Functionalized two-dimensional laminated transition metal carbide material f-MXene as well as preparation method and application thereof to rubber

A transition metal, two-dimensional layered technology, applied in the field of functionalized two-dimensional layered transition metal carbide materials, can solve the problems of less applied research, improve compatibility, improve reinforcement, and improve electrical properties and the effect on the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Weigh 2g of Ti 3 C 2 , 1g of silane coupling agent KH560 and 80g of deionized water are mixed in a 500ml three-necked flask, and the organotin catalyst (dibutyltin dilaurate) diluted with 1mL of ethanol is added dropwise, and the consumption of the catalyst is Ti 3 C 2 5% of the mass, under the constant temperature condition of 40°, the reaction was stirred at a high speed of 200rpm for 4h.

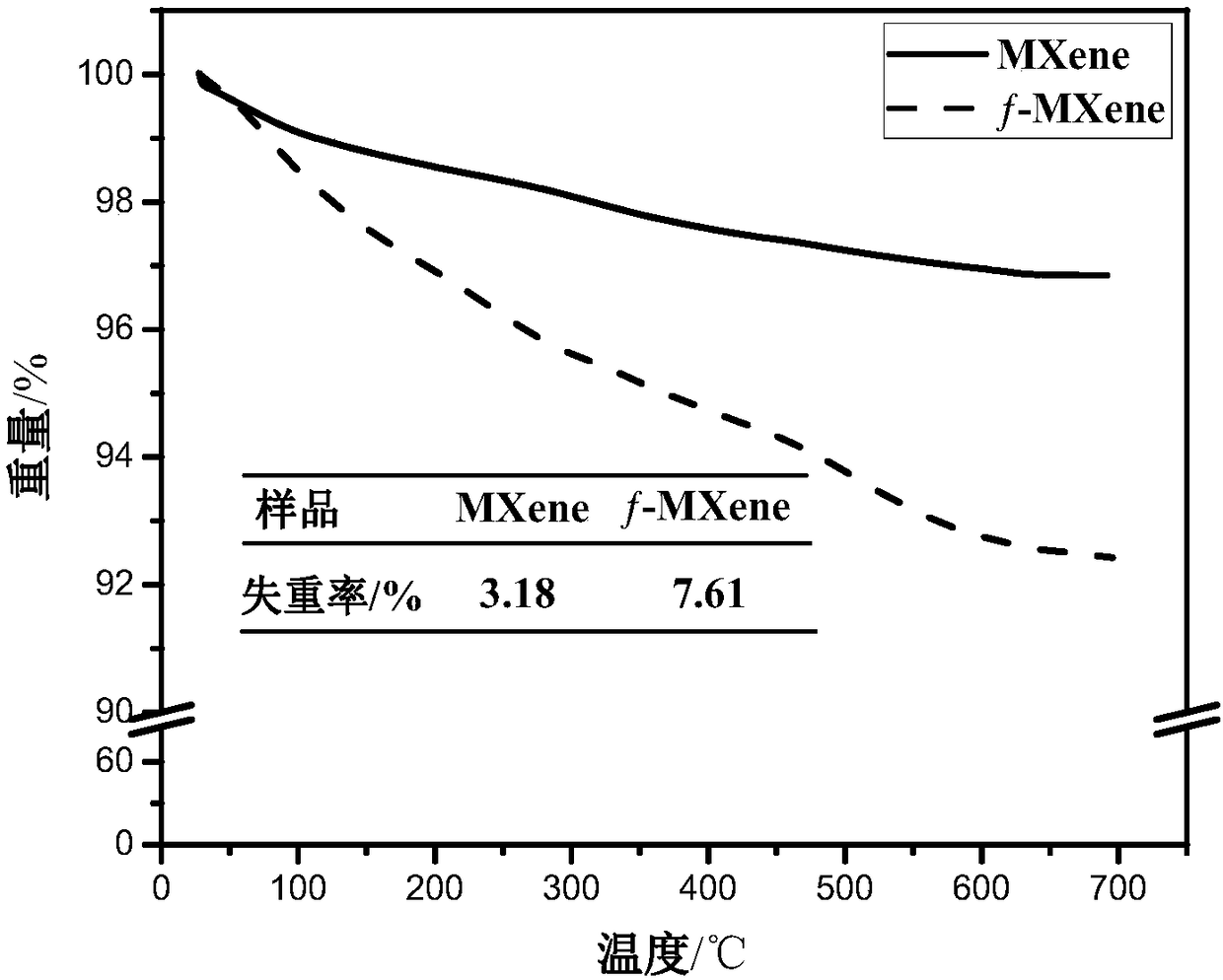

[0039] (2) The reaction product obtained in step (1) was vacuum-dried at 50° C. for 8 hours to obtain a functionalized two-dimensional layered transition metal carbide material, labeled as f-MXene. figure 1 It is the thermal weight loss curve of the functionalized two-dimensional layered transition metal carbide material f-MXene. It can be seen from the figure that the weight loss rate of MXene modified by the coupling agent increases.

[0040] (3) Prepare styrene-butadiene rubber composite material (SBR / f-MXene-3) from the functionalized two-dimensional layered transition m...

Embodiment 2

[0045] (1) Weigh 3g of Ti 3 C 2 , 2g of silane coupling agent KH560 and 80g of deionized water are mixed in a 500ml three-necked flask, and the organic tin catalyst (dibutyltin dilaurate) diluted with 1mL of ethanol is added dropwise, and the consumption of the catalyst is Ti 3 C 25% of the mass, under the constant temperature condition of 60°, the reaction was stirred at a high speed of 300rpm for 6h.

[0046] (2) The reaction product obtained in step (1) was vacuum-dried at 60° C. for 10 h to obtain a functionalized two-dimensional layered transition metal carbide material, labeled as f-MXene.

[0047] (3) Prepare styrene-butadiene rubber composite material (SBR / f-MXene-5) from the functionalized two-dimensional layered transition metal carbide material f-MXene obtained in step (2). The basic formula is shown in Table 2. Each group The unit of dosage is phr. According to the basic formula of rubber, according to the order of adding activator (ZnO+St), inorganic filler (M...

Embodiment 3

[0052] (1) Weigh 4g of Ti 3 C 2 , 3g silane coupling agent KH560 and 80g deionized water are mixed in the there-necked flask of 500ml, drop the organotin catalyst (dibutyltin dilaurate) diluted with 1mL ethanol, the consumption of catalyst is Ti 3 C 2 5% of the mass, under the constant temperature condition of 70°, the reaction was stirred at a high speed of 400rpm for 8h.

[0053] (2) The reaction product obtained in step (1) was vacuum-dried at 80° C. for 12 hours to obtain a functionalized two-dimensional layered transition metal carbide material, labeled as f-MXene.

[0054] (3) Prepare styrene-butadiene rubber composite material (SBR / f-MXene-7) from the functionalized two-dimensional layered transition metal carbide material f-MXene obtained in step (2). The basic formula is shown in Table 3. Each group The unit of dosage is phr. According to the basic formula of rubber, according to the order of adding activator (ZnO+St), inorganic filler (MXene / f-MXene), anti-aging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com