Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

450results about How to "Improve tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

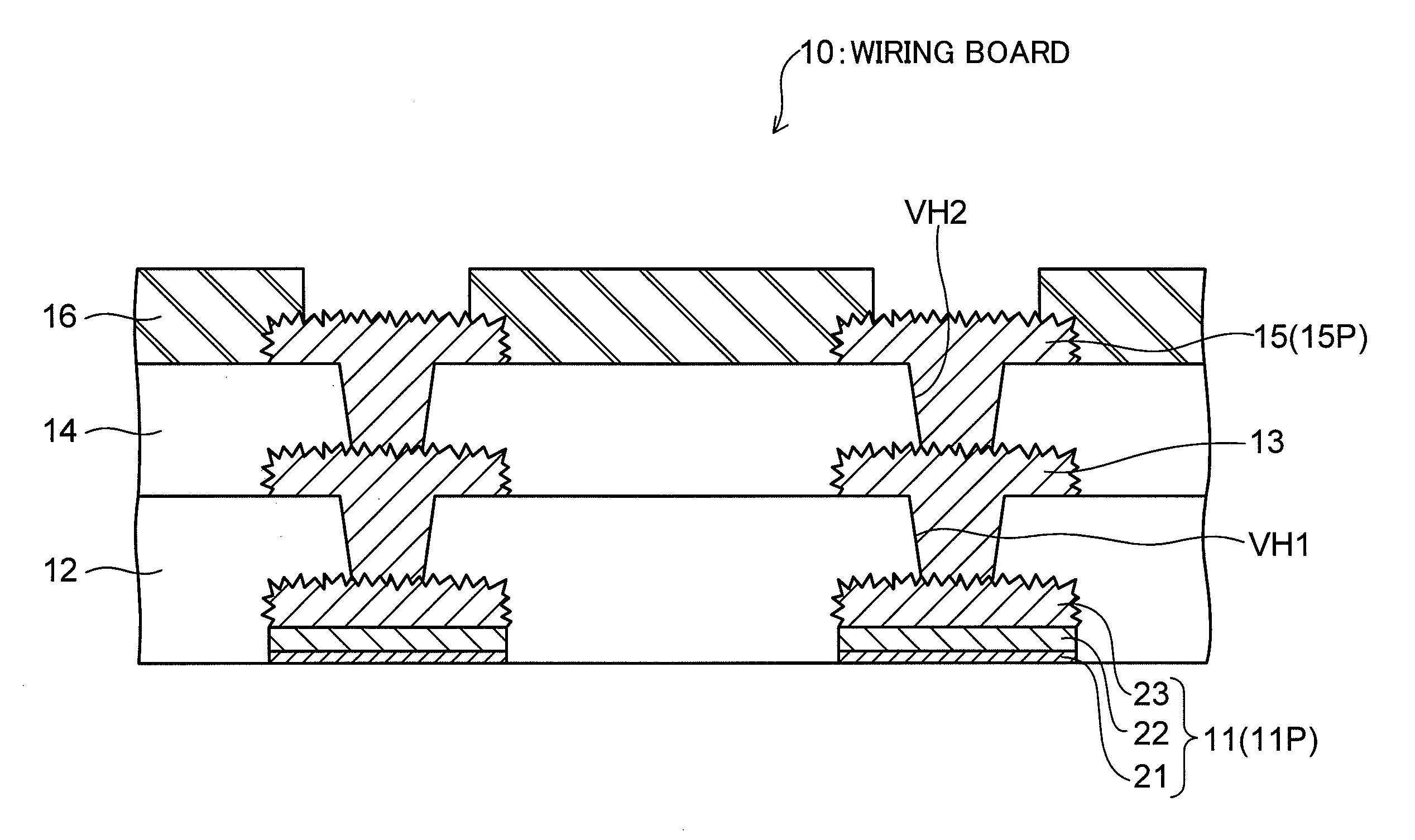

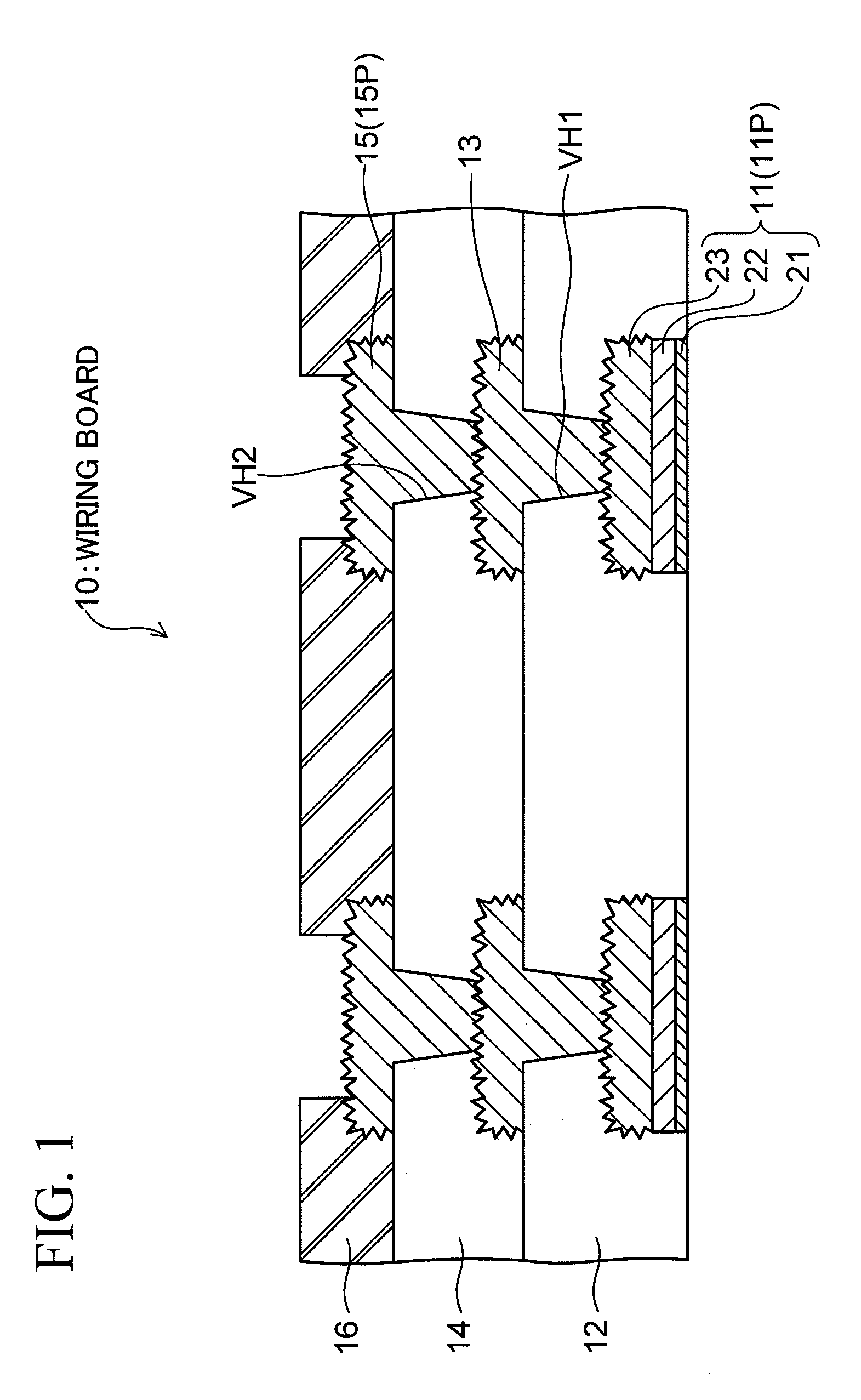

Wiring board and method of manufacturing the same

ActiveUS20100065322A1Improve tensile strengthDecreasingSemiconductor/solid-state device detailsSolid-state devicesMetalMaterials science

A wiring board includes a pad exposed from an opening portion of an outermost insulating layer. The pad includes: a first metal layer a surface of which is exposed from the wiring board; a second metal layer provided on the first metal layer and formed of a material effective in preventing a metal contained in a via inside the board from diffusing into the first metal layer; and a third metal layer provided between the second metal layer and the via, and formed of a material harder to be oxidized than that of the second metal layer. The thickness of the third metal layer is relatively thick, and is preferably selected to be three times or greater than a thickness of the second metal layer. A side surface of the third metal layer and a surface of the third metal layer to which the via is to be connected are roughed.

Owner:SHINKO ELECTRIC IND CO LTD

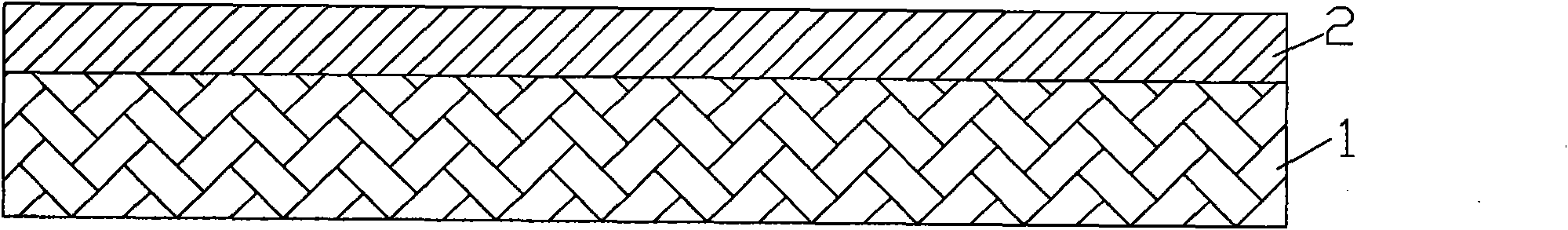

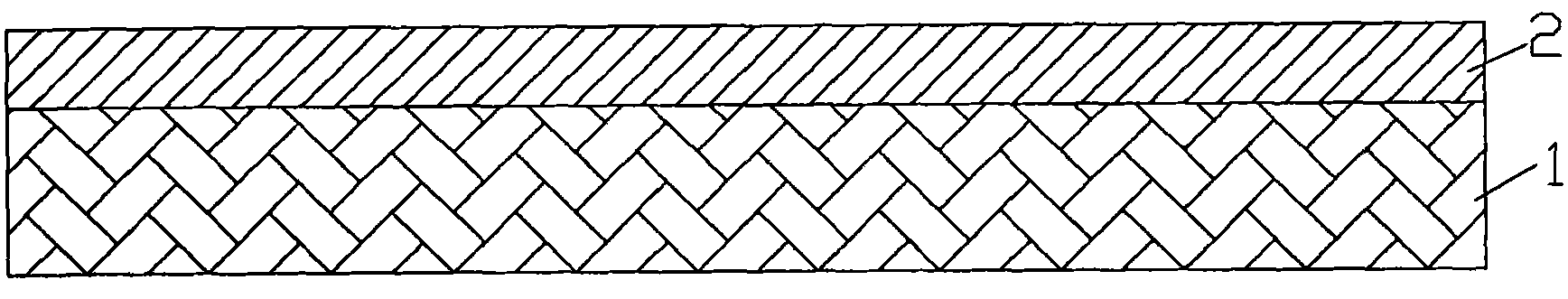

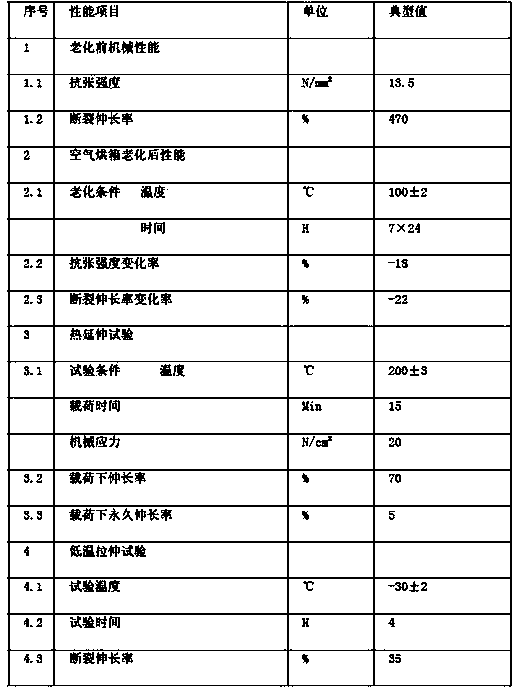

Sewing-free hot melt adhesive TPU-PU leather and preparation method thereof

ActiveCN103437195AExcellent physical and chemical propertiesHigh bonding strengthPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterPolymer science

The invention provides a piece of novel sewing-free hot melt adhesive TPU-PU leather, and a preparation method thereof. The TPU-PU leather comprises release paper, a hot melt adhesive film, a TPU film and a dry-type PU film, wherein the release paper comprises a paper bottom layer, an adhesive layer, a plastic layer, a transition layer, and a release layer; a hot melt adhesive raw material is composed of polyester polyol, diisocyanate, polyether polyol, and a plurality of additives; a TPU raw material is composed of polymer polybasic alcohol, 1,4-cyclohexane-diisocyanate, a chain extender and a plurality of functional additives; a PU raw material is composed of polyester dibasic alcohol, straight chain diol, isocyanate, TDI trimer, dimethyl formamide, butanone, black sand, and a plurality of functional addictives. Through the adoption of the preparation method, innovations are conducted on the raw material components of the release paper, the hot melt adhesive, the TPU film and the PU film; the manufactured sewing-free TPU-PU leather has the technical advantages of firmness in adhesion, durability, environment-friendly materials, no invisible harm to a human body, and the like.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

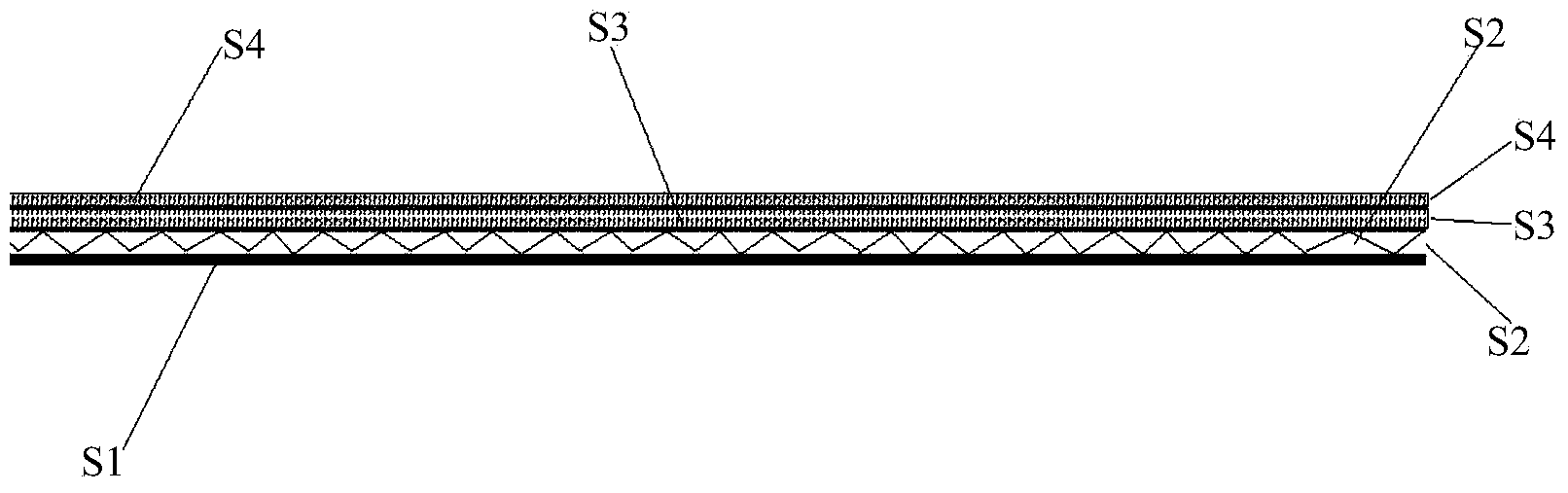

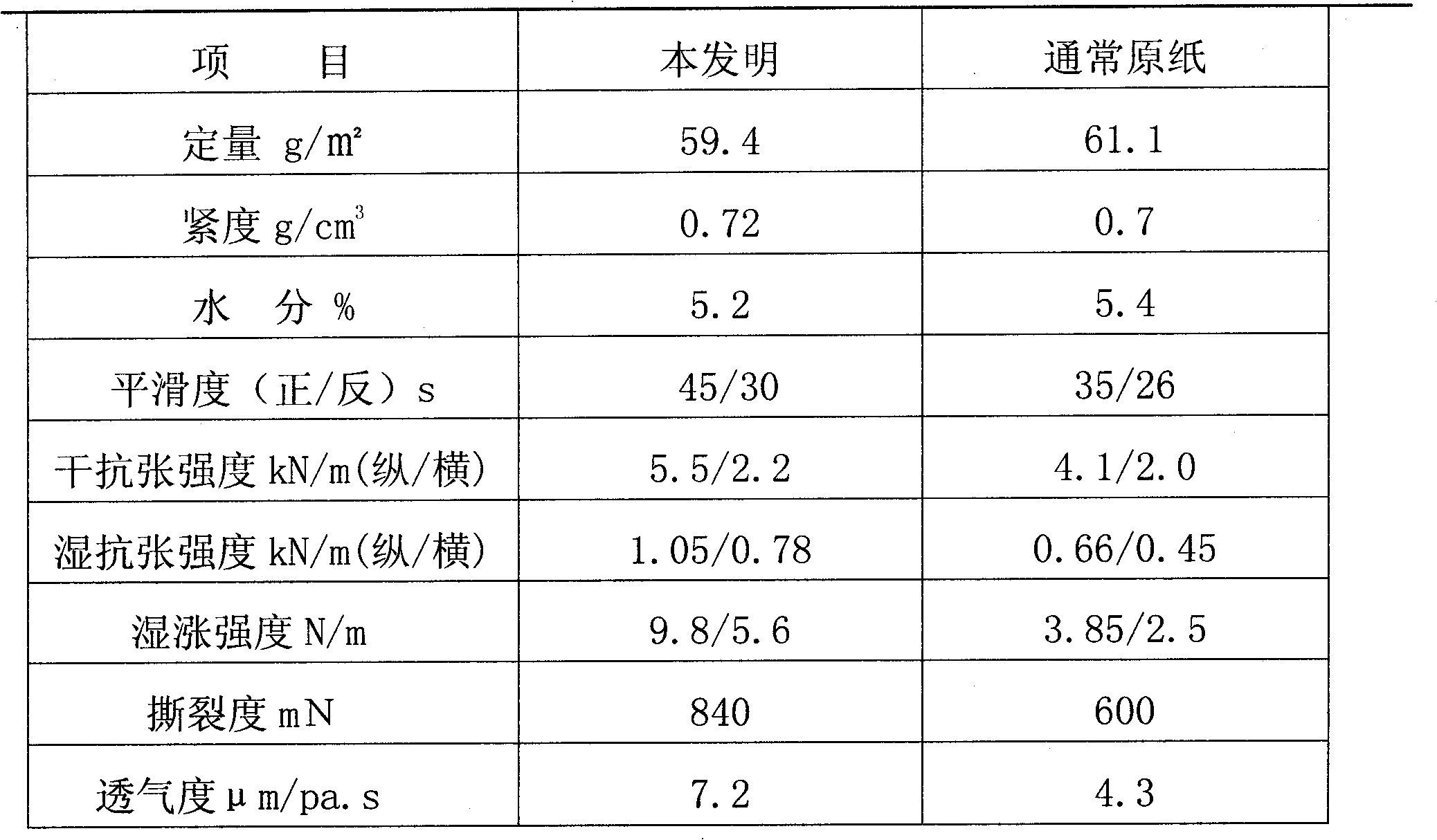

Production method for bactericidal packing paper

ActiveCN102154944AImprove breathabilityHigh strengthPaper coatingReinforcing agents additionBursting strengthCarboxymethyl cellulose

The invention discloses a production method for bactericidal packing paper, which comprises the following steps of: (1) preparation working procedure of applying glue solution to pulp; (2) preparation working procedure of applying glue solution to a surface; (3) working procedure of sizing agent repulping, selecting Southern pipes produced in America to make pulp, adding sodium carbonate and carboxymethyl cellulose into a repulping liquid; (4) working procedure of pulp matching, adding a wet strength agent; (5) working procedure of webbing and forming; (6) working procedure of applying glue solution to the surface, using modified tapicoa starch and polyvinyl alcohol for applying the glue solution to the surface; and (7) completion working procedure. The bactericidal packing paper has good air permeability, high surface strength, tearing resistance after disinfection and high bursting strength and can block bacterium invasion.

Owner:安徽华邦古楼新材料有限公司

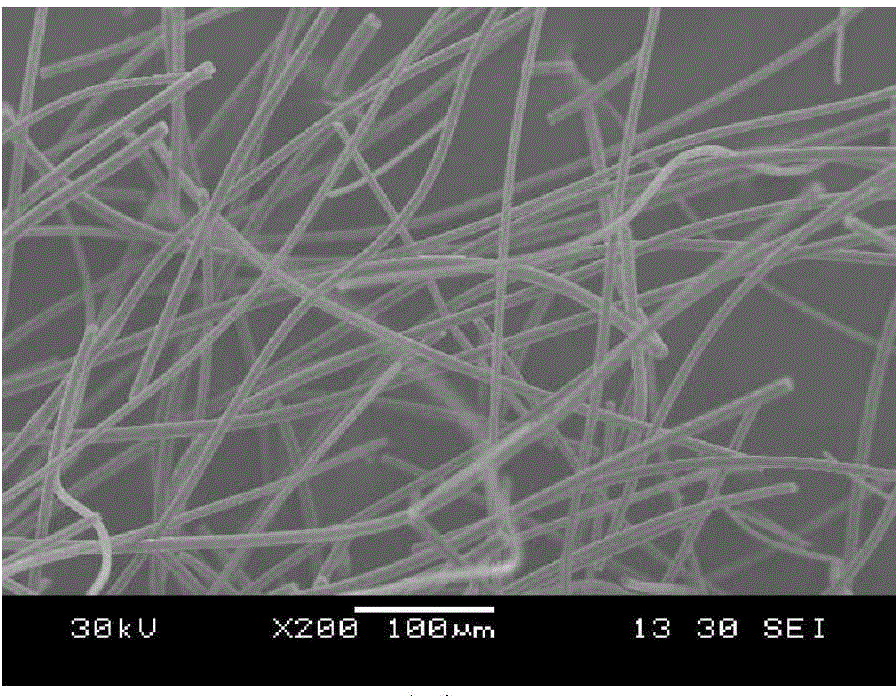

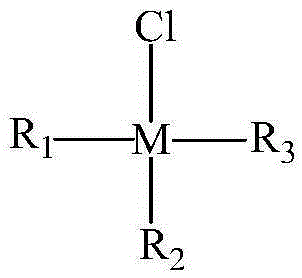

Preparation method of mullite fiber

The invention discloses a preparation method of high-purity continuous mullite fiber. The mullite fiber is prepared by adopting a sol-gel method and a centrifugal spinning technology through taking anhydrous aluminum chloride and aluminum powder as an aluminum source, tetraethylorthosilicate as a silicon source, and glacial acetic acid as a colloid stabilizer and spinning auxiliary. The preparation method comprises the following steps: firstly, preparing a mullite fiber precursor sol according to raw materials, preparing gel fibers through the centrifugal spinning technology, and finally drying and sintering at high temperature to obtain the mullite fiber. In order to improve the room-temperature and high-temperature mechanical performance of mullite, 0-2wt% of oxide second phase is added. Compared with the prior art, the mullite fiber prepared by adopting the method has the advantages that the consumed time is short, raw materials are low in price, and industrial production can be considered; the mullite fiber is higher in high-temperature resistance degree and better in physical and chemical properties compared with aluminum silicate fiber and high-purity alumina fiber; the mullite fiber can also be used as base fibers of mullite fiber felts and fiberboards, and can be further processed.

Owner:南京理工宇龙新材料科技股份有限公司 +1

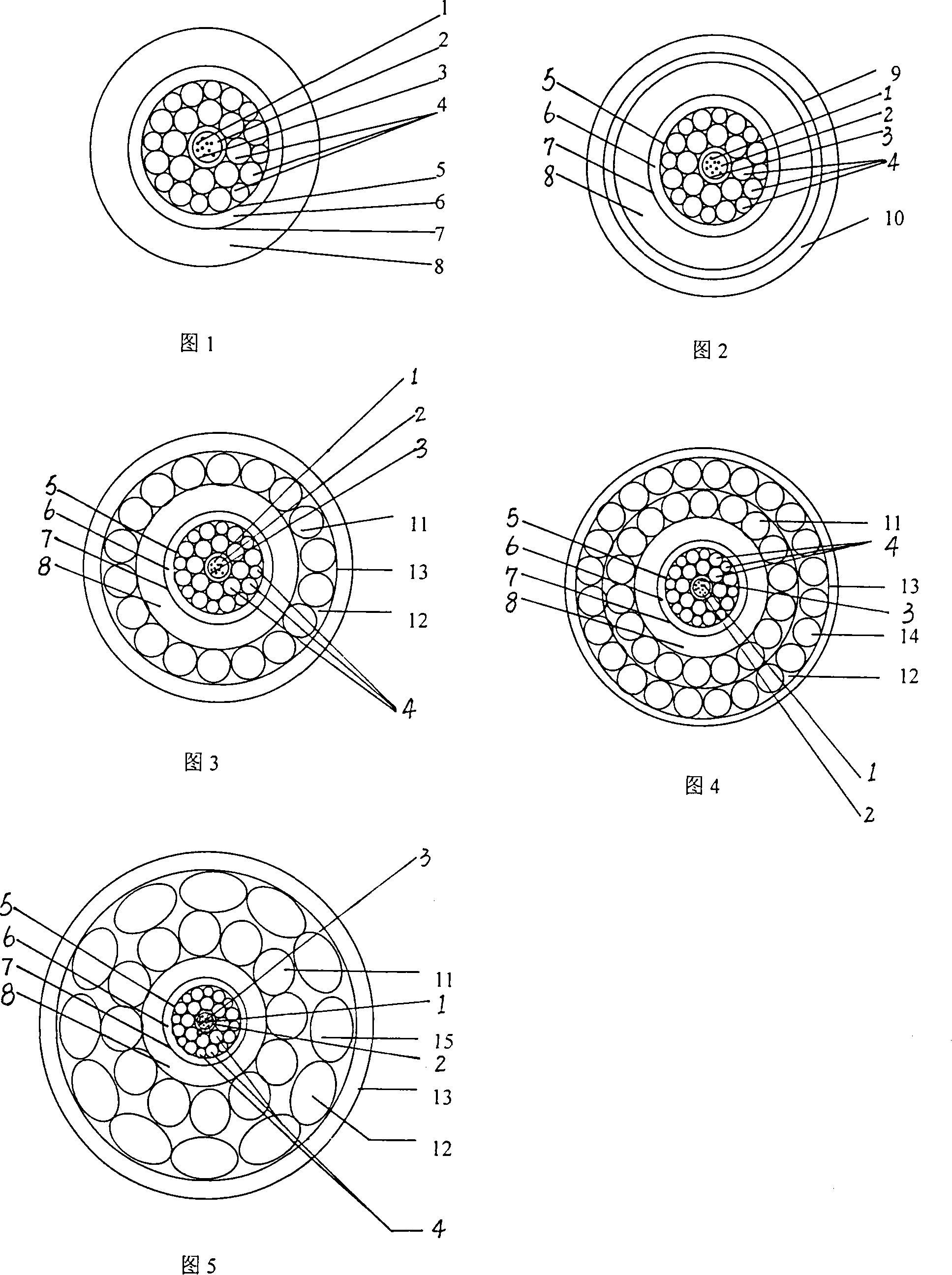

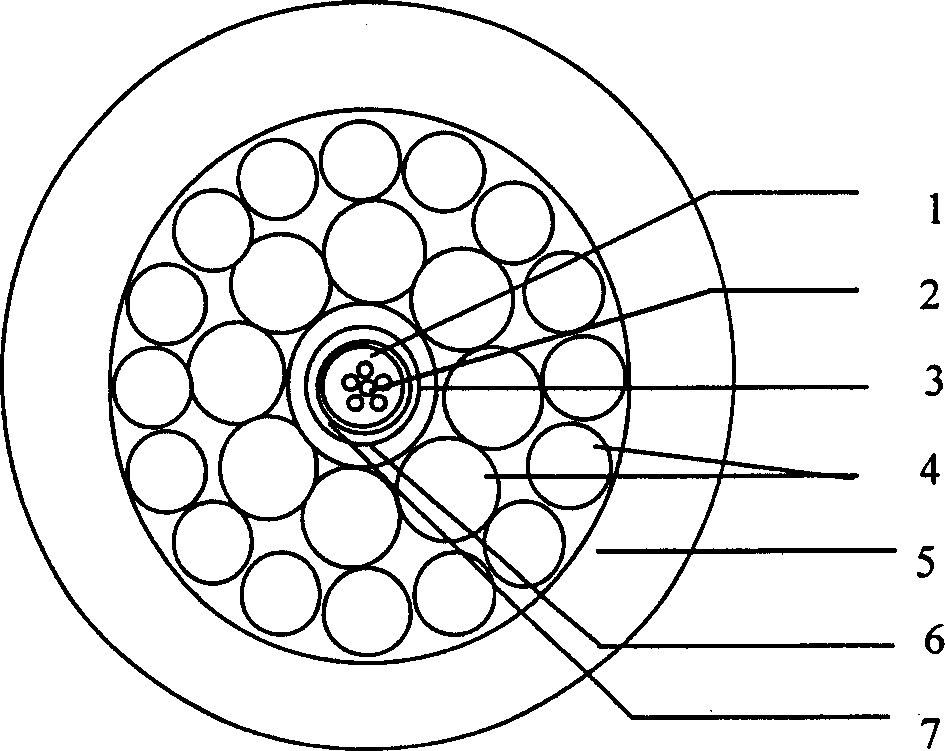

Deep sea optic cable and its manufacture method

InactiveCN101241213AGuaranteed lifeReasonable and reliable structureFibre mechanical structuresEngineeringHigh intensity

The invention provides a deep sea optical cable and producing method thereof, relating to a deep sea optical cable with a tension-resistant compact composite structure and producing method thereof. The structure of the deep sea optical cable comprises a plurality of full chromatogram high-strength optical fibres, high-strength anti-corrosion stainless steel tubes, ointment exclusive for sea cable optical fibre, special-high-strength armouring wires with three diversified diameters, a heavy viscous waterproof agent, metallic conductor brass pipes, organic plastic composite materials, and a polythene insulation material protective layer. High-strength anti-corrosion stainless steel tubes are sleeved on several full chromatogram high-strength optical fibres, ointment exclusive for sea cable optical fibre is filled into the high-strength anti-corrosion stainless steel tubes, special-high-strength armouring wires with three diversified diameters are inlaid on the outside of the high-strength anti-corrosion stainless steel tubes and are filled with heavy viscous waterproof agent of sufficient amount, the special-high-strength armouring wires are covered with the metallic conductor brass pipes, so that special tension-resistant compact composite structure is formed. Organic plastic composite materials are added on metallic conductor brass pipes, and then an insulation material protective layer is extruded thereon.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

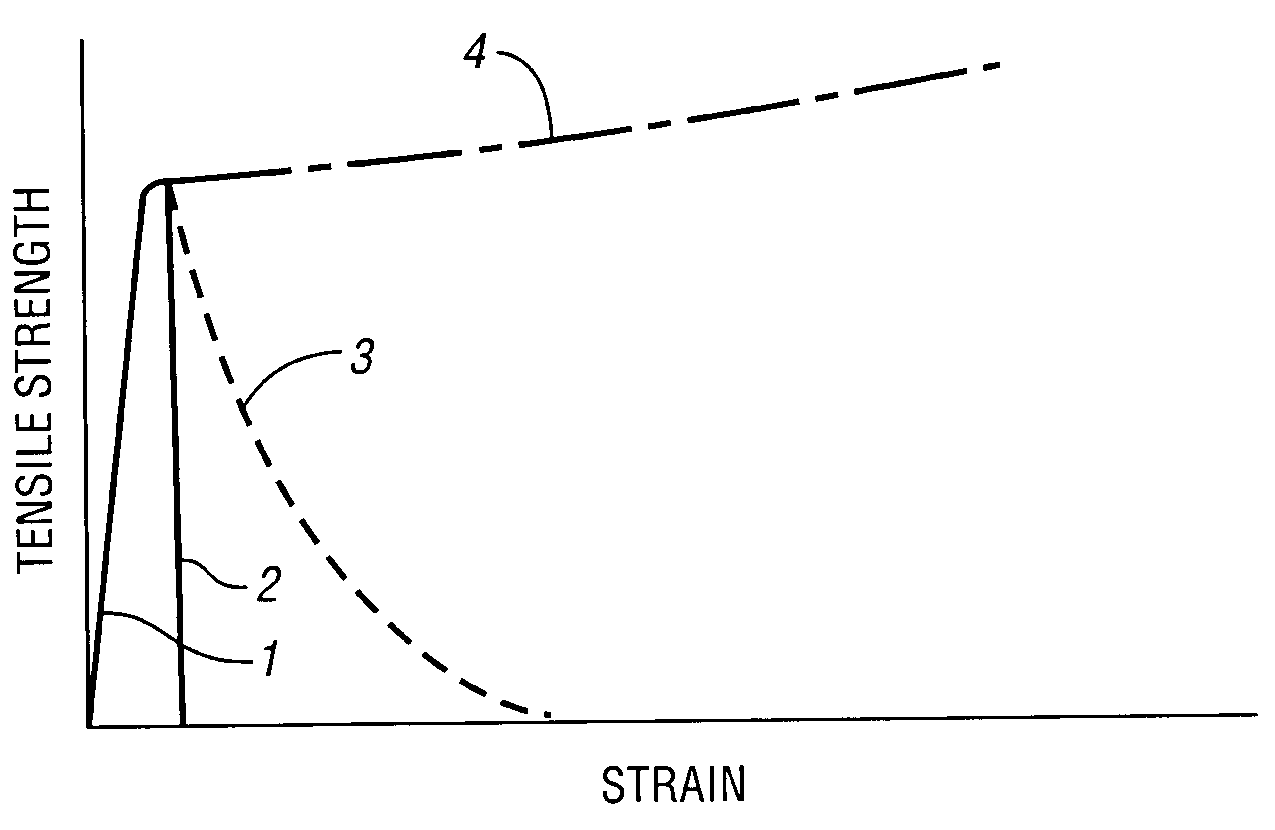

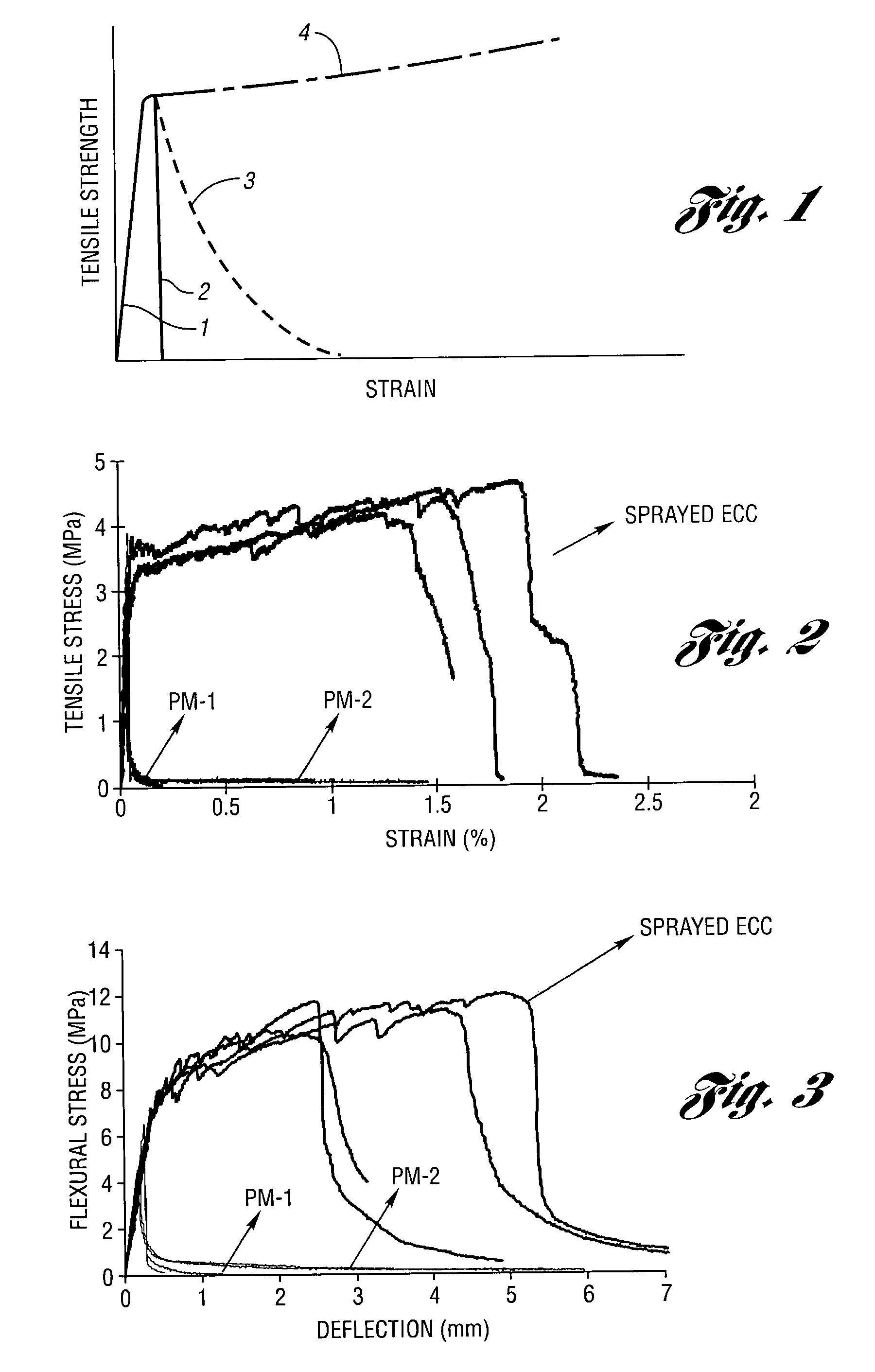

Sprayable, strain-hardening cementitious compositions

ActiveUS20050066858A1Improve tensile strain capacityImprove tensile strengthSolid waste managementNatural mineral layered productsSuperplasticizerFiber

Sprayable fiber reinforced hydraulically setting mortars exhibit strain hardening behavior, and comprise hydraulically setting cement, less than 4 weight percent matrix interactive fibers, a non-Newtonian additive, a superplasticizer, optionally a viscosity control agent, aggregate, and further additives. The ductile composites can be prepared by spraying in thicknesses higher than conventional sprayable mortars.

Owner:THE RGT OF THE UNIV OF MICHIGAN

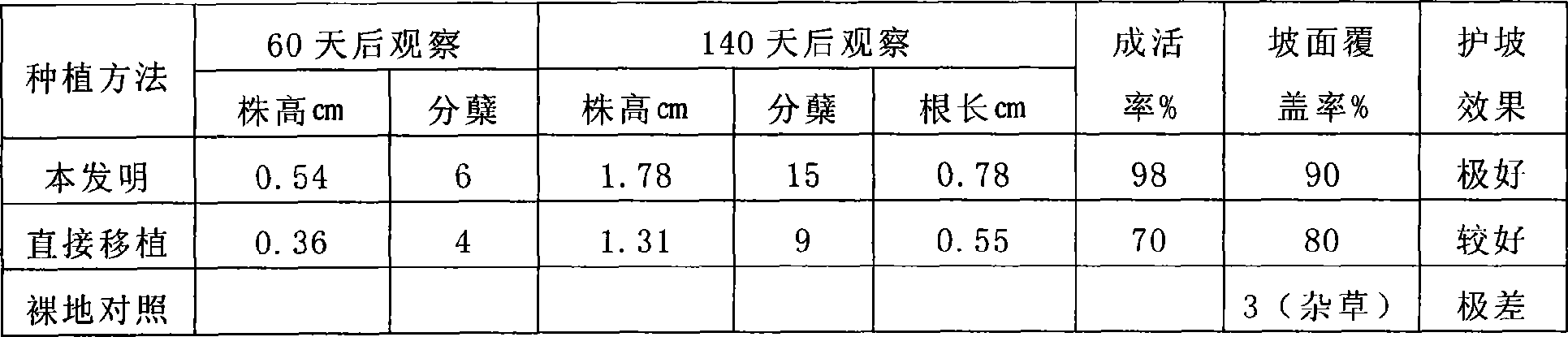

Method for growing balsamroot grass to fix soil to protect slope

The invention discloses a soil-fixation and slope-protection method by planting vetiver grass, belonging to a planting method of vegetation and aiming to provide a method for administering hungriness areas by utilizing the property of the vetiver grass and planting vetiver grass in the surface of bare hills and lands, man made side slopes, tailing areas, and the like. The technique proposal comprises the following steps: sorting out fields, digging plant grooves, filling in nutrient soil, cutting, dipping in root, wrapping slurry, making vegetation pocket seedlings, transplanting the vegetation pocket seedlings and then maintaining. The method has the advantages of improving the survival rate of the vetiver grass by about 30%, having good effect in preventing water loss and soil erosion, fixing soil and protecting slopes, and effectively improving geomorphologic landscape; the method can be widely used for revegetation in bare hills and lands, hungriness areas and hammada areas of the karst region, fixing slopes and greening of man made side slopes, and administering earth surface of tailing areas, etc.

Owner:GUIZHOU JIAOKAN ECOLOGICAL GARDENS

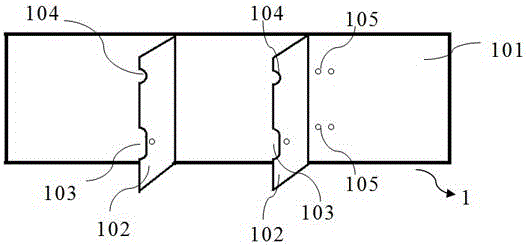

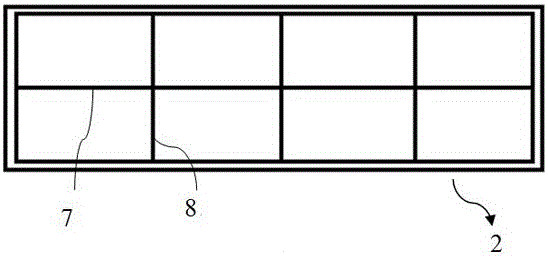

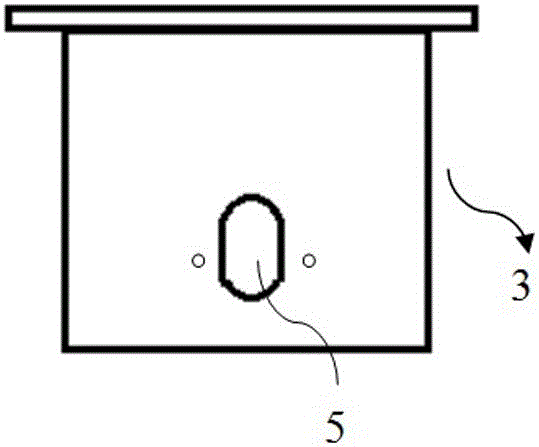

Beam specimen casting die, and method for testing mechanical performances of beam specimen

InactiveCN105973662AIncrease stiffnessHigh strengthPreparing sample for investigationUsing mechanical meansBaseboardEngineering

The invention discloses a beam specimen casting die, and a method for testing the mechanical performances of a beam specimen. The beam specimen casting die comprises a baseboard, two side boards and two adjusting boards, the two side boards are arranged at two sides of the baseboard in parallel, and the adjusting boards are arranged between the two side boards in parallel; and every side plate comprises a surface board and two connecting boards vertical to the surface board, the lower end of every connecting board is connected with a first through hole, the upper end of every connecting board is provided with a second through hole, the connecting boards of the two side plates oppositely contact each other to form a cavity, and two casting cavities are formed between the adjusting boards and the cavity. The beam specimen casting die can be reused, and can simultaneously adjust the dimensions of a specimen, the thickness of a protection layer, the bonding length of steel bars and the diameter of the steel bars.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Intelligent traveling bag with solar power generation device

InactiveCN105877090AEasy to useRealize the power supply demandTravelling sacksBatteries circuit arrangementsSolar powerMobile phone

The invention relates to the technical field of intelligent traveling bags and in particular relates to an intelligent traveling bag with a solar power generation device. A solar thin-film cell is arranged on the outer side of a bag body; a power management module provides a working power supply for a processor, a Bluetooth communication module, a mobile communication module, an alarm and a GPS positioning module; the Bluetooth communication module, the mobile communication module, the alarm and the GPS positioning module are respectively connected with the processor so as to transmit signals; the mobile communication module is connected with a network server; the network server is connected with mobile phone APP software so as to transmit the signals; and the mobile phone APP software is in signal connection with the processor by virtue of the Bluetooth communication module. According to the solar thin-film cell and a wireless charging module, electric energy supply requirements of devices and working parts in the bag are met. A composite structure of leather is reasonably improved, so that the intelligent traveling bag can achieve the advantages of high tensile strength, high tearing strength, high wear resistance and the like.

Owner:ANHUI TIANEN TRAVEL GOODS TECH CO LTD

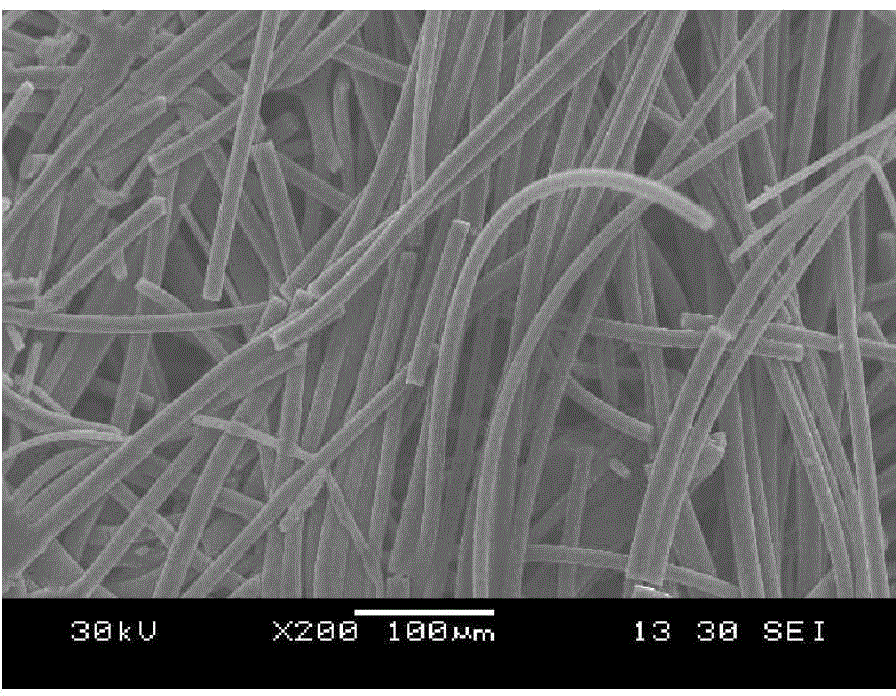

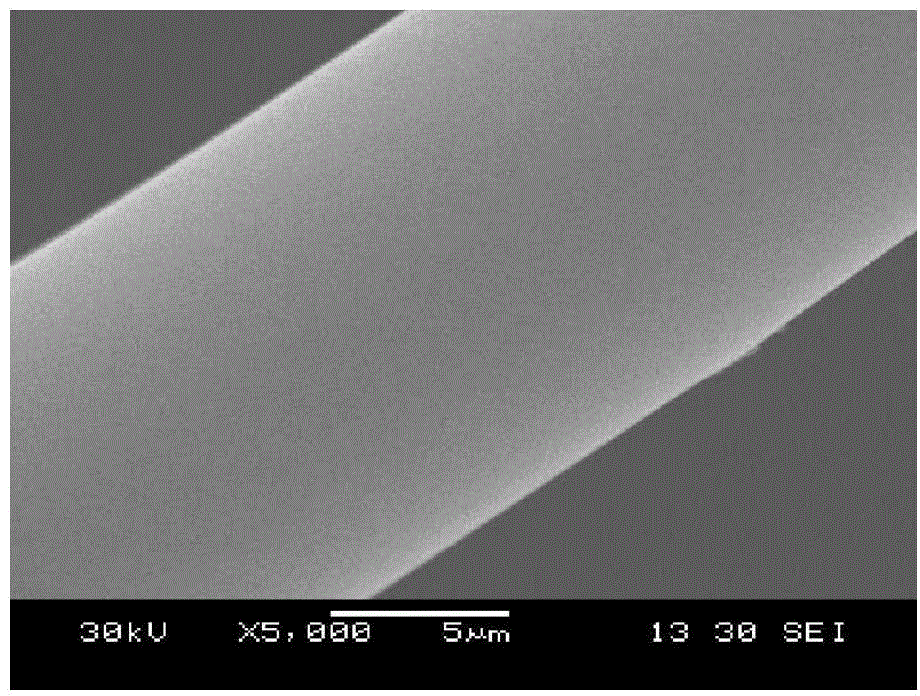

Low-temperature thermal insulation paper, preparation method and application thereof

ActiveCN101058961AGood insulation performanceImprove flame retardant performanceSynthetic cellulose/non-cellulose material pulp/paperChemical/chemomechanical pulpFiberGlass fiber

The present invention involves a low-temperature insulating paper, and relates to a preparation method of said low-temperature insulating paper and its applications. The invention prepares the low-temperature insulating paper with superfine alkali-free glass fiber and wet paper preparation process; the definite quantity of said low-temperature insulating paper is 10-20 g / m2 and the thickness is 0. 06 - 0. 09 g / m2. The preparation method of said low-temperature insulating paper includes: beating, stirring and scattering the superfine alkali-free glass fiber, and drying after stripping in paper machine, last coiling and preparing the products. The low-temperature insulating paper in the invention can be used for vacuum multi-layer insulation structure of copious cooling liquid accumulating container and complement pipes. The low-temperature insulating paper in the invention has good adiabaticity, the degassing ratio is small in vacuum, the profiling performance is good, and it has long life and wide uses.

Owner:HANGZHOU FUSHIDA SPECIAL MATERIAL

Method for direct modifying and yarn flattening of reclaimed material woven bag

InactiveCN103173891AReduce processImprove tensile strengthConjugated synthetic polymer artificial filamentsArtifical filament manufactureChemical wasteWater cooling

The invention discloses a method for direct modifying and yarn flattening of a reclaimed material woven bag, belonging to the technical fields of woven bag production and environmental protection of chemical waste substances. The method is finished by nine major processes including preparation, dosing, melting, filtration, extrusion and membrane output, water cooling, splitting, drawing and winding, and the method has the beneficial effects that the waste plastic is melted and directly subjected to yarn flattening, the process and energy consumption are reduced, and labor power is reduced; a small amount of master batch, modifier, whitening agent and lubricant is added during the dosing; after the melting, the tensile strength and fineness of the yarn-flattened material are reasonably improved through the filtration, the membrane output, the water cooling and the drawing; particularly, the water cooling is performed at 50-60 DEG C, and then the drawing times is set as 6.5; according to a test, the warp-direction pulling strength and the weft-direction pulling strength of the produced flattened yarn are both greater than 700N / 50mm, the tensile strength of the flattened yarn is greatly enhanced, and the problem of yarn breakage in a weaving process is avoided; and by adopting waste plastic as raw material, the environmental pollution is effectively reduced.

Owner:重庆市广博塑料袋有限公司

Chamois initation artificial leather and manufacturing method thereof

InactiveCN1497098AExcellent color developmentHigh fastnessDyeing processWoven fabricsElastomerChamois leather

Provided is sueded artificial leather having good color developing properties and color fastness to light in a wide range of color tones, having a good sueded feel, surface touch, and feeling, and therefore having a sense of high quality. This suedey artificial leather is composed of a three-dimensionally interwoven material formed out of ultrafine fibers having a dtex of <=0.2 and a polymeric elastic material A and satisfies the following requisites (1) to (4): (1) the three-dimensionally interwoven material contains 0-8wt.% of at least one pigment A selected from an organic pigment having an average particle diameter of 0.01-0.3[mu]m and carbon black having an average particle diameter of 0.01-0.3[mu]m, (2) the polymeric elastic material A contains 1-20wt.% of at least one of another pigment selected from another organic pigment having an average particle diameter of 0.05-0.6[mu]m and the other carbon black having an average particle diameter of 0.05-0.6[mu]m, or of pigment particles containing the other organic pigment and having the average particle diameter of 0.05-0.6[mu]m, as a pigment B; (3) the polymeric elastic material A and the three-dimensionally interwoven material are contained in a weight ratio of 15:85 to 60:40; and (4) the ultrafine fibers existing at the surface have raised fluffs of which the average length is 10-200[mu]m.

Owner:KURARAY CO LTD

Preparation method of cellulose-based composite material

The invention relates to a preparation method of a cellulose-based composite material. The method comprises the following steps: preparing a cellulose solution and a lithium magnesium silicate solution; mixing the cellulose solution with the lithium magnesium silicate solution; coagulating and regenerating in a coagulating bath; washing and drying to obtain the cellulose-based composite material. According to the preparation method, lithium magnesium silicate can form a stable nanometer flake structure in a water system, so that ultra-fine dispersion of lithium magnesium silicate nano particles in the cellulose solution is realized, and the cellulose-based composite material, which is compact and even in structure, and is significantly improved in the tensile property, is prepared; dispersing is carried out in absence of any surfactant. Therefore, the preparation method is simple in steps, and has good practical application value.

Owner:QILU UNIV OF TECH

One-step carbonization process of preparing cubic calcium carbonate of 80-100 nm size

InactiveCN1361063AImprove electrical performanceImprove flame retardant performanceCalcium/strontium/barium carbonatesCalcium hydroxideEmulsion

Into calcium hydroxide emulsion of 10-12 wt% concentration and at 20-25 deg.c, compound crystal form controlling agent is added while stirring, and then the mixture is transferred into a bubbling carbonating tower for carbonization for 50-70 min while introducing CO2 gas in the rate of 50-80 1 / min. Kg calcium hydroxide and cold water to control the temperature not higher than 60 deg.c until the pH value being reduced to 7-8. Through the one-step carbonization process, cubic calcium carbonate of 80-100 nm size is prepared. The said process is suitable for use in industrial production and has low production cost and high production efficiency, and the product has excellent dispersant characteristic and may be widely used, especially in producing silicon rubber product.

Owner:GUANGZHOU GBS HIGH TECH & IND

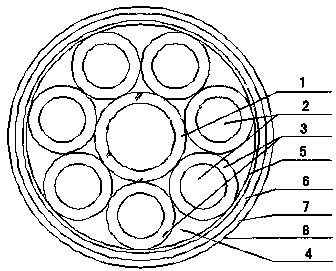

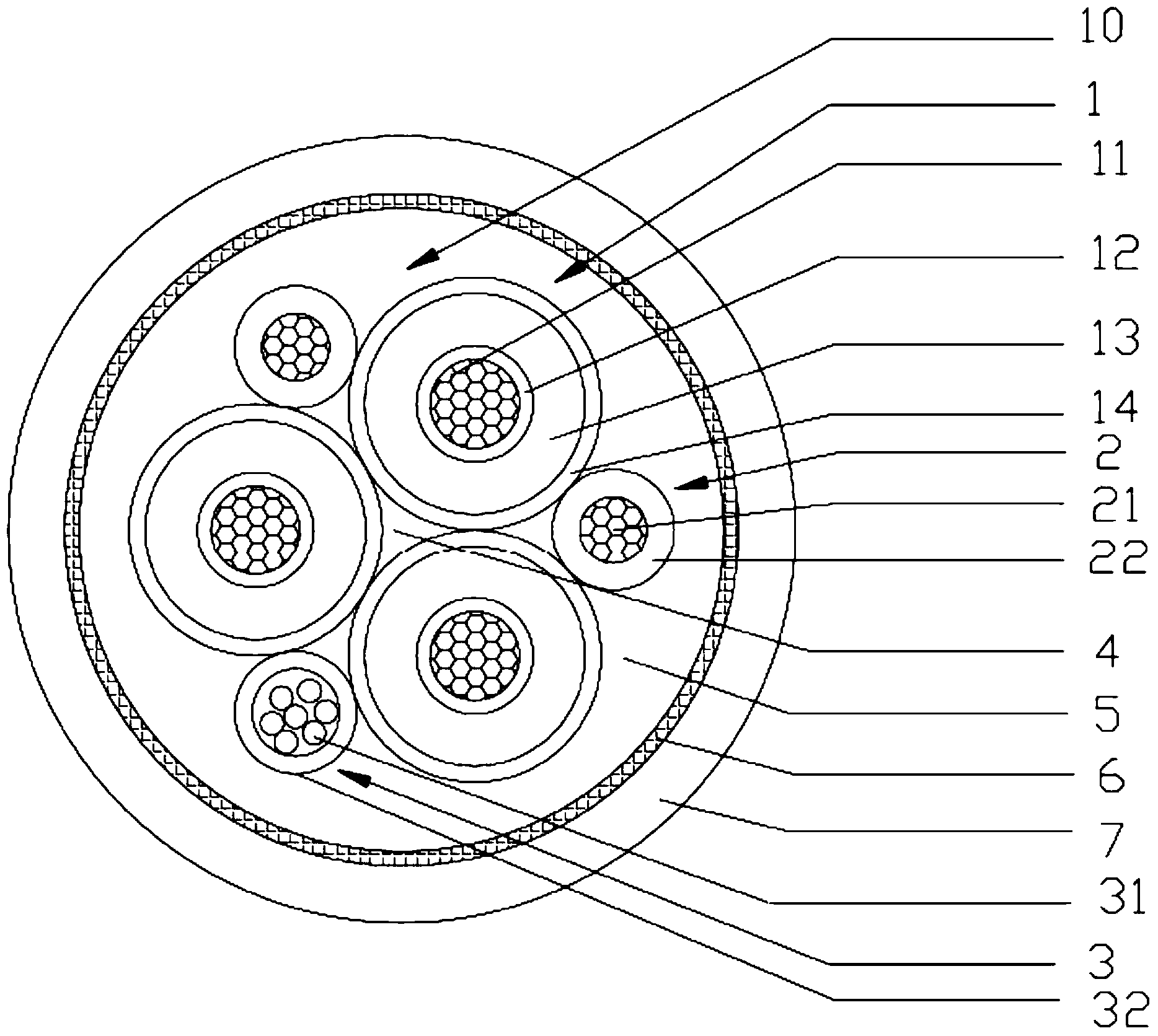

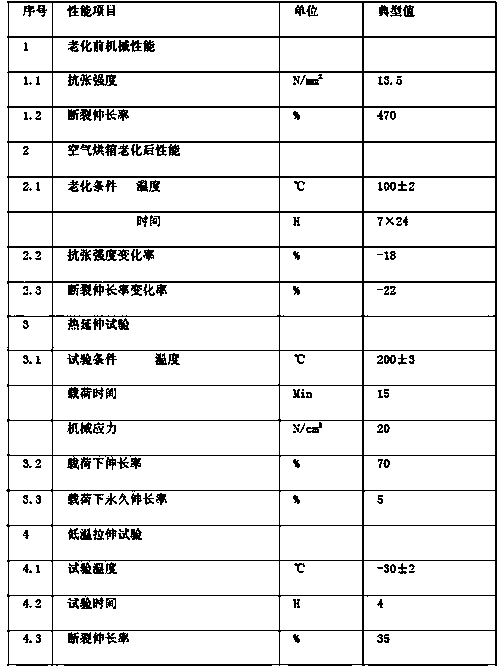

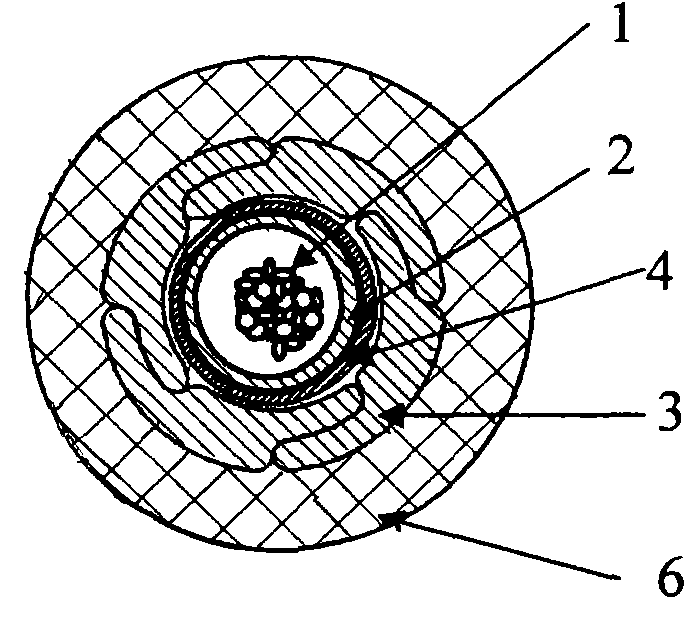

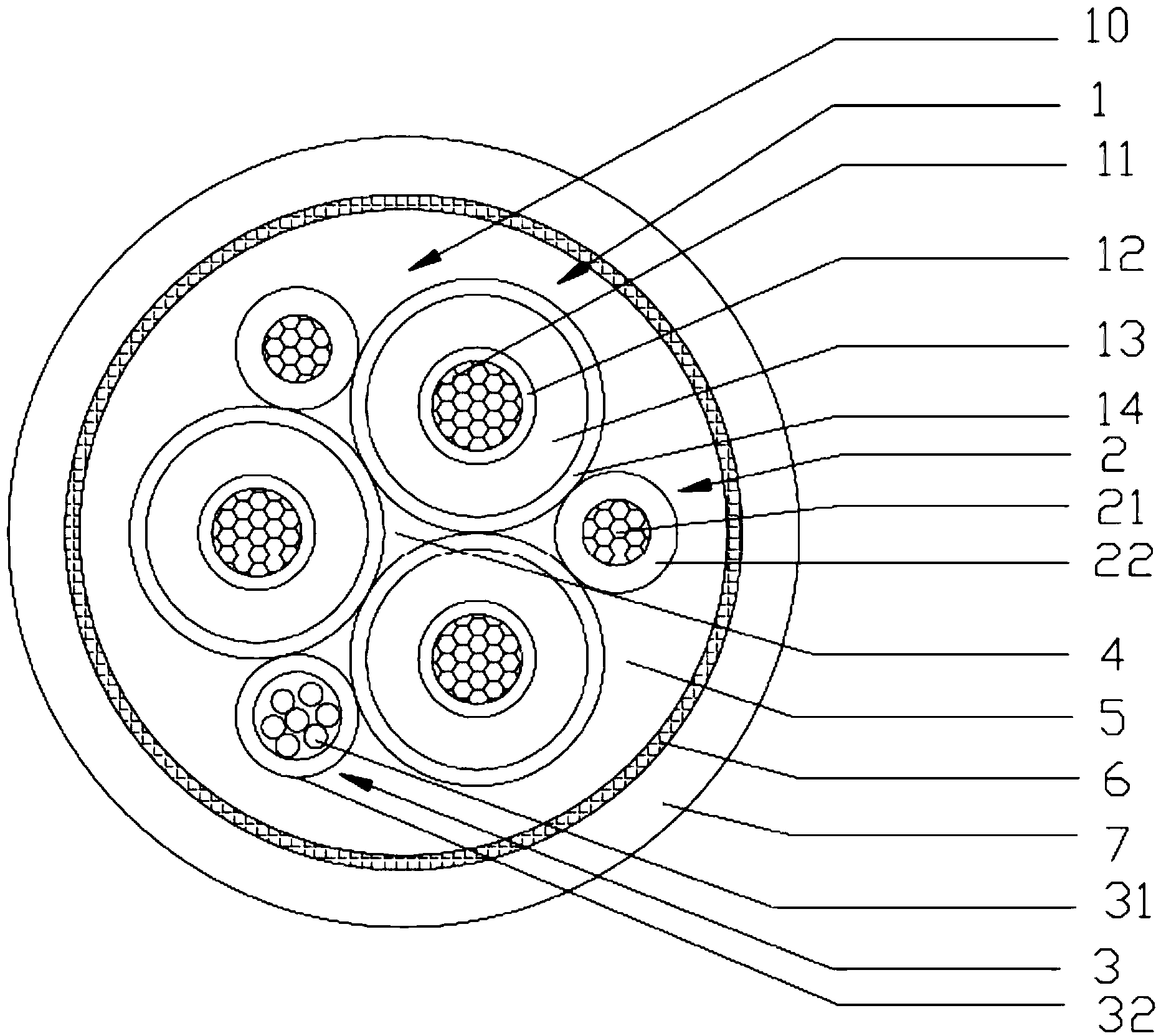

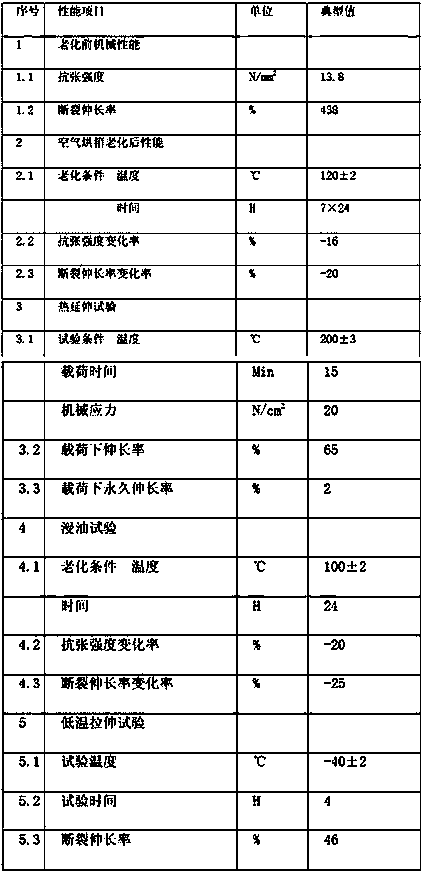

Multicore rubber jacketed flexible cable for movement

InactiveCN104078124AExtended service lifeImprove tensile strengthPower cablesFlexible cablesFlexible cableStructural engineering

The invention discloses a multicore rubber jacketed flexible cable for movement. The cable comprises a cable core, wherein a belting layer is wrapped outside the cable core in a surrounding manner; an internal sheath is wrapped outside the belting layer in an extrusion manner; a braid layer is weaved outside the internal sheath; an external sheath is wrapped outside the outermost layer in an extrusion manner; the cable core is formed by twisting a hollow-core tube in the center of the cable core and multiple insulating cable cores wrapped around the hollow-core tube in an extrusion manner; the hollow-core tube adopts a tubular TPE insulating and aramid fiber yarn straight pulling structure. According to the invention, the center of the cable adopts aramid fiber yarn straight pulling PTE insulating hollow-core tube to enable the cable to be suitable for the service environment with higher requirements, so that the tensile strength, the compression resistance, the torsion resistance and other mechanical stress of the cable can be effectively improved, and the multicore rubber jacketed flexible cable is suitable for frequent movement in the wild and on a construction site.

Owner:JIANGSU ZHONGXING CABLE

Yoga mat making method

InactiveCN103205074AIncrease elasticityImprove toughnessShock absorber matsElastomerPolyvinyl alcohol

The invention belongs to the technical field of materials, and relates to a yoga mat making method. The method comprises the following steps: weighing 20-30 parts of an elastomer, 30-50 parts of nylon, 30-60 parts of a polyvinyl alcohol resin, 10-15 parts of processing oil, 0.1-0.8 parts of an antioxidant and 5-10 parts of a softener; and putting the above weight parts of the above materials in a stirrer, uniformly stirring for 3-5min, putting the obtained mixture in an injection machine, carrying out injection molding at 180-200DEG C for 2-3min, and molding at 20-50DEG C to form a yoga mat. The yoga mat made in the invention has the advantages of good performances, difficult skidding, good wear resistance, and good environmental protection performance.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Non-universal optical unit of submarine photoelectric composite cable and making method thereof

ActiveCN1862303AReasonable designCompact structureFibre mechanical structuresOcean bottomHigh intensity

The present invention relates to a submarine photoelectric composite cable non-universal type optical unit and its manufacture method. Its structure includes the following several portions: several optical fibres, plastic tube, stainless steel tube, water-proof material, high-strength armouring steel wire and external protective layer. Said invention also provides the concrete steps of its manufacture method.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

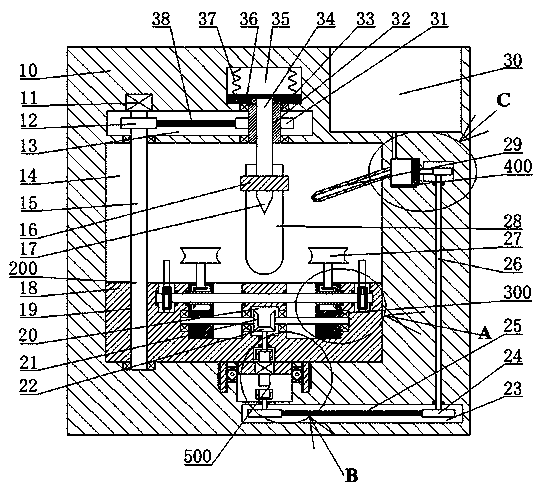

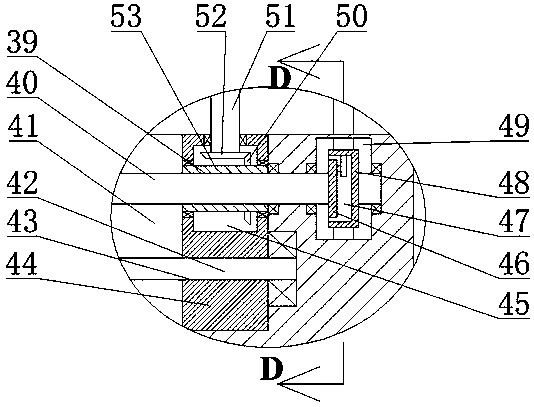

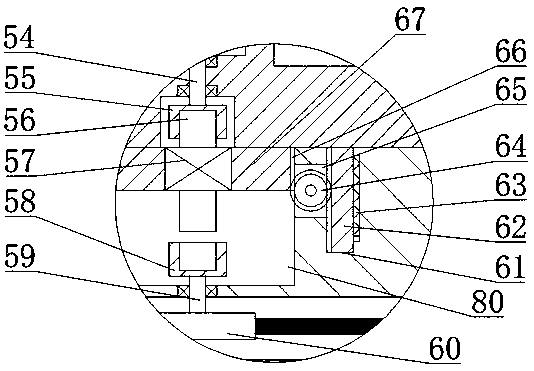

Hot-melting drilling device for air conditioner piping

InactiveCN110052648ARealize equidistant punchingImprove tensile strengthFeeding apparatusPositioning apparatusHot meltMachining process

The invention relates to the field of air conditioner accessory machining, in particular to a hot-melting drilling device for an air conditioner piping. The hot-melting drilling device for the air conditioner piping comprises a machine body and an operating cavity formed in the machine body; a through hole which penetrating through the operating cavity is formed in the machine body; a sliding frame which drives the air conditioner piping to move up and down is arranged in the operating cavity in a sliding manner; a lifting device which drives the sliding frame to move is arranged in the sliding frame; and sliding cavities which are in bilateral symmetry are formed in the sliding frame in an upward opening manner. According to the hot-melting drilling device for the air conditioner piping provided by the invention, equidistant drilling of the air conditioner piping can be realized; hot-melting drilling is realized by utilizing high-speed rotating friction of a drill bit, so that the bearable tension and torque of a hole wall are increased; the strength is higher; meanwhile, debris does not exist in a machining process; and the hot-melting drilling device for the air conditioner piping is cleaner, strong in functionality and good in stability, and facilitates production, popularization and use.

Owner:安徽亿力冷暖设备有限公司

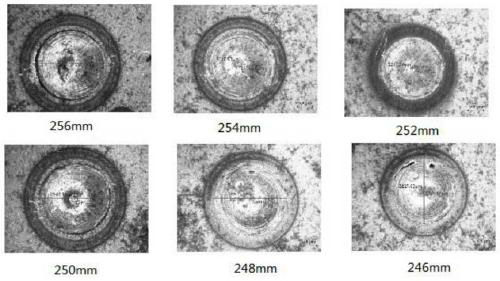

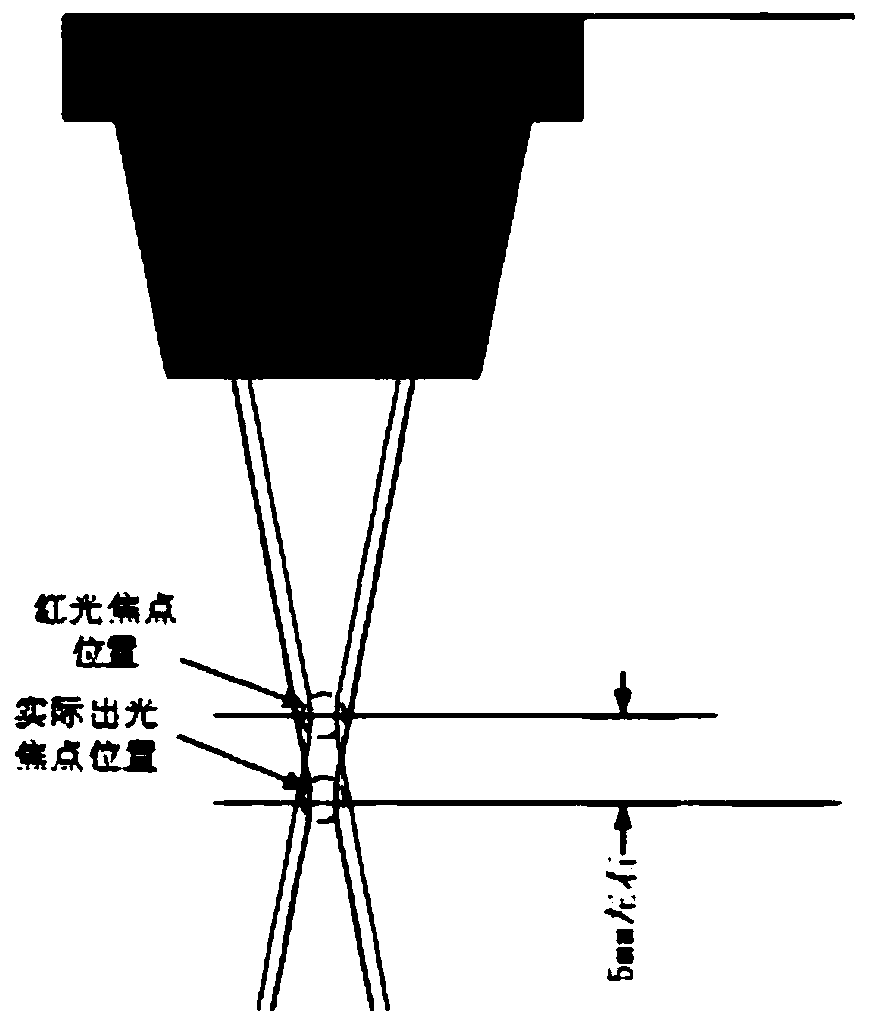

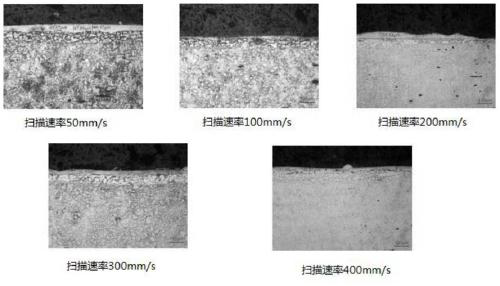

Process for preparing cladding layer on surface of copper base body by utilizing high-speed laser cladding technology

The invention discloses a process for preparing a cladding layer on the surface of a copper base body by utilizing a high-speed laser cladding technology. The process is characterized in that a lasercoaxial powder feeder is used for feeding a cladding alloy material to the surface of the copper base body, meanwhile, layer-by-layer high-speed laser cladding is performed by using an optical fiber laser or an optical fiber coupling semiconductor laser, wherein the process parameters of the laser in the cladding operation process are as follows, the focal length of a focusing lens is 250-300 mm,the cladding power is 2000-8000 W, the diameter of a light spot is 0.3-1.2 mm, the cladding scanning speed is 100-400 mm / s, and the lap joint rate is 65%. According to the preparation process of the obtained cladding layer, by utilizing the laser with the high scanning speed and adopting the specific cladding alloy powder for cooperation, the process parameters of the high-speed laser are determined, on the premise that subsequent other treatment is not needed, the cladding layer with the compact structure, without cracks and air holes and with extremely low dilution rate can be formed the surface of the copper base body, good metallurgical bonding between the cladding layer and the surface of the copper base body can be formed.

Owner:唐山中科量子激光科技有限公司

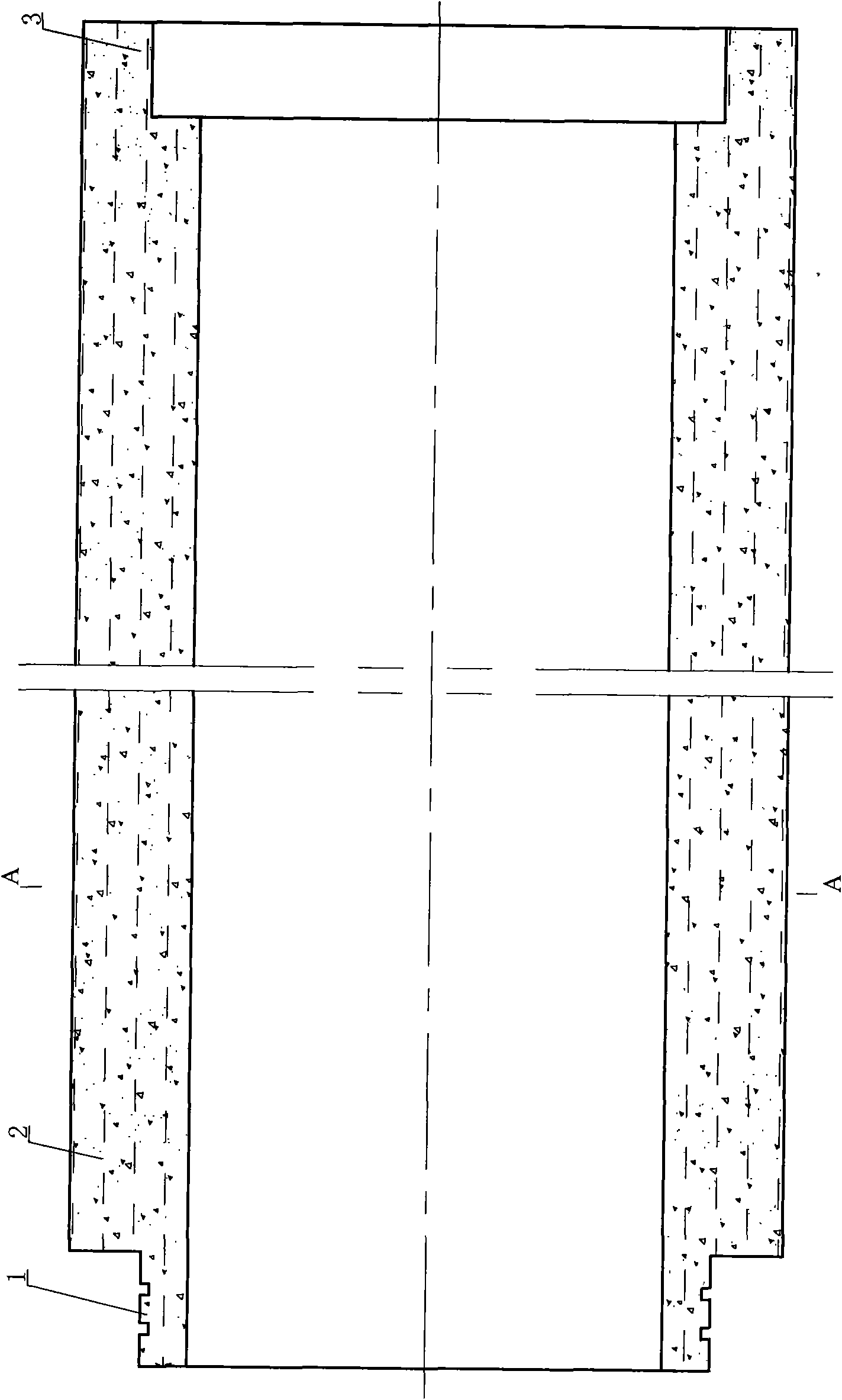

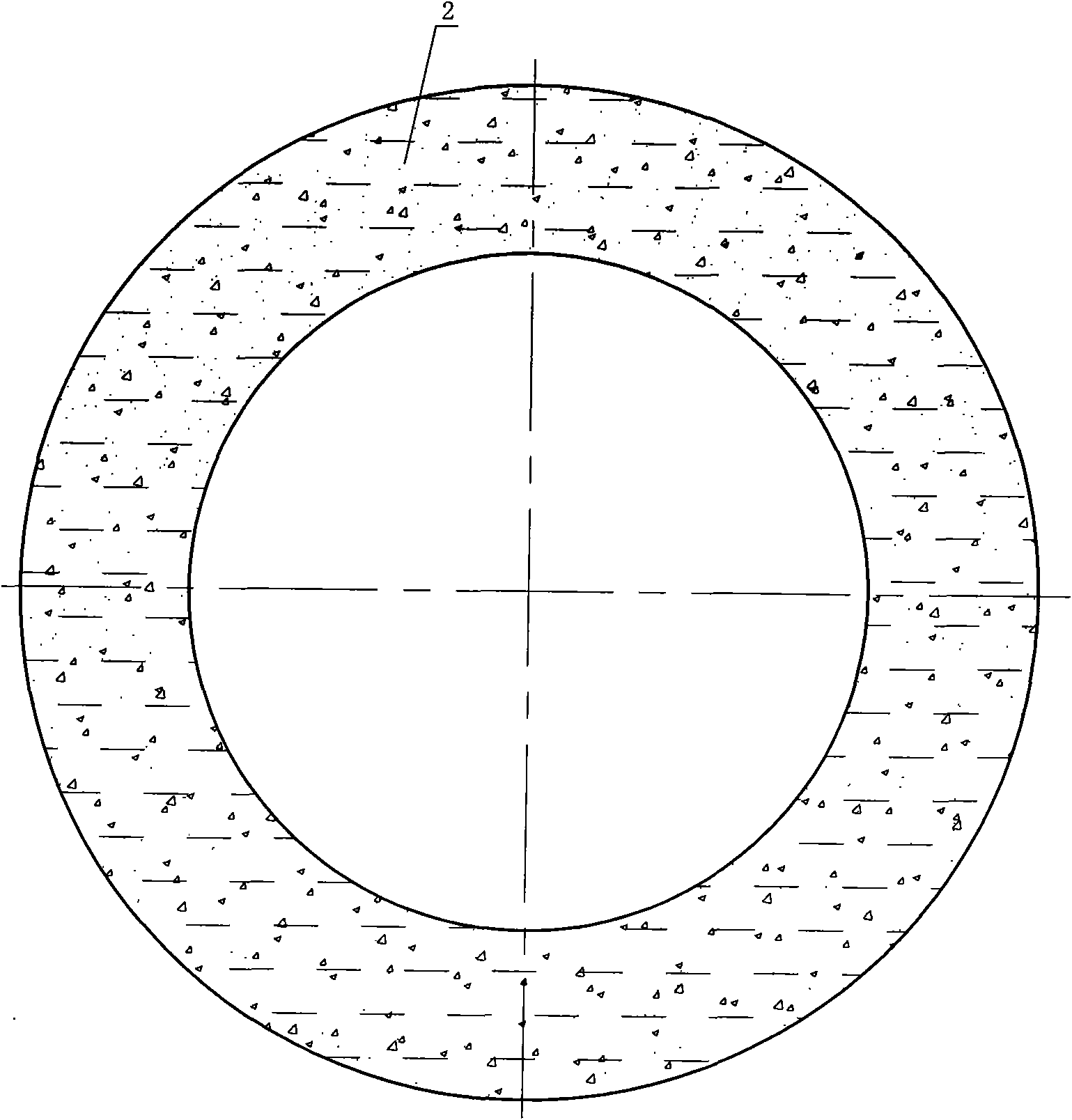

Mixed fiber concrete pipe

The invention relates to a mixed fiber concrete pipe, wherein mixed fiber concrete for forming the pipe comprises the following components according to the parts by weight: 322-540 parts of cement, 140-220 parts of water, 475-828 parts of sand, 864-1,306 parts of cobbles, 0.2-20 parts of polymer fibers and 20-140 parts of steel fibers. The mixed fiber concrete pipe has low raw material cost, light weight, high tensile strength, flexural strength, shearing strength and torsional strength, better durability and fatigue resistance, stronger capacities of shock resistance, abrasion resistance and cavitation resistance and better crack resistance, conforms to an energy saving and emission reduction policy and is a renewal product of the existing concrete pipes.

Owner:TIANJIN WATERLINE PIPELINE ENG CO LTD

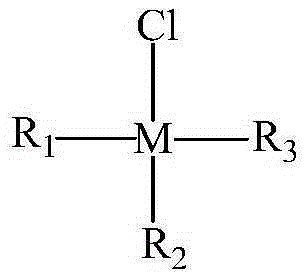

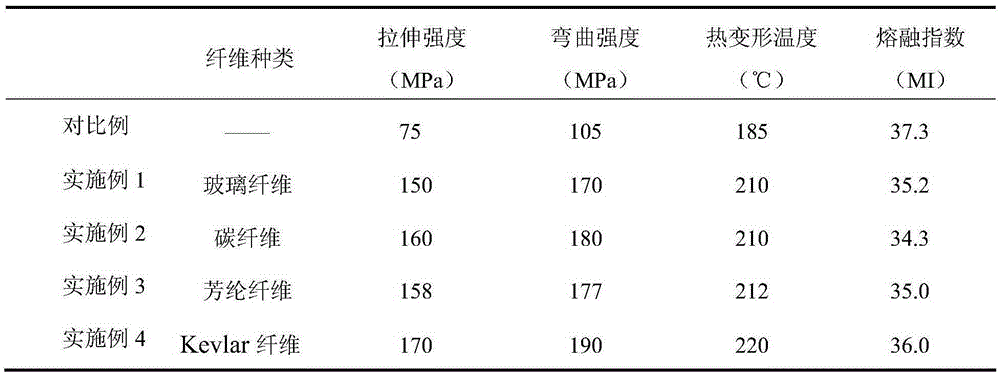

Preparation method of high-performance modified polysulfone resin

The invention discloses a preparation method of high-performance modified polysulfone resin. Monomers such as bisphenol A, 4,4'-dichlorodiphenyl sulfone and chain extender are used for preparing polysulfone resin, and then modification is conducted on the polysulfone resin through fibers, wherein when modification is conducted, a mixture comprises the components of 50%-90% of the polysulfone resin, 10%-50% of the fibers and 0.1%-5% of auxiliaries. According to the prepared high-performance modified polysulfone resin, the heat resistance is good, mechanical properties such as the stretching strength, the tensile strength, the tensile strength and the impact toughness can all be greatly improved after modification, and other excellent properties are kept constant.

Owner:JIANGMEN YOUJU NEW MATERIALS

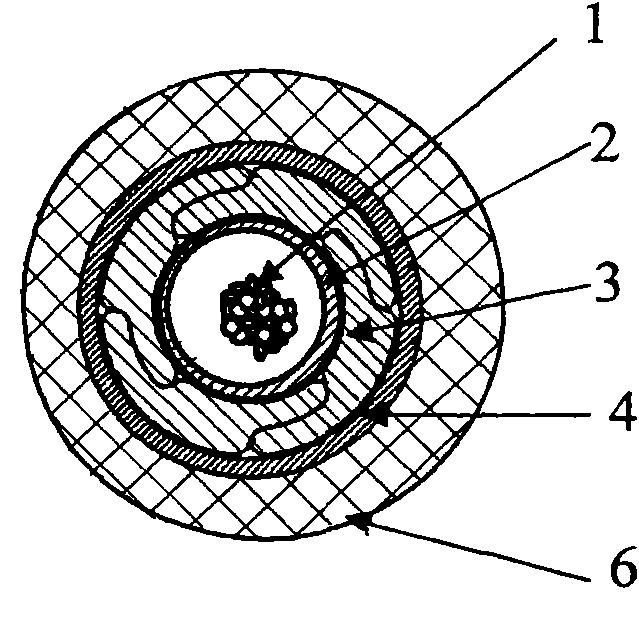

Torsion resistant photoelectric composite medium-voltage drum cable

ActiveCN104036859AExtended service lifeExtend your lifePower cables with screens/conductive layersInsulated cablesYarnPolytetramethylene terephthalate

The invention discloses a torsion resistant photoelectric composite medium-voltage drum cable. The torsion resistant photoelectric composite medium-voltage drum cable comprises a plurality of power line cores and a plurality of ground line cores which are twisted together to form a cable core, as well as at least one optical unit, a special chloroprene rubber inner sheath wrapping the cable core, a reinforcing layer which is woven at the exterior of the special chloroprene rubber inner sheath and is embedded in the special chloroprene rubber inner sheath, and a special chloroprene rubber outer sheath wrapping the reinforcing layer; in power line core conductors and ground line core conductors, the stranding directions of two adjacent layers are opposite, and the stranding direction of each layer is opposite to the stranding direction of strand lines in a corresponding layer; the reinforcing layer is a terylene wire-woven reinforcing layer; insulating layers in the power line cores are ethylene propylene rubber layers; loose bushings are made of polybutylene terephthalate plastics; water-resisting yarns are made of water-resisting aramid fibers; thixotropic composites are made of factice; and nonmetallic reinforcing members are made of aramid fibers. With the torsion resistant photoelectric composite medium-voltage drum cable of the invention adopted, the special chloroprene rubber sheaths are adopted as the inner sheath and the outer sheath of the cable, and therefore, the torsion resistant photoelectric composite medium-voltage drum cable has excellent low temperature resistance, wear resistance, oil resistance and other properties, and the service life of the cable can be prolonged.

Owner:JIANGSU HENGTONG POWER CABLE

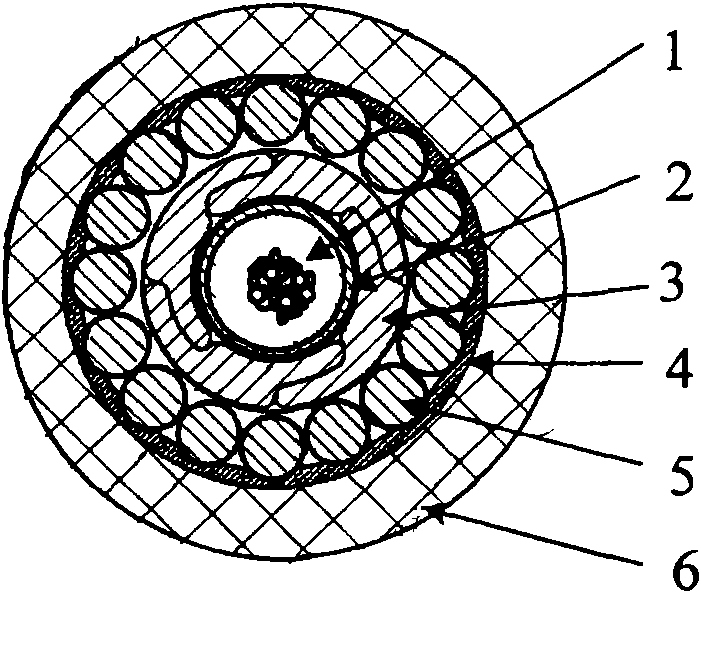

Side pressure resistant submarine optical fiber cable core

InactiveCN101943777AStable structureImprove tensile strengthFibre mechanical structuresOptical communicationCopper

The invention discloses a side pressure resistant submarine optical fiber cable core, which consists of an optical fiber, a protective tube, a side pressure resistant shell, a feed or detection copper tuber or copper strap, an internal armored steel wire, an insulating sheath and a filling wire. The side pressure resistant submarine optical fiber cable core is characterized in that a layer of tubular strong side pressure resistant shell stranded by a special-shaped wire is stranded outside the optical fiber unit. The side pressure resistant submarine optical fiber cable core has the advantages of remarkably improving the tensile stress and side pressure resistance of the cable core, ensuring that the submarine optical fiber is not damaged and facilitating safer and more reliable operation of optical communication along with very firm structure.

Owner:江苏通光海洋光电科技有限公司

Abrasion resistant fabric

The invention relates to an abrasion resistant fabric comprising base cloth formed by interweaving warps and wefts. The base cloth is formed by blending sea-island fibers and polyester fibers, wherein the sea-island fibers account for 25-35 percent of the total weight of the fabric; the polyester fibers account for 65-75 percent of the total weight of the fabric; a polytetrafluoroethylene coating is coated on the surface of the base cloth; and the polytetrafluoroethylene coating is 0.2-0.8mm thick. The invention has simple process, low cost, effectively improved tensile strength, tearing strength and abrasion resistance, enhanced wearing comfort and long service life.

Owner:WUJIANG TONGLONG TEXTILE

Industrial protection non-woven material and manufacturing method thereof

ActiveCN103526454AImprove breathabilityExcellent flame retardantFlame-proof filament manufactureNon-woven fabricsPolyesterEngineering

The invention discloses an industrial protection non-woven material and a manufacturing method of the industrial protection non-woven material. The industrial protection non-woven material comprises a PP spunbond non-woven fabric layer, an ES-mixed non-woven fabric layer and a PP melt-blown non-woven fabric layer sandwiched between the PP spunbond non-woven fabric layer and the ES-mixed non-woven fabric layer. Fire retardant mixtures of a first component are added to the PP spunbond non-woven fabric layer, and fire retardants of second components of different types are added to the PP melt-blown non-woven fabric layer. Mixed fibers of ES fibers, polyester fibers and viscose fibers are combed into a net to form the ES-mixed non-woven fabric layer. The industrial protection non-woven material has the moisture percentage similar to the moisture percentage of a human body, good gas permeability and soft and fluffy hand feelings, is comfortable to wear, has high tension stress and morphological stability in all directions, protects the structure of the melt-blown non-woven fabric layer and has the good inflaming retarding characteristic and the environment protection effect, and a guarantee is provided for the protection performance of the industrial protection non-woven material.

Owner:东营俊富净化科技有限公司

Method for manufacturing photoelectric composite medium-voltage drum cable

ActiveCN104036885AImprove performanceExtended service lifeCable/conductor manufactureRubber materialQuinoline

The invention discloses a method for manufacturing a photoelectric composite medium-voltage drum cable. The photoelectric composite medium-voltage drum cable comprises power line cores, ground line cores, at least one optical element, a special neoprene inner sheath wrapping a cable core, a reinforcing layer which is woven at the exterior of the special neoprene inner sheath and embedded in the special neoprene inner sheath and a special neoprene outer sheath wrapping the reinforcing layer; chlorinated polyethylene rubber materials include the following components of: a chlorinated polyethylene raw rubber, magnesium oxide, dibasic lead sulfate, lead sulfate tribasic, paraffin, chlorinated paraffin, antioxidant, namely, poly(1,2-dihydro-2,2,4-trimethyl-quinoline), a reinforcing agent (carbon black), flame retardant (antimony oxide), a filler (talcum powder), a filler (calcium carbonate), a reinforcing and filling agent (white carbon black), a vulcanizing promoter (triallyl isocyanurate), and a vulcanizing agent (dicumyl peroxide). With the method for manufacturing the photoelectric composite medium-voltage drum cable of the invention adopted, the cable can still keep excellent insulation performance under high temperature burning and humid conditions, and it can be ensured the cable can work normally for a long time under burning, mechanical percussion and water spraying situations.

Owner:JIANGSU HENGTONG POWER CABLE

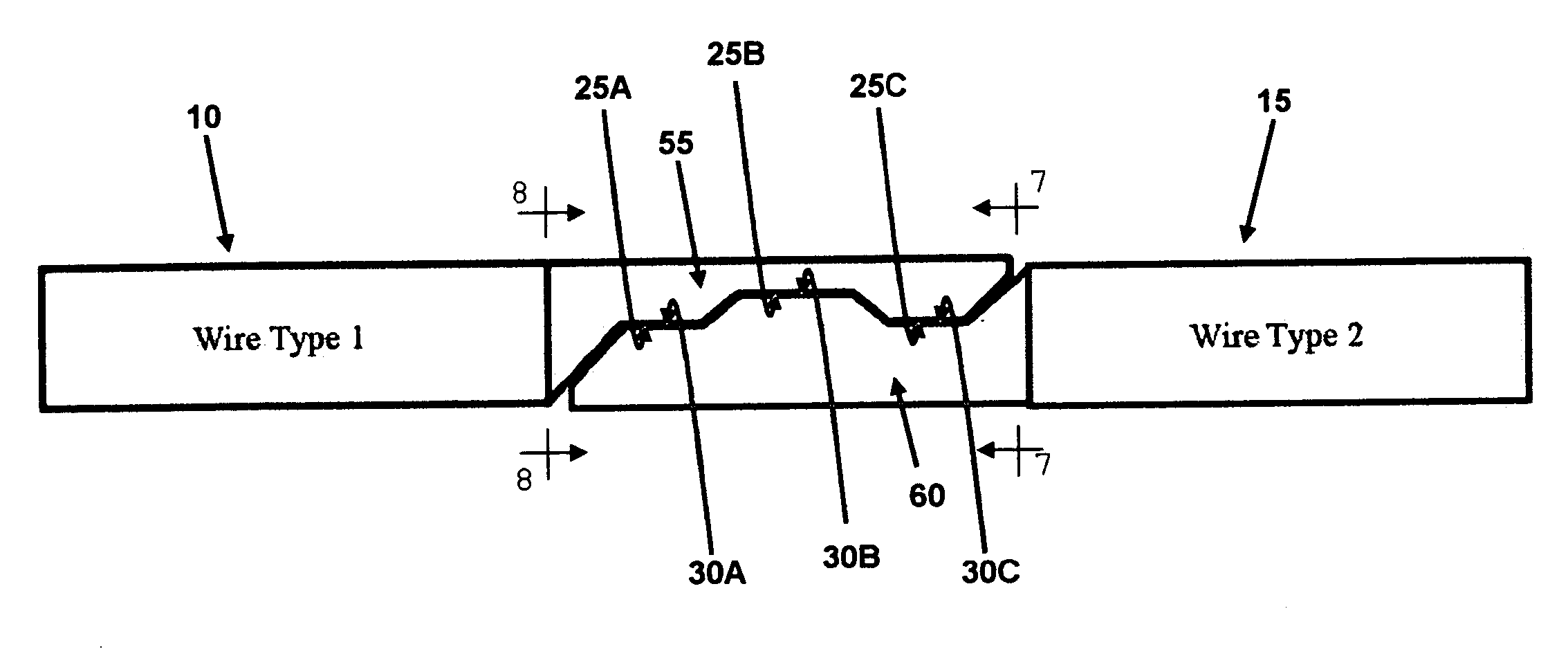

Guidewire formed with composite construction and method for making the same

InactiveUS20070282270A1Improve tensile strengthSufficient surface areaInfusion syringesRopes and cables for vehicles/pulleyWire segmentEngineering

A composite guidewire comprising a proximal wire segment having a proximal end, a distal end and a longitudinal axis extending therebetween, the distal end being formed with a first flat planar bonding face which extends parallel to the longitudinal axis, the proximal wire segment having a first elasticity; a distal wire segment having a proximal end, a distal end and a longitudinal axis extending therebetween, the proximal end being formed with a second flat planar bonding face which extends parallel to the longitudinal axis, the distal wire segment having a second elasticity; wherein the first and second flat planar bonding faces of the proximal wire segment are formed complementary to one another; and further wherein the proximal and distal wire segments are joined together by bonding the first flat planar bonding face to the second flat planar bonding face in an overlapping manner and a method for forming a composite guidewire.

Owner:CONCERT MEDICAL

Enamel wok with patterns on outer surface and manufacturing method of enamel wok

InactiveCN105274424AGood insulation performanceSimple manufacturing processPotassium feldsparCast iron

The invention discloses an enamel wok with patterns on the outer surface. The enamel wok comprises a lid and a cast iron enamel wok body. The cast iron enamel wok body is composed of a cast iron blank and a high-temperature glaze material acting on the outer surface of the cast iron blank. The cast iron blank contains carbon, silicon, manganese, phosphorus, sulfur, chromium, molybdenum, vanadium, boron and the balance iron. The glaze material contains cordierite, zircon, kaolin, potassium feldspar, quartz stone, mullite, calcined talc, zinc fluoride, nanometer titania and cerium dioxide. The formula of the glaze material of the produced wok is unique, the patterns rich in beauty can be produced on the outer surface of the wok, and the ornamental value of the wok is increased.

Owner:ANHUI ZAOSHANGHUANG MACHINERY CO LTD

Metal decorating film with hardened protective layer and preparation method thereof

InactiveCN102417796AAvoid pollutionReduce manufacturing costFilm/foil adhesivesSynthetic resin layered productsAcrylic resinBoiling point

The invention discloses a metal decorating film with a hardened protective layer and a preparation method thereof. The metal decorating film comprises a support body, a stripping layer, a decorating layer and a sticking layer. After improvements, the stripping layer and the decorating layer are coated with the hardened protective layer. The hardened protective layer comprises the following components in part by weight: 20-50 parts of multifunctional acrylic resin prepolymer, 15-25 parts of styrene-maleic anhydride copolymer resin, 0-10 parts of active diluent, 2-5 parts of photo initiator, 0.02-0.1 parts of flatting agent and 30-60 parts of solvent, wherein the solvent consists of a high-boiling-point solvent and a low-boiling-point solvent in the weight ratio of 1:5-1:2. The decorating film has the advantages of plump effect, glossiness of over 800 Gs, high heat resistance, high wear resistance, high chemical resistance performance, high coating adhesion and strong drawing force.

Owner:BAODING LUCKY INNOVATIVE MATERIALS

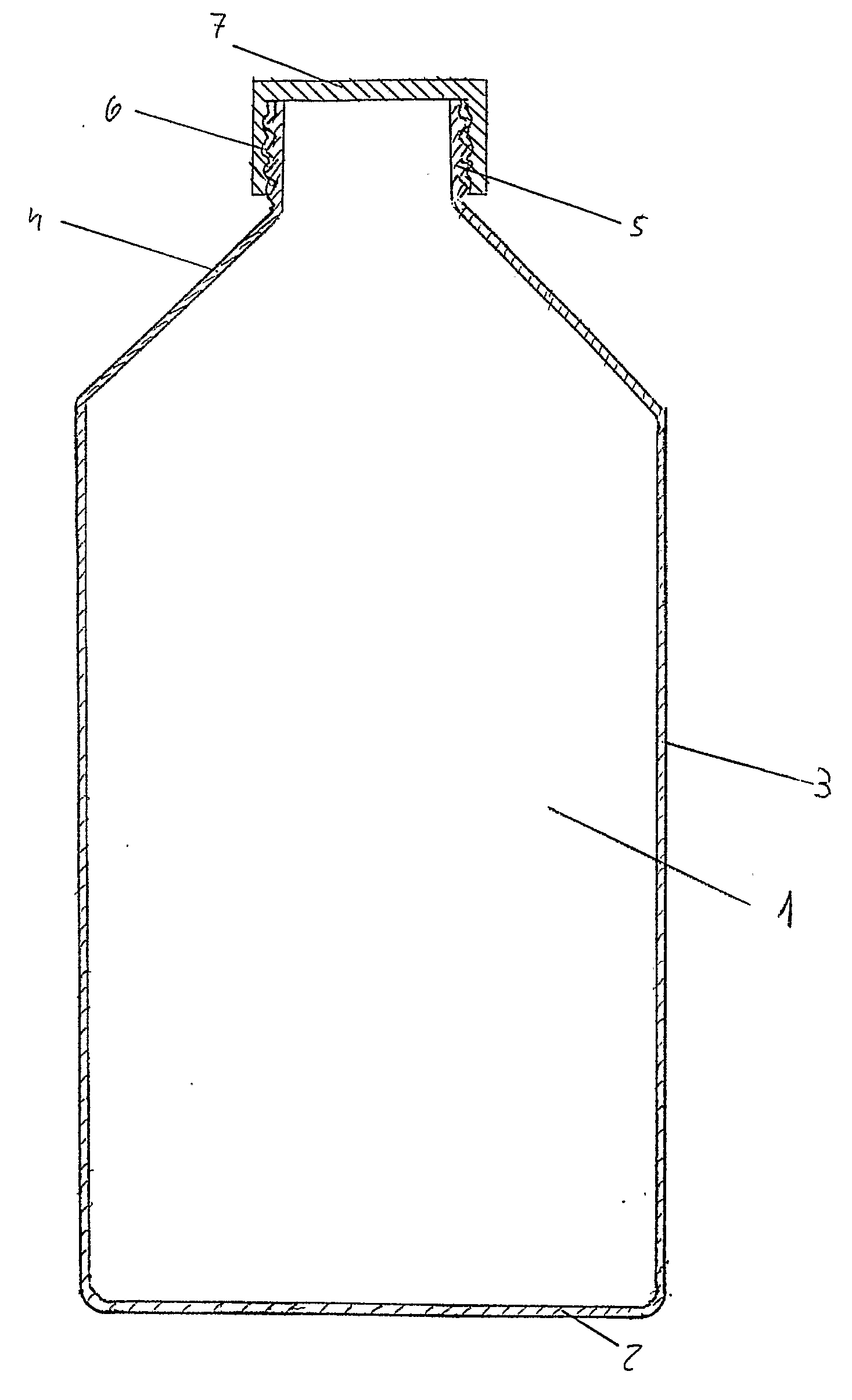

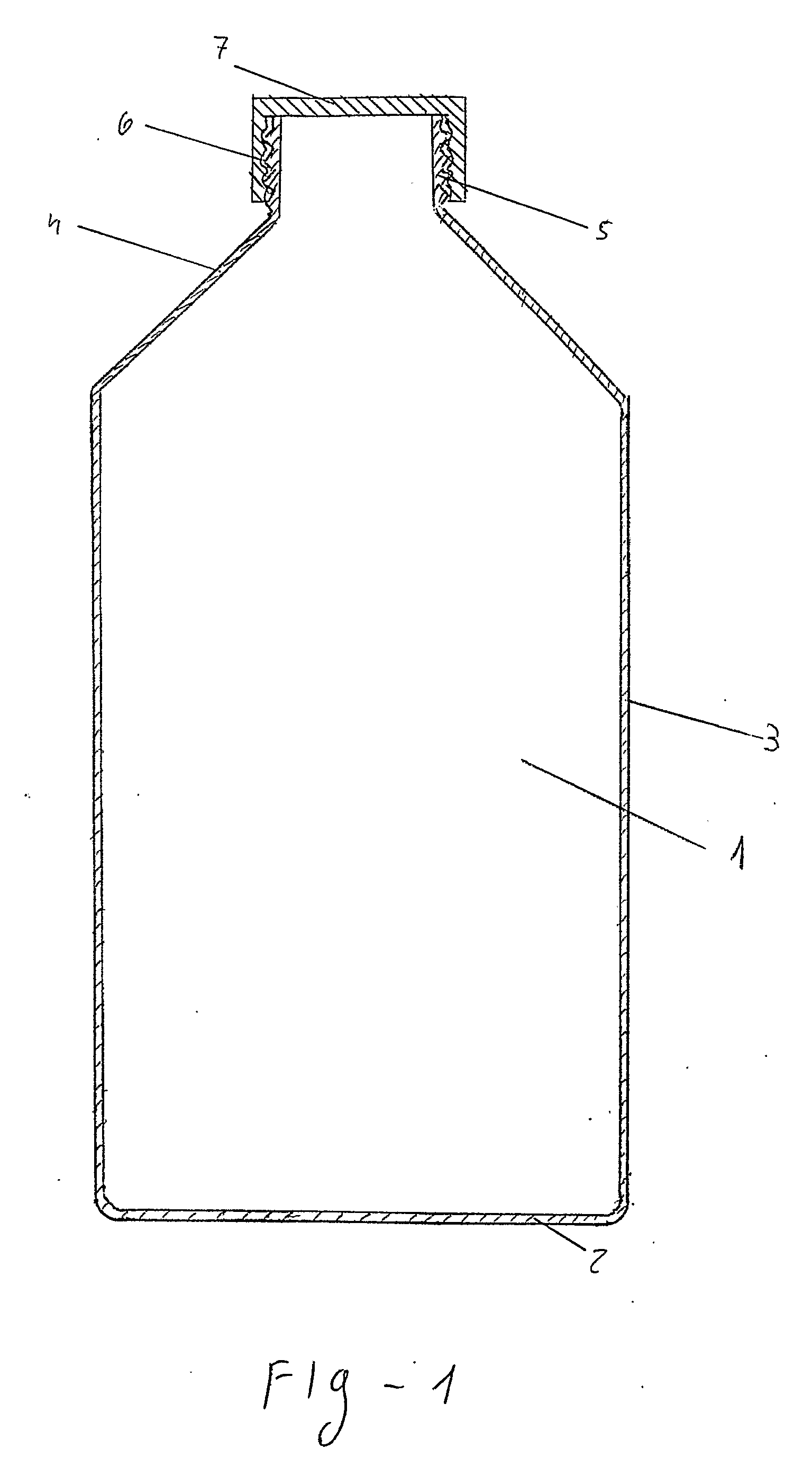

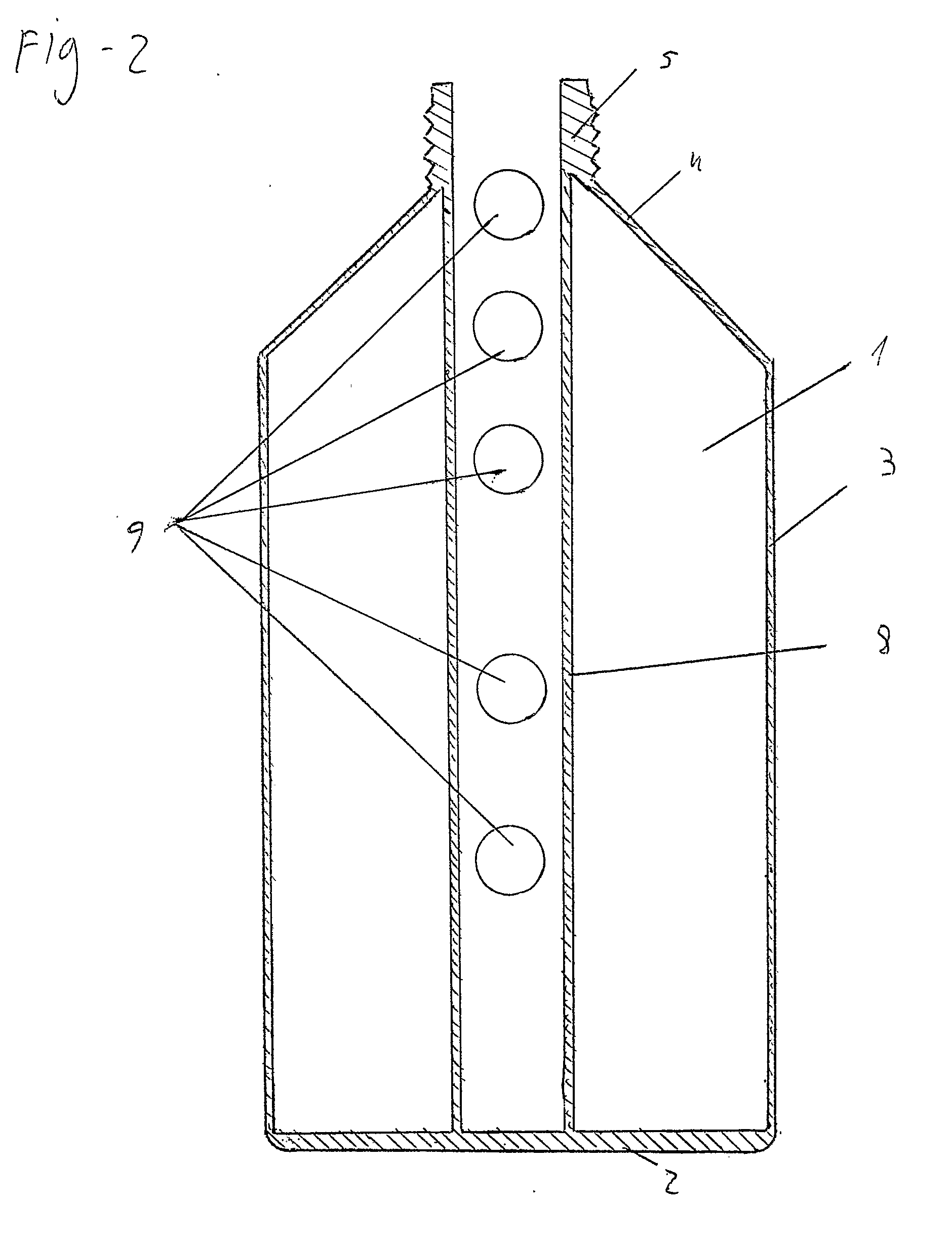

Fluid Container

InactiveUS20080245804A1Lower the volumeStable and strongBottlesInternal framesEngineeringMechanical engineering

Owner:HAMAFTEACH HAMISTOVEV LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com