Double-side-wall composite cross method construction method for large-span tunnel under complex geological condition

A complex geological condition and composite cross technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as easy deformation of support structures and unsuitable control of vault settlement, and achieve easy construction quality assurance, convenient construction, and structural integrity. Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

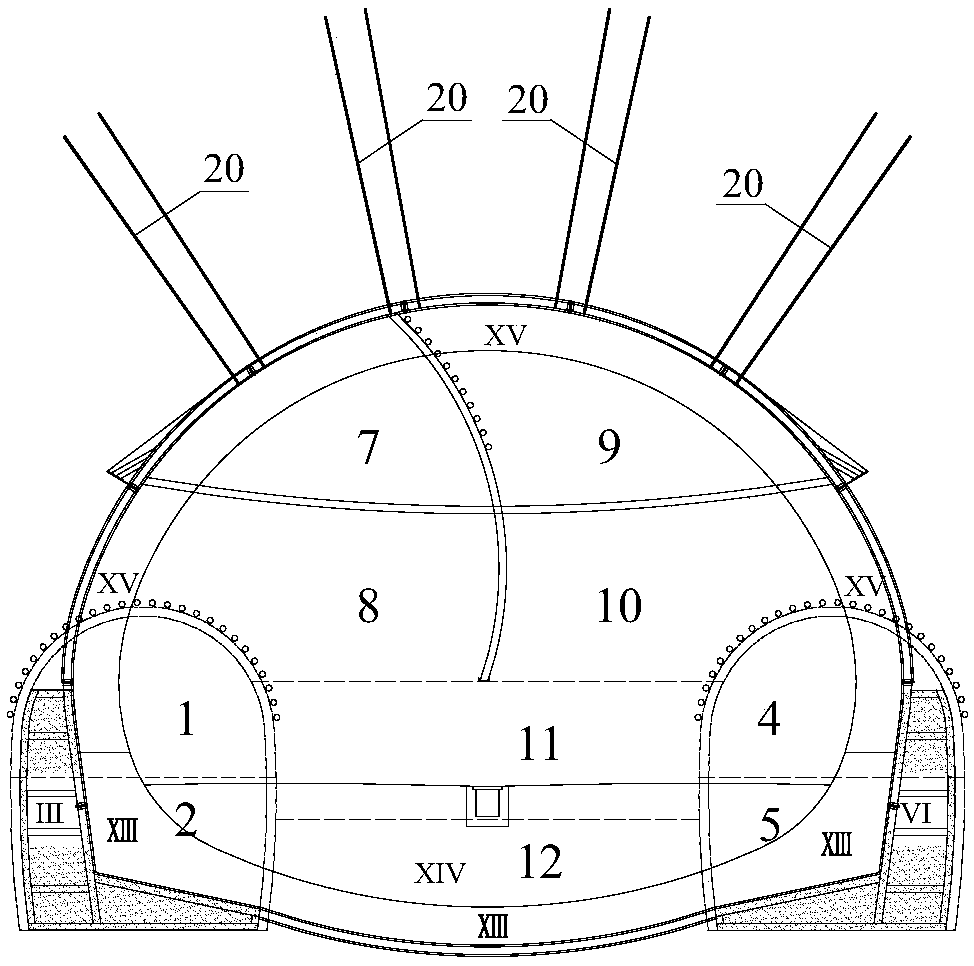

[0031] refer to Figure 1 to Figure 7 , the construction method of double-side walls of large-span tunnel composite cross method under complex geological conditions of the present invention, comprises the following steps:

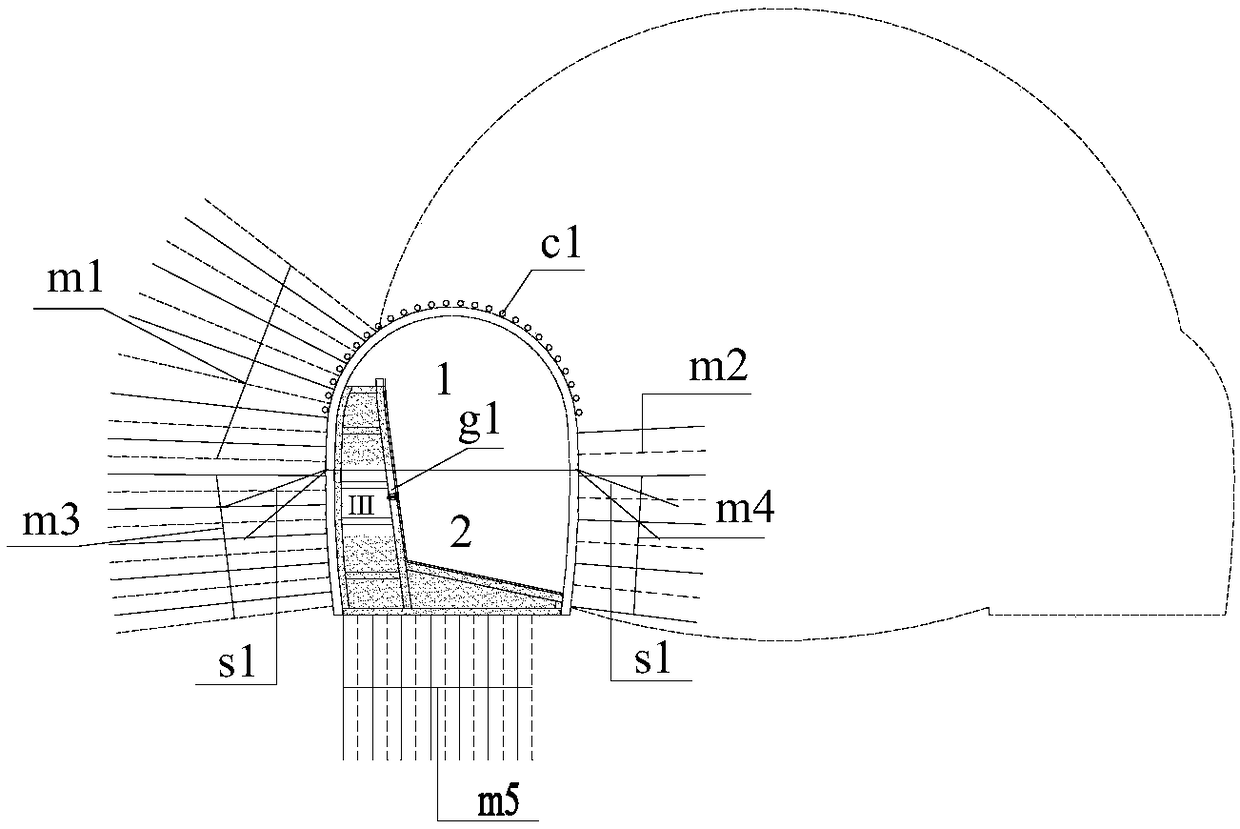

[0032] (1) Excavate the upper step 1 of the left pilot tunnel and the lower step 2 of the left pilot tunnel step by step, and implement corresponding advance support before excavation, and immediately implement corresponding initial support and temporary support after excavation;

[0033] ⑵Pour the steel frame concrete base of the left pilot tunnel III;

[0034] (3) Excavate step by step the upper step 4 of the right pilot tunnel and the lower upper step 5 of the right pilot tunnel, and implement corresponding advance support before excavation, and immediately implement corresponding initial support and temporary support after excav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com