Constructing method for flashing structure of parapet wall

A construction method and parapet technology, applied in roof drainage, roof insulation materials, etc., can solve problems such as water seepage, hollowing, and parapet cracking, and achieve the effect of overcoming common technical problems, preventing falling off and seepage, and reducing construction waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

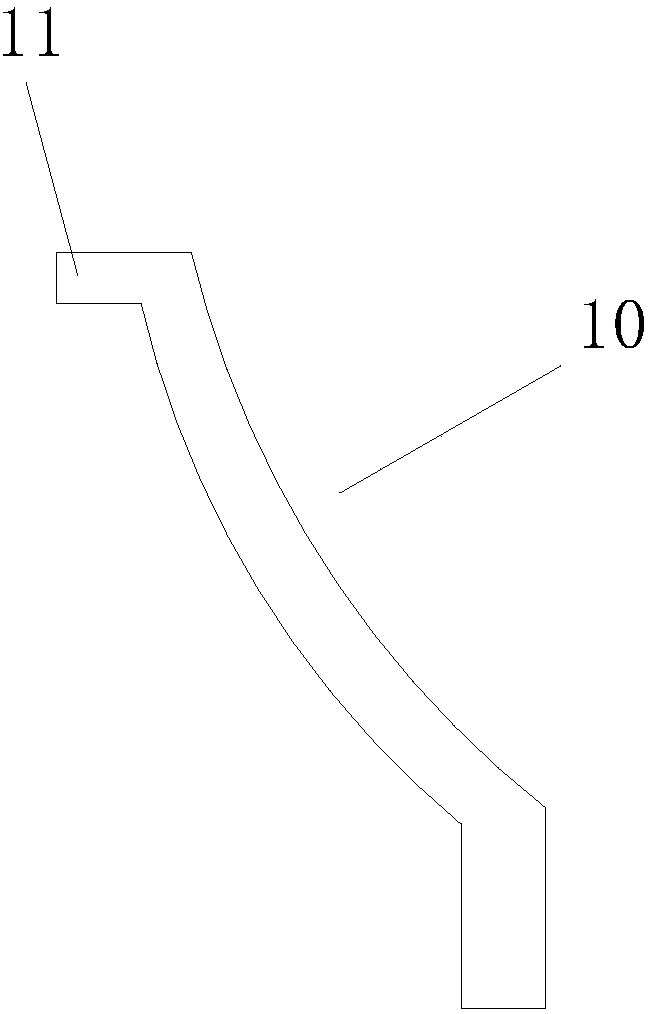

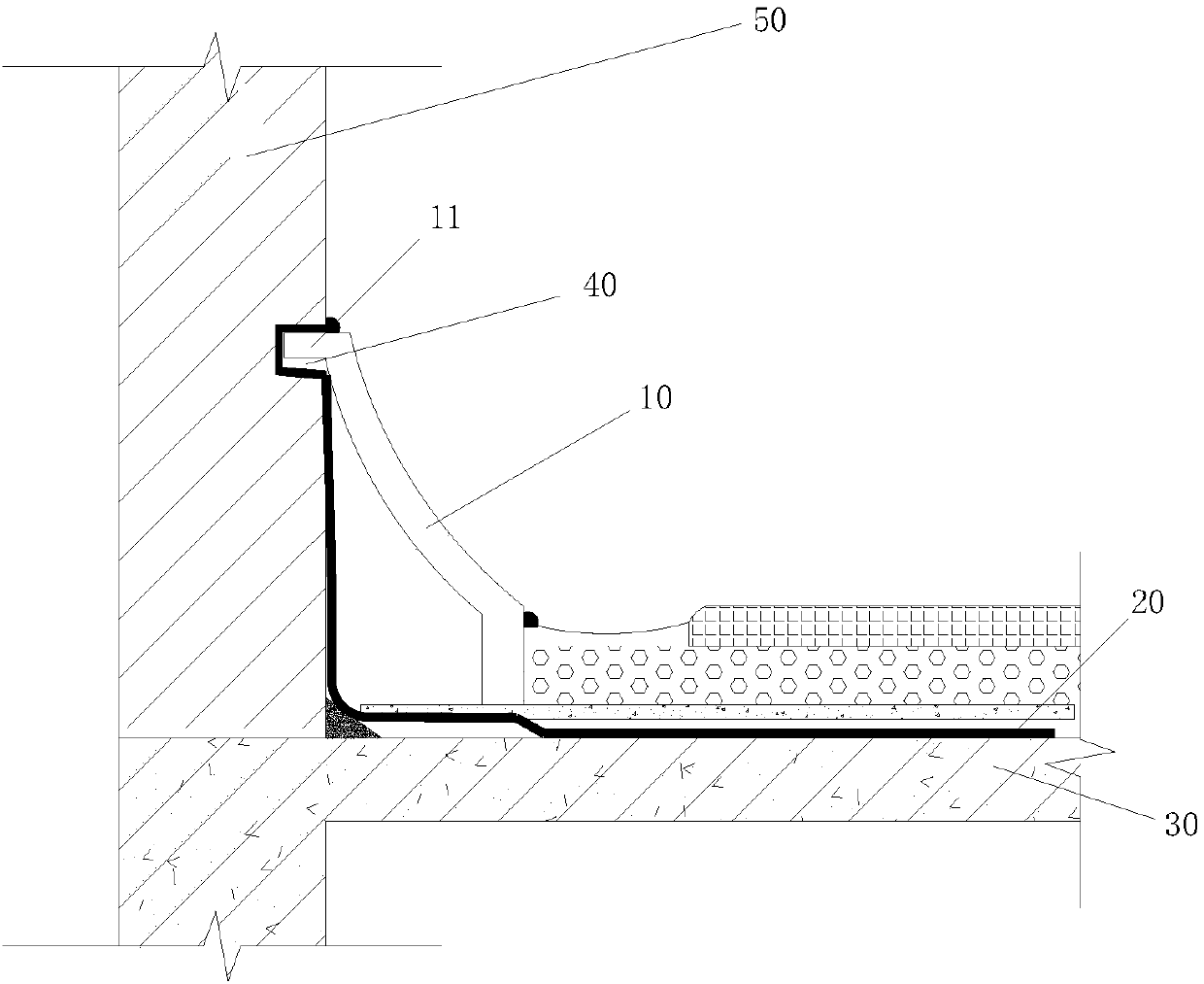

[0021] like figure 1 and figure 2 As shown, as a preferred embodiment of the present invention, the present invention provides a construction method for the flashing structure of a parapet wall, which includes the following construction steps: ① Prefabricated flashing components: making a pouring mold with an open top and detachable assembly to The assembled pouring mold has a horizontal section cavity, an arc section cavity and a vertical section cavity connected to each other, and the horizontal section cavity and the vertical section cavity are respectively connected to the two ends of the arc section cavity in a mutually perpendicular manner and facing towards The side extending away from the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com