A level shift circuit

A level-shifting circuit and level-shifting technology, applied in logic circuit interface devices, eliminating voltage/current interference, logic circuit connection/interface layout, etc., can solve the problems of high cost and high process requirements, and reduce the production process Requirements, reduce manufacturing costs, improve stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in terms of specific embodiments in conjunction with the accompanying drawings. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It is to be noted that other embodiments may be utilized or structural and functional modifications may be made to the embodiments set forth herein without departing from the scope and spirit of the invention.

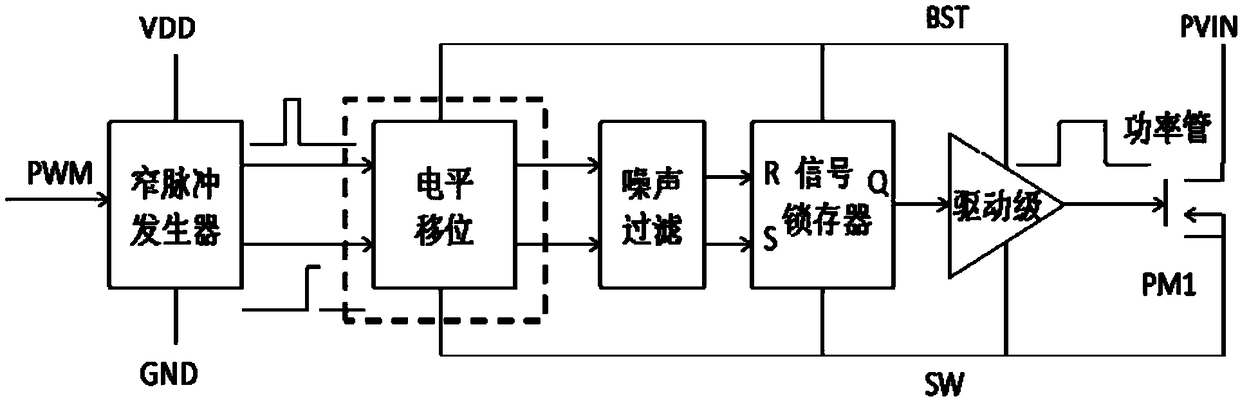

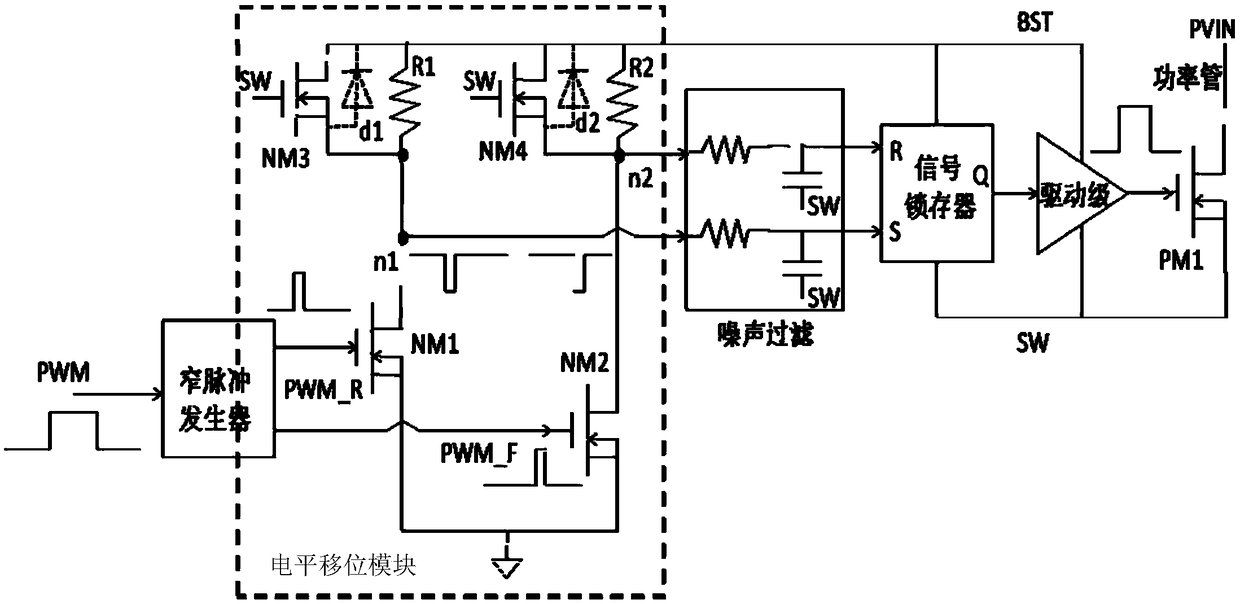

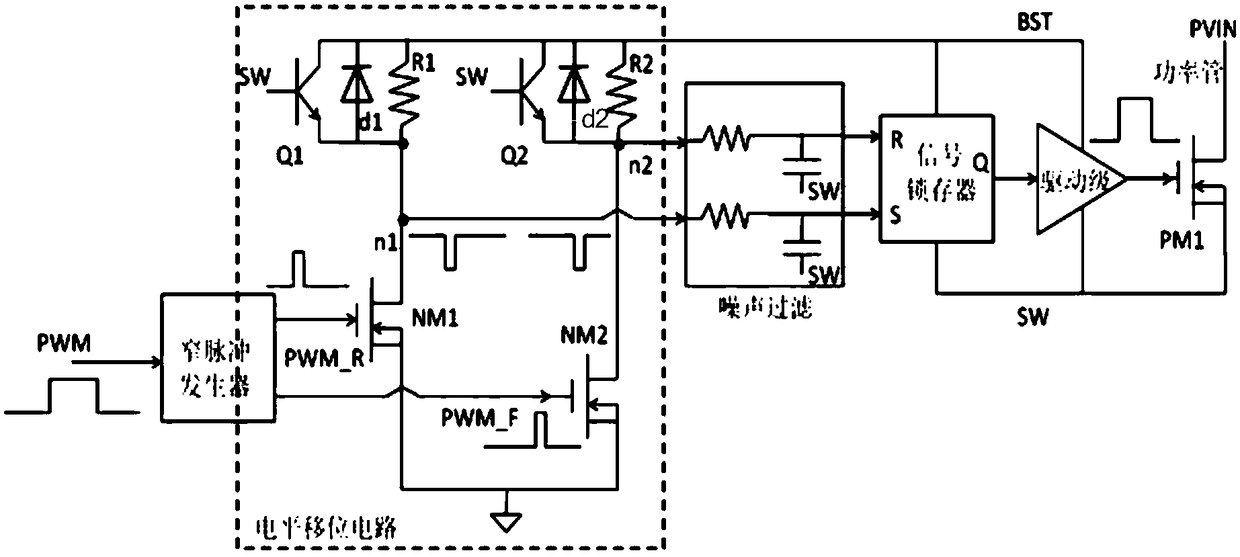

[0039] A level shift circuit provided in the present invention is used to control the on-off of the power tube, such as figure 1 As shown in the structural block diagram, it includes: a narrow pulse generator, a level shift module, a signal latch, and a driver stage circuit;

[0040] The narrow pulse generator is used to output the first narrow pulse signal according to the rising edge of the low-voltage duty ratio signal, and output the second narrow pulse signal according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com