Automatic overturning and throwing equipment for organic garbage fermentation

A technology for turning and throwing equipment and organic waste, which is applied in the direction of organic fertilizers and climate change adaptation. It can solve the problems of unprofessional adjustment, low degree of automation, and large physical damage, and achieve the effect of improving the efficiency of turning and throwing and the degree of automation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings.

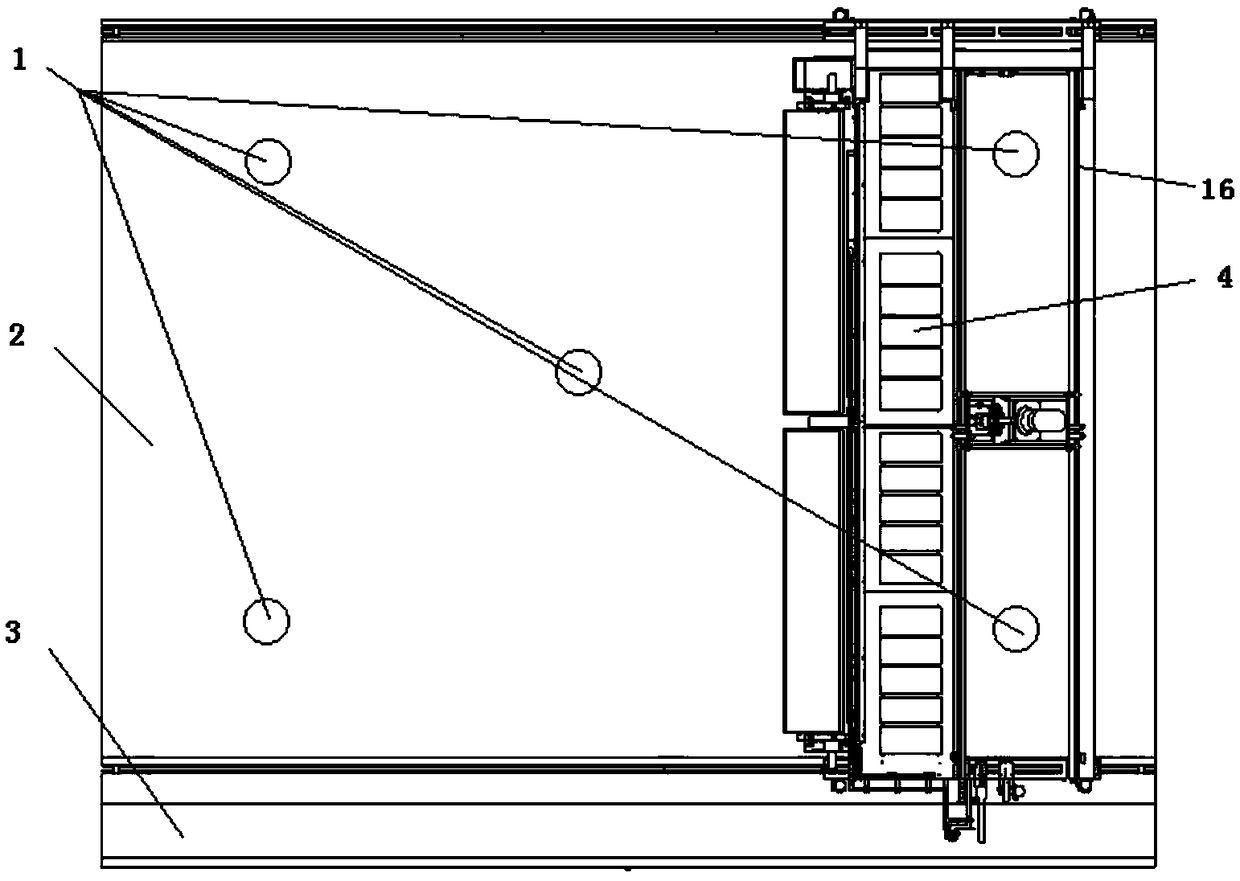

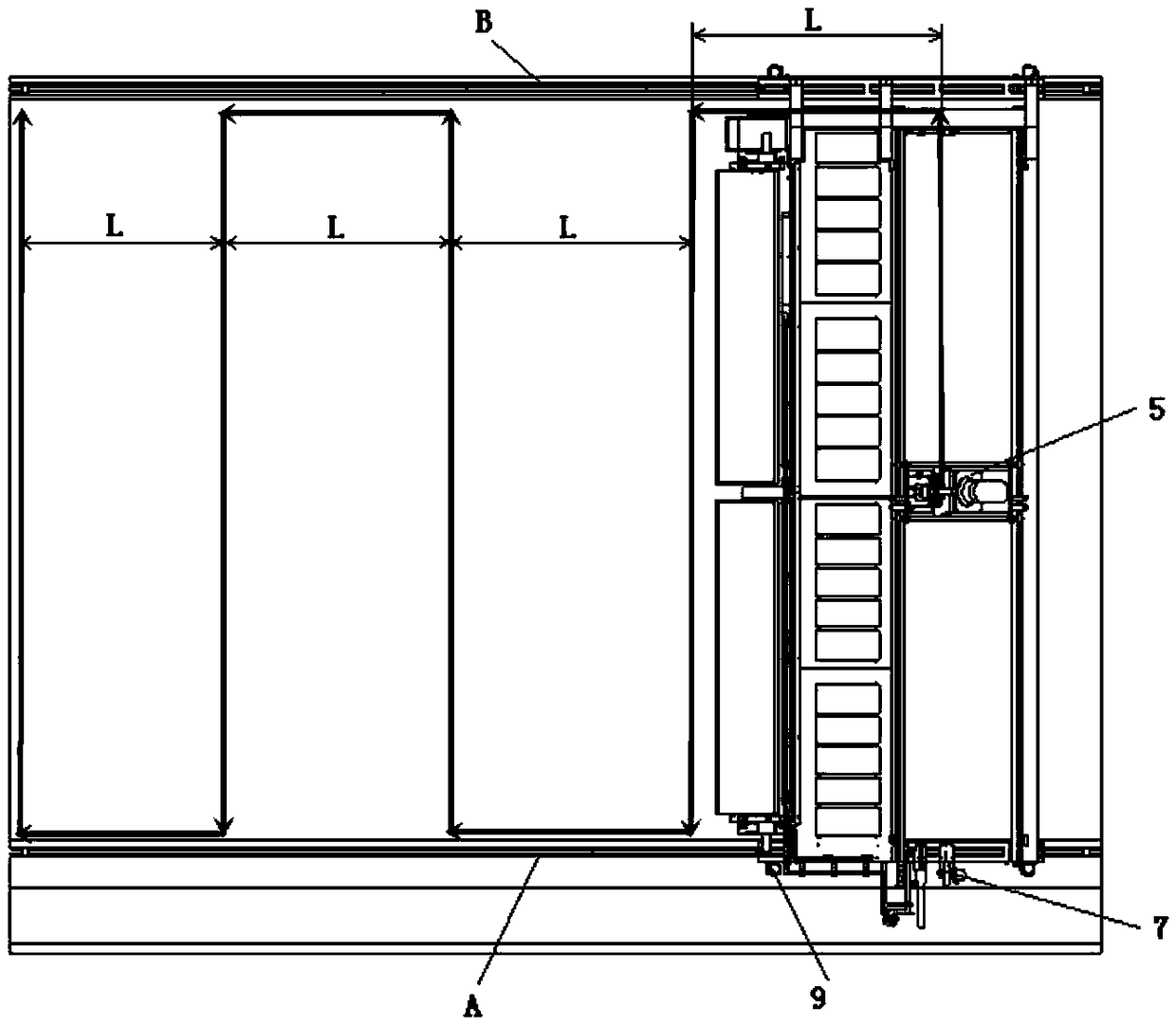

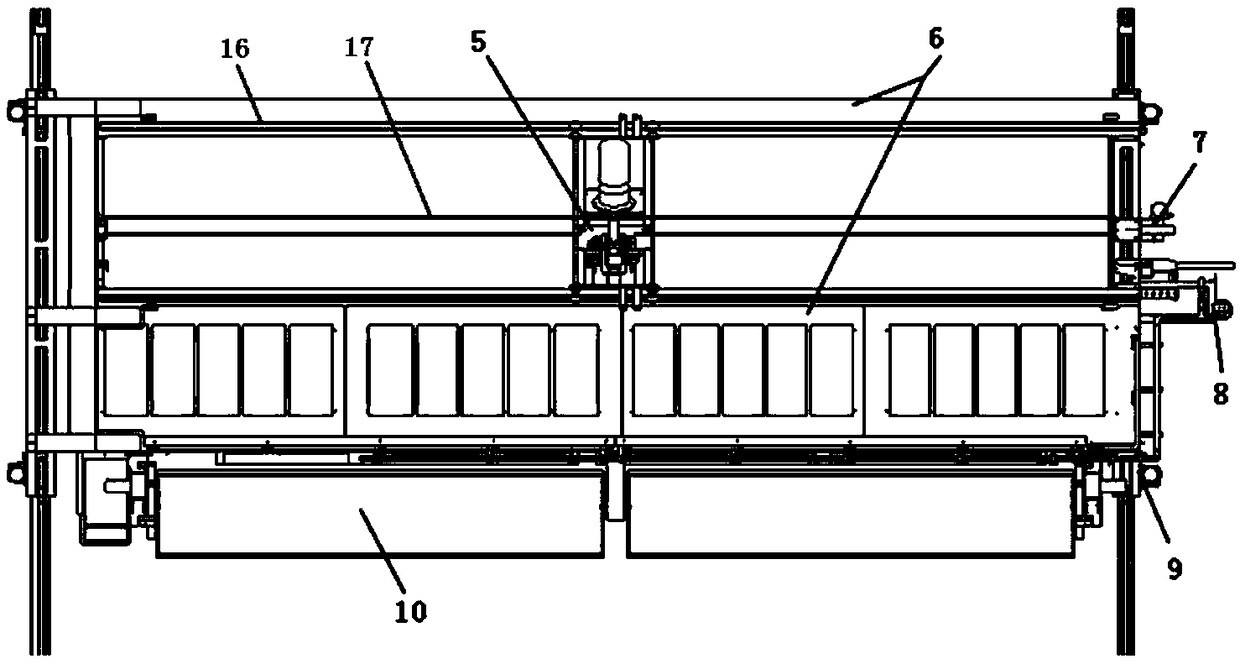

[0065] like figure 1 As shown, the infrastructure of the present invention is divided into a fermentation tank 2, a water storage tank 3 and a throwing device 3. The throwing device 3 is located above the fermentation tank 2 . The fermentation tank 2 is used for the fermentation of organic materials, and the water storage tank 3 is used for supplementing the water required for biological fermentation. Five groups of sensors 1 are buried at the bottom of the fermentation tank 2, and the five groups of sensors 1 are distributed at five sampling points at the bottom of the tank. Each group of sensors 1 includes a temperature sensor, a humidity sensor and an oxygen concentration sensor. Steel rail 16 is installed above the two side walls of fermentation feed tank 2, and the turning and throwing equipment is pressed on the rail 16 by the track wheels on both sides, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com