High-temperature resistant oil well rubber sealing ring material and preparation method thereof

A technology of rubber sealing ring and high temperature resistance, applied in the field of rubber materials, can solve the problems of reduced service life, aging and loss of rubber sealing packing, etc., and achieve poor compatibility and adhesion, good high temperature resistance, and reduced raw material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

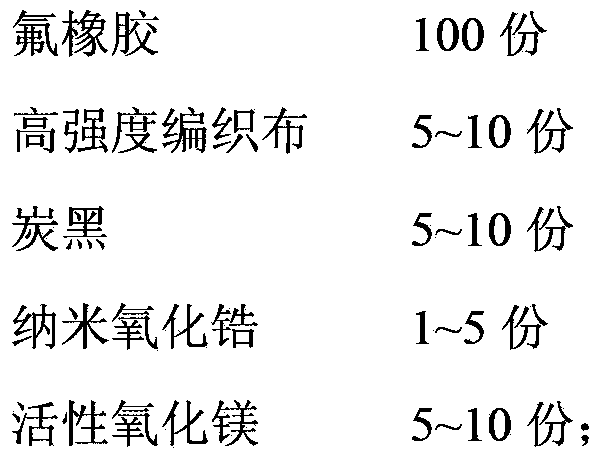

[0042] Inner glue:

[0043]

[0044] middle layer:

[0045]

[0046] Outer glue:

[0047]

[0048] (1) According to the formula in Example 1, except for the high-strength woven fabric, the raw materials of the inner and outer layer rubber and the middle layer are weighed, blended and mixed by an open mill or an internal mixer, and the mixed rubber powder is filtered separately To remove impurities to obtain pre-rubber powder;

[0049] (2) Put the pre-rubber powder obtained in step (1) through a cold-feed compound extruder (SH-36, Nanjing Jieya Extrusion Equipment Co., Ltd., the temperature of the extruder is set between 80-100°C) Extrude the inner, outer and middle layers of glue. When extruding, control the thickness of the glue layer to 10mm, and cut it into the specified size according to the need;

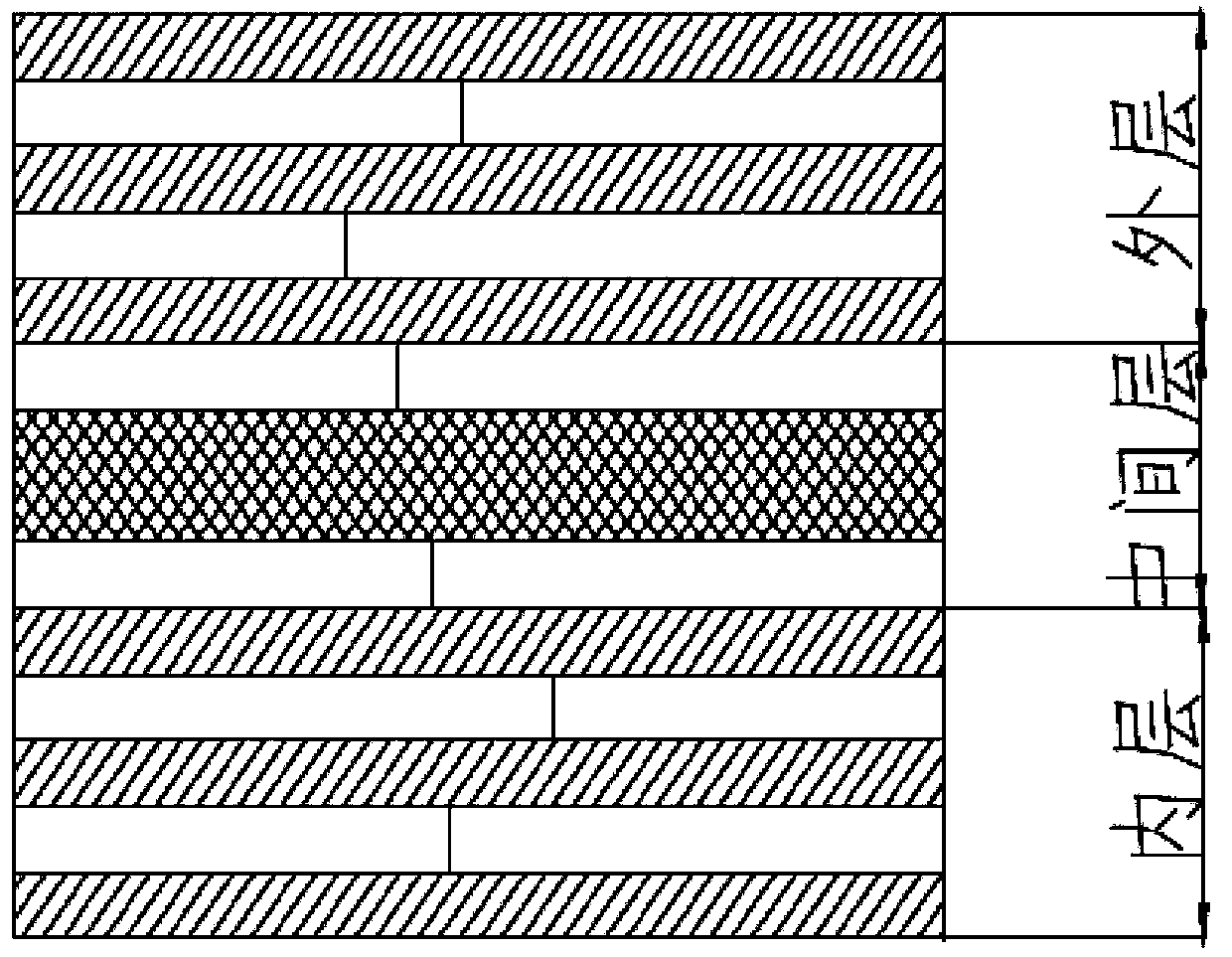

[0050] (3) In the order of "rubber-woven cloth-rubber-woven cloth-rubber", add the inner layer glue, middle layer glue, outer layer glue and woven cloth cut out in st...

Embodiment 2

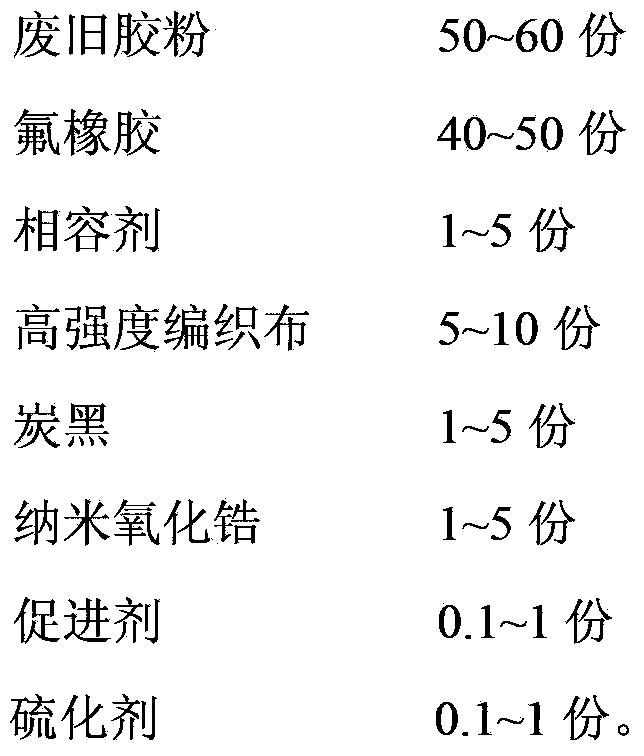

[0054] Inner glue:

[0055]

[0056] middle layer:

[0057]

[0058] Outer glue:

[0059]

[0060] The preparation method of this embodiment is similar to that of Example 1. During the preparation process: the thickness of the extruded rubber layer is 8 mm, the thickness of the added woven cloth is 0.4 mm, and the inner and outer layers are set to have a 4-layer structure, and the middle layer is 5-layer structure, the vulcanization time is 25min, and the vulcanization temperature is 165°C.

Embodiment 3

[0062] Inner glue:

[0063]

[0064] middle layer:

[0065]

[0066] Outer glue:

[0067]

[0068] The preparation method of this embodiment is similar to that of Example 1. In the preparation process: the thickness of the extruded rubber layer is 4mm, the thickness of the added woven cloth is 0.1mm, and the inner and outer layers are set to be 7-layer structure, and the middle layer is 5-layer structure, vulcanization time is 20min, and vulcanization temperature is 150°C.

[0069] The performance test of the finished product prepared by above-mentioned 3 embodiments is as follows:

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com