Tube bending machine for seamless steel tubes

A technology for seamless steel pipes and pipe bending machines, which is applied in metal processing equipment, feeding devices, positioning devices, etc., can solve problems such as inconvenience in application, and achieve the effect of promoting smoothness, simple control, and ensuring consistent radians.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

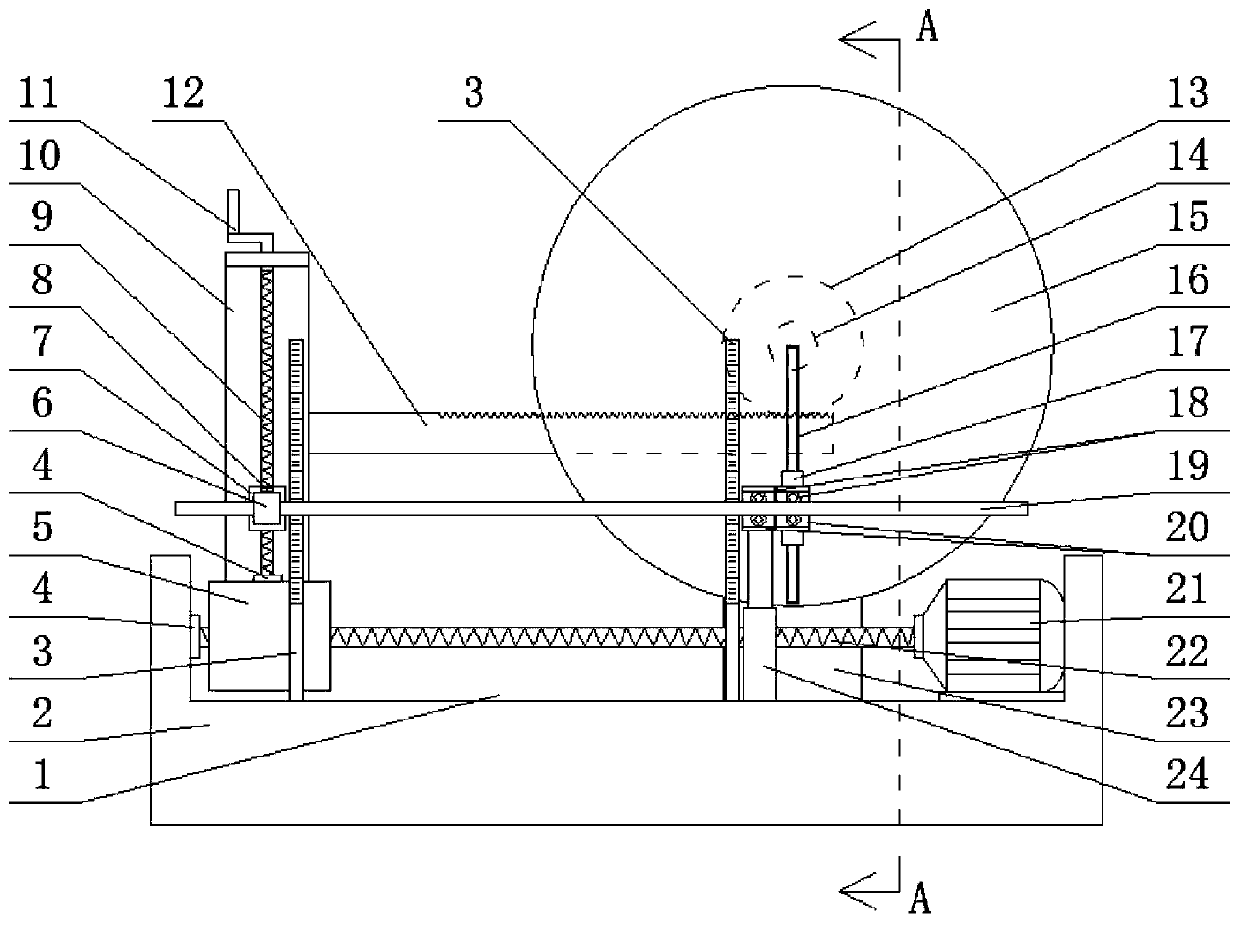

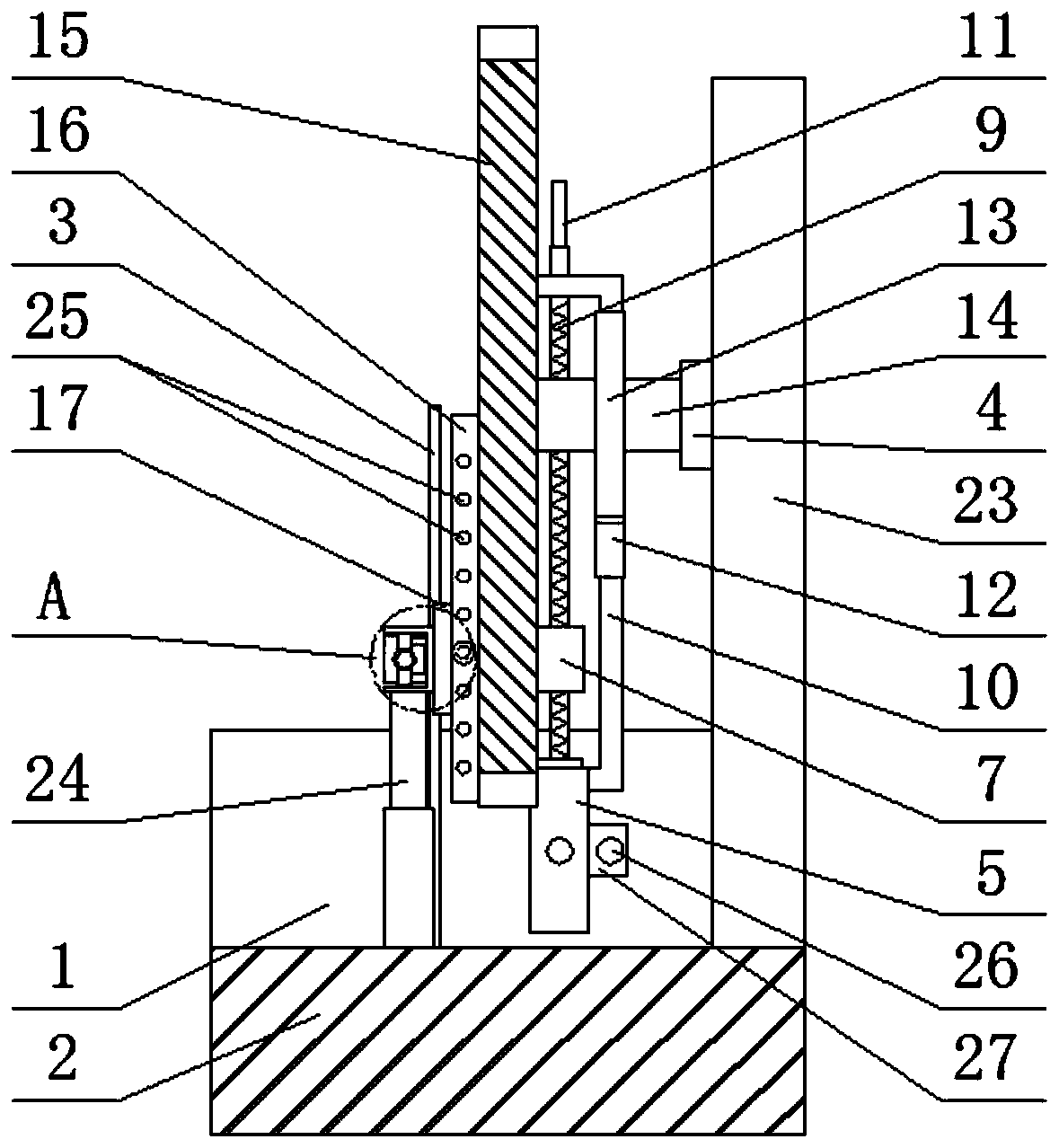

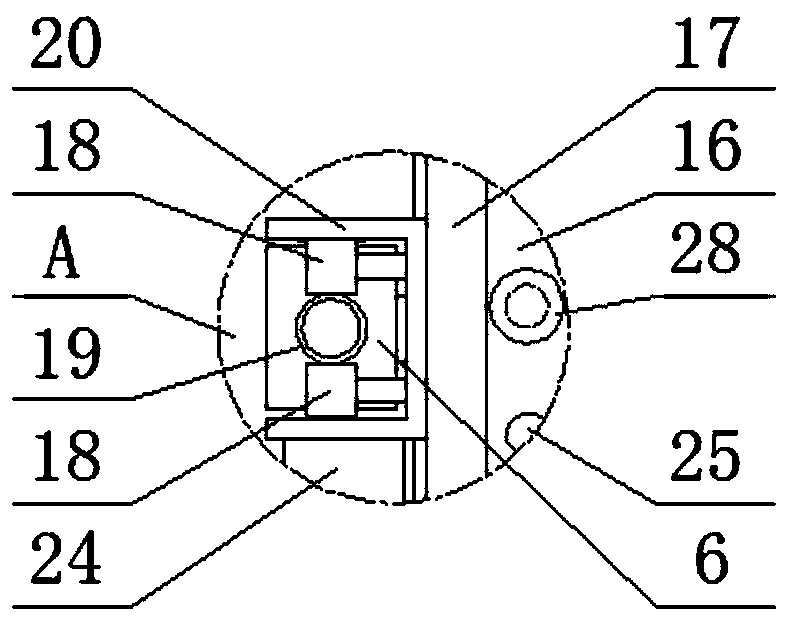

[0025] Such as figure 1 and figure 2 The illustrated seamless steel pipe bender includes a frame including a base 2 provided with a recessed installation groove 1 and a vertical plate 23 connected to the rear side of the base 2, in the installation groove 1 There is a first screw slider structure transversely arranged, the first screw slider structure includes a transverse screw 22 driven by a forward and reverse motor 21 and a transverse slider fitted on the transverse screw 22 with a thread adapter 5. A circular turntable 15 is arranged vertically above the side where the transverse screw 22 is connected to the forward and reverse motor 21, and a slide rail 16 extending along the radius is provided on a radius of the front of the circular turntable 15; The slide rail 16 is provided with an adjusting slider 17, and a U-shaped jacket 20 for clamping the seamless sleeve 19 is fixed on the adjusting slider 17, and one side of the U-shaped jacket 20 is provided. There is a hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com