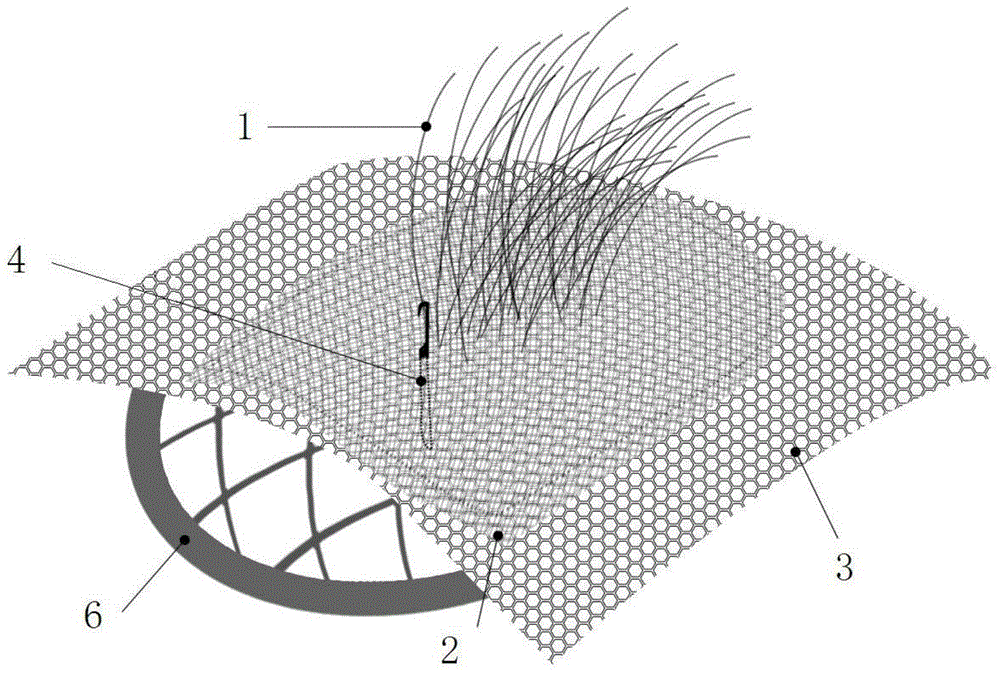

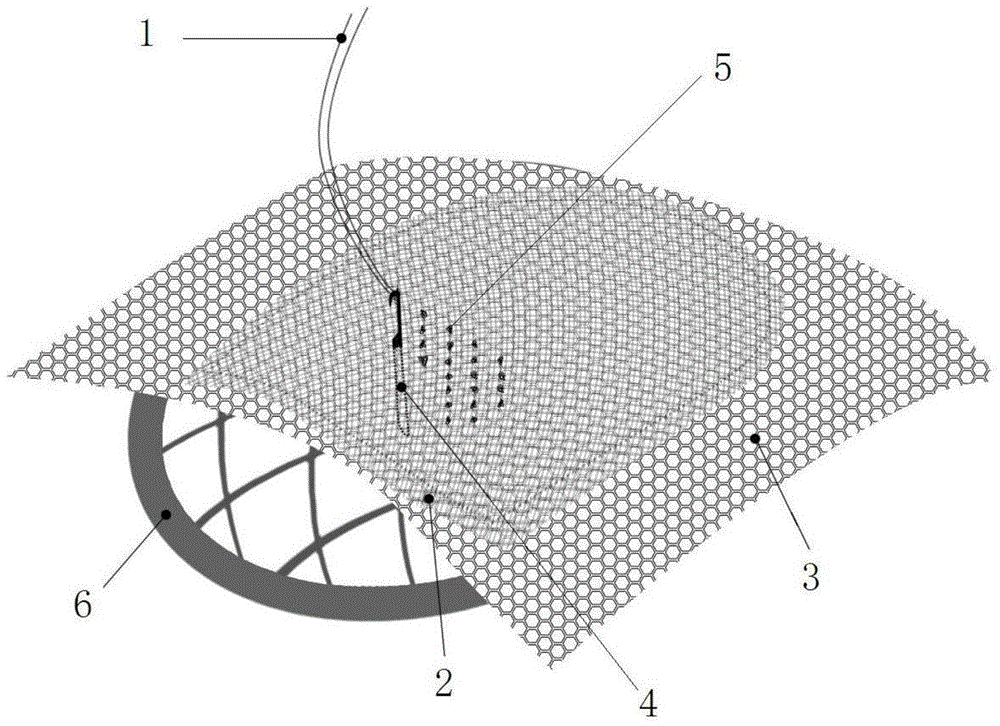

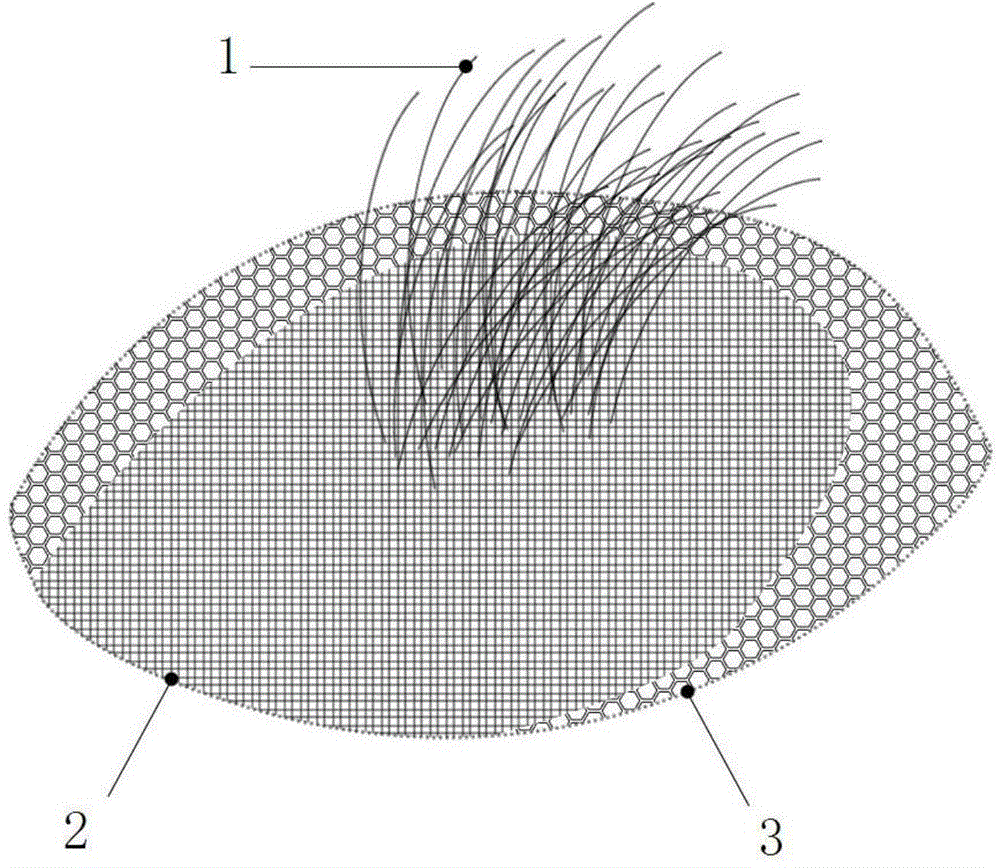

Wig production process

InactiveCN104905456ALess likely to cause unevennessVisually beautifulWigsHairpiece/toupeeSurface layer

The invention discloses a wig production process. The process comprises the following steps of fixing a wig base body composed of a surface layer hairnet and a bottom layer hairnet on a wig model with radian similar with the head radian of the human body; planning a hair flow direction on the wig base body, crocheting the wig hairline on the bottom hairnet by using a hooked bearded needle, when the wig hairline is exposed below the bottom layer hairnet and a hair knot is positioned at the back side of the bottom layer hairnet; crocheting the wig hairline exposed below the bottom layer hairnet above the surface layer hairnet after passing through the bottom layer hairnet and the surface layer hairnet in sequence; rotating the hair knot of the wig hairline on the other side of the bottom layer hairnet, wherein when the wig hairline penetrates out above the surface layer hairnet from the space between the bottom layer hairnet and the surface layer hairnet, the hair angle is set according to the preplanned hair flow direction. The wig made by using the method is light in texture, beautiful in visual sense, high in reality degree, small in clearance degree and good in ventilation effect, and can be worn all the year in a labor-saving and material-saving mode.

Owner:LYRICAL HAIR CORP

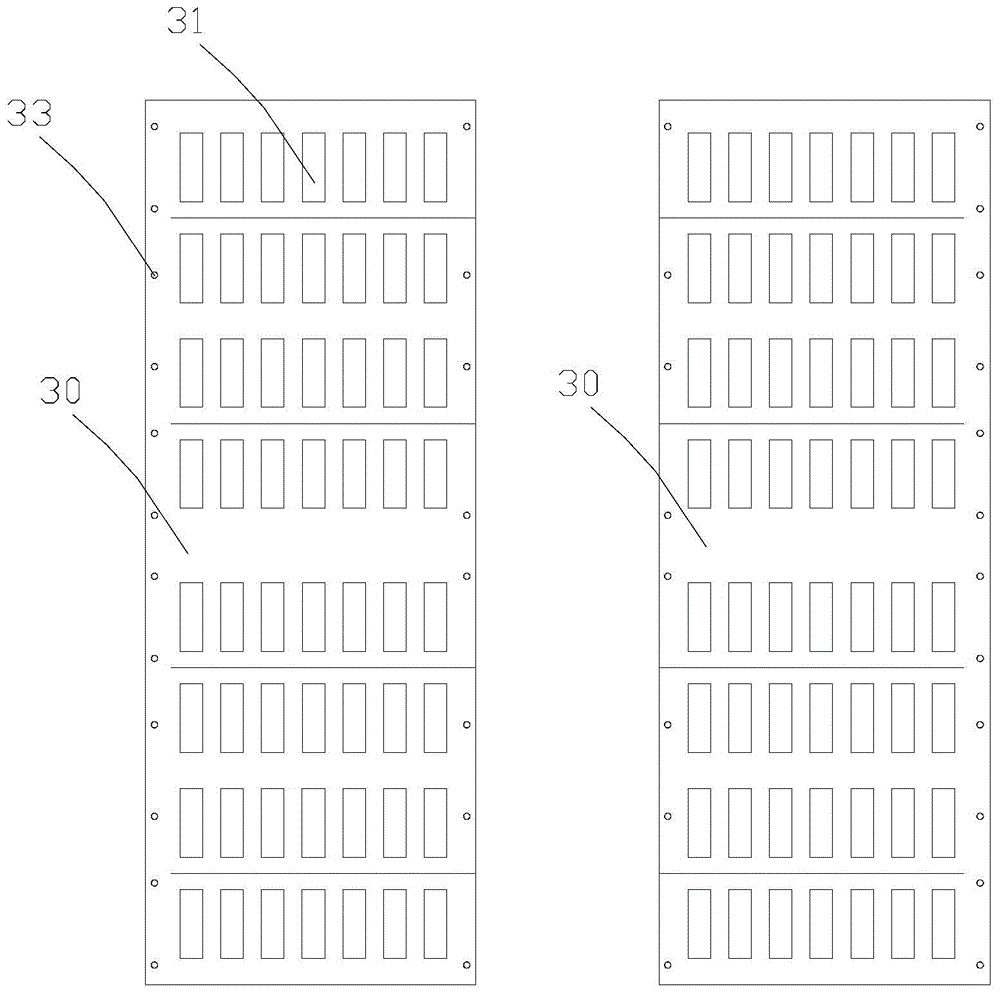

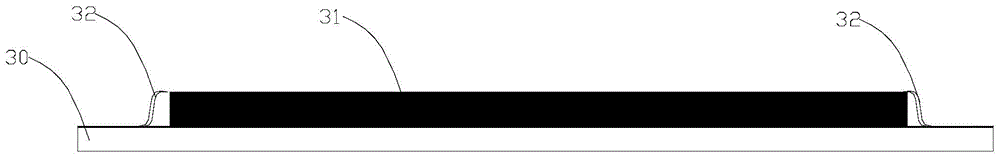

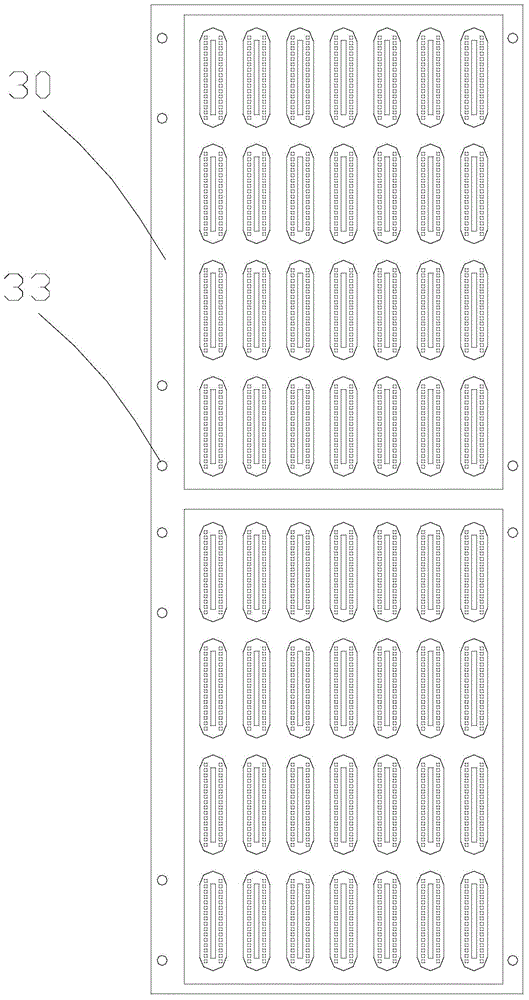

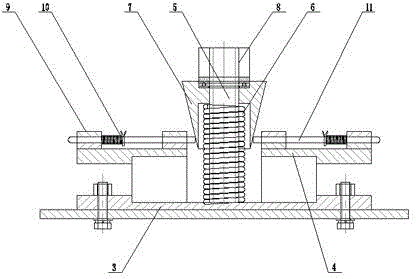

Packaging equipment possessing arc edge fingerprint identification chip and packaging and cutting method

ActiveCN104916549AGuaranteed sizeGuaranteed thicknessSemiconductor/solid-state device manufacturingHot runnerInjection port

The invention provides packaging equipment possessing an arc edge fingerprint identification chip. The equipment comprises a pair of dies. The dies are divided into an upper die and a lower die. A slot position which can accommodate a PCB is arranged in the lower die. The PCB is an entire PCB on which multiple groups of fingerprint identification devices are welded. The upper die is provided with circular or oval or flat oval cavities which can accommodate the identification devices, have a consistent shape with the fingerprint chip and possess arc edges. The cavity and the fingerprint identification devices on the PCB are correspondingly arranged. The cavities are connected to a packaging material injection port through a hot runner. The hot runner is divided into a main runner and a branch runner. The main runner is connected to the injection port. The branch runner is connected to side edges of the cavities. A distance between an inner surface of the upper die and a slot position bottom surface is equal to a thickness of the PCB. A depth of the cavities is greater than a height from the PCB surface to an upper surface of the identification devices.

Owner:深圳市东方聚成科技有限公司

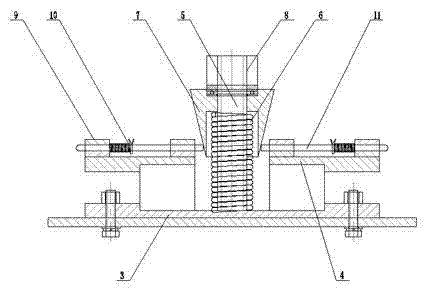

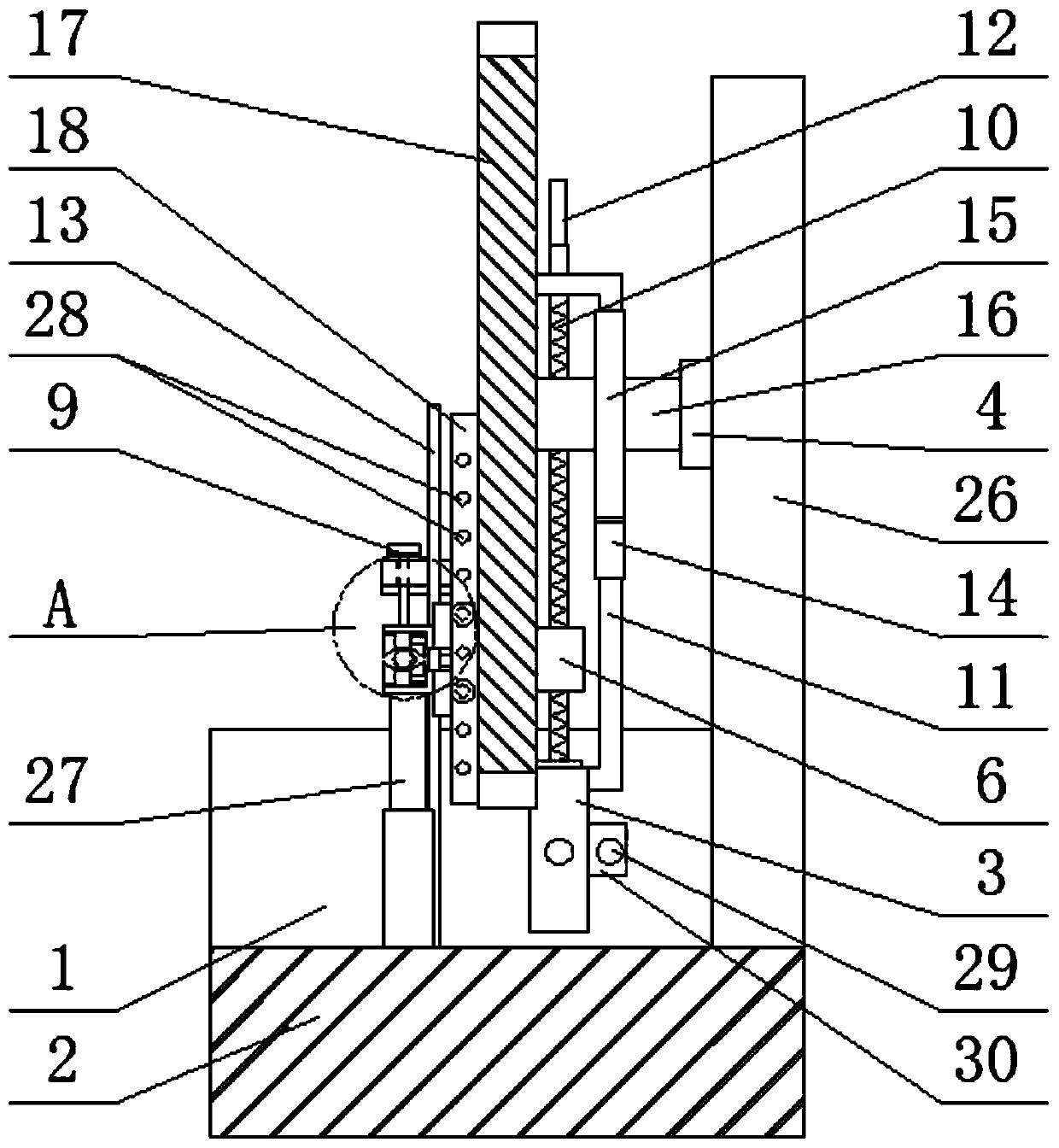

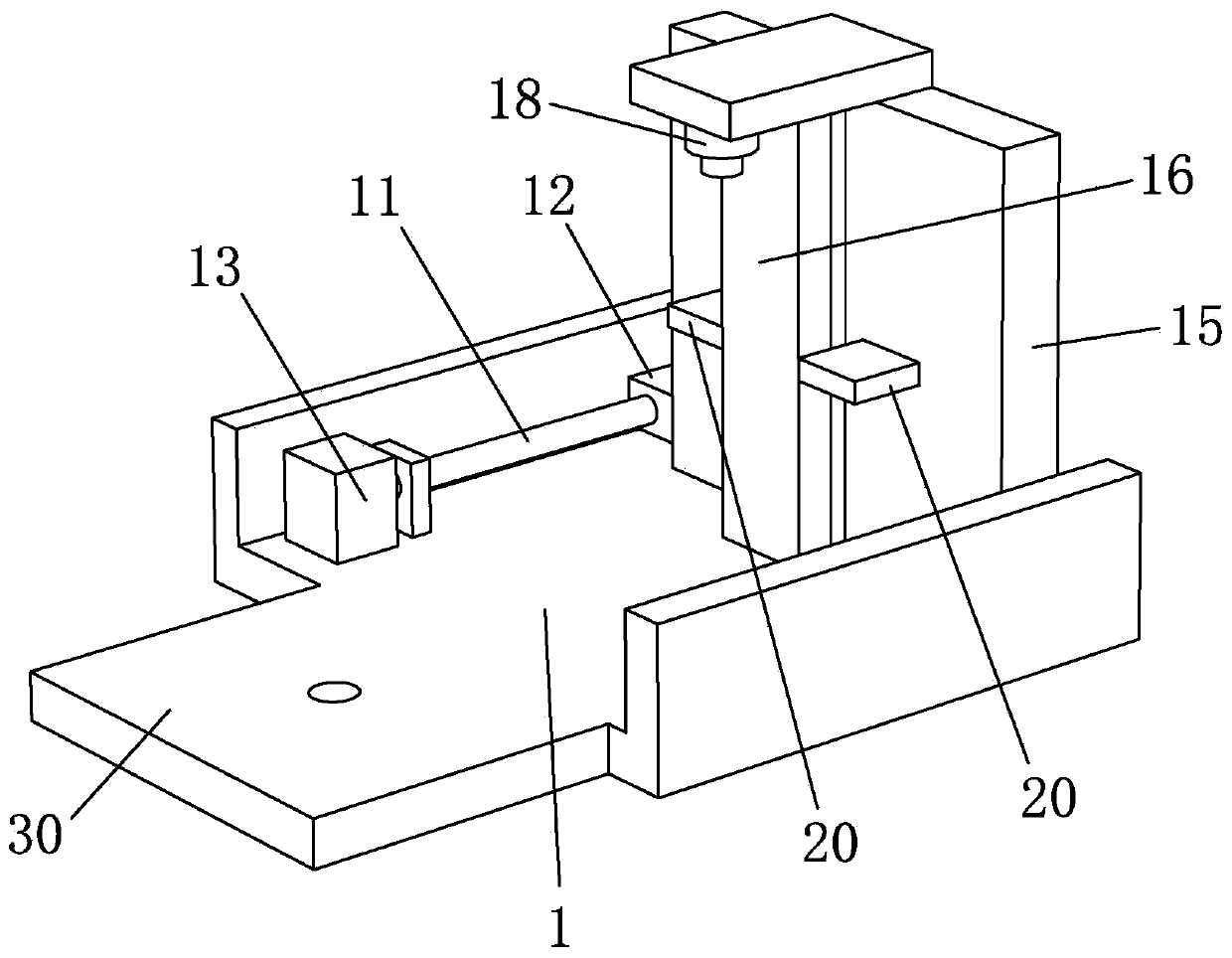

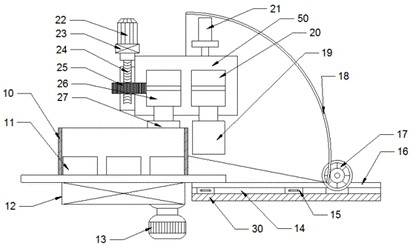

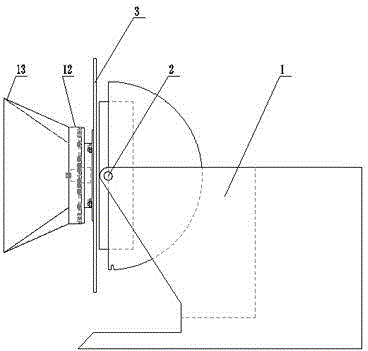

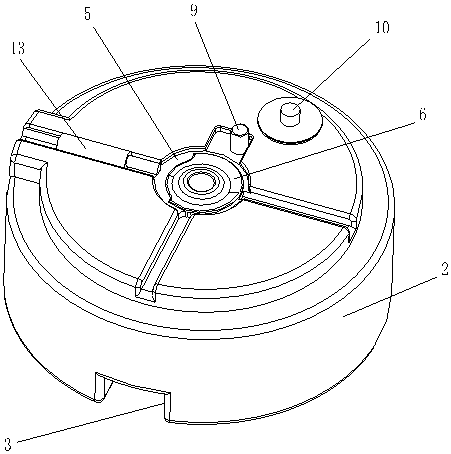

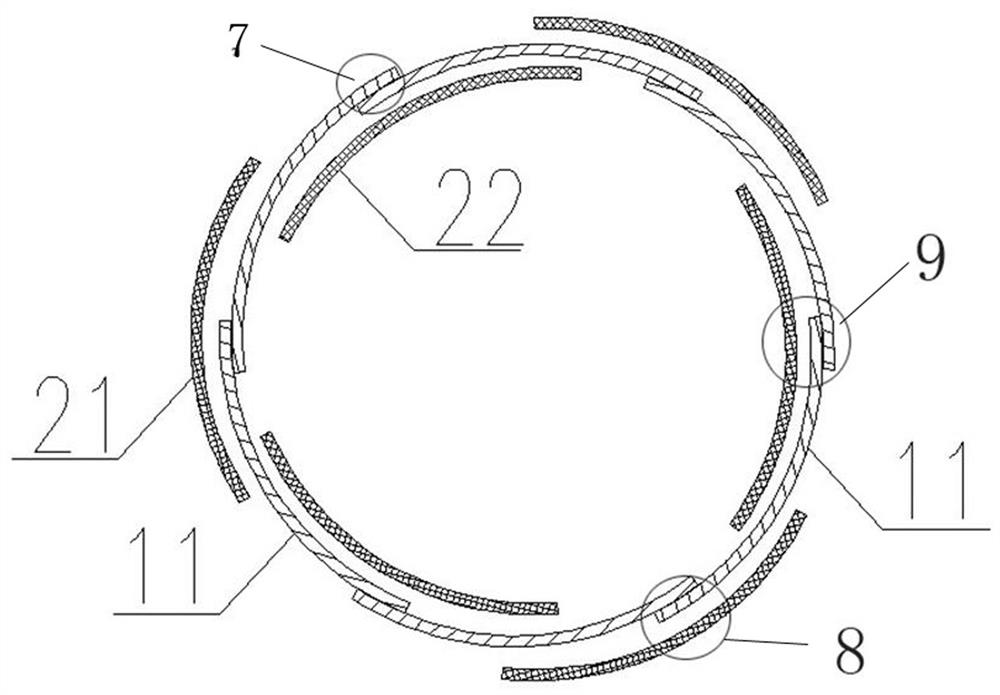

Bidirectional adjustable cylindrical welding anti-deformation fixture

ActiveCN102896455AAvoid welding deformationImprove molding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention relates to a bidirectional adjustable cylindrical welding anti-deformation fixture which comprises a rotary table, a central compressing component and more than three groups of movable supporting components, wherein the central compressing component is arranged on the rotary table, the rotary table is in a rotation state around the central compressing component, the more than three groups of movable supporting components are uniformly distributed on the rotary table around the central compressing component, and the central compressing component props against the more than three groups of movable supporting components so that the movable supporting components are simultaneously extended outwards or simultaneously retracted. According to the bidirectional adjustable cylindrical welding anti-deformation fixture disclosed by the invention, the central compressing component drives the movable supporting components to prop against and fix a cylinder workpiece, and the rotary table capable of rotating in plane and space drives the cylinder workpiece to rotate in two directions by supporting the movable supporting components so that the cylinder workpiece is located and welded; in addition, the bidirectional adjustable cylindrical welding anti-deformation fixture disclosed by the invention has the advantages of simple structure, convenience in operation, low cost and good welding effect; and the welded workpiece has less possibility of deformation.

Owner:JIANGSU JOSUN SCI&TECH CO LTD

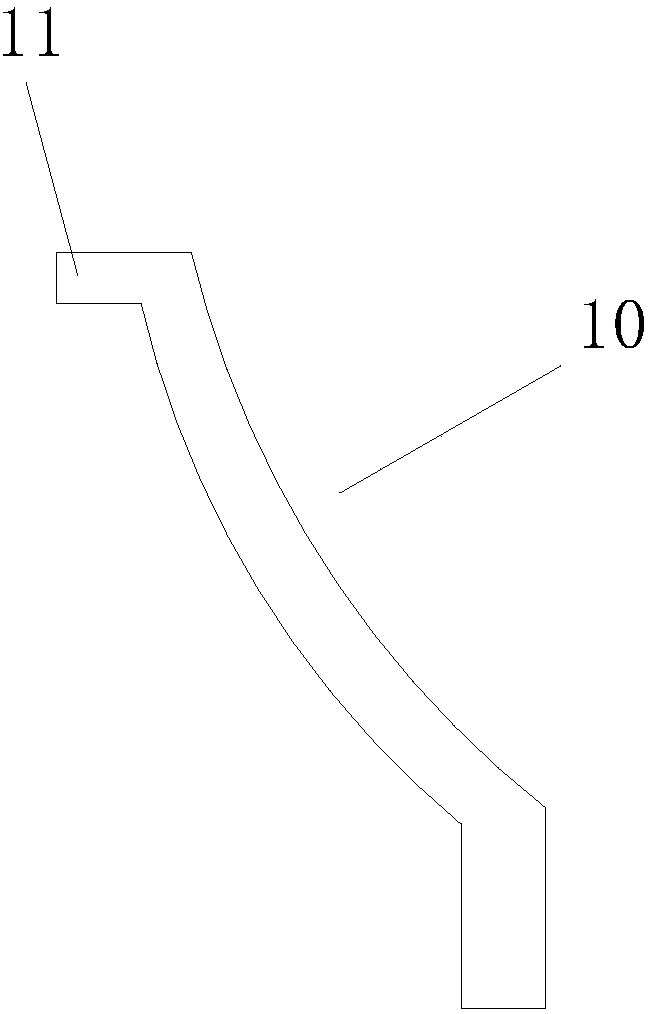

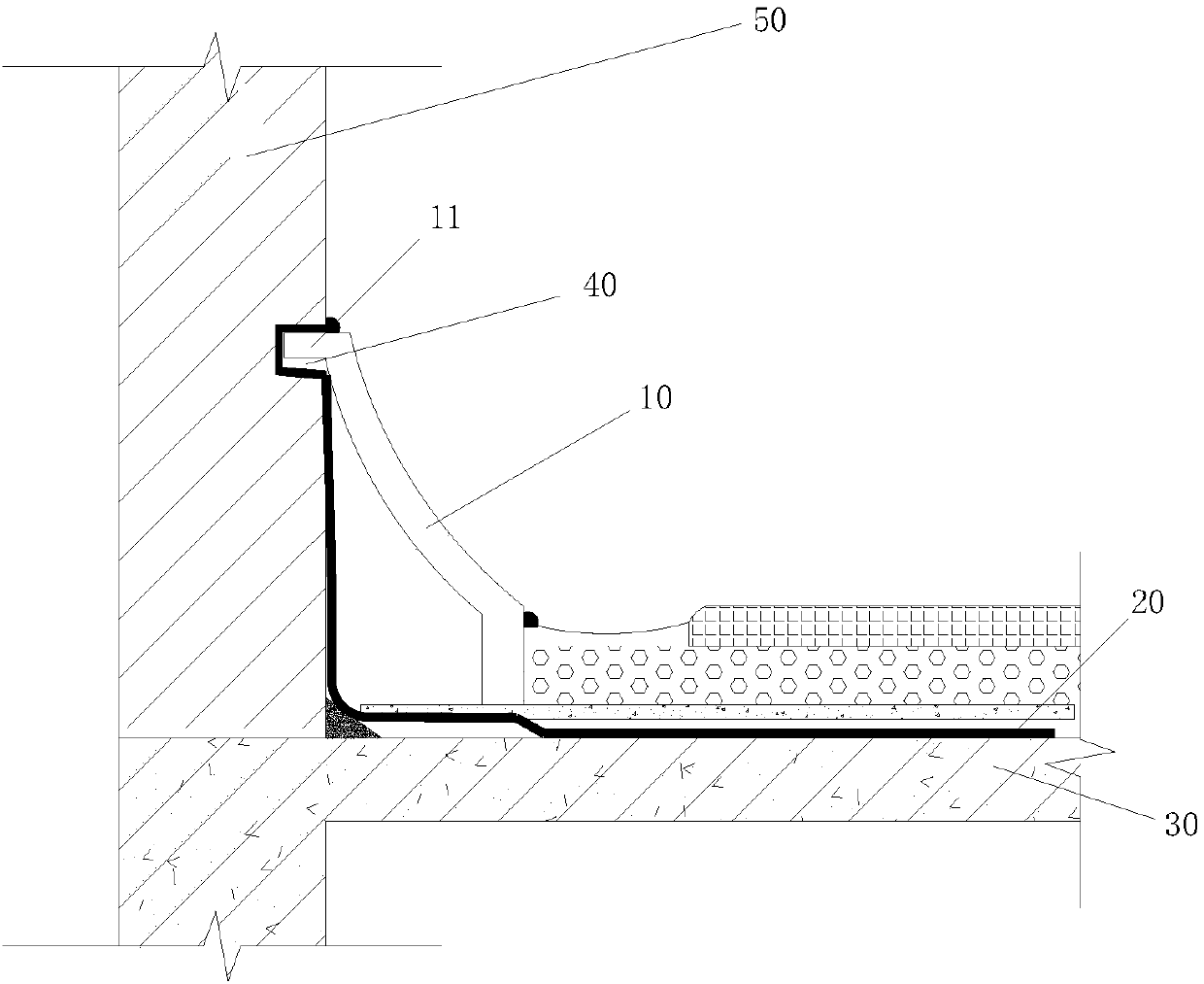

Constructing method for flashing structure of parapet wall

ActiveCN107558671AFast pre-productionConstruction quality is easy to controlRoof drainageRoof covering insulationsWater leakageSurface layer

The invention provides a constructing method for a flashing structure of a parapet wall. The constructing method comprises the construction steps of prefabricating flashing members, installing the flashing members, filling and compacting between the adjacent flashing members, coating a waterproof coating material and the like. The constructing method adopts a mode of prefabricating the flashing members, rapid pre-production of the flashing members is realized, the construction efficiency is improved, construction quality of the flashing members is convenient to control, and processing workshopconcentrated machining forming is achieved; construction pollution can be effectively reduced, construction materials are saved, and construction waste is reduced; phenomena of cracking and hollowingon the surfaces of the prefabricated flashing members cannot happen, and common technical problems are overcome; by using air permeability between the prefabricated members and a waterproof layer, the effect of heat resistance of the prefabricated members is good, deformation of the waterproof layer caused by water temperature changes is reduced, falling-off and water leakage of the waterproof layer can be effectively prevented, and the waterproof service life is prolonged; and the prefabricated flashing structure has a better appearance effect, the flashing height, width and radian are consistent, a later waterproof coating surface layer cannot fall off, and the long-term aesthetic effect can be achieved.

Owner:坤发建筑有限公司

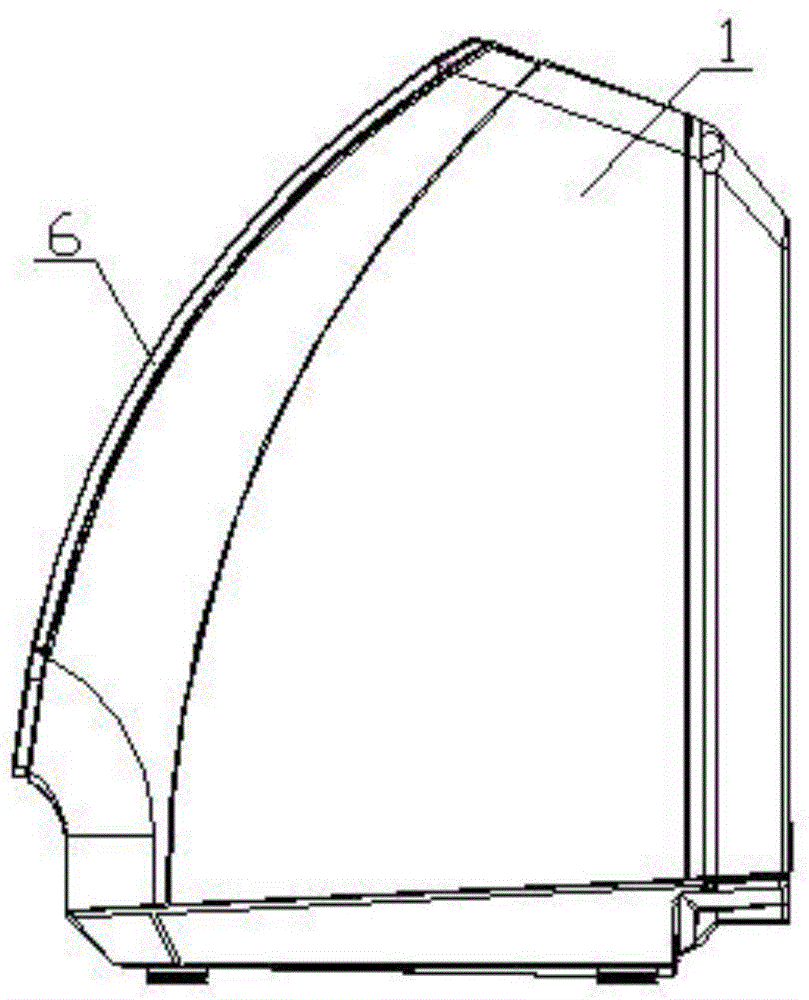

Dish-washing machine door body sealing structure and dish-washing machine

ActiveCN106468128ASimple sealing structureLow costSealing arrangementsEngineeringMechanical engineering

The invention relates to a dish-washing machine door body sealing structure and a dish-washing machine. The sealing structure comprises an inner container and a door body. Sealing is achieved between the periphery of the door body and the inner container through top sealing strips, lateral sealing strips on the two sides and bottom sealing strips, and the top sealing strips, the lateral sealing strips and the bottom sealing strips are separated with one another. The top sealing strips and the lateral sealing strips on the two sides are arranged on the inner container, and the bottom sealing strips are arranged at the bottom of the door body. The overall structure is simple, cost is low, and installation is convenient. The sealing structure can be better matched with the door body of a large radian structure so that a good sealing property between the door body and the inner container can be achieved, and reliable sealing is achieved. Moreover, the sealing structure is beneficial to prolonging the service life of the sealing strips.

Owner:QINGDAO HAIER DISHWASHER

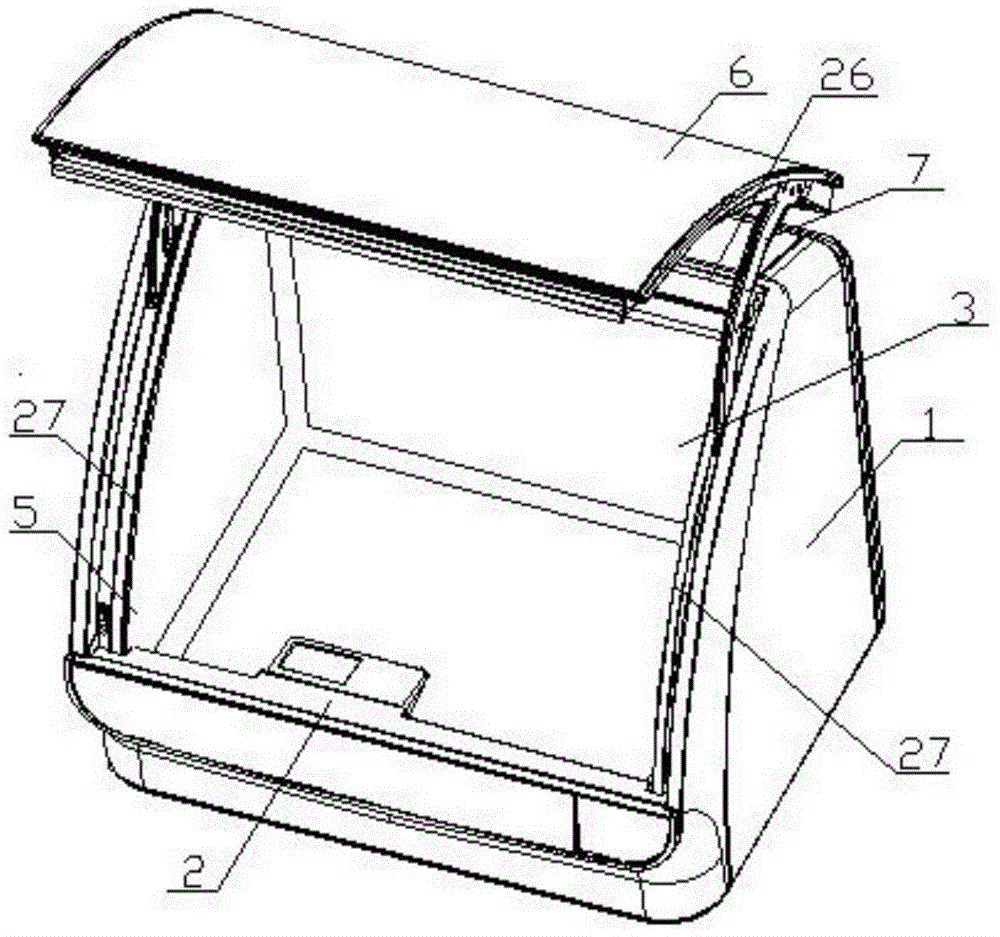

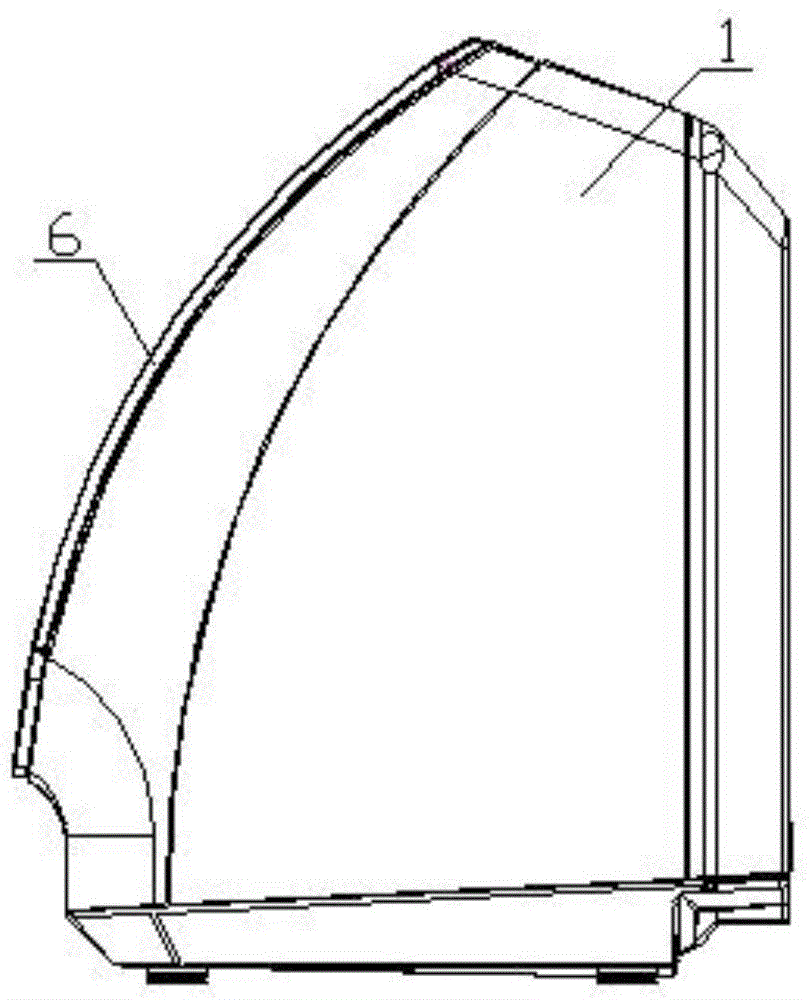

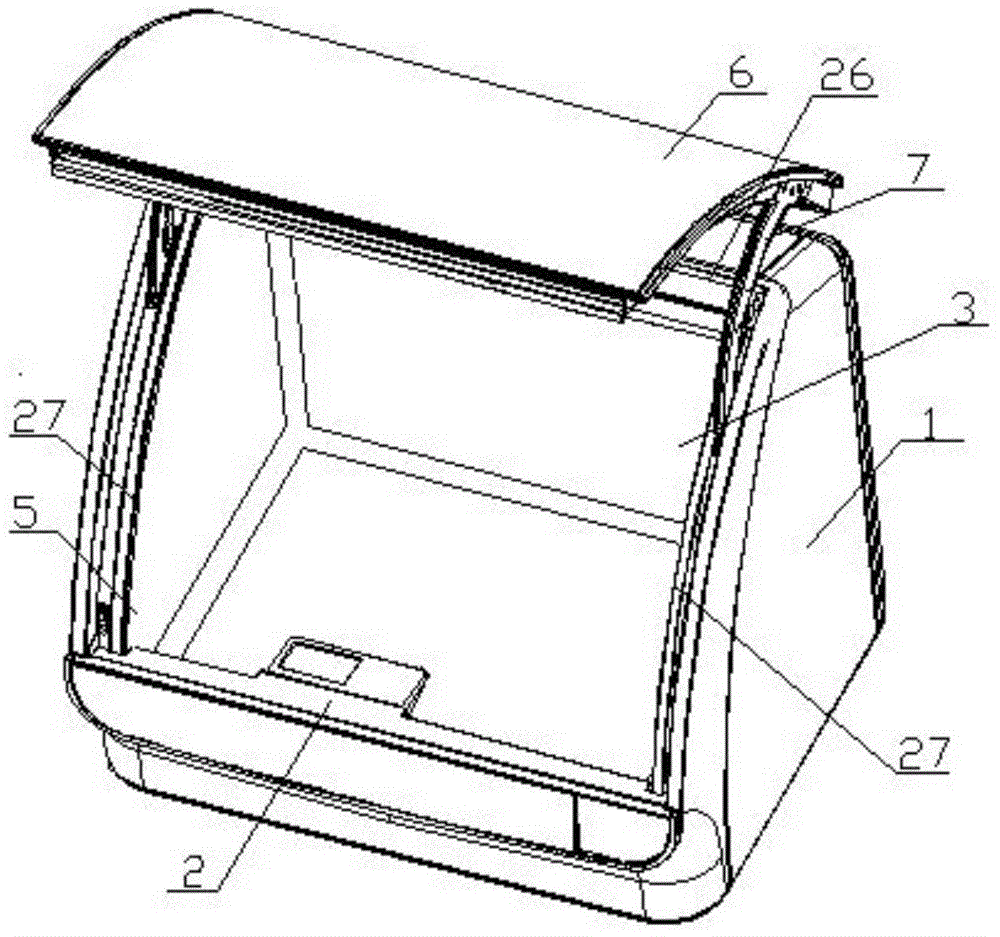

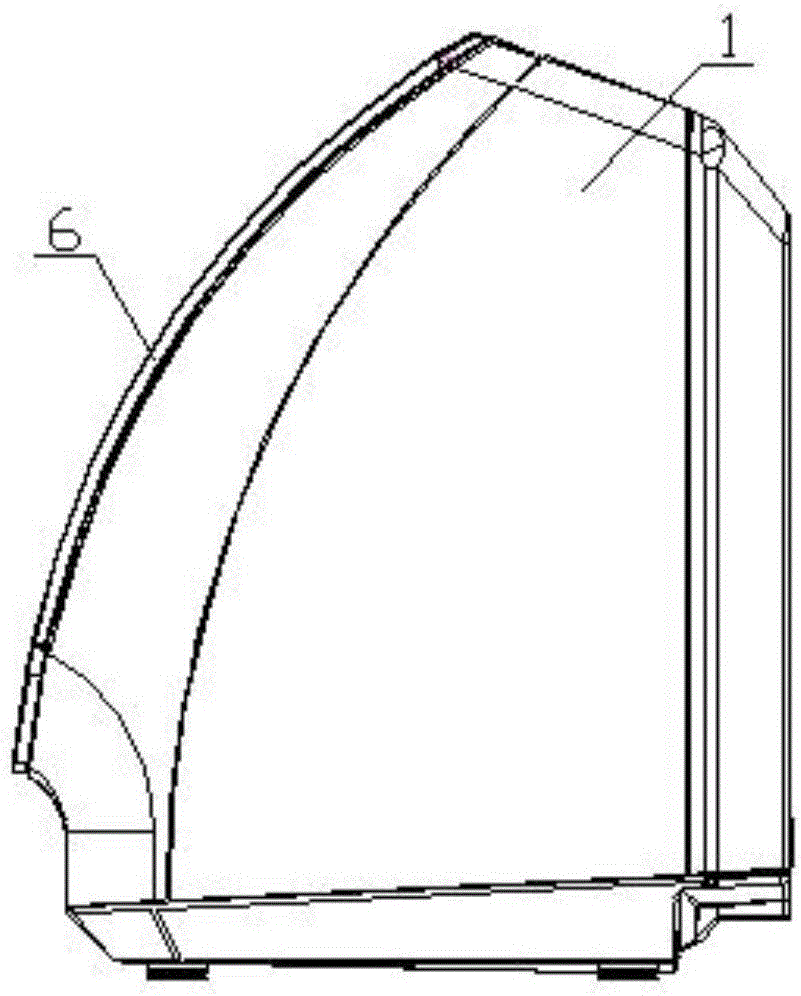

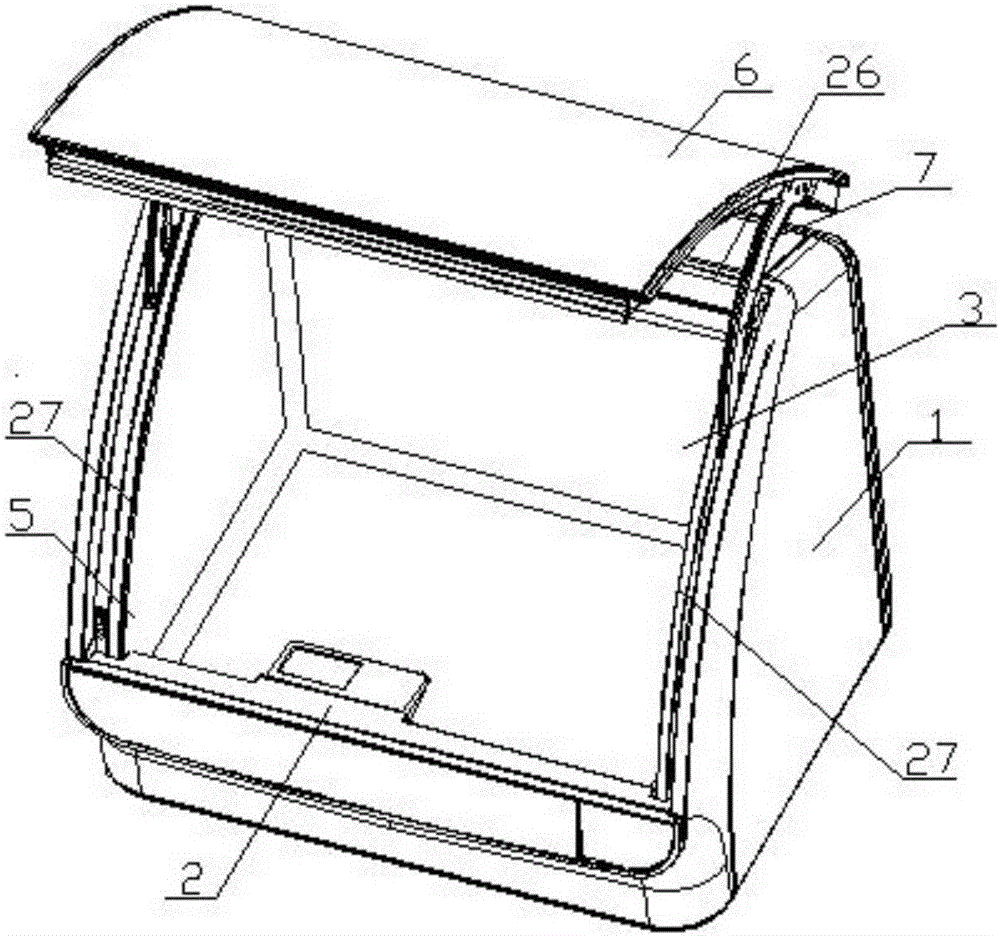

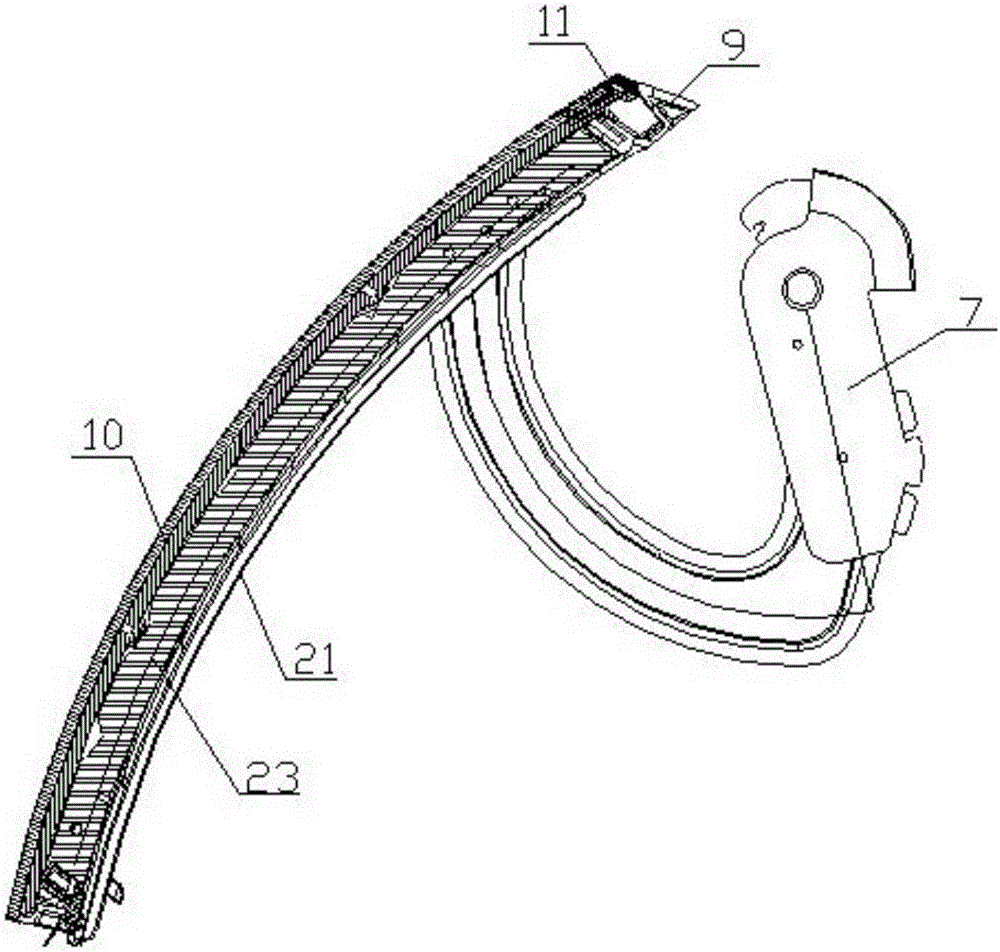

Door body of dish-washing machine and dish-washing machine

ActiveCN106466165ASimple structureConsistent arcTableware washing/rinsing machine detailsSealing arrangementsEngineeringRadian

The invention relates to a door body of a dish-washing machine and the dish-washing machine. The door body is bended from bottom to top and the overall door body is of a circular-arc-shaped structure. The door body is provided with at least one fixing part used for correcting deformation of the door body. Each fixing part has a standard radian. By the adoption of an integrated type structure, the door body is simple in structure and low in cost. By arranging the fixing parts with a correction function on a door frame, it is ensured that the radian of the door body is consistent with that of an inner container, and the sealing effect is ensured. On the premise that an exquisite appearance is ensured, it is ensured that the door body has a good sealing property, and reliable sealing of the door body and the inner container is achieved.

Owner:QINGDAO HAIER DISHWASHER +1

Intelligent temperature-control eye therapy instrument

InactiveCN107440899ACause discomfortReduce heating power consumptionBathing devicesMicrocontrollerTemperature control

The invention discloses an intelligent temperature-control eye therapy instrument which comprises a shell. The shell is of a spectacles structure, a circuit board and a control unit are arranged in the shell, physical therapy units are connected to positions of spectacle lenses on one side of the circuit board and close to eyes, and a power source is connected to the other side of the circuit board; each physical therapy unit comprises a support body, a heating element, an adsorption element and a steaming element which are sequentially connected in the direction away from the eyes to the direction of the eyes, a hollow heat-conducting support element is further arranged between the heating element and the adsorption element of each physical therapy unit, a refrigerating element is further arranged in the heat-conducting support element, and the refrigerating element is of a semiconductor-refrigerating chip; the control unit is connected with the circuit board and comprises a microprocessor, a button control module and a Bluetooth module, the button control module and the Bluetooth module are connected with the microcontroller, the microcontroller is used for controlling the physical therapy units, the button control module is used for controlling buttons, and the Bluetooth module is used for being wireless connected with external equipment.

Owner:WUXI NANLIGONG TECH DEV

General seamless steel pipe bending machine

PendingCN111389976AAchieve bendingEasy to operateMetal-working feeding devicesPositioning devicesHydraulic cylinderClassical mechanics

The invention discloses a general seamless steel pipe bending machine, and belongs to the technical field of pipe bending machines. The general seamless steel pipe bending machine comprises a rack, abending mechanism, a first clamping mechanism and a second clamping mechanism, wherein the first clamping mechanism and the second clamping mechanism are clamped on the two end sides of seamless steelpipes correspondingly; the first clamping mechanism comprises an upper clamping block and a lower clamping block; the second clamping mechanism comprises an upper clamping plate and a lower clampingplate; the bottom of the lower clamping plate is connected with a hydraulic cylinder, the lower clamping block is connected with a longitudinal sliding block sleeving a longitudinal lead screw, jacking plates are fixedly connected to the longitudinal sliding block and the lower clamping plate correspondingly, compressing screws are arranged on the jacking plates in threaded fit and penetrating modes, and a pair of rolling wheels is arranged between the upper clamping plate and the lower clamping plate; and the bending mechanism comprises a circular rotating disc with a sliding rail formed in the front face, two adjusting sliding blocks are arranged on the sliding rail, and the upper clamping plate and the lower clamping plate are fixed to the two adjusting sliding blocks correspondingly. The radian consistency of bent parts of the seamless steel pipes can be guaranteed, the bending radius can further be adjusted, the bending arc length can further be controlled, thus the general seamless steel pipe bending machine can be general for the seamless steel pipes of different pipe diameters, and application is convenient.

Owner:LIAOCHENG ANTAI PETROLEUM MACHINERY

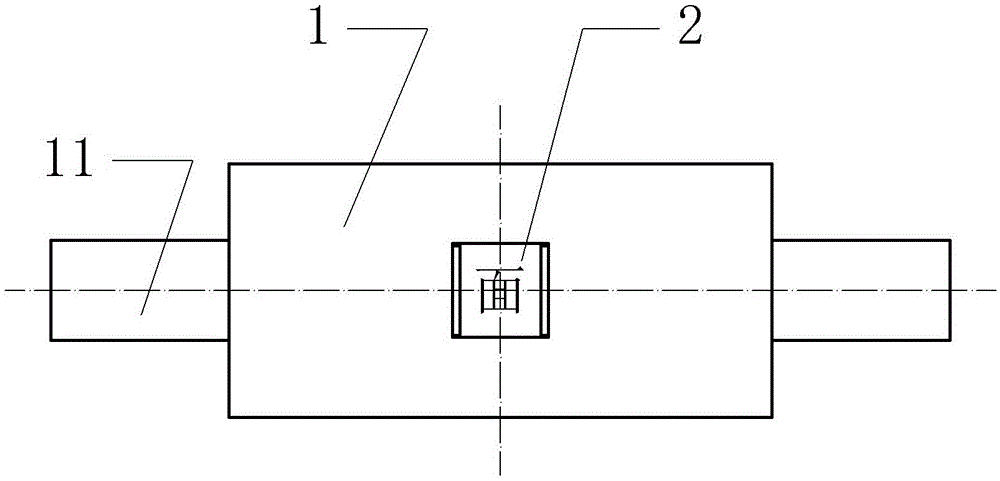

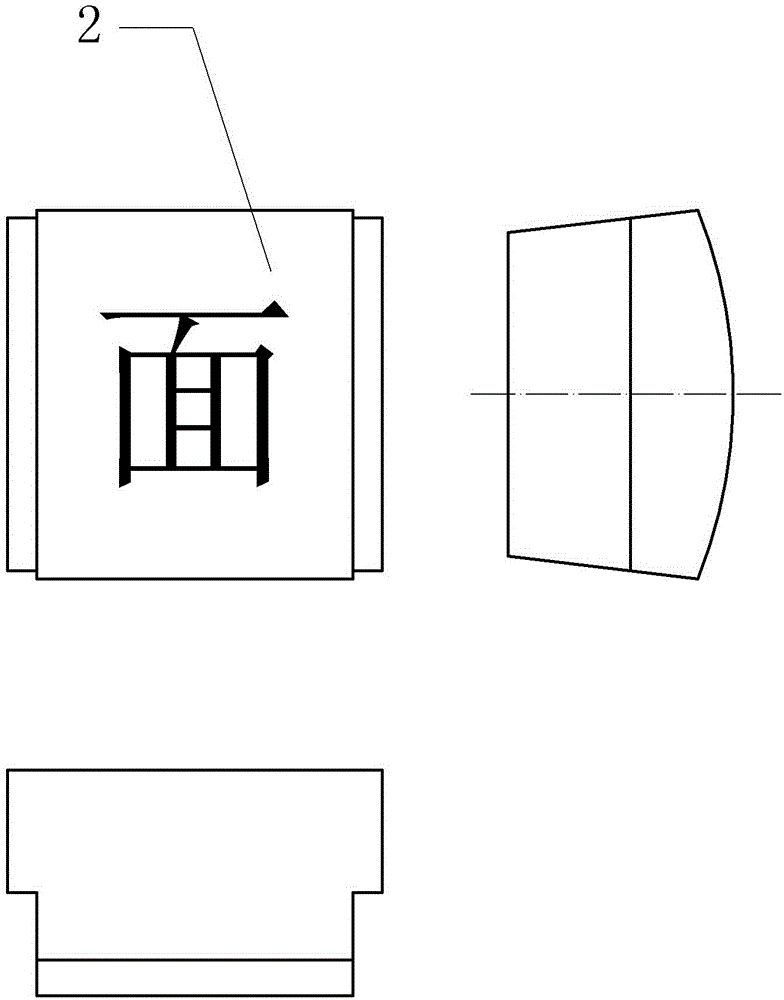

Combined die for printing characters on noodles

InactiveCN105150706AEasy to replaceAvoid paddingDough embossing machinesStampingMagnetic tension forceEngineering

The invention provides a die for printing characters on noodles, relating to cooked wheaten food processing devices. The die comprises a roller, a matrix and a cutter, wherein the roller is made of steel materials; a hole for the matrix to install is formed in the roller; the matrix is made of magnetic materials and is restrained in the hole in the roller via a magnetic force; a character on the matrix is hollowed out; the cutter is fixed on the roller via a screw; handles are arranged at the two sides of the roller and are used for gripping to roll the roller. When a new character needs to be printed, the original matrix can be dismantled and is changed with a new matrix instead, and cutting off the noodles can be achieved while printing the character. The character on the matrix is in hollow design, thus being convenient for cleaning caked flour.

Owner:CHONGQING YUXI FLOUR PROD

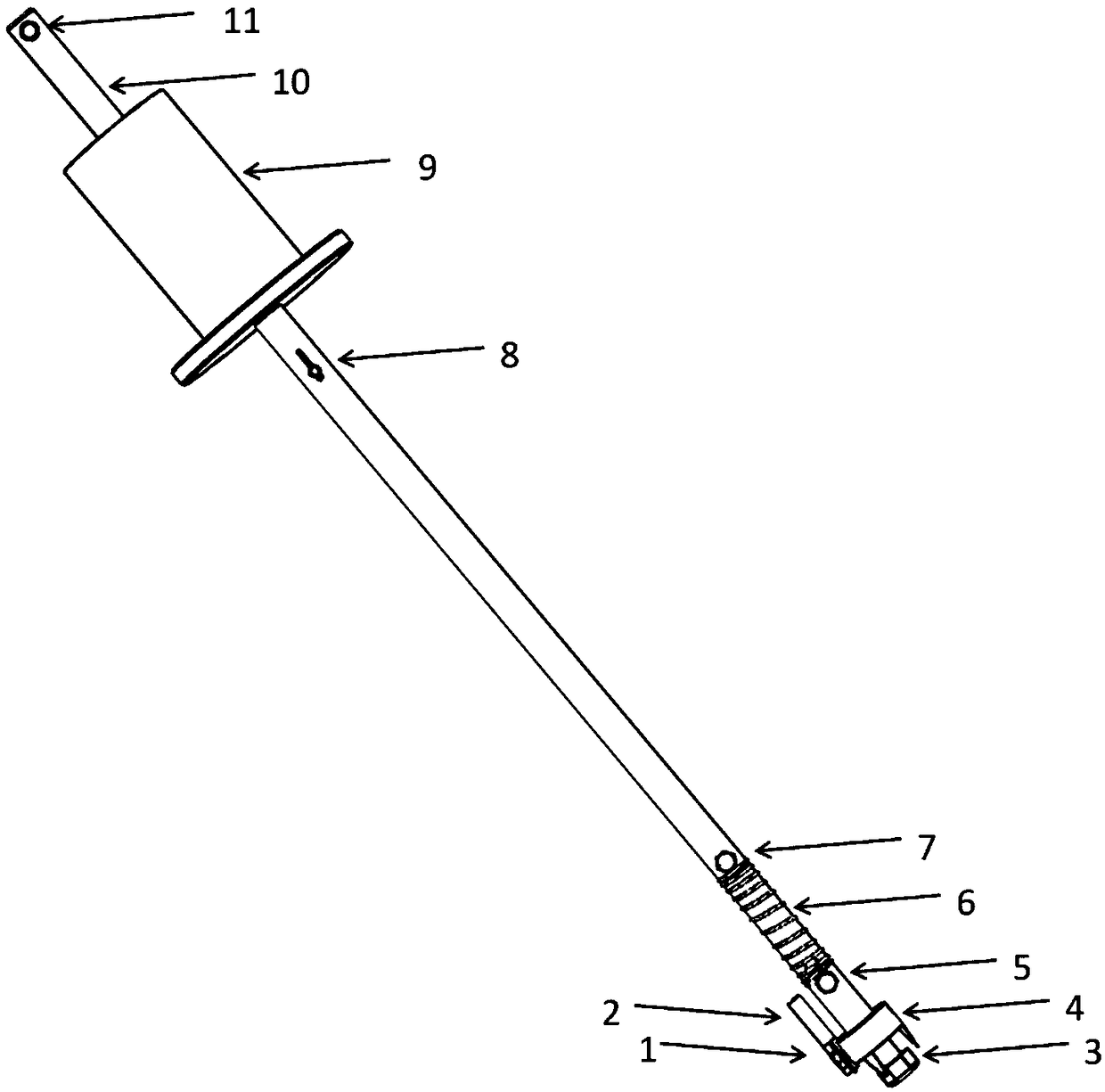

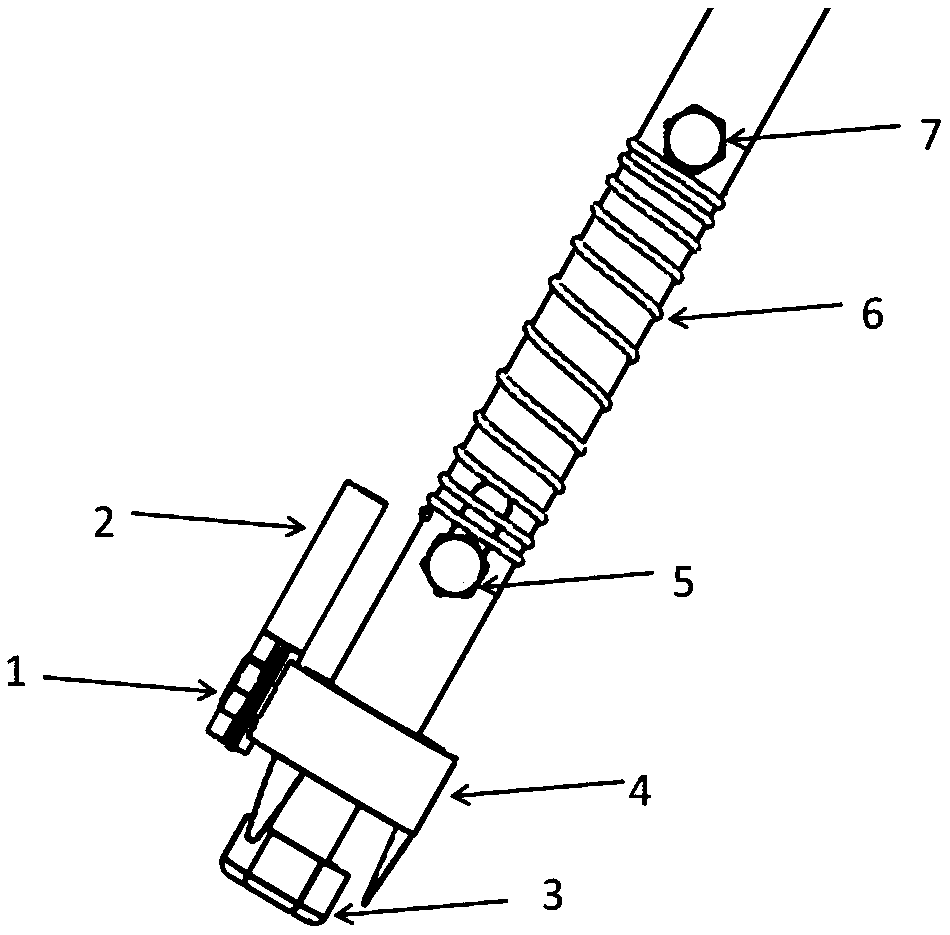

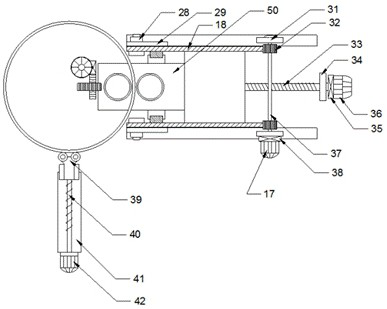

Visual bolt looseness prevention washer turn-over tool and use method thereof

The invention discloses a visual bolt looseness prevention washer turn-over tool comprising a turn-over pressure rod. A locating guide head capable of moving up and down is arranged in the lower end of the turn-over pressure rod. The locating guide head and the turn-over pressure rod are connected through a lower pin bolt. An upper pin bolt is arranged on the turn-over pressure rod and located above the lower pin bolt. The outer side of the turn-over pressure rod is sleeved with a pressure spring. The pressure spring is arranged between the lower pin bolt and the upper pin bolt. The upper endof the turn-over pressure rod and the lower end of heavy hammer sliding rod are fixedly connected. A tray is arranged on the lower portion of the heavy hammer sliding rod. The part, located above thetray, of the outer side of the heavy hammer sliding rod is sleeved with a heavy hammer. The bottom of the turn-over pressure rod is provided with a protrusion. An angle-adjustable camera is fixed to the part, located on the upper portion of the protrusion, of the lower end of the turn-over pressure rod. The visual bolt looseness prevention washer turn-over tool is an assembly, convenient to assemble and disassemble, simple and reliable in structure, low in use cost, free of quick-wear parts, convenient to use and free of maintenance.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

Corner fine optimization device for building base material

ActiveCN110977674ASave human effortImprove efficiencyEdge grinding machinesGrinding carriagesGrindingStructural engineering

The invention discloses a corner fine optimization device for a building base material. A machining table is included. A pushing device is arranged on the upper side of the machining table. A machining groove is formed in the machining table. An elevating device is arranged below the machining groove and comprises a lifting plate capable of containing a wood door. Operation through manual work isnot needed, manpower is greatly reduced, and therefore a worker does not need to hold a grinding device by hand all the time. Through design of an extrusion block, the situation that the wood door isnot aligned with an extrusion groove during ascending is avoided, and meanwhile the wood door is kept tidy when moving to the machining table. Compared with the prior art, manual tidying is not needed, and efficiency is improved. According to the scheme, through the arrangement of the grinding device capable of swinging back and forth, the grinding device grinds the side edge of the wood door, thegrinding precision is improved, the radian of the ground wood door side edge is kept consistent, and different ground radians due to manual grinding are avoided.

Owner:嘉兴极客旅游用品有限公司

Door body structure of dish-washing machine and dish-washing machine

InactiveCN106466166ASimple structureLow costTableware washing/rinsing machine detailsVentilation arrangementEngineeringMechanical engineering

The invention relates to a door body structure of a dish-washing machine and the dish-washing machine. The door body structure comprises a door body which is connected with a machine body of the dish-washing machine through a door-opening mechanism. The door body is of a top-hung integrated type structure, and is composed of a transparent material in the middle and a door frame around the door body. The transparent material is fixed to the door frame. By the adoption of the integrated type structure, the door body is simple in structure and low in cost. Due to large-area use of the transparent material in the middle of the door body, a user can observe the working conditions in the dish-washing machine through the transparent material, and consumer use is facilitated.

Owner:QINGDAO HAIER DISHWASHER

Railway vehicle car roof wind deflector

ActiveCN102975732AUniform gap sizeImprove aestheticsRailway transportAxle-box lubricationFlat roofAutomotive engineering

A railway vehicle car roof wind deflector comprises an arc-shaped wind deflector board. A fixing frame is welded on the inner side of a flat roof of a car body. An installing base is welded at the outer end of the flat roof of the car body. A reversed-T-shaped slide groove is arranged at the upper end face of the installing base along the longitudinal direction of the flat roof of the car body. A Z-shaped connecting board is welded at the upper end of the arc-shaped wind deflector board and connected with the upper end of the fixing frame through bolts. Hinges are welded at the lower end of the arc-shaped wind deflector board and fixed with the installing base through bolts. An adjusting gasket is arranged between the hinges and the installing base. A longitudinal space can be conveniently adjusted through the wind deflector board by using of the reversed-T-shaped slide groove. The sizes of gaps between the wind deflector and the flat roof can be adjusted through adjustment of a gasket, and ponding of the flat roof can be discharged from the gaps between the wind deflector and the flat roof. The gaps are even in size. The radian of the wind deflector board can be adjusted through the adjustment of the gasket, arcs of the adjacent wind deflector boards can be coincident, and degrees of beauty are improved. The railway vehicle car roof wind deflector is convenient to install and high in production efficiency.

Owner:CRRC NANJING PUZHEN CO LTD

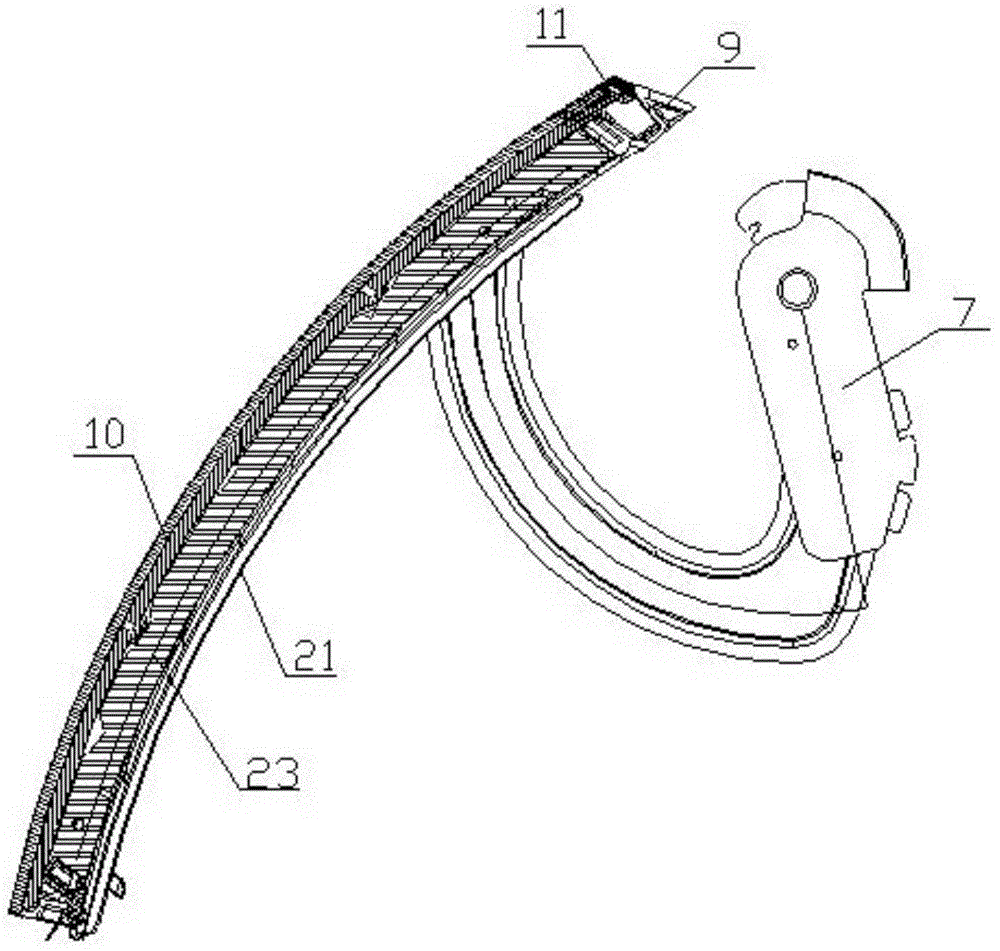

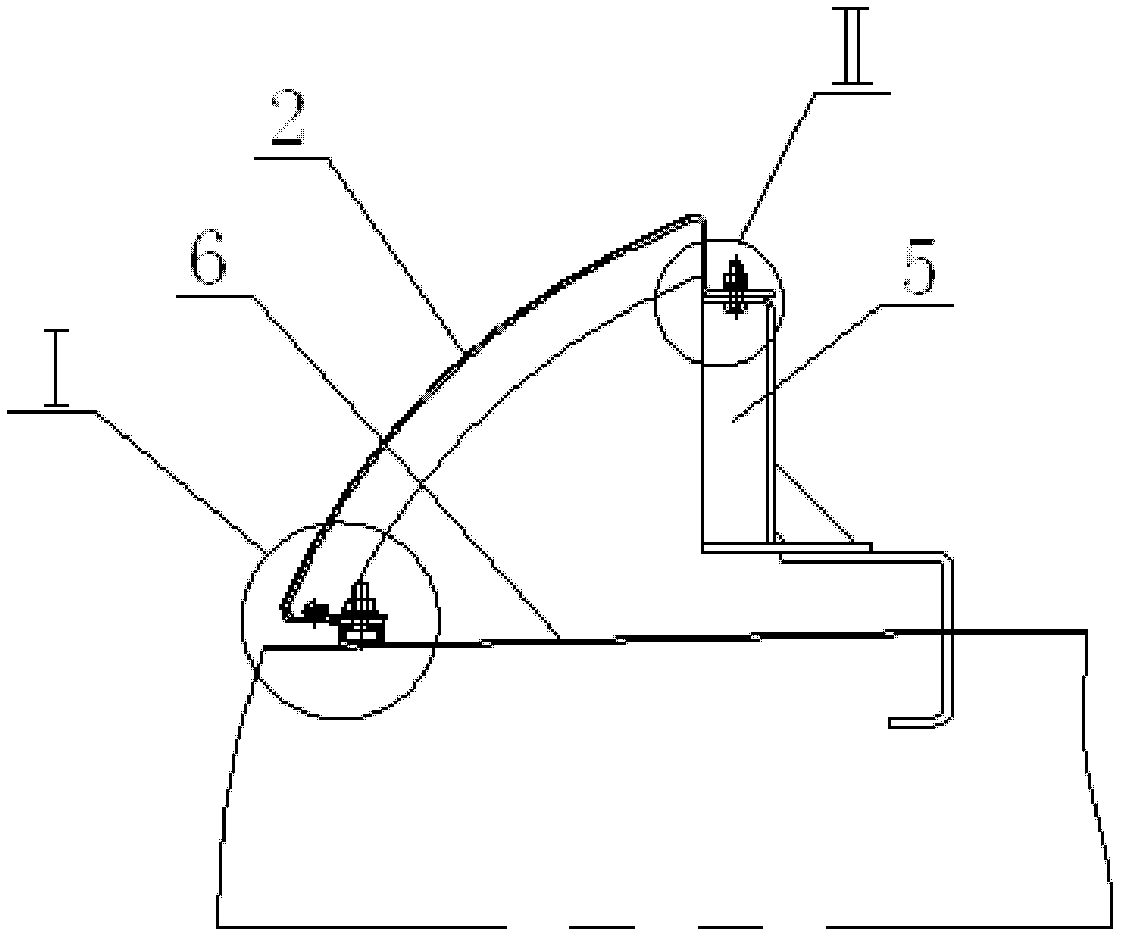

Vehicle roof fairing installing method of rail vehicle

ActiveCN102963373AConsistent arcSimple processRailway transportAxle-box lubricationFixed frameRadian

The invention relates to a vehicle roof fairing installing method of a rail vehicle. The vehicle roof fairing installing method comprises the following steps that a fixing framework and an installing seat are welded at the inner and outer sides of a vehicle roof flat plate; a Z-shaped connecting plate is welded at the inner side wall of the upper end of an arc-shaped fairing plate; a hinge is welded at the inner side wall of the lower end of the arc-shaped fairing plate; the fairing plate is hoisted in place; the Z-shaped connecting plate is fixedly arranged at the upper surface of the fixing framework; the gap between the hinge and the vehicle body flat top and the radian of the fairing plate are regulated in a mode of additionally adding a regulating gasket between a second component of the hinge and the installing seat; the position of the fairing plate is regulated in the longitudinal direction, and the gap between the adjacent fairing plates is eliminated; and screw bolts arranged at the upper and lower end parts of the fairing plate are fastened. The vehicle roof fairing installing method has the advantages that the work procedure is simple, the operation is convenient, the production efficiency is high, the gap between the hinge and the vehicle body flat top and the radian of the fairing plate can be respectively regulated, and the longitudinal gap can also be regulated. The circular arcs of installed fairings are consistent, the aesthetic degree is high, and in addition, accumulation water at the flat top can be ensured to be discharged out from the gap between the fairing and the vehicle top.

Owner:CRRC NANJING PUZHEN CO LTD

Arc panel and straight plate border line setting device for steam oven

PendingCN110900084AEasy to twist and operateLarge operating spaceWelding/cutting auxillary devicesAuxillary welding devicesBorder lineStructural engineering

The invention discloses an arc panel and straight plate border line setting device for a steam oven. The arc panel and straight plate border line setting device comprises a working table, a clamping device and a loading device. The working table is provided with an adjusting mechanism which moves in the length direction of the working table. The clamping device moves in the height direction of theadjusting mechanism. The loading device comprises a loading shell which is provided with a thread rod. The thread rod is provided with two loading plates. The thread rod is provided with adjusting nuts. Two adjusting nuts are arranged on the left side and the right side of each loading plate correspondingly. First air cylinders are arranged on the two side portions of the loading shell correspondingly. By means of the pushing effect of the first air cylinders, fixing plates of the first air cylinders fix a straight plate onto the loading plates. According to the arc panel and straight plate border line setting device, the polished end face of the straight plate makes contact with the welding position of the inner side of an arc panel in a complete attached manner, the contact portion of the straight plate and the arc panel are welded, the welding quality is improved, the welding strength of the straight plate on the arc panel is improved, and thus the overall structure obtained by machining the straight plate and the arc panel meets the stress requirement of parts of the oven.

Owner:浙江蓝炬星电器有限公司

Tube bending machine for seamless steel tubes

PendingCN111346952AAchieve bendingEasy to operateMetal-working feeding devicesPositioning devicesHydraulic cylinderGear wheel

The invention discloses a tube bending machine for seamless steel tubes, and belongs to the technical field of tube bending machines. The tube bending machine comprises a base provided with a mountinggroove; a first screw and sliding block structure arranged transversely and a round rotating disk located above the first screw and sliding block structure are arranged in the mounting groove; a sliding rail extending along the radius of the round rotating disk is arranged on the front side of the round rotating disk; an adjusting sliding block is arranged on the sliding rail; one U-shaped clamping sleeve is fixed to the adjusting sliding block; a vertically-fixed hydraulic cylinder is arranged on one side of the U-shaped clamping sleeve; the other U-shaped clamping sleeve parallel with the U-shaped clamping sleeve is fixed to the top of the hydraulic cylinder; a pair of rolling wheels are arranged on the inner side of each of the two U-shaped clamping sleeves; a driving shaft of a gear is fixedly sleeved with the back end surface of the round rotating disk; the upper end of a transverse sliding block is connected with a second screw and sliding block structure arranged longitudinally; and a rack plate meshing with the gear is connected onto the second screw and sliding block structure. With the adoption of the tube bending machine, collapsing or internal wrinkling of the inner arc sides of the seamless steel tubes can be prevented, the radian consistency of the bent part of the seamless steel tubes can be guaranteed, the bending radius can be adjusted, the bending arc lengthcan be controlled, and the tube bending machine is relatively convenient to use.

Owner:LIAOCHENG ANTAI PETROLEUM MACHINERY

Field racing natural grassland hand-held marking car

The invention discloses a walking line-marking vehicle for field event native pasture and mainly relates to the field of field event equipment. The walking line-marking vehicle comprises a chassis frame for fixing a hopper, wherein a linear wheel rack is arranged on the front side of the chassis frame; a front wheel is mounted at the front end of the linear wheel rack; a transverse bracket is arranged on one side of the linear wheel rack; a marking wheel is arranged at the outer end of the transverse bracket; rear wheels are mounted on two sides of the chassis frame; a blanking channel corresponding to the marking wheel is formed in the bottom of the left side / right side of the hopper; a screen of which the front side is capable of springing is arranged in the blanking channel, and the springing of the screen is linked with the front wheel; a screened product outlet is formed in the rear side of the blanking channel; and a movable trailer used for receiving materials is arranged on the outer side of the screened product outlet. The walking line-marking vehicle disclosed by the invention has the beneficial effects that the line marking efficiency and quality can be obviously improved, the line marking retention degree is obviously improved compared with that in the prior art, the operating difficulty is lowered, and people are able to rapidly draw accurate, elegant, standard and durable race lines with the walking line-marking vehicle.

Owner:XUCHANG UNIV

Plastic steel air duct flange machining device and machining method

According to the plastic steel air duct flange machining device and method, a first servo motor of a fixing assembly of the device controls an annular workpiece to rotate and move through a main shaft speed reducer and a rapid chuck; a third servo motor of the clamping assembly controls a lead screw worm gear to rotate through a third planetary reducer, controls a pressing lead screw to push or pull a sliding block and controls the clamping distance between a sliding roller and a fixed bottom roller. A second servo motor of the overturning assembly controls a rotating gear to crawl along a gear ring through a second planetary reducer, drives a main fixing table to rotate around a center fixing shaft through a second fixing support and enables a sliding roller and a fixed bottom roller to rotate to drive a clamping part, clamped between the sliding roller and the fixed bottom roller, of the extruded and extended workpiece to overturn, and workpiece flanging is completed. According to the flanging device, heating is not needed in the flanging process, a machined air duct flange is high in precision, the radian formed by flanging is consistent, the end face of the flange is flat, stress concentration of a bent part can be effectively avoided, and the flanging quality is high.

Owner:TIANJIN AOLIANTE STEEL STRUCTURE INSTALLATION ENG

Bidirectional adjustable cylindrical welding anti-deformation fixture

ActiveCN102896455BAvoid welding deformationImprove molding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention relates to a bidirectional adjustable cylindrical welding anti-deformation fixture which comprises a rotary table, a central compressing component and more than three groups of movable supporting components, wherein the central compressing component is arranged on the rotary table, the rotary table is in a rotation state around the central compressing component, the more than three groups of movable supporting components are uniformly distributed on the rotary table around the central compressing component, and the central compressing component props against the more than three groups of movable supporting components so that the movable supporting components are simultaneously extended outwards or simultaneously retracted. According to the bidirectional adjustable cylindrical welding anti-deformation fixture disclosed by the invention, the central compressing component drives the movable supporting components to prop against and fix a cylinder workpiece, and the rotary table capable of rotating in plane and space drives the cylinder workpiece to rotate in two directions by supporting the movable supporting components so that the cylinder workpiece is located and welded; in addition, the bidirectional adjustable cylindrical welding anti-deformation fixture disclosed by the invention has the advantages of simple structure, convenience in operation, low cost and good welding effect; and the welded workpiece has less possibility of deformation.

Owner:JIANGSU JOSUN SCI&TECH CO LTD

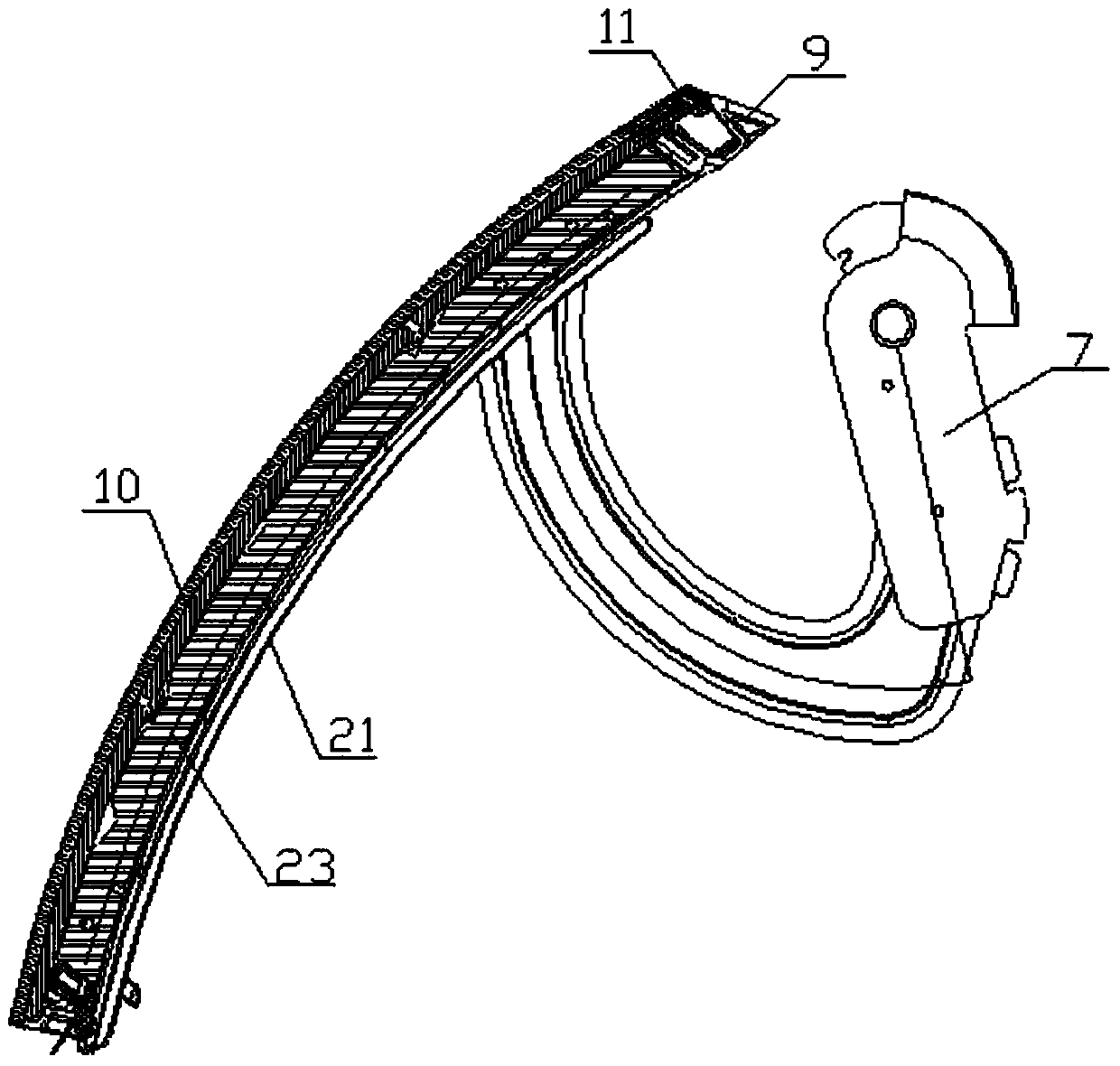

Open-loop expanding machine suitable for flat conducting bar

PendingCN114453467AConsistent arcGood excitationMetal-working feeding devicesPositioning devicesElectric machineryEngineering

The invention discloses an open-loop expanding machine suitable for a flat guide bar, which comprises a first clamping device, a second clamping device and a radian clamping device, the first clamping device, the second clamping device and the radian clamping device are used for placing a workpiece, and the radian clamping device is arranged between the first clamping device and the second clamping device. The device comprises a first clamping device, a second clamping device, a radian clamping device, a central shaft, a left-right rotating power mechanism, a radian plate stabilizing motor, a reverse pulling mechanism and a control center, and the first clamping device, the second clamping device and the radian clamping device are all arranged at the axis position of the central shaft; the second clamping device is driven by the left-right rotating power mechanism to concentrically rotate around the center shaft so as to move towards the inner side, and the second clamping device limits the moving speed of moving towards the inner side under the reverse pulling force of the reverse pulling-in mechanism. The device solves the problem of consistent radian of the end part of the guide bar, is high in automation degree, is economical, can replace different dies, and greatly accelerates the processing period.

Owner:株洲兆源机电科技有限公司

Door body sealing structure of dishwasher and dishwasher

ActiveCN106468128BSimple sealing structureLow costSealing arrangementsEngineeringMechanical engineering

The invention relates to a dish-washing machine door body sealing structure and a dish-washing machine. The sealing structure comprises an inner container and a door body. Sealing is achieved between the periphery of the door body and the inner container through top sealing strips, lateral sealing strips on the two sides and bottom sealing strips, and the top sealing strips, the lateral sealing strips and the bottom sealing strips are separated with one another. The top sealing strips and the lateral sealing strips on the two sides are arranged on the inner container, and the bottom sealing strips are arranged at the bottom of the door body. The overall structure is simple, cost is low, and installation is convenient. The sealing structure can be better matched with the door body of a large radian structure so that a good sealing property between the door body and the inner container can be achieved, and reliable sealing is achieved. Moreover, the sealing structure is beneficial to prolonging the service life of the sealing strips.

Owner:QINGDAO HAIER DISHWASHER

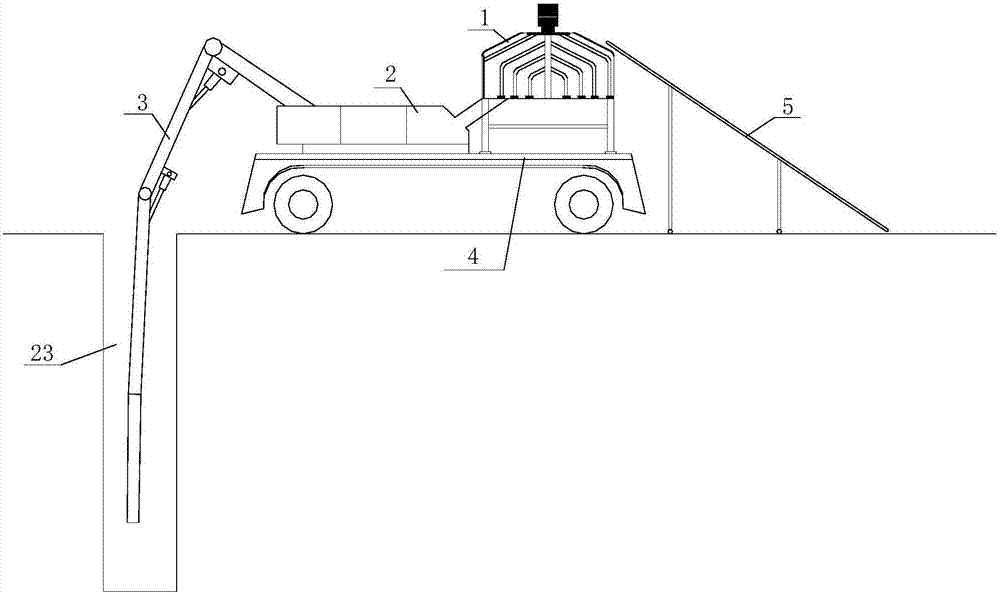

Mixture stirring and conveying device and construction method

PendingCN107972179AStir fully and evenlyFully contactedDischarging apparatusCement mixing apparatusEngineeringDynamical system

The invention discloses a mixture stirring and conveying device and a construction method. The device comprises a stirring machine, a conveying pump, a movable conveying pipe, a moving platform, and atransmission machine for conveying a material to be stirred to the stirring machine. The stirring machine comprises a stirring bin, a stirring system and a power system; the stirring system comprisesa plurality of stirring paddle groups; the stirring paddle groups are uniformly distributed on the periphery of the power system; each stirring paddle group comprises an outer stirring paddle and a plurality of inner stirring paddles; one outer stirring paddle in each two adjacent stirring paddle groups is provided with a side stirring blade clinging to a side wall of the stirring bin, and the bottom part of the other outer stirring paddle in each two adjacent stirring paddle groups is provided with a bottom stirring blade clinging to a bottom wall of the stirring bin, so that the material isstirred more uniformly; and shapes of the outer stirring paddles and the inner stirring paddles correspond to a shape of the side wall of the stirring bin, and the outer stirring paddles and the inner stirring paddles are arranged parallel to the side wall of the stirring bin, so that the material to be stirred can fully contact the outer stirring paddles and the inner stirring paddles, and is stirred more uniformly.

Owner:SHANGHAI CONSTR NO 1 GRP

Voice coil wire bending fixture and bending method

ActiveCN107846654AIncrease productivityGuarantee product qualityElectrical transducersLoudspeakerEngineering

The invention relates to a voice coil wire bending fixture and a voice coil wire bending method. The fixture comprises a bearing platform and a wire bending pedestal can be placed in the front of thebearing platform, wherein the middle part of the top surface of the bending wire pedestal is sunk to form a vibrating diaphragm placement area in which a vibrating diaphragm tray is arranged, a firstwrapping post and a wire pressing block biased to one side of the vibrating diaphragm tray are arranged on the top surface of the wire bending pedestal, the rear part of the bearing platform is connected with a swinging support arm which can be vertically lifted or swung, a second wrapping post vertically extending downwards is connected with the front end of the swinging support arm, and when theswinging support arm is horizontally placed, the bottom end of the second wrapping post is closed to and suspended above the vibrating diaphragm tray. According to the voice coil wire bending fixtureand bending method provided by the invention, loudspeakers with the voice coil wires having unified curvature or linetype can be efficiently produced, the production efficiency is improved, and the product quality is ensured.

Owner:SHENGDIAN ELECTRONICS TECH HUIZHOU

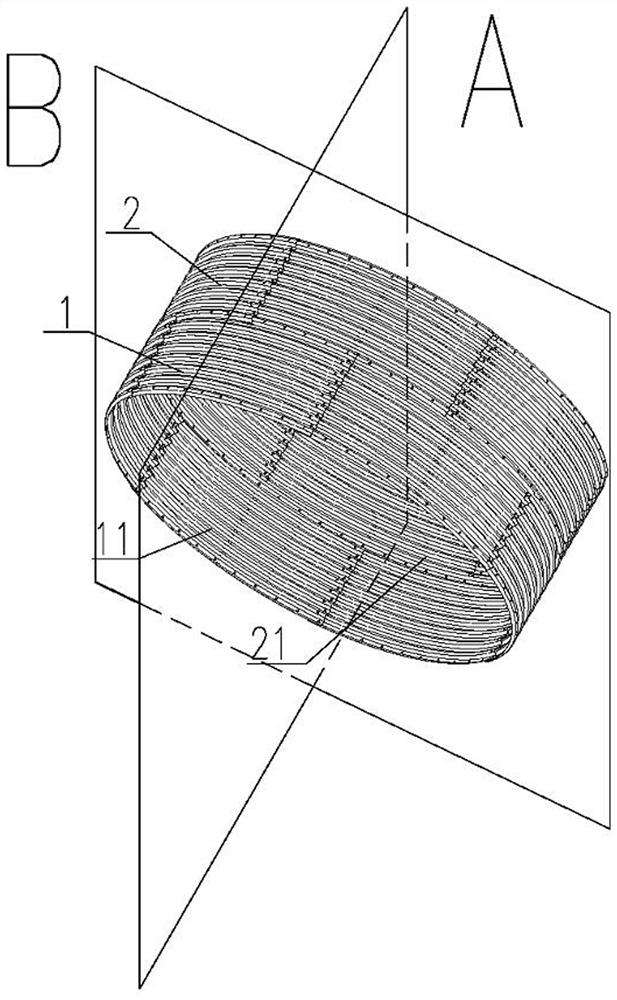

Assembled steel corrugated pipe culvert

ActiveCN111926724AConsistent sizeConsistent arcGround-workSewer pipelinesArchitectural engineeringAssembly (construction)

The invention relates to an assembled steel corrugated pipe culvert comprising at least two pipe culvert units which are sequentially arranged in an axial direction. A corrugated plate of each pipe culvert unit is provided with an axial connecting part which is axially connected with the next pipe culvert unit. The corrugated plates of the next pipe culvert units are sequentially attached to the inner sides and the outer sides of the previous pipe culvert units. The axial connecting parts of the corrugated plates of the next pipe culvert units are sequentially arranged on the inner sides and the outer sides of the circumferential splicing double-layer parts of the previous pipe culvert units; the multiple axial splicing double-layer parts of the previous pipe culvert units sequentially form lower layer circumferential splicing three-layer parts located on the lower layers and upper layer circumferential splicing three-layer parts located on the upper layers of the axial connecting parts of the corrugated plates of the next pipe culvert units, and the lower layer circumferential splicing three-layer parts and the upper layer circumferential splicing three-layer parts are fixedly connected through bolt assemblies. According to the assembed steel corrugated steel pipe culvert, products of different sizes do not need to be produced, corrugated plates do not need to be distinguishedduring field construction, and the production and assembly construction efficiency is improved.

Owner:CSIC HAIWEI ZHENGZHOU HIGH TECH CO LTD +1

Metal blade forming machine

ActiveCN101444813BConsistent arcNot easy to bendMetal-working feeding devicesPositioning devicesMolding machineEngineering

The invention relates to a metal blade forming equipment used for processing heating and ventilating equipment. A metal blade forming machine comprises a frame (1), a motor (6) and a rolling forming mechanism (3), a material cutting mechanism (4) and a material throwing mechanism (5) which are arranged on the frame. The blade forming machine adopts fully-automatic operation and has high processing efficiency; the rolling forming mechanism ensures that the radians of a profiled blade are consistent, and the whole blade does not flex easily; the material cutting mechanism ensures the standard of the cut blade length and size; and the material throwing mechanism ensures the consistency and the high speed for outputting the formed blade.

Owner:宁波朗迪智能机电有限公司

Online replaceable wear-resisting elbow

The invention relates to an online replaceable wear-resisting elbow. The online replaceable wear-resisting elbow comprises an elbow body. The elbow body is internally provided with an inside liner layer. The elbow body is further provided with a protection device. The protection device is composed of outer arc steel and a wear-resisting layer. The outer arc steel is provided with screw holes A. The wear-resisting layer comprises a second sealing layer, a first sealing layer and a contact layer. The upper middle portion of the second sealing layer is provided with an arc-shaped groove A. The lower portion of the second sealing layer is provided with a first sealing layer. The middle portion of the first sealing layer is provided with an arc-shaped groove B. The lower portion of the first sealing layer is provided with the contact layer. The lower portion of the contact layer and the inside liner layer form a smooth arc. The outer side faces of a fixed seat is provided with connecting racks. The inner side face of the fixed seat is provided with a rubber sealing strip. The upper portion of the fixed seat is provided with screw holes B. The sides, close to the fixed seat, of the connecting racks are provided with connecting arms. The connecting arms are provided with screw holes C. The tail ends of the connecting arms are provided with sealing bars. The middle portions of the connecting racks are further provided with adjusting bolts. The online replaceable wear-resisting elbow has the advantages of being convenient to replace, long in service life and low in replacement cost.

Owner:郑州中海威环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com