Combined coding type vortex lattice absolute position sensor

An absolute position and eddy current grid technology, applied in the field of measuring instruments, can solve problems such as poor reliability, large sensor errors, small size, etc., and achieve the goals of improving measurement accuracy and stability, increasing error averaging effect, and improving measurement sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

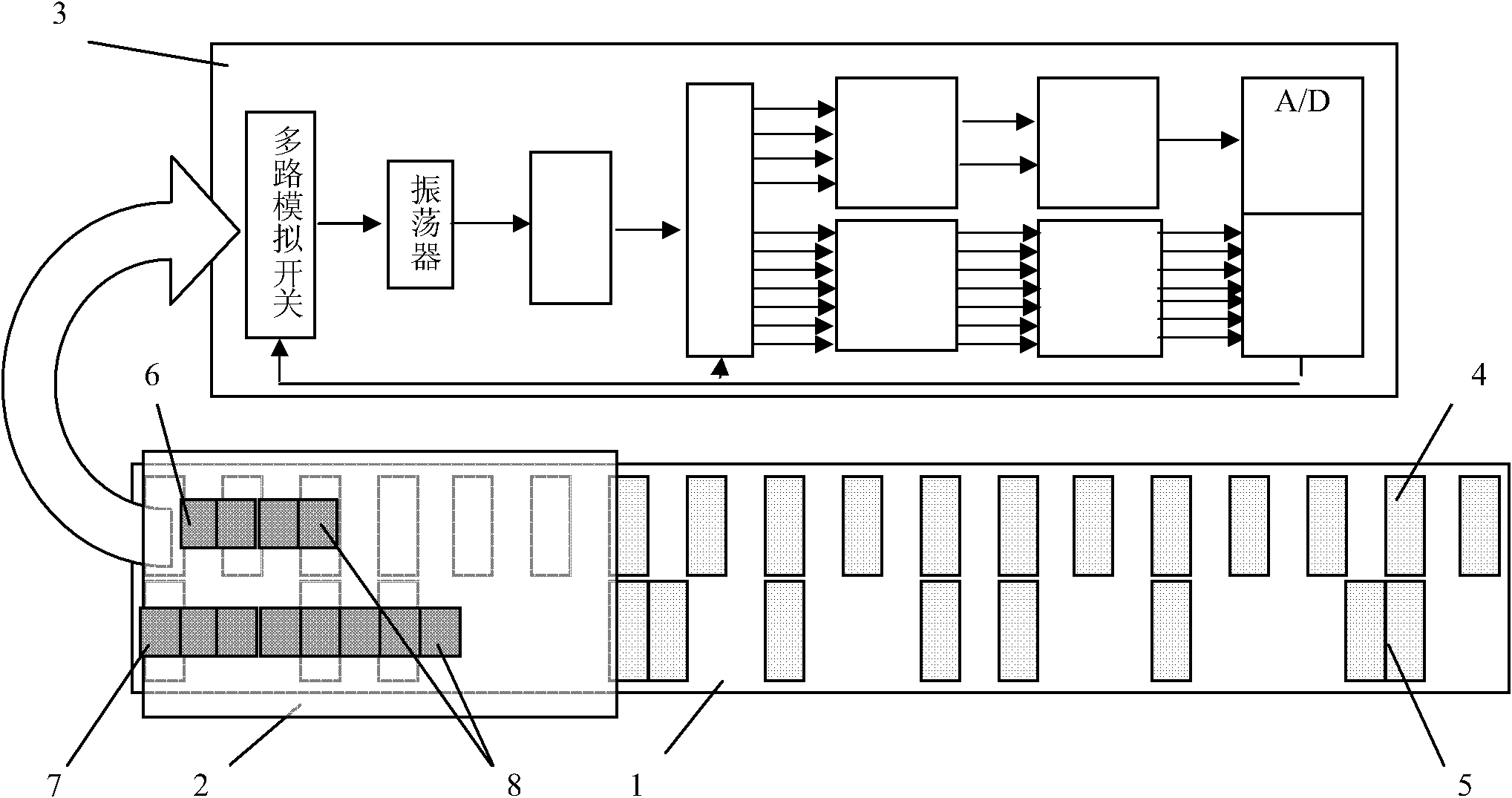

[0025] Such as figure 1 As shown, this embodiment includes: a fixed grid 1, a movable grid 2 and a control mechanism 3, wherein: the movable grid 2 is movably arranged on the fixed grid 1 and connected with the control mechanism 3 to output sensing signals.

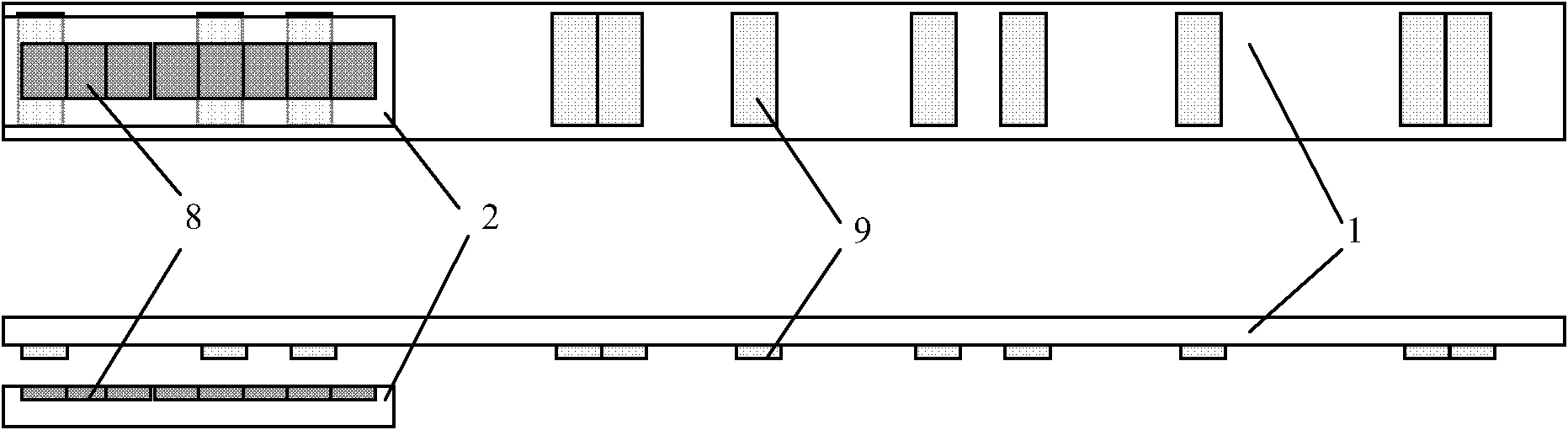

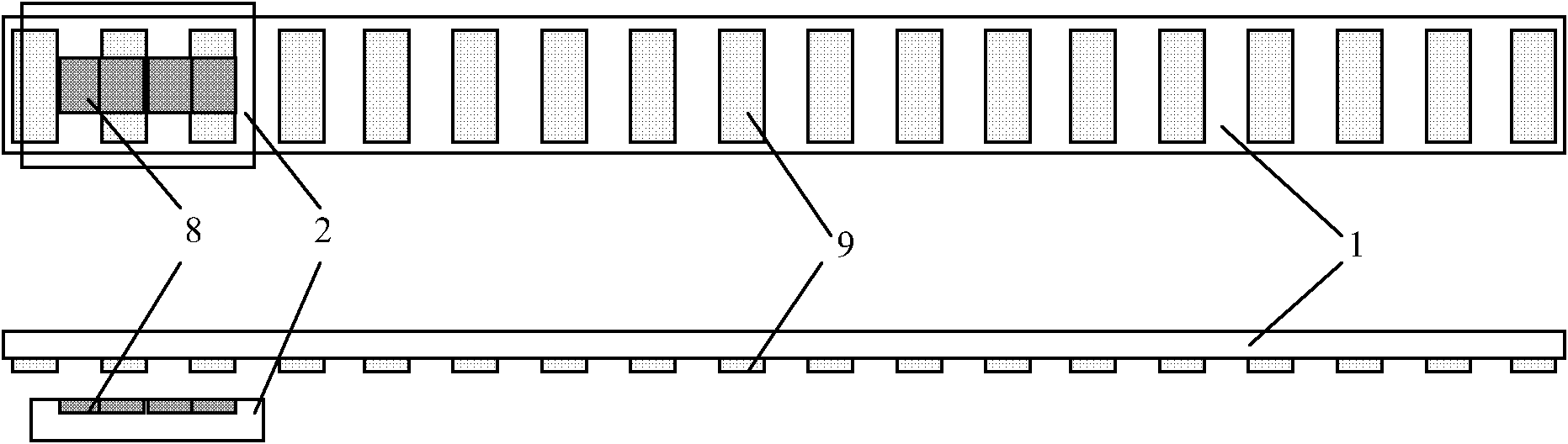

[0026] The fixed grid 1 includes: a measuring code track 4 and a positioning code track 5 parallel to each other;

[0027] The moving grid 2 includes: two moving grid code tracks 6, 7 corresponding to the measurement code track 4 and the positioning code track 5;

[0028] The positioning code track 5 is provided with several independent metal positioning con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com