Vehicle roof fairing installing method of rail vehicle

An installation method and rail vehicle technology, which are applied to railway car body, transportation and packaging, railway car body parts, etc., can solve problems such as easy formation of water accumulation, and achieve the effect of simple process, high aesthetics and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with examples. However, the invention is not limited to the examples given.

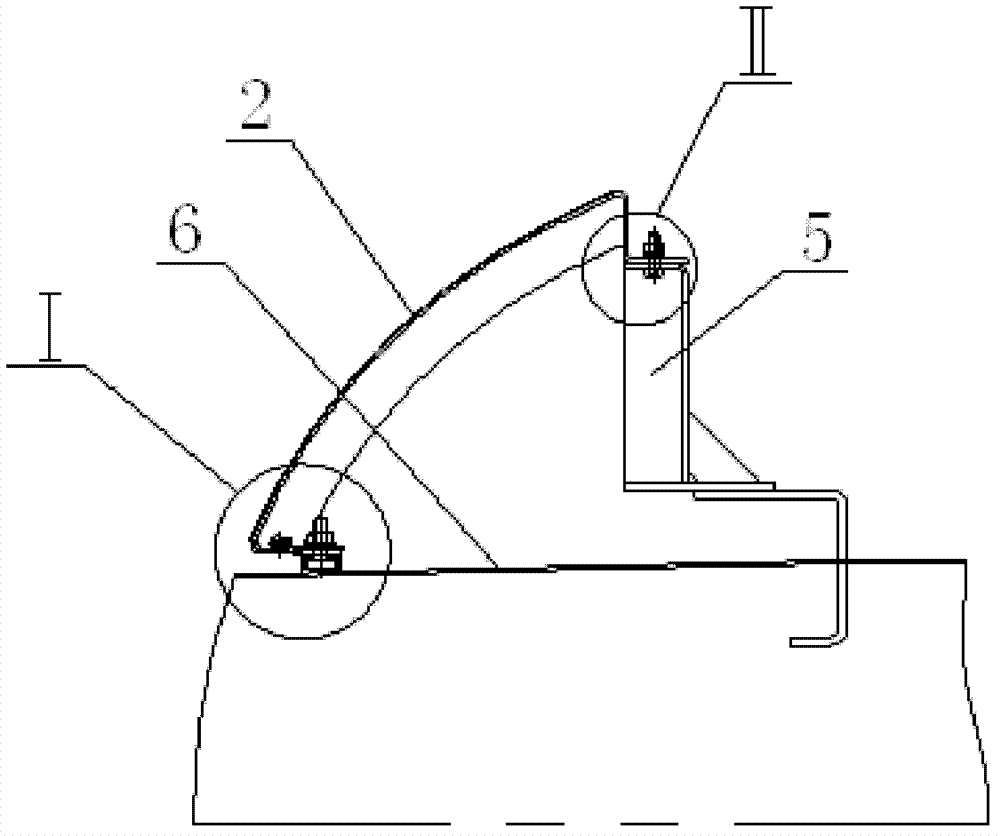

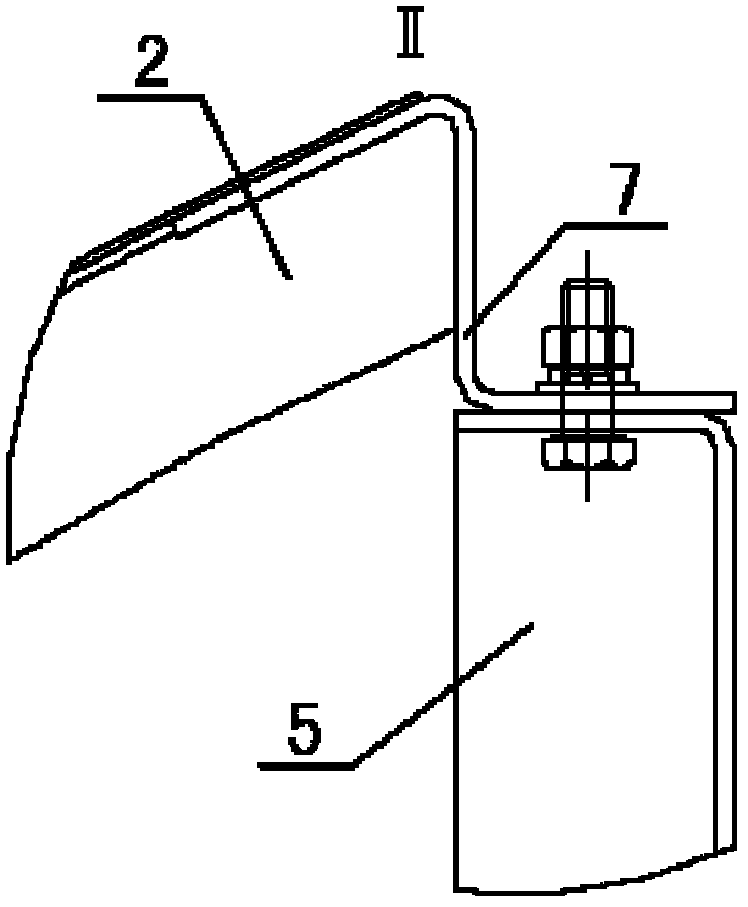

[0019] like figure 1 , figure 2 , image 3 As shown, the rail vehicle roof deflector to be installed for the invention comprises: an arc deflector plate 2, a fixed frame 5 welded on the inside of the flat top 6 of the car body, and a mounting seat welded on the outside of the flat top 6 of the car body 1. The upper end surface of the mounting seat 1 has an inverted T-shaped chute opened longitudinally along the flat top of the car body, and the upper end of the arc-shaped spoiler plate 2 is welded with a Z-shaped connecting plate 7, and the upper end of the Z-shaped connecting plate 7 and the fixed frame 5 Connected by bolts, the lower end of the arc-shaped shroud plate 2 is welded with a hinge 3 , the hinge 3 is fixed to the mounting seat 1 by bolts, and an adjusting gasket 4 is arranged between the hinge 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com