Mirror-like silver ink and preparation method thereof, and printed matter

A technology of mirror silver and ink, applied in the directions of printed matter, ink, printing, etc., can solve the problem of low heat resistance temperature of mirror silver ink, and achieve the effect of simplifying the process, good mirror effect and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

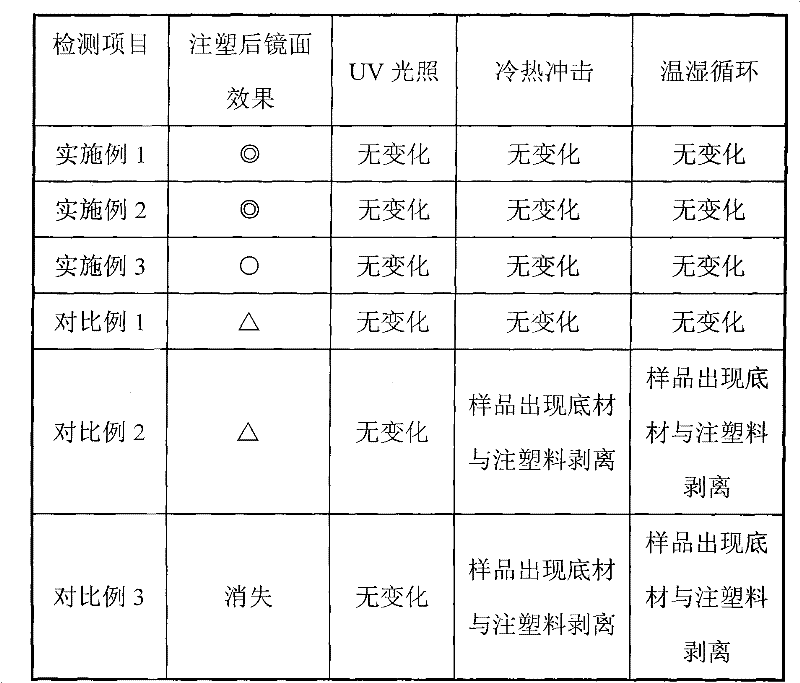

Examples

preparation example Construction

[0022] Simultaneously, the preparation method of above-mentioned specular silver ink disclosed by the present invention comprises the following steps:

[0023] (1) Prepare materials according to the following components and content (wt%):

[0024] Aluminum paste 45~59;

[0025] Main resin 20~30;

[0026] The first solvent 20~30;

[0027] Auxiliary 0.5~1.5;

[0028] (2) Mix the first solvent, additives, aluminum paste, and main resin in sequence, and fully stir evenly after each addition. The main resin is prepared in proportion to ether-modified polyurethane resin and CAB-modified acrylic resin.

[0029] In addition, the present invention also provides a printed matter, which is a printed matter printed on a substrate using the mirror silver ink disclosed in the present invention. The substrate used is a plastic sheet, and its composition is one or more of PC, PET, PMMA, PE, and PP.

Embodiment 1

[0032] This example is used to illustrate the ink composition of the present invention, its preparation method, and printed matter.

[0033] (1) First weigh the required first solvent according to the proportion of the formula, then slowly add the required amount of additives dropwise and stir for 5 minutes; then add the aluminum paste and stir for 15 minutes; finally add the main resin and stir for 15 minutes to get the mirror silver Ink; each component and its content in the ink composition are as follows:

[0034] First solvent: (14wt% ethylene glycol butyl ether and 10wt% ethyl acetate) 24wt%

[0035] Additive: EDL-CR200 1wt%

[0036] Aluminum paste: Ciba Metasheen 41-0710 (thickness of aluminum sheet is 0.03μm, average particle size is 10μm) 50wt%

[0037] Main resin: (12.5wt% ether modified polyurethane resin and 12.5wt% CAB modified acrylic resin) 25wt%

[0038] (2) The ink composition of step (1) is printed on the PC sheet, and the printing screen adopts a nylon or ...

Embodiment 2

[0040] Adopt the same method as Example 1 to prepare the ink composition, and print the PC sheet, the difference is that each component and content in the ink composition are as follows:

[0041] The first solvent: (14wt% ethylene glycol butyl ether and 10wt% ethyl acetate) 24wt%

[0042] Additive: EDL-CR200 1wt%

[0043]Aluminum paste: Ciba Metasheen 41-0710 (thickness of aluminum sheet is 0.03μm, average particle size is 10μm) 55wt%

[0044] Main resin: (10wt% ether modified polyurethane resin and 10wt% CAB modified acrylic resin) 20wt%

[0045] Through the above steps, printed matter A2 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com