Single-component dealcoholization-type organic silicon sealant

A dealcoholized, silicone technology, used in adhesives, other chemical processes, chemical instruments and methods, etc., can solve the problems of lack of "double 85" resistance, unsatisfactory effect, and inability to bond and seal solar modules. To achieve good reinforcement, reduce the requirements of production process, improve the effect of crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

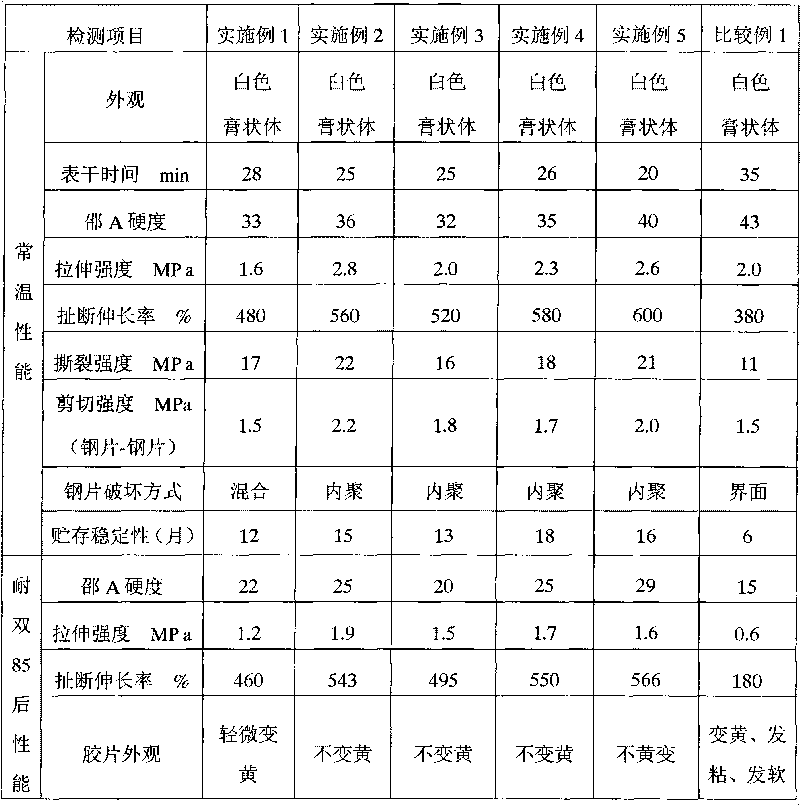

Examples

Embodiment 1

[0037] Hydroxyl Terminated Dimethicone Polymer 60%Wt

[0038] Nano Calcium Carbonate 26%Wt

[0039] Methyltrimethoxysilane 9%Wt

[0040] Ethyl acetoacetate-isopropyl titanate chelate 0.2% Wt

[0041] Fumed Silica 2%Wt

[0042] Tetrabutyl titanate 2%Wt

[0043] Aminopropyltriethoxysilane 0.1%Wt

[0044] Glycidoxypropyltrimethoxysilane 0.1%Wt

[0045] Dimethicone 0.6%Wt

Embodiment 2

[0047] Hydroxyl Terminated Dimethicone Polymer 45%Wt

[0048] Nano Calcium Carbonate 35%Wt

[0049] Methyltriethoxysilane 7%Wt

[0050] Ethyl acetoacetate-isopropyl titanate chelate 0.2% Wt

[0051]Fumed Silica 5%Wt

[0052] Tetrabutyl titanate 0.8%Wt

[0053] Aminopropyltriethoxysilane 1%Wt

[0054] Glycidoxypropyltrimethoxysilane 1%Wt

[0055] Dimethicone 5%wt

Embodiment 3

[0057] Hydroxyl Terminated Dimethicone Polymer 53%Wt

[0058] Nano Calcium Carbonate 30%Wt

[0059] Vinyltrimethoxysilane 6%Wt

[0060] Ethyl Acetoacetate-Isopropyl Titanate Chelate 2%Wt

[0061] Fumed Silica 3%Wt

[0062] Propylisotitanate 0.2%Wt

[0063] Aminopropyltriethoxysilane 0.4%Wt

[0064] Glycidoxypropyltrimethoxysilane 0.4%Wt

[0065] Dimethicone 5%wt

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com