Abnormal-shape single-bent toughened glass processing equipment

A tempered glass and processing equipment technology, applied in glass manufacturing equipment, glass production, glass molding, etc., can solve problems such as difficult glass installation, inaccurate arc, and reduced yield, so as to save empty furnace time and ensure accuracy , the effect of the same arc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

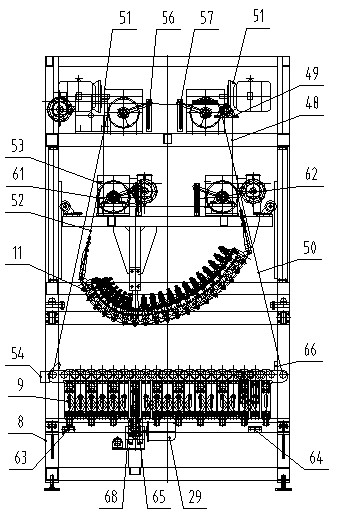

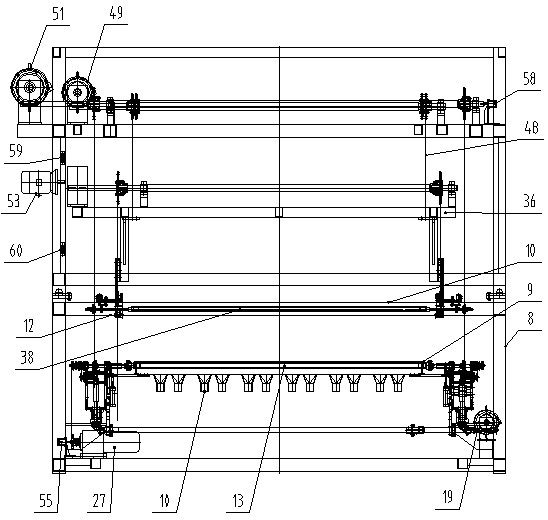

[0030] Such as Figure 1 to Figure 10 As shown, the special-shaped single-bending tempered glass processing equipment of the present invention, the special-shaped single-bending tempered glass processing equipment, includes a loading table 1, a multi-station furnace body 2, a forming section 3, a unloading table 5 with a cooling device 4, and a fan 67. The air duct system 6 and the control system connected to the fan 67, the forming section 3 includes a frame 8, the frame 8 is provided with a lower arc-changing mechanism 9, and the lower air grid assembly 10 arranged on the lower arc-changing mechanism 9 is located at the lower The upper arc changing mechanism 11 which is above the arc changing mechanism 9 and can slide up and down along the frame 8, the upper air grid assembly 12 arranged on the upper arc changing mechanism 11, is located below the lower arc changing mechanism 9 and is connected to the lower arc changing mechanism 9 The arc regulating mechanism 19 and the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com