General seamless steel pipe bending machine

A technology of seamless steel pipe and pipe bending machine, which is used in metal processing equipment, feeding device, positioning device, etc. Promotes smooth, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

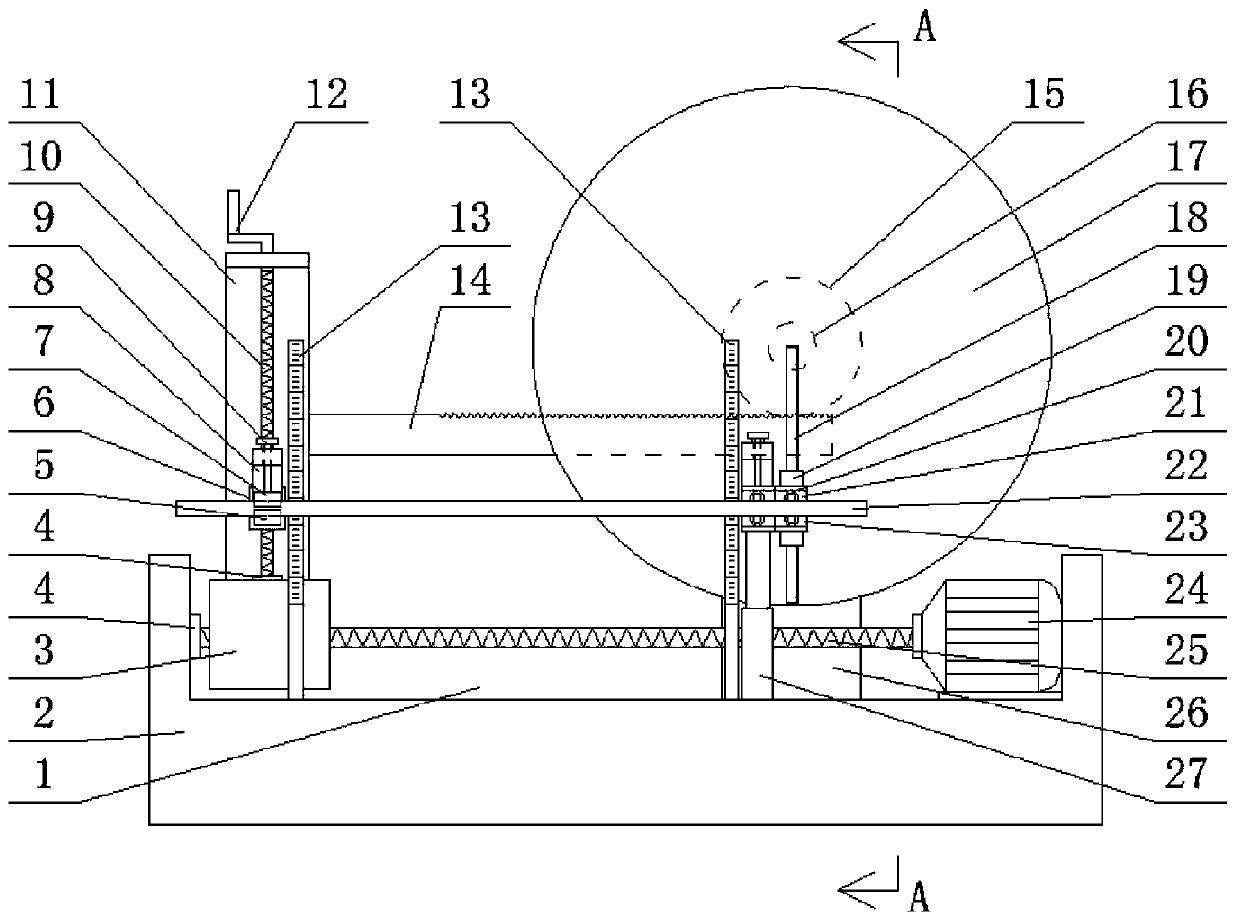

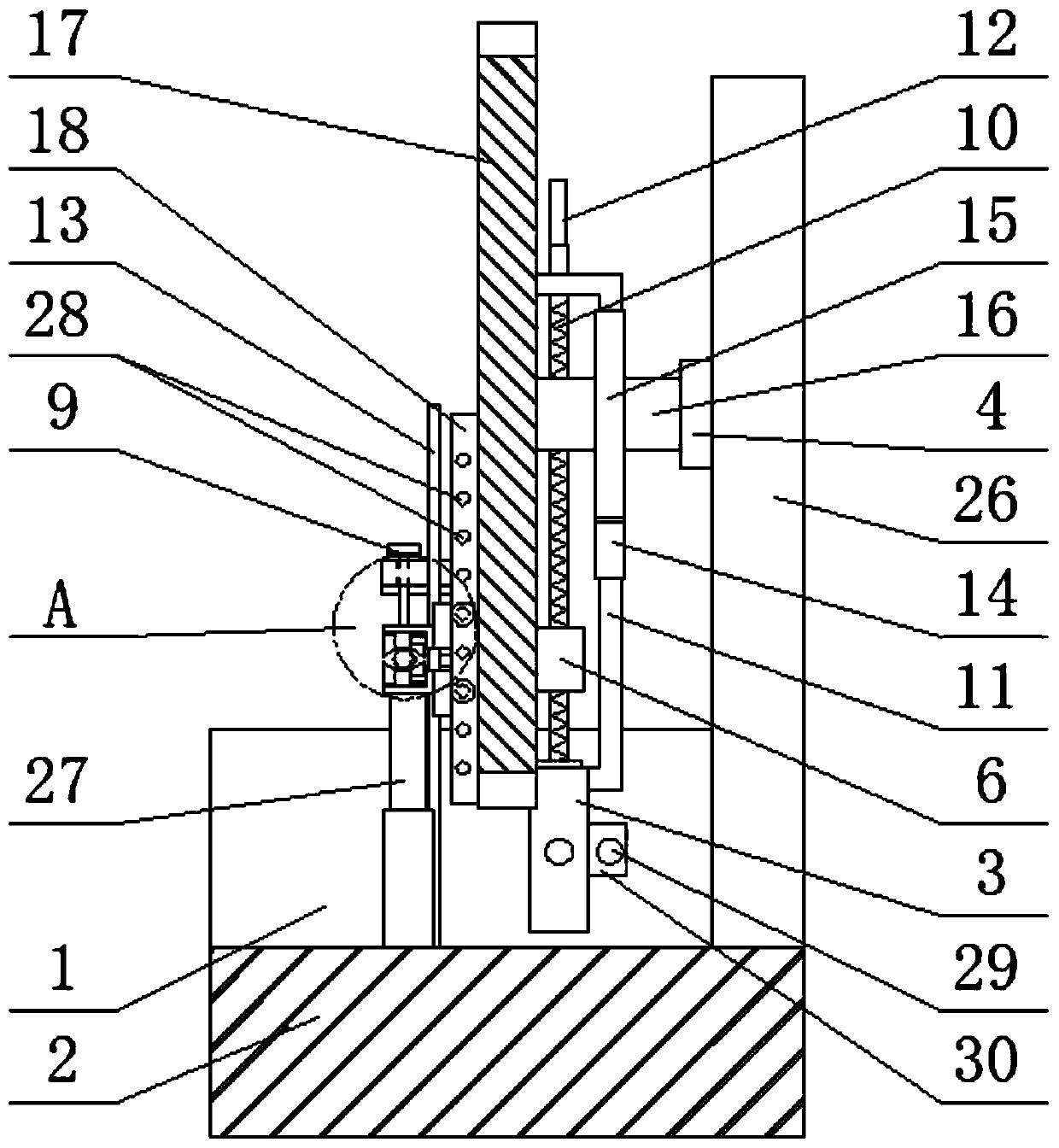

[0031] Such as figure 1 and figure 2A general seamless steel pipe bending machine shown includes a frame, a bending mechanism, and a first clamping mechanism and a second clamping mechanism respectively clamped on both ends of the windless steel pipe. The frame includes The base 2 of the recessed installation groove 1 and the vertical plate 26 connected to the rear side of the base 2 are provided with a horizontally arranged first screw slider structure in the installation groove 1, and the first screw slider structure includes The horizontal lead screw 25 driven by the forward and reverse motor 24 and the horizontal slider 3 that is threaded and fitted on the horizontal screw 25, the upper end of the horizontal slider 3 is connected with the longitudinal screw 10 arranged vertically through the bearing 4, And the thread on the longitudinal lead screw 10 is fitted with a longitudinal slider 6, the rear side of the transverse slider 3 is vertically fixed with an inverted L-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com