Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82results about How to "Good structural strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

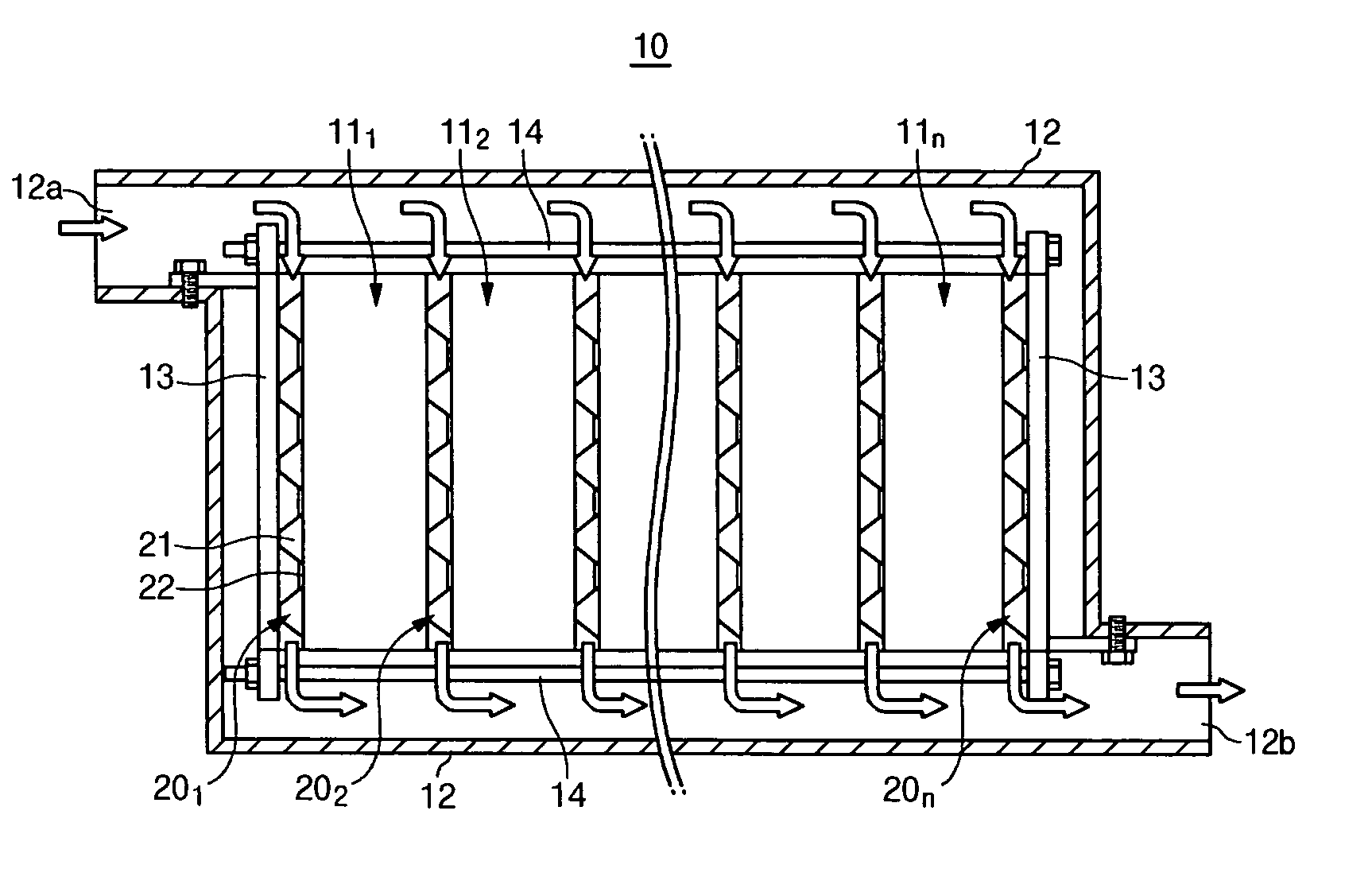

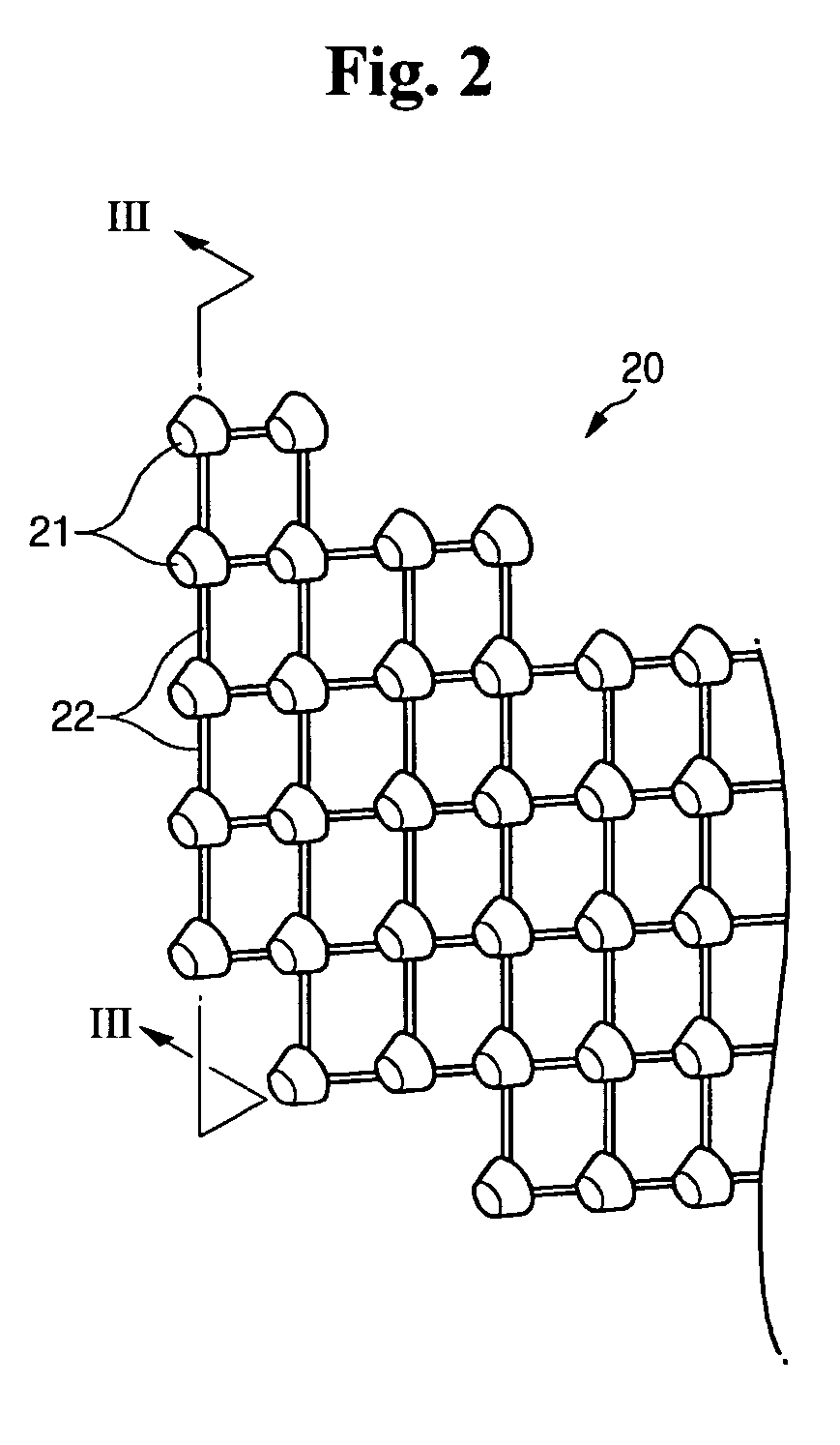

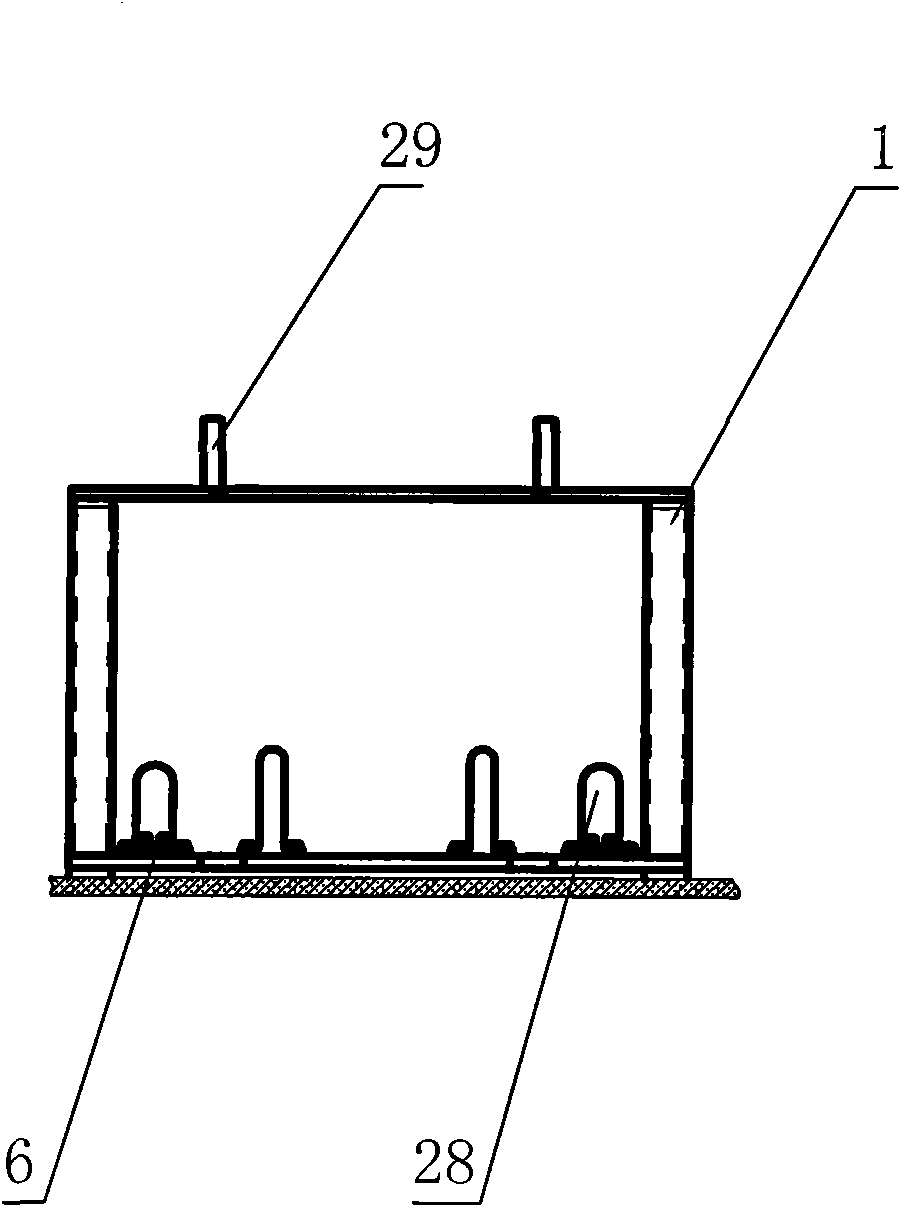

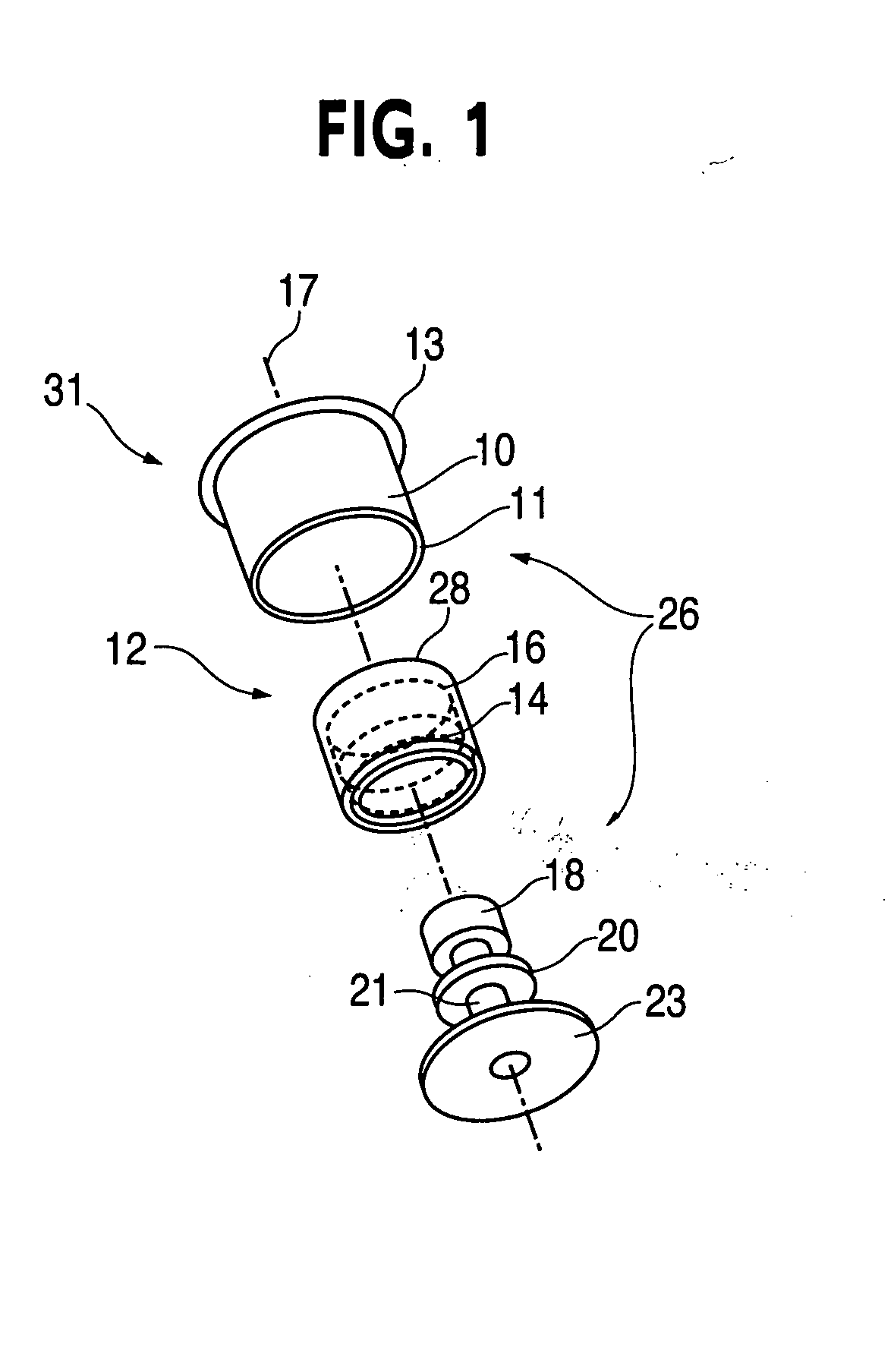

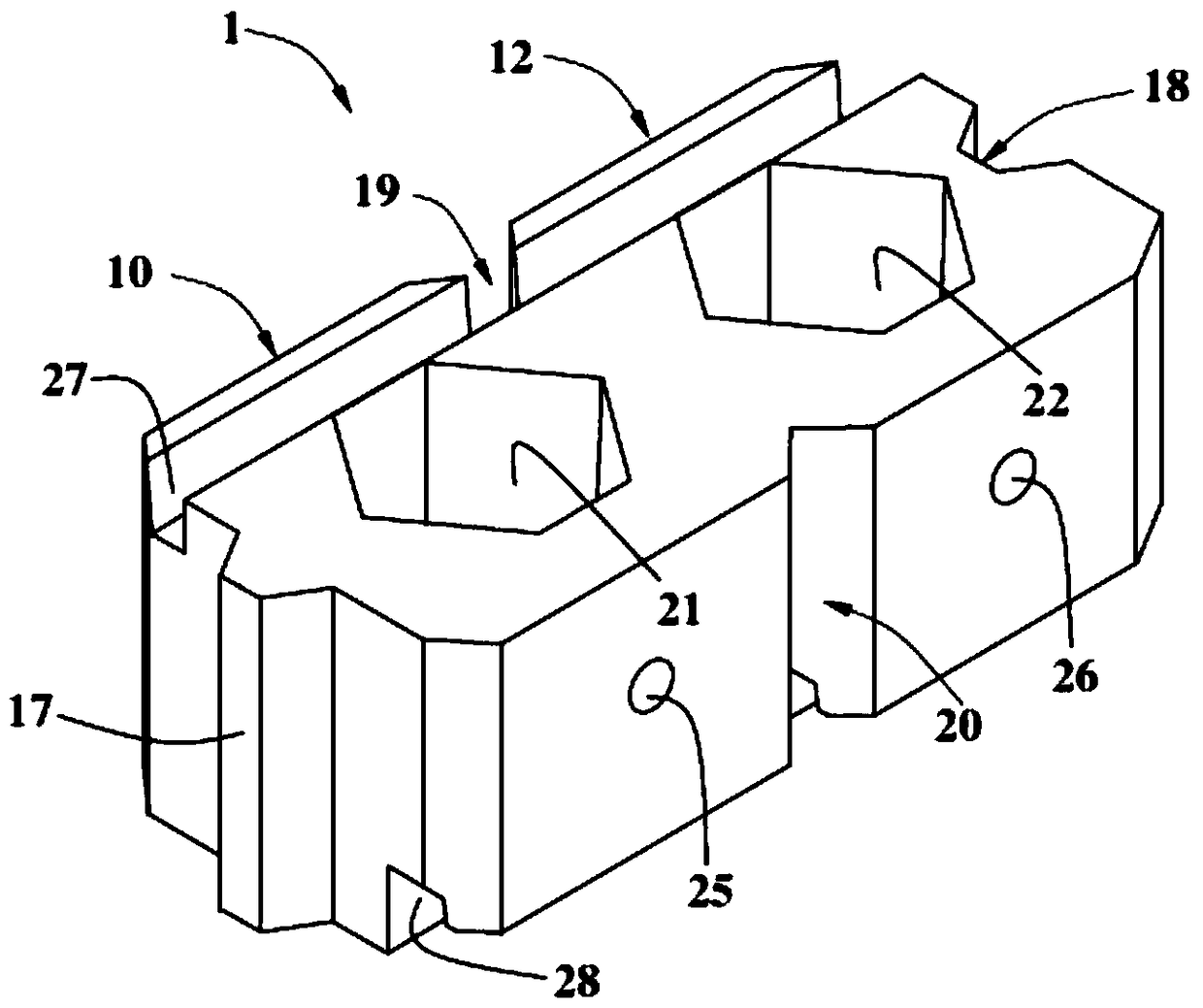

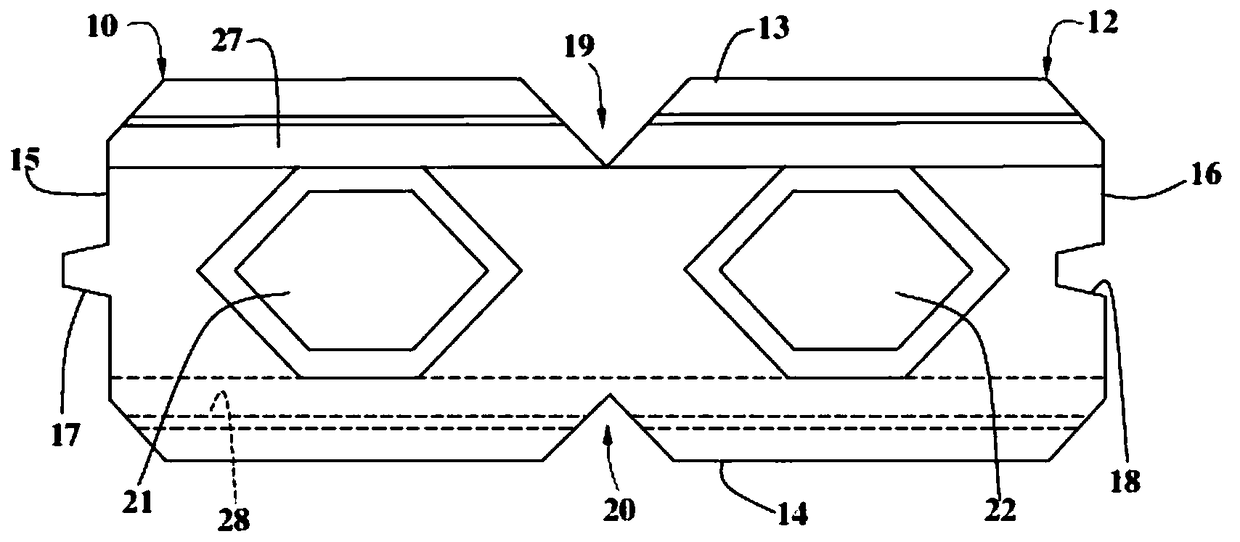

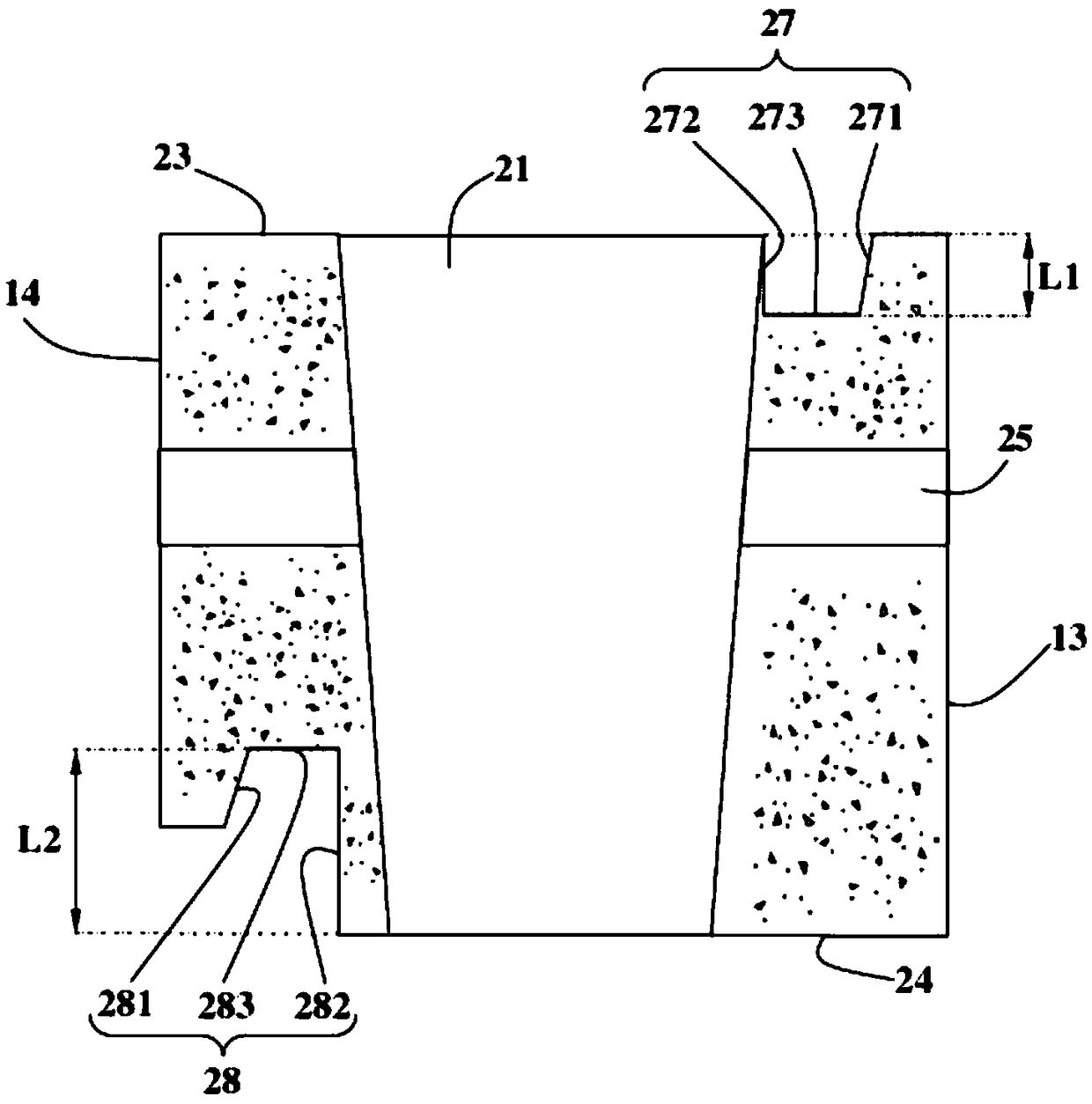

Battery module

InactiveUS20060115720A1Good structural strengthReduce weightPrimary cell to battery groupingCell temperature controlElectrical and Electronics engineeringCooling medium

A battery module includes unit batteries spaced apart from each other and having a cooling medium flow path defined in the space. The battery module includes a barrier rib disposed between the unit batteries, the barrier rib having a plurality of interconnected protrusions.

Owner:SAMSUNG SDI CO LTD

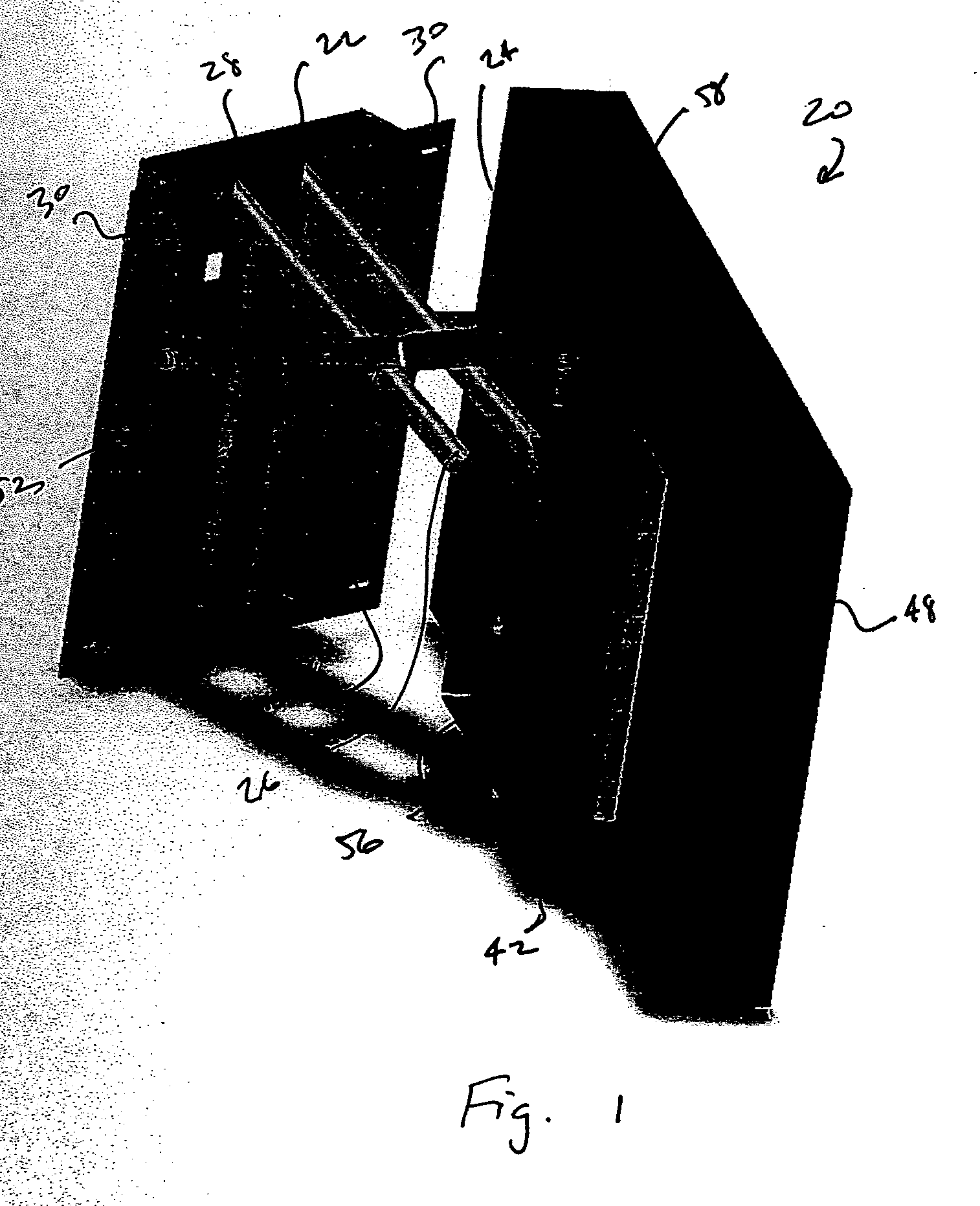

Motorized mount for electronic display

InactiveUS20070158515A1Good structural strengthSmooth movementStands/trestlesKitchen equipmentDisplay deviceEngineering

A motorized mount for an electronic display includes a biaxially shiftable mount assembly including a positioning assembly being translatably shiftable in a plane and a rotator assembly operably coupled to the positioning assembly, the rotator assembly being rotatably shiftable about an axis, the axis being orthogonally disposed relative to the plane. A method of selectively positioning an electronic display is further included.

Owner:LEGRAND AV INC

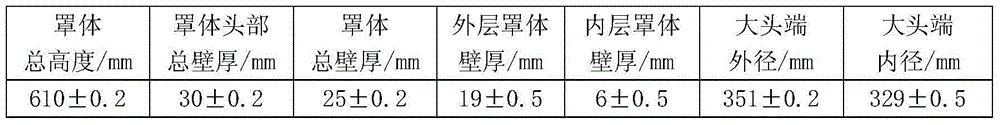

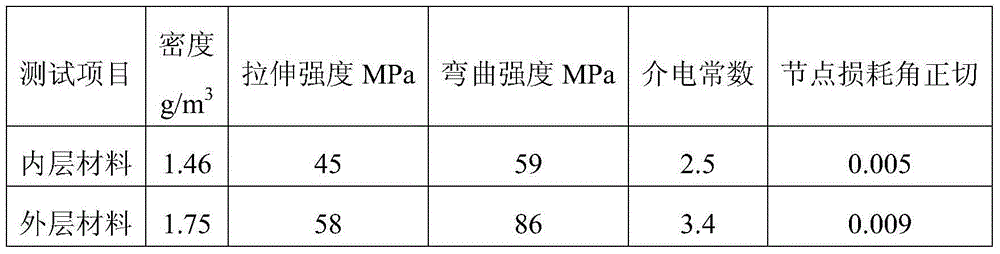

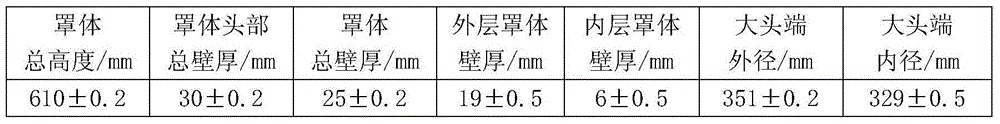

Moulding method of variable-density broadband wave-transparent quartz composite ceramic antenna housing body

ActiveCN104446584AGood structural strengthImprove impregnation composite effectBroadbandVariable density

The invention discloses a moulding method of a variable-density broadband wave-transparent quartz composite ceramic antenna housing body. The method comprises the following steps: according to dimension and quality request of the housing body, integrally weaving an outer material and an inner material to obtain an inner and outer housing body fabric; putting the housing body fabric in water to be cooked and soaking in acid liquor; then, putting the housing body fabric in an utensil filled with a silica sol for dipping and compounding; and finally machining a housing body blank to a required dimension to obtain the antenna housing body. According to the moulding method disclosed by the invention, the outer layer of the housing body fabric is woven by quartz fiber yarns, so that the volume percentage of the quartz fiber yarns is 40-45% while the inner layer of the housing body fabric is woven by hollow quartz fiber yarns, so that the volume percentage of the hollow quartz fiber yarns is 25-30%, therefore, the fiber volume percentages of the inner and outer layers of the housing body fabric are different. Meanwhile, the inner and outer layers are integrally attached and woven, the layering problem is avoided, and the housing body has relatively good structural strength is powerfully guaranteed as a result of relatively good strength of a reinforcement.

Owner:湖北三江航天江北机械工程有限公司

Preparation method of carbon fiber reinforced carbon-silicon carbide dual-ceramic based gradient composite material

The invention discloses a preparation method of a carbon fiber reinforced carbon-silicon carbide dual-ceramic based gradient composite material. The preparation method is characterized by comprising the following steps: (a), carrying out thermal treatment onto the fibers by adopting different temperatures; (b), dipping the fibers which are not subjected to thermal treatment and the thermally-treated fibers obtained in the step (a) in resin glue liquor, drying, continuously superposing and laying up, applying a certain pressure after laying up, and carrying out curing and post-curing treatment in sequence to prepare a composite material biscuit body with fiber / base body interface adhesive strength in gradient change; (c), carrying out high-temperature pyrolysis onto the composite material biscuit body obtained in the step (b) to obtain a carbon / carbon porous body with porosity in gradient change; (d), carrying out liquid silicon permeation onto the carbon / carbon porous body obtained in the step (c) under a high temperature to obtain the C / C-SiC composite material with SiC ceramic base body content in gradient change. The preparation method disclosed by the invention is simple in process, short in preparation period, low in cost and capable of preparing a large workpiece with a complex shape.

Owner:DALIAN UNIV OF TECH

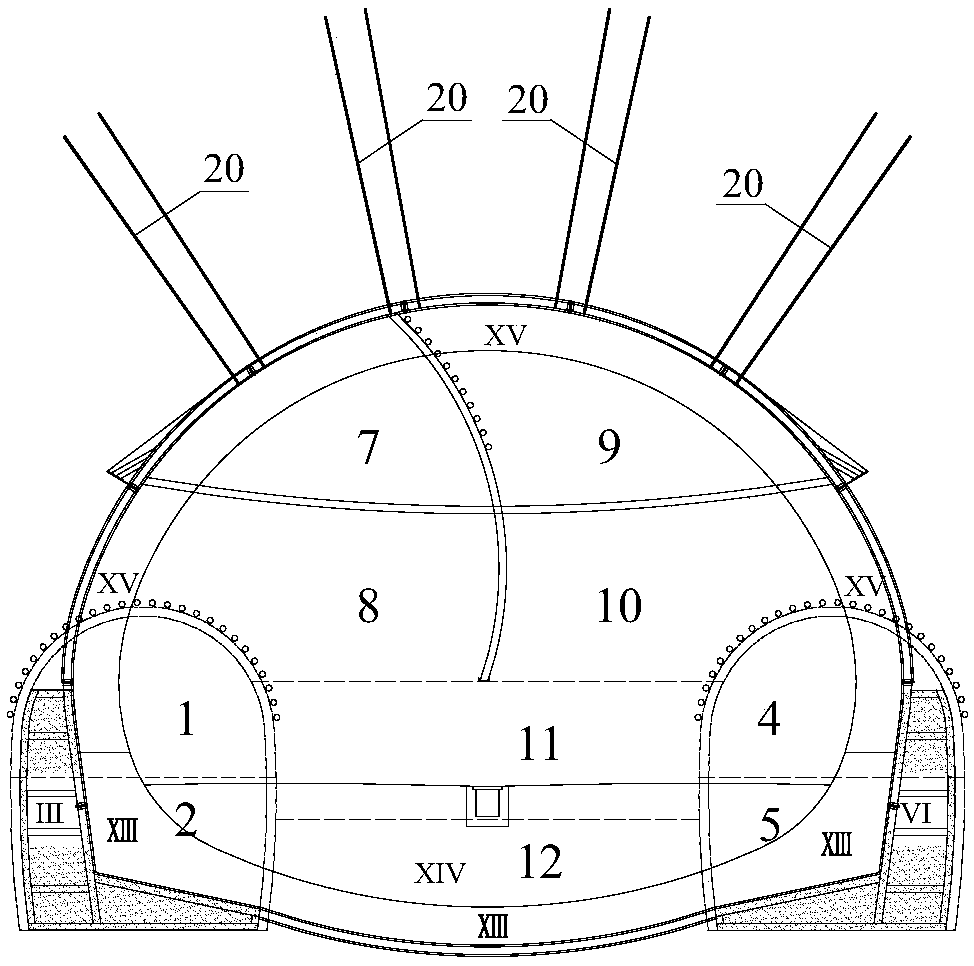

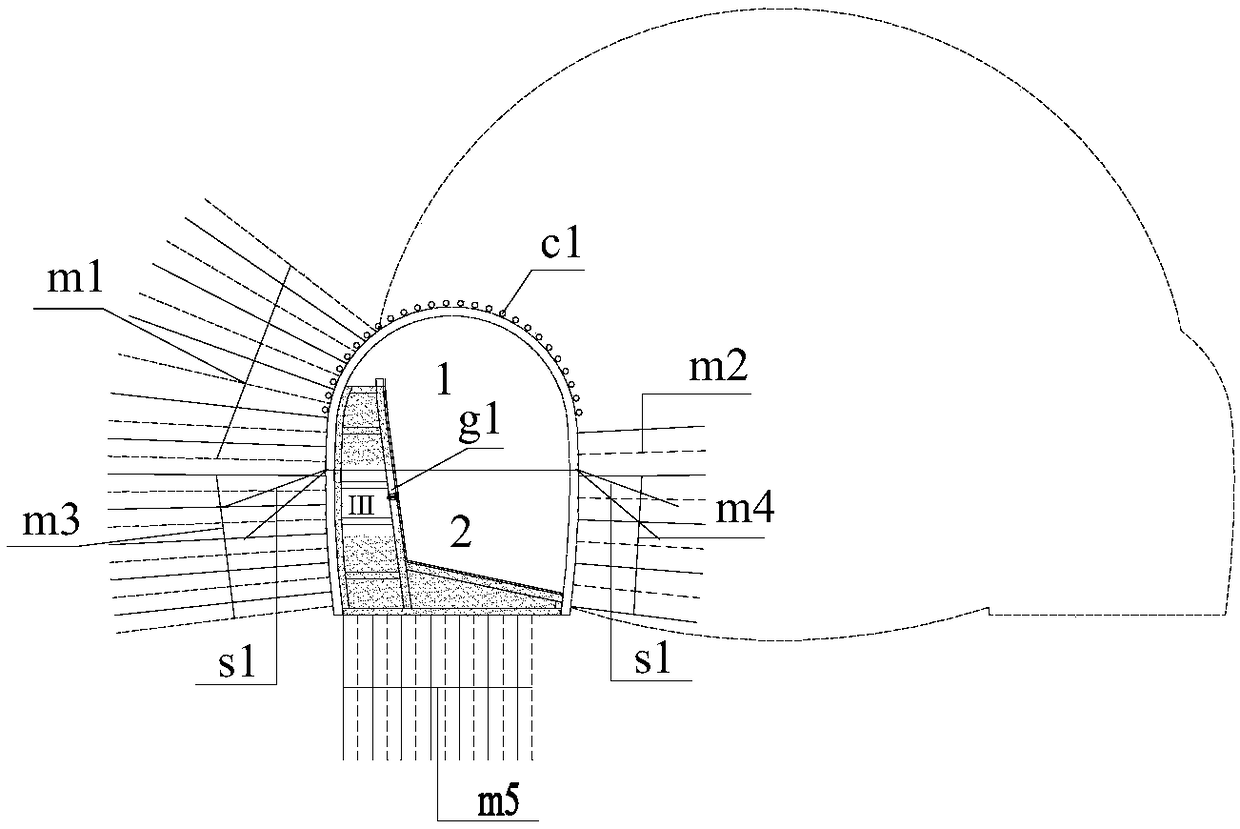

Double-side-wall composite cross method construction method for large-span tunnel under complex geological condition

InactiveCN108487911AControl vault sinkingGood structural strengthUnderground chambersTunnel liningClerestorySupport system

The invention provides a double-side-wall composite cross method construction method for a large-span tunnel under the complex geological condition. The double-side-wall composite cross method construction method is used for solving the technical problems that during construction of a soft rock large-span tunnel, arch crown settlement is not easy to control and a support structure is prone to deforming, optimizing structural force, improving construction convenience and determining construction safety. According to the double-side-wall composite cross method construction method, pilot tunnelson the two sides are constructed firstly, and primary support side wall foundations are constructed in the pilot tunnels to serve as a bearing foundation of an upper primary support system, so that the problems that during construction of the soft rock large-span tunnel, arch crown settlement is not easy to control and the support structure is prone to deforming are solved; bases only serve as thebearing foundation of primary support, under the premise that the stability of the arch wall primary support system is guaranteed, an arch wall secondary lining can still be constructed through an integral formwork trolley, the technique is simple and convenient, the integrity of the secondary lining is guaranteed, the waterproof effect is good, and the construction quality is controllable; and the pilot tunnels on the two sides adopt the excavated section of an arc-shaped arch crown, compared with conventional pilot tunnels constructed through a double-side-wall heading method, the structureforce is more excellent, construction is convenient, and the construction quality of the support system is easy to ensure.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

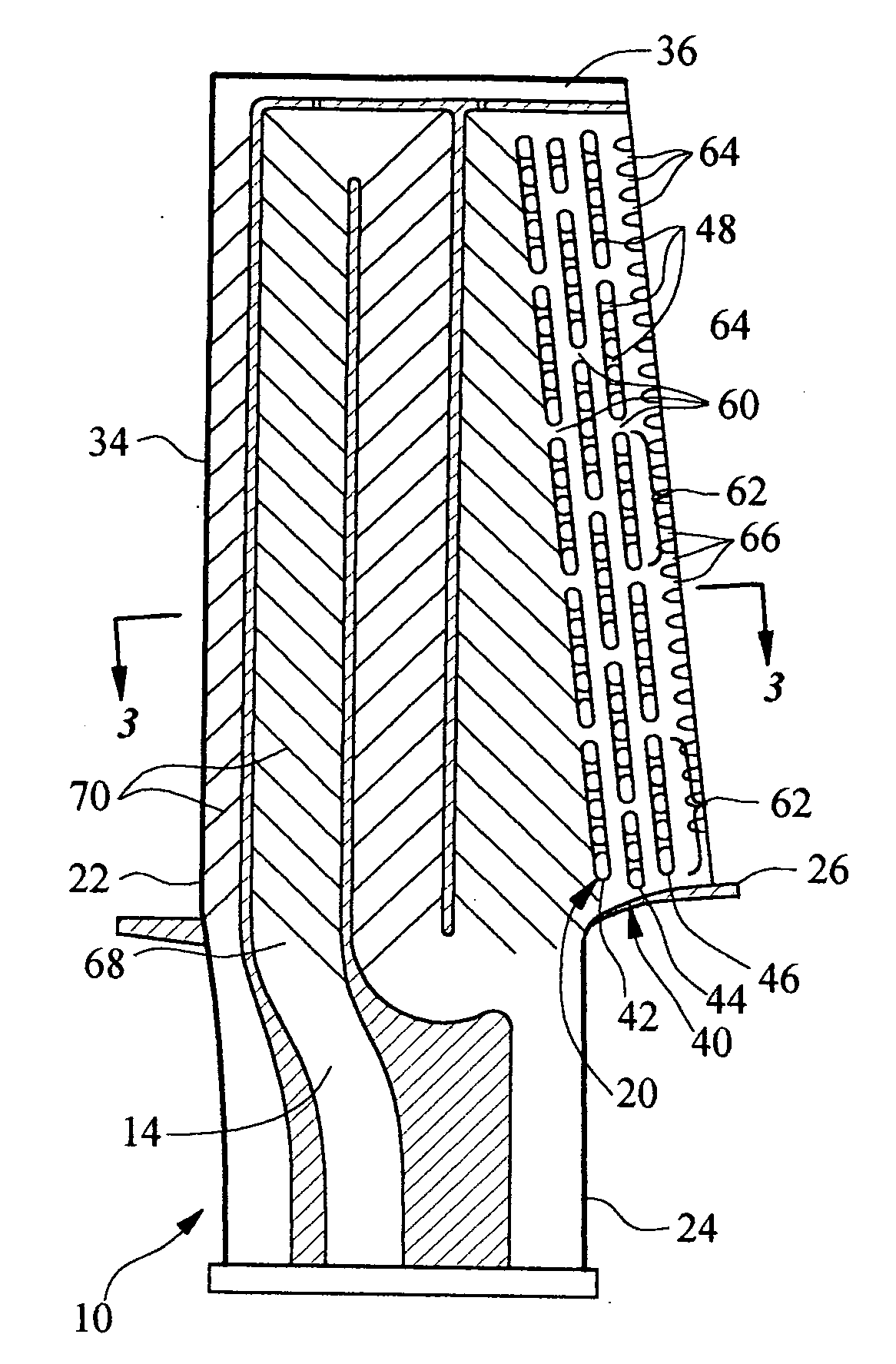

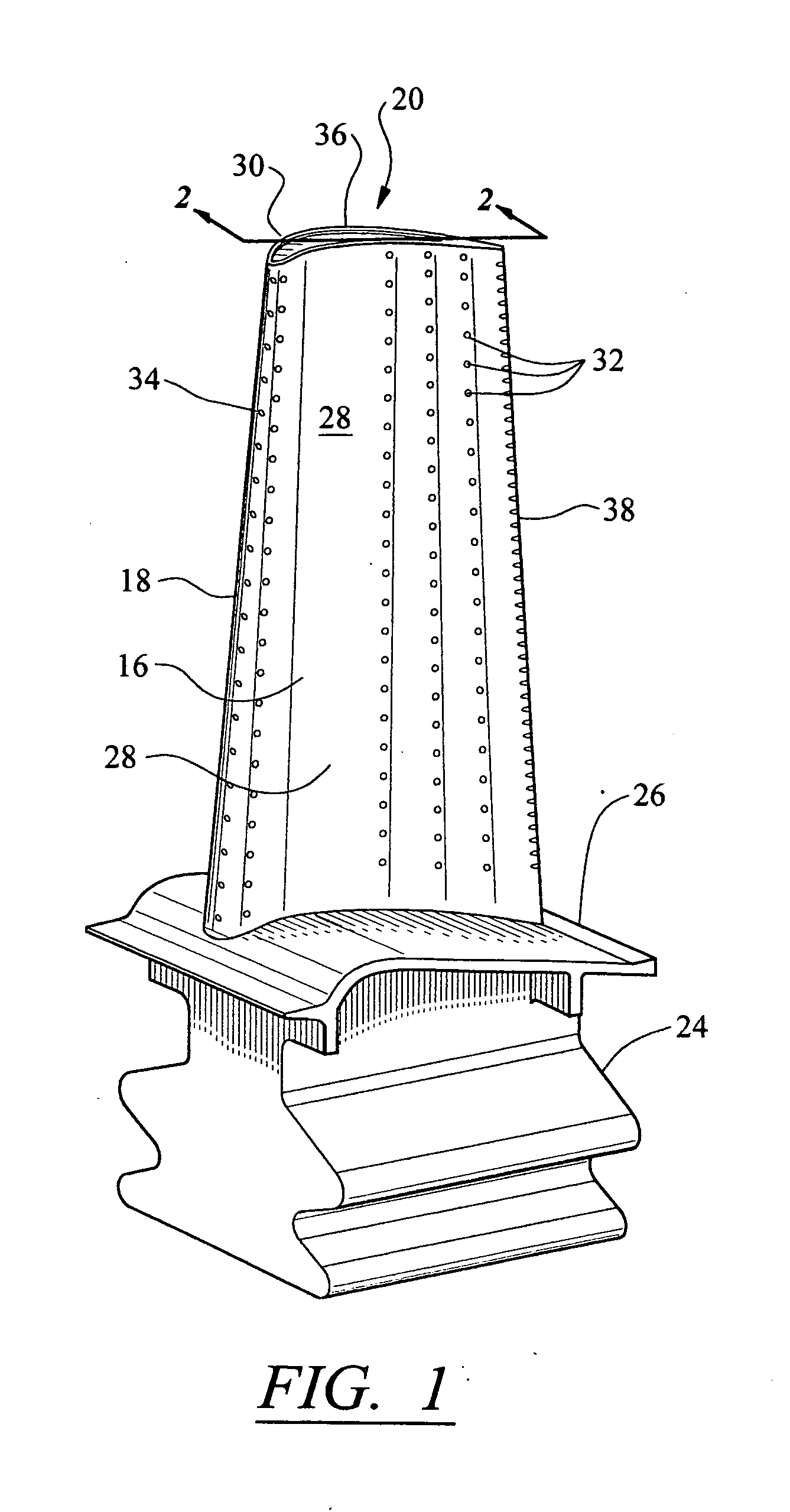

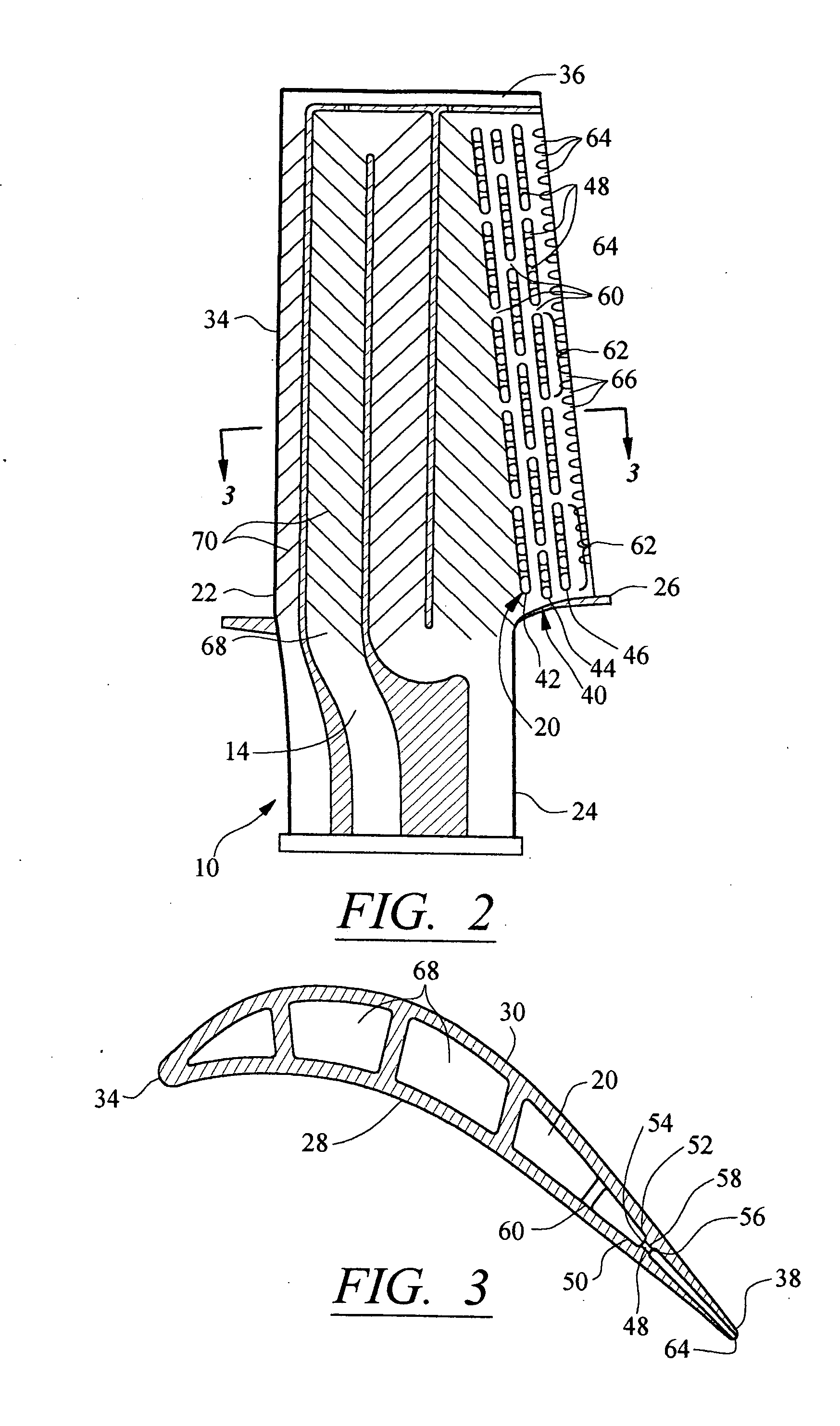

Turbine airfoil trailing edge cooling system with segmented impingement ribs

InactiveUS20060269408A1Improve cooling efficiencyGood structural strengthEngine fuctionsBlade accessoriesTrailing edgeCooling channel

A cooling system for a turbine airfoil of a turbine engine having multiple segmented ribs aligned together spanwise within a trailing edge cooling channel. The segmented ribs may be positioned proximate to a trailing edge of the turbine airfoil to facilitate increased heat removal with less cooling fluid flow, thereby resulting in increased cooling system efficiency, and to increase the structural integrity of the trailing edge of the airfoil. The segmented ribs may include crossover orifices that provide structural integrity to ceramic cores used during manufacturing to prevent cracking and other damage.

Owner:SIEMENS ENERGY INC

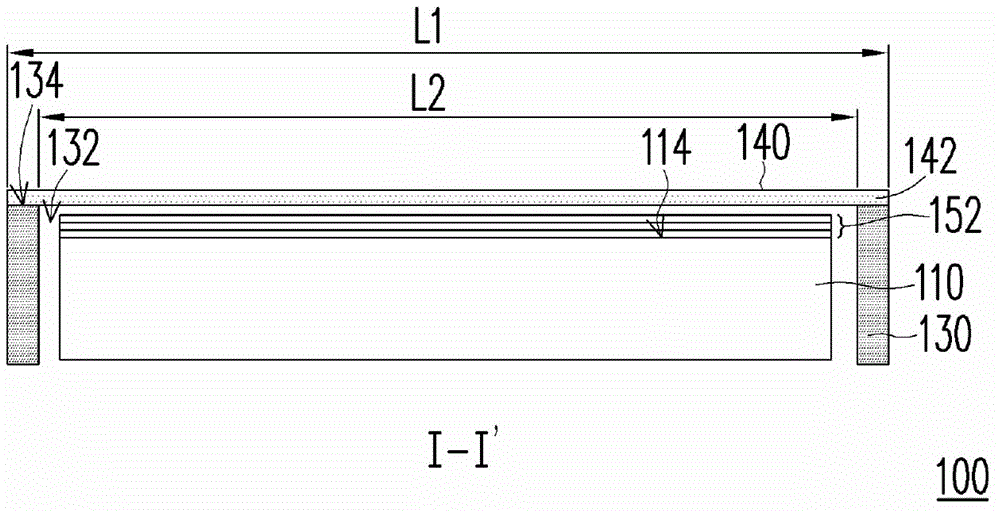

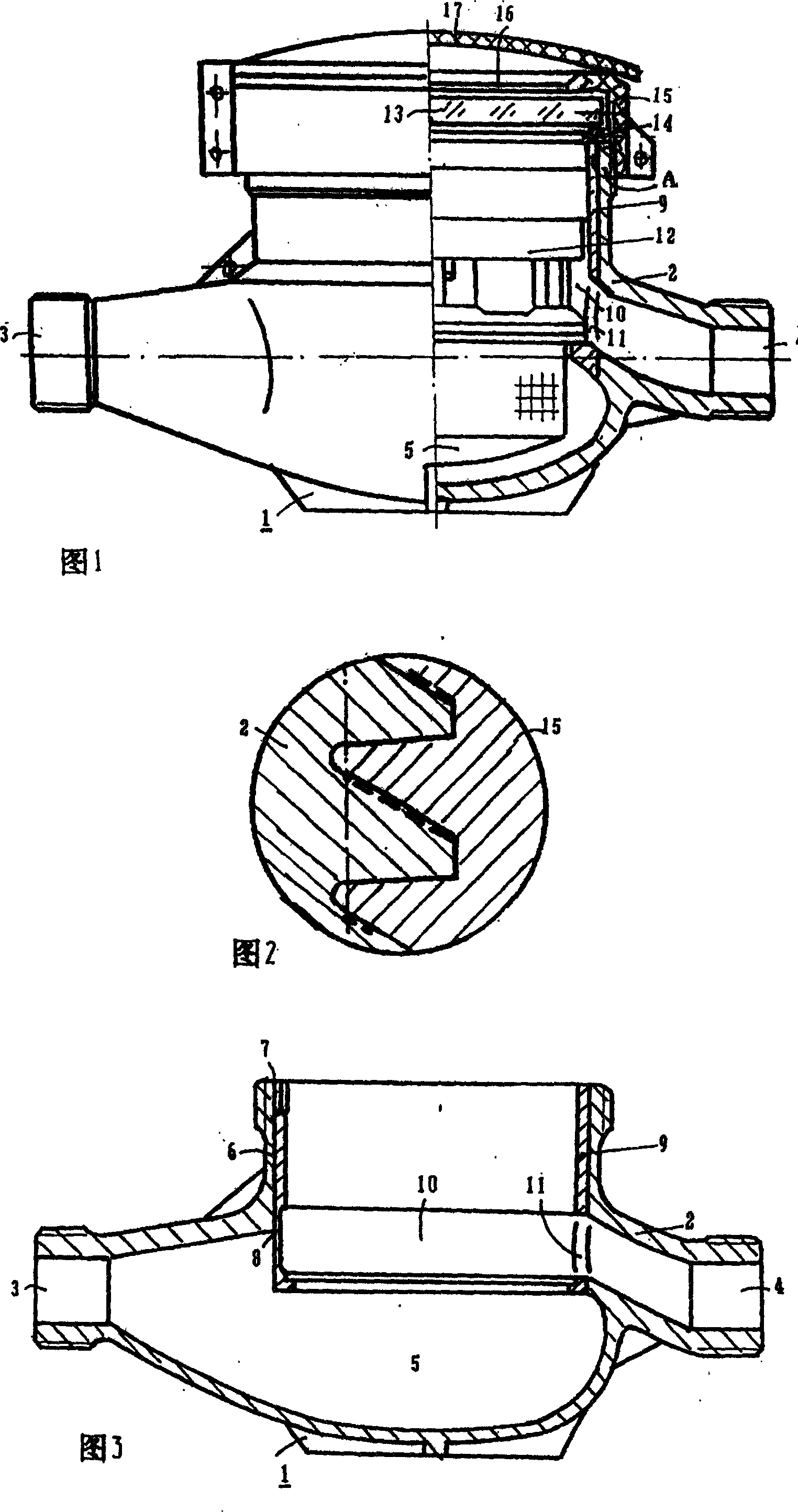

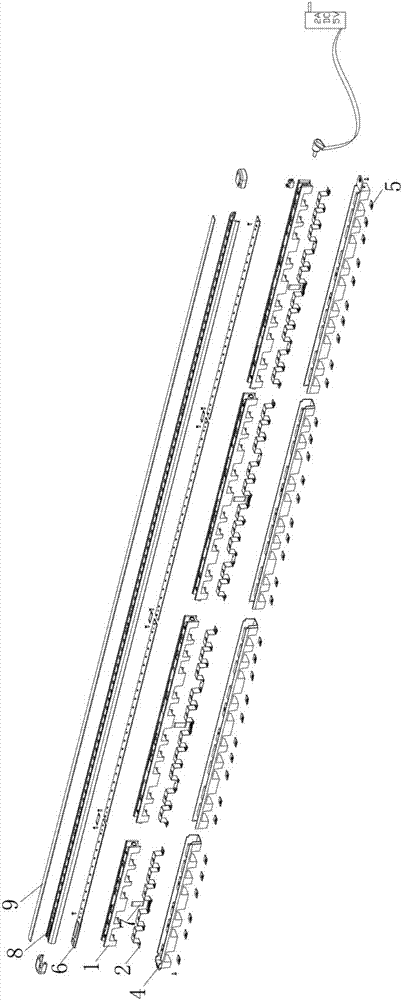

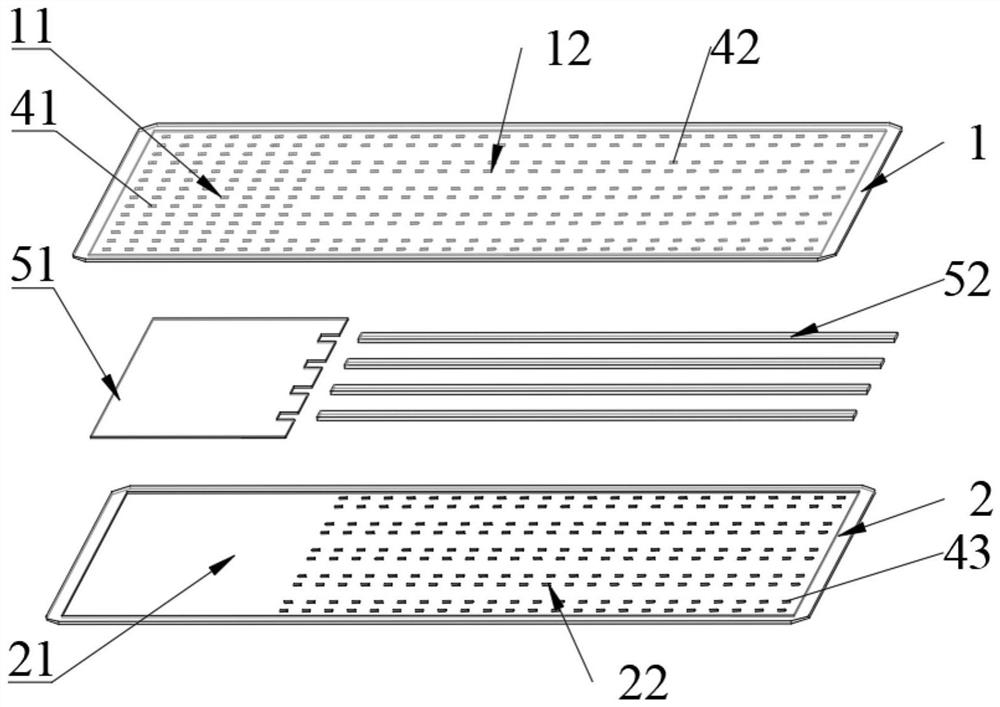

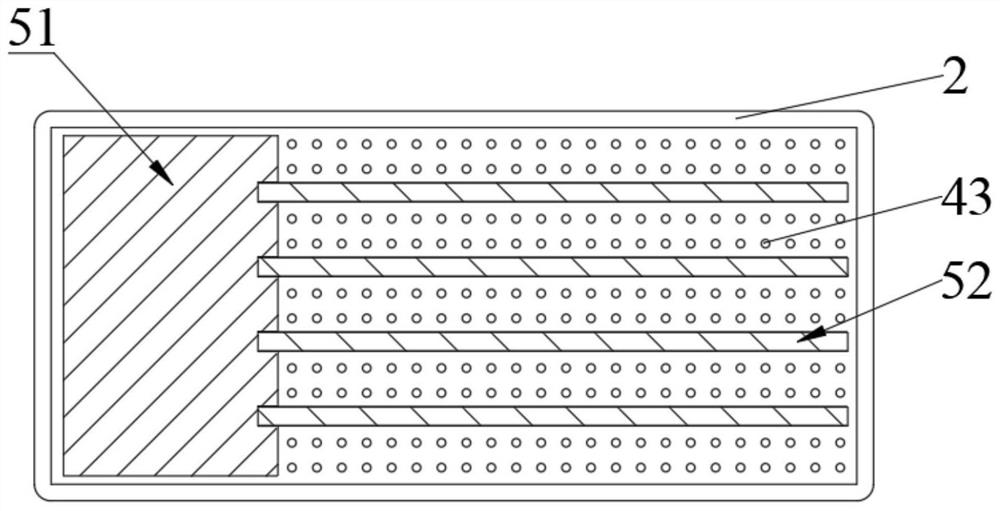

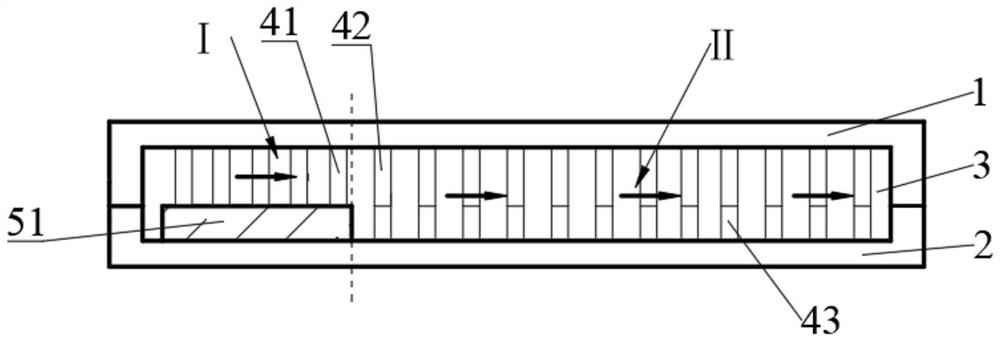

Backlight module and display device

InactiveCN102865504AGood structural strengthGuaranteed display qualityLight fasteningsNon-linear opticsExit surfaceOptoelectronics

The invention relates to a backlight module which comprises a light guiding plate, a light emitting element, a bearing frame, and a light transmitting film. The light guiding plate comprises a light entering surface and a light exiting surface. The light emitting element is disposed beside the light entering surface, and is suitable for emitting light which passes through the light entering surface, enters the light guiding plate, and exits the light guiding plate through the light exiting surface. The bearing frame is disposed at the periphery of the the light guiding plate so as to form an opening exposing the light exiting surface, and has a top surface. The light transmitting film is disposed on the bearing frame, and the periphery of the light transmitting film is attached to the top surface of the bearing frame to seal the opening. The invention also provides a display device using the backlight module, wherein a display panel is disposed on the light transmitting film.

Owner:AU OPTRONICS CORP

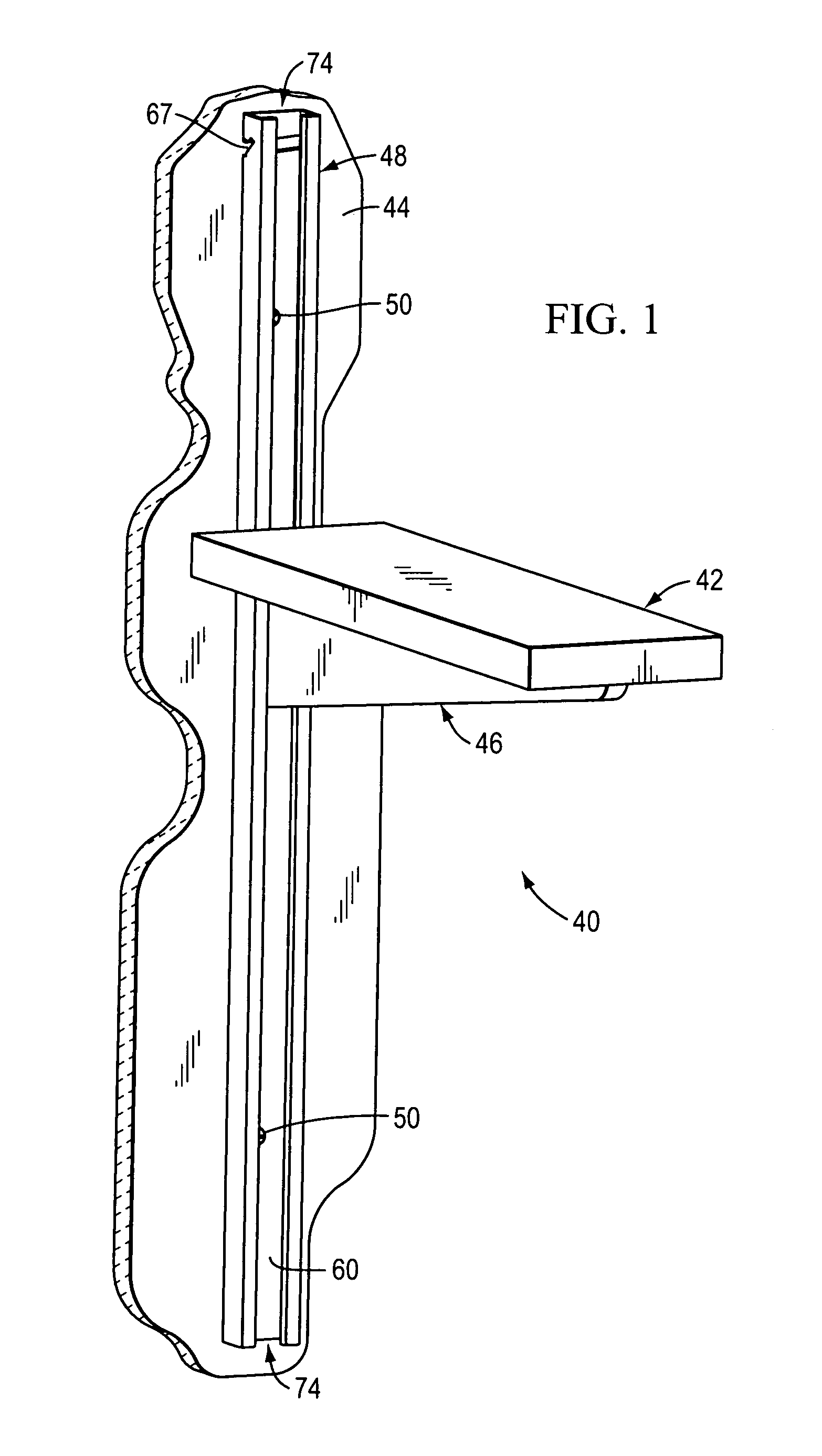

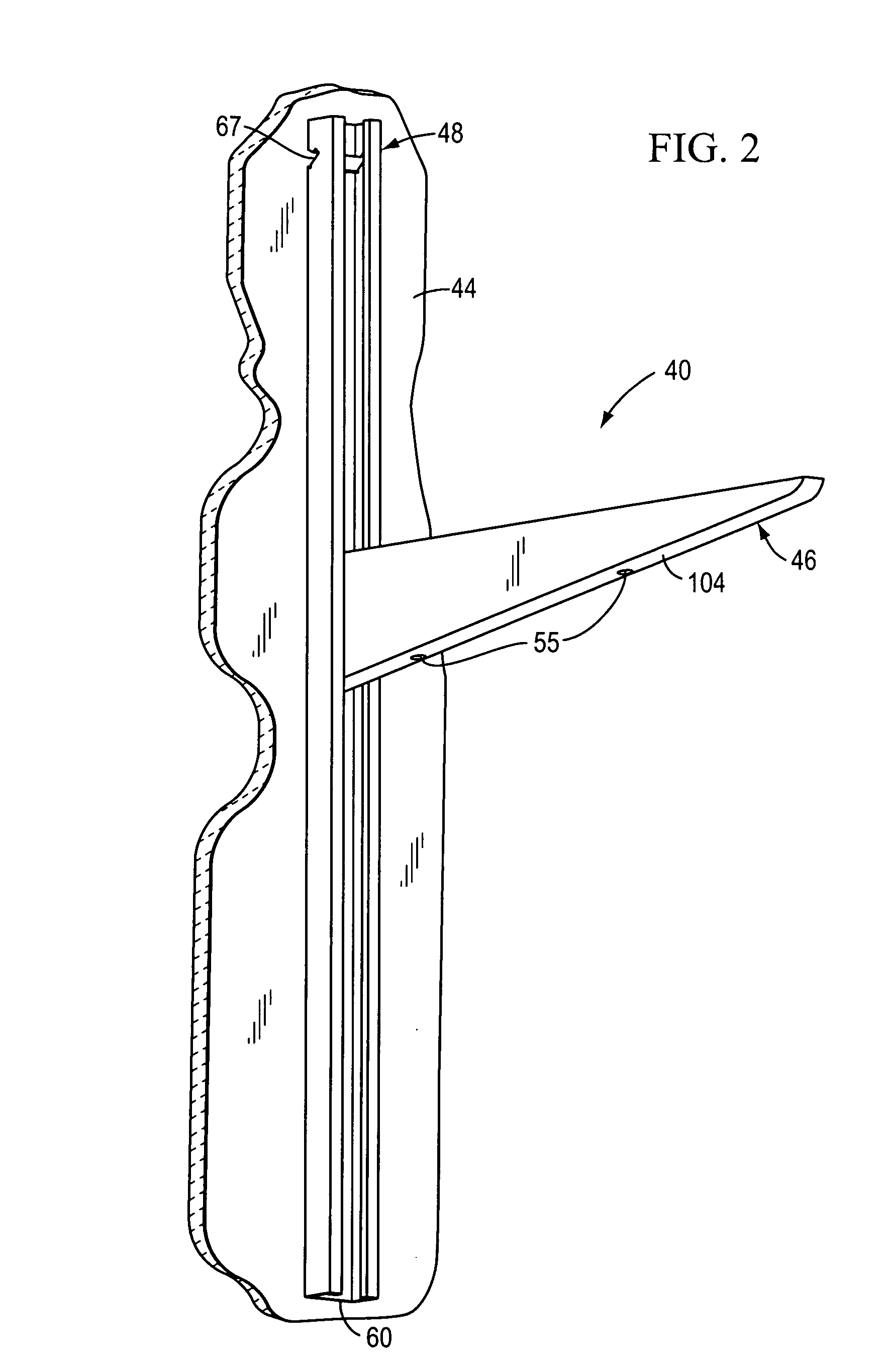

Shelf support bracket and wall standard

ActiveUS20100258692A1Improve aesthetic displayGood structural strengthFurniture partsStands/trestlesMechanical engineeringSupport system

A shelf support system is provided for supporting one or more shelves at selected elevations on a vertical surface. The system includes at least one standard having a rear wall, a first mounting wall extending from the rear wall, and a second mounting wall extending from the rear wall. The first and second mounting walls define between them a channel open to the front of the standard. At least one of the first and second walls defines notches which are not visible from the front of the standard, and the notches are adapted to receive a retention member on a bracket or shelf support which can be disposed within the channel of the standard. The shelf support can be tilted to an orientation that permits it be moved up or down within the standard to a different position, or to be removed from the standard altogether, or to be reinserted into the standard.

Owner:KNAPE & VOGT MFG

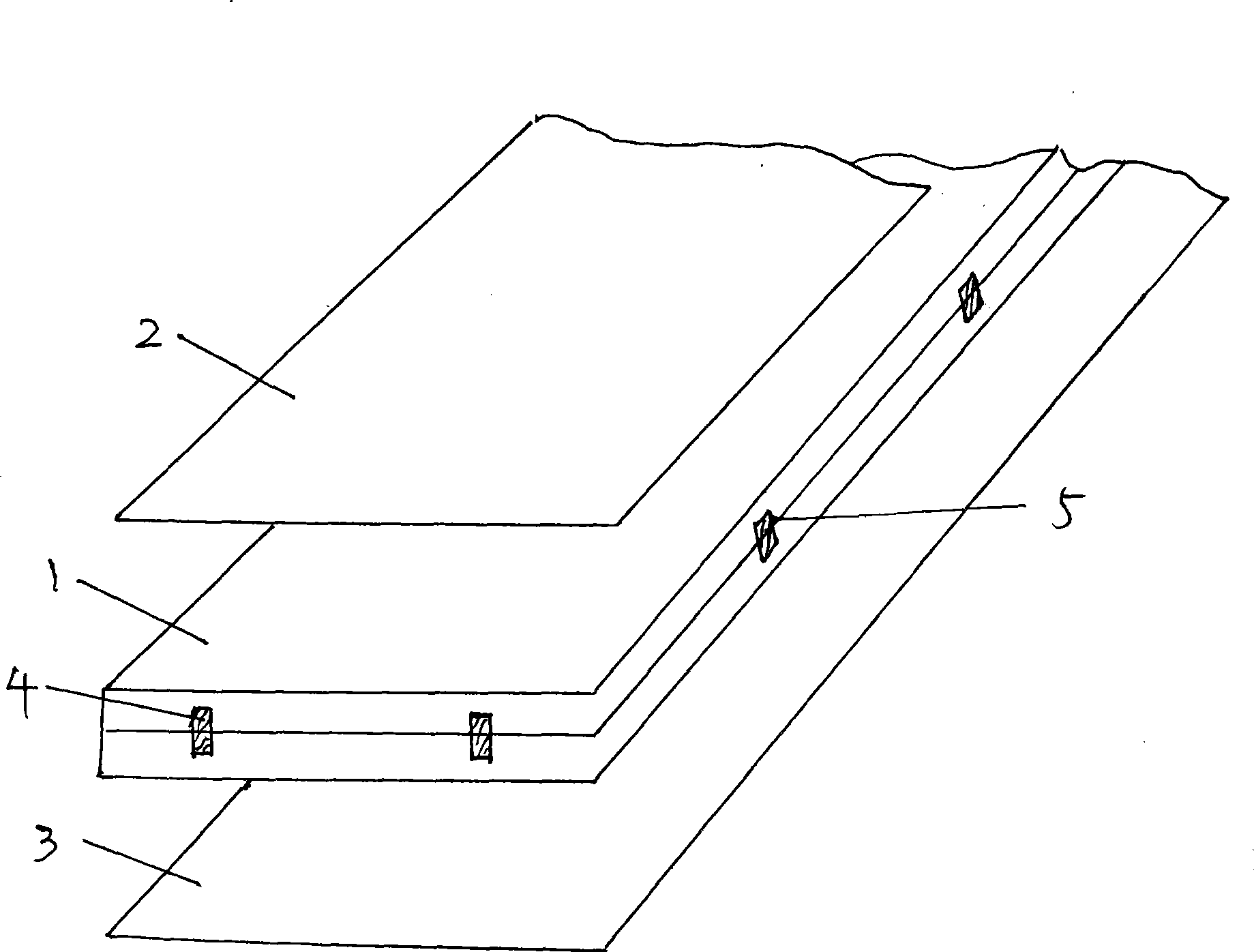

Laminating wooden floor with prestress structure

ActiveCN101463644AGood structural strengthStable structure and performanceFlooringProduct processingPrestressed structure

The invention provides a laminated wood floor of a prestressed structure. The floor is formed by bonding at least an upper medium-density fiber board and a lower medium-density fiber board at high pressure and low temperature. At least one spatially structured high-elasticity plastic component is clamped between the upper medium-density fiber board and the lower medium-density fiber board. The high-elasticity plastic component is embedded in a groove which is arranged in at least one medium-density fiber board; the high-elasticity plastic component is a spatially structured frame composed of a longitudinal rib and a horizontal rib, and the longitudinal rib and the horizontal rib form an radian which bulges upwards or downwards, and the high-elasticity plastic component is arranged between the upper medium-density fiber board and the lower medium-density fiber board to form a core board. The laminated wood floor has the advantages of good structural strength and stable structural properties, effectively ensures that the floor is not affected by environmental change during use, prolongs the service life, provides possibility of mass product processing, greatly saves wood resources, reduces the cost and the like.

Owner:DER FUTURE SCI & TECH HLDG GRP CO LTD

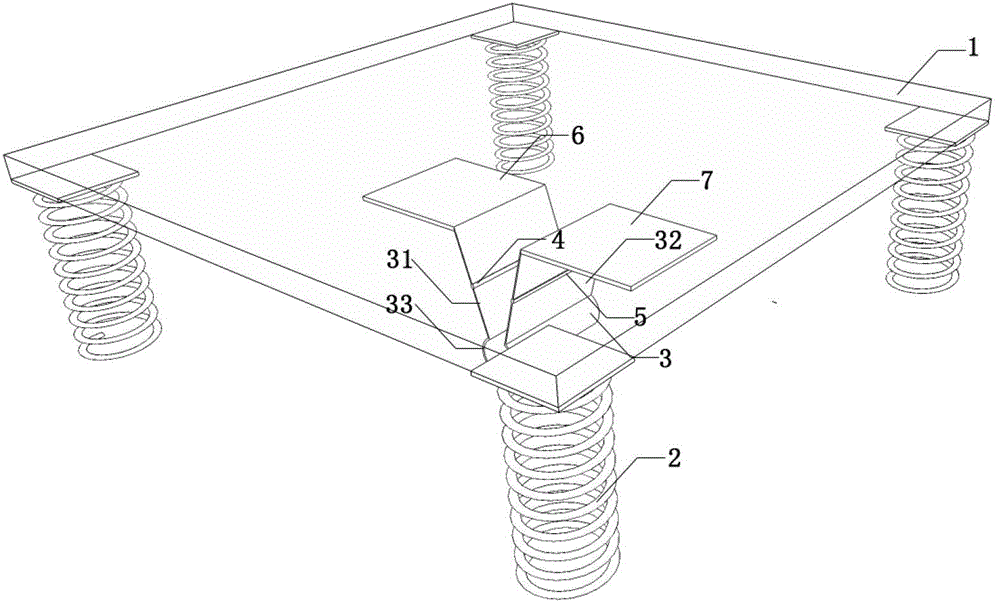

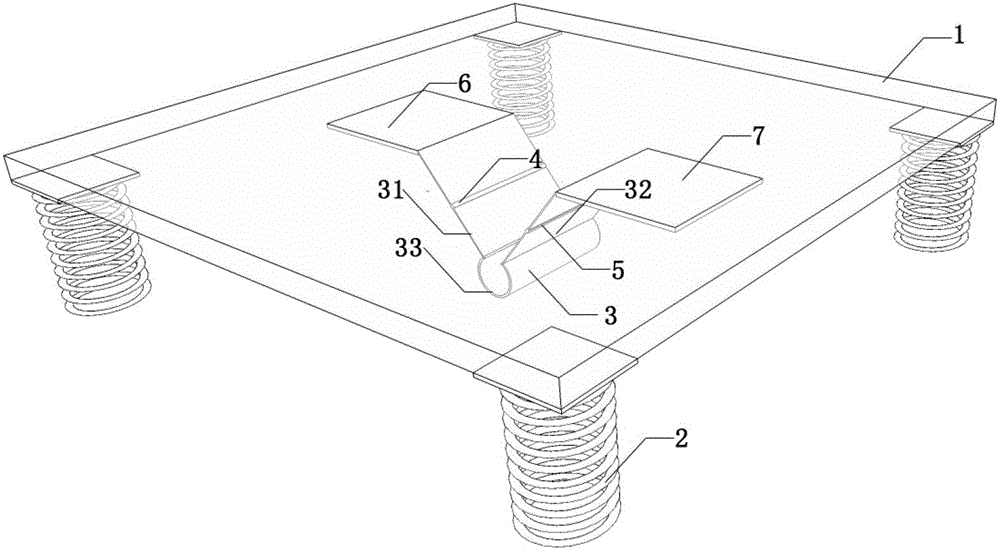

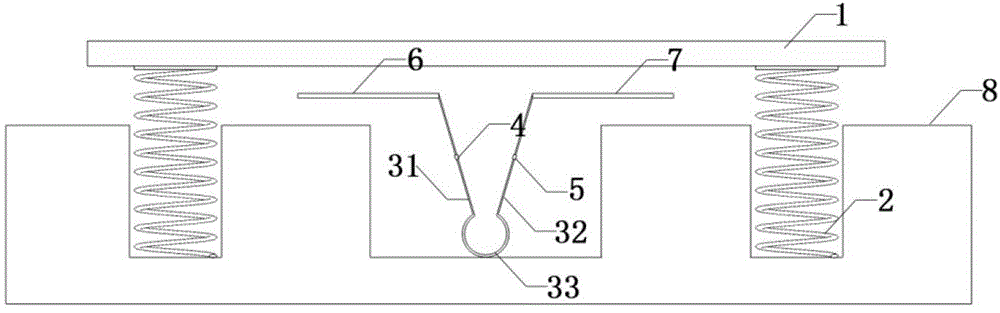

Device for automatically detecting berth status of parking lot

ActiveCN102982697AGood structural strengthExtended service lifeIndication of parksing free spacesAerospace engineeringPower consumption

The invention discloses A device for automatically detecting the berth status of a parking lot. The device comprises a bearing plate, a support component mounted on the ground and used for supporting the bearing plate, an elastic piece positioned under the bearing plate and having deformation when the bearing plate is under press, an inductive element used for inducing the deformation of the elastic piece, and a communication module triggered by the inducing element. The device for automatically detecting the berth status is low in power consumption and cost, is convenient to mount, and facilitates large-scale and rapid popularization.

Owner:ZHEJIANG UNIV

Tyre dismounting machine

InactiveCN101844493AImprove efficiencyPrecise positioningTyre repairingMechanical engineeringHydraulic pressure

The invention discloses a tyre dismounting machine, comprising a rack, a jacking device, a conveyer device used for conveying the jacking device in and out the bottom of the rack, a brake block device arranged on the conveyer device and a rimmer pressing device arranged at the top of the rack. The rimmer of the invention is positioned by the jacking device and is conveyed to the bottom of the rimmer pressing device by the conveyer device, rubber tyre is placed at the top of the rack and is positioned by the brake block device, the entire process is realized by cylinder, efficiency is high, and positioning is accurate; the rubber tyre is horizontally placed at the top of the rack, pressure is vertically applied to the rimmer by the rimmer pressing device, and the tyre is pressed out from the rubber tyre, the dismounting manner in the prior art is changed, the rimmer pressing device adopts hydraulic driving, pressure is large, and the rimmer can be rapidly pressed out from the rubber tyre; and the rubber tyre is pressed on the rack, the rimmer pressing device adopts a rimmer clamping ring to be touched with the rimmer, entire stress is realized when in pressure application, stress is uniformly distributed, and friction between the rimmer and the rubber tyre is reduced.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

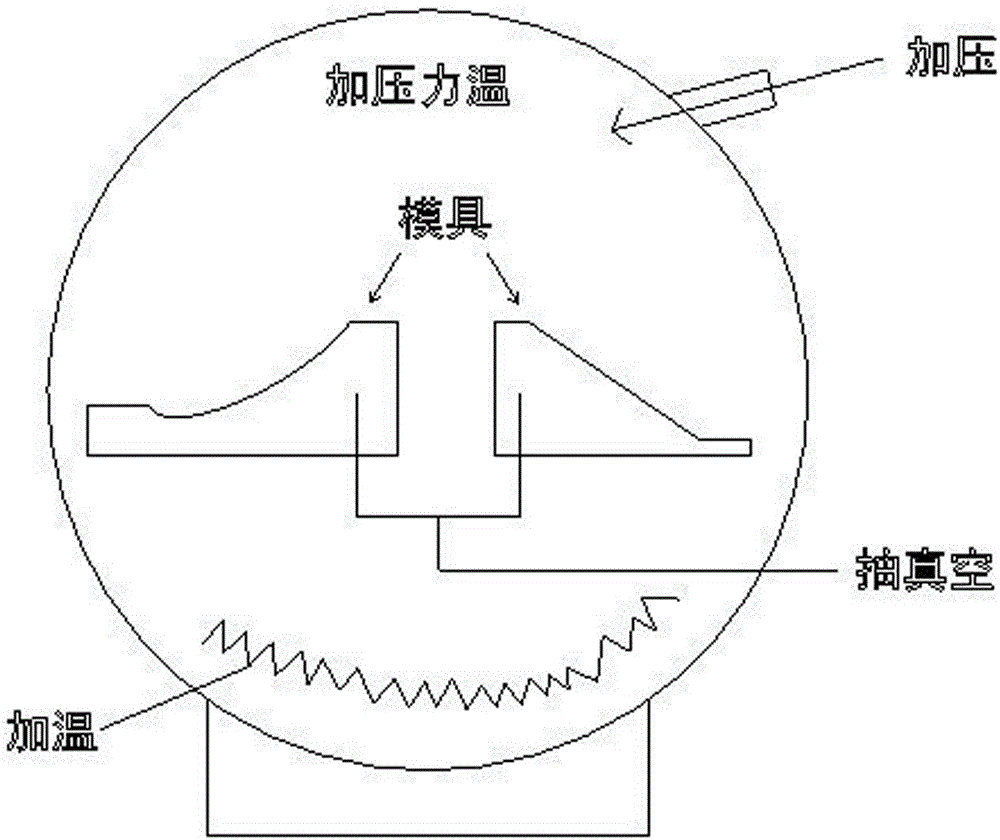

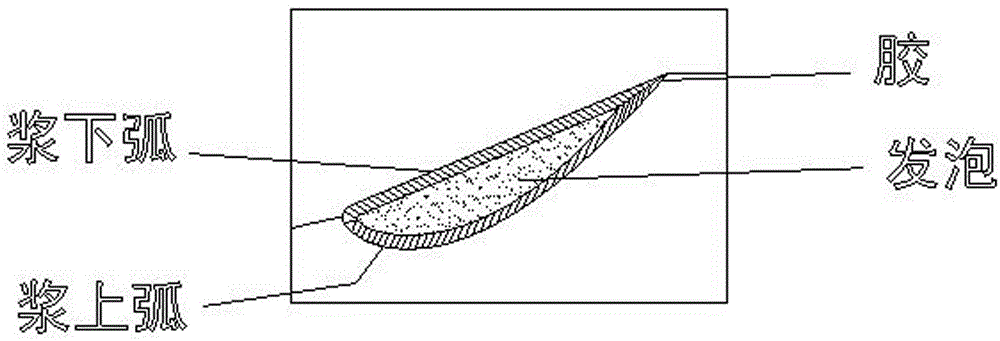

Manufacturing process of propeller and large efficient blade propeller of fan

InactiveCN104476782AProduct structure is compactGood structural strengthDomestic articlesPropellerManufacturing engineering

The invention discloses a manufacturing process of a propeller and a large efficient blade propeller of a fan. The manufacturing process comprises the following steps: preparing a necessary propeller manufacturing external die and a polystyrene cystosepiment preform, wherein the structures of the preform and the propeller to be manufactured are the same, but the size of the preform is reduced by a circle according to a ratio compared with the size of the propeller to be manufactured, and the polystyrene cystosepiment preform is manufactured for bracing the interior of a soft air bag, so that a prepreg can be conveniently paved; after sleeving the air bag outsides the polystyrene cystosepiment preform, integrally paving the prepreg outsides the air bag, and finally manufacturing the needed product by virtue of a single-air bag process or a multi-air bag process. The product has a very compact structure and is very good in structure strength and light in weight; on the aspect of procedure, the product is finished by one time, the procedure is simple, is short in consumed working hour and very high in efficiency and is capable of shortening the working hour by four fifths compared with the conventional method; on the aspect of quality, as the product is integrally finished in the die, the strength of a workpiece is very large, the finished product rate is very high, and the standardization is very good.

Owner:郑伟

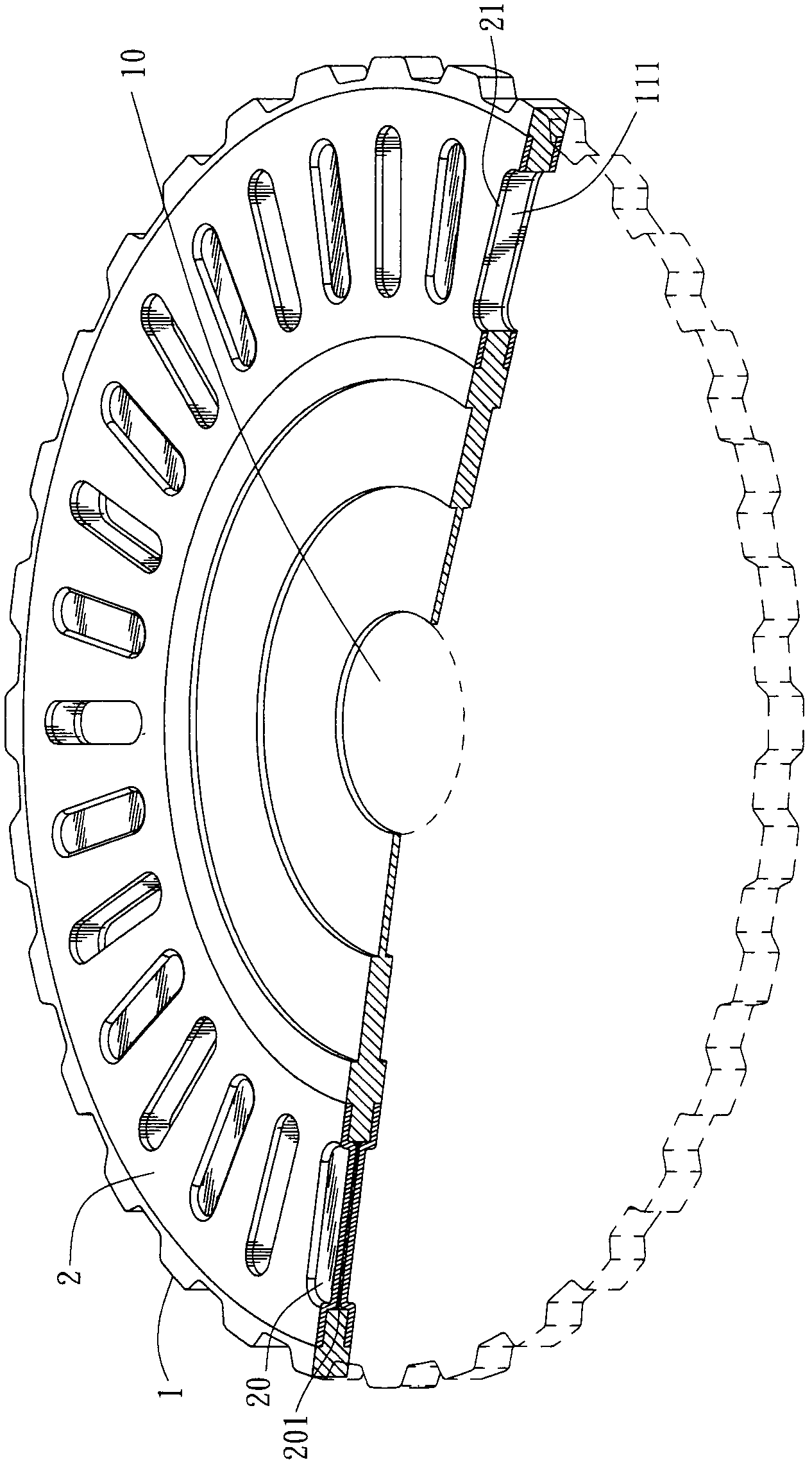

Brake disk

InactiveCN103434600AGood structural strengthPrevent deformation and breakageCycle brakesSoftware engineering

The invention provides a brake disk, which comprises a body and at least two heat dissipation components. The body is provided with an annular part, and a middle axle is defined by the body by the annular part. The annular part is provided with a brake part to be clamped by a brake device of a bicycle; at least one joint part extends towards the middle axle from the body and is combined with a flower hub of the bicycle; at least one junction part is arranged between the joint part and the brake part; each junction part is provided with at least one first fixed part; the two heat dissipation components are respectively arranged at two opposite sides of the body; each heat dissipation component is provided with at least one second fixed part to be fixedly combined with the at least one first fixed part of each junction part, and thus, when the brake part is clamped by the brake device, the heat dissipation components are capable of transferring heat, generated by the body due to braking, to the heat dissipation components by the at least one junction part to achieve a better heat dissipation effect.

Owner:温芫鋐

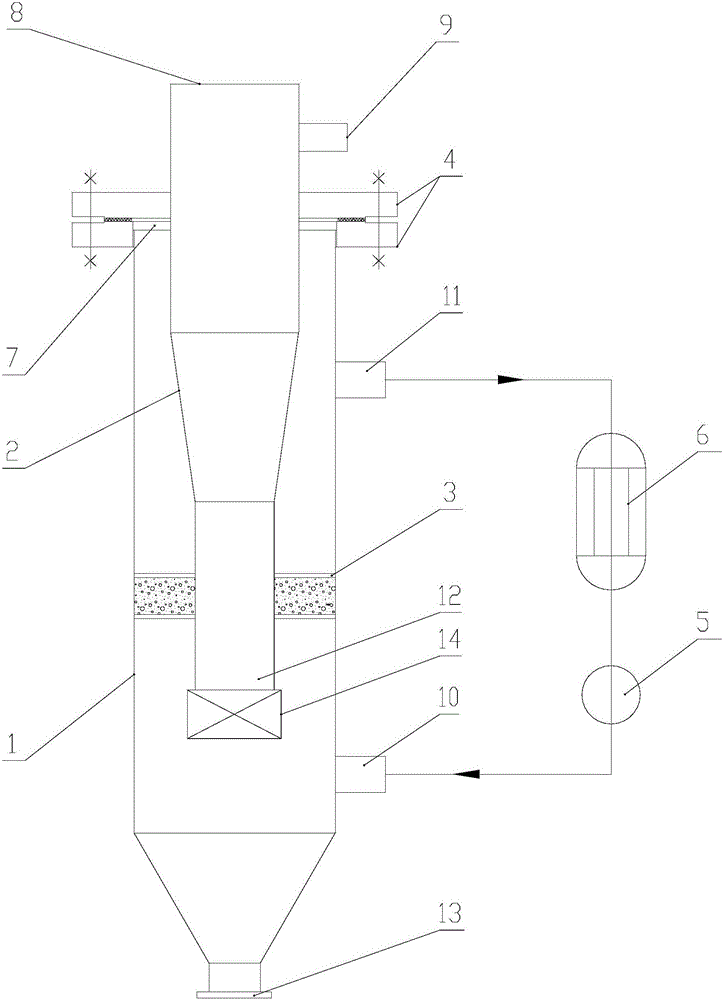

Supercritical water oxidation process and catalytic wet oxidation process combined reactor

ActiveCN106745660AGreat operating flexibilityGood structural strengthWater contaminantsWater/sewage treatment by oxidationSalting outReaction tube

The invention discloses a supercritical water oxidation process and catalytic wet oxidation process combined reactor. A main reaction tube is vertically arranged in a casing and is fixed by a cover plate flange at an opening of the casing; an upper opening is closed; a frame type sieve plate is circularly arranged between the casing and the main reaction tube inside the casing and is fixed; a catalyst is stored in the frame type sieve plate; a wastewater inlet and an oxygen inlet are formed in the upper part of the main reaction tube; a clear water outlet and a clear water inlet which are respectively formed in the upper side and the lower side of the frame type sieve plate are formed in the wall surface of the casing; the clear water outlet is sequentially connected into a heat exchanger and a circulating pump towards a direction of the clear water inlet; a saline water outlet is formed in the bottom of the casing. According to the reactor disclosed by the invention, a supercritical water oxidation process and a catalytic wet oxidation process are respectively used or are simultaneously and jointly used; supercritical oxidation is performed in the main reaction tube; catalytic wet oxidation is performed outside the main reaction tube; the reactor has relatively-high operation elasticity, provides optimization selection possibility for wastewater treatment with different fields, different concentrations and different treatment requirements and has the advantages of good structural strength, low manufacturing cost and convenience in arrangement; the problem of scale blockage of a supercritical water oxidation reactor due to high-temperature corrosion and salting out is effectively solved.

Owner:JIANGSU KUNZHONG MACHINERY

Environment-friendly ceramic tile and manufacturing method thereof

InactiveCN105601321AGood structural strengthGood microporous structureCeramicwareTalcEnvironmental resistance

The invention provides an environment-friendly ceramic tile. The environment-friendly ceramic tile is prepared from components in parts by weight as follows: 60-80 parts of diatomaceous earth, 5-10 parts of pyrophyllite, 1-5 parts of ball clay, 3-9 parts of spodumene, 5-10 parts of albite and 2-5 parts of talc. The environment-friendly ceramic tile is light in mass and high in structural strength and has functions of dehumidification, deodorization, indoor air purification and the like; with the adoption of a manufacturing method of the environment-friendly ceramic tile, the best structural strength and the best cellular structure of the ceramic tile can be guaranteed.

Owner:CHONGQING LEHU TECH CO LTD

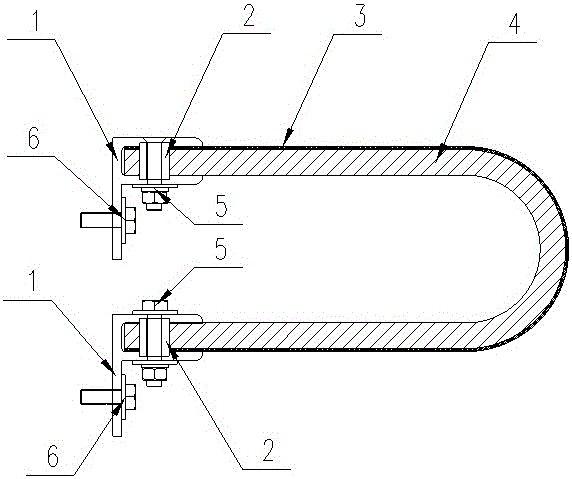

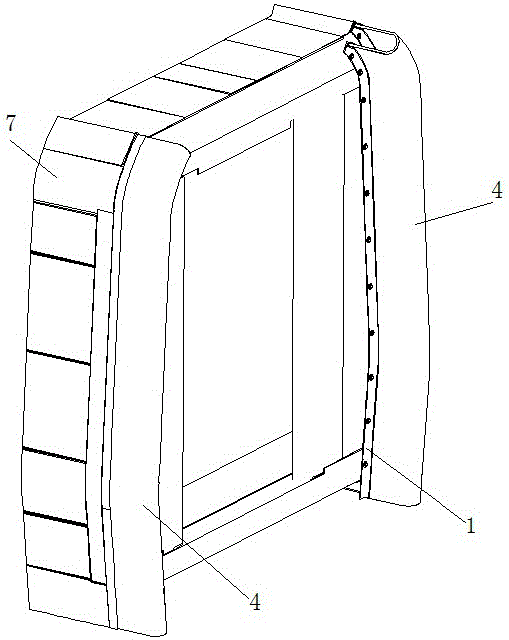

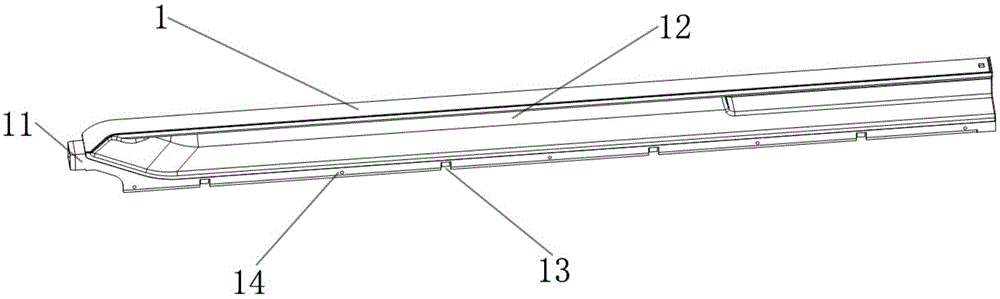

External windshield and rail vehicle with same

InactiveCN106428054AGood structural strengthExtended service lifeRailway transportAxle-box lubricationEngineeringTroffer

The invention discloses an external windshield. The external windshield comprises a rubber bag and two mounting bases which are arranged in parallel; each mounting base comprises a strip-shaped body and a first vertical part and a second vertical part which are perpendicular to the strip-shaped body and are arranged in parallel, wherein a groove is formed between the first vertical part and the second vertical part; the two side edges of the rubber bag are inserted into grooves of the two parallel mounting bases and fixed in the grooves. The external windshield has the advantages of being higher in structural strength, better in wear resistance, easy and convenient to mount and higher in maintainability.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO +1

Structural elements and method for fabricating structural elements

InactiveUS20070051060A1High insulation qualityGood structural strengthBuilding roofsRoof coveringStructural elementEngineering

A composite panel structure includes a flange beam assembly including: a web assembly; and a first flange assembly attached in an essentially perpendicular fashion to the web assembly. The composite panel structure further includes at least two panel assemblies. Each panel assembly includes: a foam layer; a first high-density material layer secured to the foam layer; and at least one recess configured to receive at least a portion of the first flange assembly.

Owner:IGREEN CONSTR

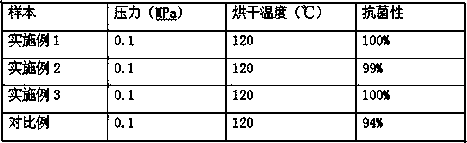

Antibacterial flame-retardant needle-punched compound nonwoven fabric preparation method

InactiveCN109733026AGood structural strengthEasy to makeSynthetic resin layered productsNon-woven fabricsNano zinc oxideToxicity

The invention discloses an antibacterial flame-retardant needle-punched compound nonwoven fabric preparation method. An antibacterial flame-retardant needle-punched compound nonwoven fabric has advantages of high structural strength and texture compactness, environmental friendliness, safety, reliability, convenience in manufacturing, wide application range and the like and provides a cottony comfortable handfeel. Antibacterial microcapsules are uniformly distributed in an antibacterial layer, excellent broad-spectrum, slow-release and bactericidal effects are achieved, drug tolerance and toxicity are avoided, and antibacterial and bacteriostatic effects are effectively achieved due to adding of nano zinc oxide and chitosan. Owing to adding of essence aromatic substances, the microcapsulescontinuously emit aroma in a utilization process to mask odors, and a high popularization and application value is achieved. The practice proves that the antibacterial effect is still kept even the fabric is washed for multiple times, and the antibacterial nonwoven material is promising in prospect.

Owner:HUBEI ZHIQUAN PATENT TECH APPL DEV CO LTD

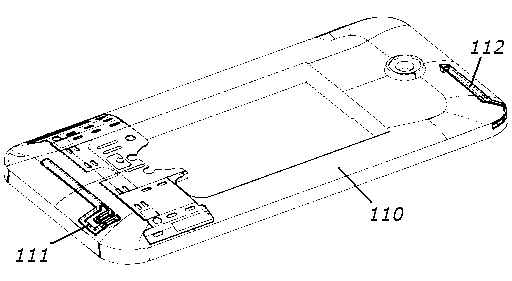

Bijection plating antenna shell and manufacturing method thereof

ActiveCN102800920AGood structural strengthStructural strength is not easy to breakAntenna supports/mountingsRadiating elements structural formsBatch productionEngineering

The invention discloses a bijection plating antenna shell and a manufacturing method thereof. The bijection plating antenna shell comprises a shell and an internal antenna arranged on the surface of the shell, wherein the shell is formed from plating plastics and non-plating plastics through a bijection injection molding die; and the internal antenna is a metal layer plated on the surface of the plating plastics. Due to the bijection injection molding and surface plating technology, the manufactured antenna has good structural strength and is not easily broken; the combination between the antenna and the shell is relatively tight, and warp is not easily caused; the using performance of the antenna is better; the batch production speed is high, and the production cost is low; and the products obtained by batch production have stable quality and good consistency.

Owner:CHITWING DONGGUAN TECH

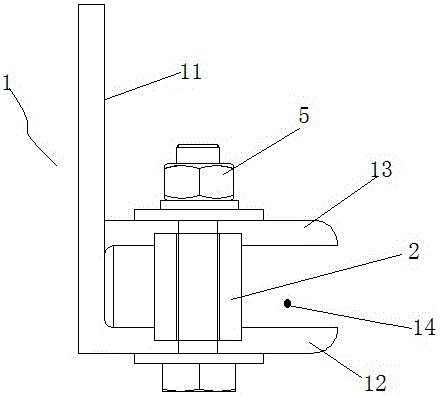

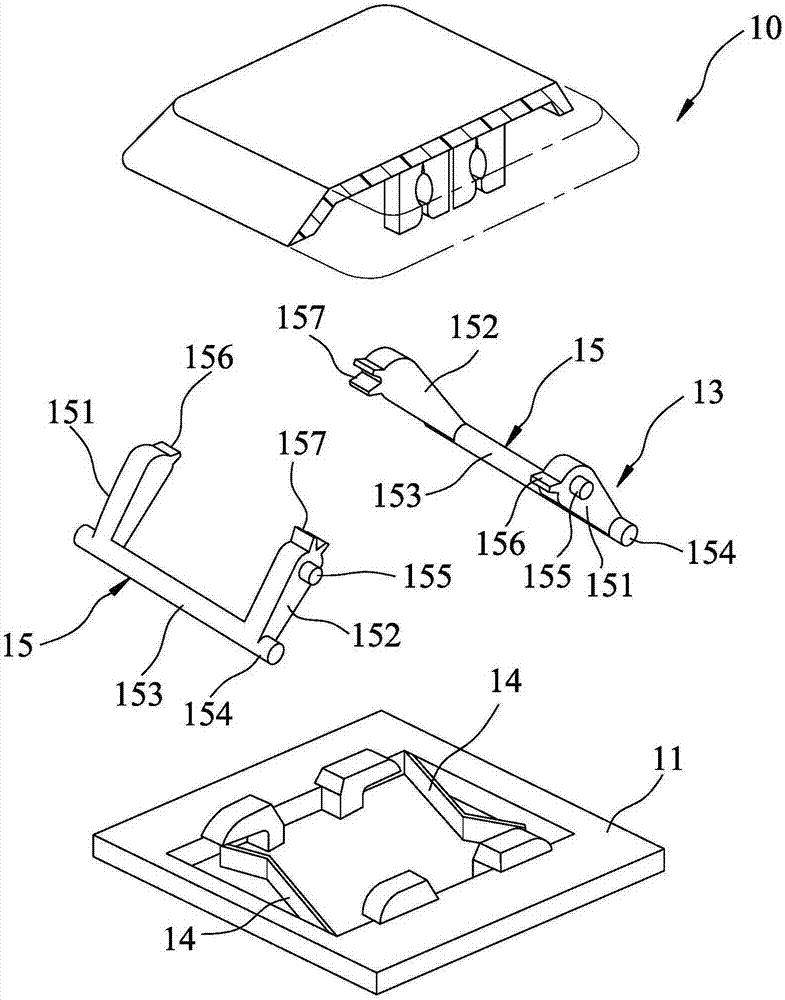

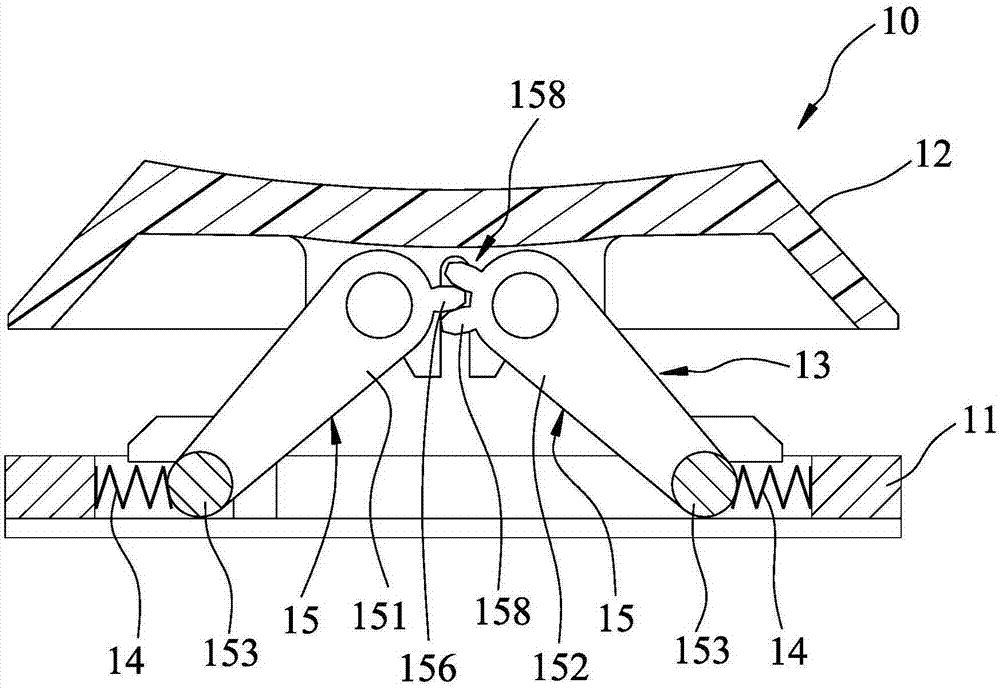

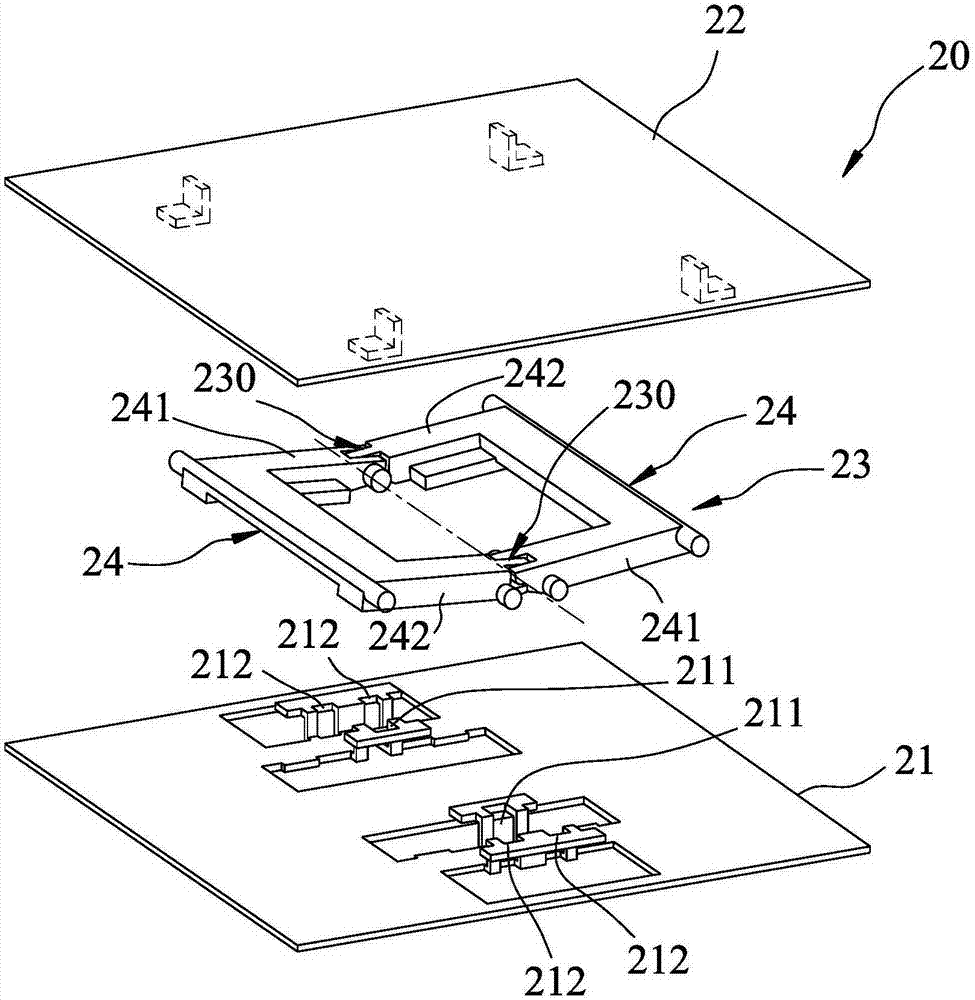

Dual-seesaw supporting mechanism and thin word key

InactiveCN105448566AImprove assembly efficiencyGood structural strengthEmergency actuatorsElectric switchesAerospace engineering

Owner:SUNREX TECH

Aluminum alloy and plastic joint handle and French door and refrigerator comprising same

InactiveCN105066568AAvoid pinch problemsGood structural strengthWing handlesLighting and heating apparatusEngineeringRefrigerated temperature

The invention relates to an aluminum alloy and plastic joint handle and a French door and a refrigerator comprising the same. The joint handle comprises a plastic hidden handle and an aluminum alloy vertical post machined part. The plastic hidden handle is provided with a recessed cavity with which people open or close door bodies. The recessed cavity is arranged in the outer side face of the plastic hidden handle and recessed inwards. The plastic hidden handle is installed on the aluminum alloy vertical post machined part. The French door comprises the two door bodies arranged in parallel. The neighboring sides of the two door bodies are provided with the aluminum alloy and plastic joint handles arranged in symmetry. The aluminum alloy vertical post machined parts are fixedly installed on the neighboring sides of the two door bodies. The recessed cavities of the plastic hidden handles are arranged oppositely. According to the aluminum alloy and plastic joint handle and the French door and the refrigerator comprising the same, the plastic hidden handle is installed on the aluminum alloy vertical post machined part by adopting the plug-in, buckle and screw fixation scheme, or all other reasonable modes, e.g., gluing, clamping hooks and other fixation modes.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

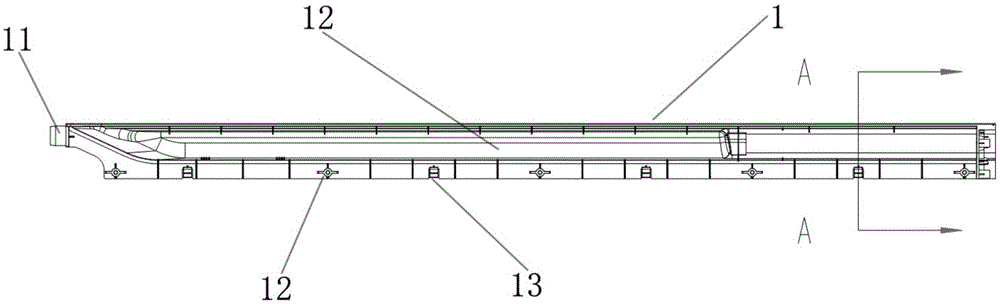

Shell structure of water meter

InactiveCN1963413AGood structural strengthExtended service lifeVolume meteringWater tanksEnvironmental engineering

This invention relates to water meter shell structure composed of shell and water ring tank, wherein, the shell core chamber and column water ring tank chamber with top mouth larger than down one; the water ring tank is of round cylinder with inside circle of round ring tank; the water ring tank outside and water tank inside are matched with water tank imbedded into water ring chamber to connect tank open to shell exit to form shell; the shell is fixed with water machine chip into machine chip matched with water ring tank.

Owner:TIANJIN JINNAN KAIDA ELECTRONIC CO LTD

Piano key displacement detection device

InactiveCN106952465AReduce volumeGood structural strengthNon-electrical signal transmission systemsUsing optical meansPrinted circuit boardEngineering

The invention relates to a piano key displacement detection device. The piano key displacement detection device comprises an installation support arranged on a piano keyboard; the lower surface of the installation support is provided with a flexible printed circuit board; the flexible printed circuit board is provided with a plurality of optical detection units, and the optical detection units are arranged to be right above piano keys, and are used for detecting displacement of the piano keys. According to the piano key displacement detection device, a three-layer composite mechanical structure is adopted; the piano key displacement detection device is provided with the flexible printed circuit board, so that the optical detection units can be arranged to be close to the piano keys, and the size of the whole piano key displacement detection device is reduced.

Owner:上海天域知音艺术有限公司

Large-plane vapor chamber of composite wick

PendingCN111780603AGuaranteed uniformityGuaranteed stabilityIndirect heat exchangersHeat exchange apparatusLiquid stateEngineering

The invention relates to a large-plane vapor chamber of a composite wick. The large-plane vapor chamber comprises an upper cover plate and a lower cover plate, wherein the edges of the upper cover plate and the lower cover plate are connected in a sealed mode to form a sealed working medium cavity. The sealed working medium cavity is in a vacuum state and is filled with a liquid working medium. The upper cover plate is provided with a first area and a second area. The first area is close to an evaporation end and is provided with a plurality of first supporting columns which are densely distributed. The second area is provided with a plurality of second supporting columns which are distributed sparsely. Second wicks are arranged in the gaps between the second supporting columns. The lowercover plate is provided with a third area and a fourth area. The dimension of the third area corresponds to that of the first area, and the third area is used for storing first wicks. The dimension ofthe fourth area corresponds to that of the second area, the fourth area is provided with third supporting columns which are distributed sparsely, and the number and distribution mode of the third supporting columns correspond to those of the second supporting columns. By means of the large-plane vapor chamber, the problems that the flowing space of vapor in large-plane vapor chambers is not enough, the heat transfer performance is poor, and the structural strength is poor can be solved.

Owner:WUXI JONES TECH +3

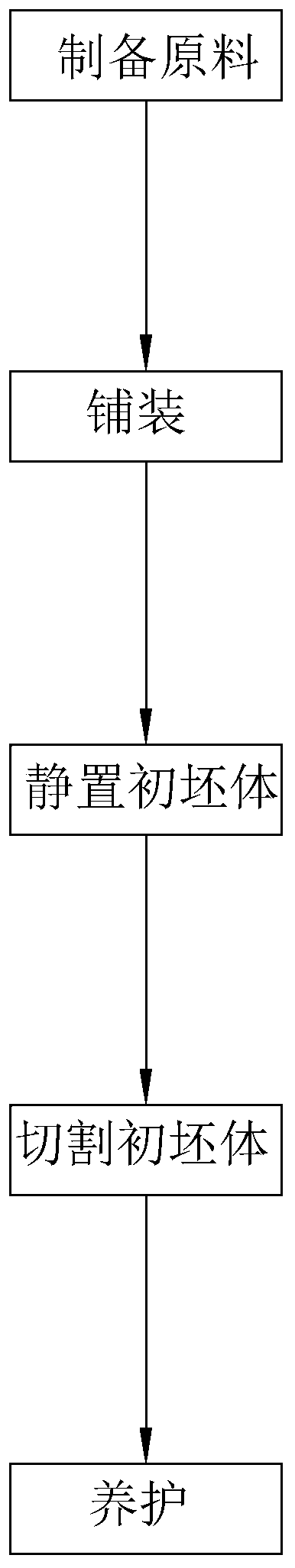

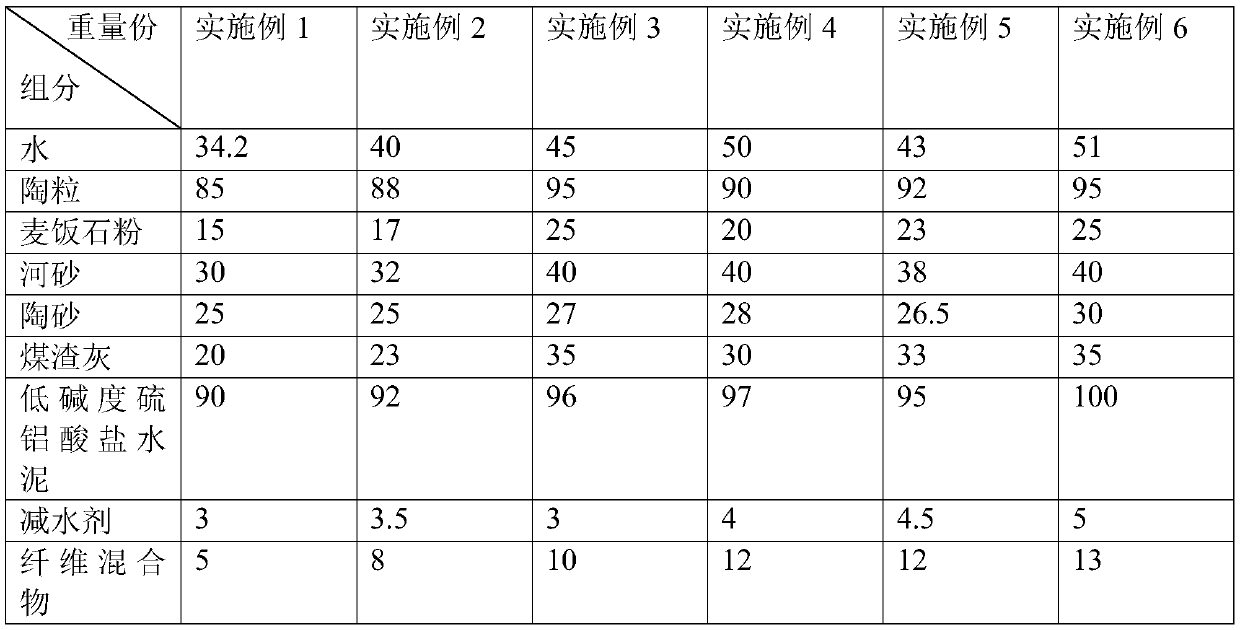

Light sound insulation wallboard and preparation method thereof

InactiveCN110981371ALight in massGood structural strengthCeramic shaping apparatusCement mixing apparatusRiver sandChemistry

The invention relates to the field of wallboard preparation processes, in particular to a light sound insulation wallboard and a preparation method thereof. The light sound insulation wallboard is prepared from the following components in parts by weight: 34.2-51 parts of water, 85 to 95 parts of ceramsite, 30 to 40 parts of river sand, 25 to 30 parts of pottery sand, 20 to 35 parts of fly ash, 90to 100 parts of low-alkalinity sulphoaluminate cement, 15 to 25 parts of medical stone powder; 3-5 parts of a water reducing agent, and 5-13 parts of a fiber mixture. The light sound insulation wallboard and the preparation method thereof have the beneficial effects that the mixture D is obtained through specific components in parts by weight, then the mixture D is paved through a wallboard machine, the wallboard is prepared through the steps of standing, cutting, maintaining and the like, and the prepared wallboard has the advantages of being light in weight and good in sound insulation effects.

Owner:广东筑城建筑工业有限公司

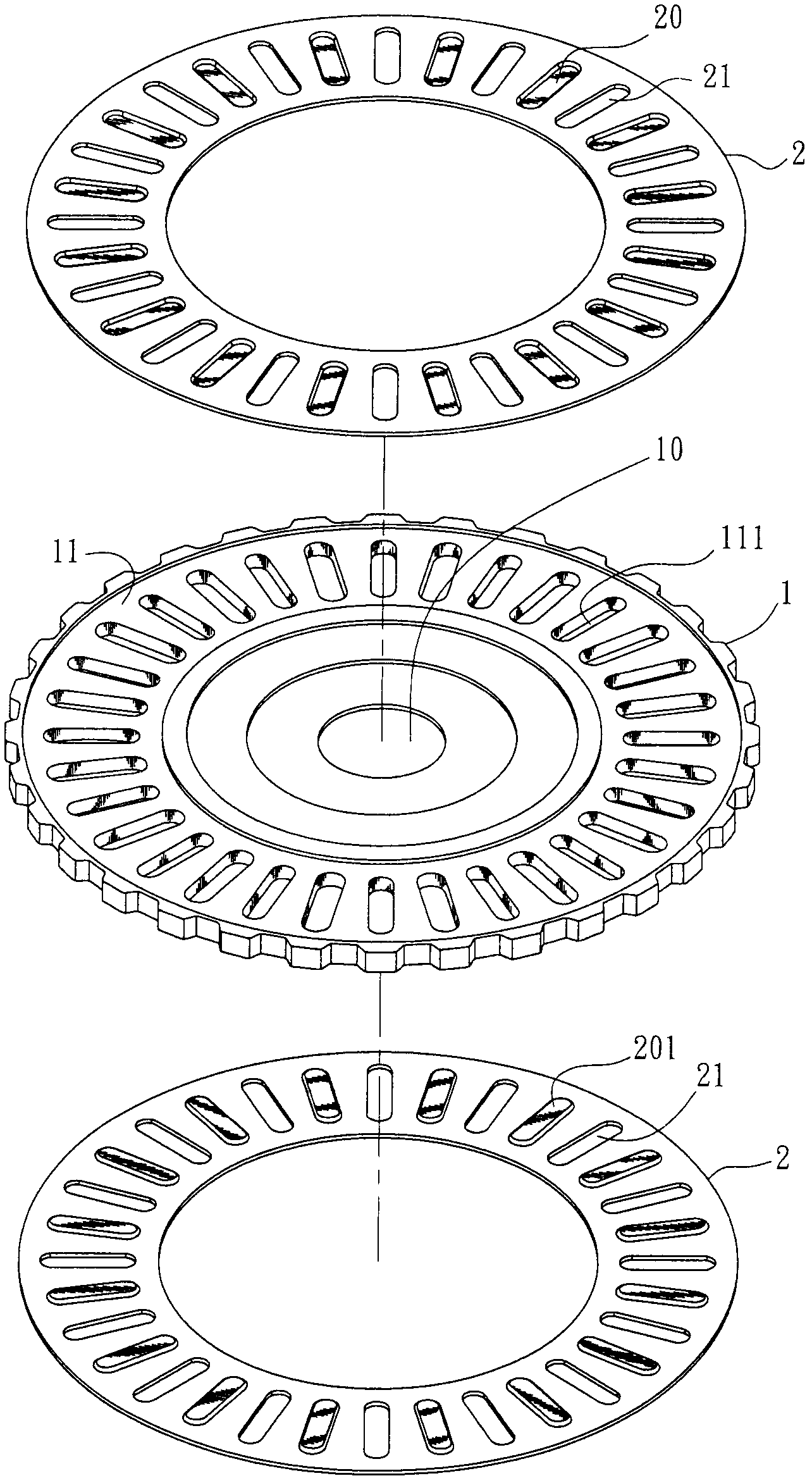

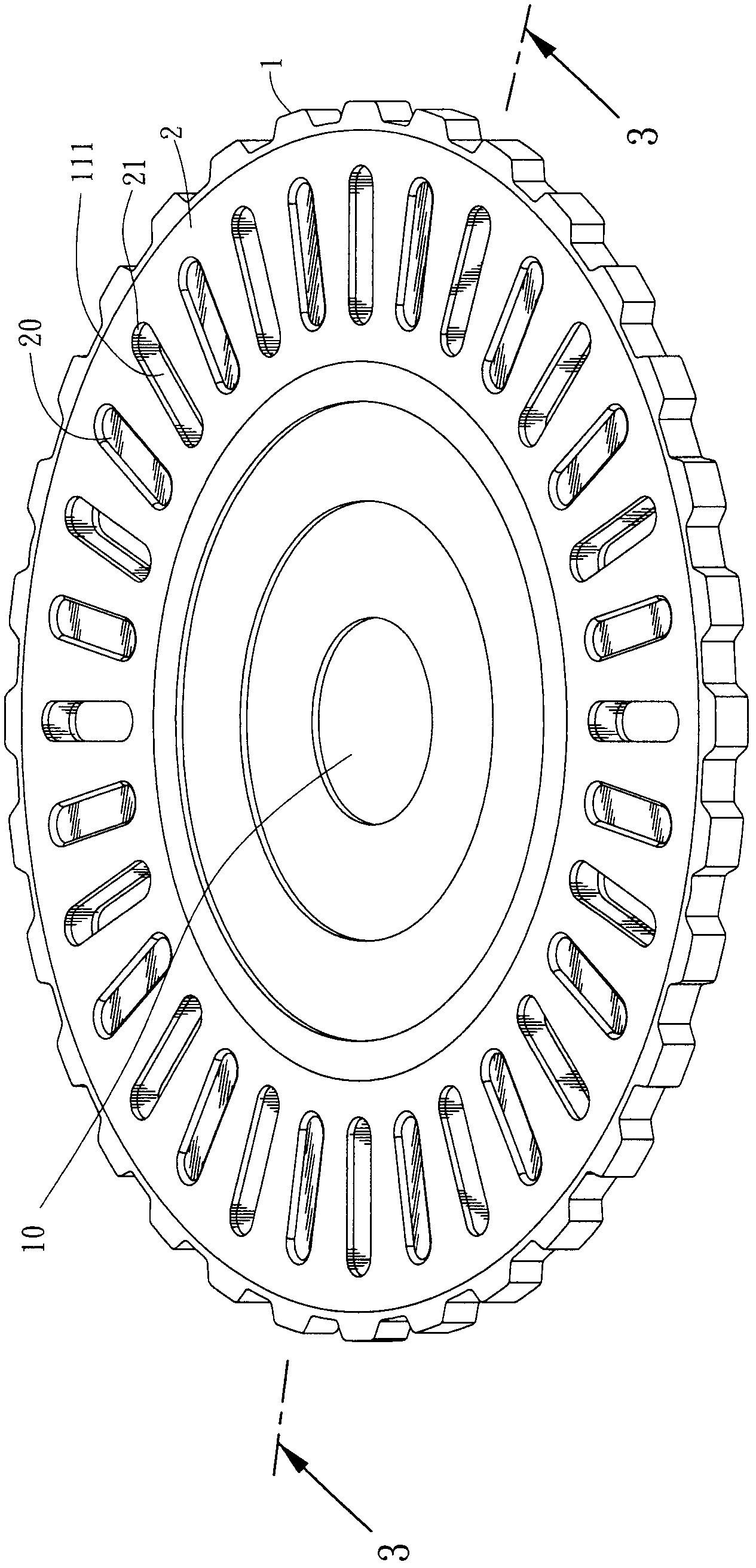

Wear-resistant disk

The invention discloses a wear-resistant disk. The wear-resistant disk comprises a carrying disk which is used for assembling a wheel hub and made of a light metal material; a plurality of annular holes are annularly formed in the carrying disk; two circular annular wear resistance frames are arranged on two sides of the carrying disk respectively to provide a wear resistance effect; both wear resistance frames are made of irony metal; a plurality of notches are annularly formed in the outer sides of both wear resistance frames; on the inner side of each wear resistance frame, a protruded surface is formed on the inner wall of each notch; the notches of both wear resistance frames are flush with the annular holes of the carrying disk, the protruded surface of each notch is embedded into each annular hole from two sides of the carrying disk; and the two relative protruded surfaces are combined correspondingly in the annular holes of the two wear resistance rings to ensure that the carrying disk and the two wear resistance frames are integrated, and the shearing force which is produced by a brake is transmitted to the carrying disk by the wear resistance frames. The wear-resistant disk has the advantages of light weight, wear resistance and high structural strength and density, and reduces production cost.

Owner:ASHIMA LTD

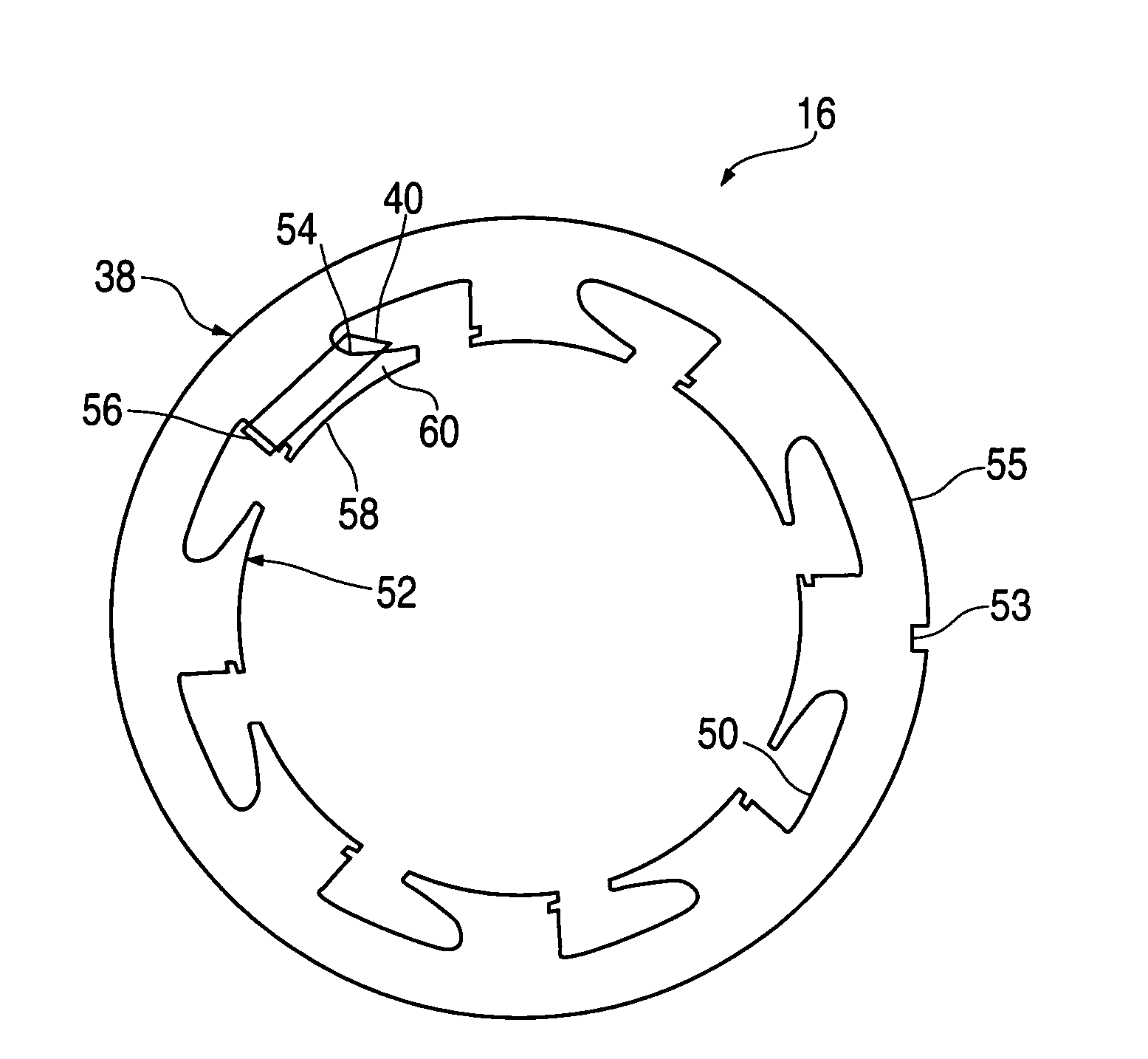

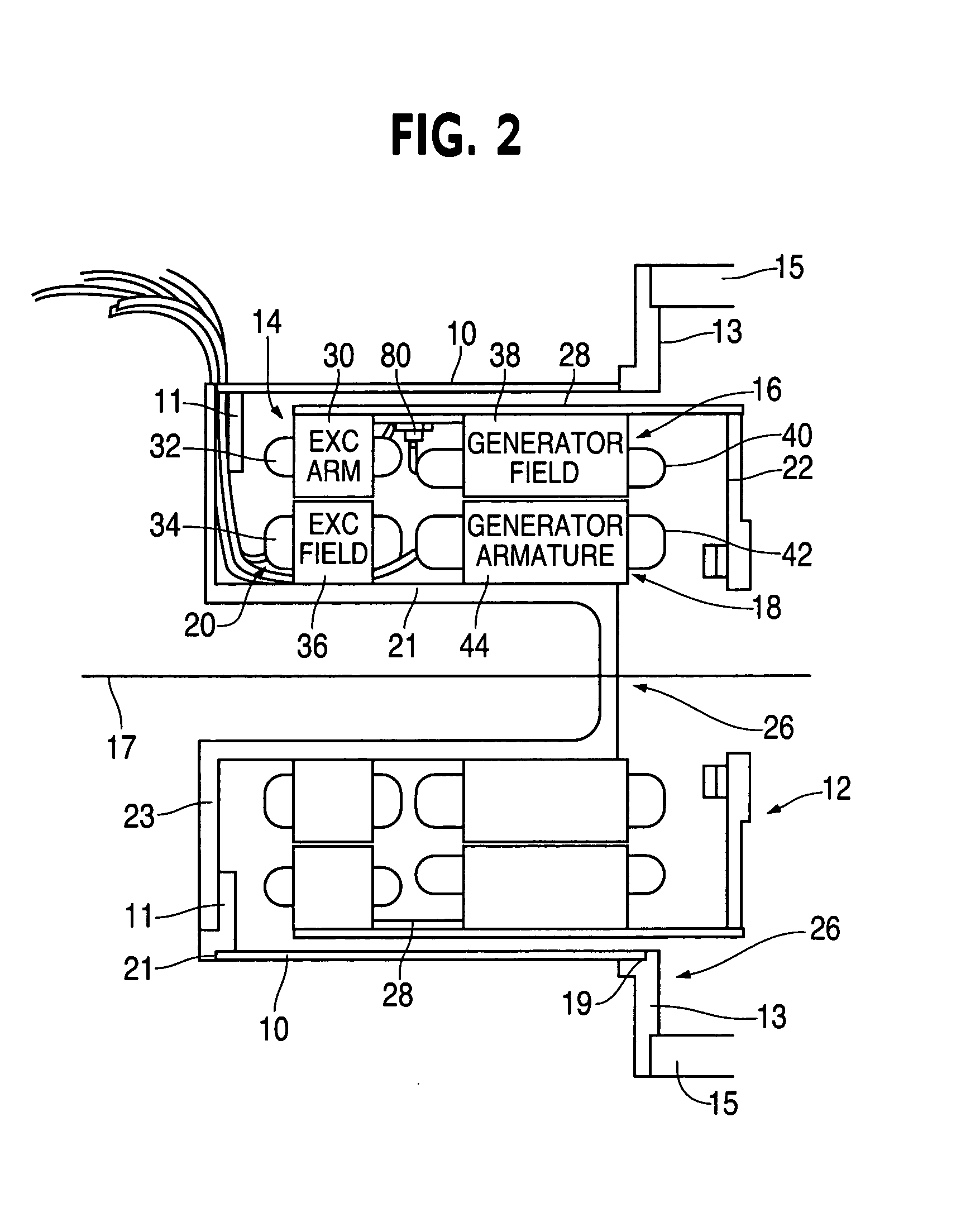

Electrical machine having centrally disposed stator

InactiveUS20070024150A1Good structural strengthImprove structural strengthSynchronous generatorsMagnetic circuit rotating partsStatorEngineering

An electrical generator comprising a stator having stator windings and a rotor having rotor windings. The rotor and the rotor windings extend about the stator windings. The rotor includes an annular rotor housing. On an inside of the rotor housing are mounted the rotor windings. The stator includes an end member with a central member extending therefrom. The stator windings are mounted on the central member. The stator also includes an annular stator housing that extends about the central member, including the stator windings, and the rotor. The end member attaches to the stator housing thereby positioning the stator windings in a central location. The stator housing and the end member enclose the stator windings and the rotor windings therein. The rotor housing further includes a rotor mounting member on an end. The stator housing includes a stator mounting member on an end thereof, and a stator windings mounting member on an opposite end. The stator windings include an exciter field winding and a generator armature winding. The rotor windings include an exciter armature winding and a generator field winding. The exciter armature winding is disposed radially outwardly from and adjacent to the exciter field winding. The generator field winding is disposed radially outwardly from and adjacent to the exciter armature winding.

Owner:TELEFLEX CANADA

Slope protection brick

ActiveCN109006033AAvoid displacementAvoid deformationCoastlines protectionExcavationsBrickEngineering

The invention discloses a slope protection brick, which comprises a first body and a second body that are connected with each other. Both the first body and the second body are polygonal. The two endsof the slope protection brick are respectively provided with a convex part and a concave part, and the adjacent two slope protection bricks can be connected in series through the convex part and theconcave part. The slope protection brick further comprises a longitudinal through hole and a transverse through hole which are beneficial to drainage of the slope soil. The slope protection brick alsocomprises a first groove and a second groove for stepwise stacking the slop protection bricks along the slope soil.

Owner:刘承旻

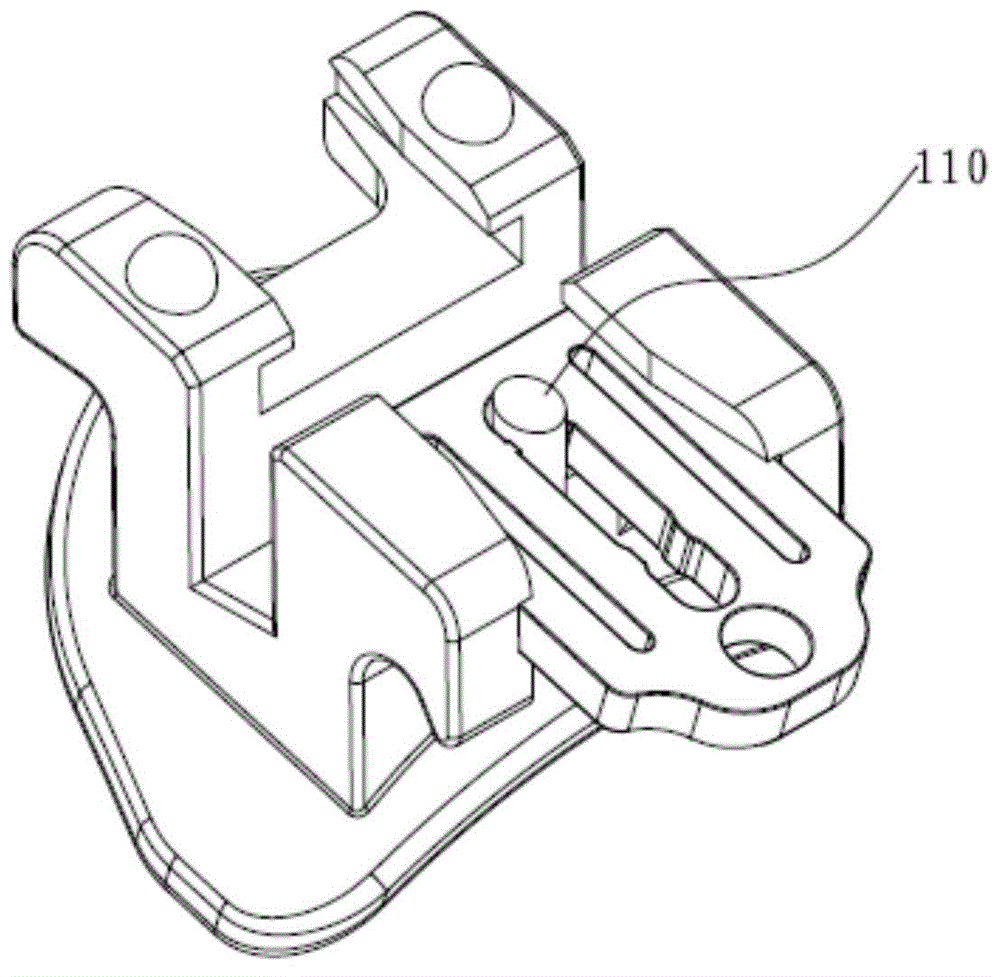

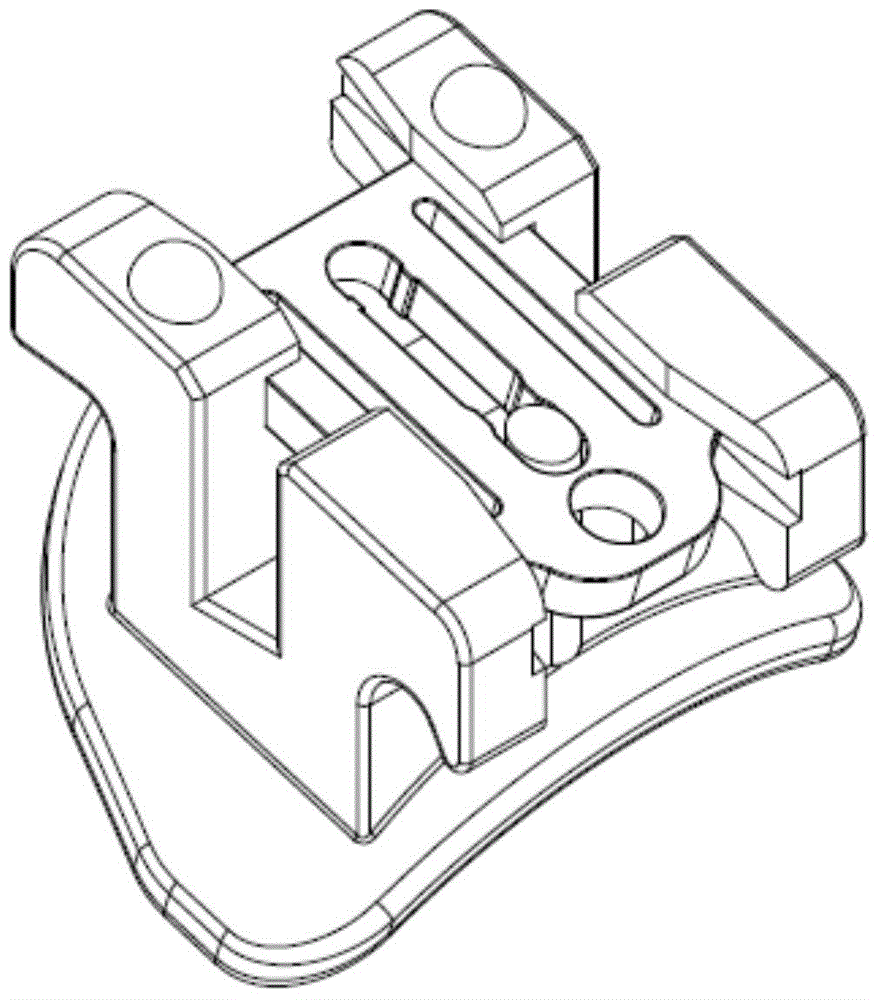

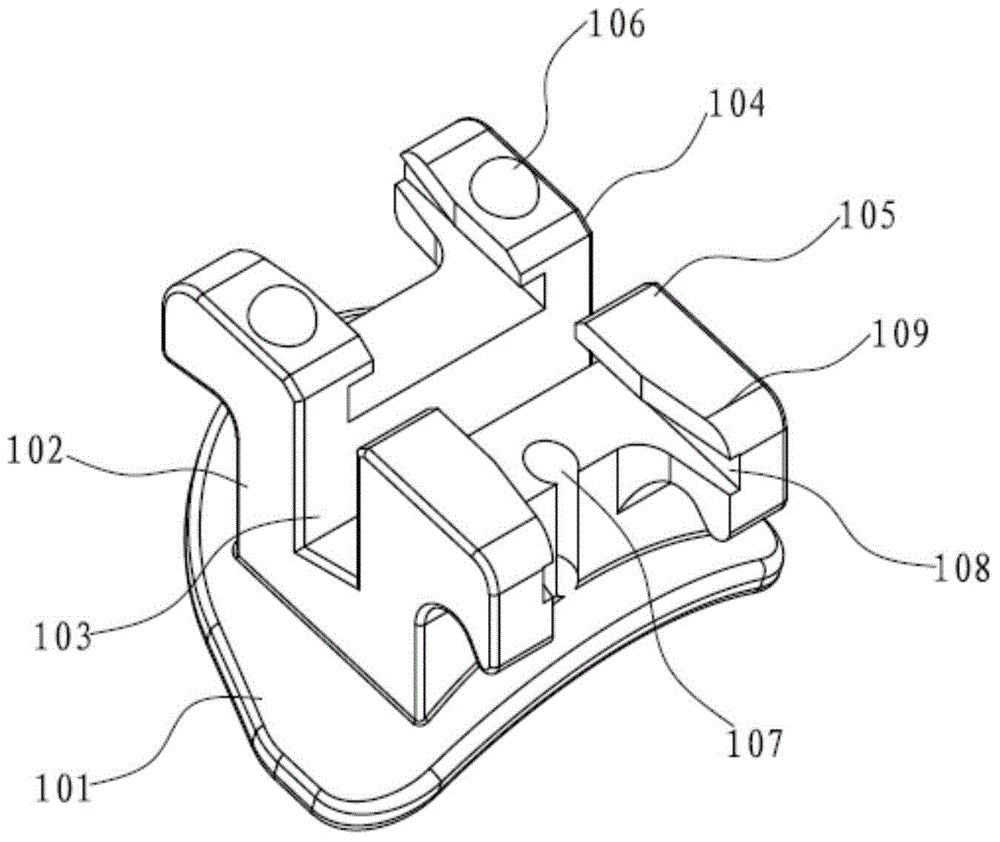

Conveniently-cleaned passive slip cover self-ligating bracket

InactiveCN104970892AComplete structureGood structural strengthArch wiresBracketsEngineeringMechanical engineering

Owner:ZHEJIANG SHINYE MEDICAL TECH CORP LTD

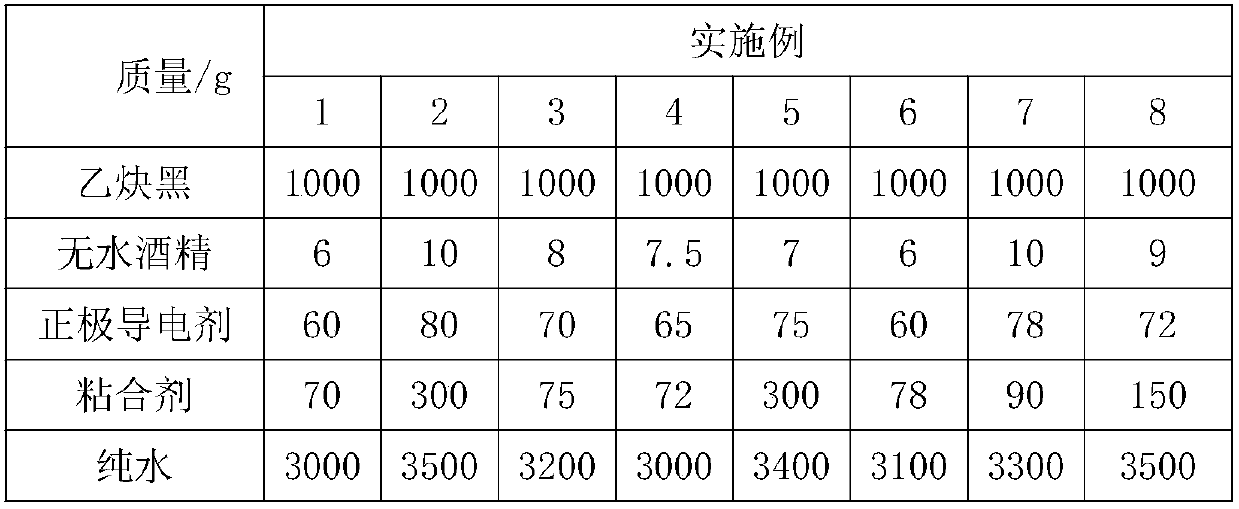

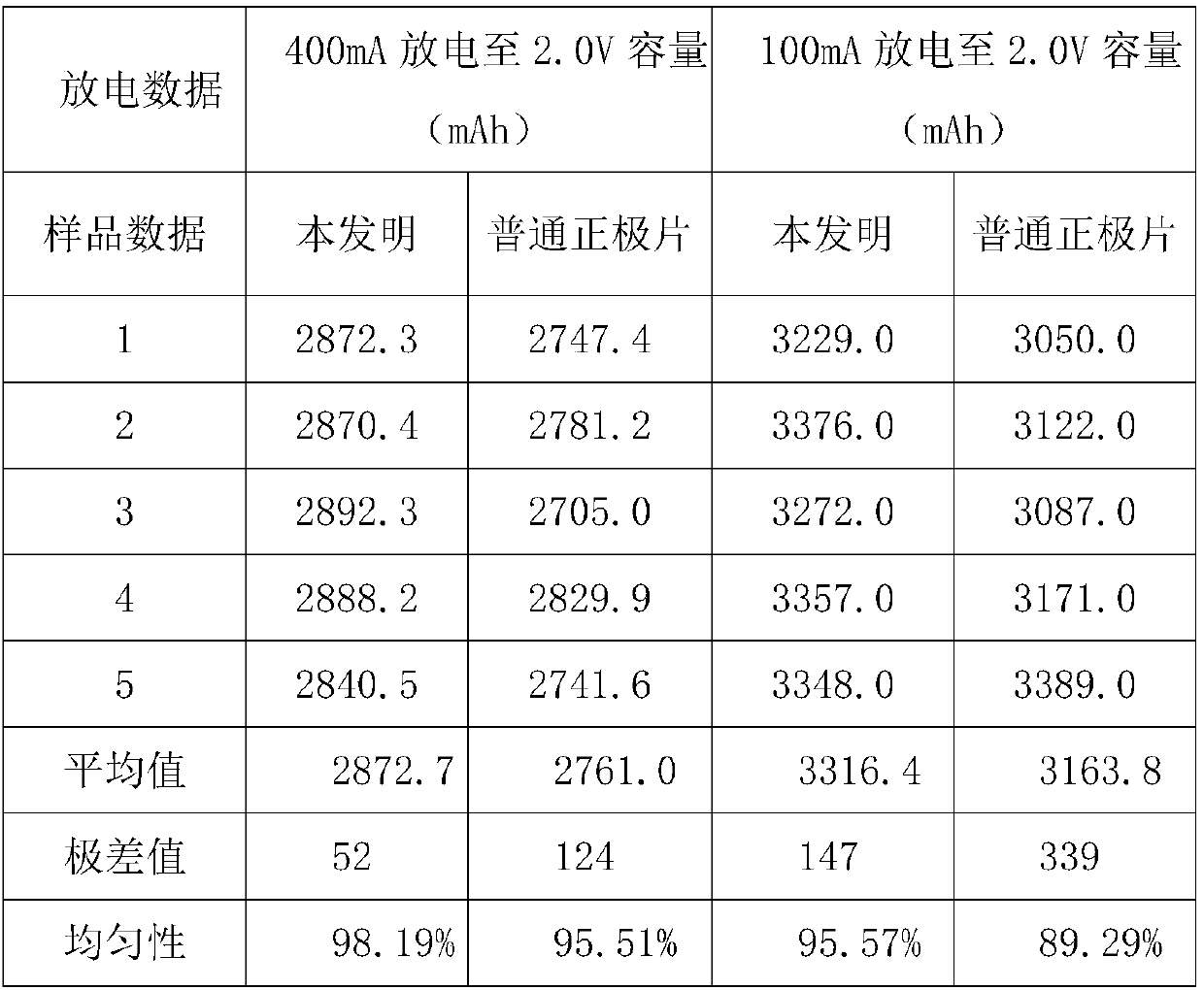

Preparation method of lithium thionyl chloride power type battery positive electrode

InactiveCN107910497AGood structural strengthWell-developed mesh structureElectrode rolling/calenderingLi-accumulatorsSolventLithium

The invention discloses a preparation method of a lithium thionyl chloride power type battery positive electrode. The preparation method comprises the steps of 1) performing powder material pretreatment; performing material mixing to form a half-dried wet material and performing uniform stirring; putting the half-dried wet material into a banded extruder with the sieving pore diameter of 0.5-1.5mmto be subjected to band extrusion to obtain a strip-shaped material with the length of 1-2cm; putting the strip-shaped material into a centrifuging pelletizing machine to obtain a fine pellet material with the grain diameter of 0.5-1.5mm; and performing vacuum drying on the fine pellet material for 8-10h; 2) putting the fine pellet material on a net: performing smashing on the obtained dried finepellet material into a fine powder material; performing uniform mixing on the fine powder material and an aqueous solvent to obtain a half-dried powder material; and putting the half-dried powder material on a nickel net to be subjected to vacuum drying and fibering; and 3) positive electrode forming: performing rolling by adopting a rolling mill to prepare a positive electrode body with requiredthickness. By processing the wet material through the extruder and the pelletizing machine, the formula materials in the finally prepared positive electrode are more uniform in distribution, and higher structural strength, more developed net-hole structure, no powder falling-off, and more environment friendly and safer production process are achieved, and continuous production operation can be realized.

Owner:武汉孚安特科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com