Visual bolt looseness prevention washer turn-over tool and use method thereof

A kind of anti-loose gasket and folding technology, which is applied in the field of installation of reactor pressure vessels in nuclear power plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

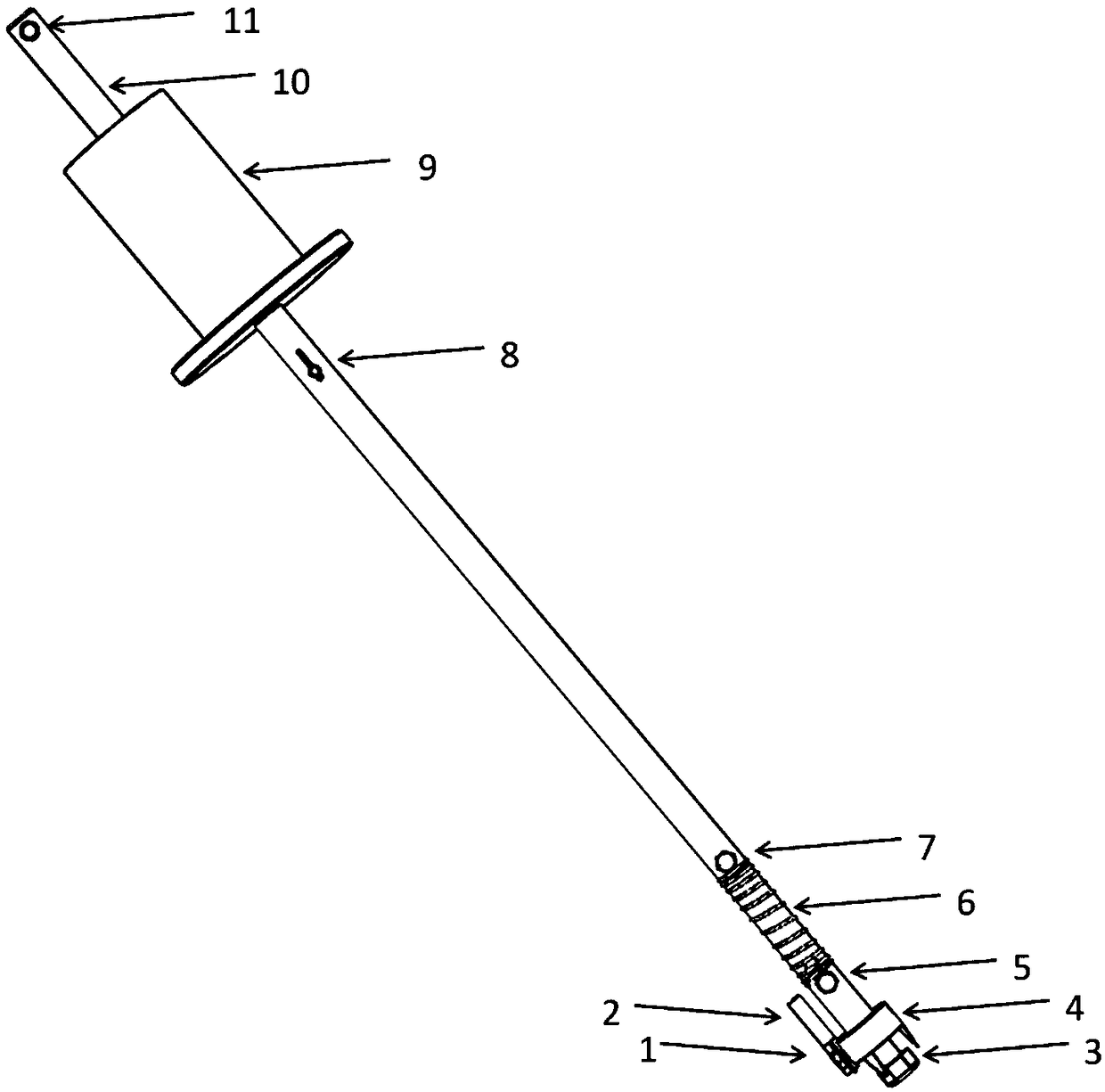

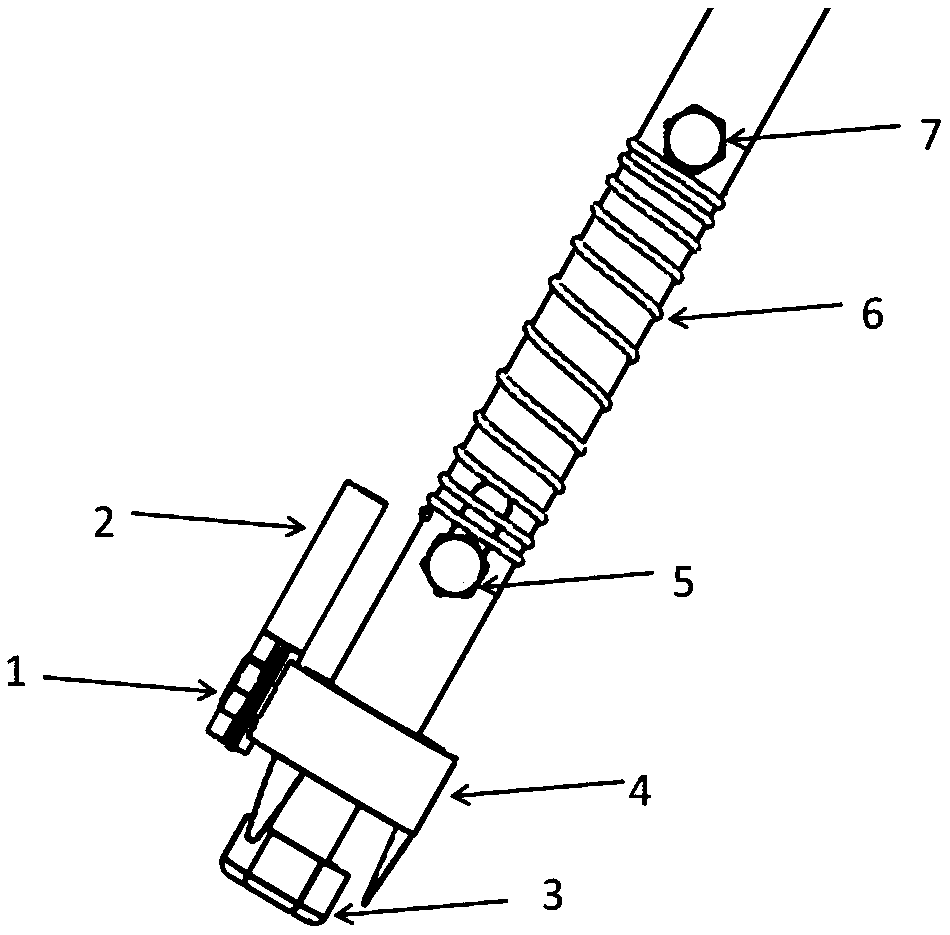

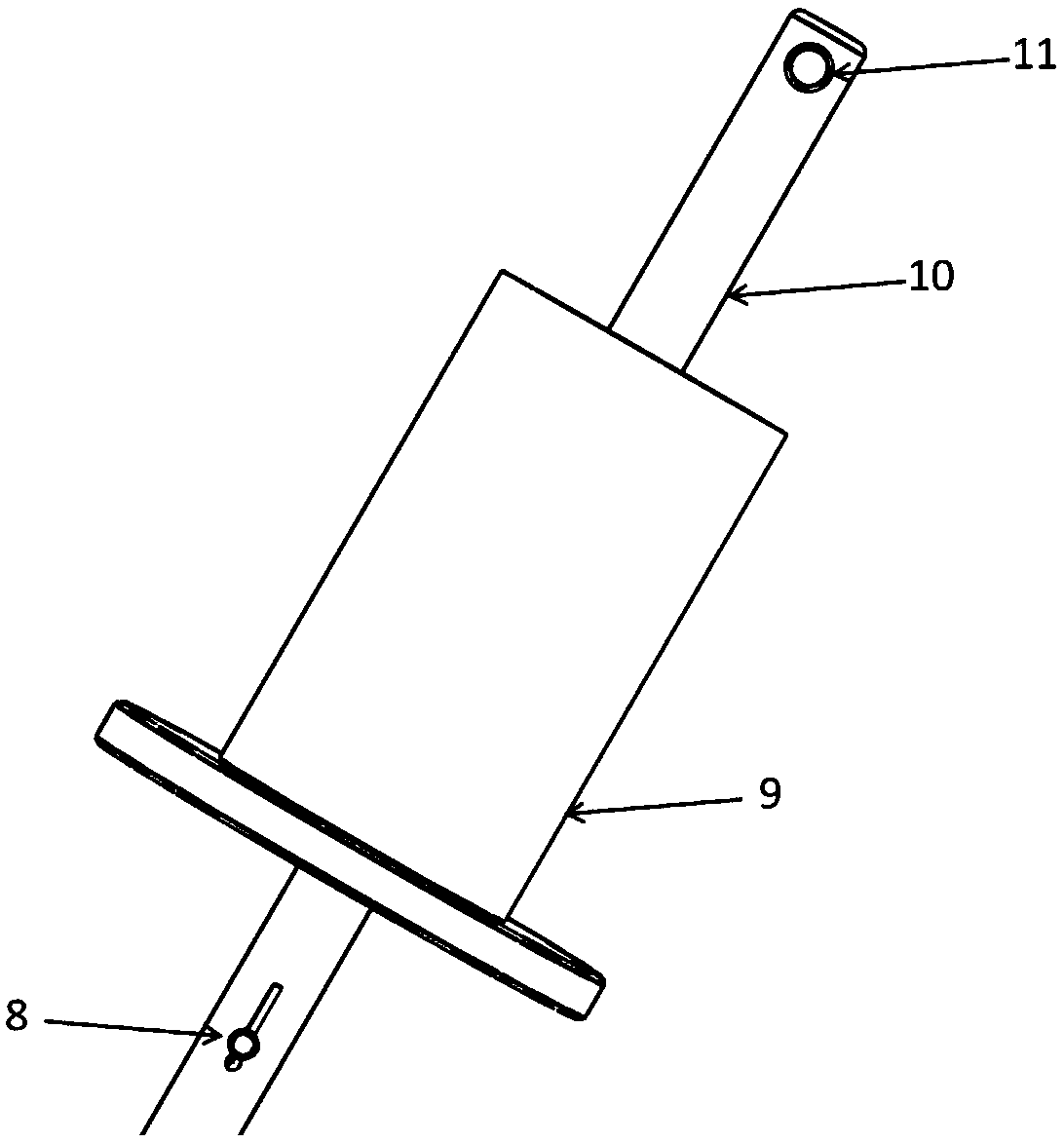

[0027] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

[0028] The invention is a visual bolt anti-loosening washer folding tool, which is in an up-and-down structure in terms of structural composition, and is convenient for assembly and disassembly. Such as Figure 1-Figure 6 As shown, it includes a folding compression rod 4, and the folding compression rod 4 has 3 through holes from top to bottom, respectively assembling the connecting pin 8, the upper pin bolt 7, and the lower pin bolt 5, wherein the lower part is assembled The hole of pin bolt 5 is a vertical strip hole. Cotter pins are all installed on the upper pin bolt 7 and the lower pin bolt 5 . The lower end of the folding pressing rod 4 is connected with the positioning guide head 3, and the positioning guiding head 3 and the folding pressing rod 4 are connected together by the lower pin bolt 5.

[0029] The positioning g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com