Silica sol reinforced water-based organic silicone elastomer as well as preparation method and application thereof

A technology of organosilicon and silica sol, which is applied in chemical instruments and methods, adhesives, and other chemical processes, and can solve problems such as poor mechanical properties, difficulty in cleaning hands and utensils in contact with silicone rubber, and non-adhesion to wet substrates. , to achieve good mechanical strength, compatibility and reinforcement performance, good fluidity and coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

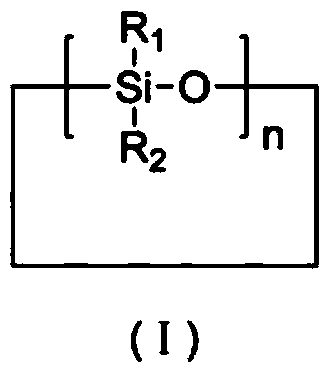

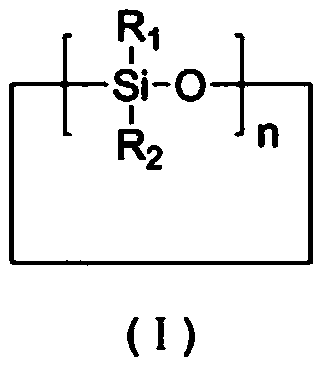

Method used

Image

Examples

Embodiment 1

[0030](1) Add 1g of octadecyltrimethylammonium chloride, 0.5g of potassium hydroxide and 1g of isomeric tridecyl alcohol polyoxyethylene ether into a 500mL glass cup, and dissolve them in 65.5g of water. After the dissolution is complete, add 30g of octamethylcyclotetrasiloxane (D4), stir to make it evenly mixed, then shear and emulsify in a shear emulsification mixer at a shear rate of 1000 rpm for 10 minutes, transfer the resulting mixture to a high-pressure homogeneous In the machine, homogenize under 40MPa homogeneous pressure for 3 times, then pour into a 500mL four-necked flask, heat to 60°C, continue stirring at 500 rpm for 10min, and react for 5 hours to obtain a linear polysiloxane emulsion ;

[0031] (2) Cool the above-mentioned linear polysiloxane emulsion to 50°C, add 1.5g of tetraethyl orthosilicate and 0.5g of 40nm colloidal silica sol in sequence, and continue the constant temperature reaction for 3 hours to obtain a silicone elastomer with a certain viscosity ...

Embodiment 2

[0034] (1) Add 1.5g of octadecyltrimethylammonium chloride, 1.5g of potassium hydroxide and 0.5g of isomeric tridecyl alcohol polyoxyethylene ether into a 500mL glass cup, dissolve with 65.0g of water, and wait until fully dissolved , add 30g of octamethylcyclotetrasiloxane (D4), stir to make it evenly mixed, then shear and emulsify at a shear rate of 3000 rpm for 10 minutes in a shear emulsification mixer, and transfer the resulting mixture to high pressure In the homogenizer, homogenize for 3 times under 40MPa homogenizing pressure, pour it into a 500mL four-necked flask, heat to 65°C, keep stirring at 500 rpm for 10min, and react for 6 hours to obtain linear polysiloxane alkane emulsion;

[0035] (2) Cool the above-mentioned linear polysiloxane emulsion to 55°C, add 1.5g of γ-aminopropyltriethoxysilane and 1.0g of 50nm colloidal silica sol in sequence, and continue the constant temperature reaction for 2.5 hours to obtain a certain viscosity Silicone elastomer emulsion;

...

Embodiment 3

[0038] (1) Add 1.5g of octadecyltrimethylammonium chloride, 1.0g of sodium hydroxide and 1.5g of isomeric tridecyl alcohol polyoxyethylene ether into a 500mL glass cup, dissolve with 64.0g of water, and wait until fully dissolved , add 30g octamethylcyclotetrasiloxane (D 4 ), stirred to make it evenly mixed, and then sheared and emulsified in a shear emulsifying mixer at a shear rate of 5000 rpm for 10 minutes, and transferred the resulting mixture to a high pressure homogenizer, and homogenized under a homogenizing pressure of 30MPa After 2 times, pour it into a 500mL four-neck flask, heat to 70°C, keep stirring at 500 rpm for 10min, and react for 7 hours to obtain a linear polysiloxane emulsion;

[0039] (2) Cool the above-mentioned linear polysiloxane emulsion to 60°C, add 2.0g tetraethyl orthosilicate and 1.5g silica sol with a colloidal particle size of 60nm in sequence, and continue the constant temperature reaction for 3 hours to obtain a silicone elastomer with a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com