PFF integral composite reversed filtering layer and construction method thereof

A composite anti-filter layer and integrated technology, which is applied in artificial islands, water conservancy projects, infrastructure engineering, etc., can solve problems such as vertical molding, multiple demoulding processes, loose integrity, and difficult formation of the anti-filter layer, and achieve construction The effect of easy quality assurance and simplified construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

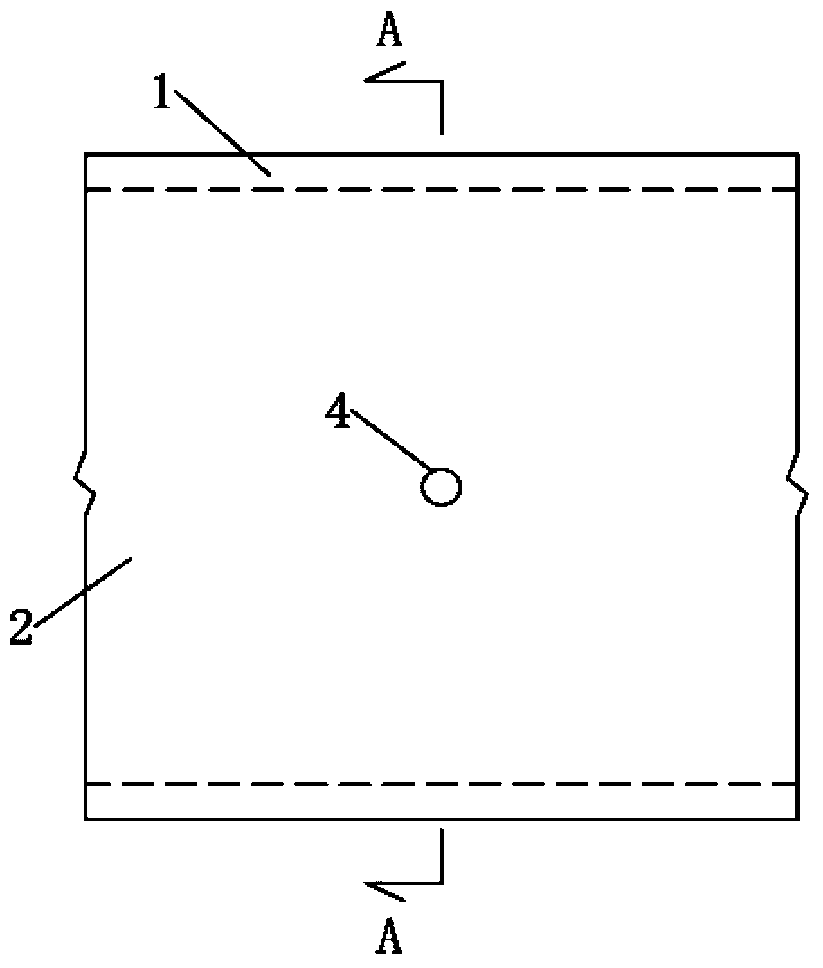

[0034] As shown in the figure, a PFF integral composite reverse filter layer has a rectangular plate-shaped structure with a width of 0.2 to 6 meters, preferably 0.5 to 2 meters. The length can be determined according to the use and transportation requirements, but the preferred Packed in rolls.

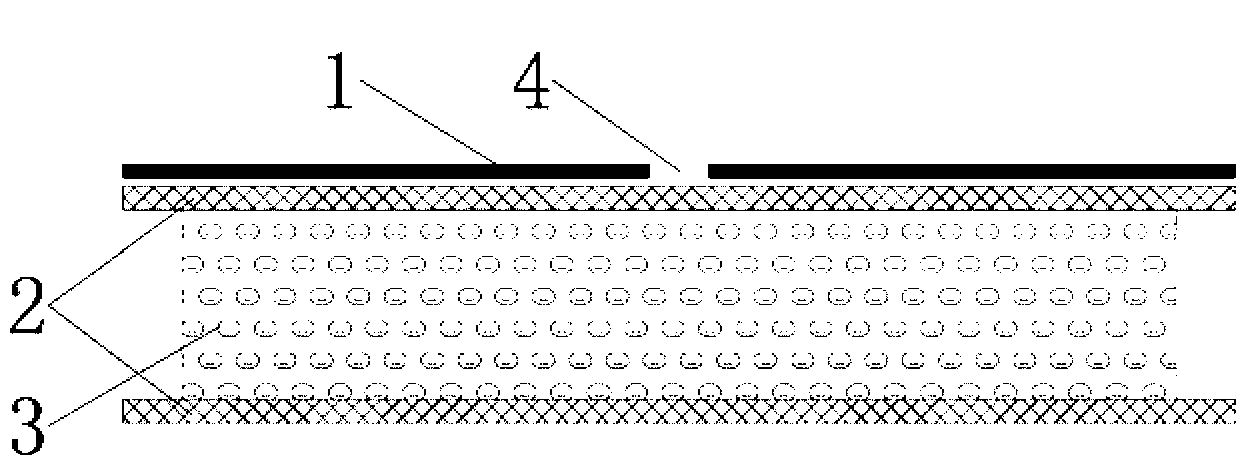

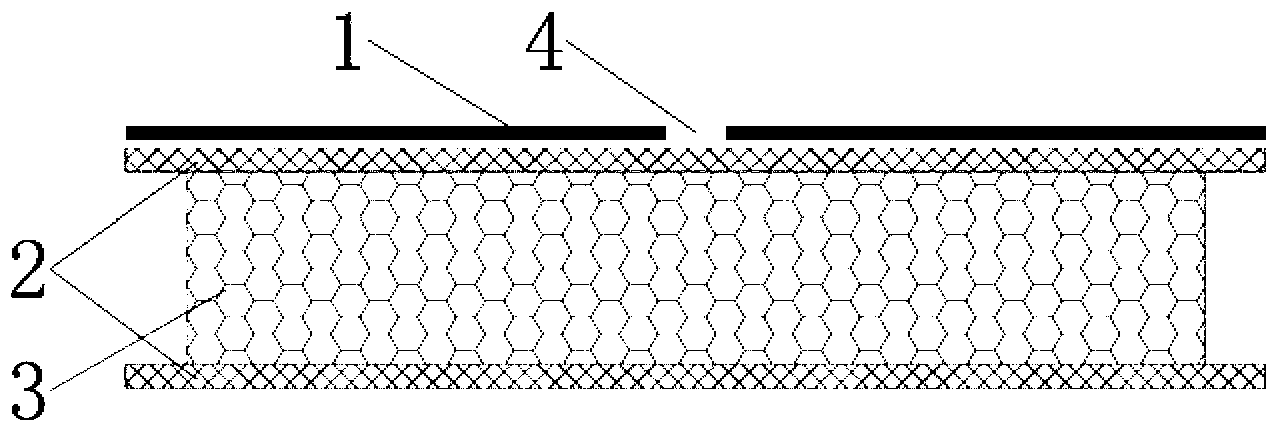

[0035] The PFF integrated composite reverse filter layer described in this embodiment includes an integral structure composed of a water-repellent layer 1, a reverse filter permeable layer 2 and a reverse filter drainage layer 3. The reverse filter permeable layer 2 is arranged on the water-resistant layer 1 And between the filter drainage layer 3.

[0036] In this example:

[0037] The role of the water-resistant layer 1 has the follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com