Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

380results about How to "Good reinforcing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

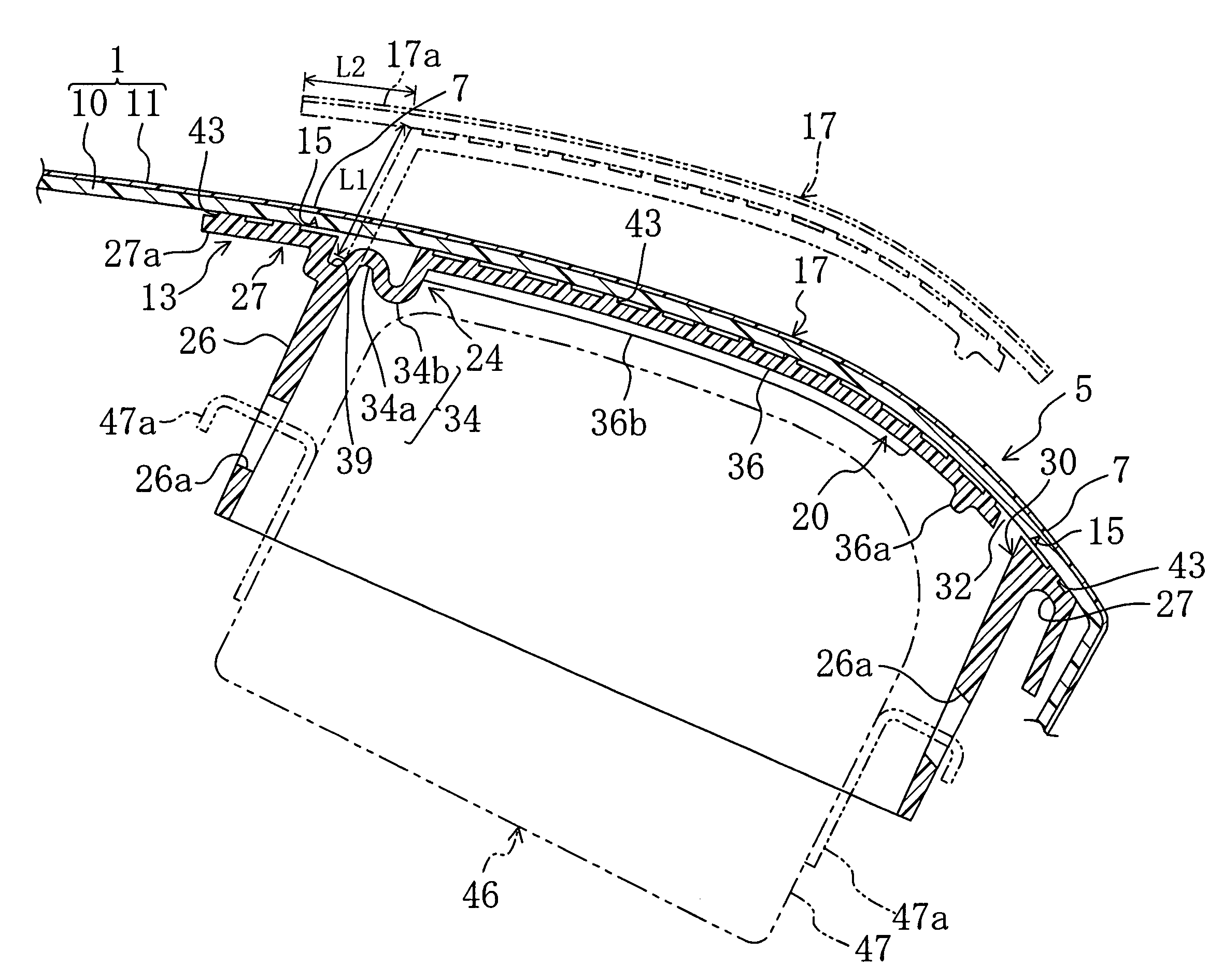

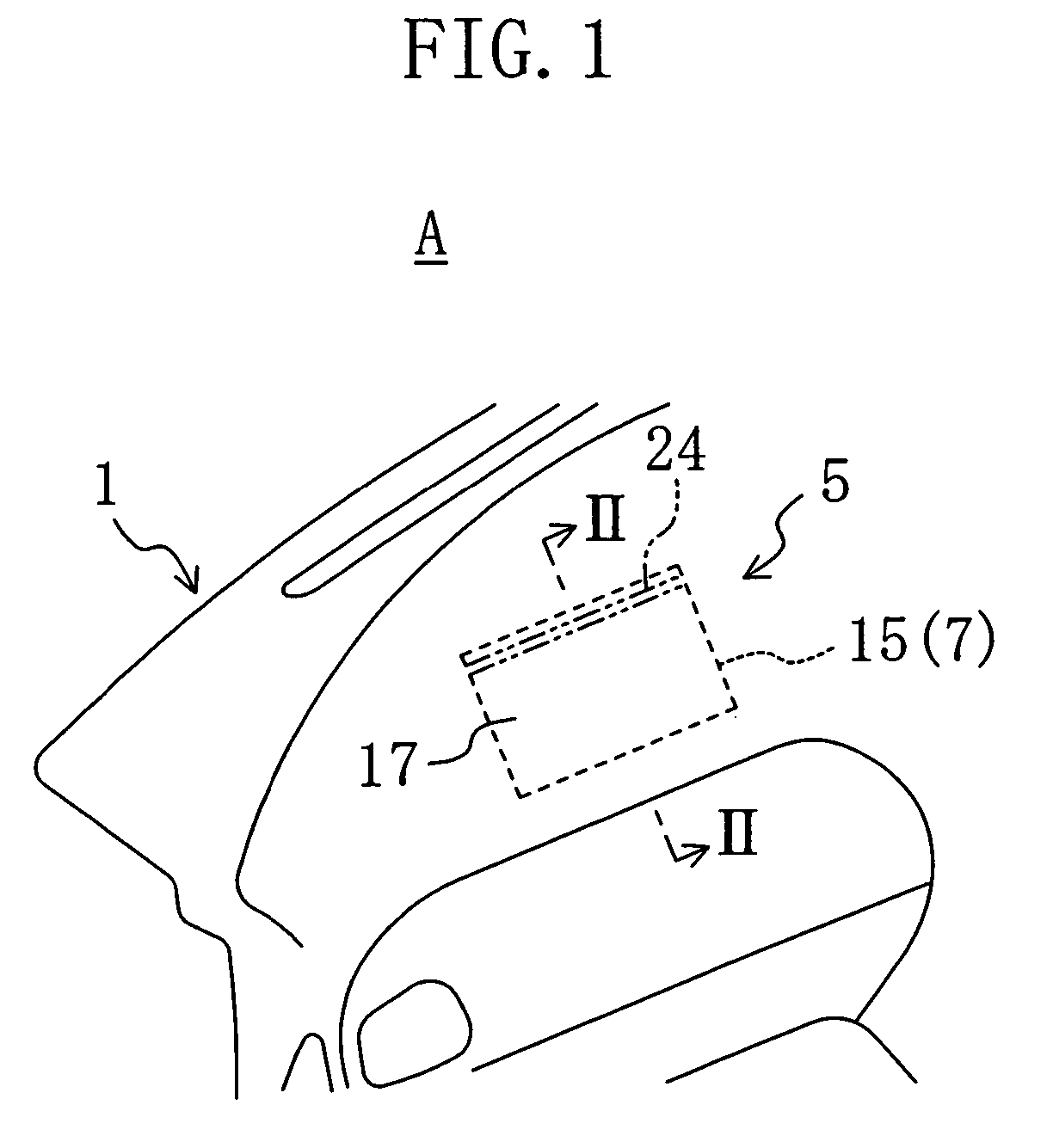

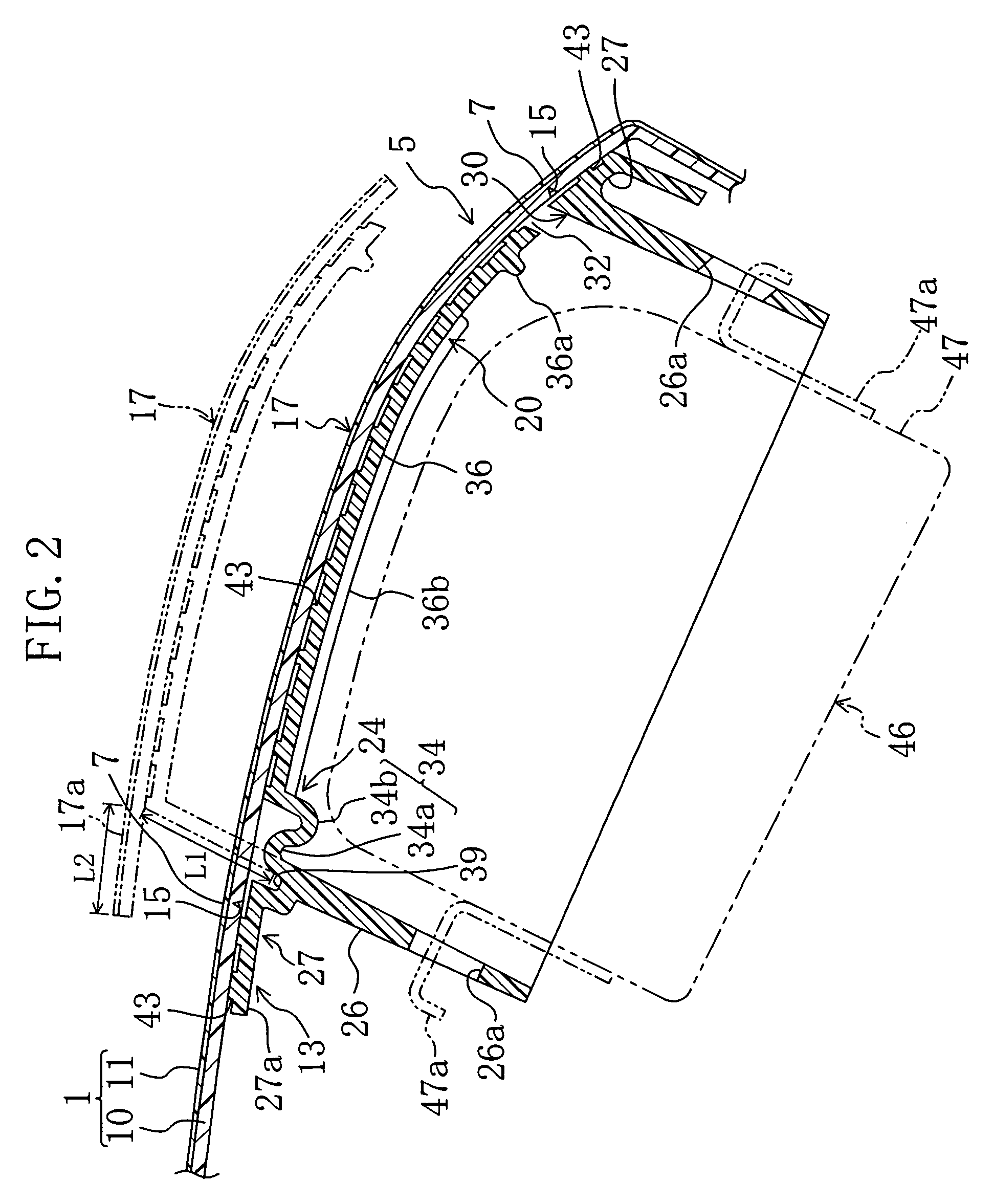

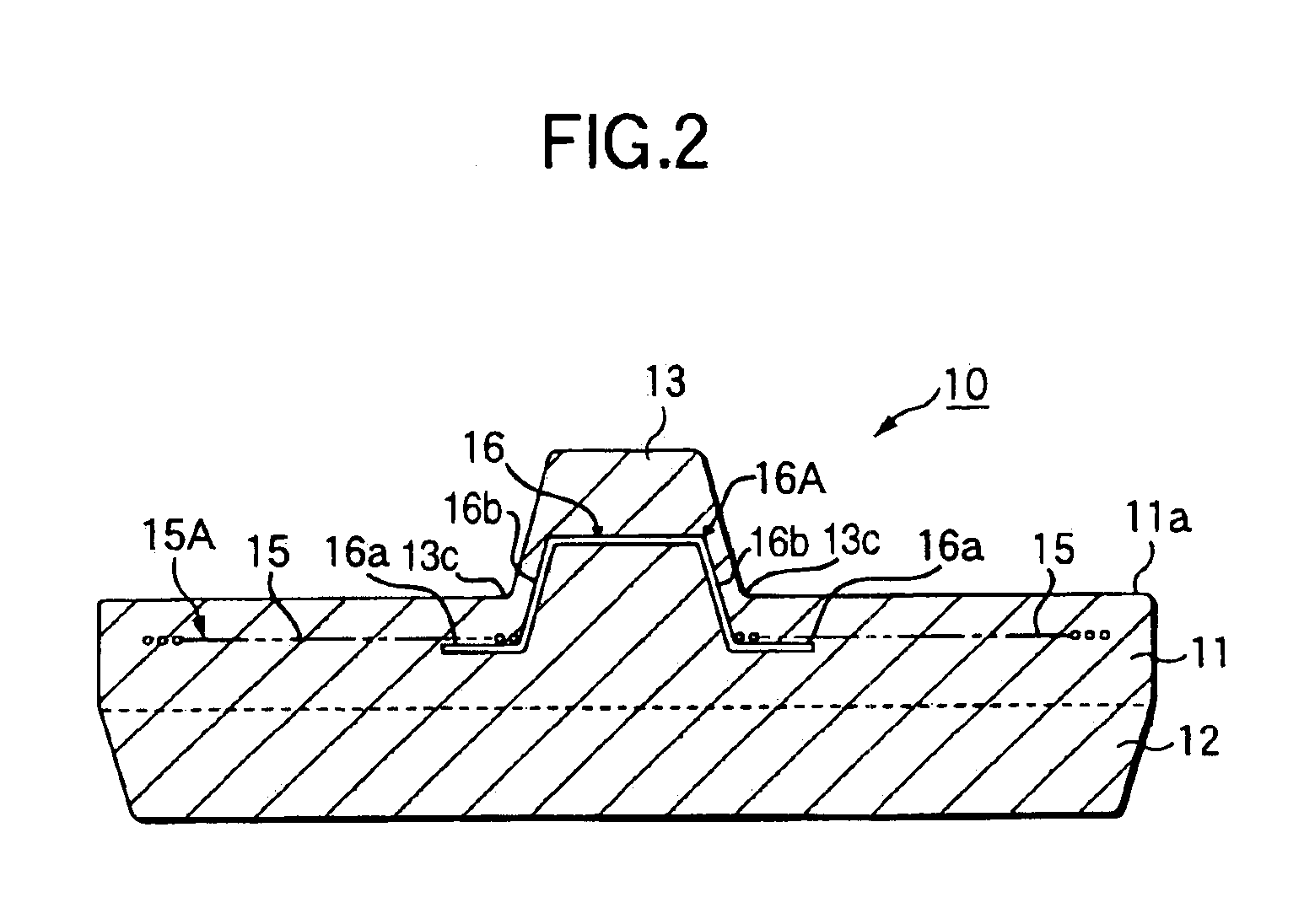

Vehicle air bag door

ActiveUS7178825B2Cracking and scattering can be preventedGood reinforcing effectPedestrian/occupant safety arrangementElectrical and Electronics engineering

Owner:DAIKYONISHIKAWA CORP

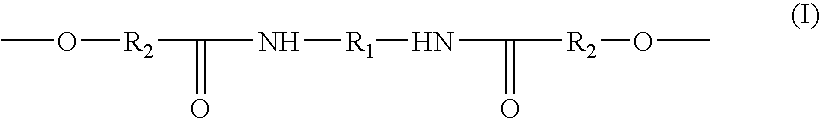

Size composition

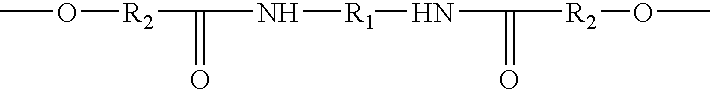

InactiveUS20080081870A1High impact strengthOvercome disadvantagesLiquid surface applicatorsCoatingsStructural unitPolymer chemistry

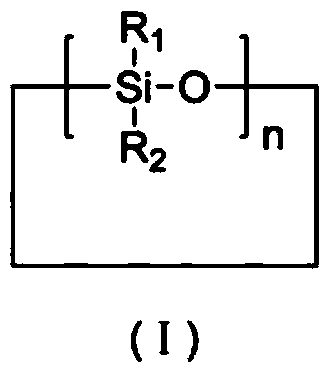

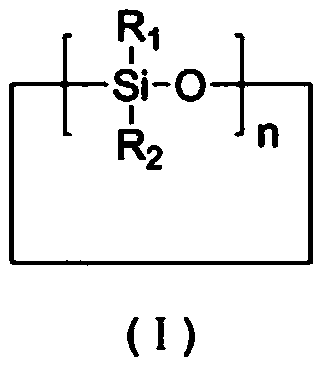

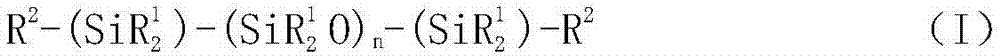

The invention relates to polyurethane-polyurea dispersions comprising structural units of formula (I) in which R1 is an aliphatic or cycloaliphatic radical having 2 to 18 C atoms and R2 is an aliphatic radical having 3 to 5 C atoms. Preparation of the polyurethane-polyurea dispersion and use as a size composition is also disclosed.

Owner:BAYER MATERIALSCIENCE AG

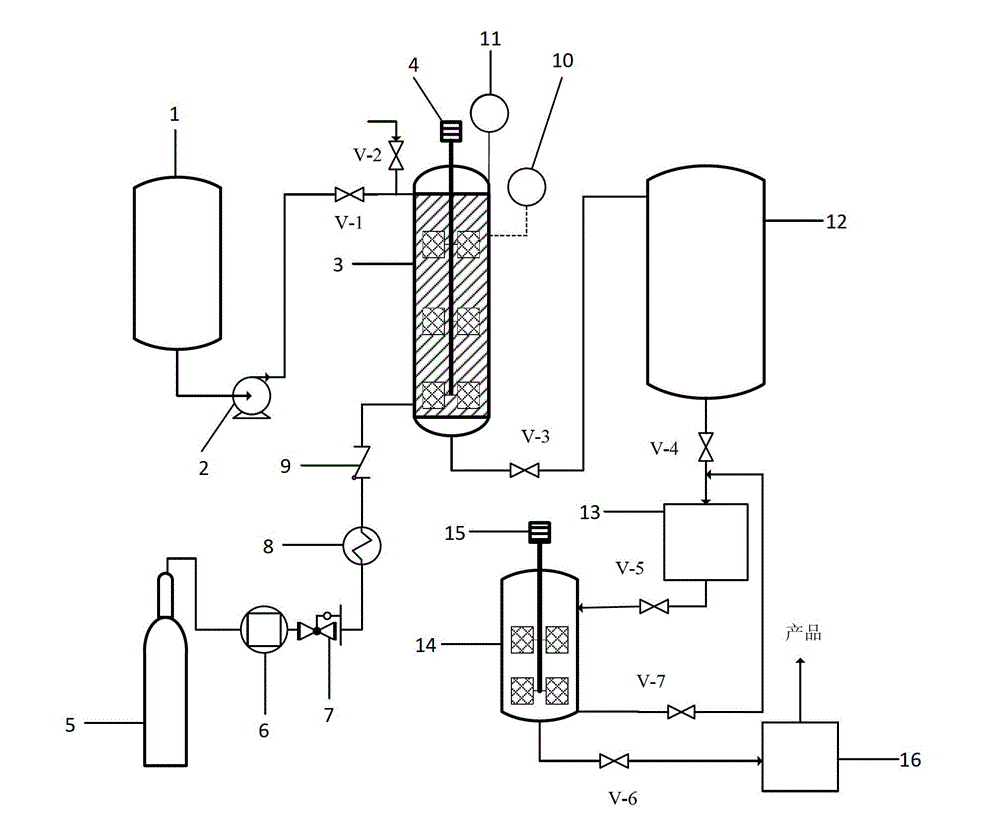

White carbon black rubber reinforcer and preparation method thereof

The invention relates to white carbon black rubber reinforcer and a preparation method thereof, and relates to rubber reinforcers. The white carbon black rubber reinforcer is white carbon black powder. By weight percent, nanoparticles in the white carbon black powder account for more than 80% of the total white carbon black powder. The preparation method includes: adding sodium silicate solution into a reactor, adding surfactant and silane coupling agent, heating, preheating carbon dioxide by a preheater, and adding the preheated carbon dioxide in the reactor for reaction to obtain reaction liquid; relieving the reactor to normal pressure, transferring the reaction liquid in the reactor to an ageing tank, and allowing for ageing to obtain aged slurry; rinsing and filtering the aged slurry, subjecting the aged slurry to solid-liquid separation to obtain filter cakes, washing the filer cakes, adding water to make slurry, adding sulfuric acid solution for acidification to keep pH of the acidified slurry at 3-7, continuing to filter and rinse until detected filtrate of saturated barium hydroxide solution has no precipitation, making the rinsed filter cakes into slurry, and drying the slurry to obtain the white carbon black rubber reinforcer.

Owner:XIAMEN UNIV

Single-component dealcoholization-type organic silicon sealant

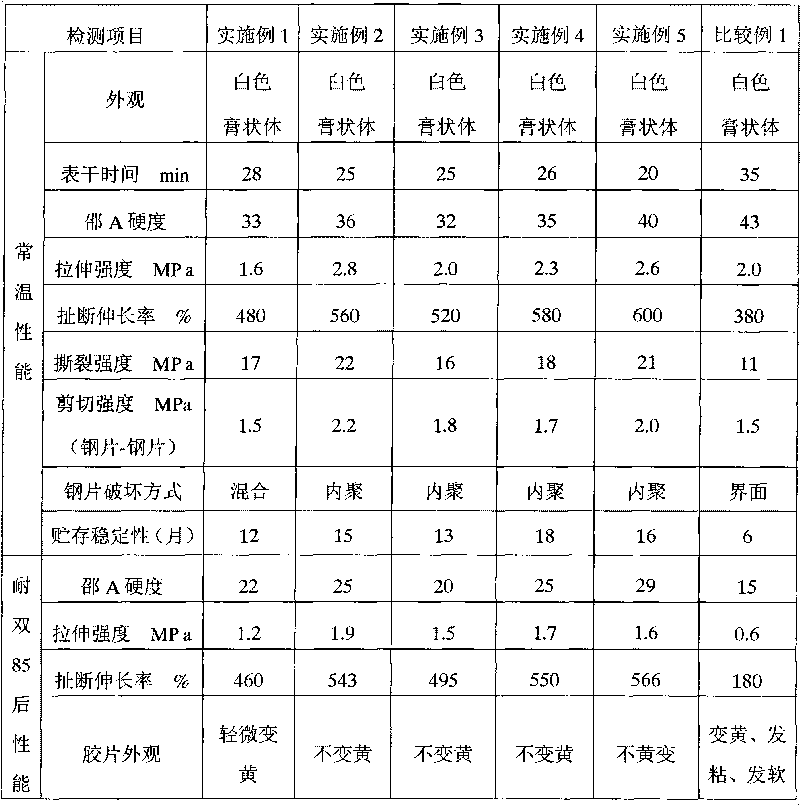

InactiveCN101760172AReduce the requirements of the production processIncrease crosslink densityOther chemical processesAdhesivesChemistryCalcium carbonate

The invention relates to a single-component dealcoholization-type organic silicon sealant which belongs to the technical field of single-component organic silicon sealant and mainly solves the problem of poor adhesiveness and storage stability of the traditional sealant. The single-component dealcoholization-type organic silicon sealant comprises the following components in percentage by weight: 30-70 wt% of hydroxy-terminated poly dimethylsiloxane polymer, 15-50 wt% of nano-scale calcium carbonate, 2-10 wt% of alkoxy silane crosslinker, 0.1-3 wt% of titanate chelate catalyst, 1-5 wt% of thixotropic agent, 0.05-2 wt% of titanate catalyst, 0.1-2 wt% of coupling agent and 0.5- 5wt% of silicone oil plasticizer. The invention has favorable mechanical performance and excellent adhesiveness as well as double-85 resistant performance, has simple construction process and is widely used for splicing and sealing solar modules in the solar photovoltaic industry.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

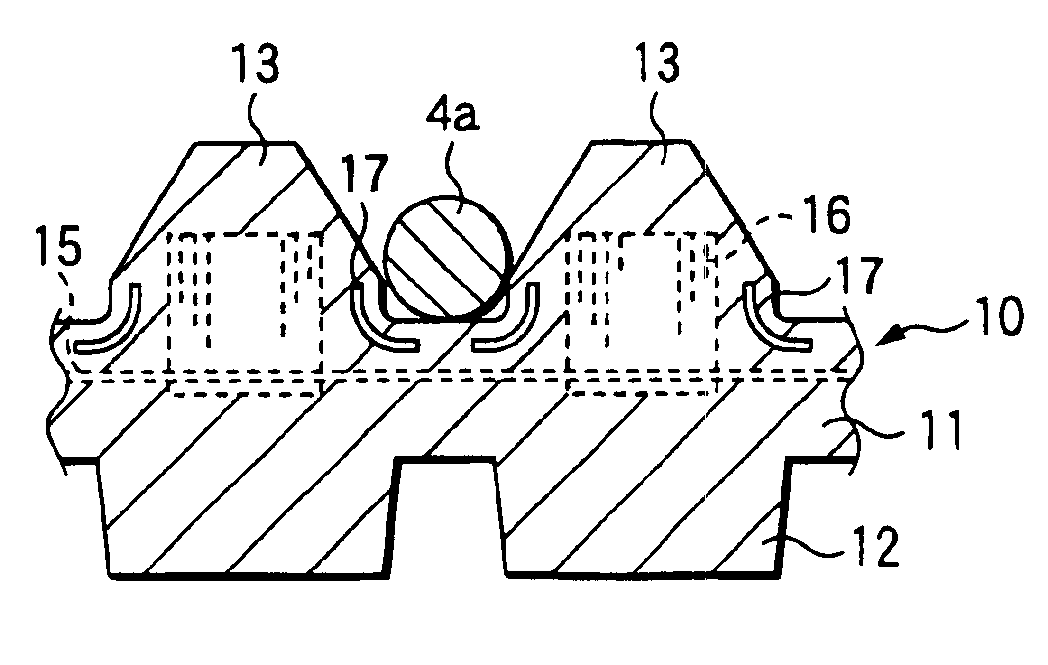

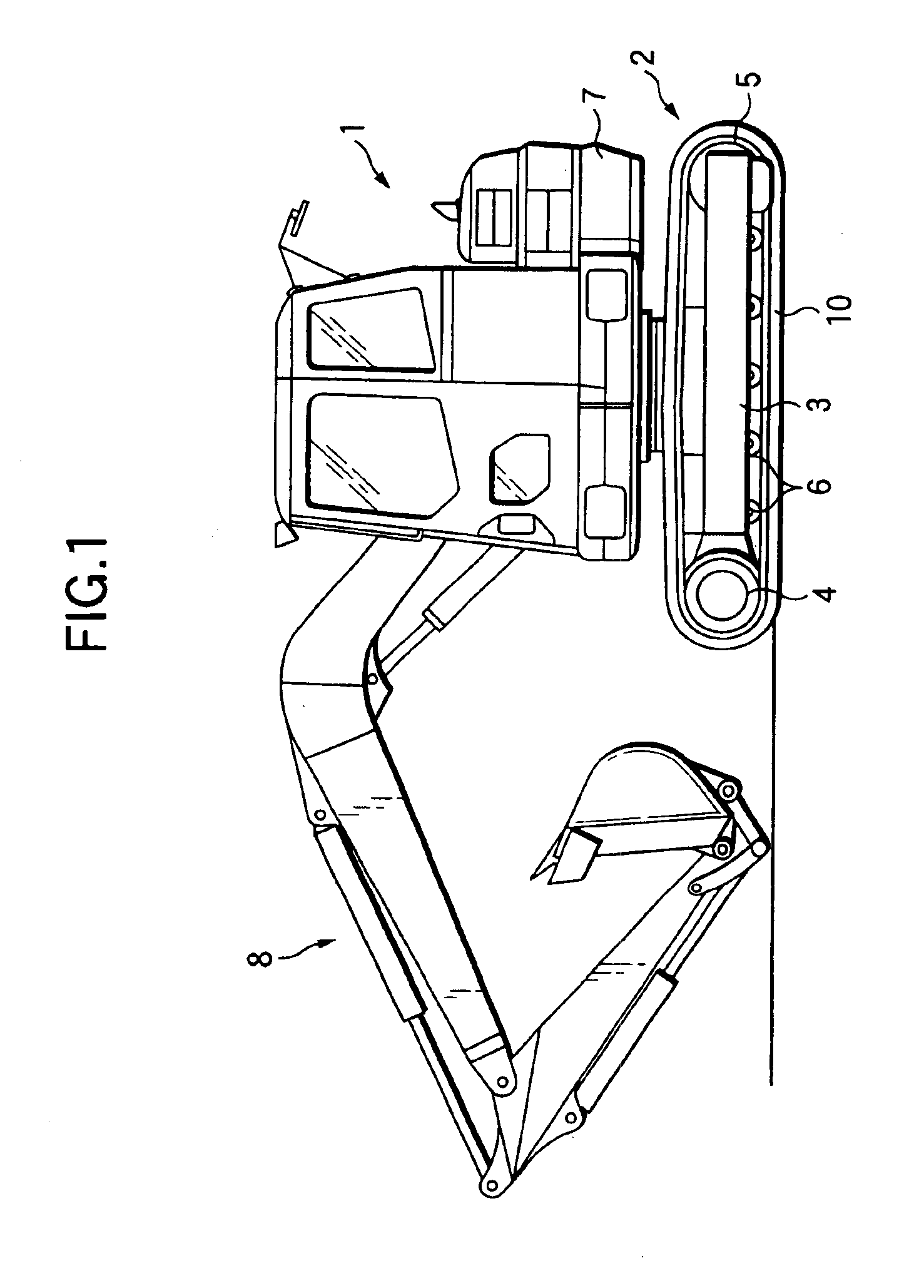

Elastic-bodied crawler

InactiveUS6932442B2Increased durabilityDriven projectionDriving beltsEndless track vehiclesElastomerEngineering

An elastic-bodied crawler, in which damages, such as local wear, coming-off of driven projections and the like in use, are prevented from being brought about, and frictional resistance is decreased at engaging portions to provide for durability, comprises a body with a reinforcement layer of reinforcement cables embedded therein circumferentially, driven projections provided in a predetermined pitch on an inner peripheral surface of the body, lug portions formed on an outer surface of the body, and reinforcement members (driven projection reinforcement cables) embedded to bridge the driven projections and the body.

Owner:KOMATSU LTD

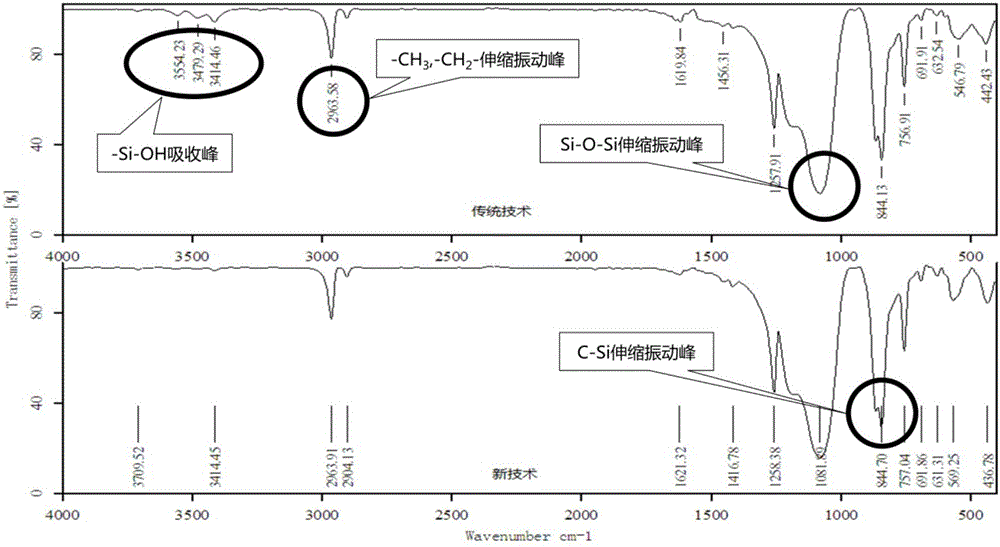

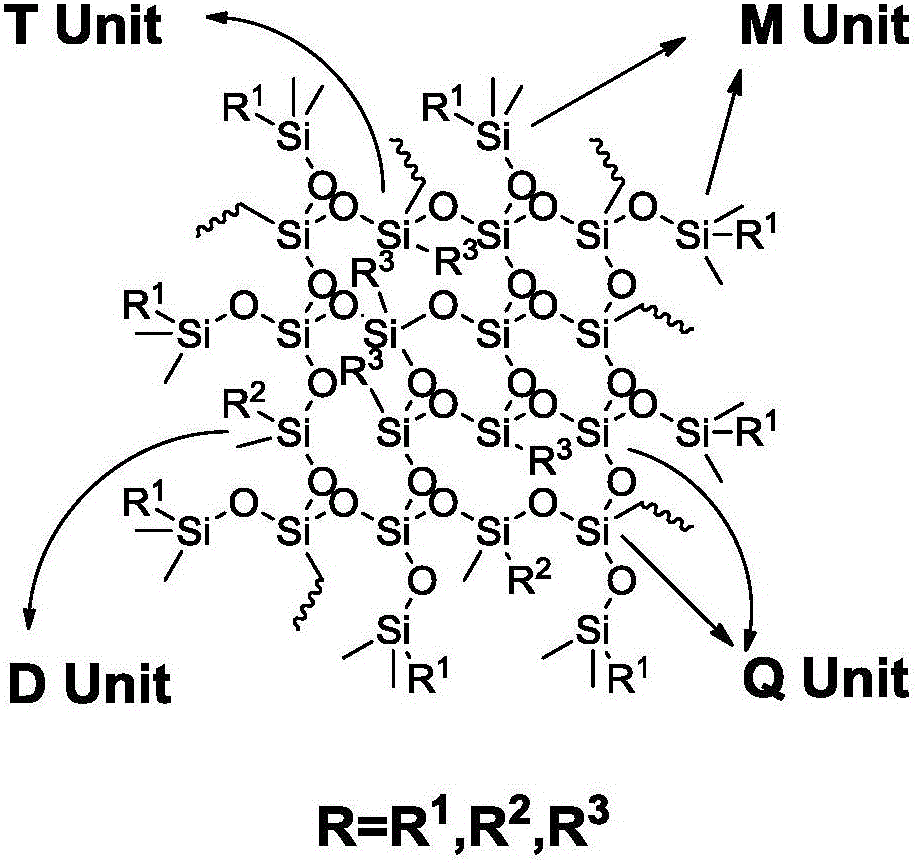

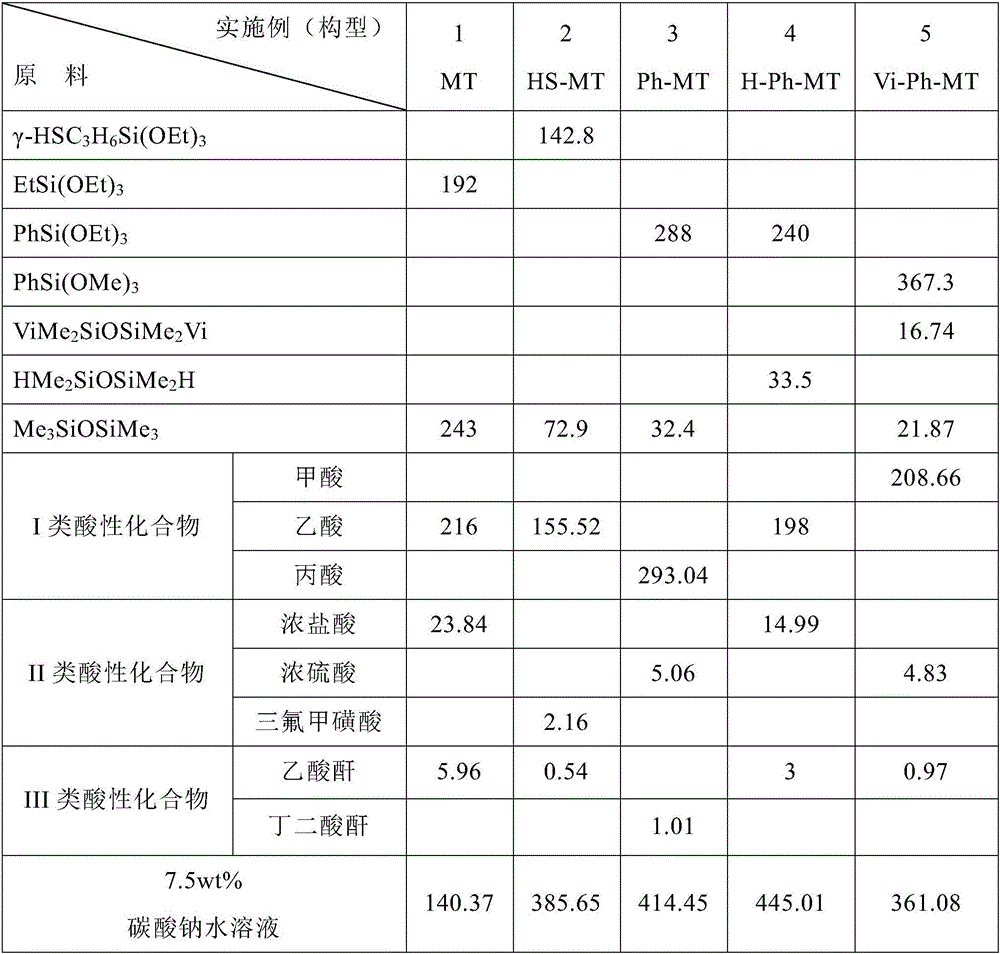

Preparation method of organopolysiloxane resin

The invention discloses a preparation method of organopolysiloxane resin. The preparation method includes the steps of (1), taking alkoxyorganosilane, an end-capping reagent and an acidic compound as preparation raw materials; (2), feeding the preparation raw materials with uniform stirring, wherein the feeding molar ratio of the end-capping reagent to the alkoxyorganosilane to the acidic compound is (0-40):1:(0.2-5); (3), adjusting the temperature at 40-150 DEG C at which condensation polymerization reaction is conducted for 2-20 hours; (4), terminating the condensation polymerization reaction, adjusting a reaction mixture to be neutral, and purifying a reaction product so as to obtain the organopolysiloxane resin. The preparation method of the organopolysiloxane resin has the advantages of environmental protection and no pollution during production, low energy consumption, short period, high product yield and the like and is more excellent in performance.

Owner:GUANGDONG BIOMAX SIANDF NEW MATERIAL CO LTD

Vinyl silicon resin for reinforcing organic silicon pouring sealant and preparation method thereof

The invention discloses a vinyl silicon resin for reinforcing an organic silicon pouring sealant and a preparation method thereof. The preparation method comprises the following steps of: adding an appropriate amount of hexamethyl disiloxane and tetramethyl divinylsiloxane into a mixture of hydrochloric acid, an organic solvent and water to perform reaction for some time and then adding tetraethoxysilane and bis-functional or trifunctional siloxane to perform reaction; adding a certain amount of hexamethyl disiloxane and tetramethyl divinylsiloxane according to circumstances, standing and demixing after the reaction is finished, washing lower mixed liquor with deionized water until the liquor is neutral, and drying the liquor to obtain the vinyl silicon resin. The spherical core of the silicon resin prepared by the method, namely SiO2 has high content, and the spherical shell is tightly encircled by an R3SiO0.5 layer, so the silicon resin has good reinforcing effect; and the resin hashigh solubility or dispersibility in silicon rubber, can be separately used as a reinforcing filler for the organic silicon pouring sealant, and can also be matched with other fillers, so that the organic silicon pouring sealant with required performance can be obtained.

Owner:GUANGZHOU GLORYSTAR CHEM +1

Reinforced plastic pipe

InactiveUS20070062595A1Adding to of cost of manufactureAdding to weightSynthetic resin layered productsCorrosion preventionBursting strengthPolyolefin

Plastic pipes, such as high density polyethylene plastic pipes, useful for distributing natural gas and which have improved impact resistance and burst strength. The plastic pipe has an inner and an outer surface, with the inner surface defining a channel for conveying natural gas and the like. A fabric overlies the outer surface, preferably in a helical wrap. The fabric is formed of high tenacity polyolefin fibers, preferably polyethylene and / or polypropylene fibers. The fabric provides the pipe with improved burst strength and impact resistance. The pipe can be used to transport natural gas under low pressure or higher pressures.

Owner:HONEYWELL INT INC

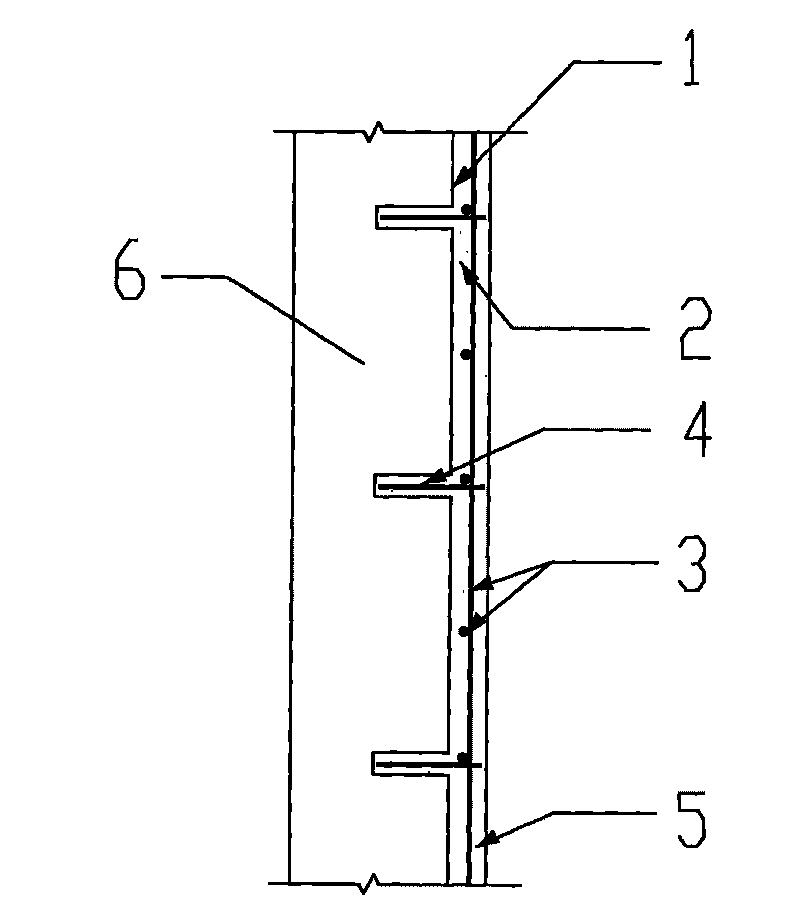

Building strengthening method

InactiveCN101691818AGood reinforcing effectWork together wellBuilding repairsPolymer modifiedFireproofing

The invention discloses a building strengthening method, which comprises the following steps of: 1) clearing the surface of a structure to be strengthened to expose a hard part; 2) carrying out water spray wetting on the structure to be strengthened; 3) implanting pins connecting a reinforcing steel bar net and the structure to be strengthened, and bonding the reinforcing steel bar net; 4) spraying an interface agent coating on the surface of the structure to be strengthened; and 5) spraying a polymer modified cement mortar bond layer and a polymer modified cement mortar protective layer by layers on the interface agent coating. The method can effectively improve the bearing capacity of the structure to be strengthened, improves the rigidity of the structure to be strengthened, and has less occupied space; a molded surface strengthening structure and the structure to be strengthened have the advantages of reliable bond, compactness, no crack, waterproofing, permeability resistance, fireproofing, high-temperature resistance, Cl-corrosion resistance, carbonization prevention, rust resistance and good durability; and a construction process is simple, formworks are not needed to be built, the speed of improving the strength of polymer modified cement mortar is high, and a construction period is greatly shortened. The method can be simultaneously applied to repairing and strengthening of the existing concrete structures and masonry structures, and solves the problems of breakage and aging of materials and insufficient structural strength of an old building.

Owner:上海维固工程实业有限公司

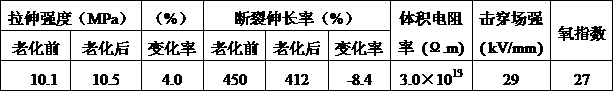

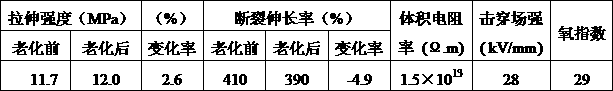

Ethylene-propylene-diene monomer rubber used for manufacturing wind energy cable and preparation method thereof

ActiveCN102617942AImprove mechanical propertiesEasy to stretchPolymer scienceDecabromobiphenyl ether

The invention discloses an ethylene-propylene-diene monomer rubber used for manufacturing a wind energy cable and a preparation method thereof. The ethylene-propylene-diene monomer rubber comprises the following components: 90-110 parts of ethylene-propylene-diene monomer rubber, 1-4 parts of anti-aging agent, 0.2-0.5 part of stearic acid, 2-9 parts of paraffin oil, 2-5 parts of lead sulfate tribasic, 1-4 parts of zinc oxide, 80-120 parts of activated kaolin, 0.3-1.5 parts of coupling agent, 0.5-2.6 parts of cross-linking agent, 0.5-2.0 parts of assistant crosslinker, 1-3 parts of semi-reinforcing carbon black, 1-4 parts of plasticizer, 0.5-2 parts of antimonous oxide, 0.5-2 parts of zinc borate, 1-5 parts of basic magnesium carbonate, 1-4 parts of antioxygen, 0.1-0.5 part of sulphur, 2-5parts of epoxidized soybean oil, 5-15 parts of decabromodiphenyl ether, 12-30 parts of antimony oxide and 2-5 parts of organic modified bentonite. The material has the advantages of wide applicable temperature range, god performance and long service life.

Owner:无锡市远登电缆有限公司

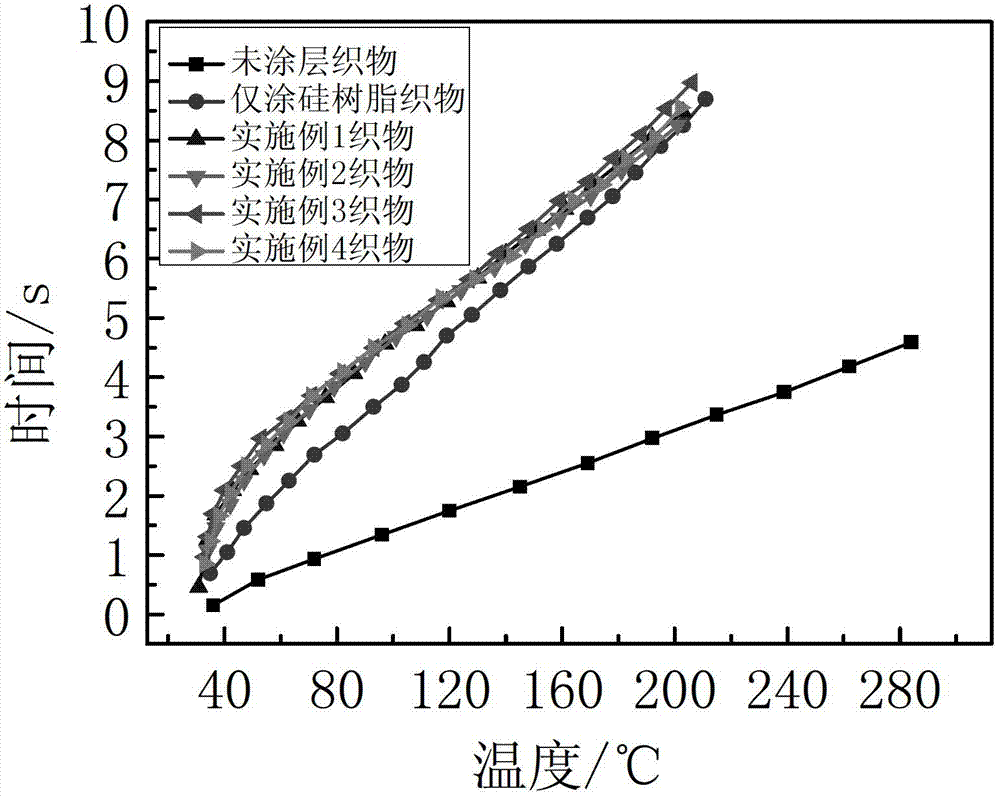

Heat-insulating and ablation-resistant glass fiber fabric and preparation method thereof

ActiveCN103205896AImprove heat resistanceImprove crack resistanceFibre treatmentResin coatingEngineering

The invention provides a heat-insulating and ablation-resistant glass fiber fabric and a preparation method thereof, belonging to the technical field of thermal protection fabrics and preparation thereof. The heat-insulating and ablation-resistant glass fiber fabric product comprises a fabric layer and coating layers on the front and back surfaces of the fabric layer, wherein the thicknesses of the coating layers on the front and back surfaces of the fabric layer are controlled at 30-80 micros; the fabric layer is made from glass fiber fabrics; the coating layers are composite organic silicon resin coating layers which are prepared by mixing an organic silicon resin solution, white carbon black, mica powder and the like in certain percentage by weight; a solute of the organic silicon resin solution is phenyl methyl silicone, a solvent of the organic silicon resin solution is dimethylbenzene, toluene or a mixture of the two, and the mass ratio of the solvent to the solute is 1:1; and a preparation method of a composite organic silicon resin coating layer solution comprises the following steps of: sequentially adding the white carbon black, the mica powder, wollastonite in powder and metallic oxide into the organic silicon resin solution, and stirring to ensure that the substances are uniformly dissolved. The heat-insulating and ablation-resistant glass fiber fabric is simple in process, easy to operate, and excellent in heat resistance, weather resistance, insulating property, reinforcement performance, scrubbing resistance and weathering resistance.

Owner:赵晓明 +1

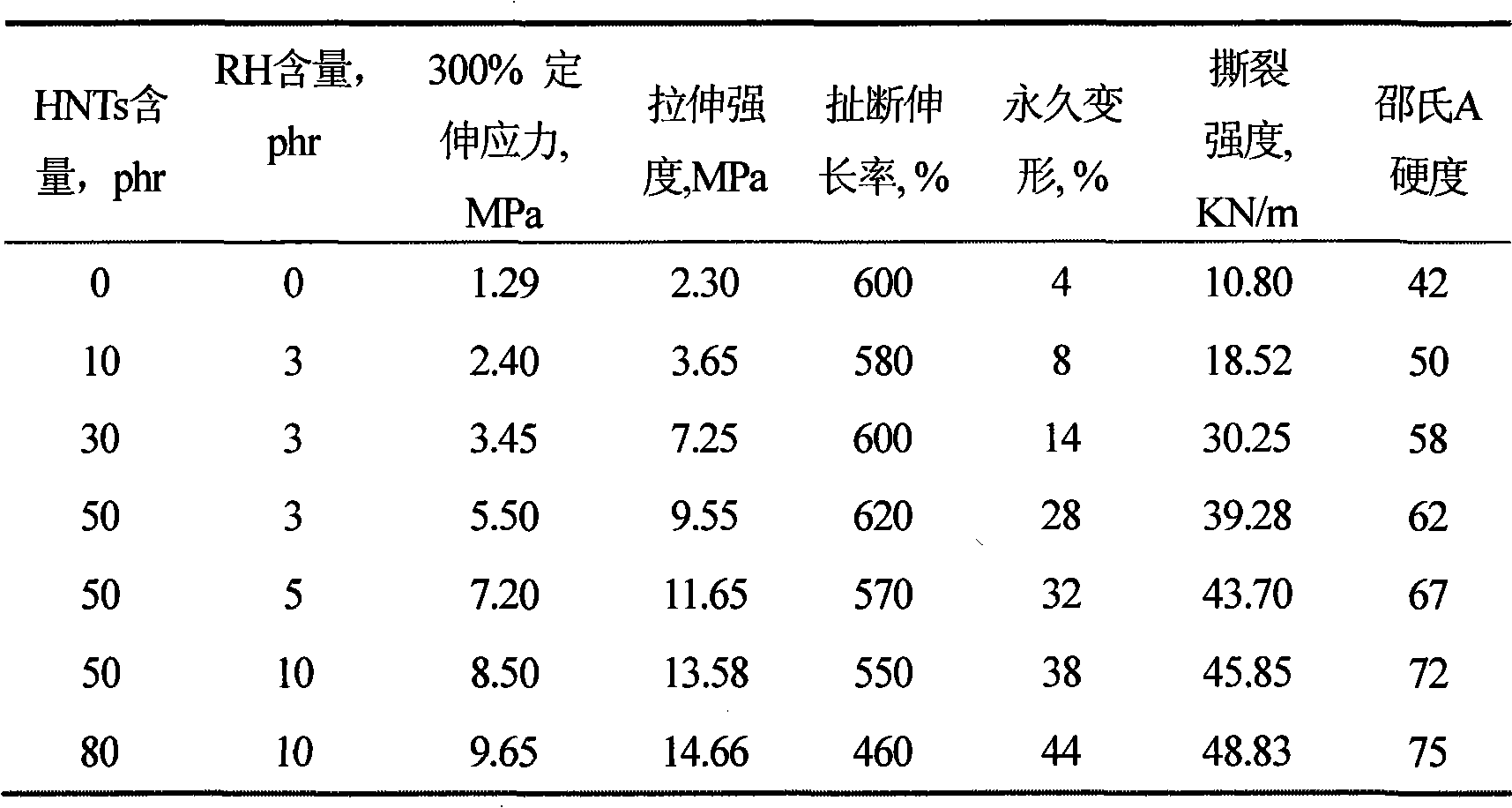

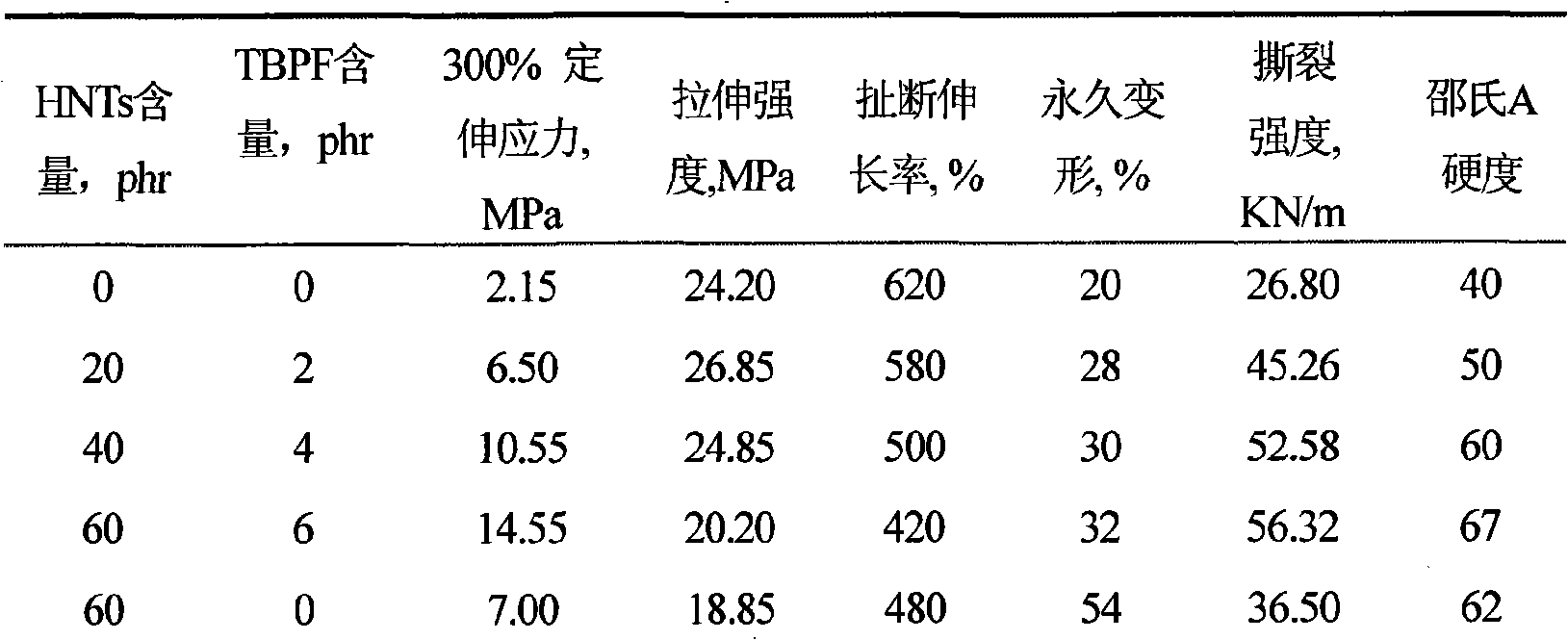

Preparation method for rubber/keramite nano-tube nano-composite material

The invention relates to preparation method of rubber / halloysite nanotube nano-composite material, the invention adopts the preparation method that the rubber, the halloysite nanotube and modifying agent are mixed according to the mass ratio of 100:5 to 100 : 0.5-20 through the ordinary rubber pugging equipment and technique, then the sulphation is performed through the ordinary sulphidizing process and equipment to realize the in-situ modification, and finally, the rubber / halloysite nanotube nano-composite material with nano-dispersion, good interfacial bonding and good performance. Wherein, the modifying agent comprises compound in-situ generated phenolic resin, alkyl phenolic resin, modified rubber, methacrylic acid metal salt and one or more than one mixture (s) in the sulfur-containing organosilane coupling agent. The preparation method of rubber / halloysite nanotube nano-composite material has the advantages that the defects that the rubber / halloysite nanotube nano-composite material is difficult to be dispersed, the interfacial bonding is not good, the performance can not be improved observably can be overcome, and the preparation method can be applied in a variety of rubber products, rubber toughening plastics and binding agents and the like.

Owner:SOUTH CHINA UNIV OF TECH

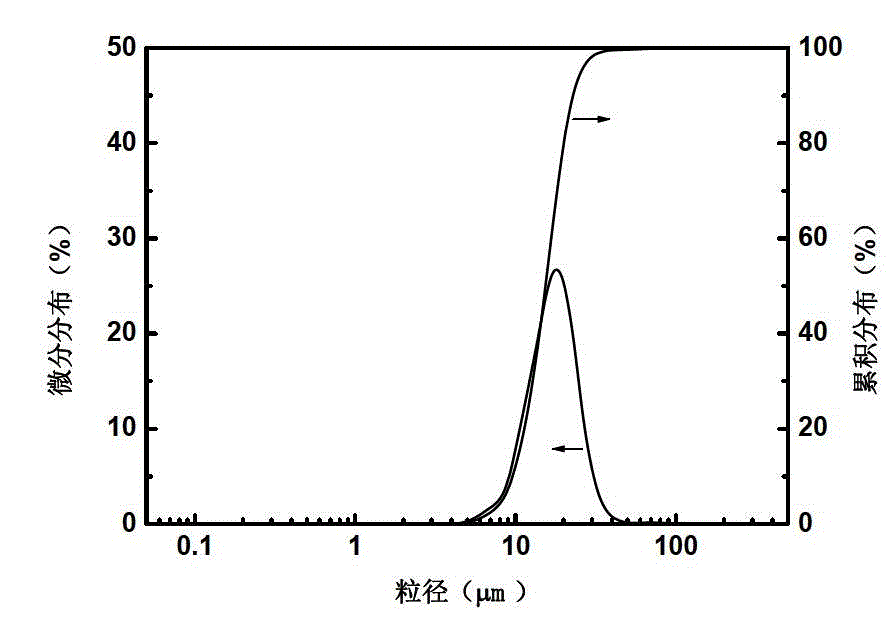

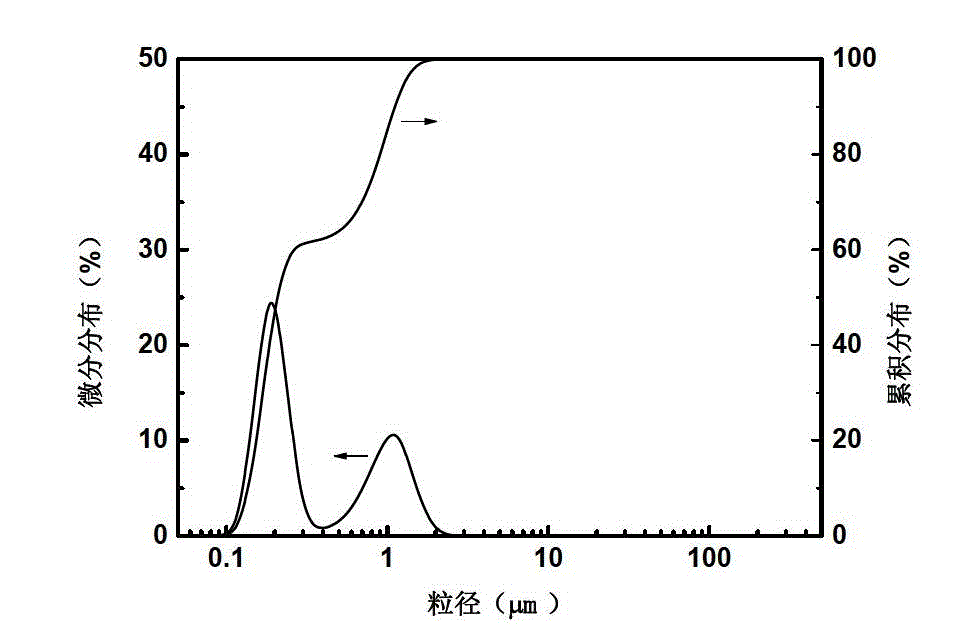

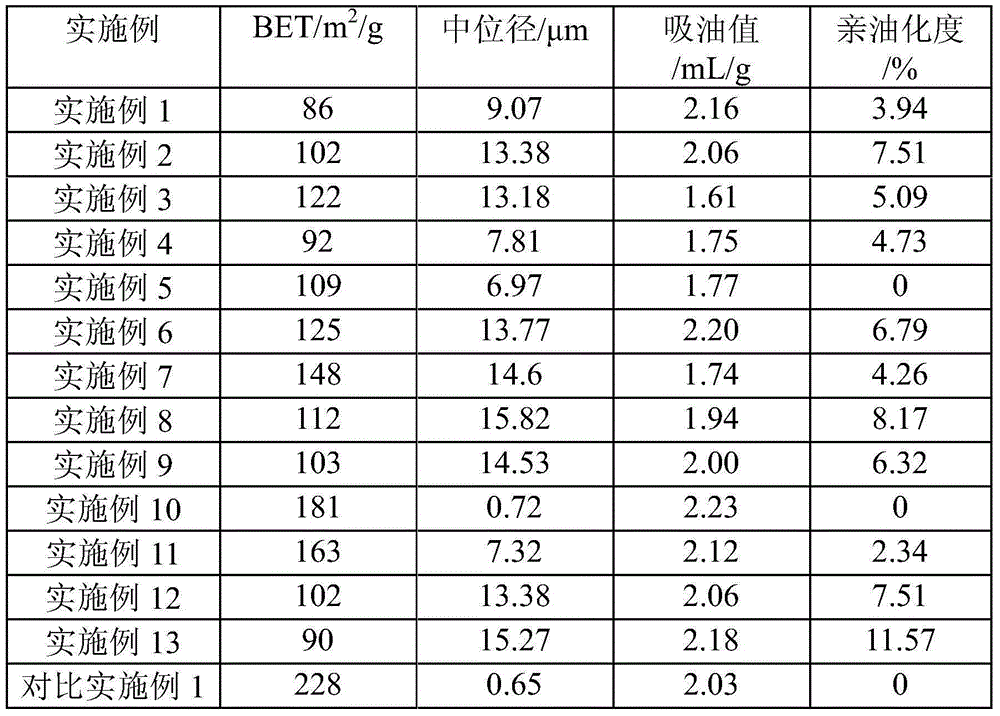

Preparation method for hydrophobic high-dispersion white carbon black

InactiveCN105060304AReduced surface hydroxyl contentReduce rolling resistanceSilicaReaction temperatureSodium silicate

The invention relates to a preparation method for hydrophobic high-dispersion white carbon black. According to the method, the hydrophobic high-dispersion white carbon black is prepared by taking sodium silicate and sulfuric acid as raw materials and using a silane coupling agent KH570 to modify through a precipitation method. The modulus of the sodium silicate in the method is 3.2-3.5, and the concentration of SiO2 in the sodium silicate is 0.67-2.01mol / L. The concentration of dilute sulphuric acid is 1.5-3.5 mol / L. The precipitation reaction temperature is 80-90 DEG C, and the pH value is 3.5-9. Dosage of a modifier accounts for 0.1-3% of the total volume of a reaction liquid, and the modifying reaction time is 30-150 minutes. Finally, the product is washed, filtered and dried. According to the preparation method, the hydrophobicity and the dispersion of conventional white carbon black are improved; the problems that white carbon black in a conventional precipitation method has many silanol groups on surface, and is liable to unite, poor in structure, poor in compatibility with rubber and low in reinforcing property are solved. Moreover, the process is simple, the product stability is good and the technological economy is good.

Owner:CHANGZHOU UNIV +1

Preparation of oil-extended montmorillonite-extended latex coprecipitation rubber

The invention relates to a preparation method for oil-filled montmorillonite-filled emulsion coprecipitated rubber. The rubber comprises the following main components in portion by weight: 100 portions of rubber, 1 to 80 portions of montmorillonite, 1 to 80 portions of oil, 0.1 to 5 portions of coupling agent and 0.1 to 5 portions of age resistor. The preparation method comprises the following steps: adding organic modified montmorillonite or unmodified montmorillonite suspension, coupling agent and age resistor in rubber emulsion and stirring for 1 to 30 minutes while keeping the temperature at 30 to 80 DEG C; adding emulsible oil in the mixture and stirring 1 to 30 minutes; then, respectively synchronously adding the mixture, flocculant and protonic acid, in the aqueous solution of inorganic salt and flocculating agent step by step and stirring for 1 to 30 minutes while keeping pH value between 3 and 4; adding inorganic alkali and adjusting the pH value to 7, and flocculating while stirring; dehydrating and drying the floccule to obtain the oil-filled montmorillonite-filled emulsion coprecipitated rubber. The coprecipitated rubber prepared by the method has excellent performance and ideal reinforcing effect, and can be filled with more montmorillonite while ensuring uniform dispersion, thereby substantially reducing production cost and pollution; moreover, the coprecipitated rubber has simple process and can meet the requirements of different users through adjusting the dosage ratio of filled oil and montmorillonite, thereby having great application value.

Owner:QINGDAO UNIV

Itaconate/isoprene copolymer type biology base elastomer tread rubber and preparation method thereof

ActiveCN104725756AGood dispersionReduce hardnessSpecial tyresRolling resistance optimizationElastomerPolymer science

The invention discloses itaconate / isoprene copolymer type biology base elastomer tread rubber and a preparation method thereof, belonging to the technical field of tires. Every 100 parts of itaconate / isoprene copolymer type biology base elastomer tread rubber can contain 5-40 weight parts of conjugated diene rubber and 60-120 parts of coordination fillers, the above fillers comprise more than 50 parts of silicon dioxide, 1-15 parts of silane coupling agent, 2-6 parts of zinc oxide, 1-3 parts of stearic acid, 1-4 parts of anti-aging agent, 1-4 parts of accelerant, 0-30 parts of fillers except silicon dioxide and 1-3 parts of sulfur. The biology base tire tread rubber is low in rolling obstruction, is proper in abrasion resistance and wet road holding property, and is a novel biology base elastomer 'green tire'.

Owner:BEIJING UNIV OF CHEM TECH +1

Silica sol reinforced water-based organic silicone elastomer as well as preparation method and application thereof

ActiveCN103897398AImprove liquidityEasy to cleanOther chemical processesFibre treatmentWater basedCross-link

The invention belongs to the field of organic silicone elastomers and discloses a silica sol reinforced water-based organic silicone elastomer as well as a preparation method and application thereof. The preparation method comprises the following steps: polymerizing organosiloxane monomers in the presence of a composite surfactant and a catalyst to obtain a linear polysiloxane emulsion, adding a cross-linking agent and a reinforcing agent in sequence to obtain an organic silicone elastomer emulsion, coating a matrix with the emulsion, and drying for forming to obtain the organic silicone elastomer. The organic silicone elastomer is prepared through an aqueous emulsion polymerization method in the presence if good-compatibility silica sol serving as the reinforcing agent, has the advantages of good flowability, convenience in coating and good mechanical property, and can be used as a waterproof coating, a fabric coating, an adhesive, putty or a sealing agent.

Owner:国科广化(南雄)新材料研究院有限公司

Reinforcing filler used for rubber latex product, preparation method thereof and application thereof

ActiveCN101696282APrevent each other from approachingClose to each other to preventPigment treatment with macromolecular organic compoundsPigment physical treatmentParaffin waxCellulose

The invention relates to reinforcing filler used for a rubber latex product, a preparation method thereof and application thereof. The reinforcing filler consists of the following components in part by weight: 50 to 80 parts of base material, 0.01 to 0.4 part of dispersant, 0.001 to 0.5 part of surface treating agent, 0.01 to 1 part of emulsion and 20 to 50 parts of water, wherein the base material is any one of heavy calcium carbonate powder, kaolin powder and argil powder; the dispersant is any one of casein, methylene dinaphthalene sodium sulfonate, sodium polyacrylate, potassium hydroxide and ammonia water; the surface treating agent is any one of bentonite, cellulose, swelling soil and attapulgite; and the emulsion is any one of mineral oil, vaseline, liquid paraffin and polyoxychloroethylene wax. The reinforcing filler has economic formulation and good reinforcing effect. The preparation method is a conventional stirring and grinding method. The process is simple, and little equipment is used. The application comprises the following steps: adding the reinforcing filler into rubber latex, blending the mixture evenly, forming a layer of film on a die by adopting a soaking and casting method, and then drying the film for 15 to 30 minutes at a temperature of between 110 and 130 DEG C to obtain the reinforced filled rubber latex product. The reinforcing filler is favorable for improving the tensile strength of the rubber latex product and reducing the usage amount of the latex.

Owner:BENGBU RUIJIE TECH

Preparation method for MDTQ type methyl phenyl vinyl silicone resin

A preparation method for MDTQ type methyl phenyl vinyl silicone resin is characterized by comprising the following steps: mixing MDT type methyl phenyl vinyl silicone resin prepolymer solution containing a hydroxyl with MQ type silicone resin prepolymer solution containing a hydroxyl, heating and reflowing, so as to distil off water generated from condensation; stirring for reaction, stopping heating, and cooling to the room temperature; then washing until the mixture is neutral, drying, decoloring, and separating out a solvent and a low-molecular-weight compound under the vacuum condition, so as to obtain the colorless and transparent MDTQ type methyl phenyl vinyl silicone resin reinforced by the MQ silicon resin. The methyl phenyl vinyl silicone resin provided by the invention is high in light transmittance, clear and transparent, has excellent intermiscibility with phenyl vinyl silicone oil and phenyl hydrogen-contained silicon resin, can be used for preparing phenyl silicone rubber, has excellent reinforcing effect, and enables the silicone rubber to be excellent in resilience, tearing resistant, hot-cold impact resistant, heatproof, radiation resistant and ageing resistant.

Owner:江西新嘉懿新材料有限公司

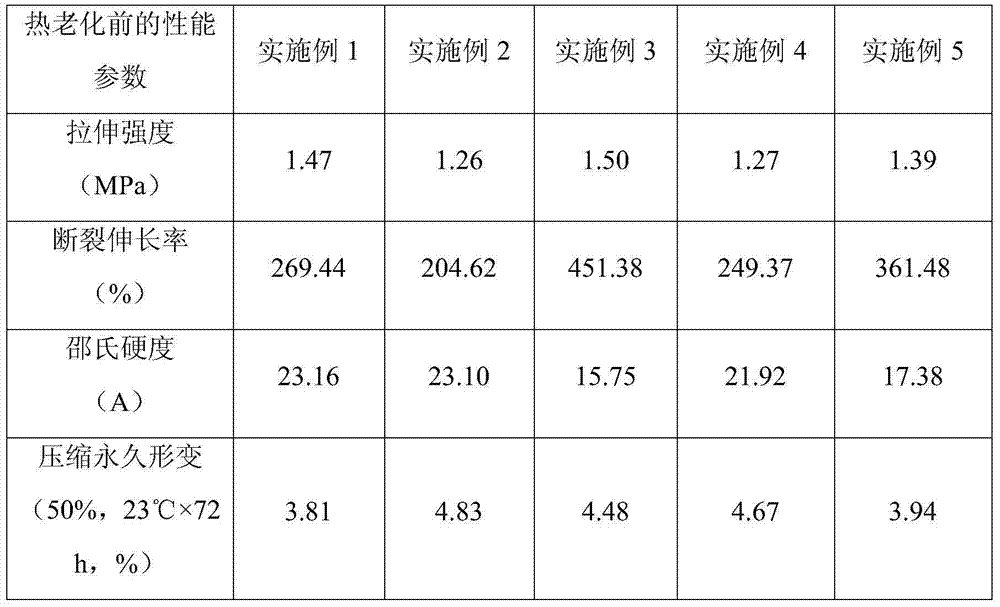

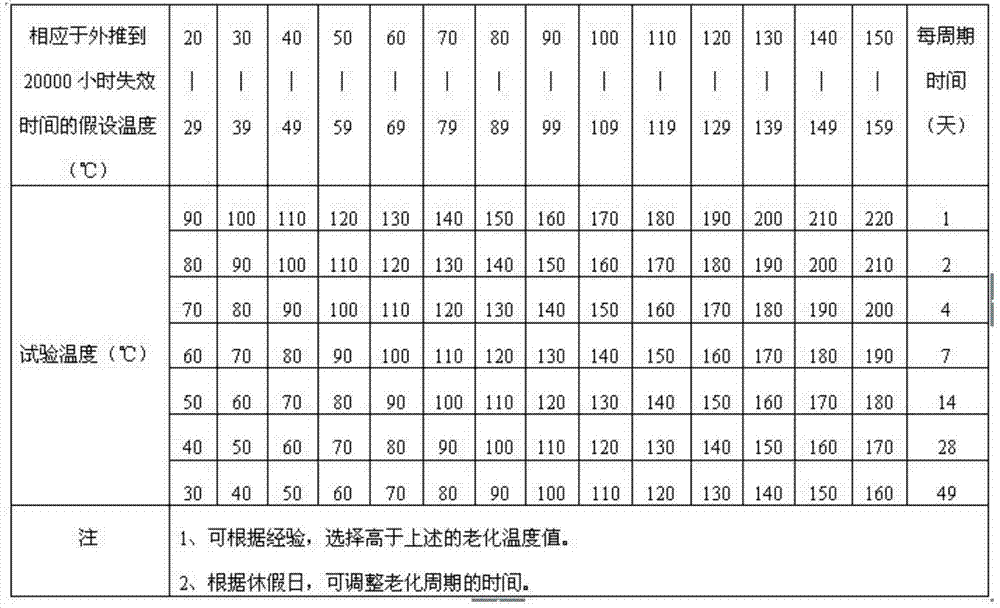

High-temperature-resistant silicone rubber foam material and preparation method thereof

The invention discloses a high-temperature-resistant silicone rubber foam material and a preparation method thereof. The preparation method of the high-temperature-resistant silicone rubber foam material is characterized by comprising the following steps: mixing 100 parts of silicone rubber base stock, 20-35 parts of a reinforcing agent, 2-3 parts of a structure controlling agent, 0-0.2 part of colour master batch, 60-150 parts of a pore-forming agent and 4-5 parts of a radiation sensitizer, moulding, crosslinking through gamma ray radiation, forming pores through subsection dissolving-out, and drying, so that the silicone rubber foam material which is resistant to high temperature of 250 DEG C and still maintains excellent performance after equivalent time of 20000 hours can be obtained. The preparation method of the high-temperature-resistant silicone rubber foam material has the advantages that radiation crosslinking and dissolving-out pore forming are combined, so that crosslinking is uniform, control is easy, energy conservation and environmental protection are realized, a technology is concise, reproducibility is good, and production efficiency is high; the high-temperature-resistant silicone rubber foam material still maintains high tensile strength, high weight loss, low longitudinal deformation and low surface hardness after the equivalent time of 20000 hours at the temperature of 250 DEG C, permanent compressive deformation is slightly increased, the high-temperature-resistant silicone rubber foam material does not become brittle or hard, and the high-temperature-resistant silicone rubber foam material can serve as filling and positioning, sealing cushion, cable insulation as well as buffer and vibration-absorptive materials or parts which are used in high-temperature environment.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

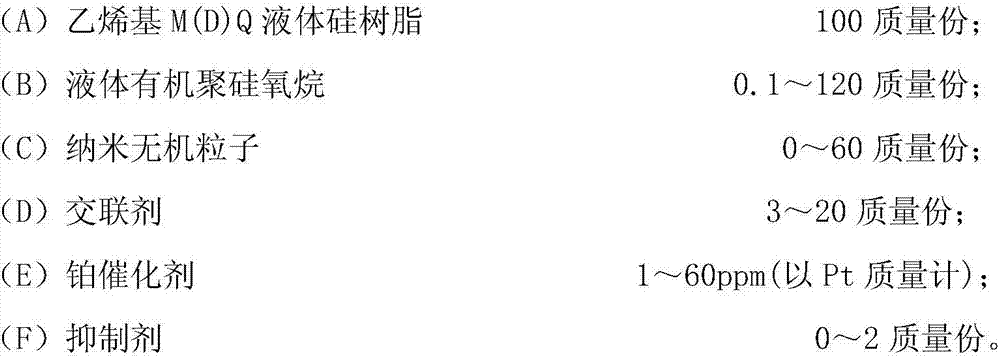

Liquid silicon resin foam material and preparation method thereof

The invention discloses a liquid silicon resin foam material. The liquid silicon resin foam material comprises the following components: (A) 100 parts by mass of vinyl M(D)Q liquid silicon resin; (B)0.1 to 120 parts by mass of liquid organopolysiloxane; (C) 0 to 60 parts by mass of micro-nano inorganic particles; (D) 1 to 30 parts by mass of a crosslinking agent; (E) 1 to 60 ppm of a platinum catalyst (based on the weight of Pt); and (F) 0 to 2 parts of an inhibitor. The invention also discloses a preparation method of the liquid silicon resin foam material. According to the liquid silicon resin foam material obtained by the method, no matter a compression molding forming method or an injection and casting molding method is used, the liquid silicon resin foam material with high mechanicalstrength and good appearance can be obtained.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Attapulgite/hydrotalcite compound flame retardant material and preparation method thereof

The invention relates to the fields of halogen free flame retardant materials and preparation technology thereof, in particular to an attapulgite / hydrotalcite compound flame retardant material and preparation method thereof. The attapulgite / hydrotalcite compound flame retardant material has hydrotalcite and attapulgite; the mass ratio between the hydrotalcite and the attapulgite is 0.4-2.5 to 1. The attapulgite is used as a substrate to prepare the attapulgite / hydrotalcite compound flame retardant material in situ as the surface of the attapulgite is electronegative and can absorb electropositive nano hydrotalcite in situ. The attapulgite and the hydrotalcite are used for simultaneously retarding flame and inhibiting smoke. The attapulgite / hydrotalcite compound flame retardant material has the functions of retarding flame and inhibiting smoke, so that the technical problem of undesirable smoke inhibiting effect of the current flame retardant material is solved.

Owner:常州纳欧新材料科技有限公司

Epoxy resin curing agent and preparation method thereof

PendingCN109824869AShort curing timeImprove adhesionAnti-corrosive paintsEpoxy resin coatingsDiethylenetriaminePolyamide

The invention relates to an epoxy resin curing agent. The epoxy resin curing agent comprises, by weight , 30-50 parts of polyamine compound, 20-40 parts of benzyl alcohol, 5-10 parts of epoxy resin, 3-8 parts of propylene carbonate, 10-20 parts of polyether 400, 0.05-0.1 part of yellow-resistant auxiliary and 1-10 parts of amino-terminated hyperbranched polyamide surface grafted graphene oxide, wherein the polyamine compound comprises one or two of aliphatic polyamine and cycloaliphatic polyamine; the aliphatic polyamine is diethylenetriamine, triethylene tetramine or hexanediamine; the cycloaliphatic polyamine is m-xylylenediamine or isophorone diamine; the polyamine compound comprises isophorone diamine and triethylene tetramine, and the mass ratio of the isophorone diamine to the triethylene tetramine is (1-4):1.

Owner:XIAMEN YUANCHUANGLI TECH SERVICE CO LTD

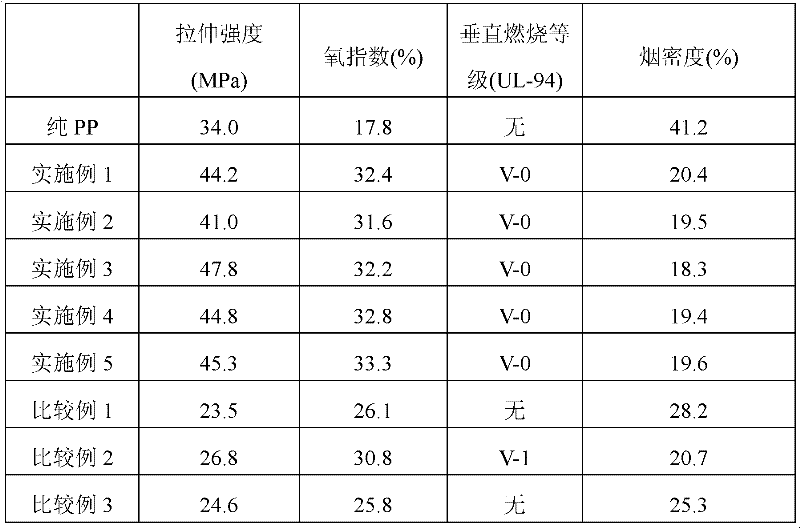

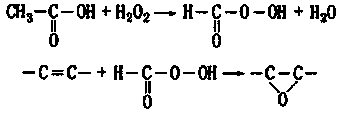

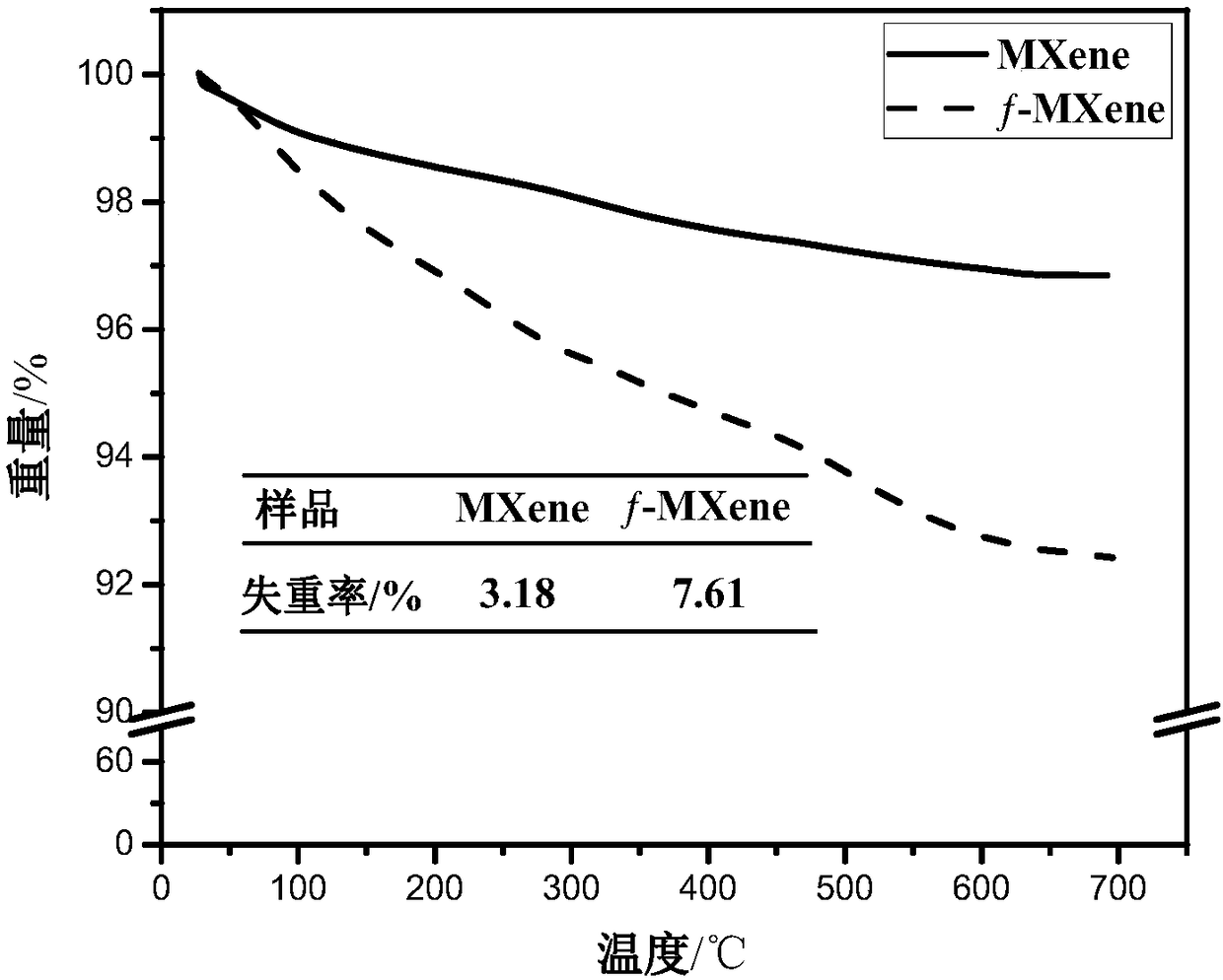

Functionalized two-dimensional laminated transition metal carbide material f-MXene as well as preparation method and application thereof to rubber

InactiveCN108610511AImprove electrical performanceImprove mechanical propertiesTransition metal carbidesPtru catalyst

The invention discloses a functionalized two-dimensional laminated transition metal carbide material f-MXene as well as a preparation method and application thereof to rubber, and belongs to the fieldof a carbide composite material. The preparation method comprises the following steps: mixing transition metal carbide MXene, a silane coupling agent and water, adding an organic tin catalyst, performing stirring reaction at 40 to 80 DEG C, and performing vacuum drying to obtain the functionalized two-dimensional laminated transition metal carbide material, marked as f-MXene. The transition metalcarbide is applied in the field of rubber for the first time; and the modified carbide material MXene overcomes the defects that the two-dimensional laminated transition metal carbide material MXenehas low compatibility with rubber latex and is liable to agglomerate, and has the advantages of improving bonding of a matrix and an interface, improving the electric property and the mechanical property of the rubber, and the like. Furthermore, the preparation process is environmentally friendly, efficient and energy-saving, the recovery rate of the product is high, and the functionalized two-dimensional laminated transition metal carbide material f-MXene is environment-friendly rubber filler and has wide application prospect in the industrial production of the rubber.

Owner:SOUTH CHINA UNIV OF TECH

Environment-friendly high-elasticity rubber material

The invention discloses an environment-friendly high-elasticity rubber material which is prepared from the following raw materials in parts by weight: 30-40 parts of powder nitrile-butadiene rubber, 10-18 parts of polyvinyl chloride thermoplastic elastomer, 10-20 parts of ABS (acrylonitrile-butadiene-styrene) resin, 3-5 parts of p-tert-butyl phenol-formaldehyde resin, 1.5-2 parts of sulfur, 1.2-1.8 parts of accelerator TMTD (tetramethyl thiuram disulfide), 2-4 parts of magnesium oxide, 1-3 parts of zinc oxide, 5-8 parts of epoxy soybean oil, 0.5-1 part of paraffin, 1-3 parts of zinc-barium stabilizer, 2-3 parts of organophosphate, 20-30 parts of modified kaolin, 15-20 parts of silica white, 1.5-3 parts of carbon master batch and 0.5-1.5 parts of novel rubber reinforcing agent XRE. The rubber material has the advantages of excellent elasticity, wear resistance, favorable tear resistance and low cost, and reduces the hazard to the environment.

Owner:宁国日格美橡塑股份有限公司

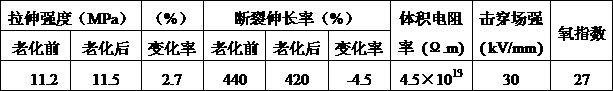

High-strength high-elongation flame retardant rubber insulated cable material and preparation process thereof

ActiveCN103232630AOvercome the difficulty of swinging glueImprove electrical performancePlastic/resin/waxes insulatorsInsulated cablesElastomerParaffin wax

The invention discloses a high-strength high-elongation flame retardant rubber insulated cable material and a preparation process thereof. The high-strength high-elongation flame retardant rubber insulated cable material comprises the following components in parts by weight: 8-14 parts of chlorinated polyethylene (CPE), 15-21 parts of ethylene-octylene copolymer elastomer (POE), 3-6 parts of fumed silica, 15-19 parts of aluminium hydroxide, 13-18 parts of calcined clay, 5-8 parts of 800# paraffin base rubber oil, 0.5-1 part of active magnesium oxide, 4-7 parts of superfine talcum powder, 1-2 parts of zinc oxide, 0.3-0.6 part of environmental stabilizer, 1-2 parts of microcrystalline wax, 0.5-1 part of titanium dioxide, 0.5-0.8 part of 4,4' bis(alpha, alpha dimethyl benzyl) diphenylamine, 1-2 parts of dicumyl peroxide and 1-1.5 parts of triallyl cyanurate. By adopting the high-strength high-elongation flame retardant rubber insulated cable material, uniform addition of inorganic powder is facilitated, a process range is wide, higher elongation at break is still maintained when a continuous vulcanizing temperature is 190-210 DEG C, a fire retardant and a high reinforced filler are added without reducing electrical property, and tensile strength and oxygen index are greatly increased; and cost is greatly reduced.

Owner:JIANGSU HENGTONG POWER CABLE

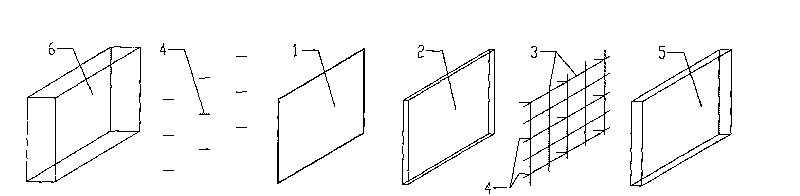

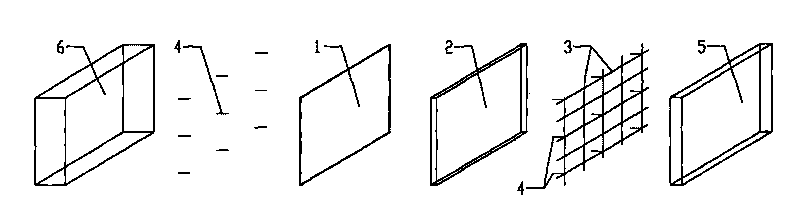

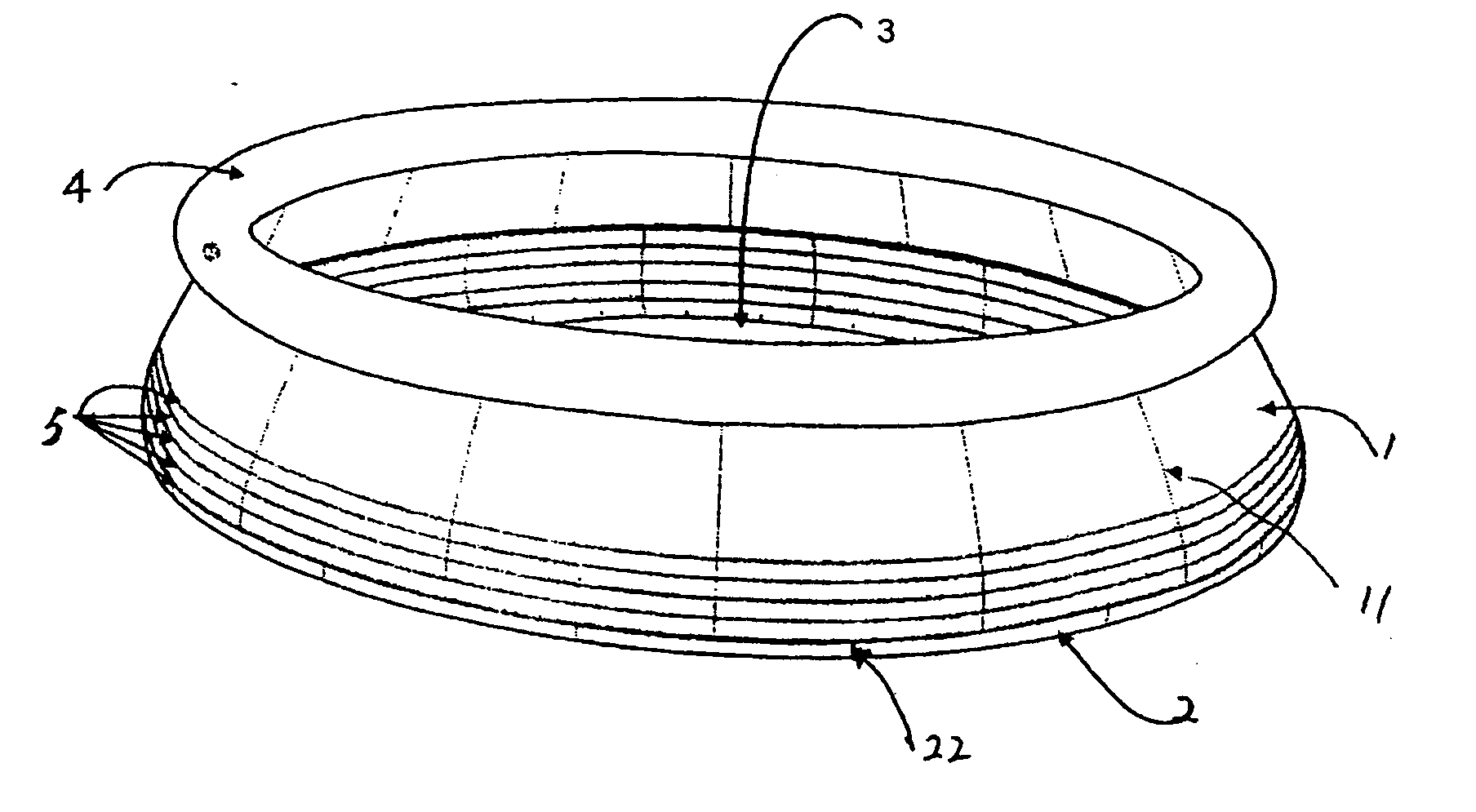

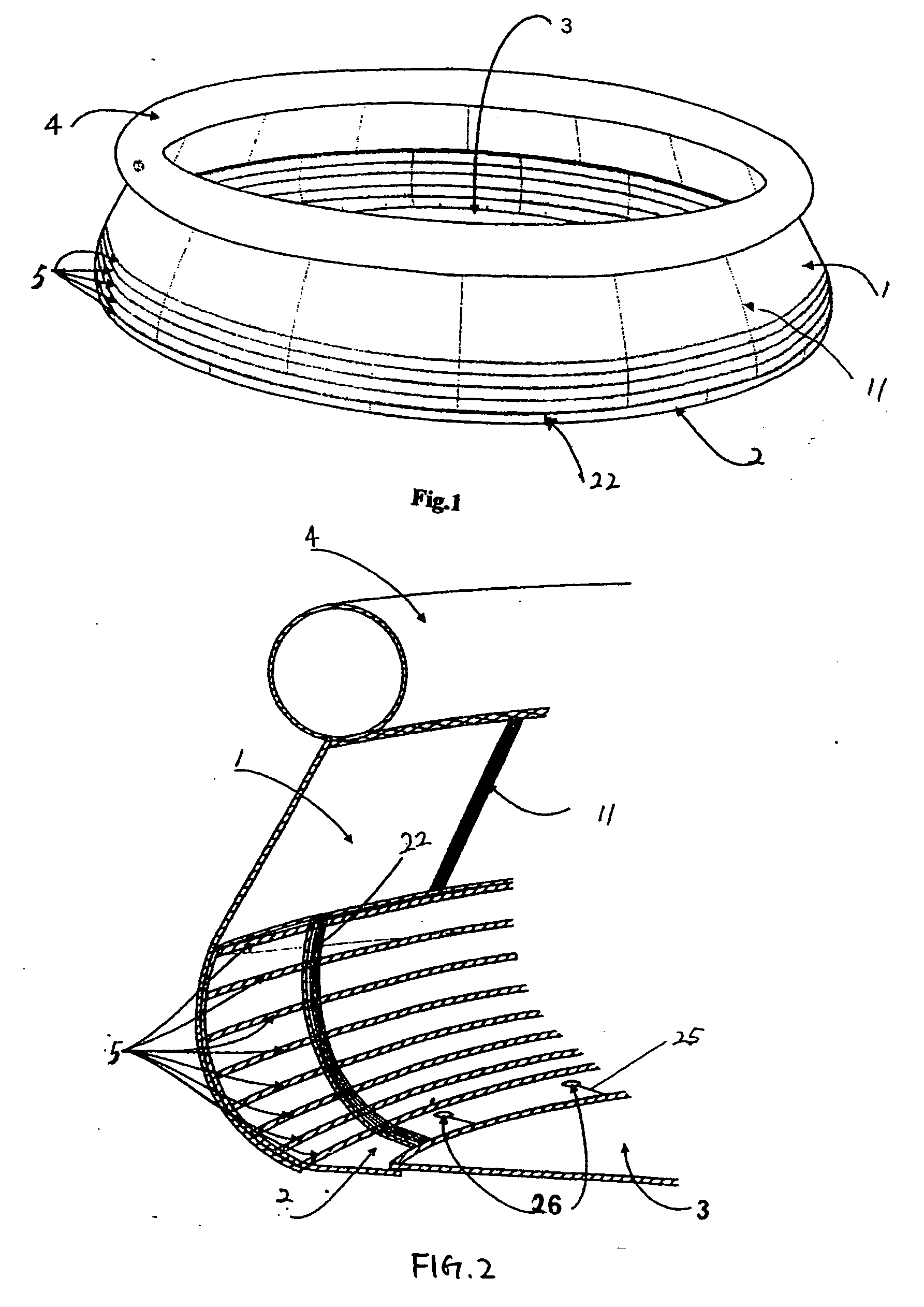

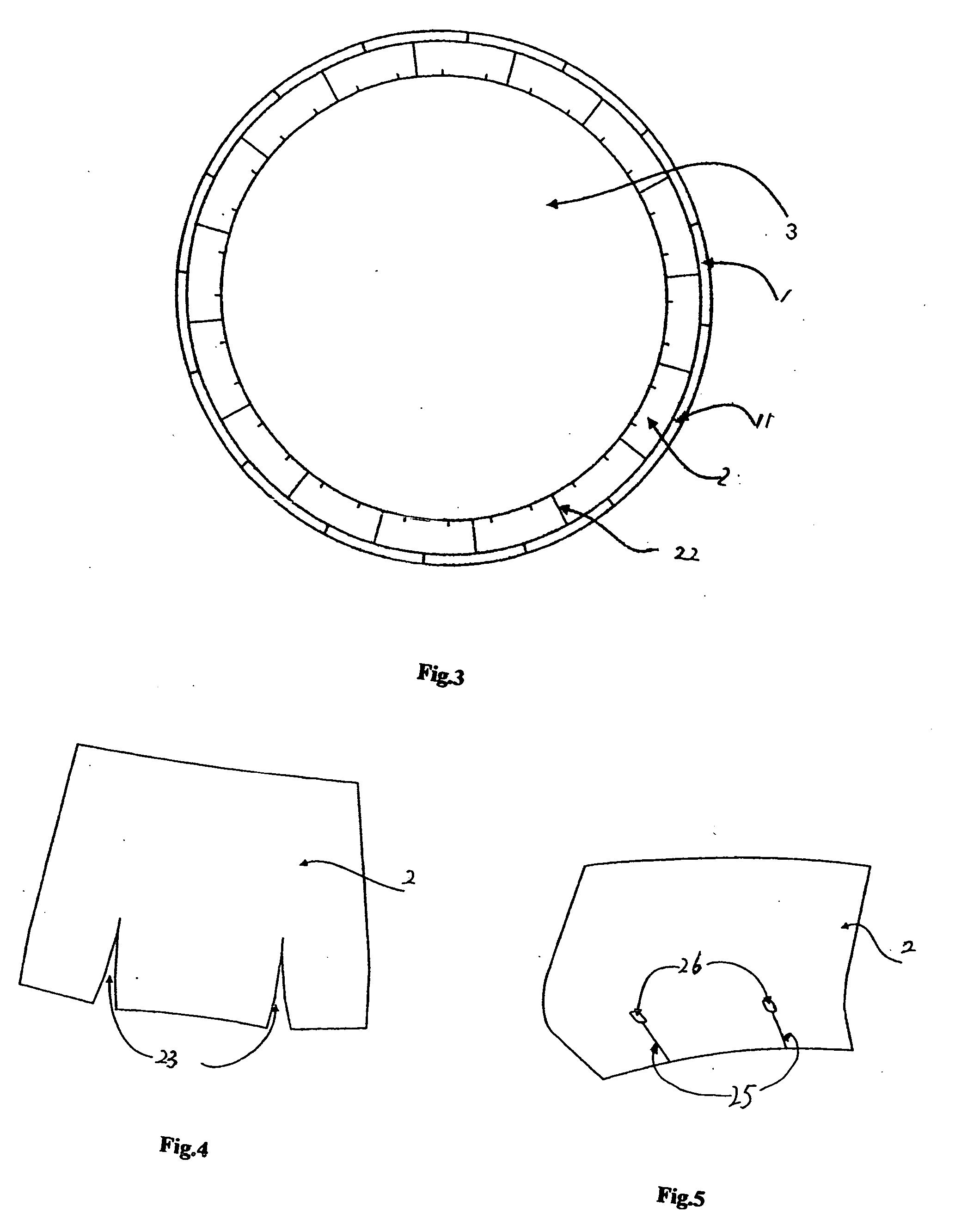

Plastic swimming pool with enhanced structure

ActiveUS20060162062A1Improve efficiencyGood reinforcing effectGymnasiumRigid containersClosed loopEngineering

A plastic swimming pool with an enhanced structure comprises a pool wall, a connecting sheet, a base sheet and an inflatable ring, said pool wall is connected with the base sheet via the connecting sheet, the inflatable ring is mounted on a top of the pool wall, said pool wall is formed by connecting a plurality of sidewalls at both sides of them with each other into a loop, the connecting sheet is bonded to the inner side of the lower portion of the pool wall, the connecting sheet is formed by connecting a plurality of material sheets at both sides of them with each other into a loop as well, the welding seams between the sidewalls and the welding seams between the material sheets of the connecting sheet are staggered; the width of an interface for welding the sidewalls and the connecting sheet is more than 80 mm and reinforcing seals are provided in the interface where the sidewalls and the connecting sheet are bonded, and a bottom ring of the connecting sheet is connected directly with the base sheet. The advantage of the present invention is that the reinforcing sheet is integrated with the connecting sheet, meanwhile, the material sheets having reinforcing function become a closed loop around the pool wall, hence, the pool wall is reinforced, the welding seams are protected and possibility of water-leaking is decreased.

Owner:BESTWAY USA A CORP OF DELAWARE

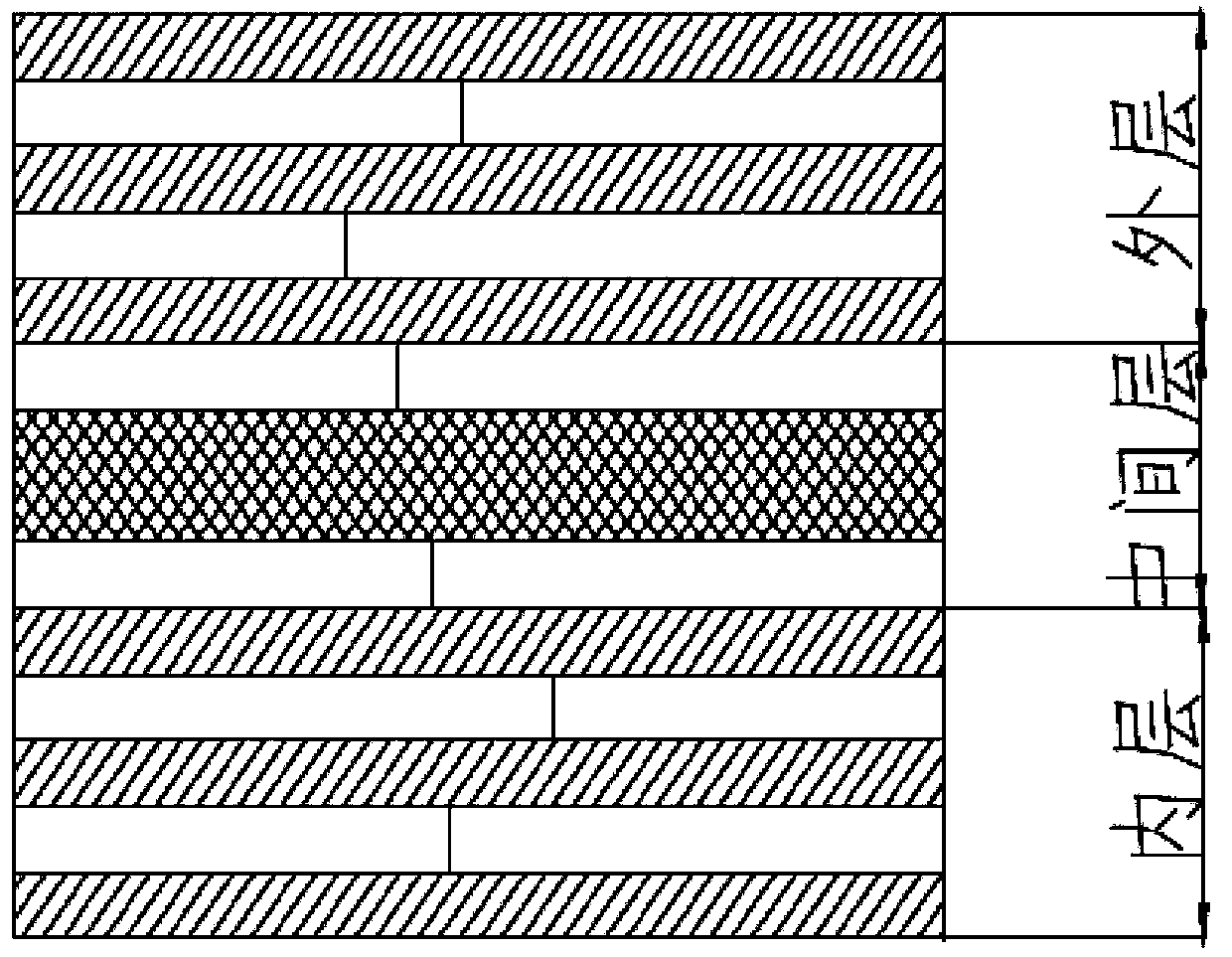

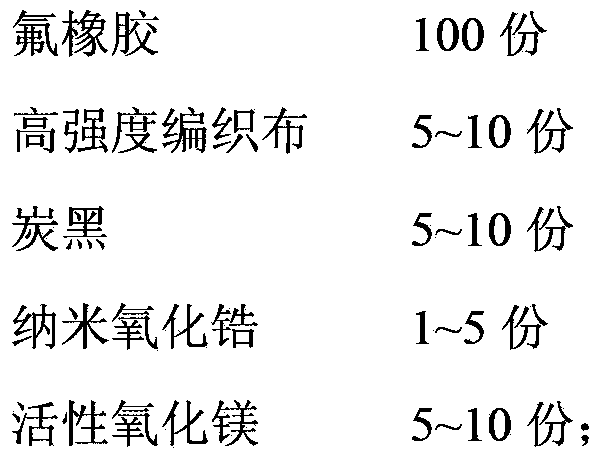

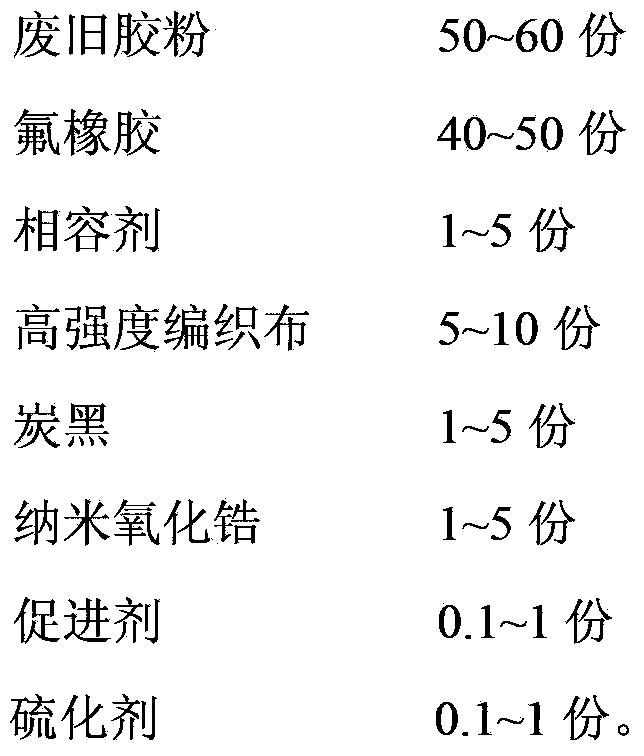

High-temperature resistant oil well rubber sealing ring material and preparation method thereof

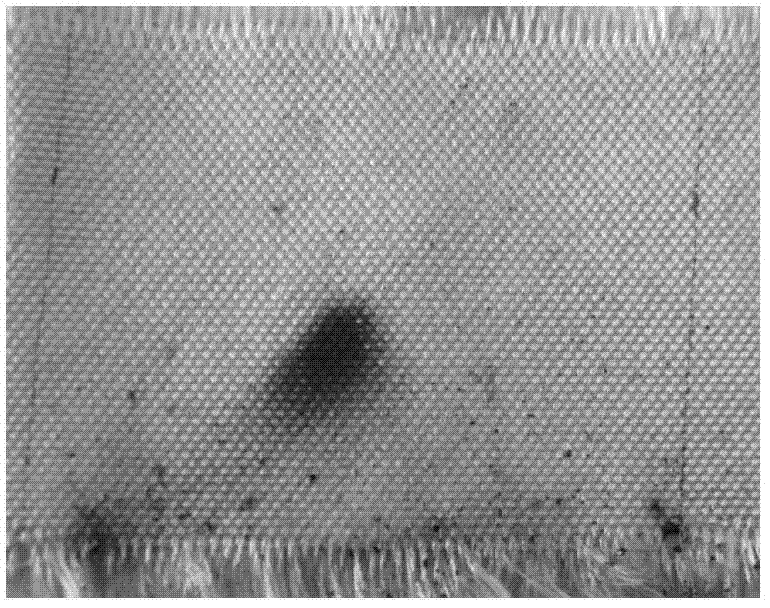

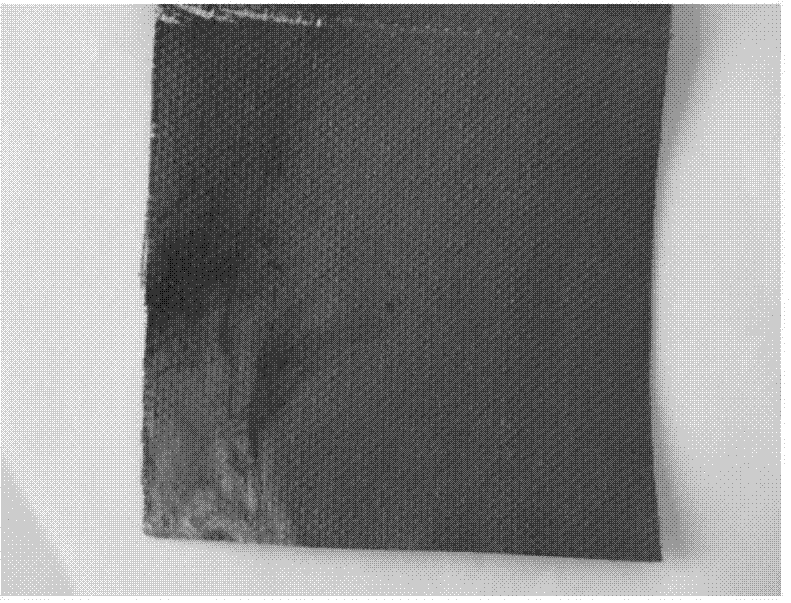

ActiveCN103496229AGood high temperature resistanceReduce raw material costsEngine sealsLaminationFilling materialsCarbon black

The invention provides a high-temperature resistant oil well rubber sealing ring material and a preparation method thereof. The rubber sealing ring material is composed of three parts: the inner layer and the outer layer are both composed of high-strength knitted cloth added with inorganic materials such as carbon black, nano zirconia, and the like; the middle layer is prepared through following steps: compounding rubber powder, which has been desulfurated through thermal mechanical shearing, with fluoro-rubber, adding a compatilizer to increase the compatibility between the rubber powder and the fluoro-rubber; then adopting high-strength knitted cloth, which has been subjected to a surface treatment, as the support body, adding inorganic filling materials such as carbon black, nano zirconia, and the like, and subjecting the knitted cloth added with inorganic filling materials to a high-temperature sulfide cross-linked forming so as to obtain the middle layer. The sealing ring knitted cloth and the rubber base material are subjected to processes of multi-layer compounding and sulfide forming. The sealing ring prepared by the invention has a good high-temperature resistant performance, and is capable of being used in areas with a large temperature difference for a long period.

Owner:CHANGZHOU UNIV

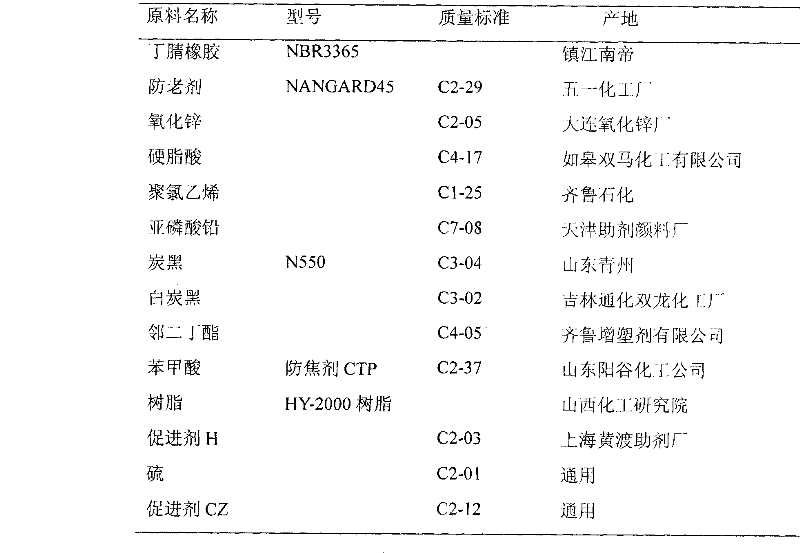

Preparation method of nitrile butadiene rubber for preparing seal ring of floating oil seal with high wear resistance

The invention relates to a preparation method of nitrile butadiene rubber for preparing a seal ring of a floating oil seal with high wear resistance. The preparation method comprises a formula and a preparation process, wherein the formula comprises the following components: nitrile butadiene rubber, N-550 carbon black, high-wear resistant carbon black, semi-reinforced carbon black, calcium carbonate, polyvinyl chloride, stearic acid, dibutyl ester, sulfur, accelerant, accelerant TE, accelerant TMTD, anti-aging agent RD, anti-aging agent 4010 and zinc oxide; the preparation process comprises the following steps: adjusting the temperature of a mixing machine to 100 DEG C, keeping the rotational speed at 32 revolutions / min, putting rubber raw material, a filling agent, a softening agent, an acidifying agent, the anti-aging agents and an activator into the mixing machine to mix for 20min, controlling the rubber temperature below 130 DEG C to discharge the rubber, then transferring to an open mill, and cooling extruded sheets to obtain a master batch; and putting the master batch into the mixing machine, adding a vulcanizing agent, blending, mixing, controlling the rubber temperature below 100 DEG C to discharge the rubber to the open mill, then cooling the extruded sheets, standing and curing to obtain the nitrile butadiene rubber for preparing the seal ring of the floating oil seal with high wear resistance.

Owner:ZHEJIANG GUANGLI ENG MACHINERY

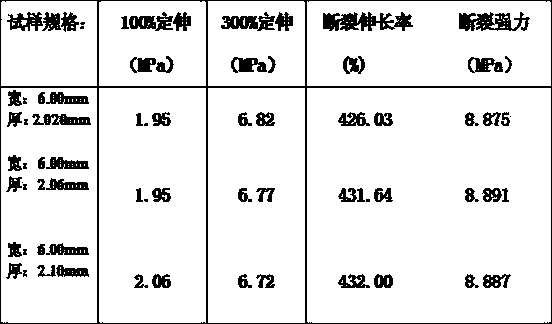

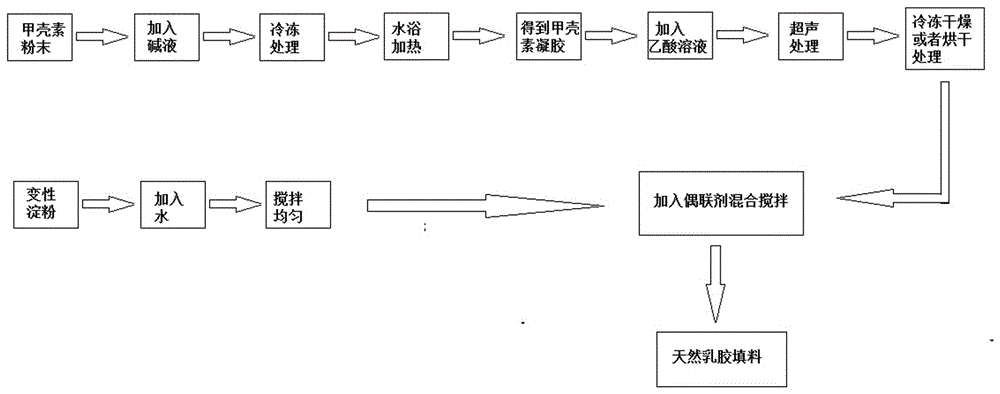

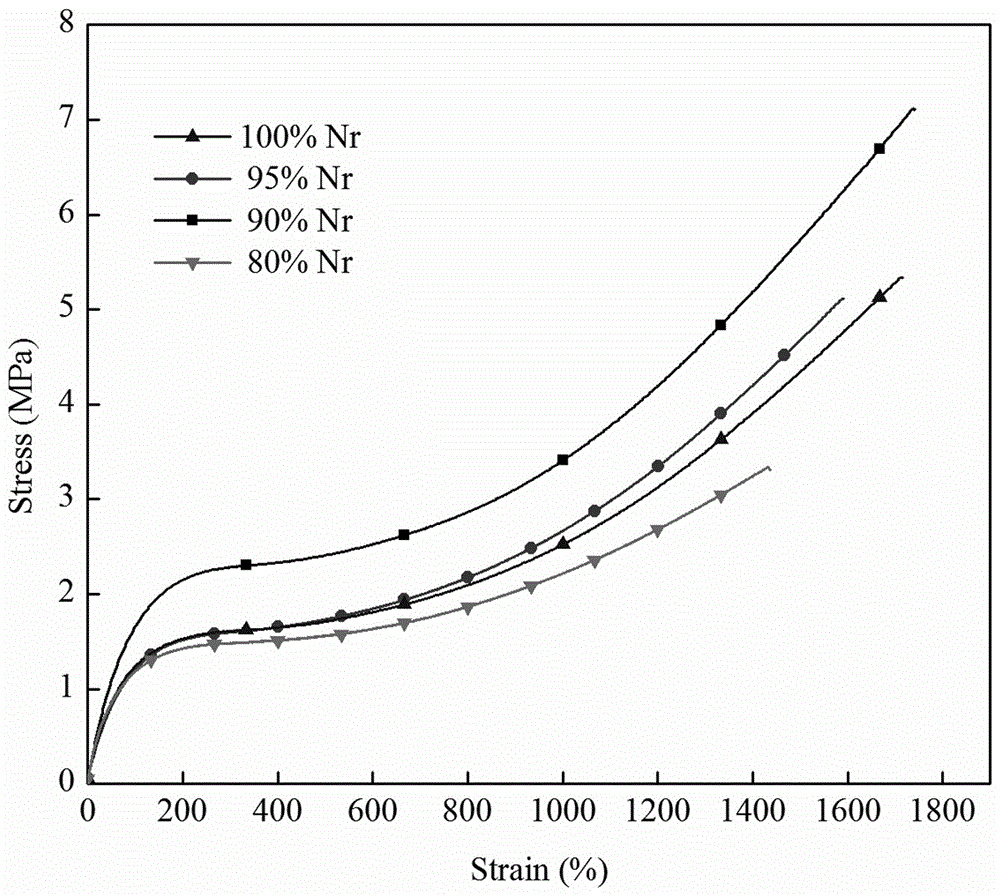

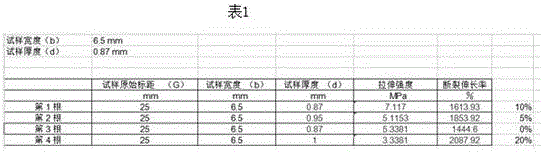

Preparation method and application for natural latex packing

The invention relates to a preparation method and application for natural latex packing. The natural latex packing is prepared by taking chitin and modified starch as main raw materials and by combining the technologies of freezing-thawing, ultrasound and the like with a chemical modifying method, and has double functions of reinforcing and resisting bacteria. The preparation method for the natural latex packing provided by the invention is simple in process, wide in raw material source and low in cost; the prepared natural latex packing is safe and environment-friendly, and can be used for partially replacing carbon black, white carbon black, raw rubber and the like in rubber industry; the pollution to the environment is reduced, and the production cost of a rubber product is reduced; moreover, rubber composite packing is endowed with a certain antibacterial property, so that the antibacterial effect of the rubber product is improved, the rubber quality is improved, and the application range of a rubber impregnated product is enlarged.

Owner:GUANGXI UNIV

High hardness butadiene-acrylonitrile rubber and preparation method thereof

InactiveCN102127252AImproved ozone and weathering resistanceImprove tensile strengthPhosphoric acidChemistry

The invention discloses high hardness butadiene-acrylonitrile rubber, which consists of the following components in part by weight: 80 to 120 parts of butadiene-acrylonitrile rubber, 1 to 4 parts of antiager, 2 to 7 parts of zinc oxide, 0.5 to 2 parts of stearic acid, 20 to 40 parts of polrvinyl chloride, 0.5 to 2 parts of lead phosphite, 20 to 40 parts of carbon black, 25 to 50 parts of white carbon black, 6 to 12 parts of o-dibutyl ester, 0.2 to 1 part of benzoic acid, 40 to 60 parts of resin, 3 to 8 parts of promoter H, 0.5 to 3 parts of promoter CZ, and 1 to 4 parts of sulfur. The prepared butadiene-acrylonitrile rubber has the hardness of 65+ / -5 (Shore hardness), the elongationatbreak of over 120 percent and the modulus of compression of 60MPa; and bumping adaptor maintaining and fitting layers prepared from the high hardness butadiene-acrylonitrile rubber have the properties of high hardness and high modulus, can meet turning accuracy requirement and high modulus requirement, also meet the requirements on rigidity and marine service environment, have been applied to bumping adaptor products, and can meet operating requirement through property inspection.

Owner:713 RES INST OF CHINA SHIPBUILDING IND CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com