Metal blade forming machine

A technology for metal blades and forming machines, which is applied in metal processing equipment, feeding devices, positioning devices, etc., and can solve the problems of easy deformation of the blade curvature, unbalanced length, and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

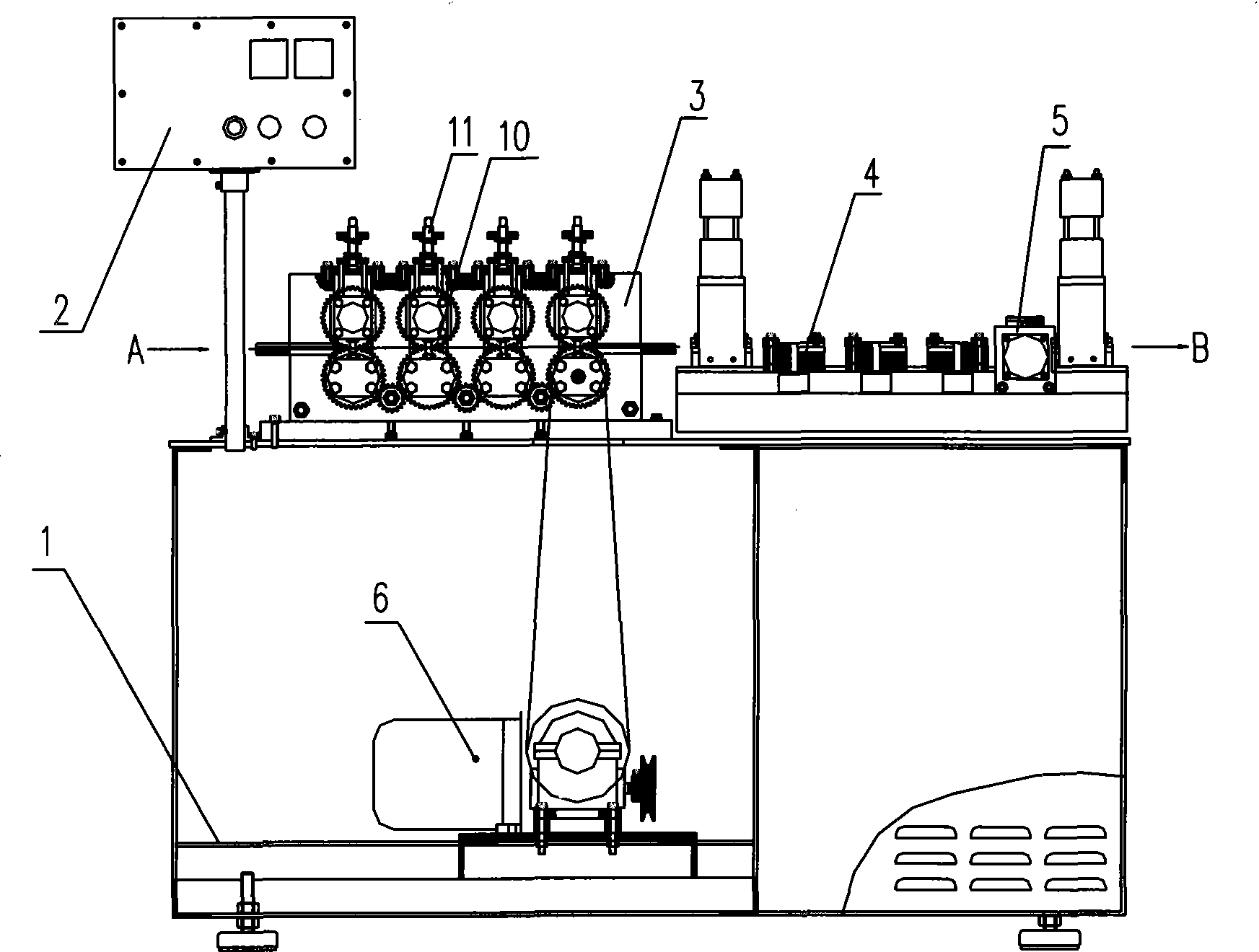

[0023] Attached below Figure 1-6 A detailed description will be made to the specific embodiment of the present invention.

[0024] Such as Figure 1-6 The metal blade forming machine shown is composed of a feeder, a frame 1, a motor 6, and an automatic control device 2, a rolling forming mechanism 3, a cutting mechanism 4 and a throwing mechanism arranged on the frame from left to right. Material mechanism 5. The feeder sends the sheet metal to the roll forming mechanism.

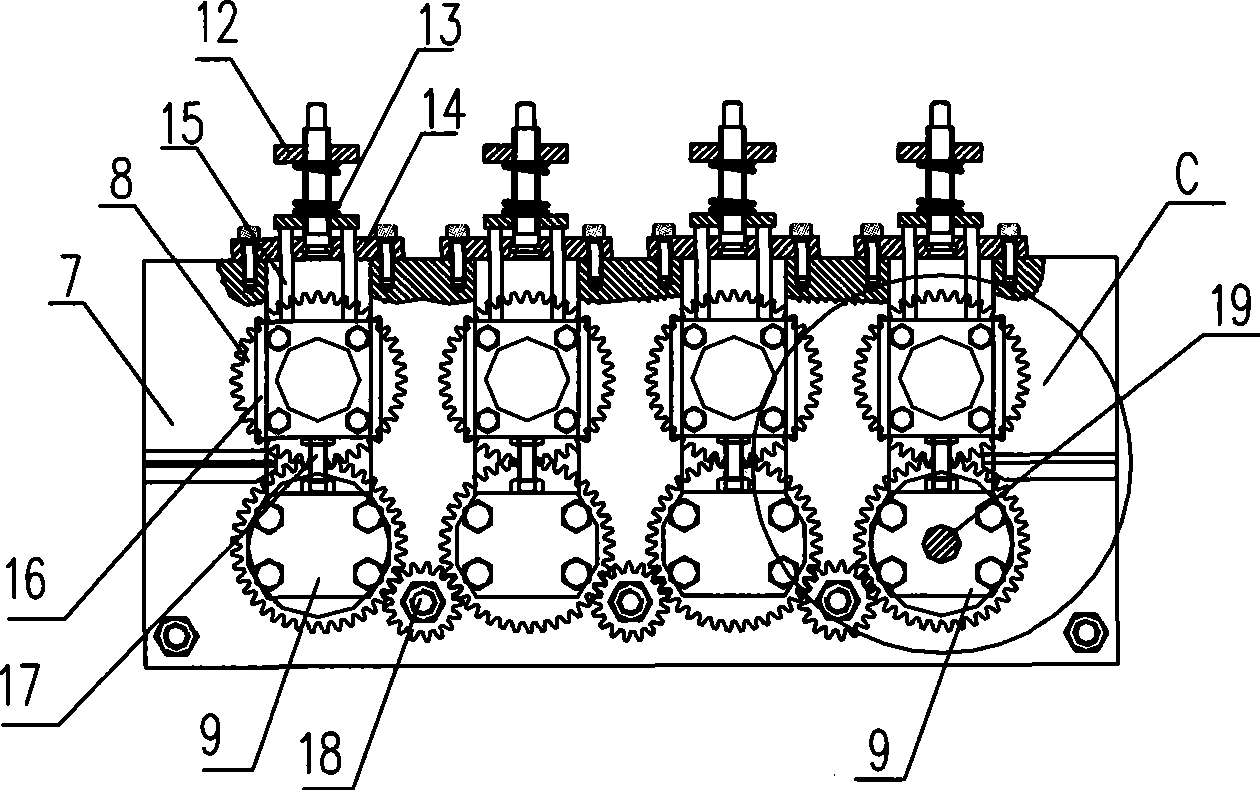

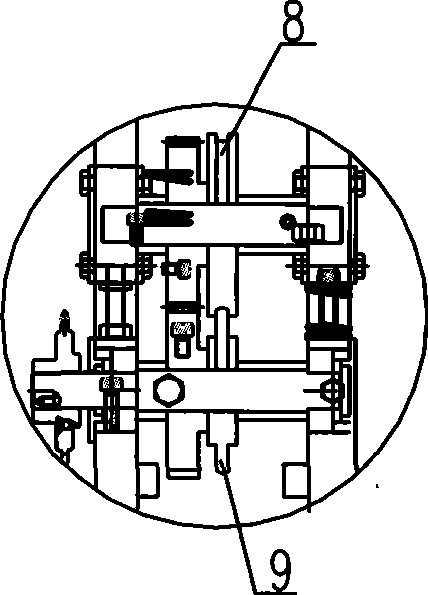

[0025] The rolling forming mechanism 3 consists of side plates 7, 4 sets of profiling wheels 10 arranged horizontally from left to right, and 4 sets of pressing devices 11 corresponding to the number of profiling wheels 10 and arranged above it. The profiled wheel set 10 is composed of a profiled concave wheel 8 with an arc-shaped groove and a profiled cam 9 with an arc-shaped protruding head matched therewith. Adjacent profiling wheel sets 10 are connected by intermediate wheels 18 to ensure that all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com