Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94results about How to "Avoid thickness thinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

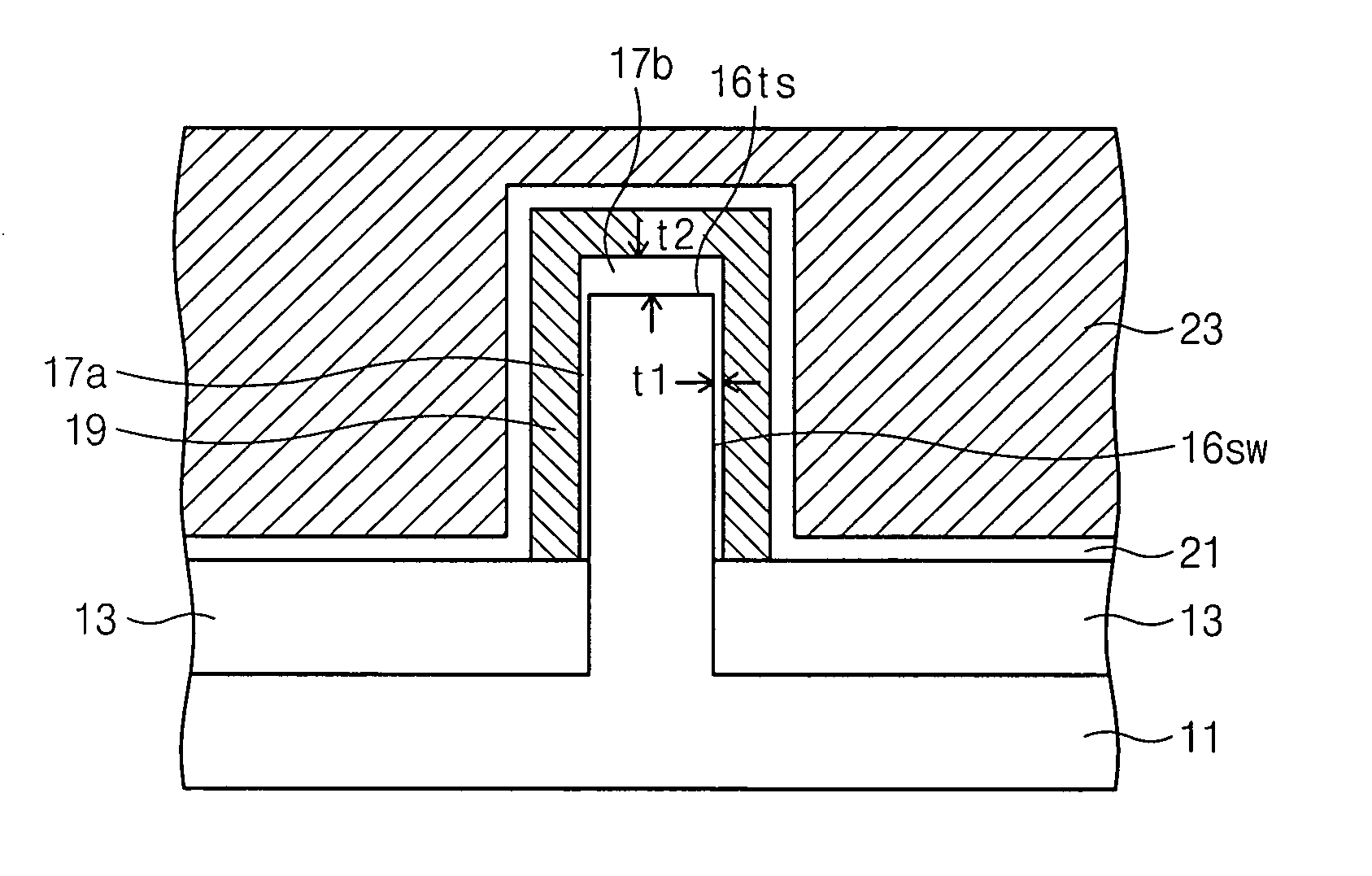

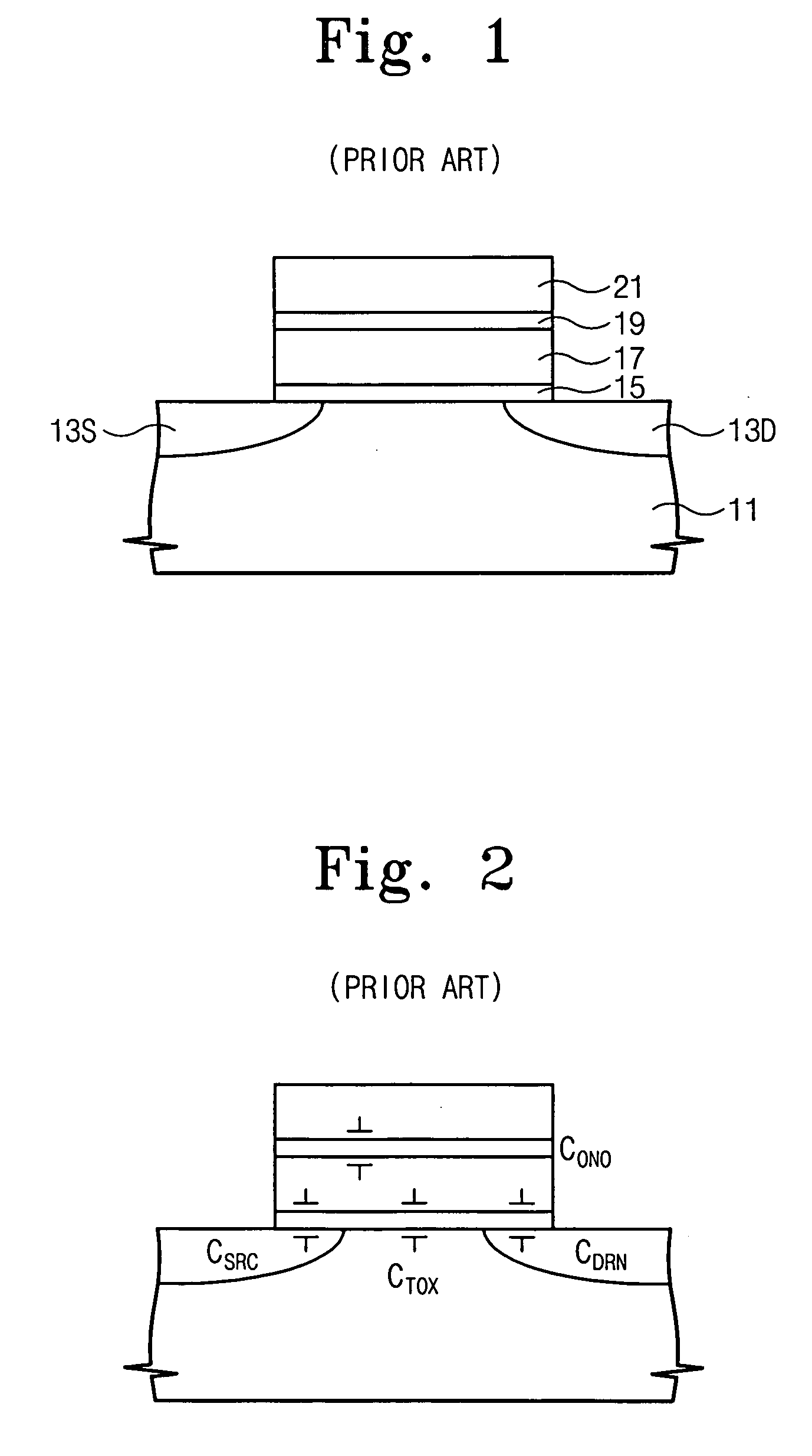

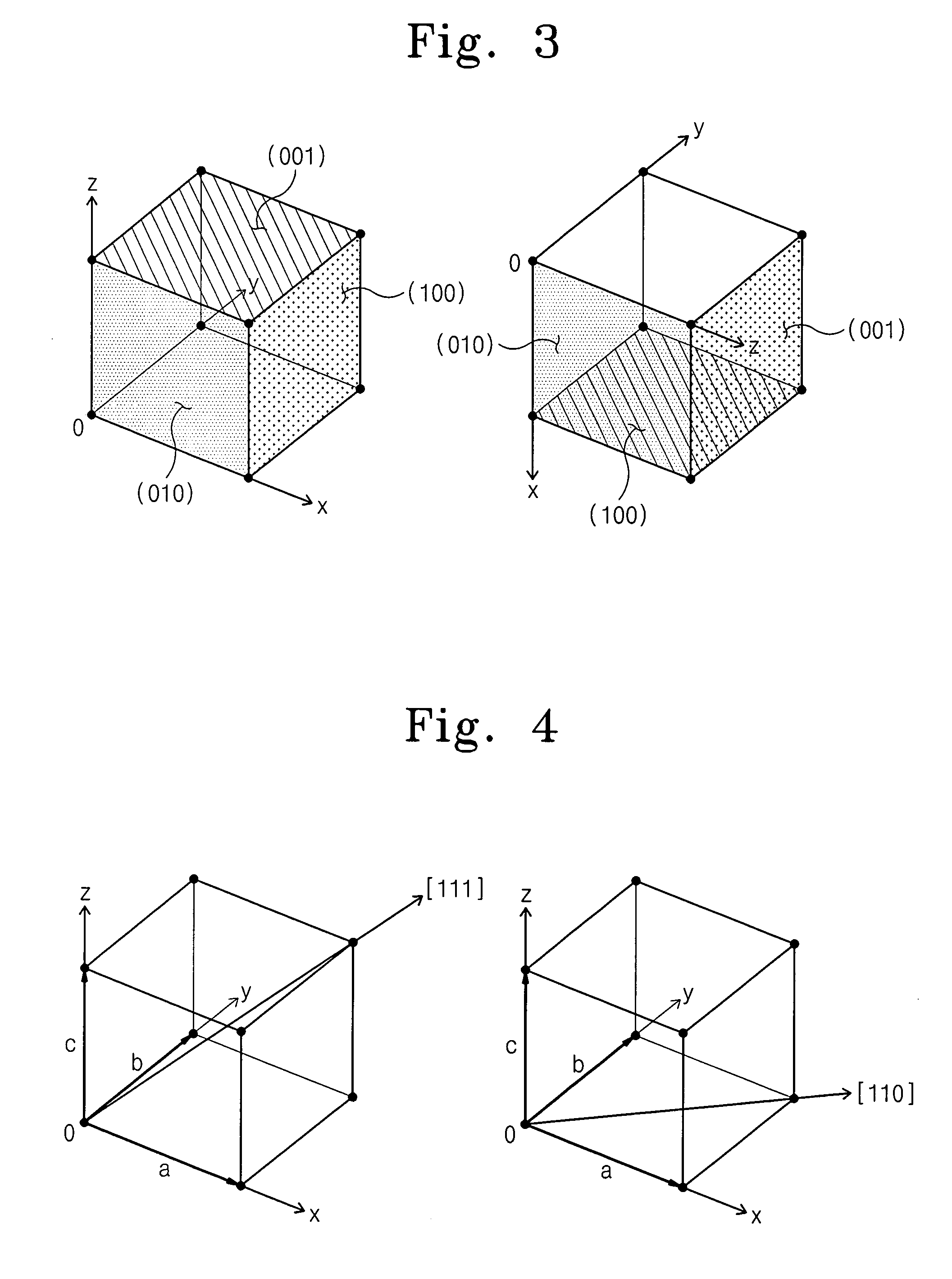

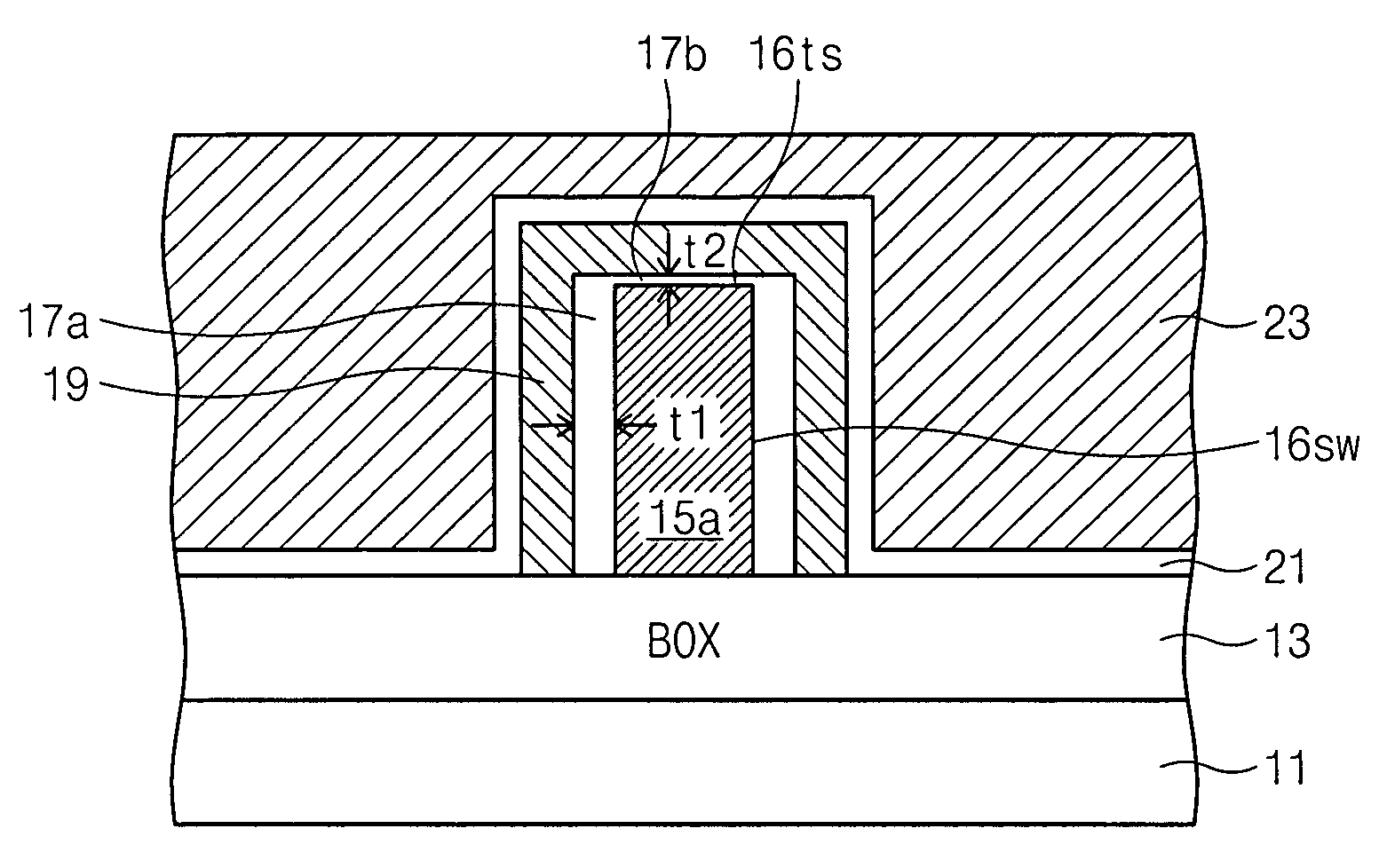

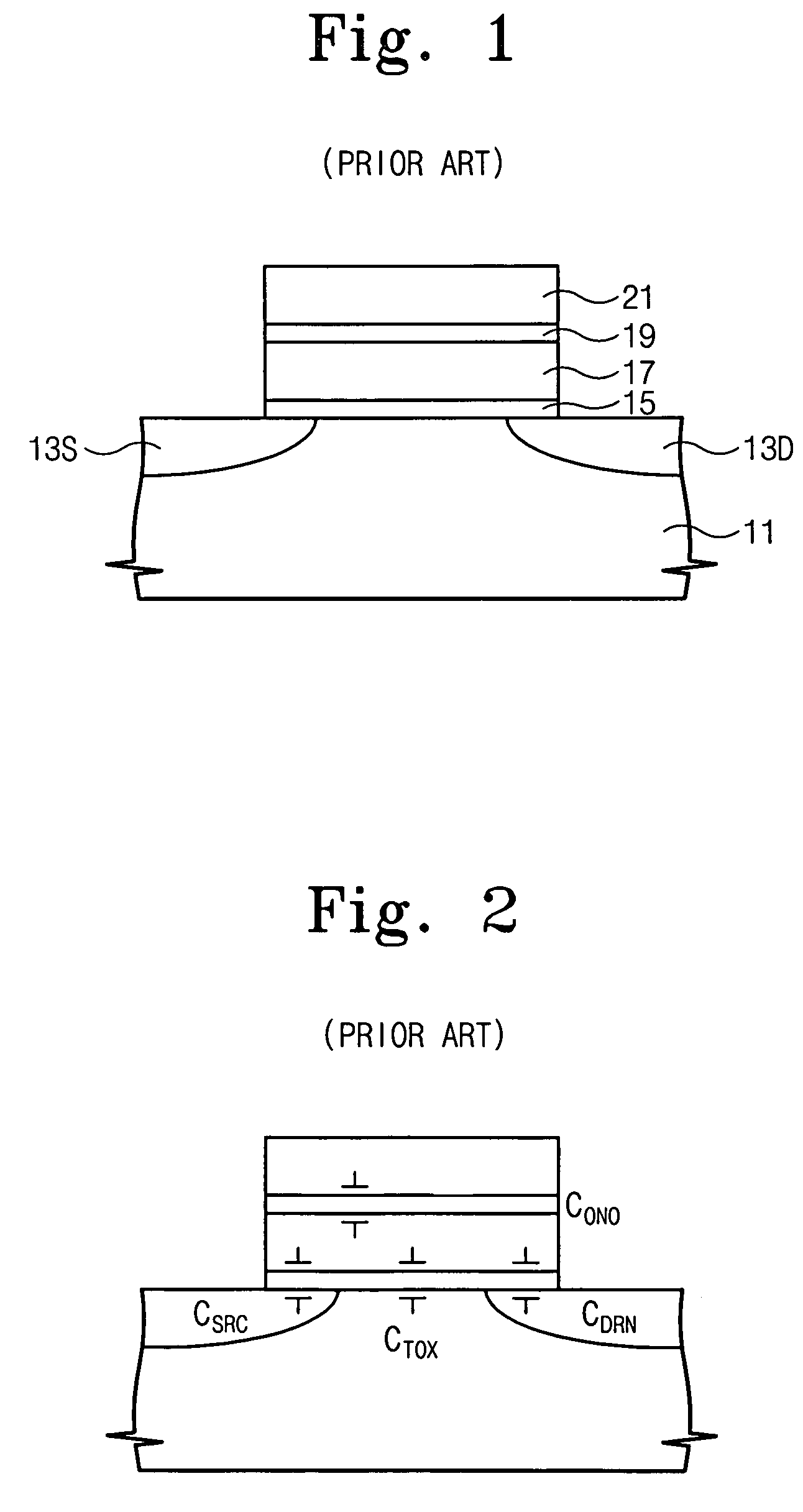

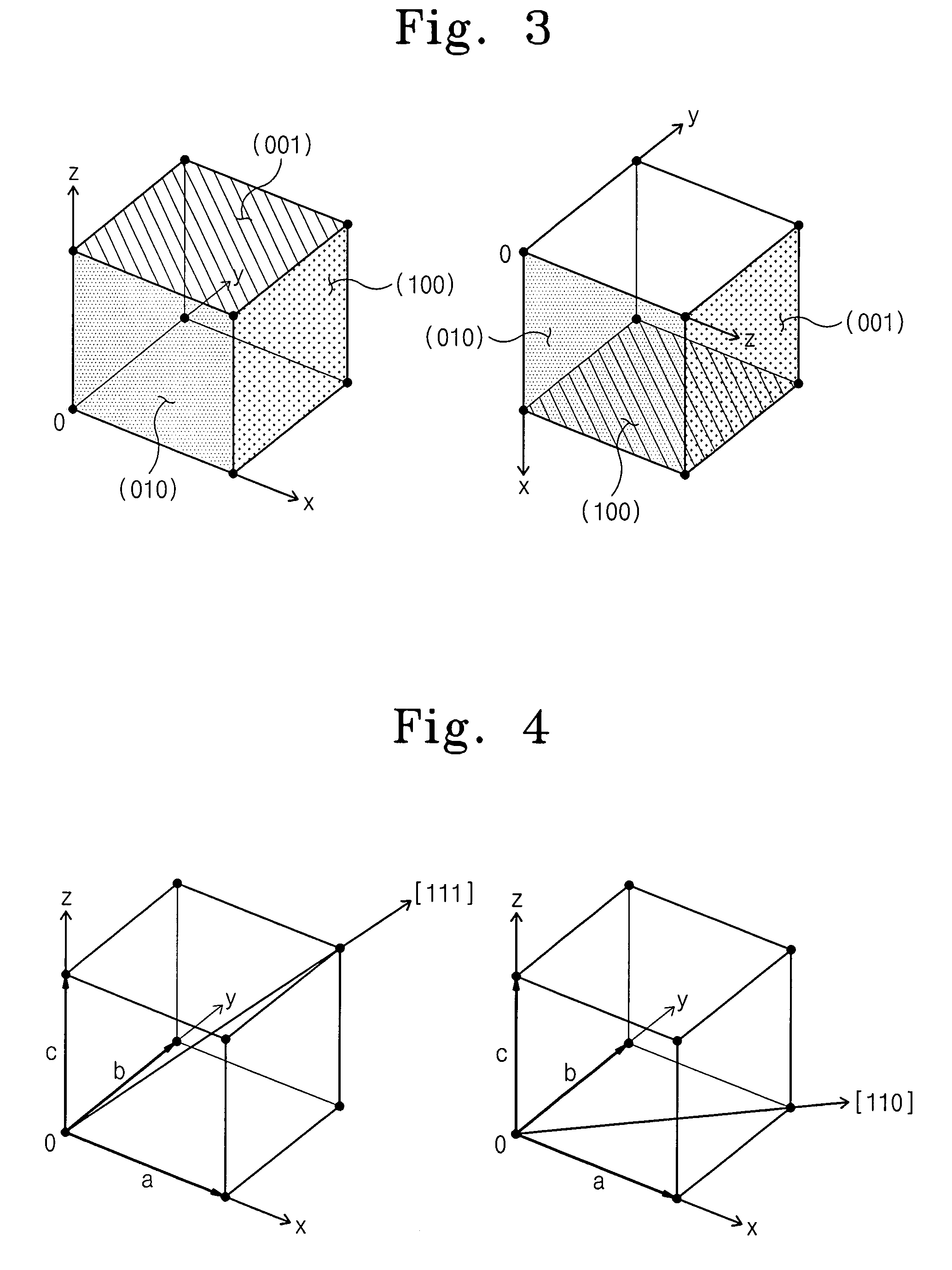

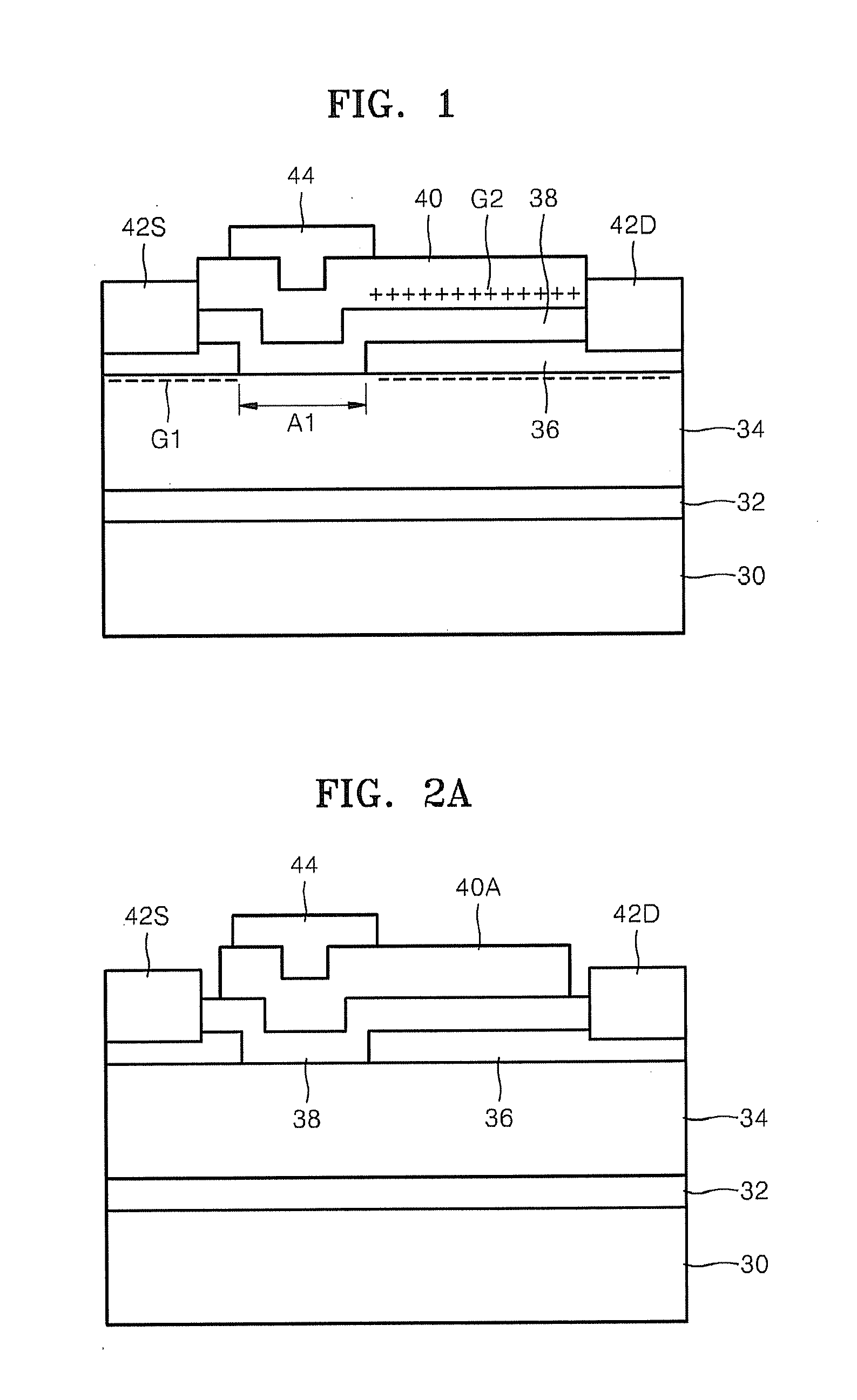

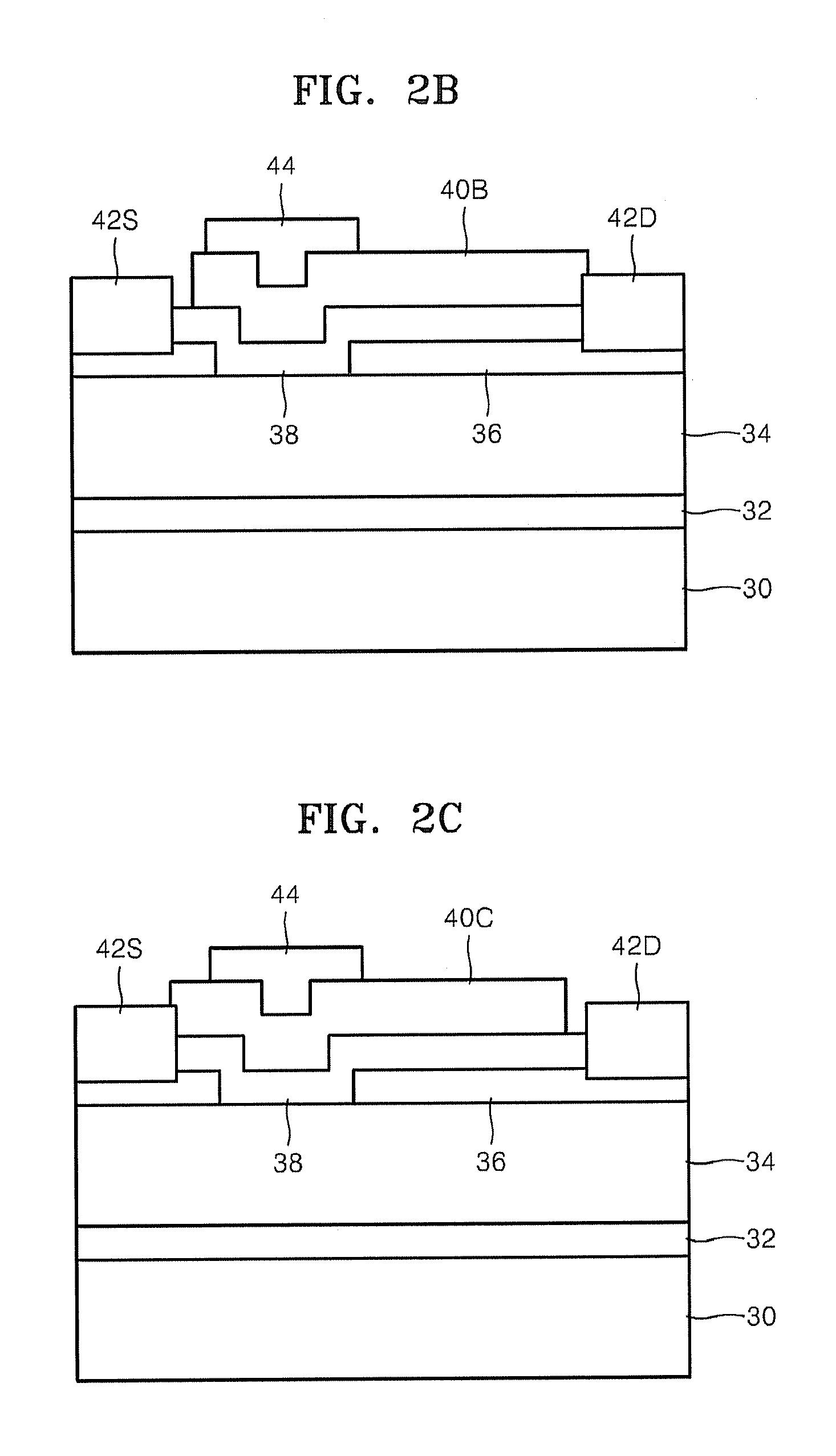

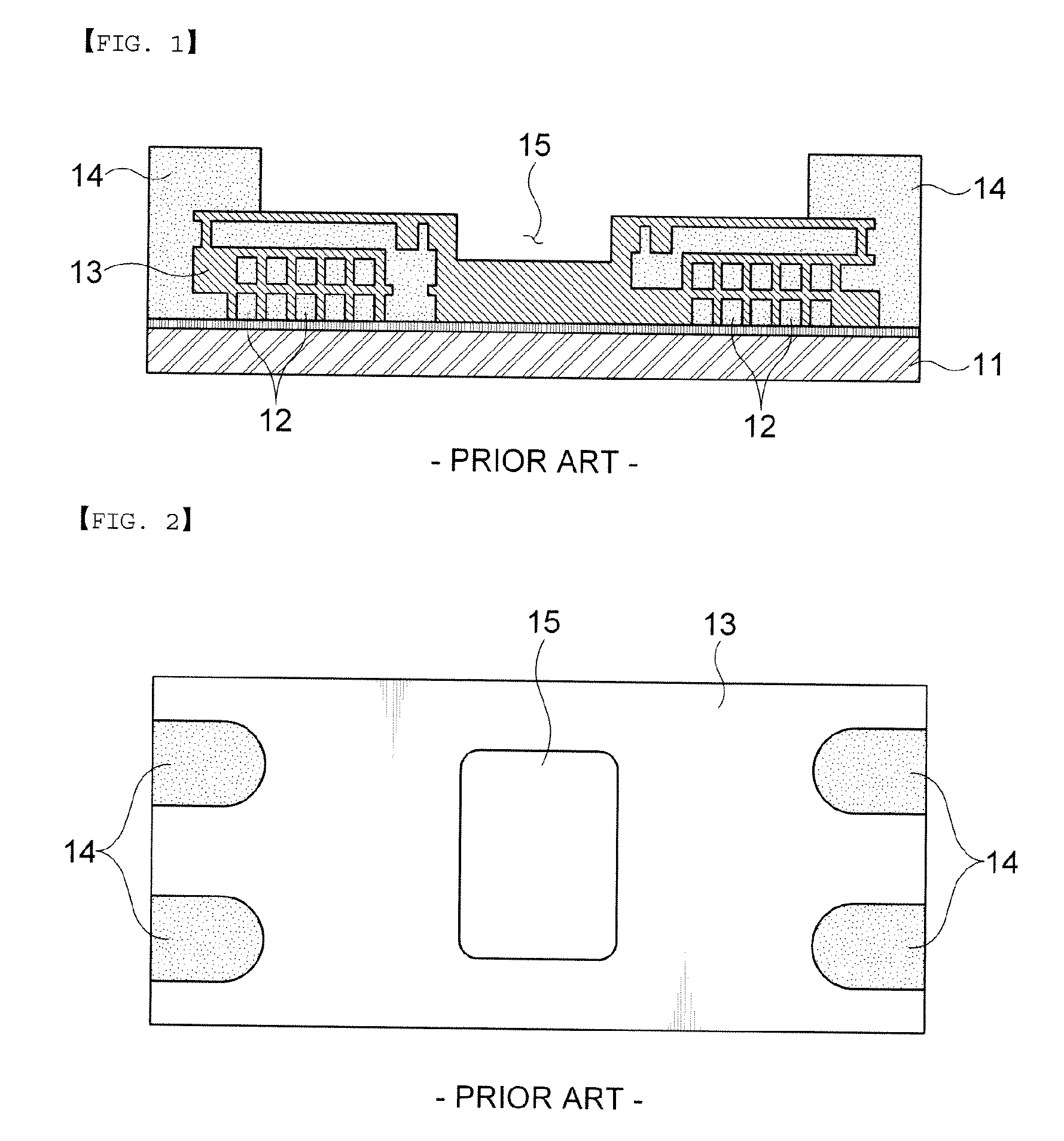

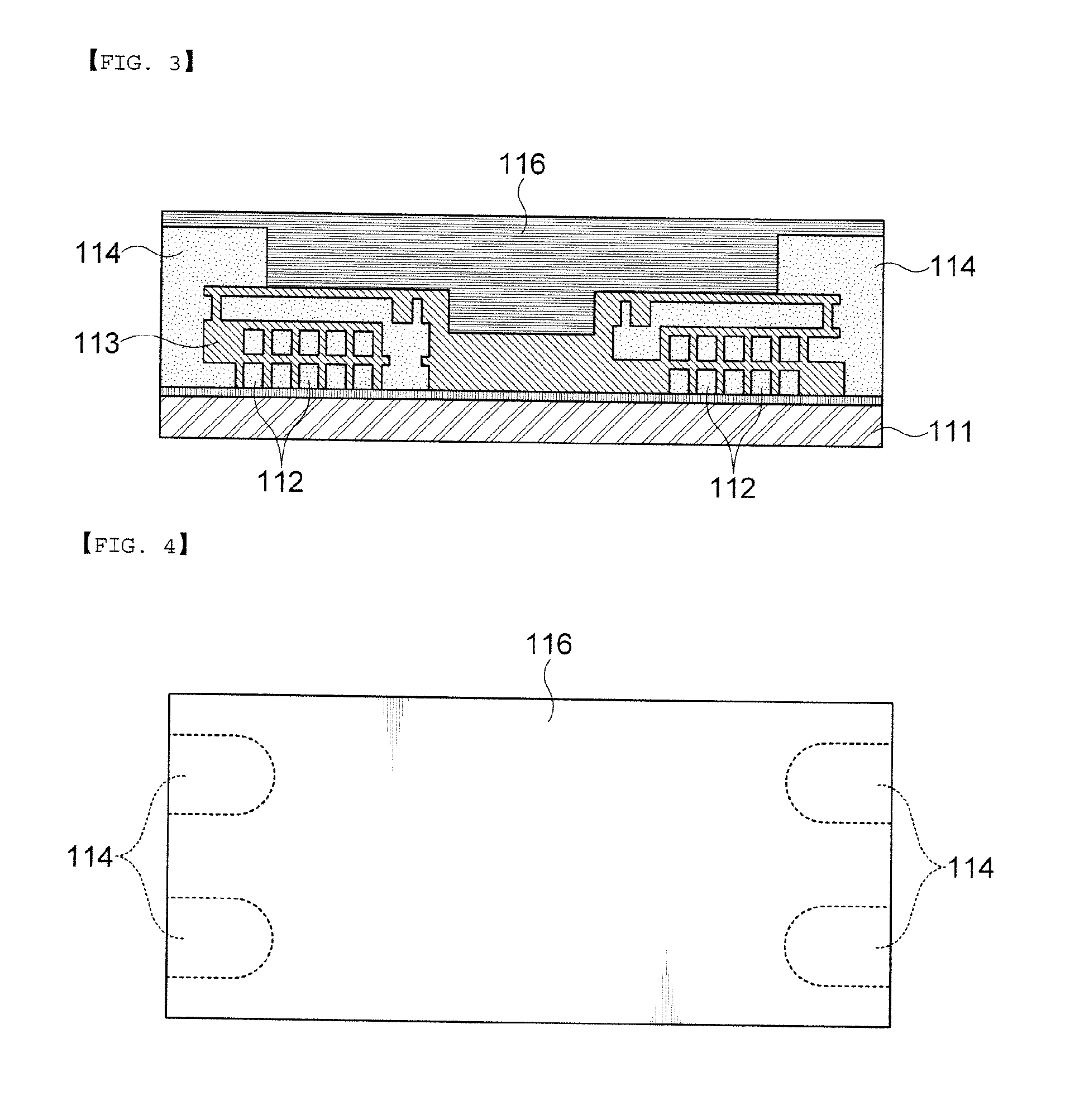

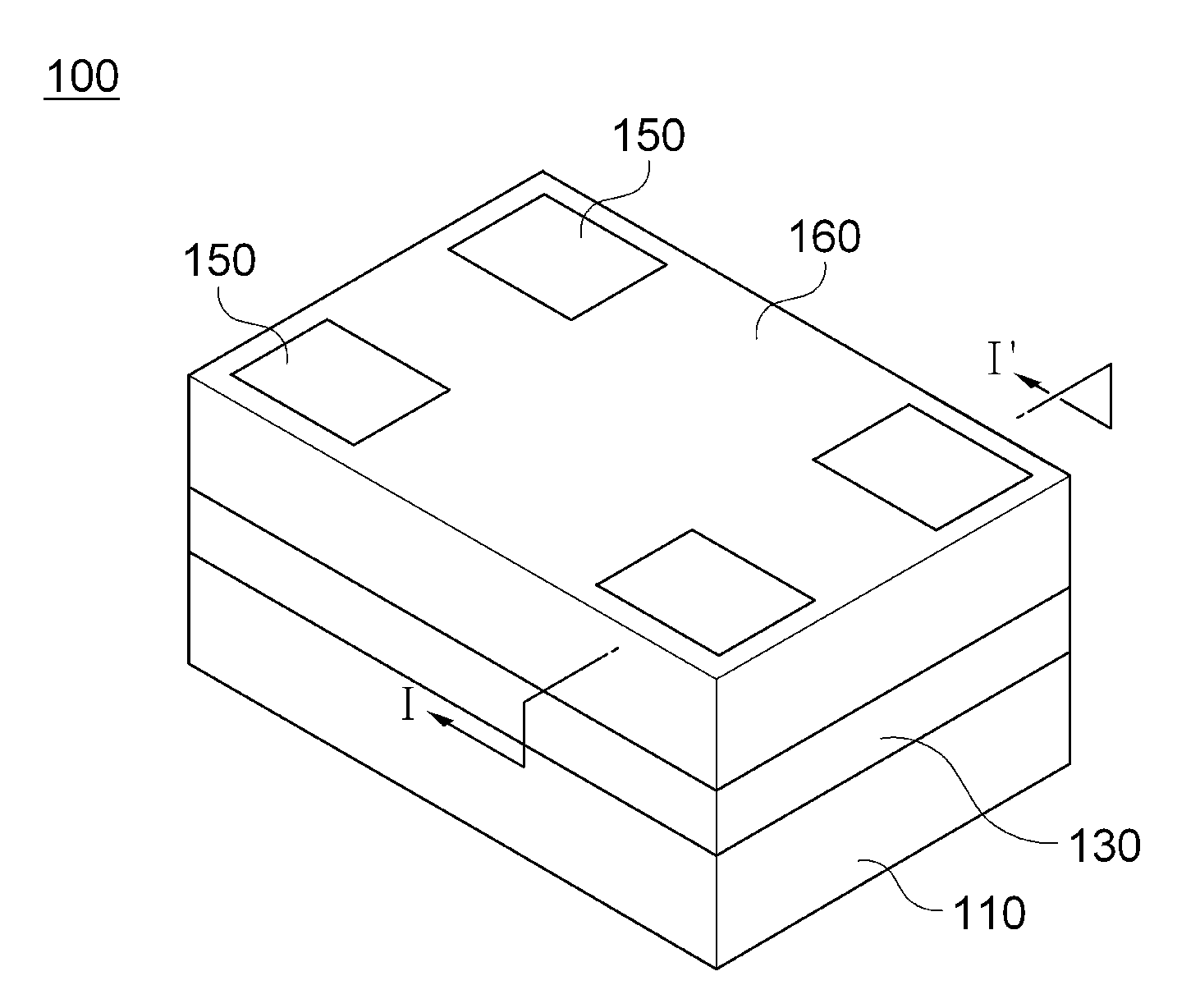

Flash memory device using semiconductor fin and method thereof

ActiveUS20060044915A1Improve scalabilityProgramming and erasing efficiencySolid-state devicesSemiconductor/solid-state device manufacturingCoupling ratioEngineering

A flash memory device according to the present invention includes a semiconductor fin including a top surface and a side surface originated from different crystal planes. The flash memory device comprises: insulating layers having different thicknesses formed on a side surface and a top surface of the semiconductor fin, a storage electrode, a gate insulating layer and a control gate electrode sequentially formed on the insulating layers. A thin insulating layer enables charges to be injected or emitted through it, and a thick insulating layer increases a coupling ratio. Accordingly, it is possible to increase an efficiency of a programming or an erase operation of a flash memory device.

Owner:SAMSUNG ELECTRONICS CO LTD

Flash memory device using semiconductor fin and method thereof

ActiveUS7285820B2Improve scalabilityProgramming and erasing efficiencyTransistorSolid-state devicesCoupling ratioCrystal plane

A flash memory device according to the present invention includes a semiconductor fin including a top surface and a side surface originated from different crystal planes. The flash memory device comprises: insulating layers having different thicknesses formed on a side surface and a top surface of the semiconductor fin, a storage electrode, a gate insulating layer and a control gate electrode sequentially formed on the insulating layers. A thin insulating layer enables charges to be injected or emitted through it, and a thick insulating layer increases a coupling ratio. Accordingly, it is possible to increase an efficiency of a programming or an erase operation of a flash memory device.

Owner:SAMSUNG ELECTRONICS CO LTD

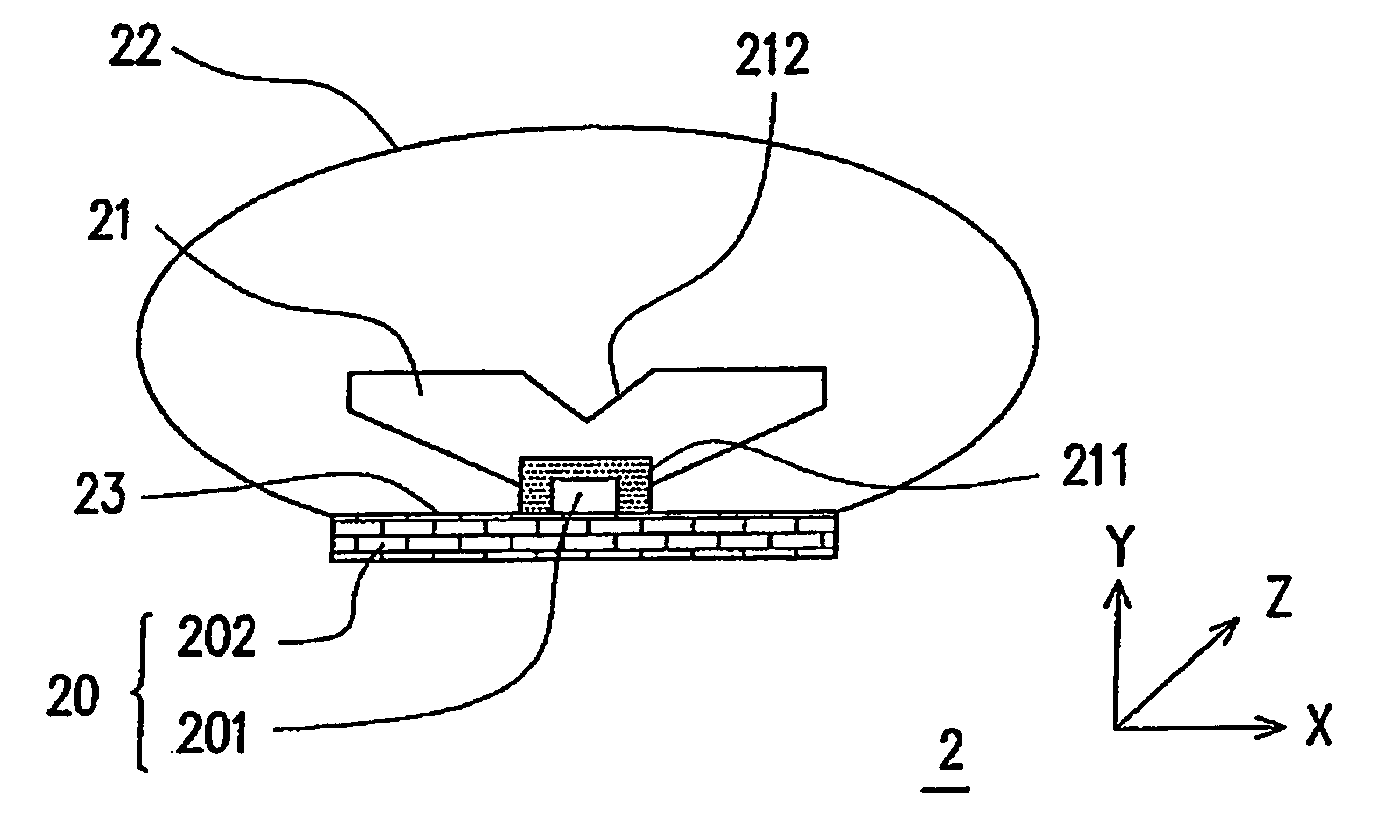

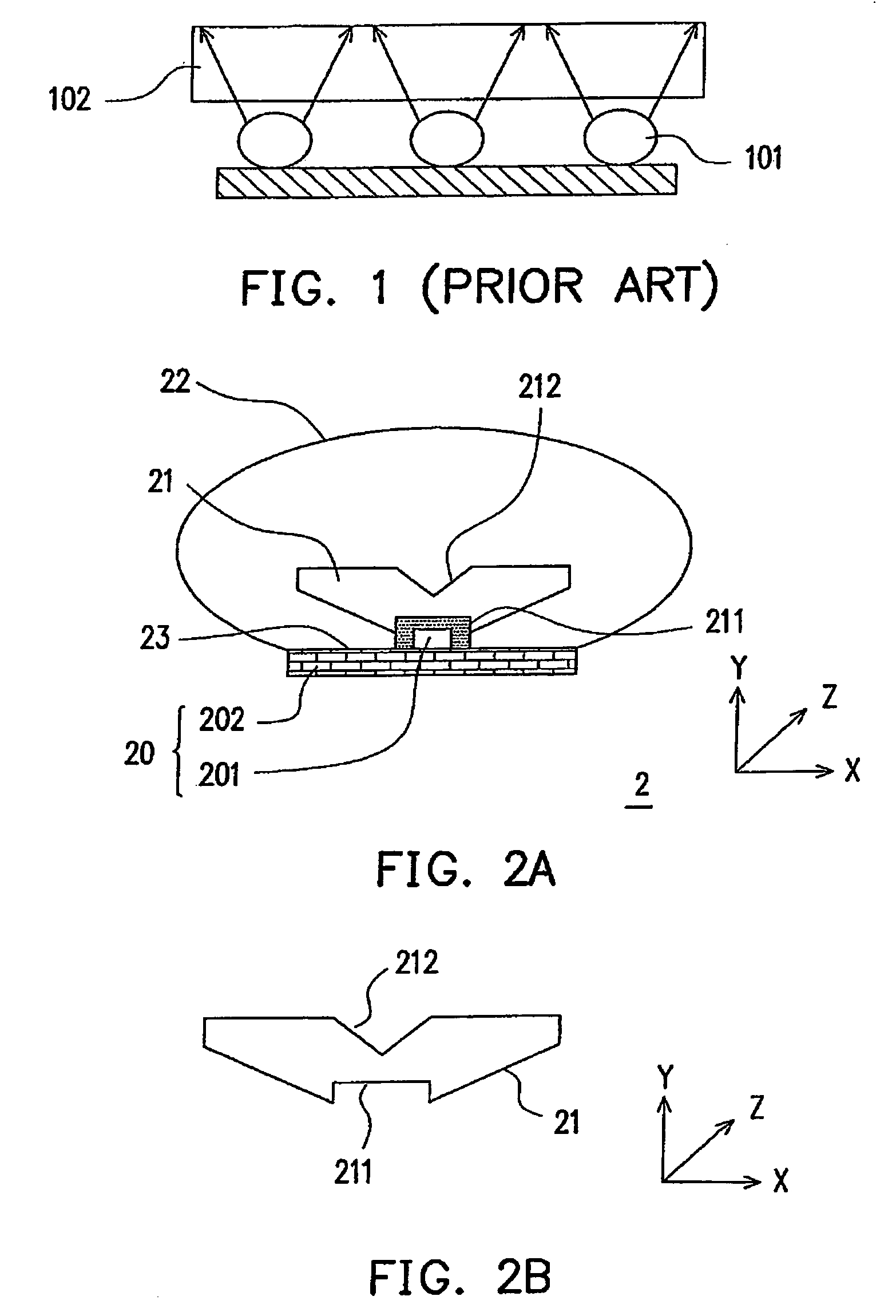

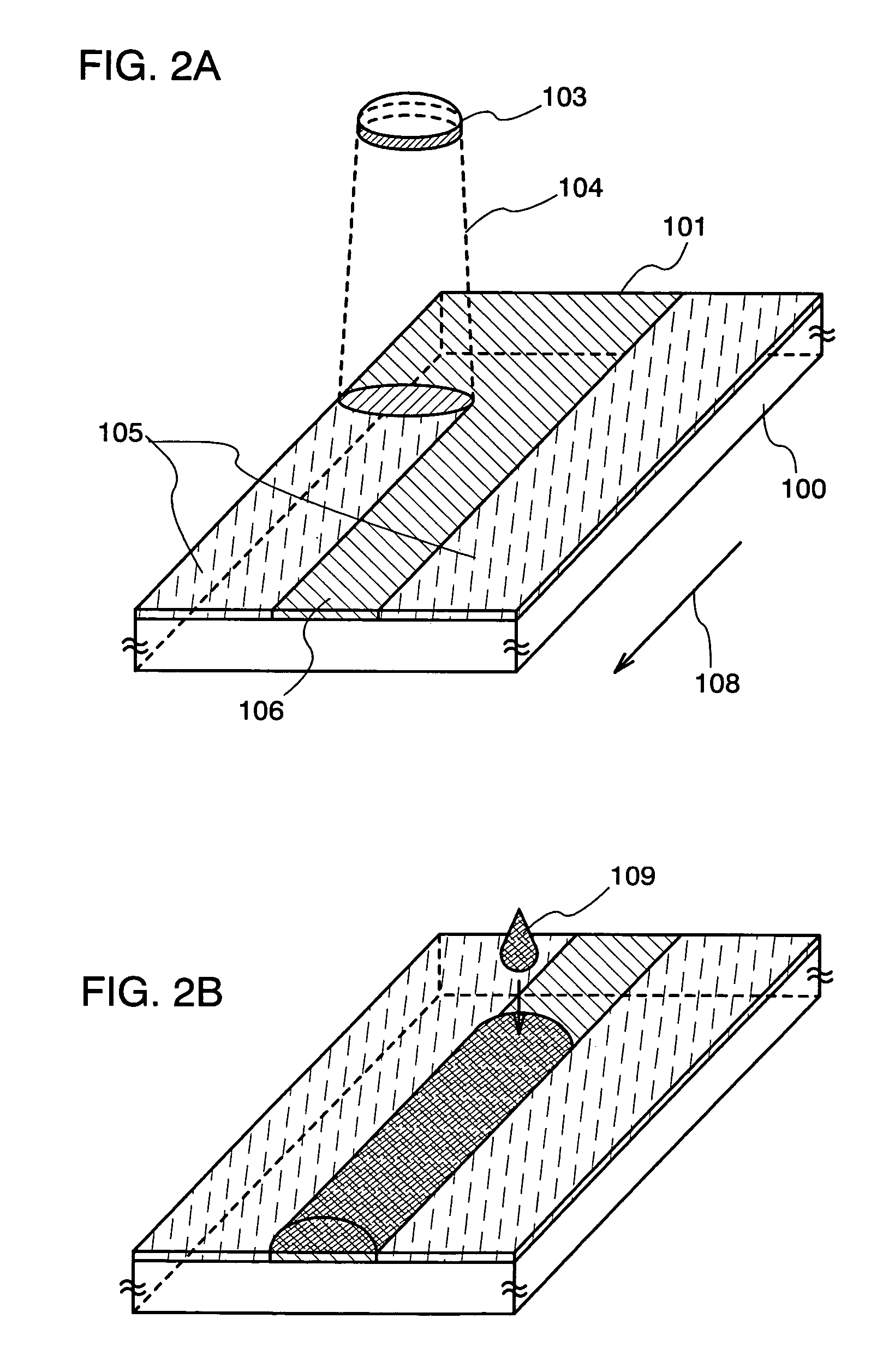

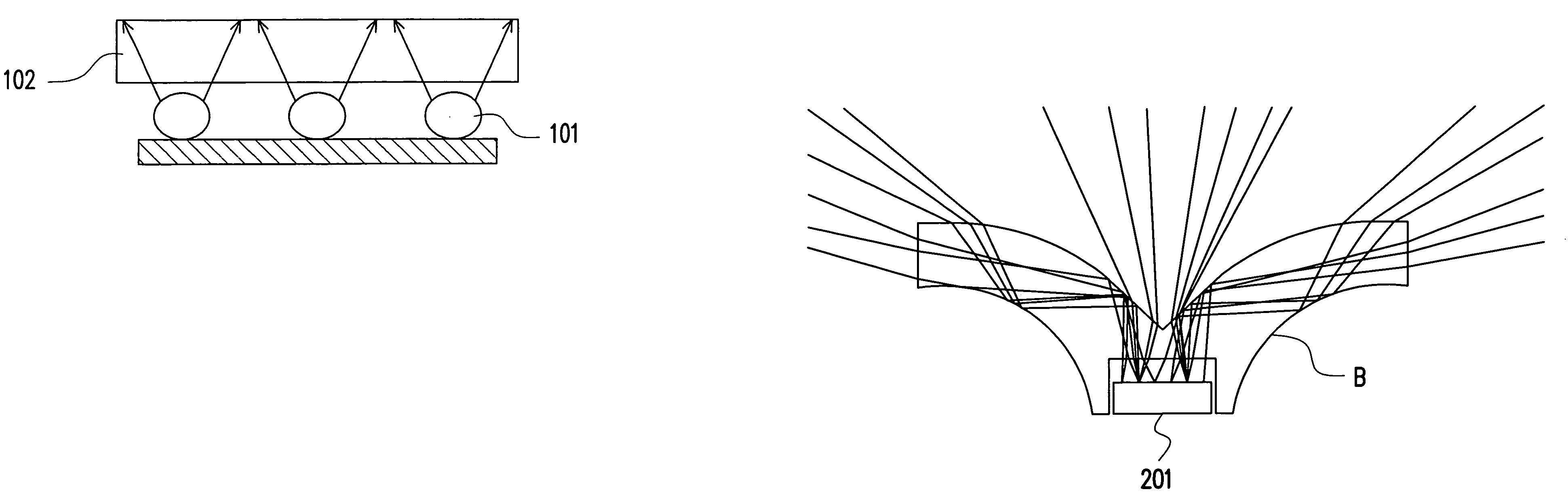

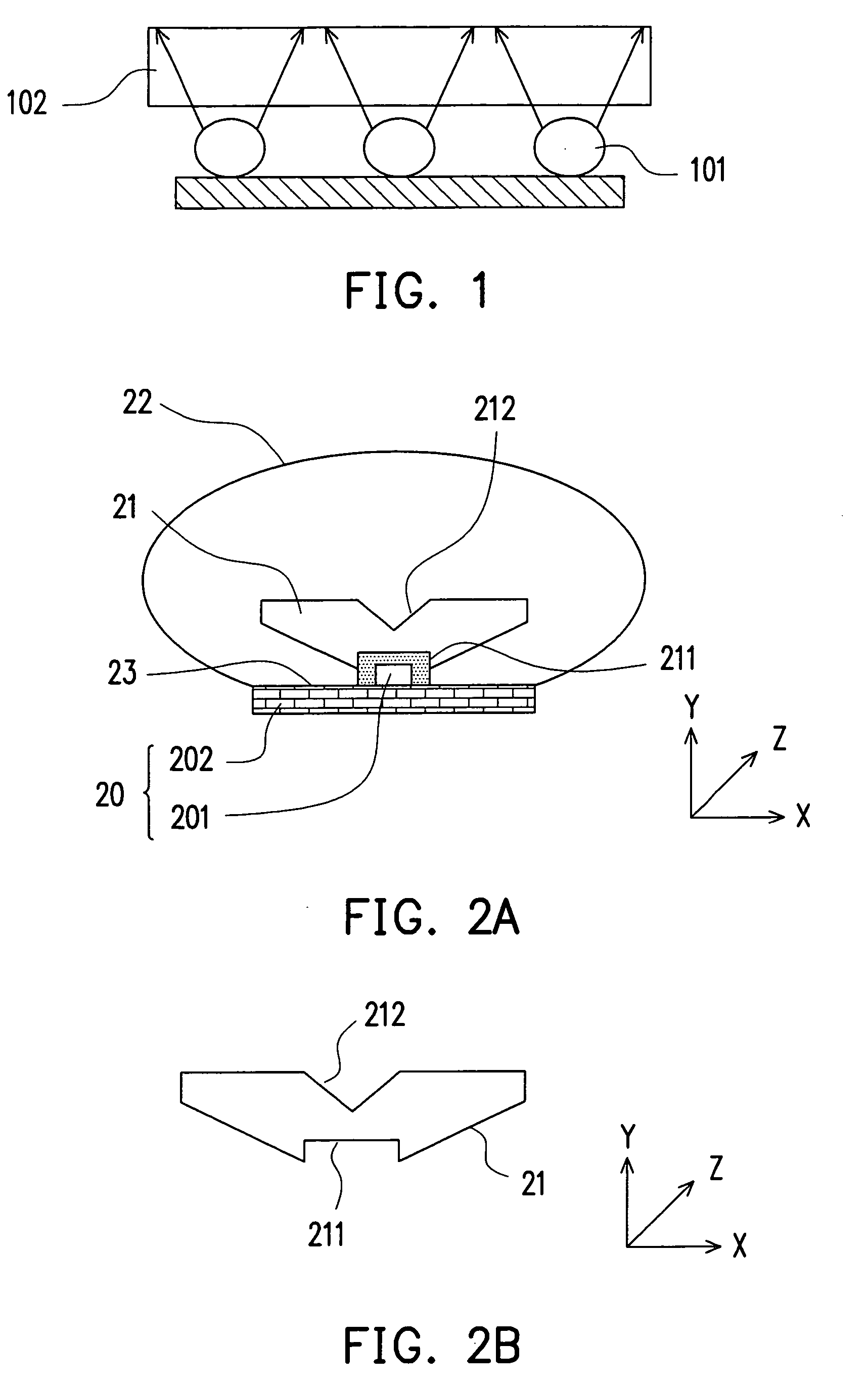

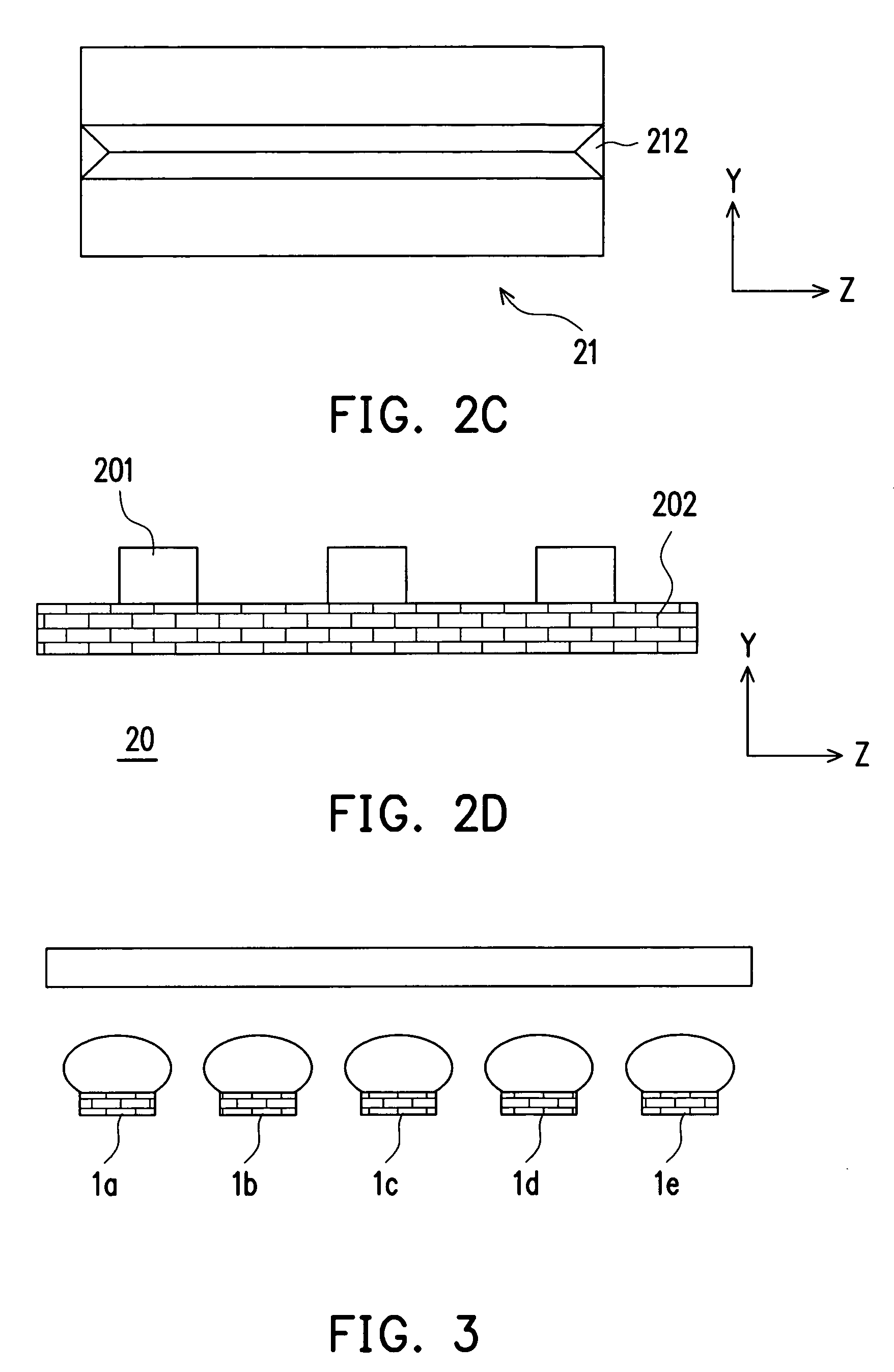

LED light source

ActiveUS7246931B2Uniform brightnessReduce thicknessPoint-like light sourceLighting heating/cooling arrangementsLight guideLight-emitting diode

A tube type light emitting diode light source including a light source generator, a light guide and a diffuser is provided. The light source generator includes LEDs arranging in a line. The light guide has a grooved light incident surface and a grooved light-guiding surface. The grooved light incident surface encompasses the LEDs, and the grooved light-guiding surface is adapted for changing the propagating direction of an incident light. The diffuser covers the light guide.

Owner:EPISTAR CORP

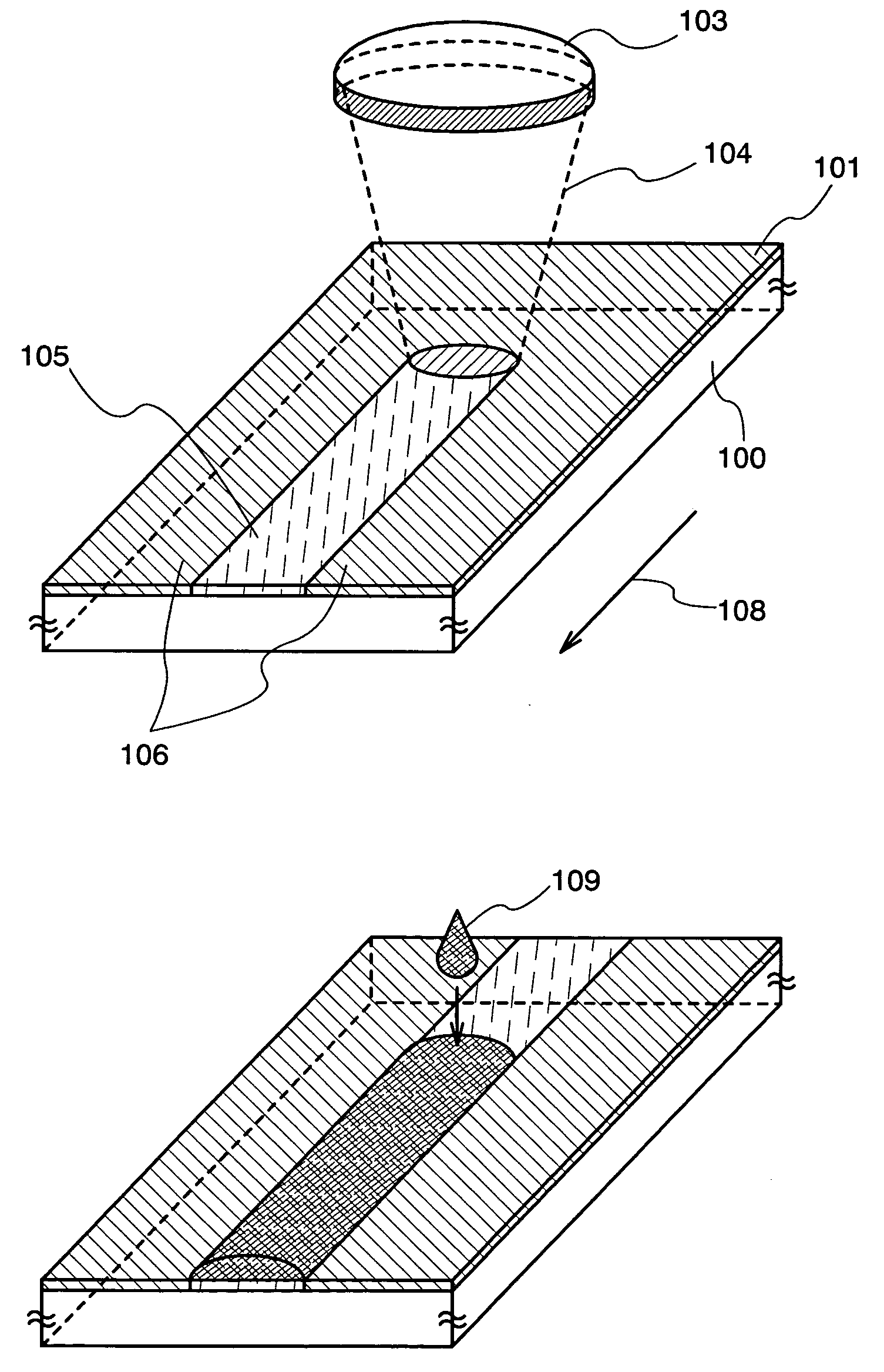

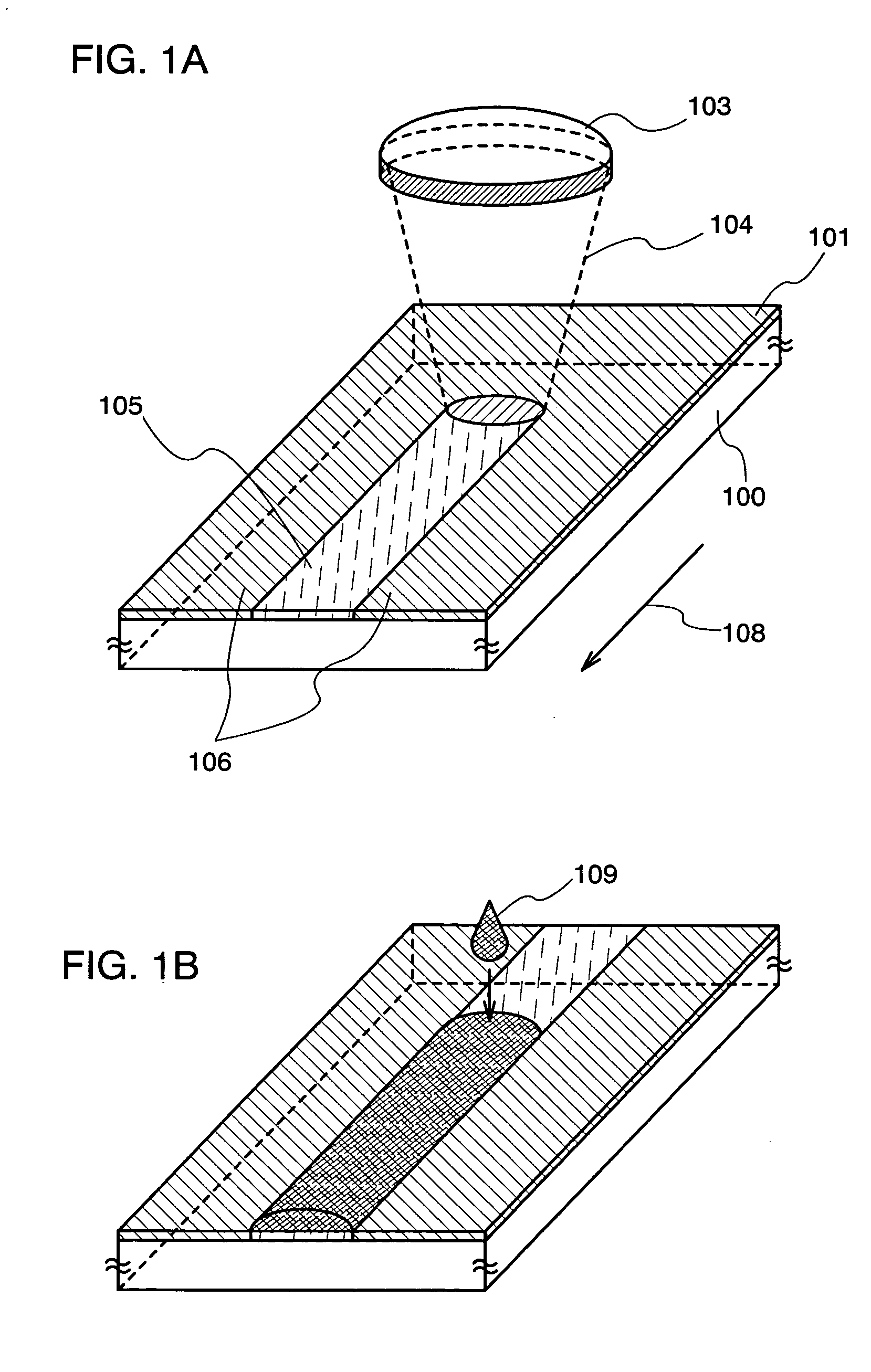

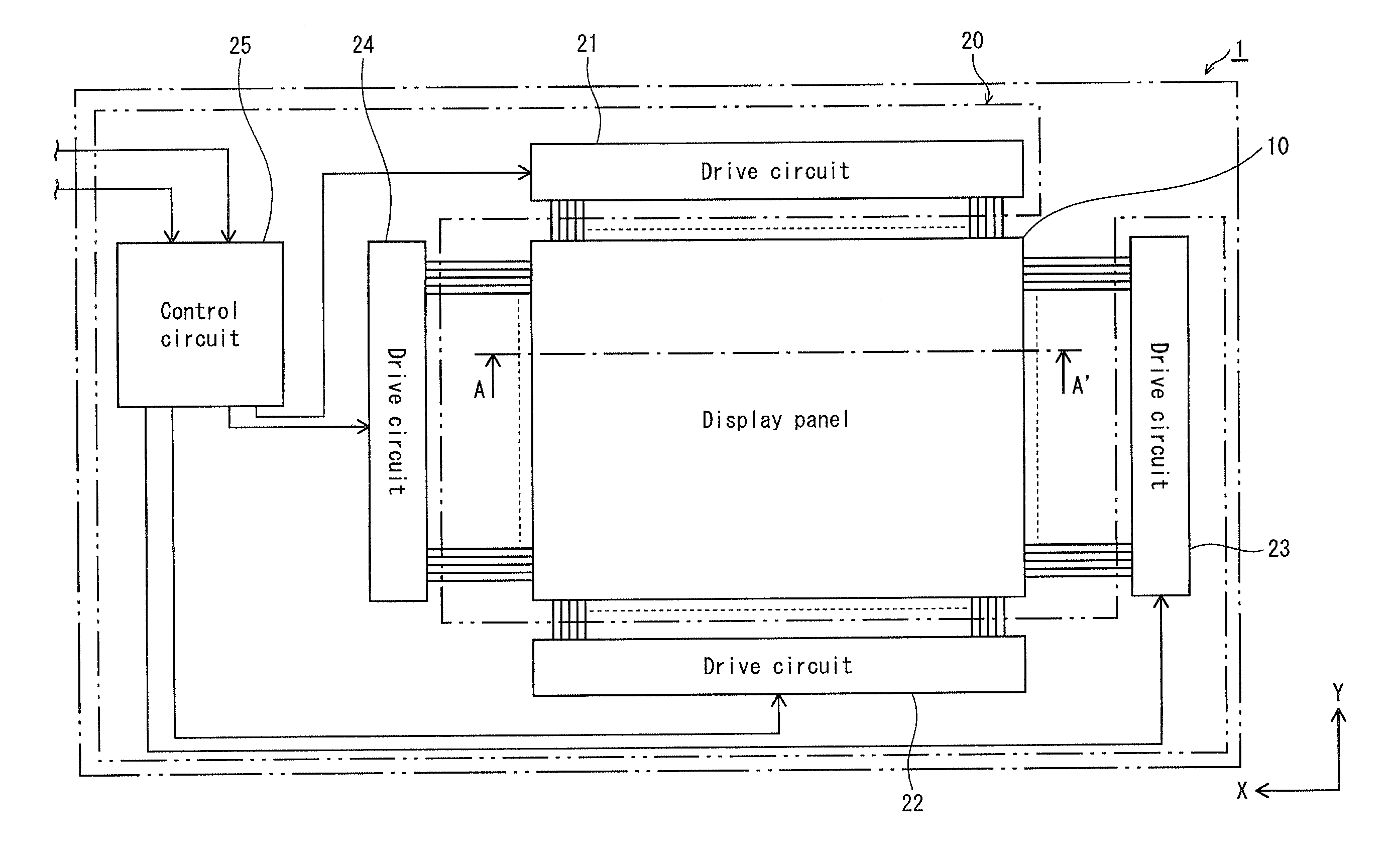

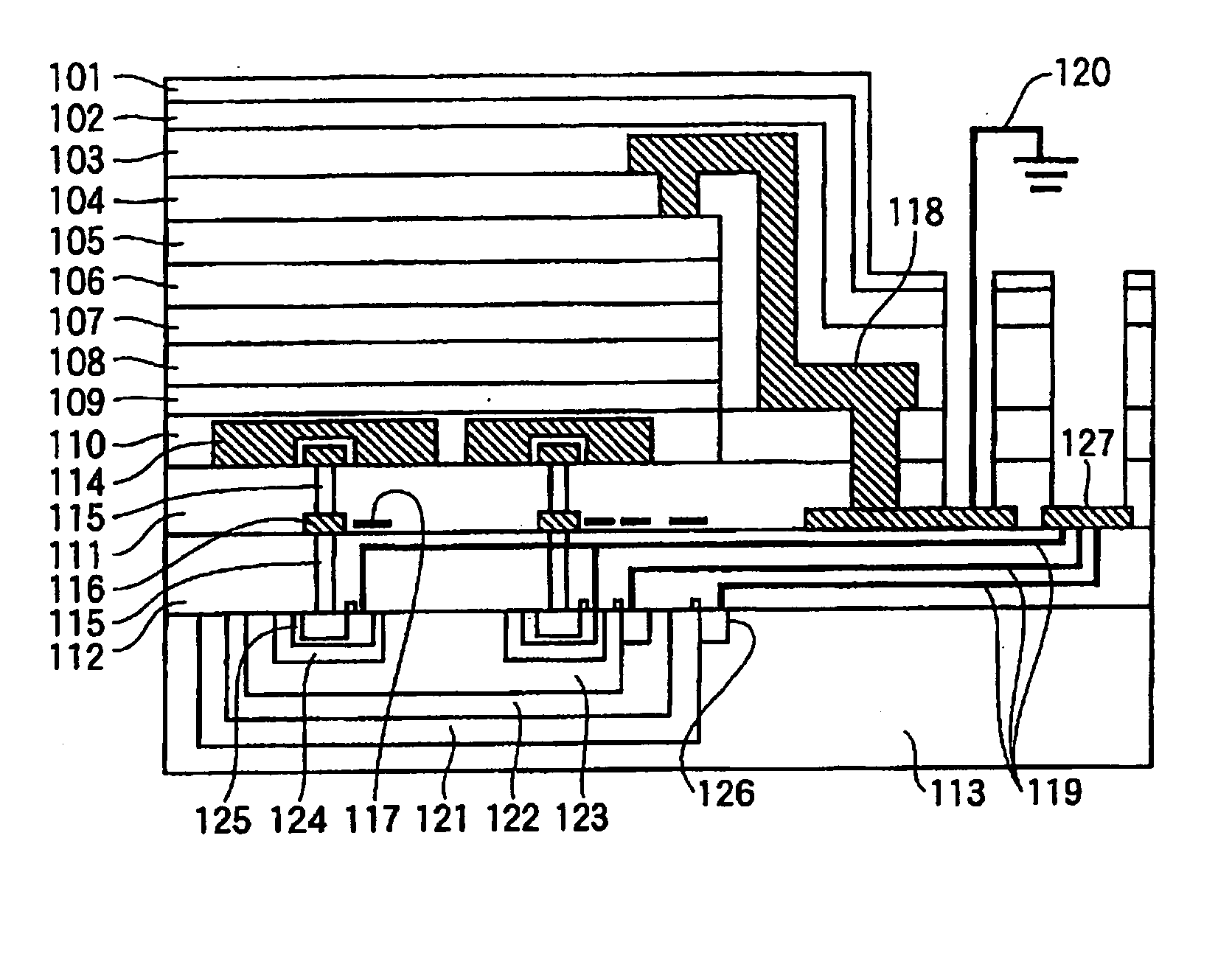

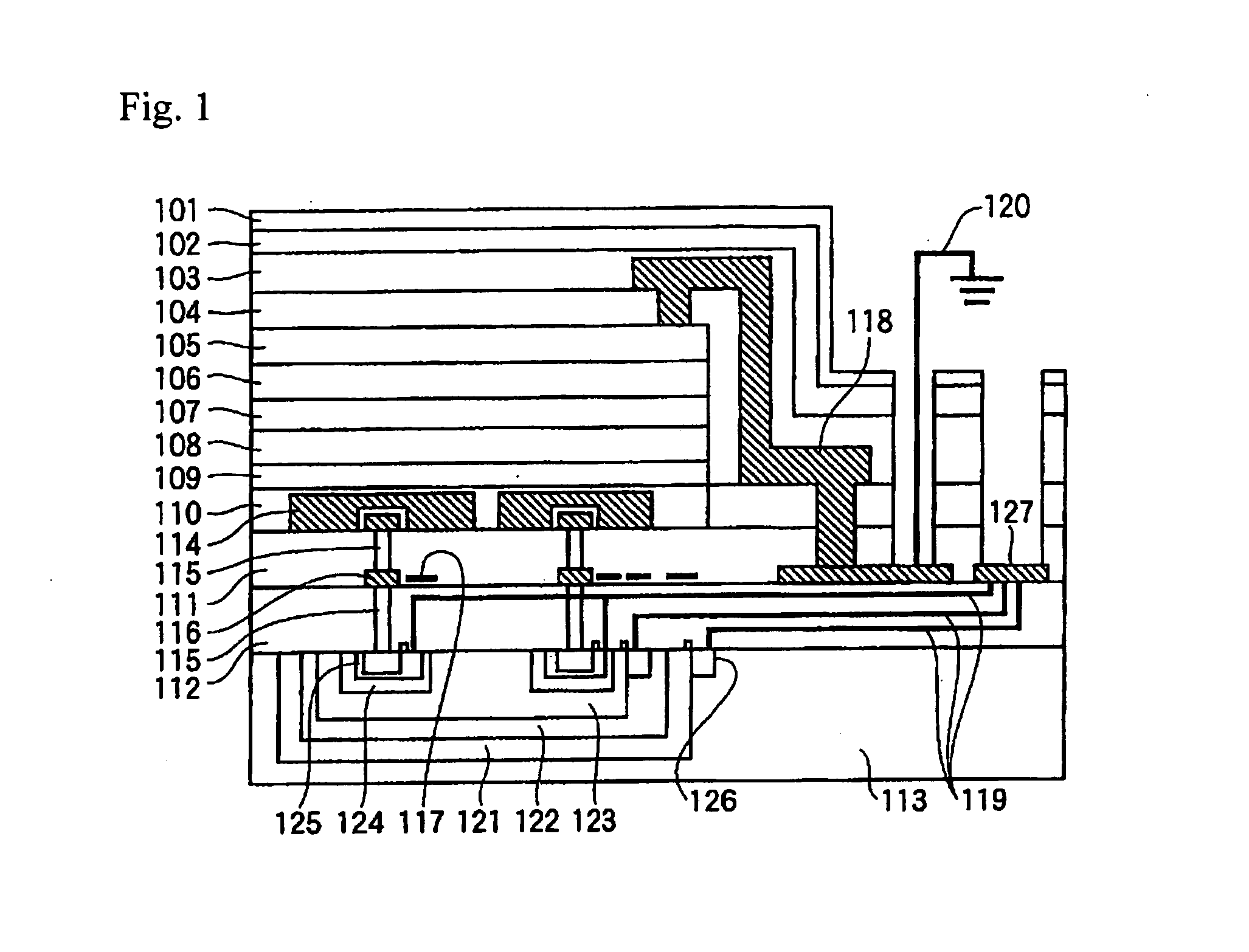

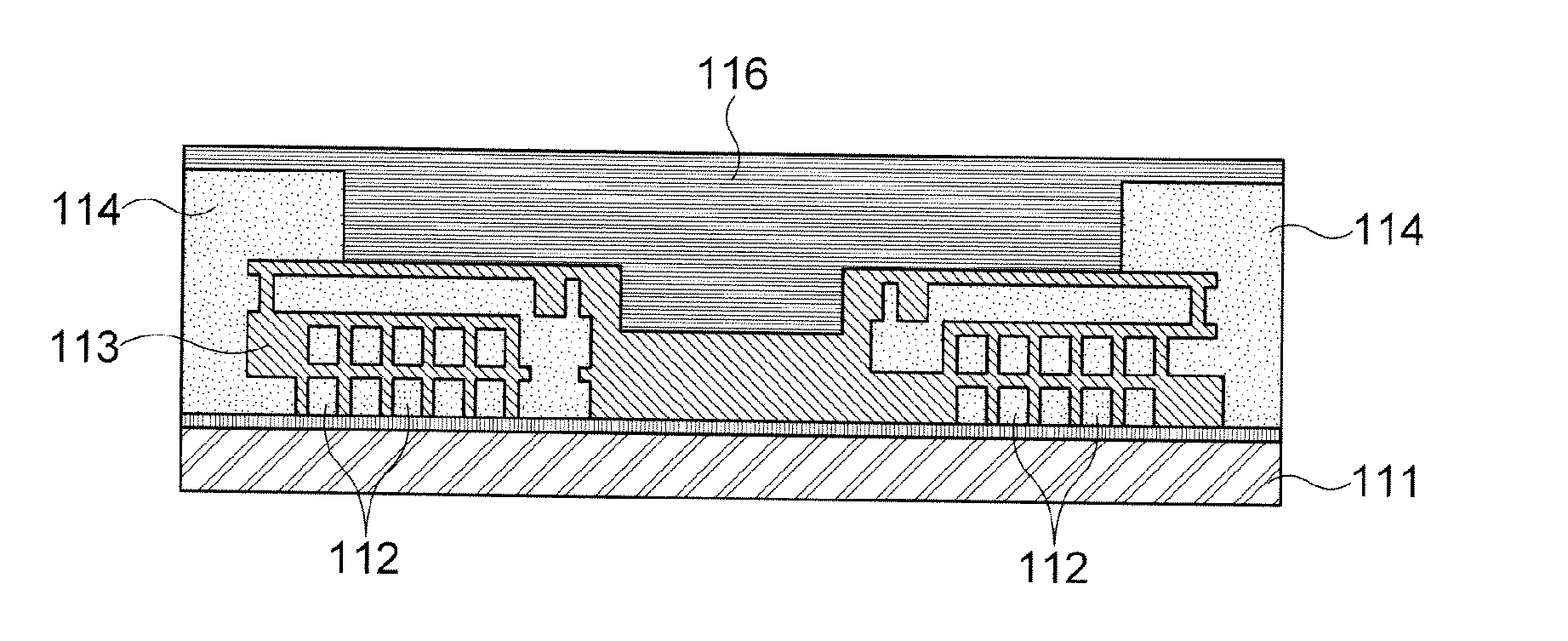

Method for manufacturing wiring, thin film transistor, light emitting device and liquid crystal display device, and droplet discharge apparatus for forming the same

InactiveUS20050095356A1Easy to controlAvoid spreadingTransistorPhysical/chemical process catalystsLiquid-crystal displayDevice material

As a semiconductor device, specifically, a pixel portion included in a semiconductor device is made to have higher precision and higher aperture ratio, it is required to form a smaller wiring in width. In the case of forming a wiring by using an ink-jet method, a dot spreads on a wiring formation surface, and it is difficult to narrow width of a wiring. In the present invention, a photocatalytic substance typified by TiO2 is formed on a wiring formation surface, and a wiring is formed by utilizing photocatalytic activity of the photocatalytic substance. According to the present invention, a narrower wiring, that is, a smaller wiring in width than a diameter of a dot formed by an ink-jet method can be formed.

Owner:SEMICON ENERGY LAB CO LTD

LED light source

ActiveUS20060126343A1Uniform brightnessReduce thicknessPoint-like light sourceLighting heating/cooling arrangementsLight guideLight-emitting diode

A tube type light emitting diode light source including a light source generator, a light guide and a diffuser is provided. The light source generator includes LEDs arranging in a line. The light guide has a grooved light incident surface and a grooved light-guiding surface. The grooved light incident surface encompasses the LEDs, and the grooved light-guiding surface is adapted for changing the propagating direction of an incident light. The diffuser covers the light guide.

Owner:EPISTAR CORP

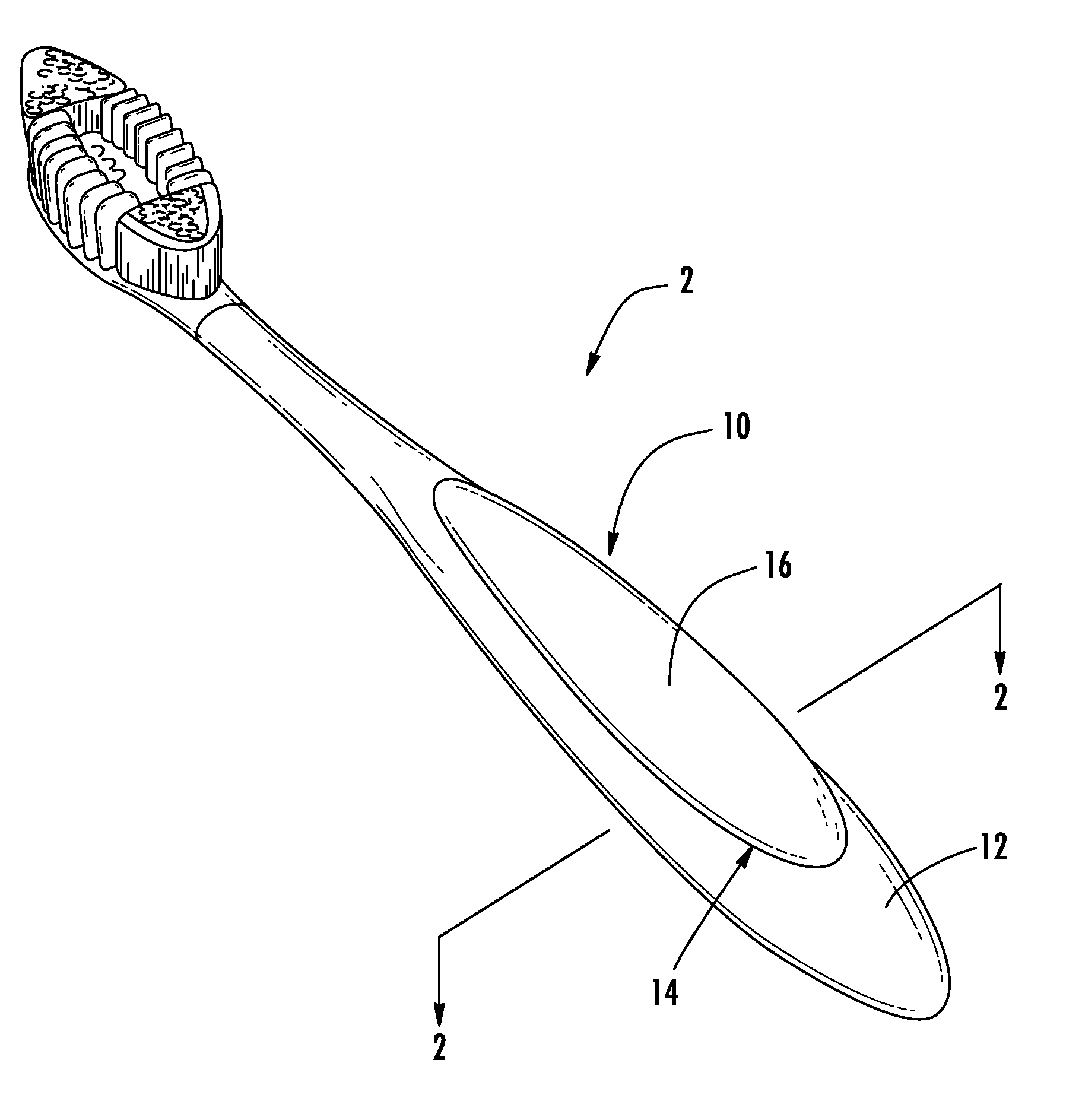

Handle with soft gel cushioning member

InactiveUS20070143942A1Low durometer gripThicker thicknessCarpet cleanersBrush bodiesRigid coreEngineering

The handle construction of the present invention includes a low durometer grip portion that provides comfort and an ergonomic benefit to the user. The handle includes a rigid core with a gel member received in a recessed seat. The gel member preferably has a durometer of 65 Shore 00 or less. A thin top finish layer, of elastomeric or polymer film, is optionally provided on the top of the gel member, such as in a thickness of less than 4 thousandths of an inch in thickness (<4 mil) to provide a durable and aesthetic surface. The combination of the molded low durometer gel member, with an otherwise rigid handle, allows for the creation of an overall handle that has areas that are more rigid along with areas that exhibit a very soft feel.

Owner:POLYWORKS +1

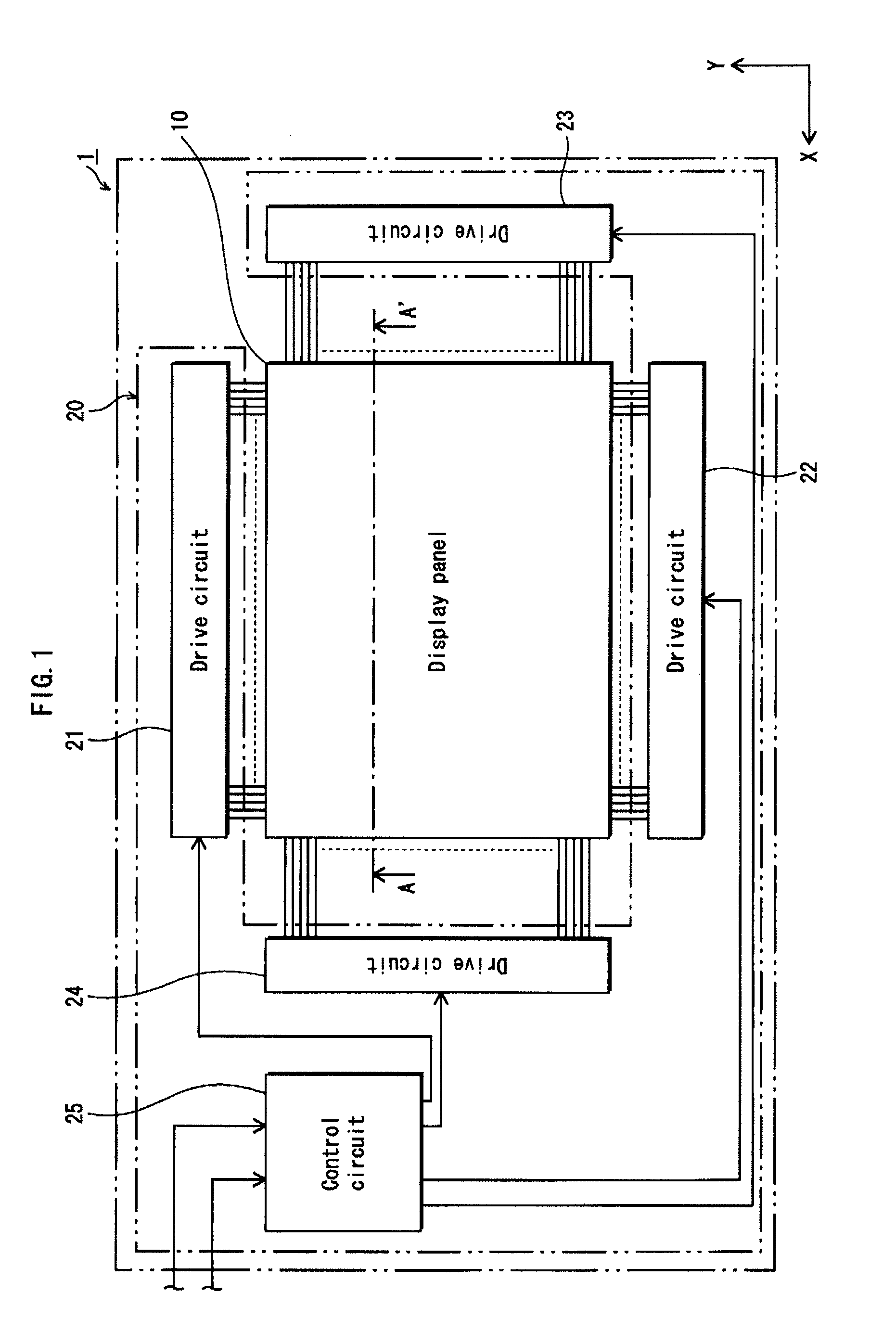

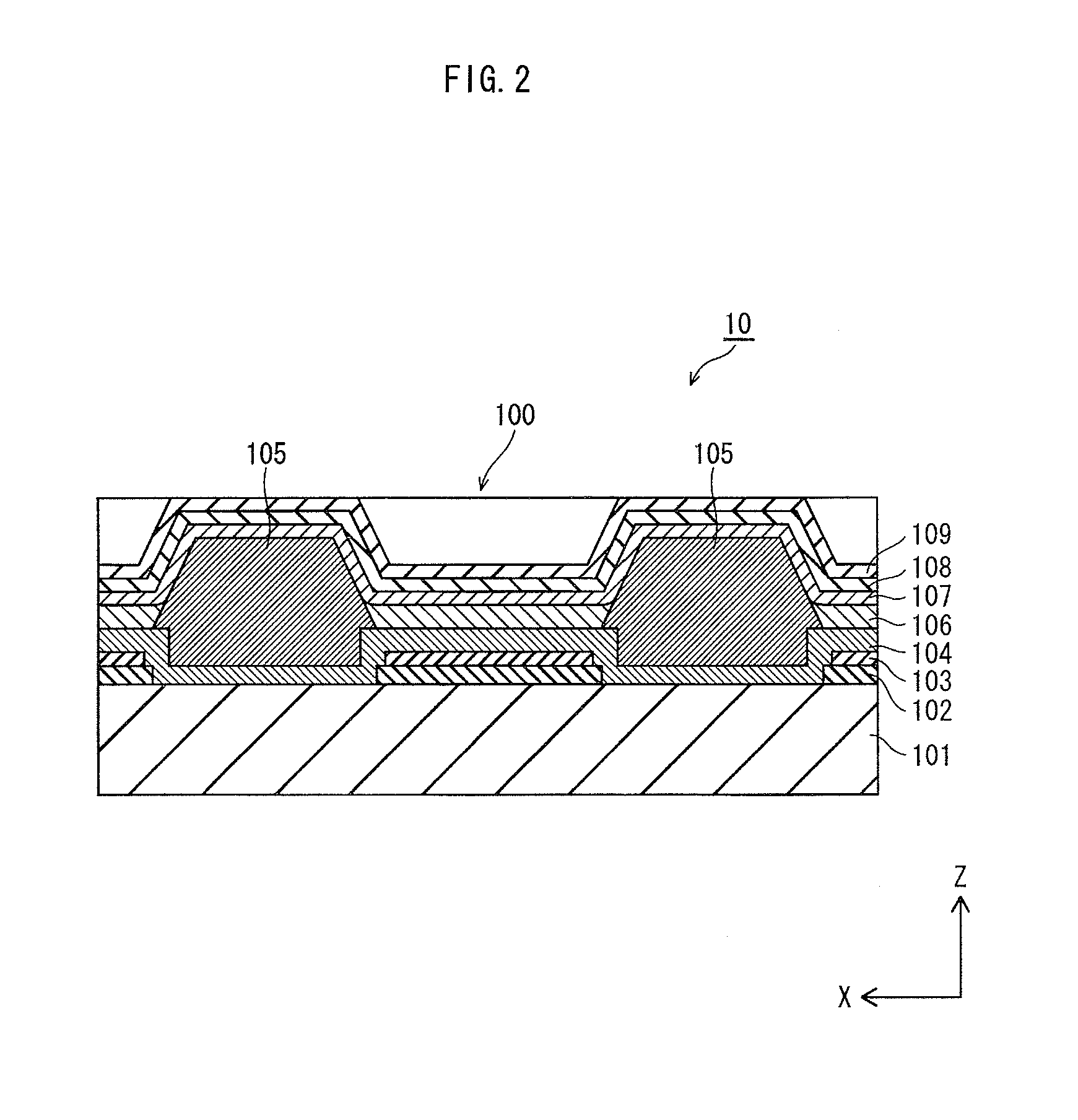

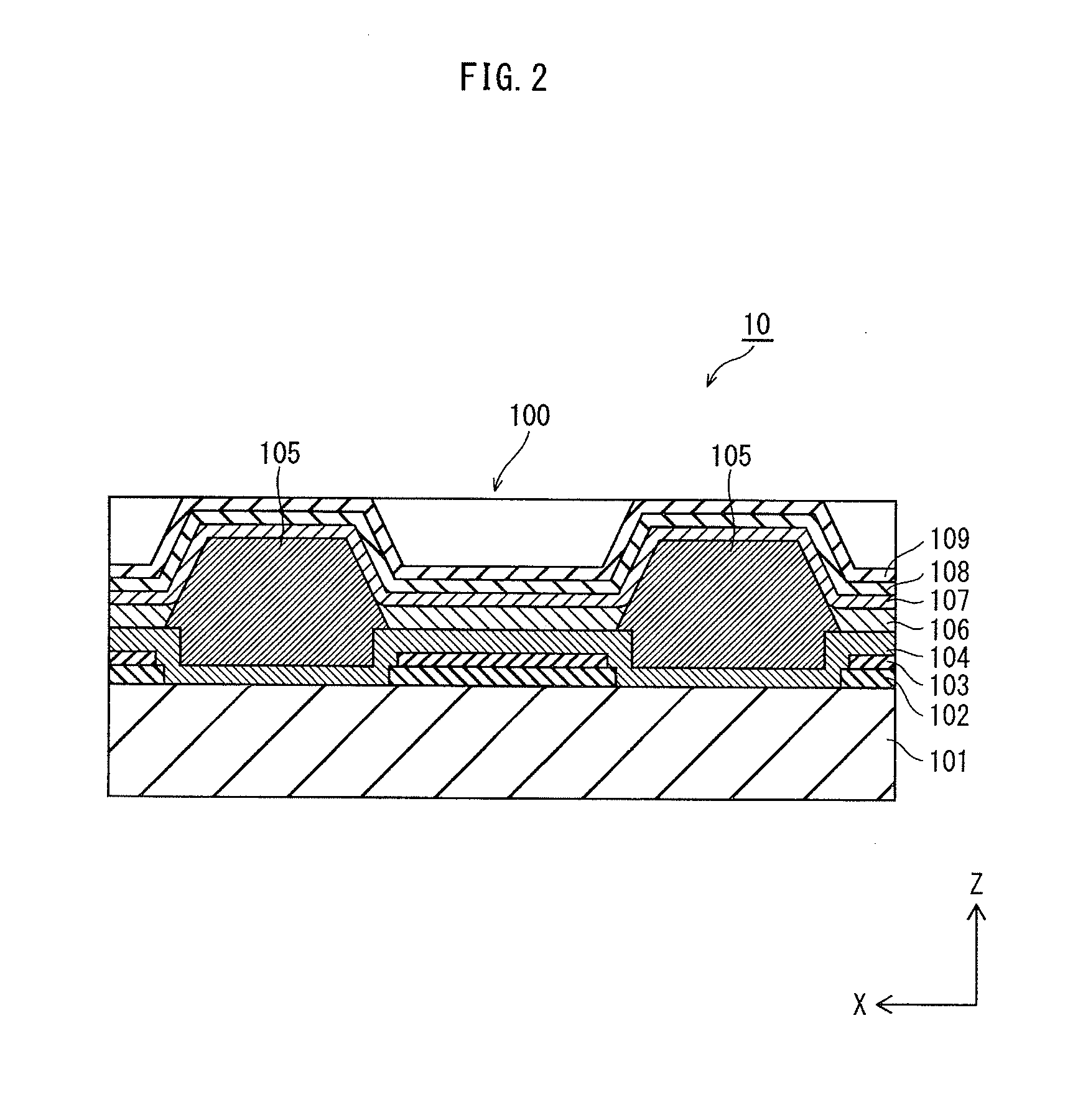

Display device and manufacturing method thereof

ActiveUS20110180821A1Uniform film shapeAvoid thickness thinningSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceLight-emitting diode

Owner:JOLED INC

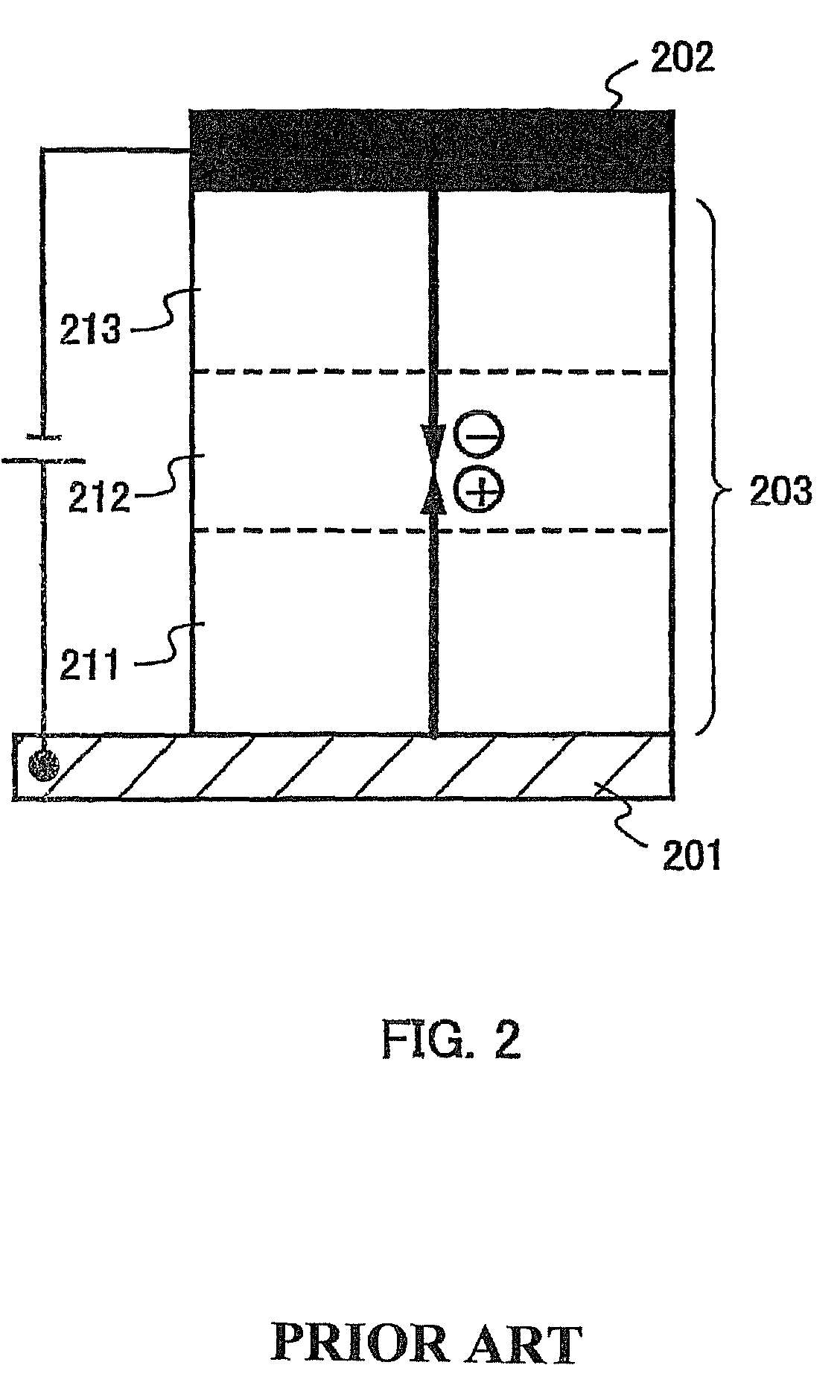

Display device and manufacturing method thereof

ActiveUS20110198624A1Uniform film shapeReduce film thicknessElectroluminescent light sourcesSolid-state devicesDisplay deviceLight-emitting diode

A display device includes an array of light emitting cells. Each light emitting cell includes first and second electrodes, and an organic light emitting layer located between the first and second electrodes. Banks are above the first electrode that partition the organic light emitting layer to define each of the light emitting cells. First and second light emitting cells are adjacent to one another and located in a peripheral region of the array. The first light emitting cell is closer to a center of the array than the second light emitting cell. A first bank borders the first light emitting cell and the second light emitting cell. An inclination angle of an innermost sidewall of the first bank that is adjacent the first light emitting cell is greater than an inclination angle of an outermost sidewall of the first bank that is adjacent the second light emitting cell.

Owner:JOLED INC

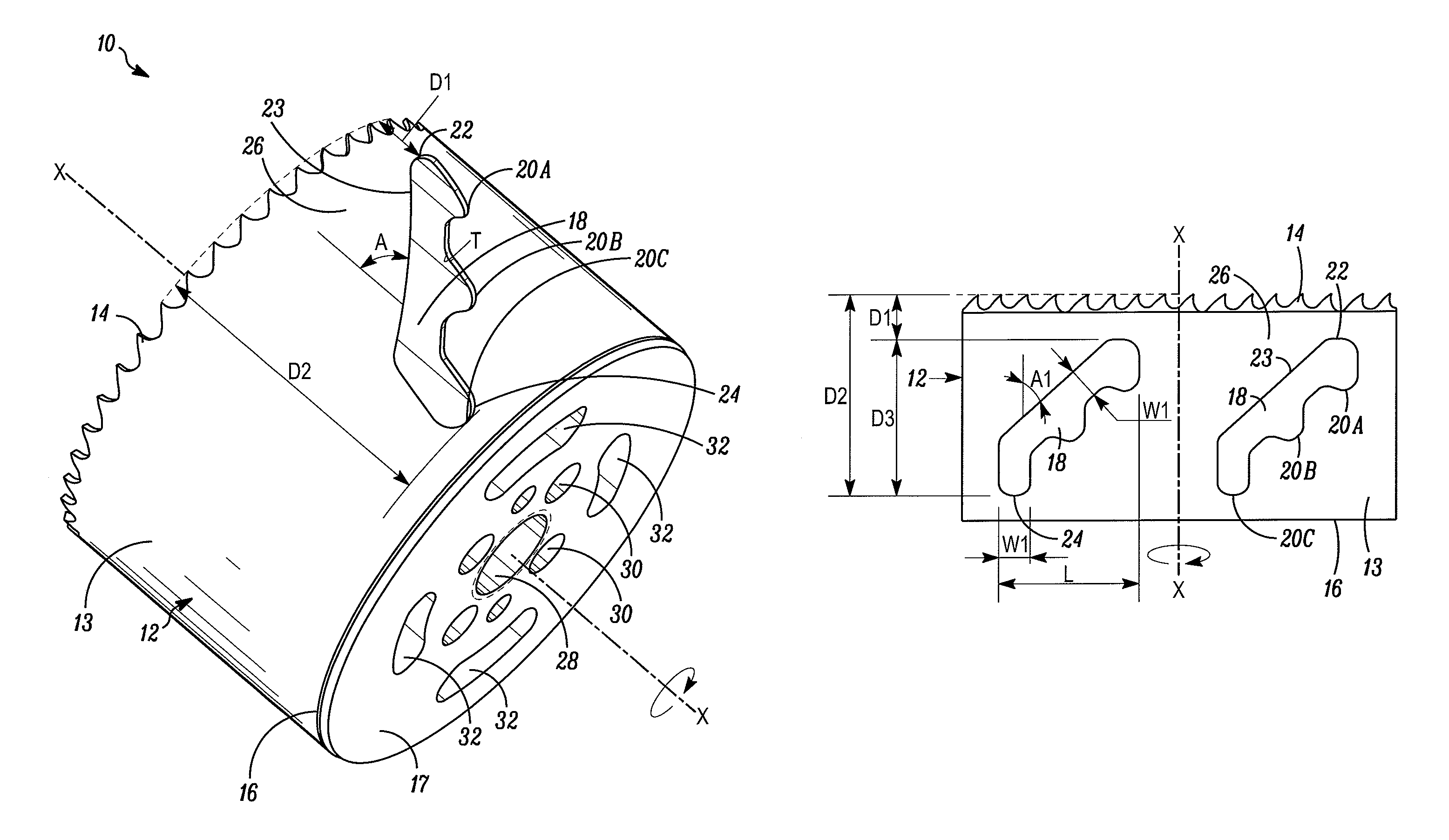

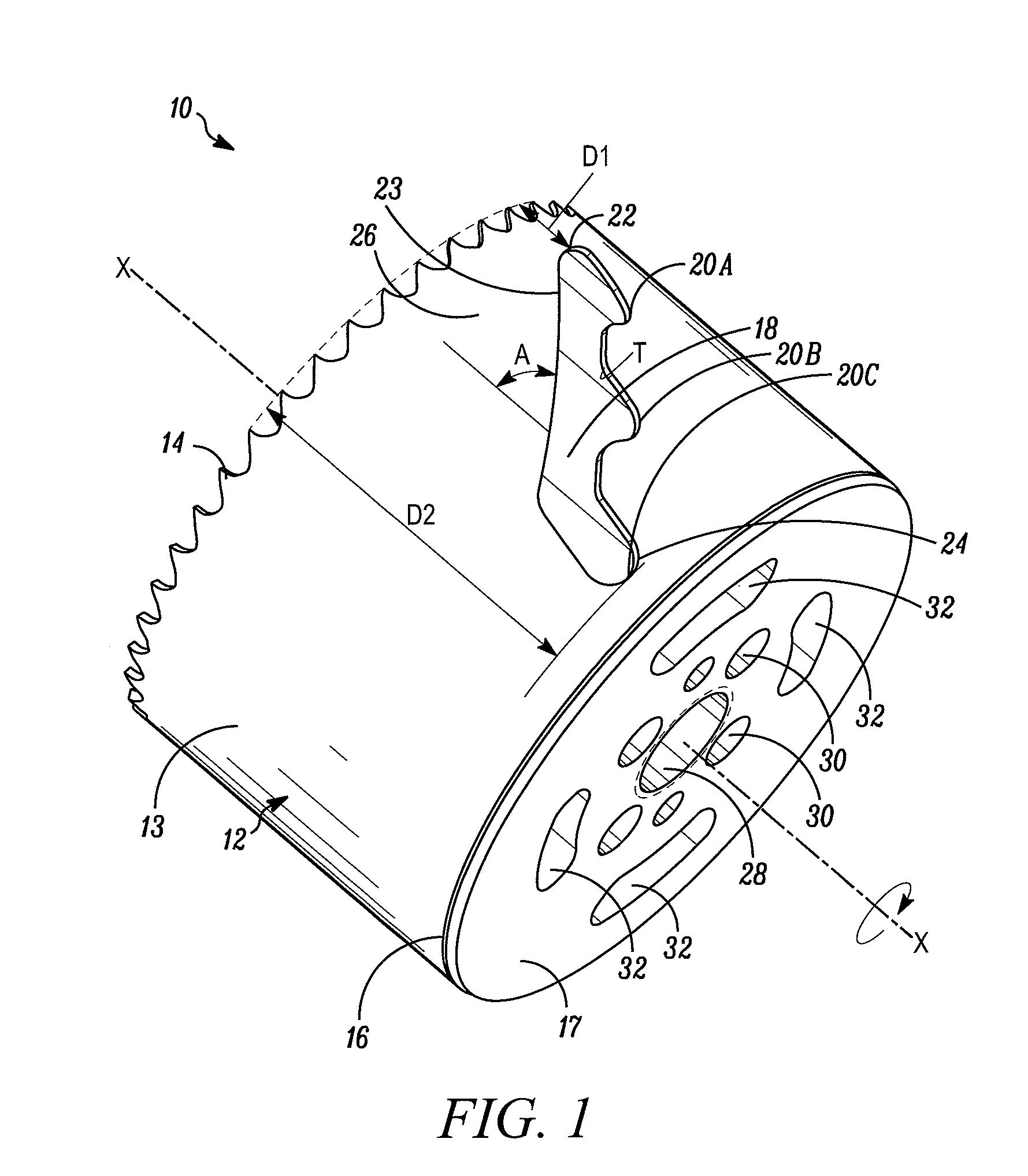

Hole cutter with minimum tooth pitch to blade body thickness ratio

ActiveUS8573907B2Avoid collectingSmall volumeTransportation and packagingCircular sawsEngineeringMetal working

A hole cutter for cutting a work piece, such as a wood and / or metal work piece, has a substantially cylindrical blade body defining a wall thickness within the range of about 0.032 inch to about 0.038 inch, and a cutting edge formed on one end of the blade body including a plurality of teeth defining an average tooth pitch within the range of about 3.5 TPI to about 5.5 TPI for cutting the work piece and forming chips therefrom. The substantially cylindrical blade body and cutting edge define an average tooth pitch to blade body thickness ratio of at least about 110.

Owner:BLACK & DECKER INC

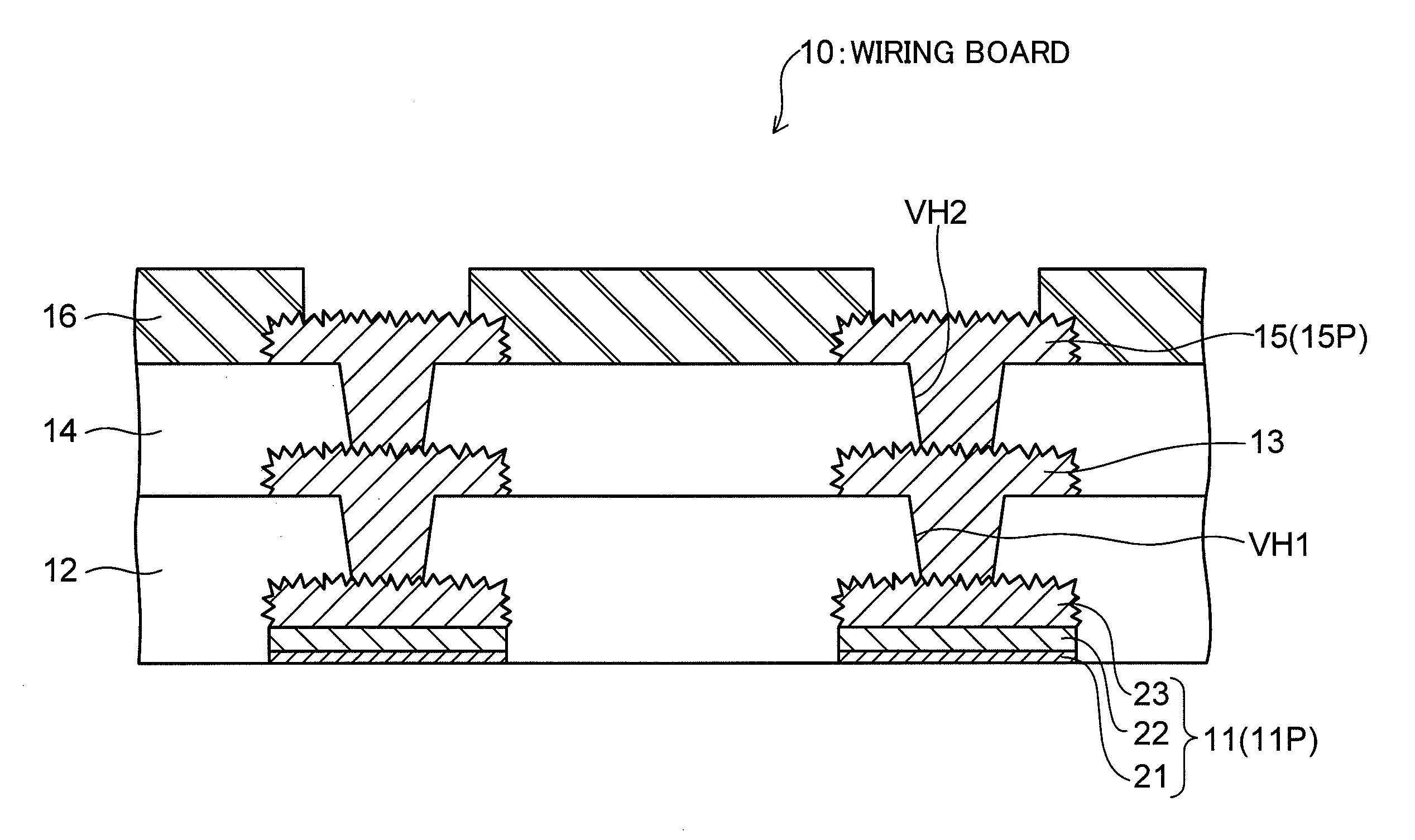

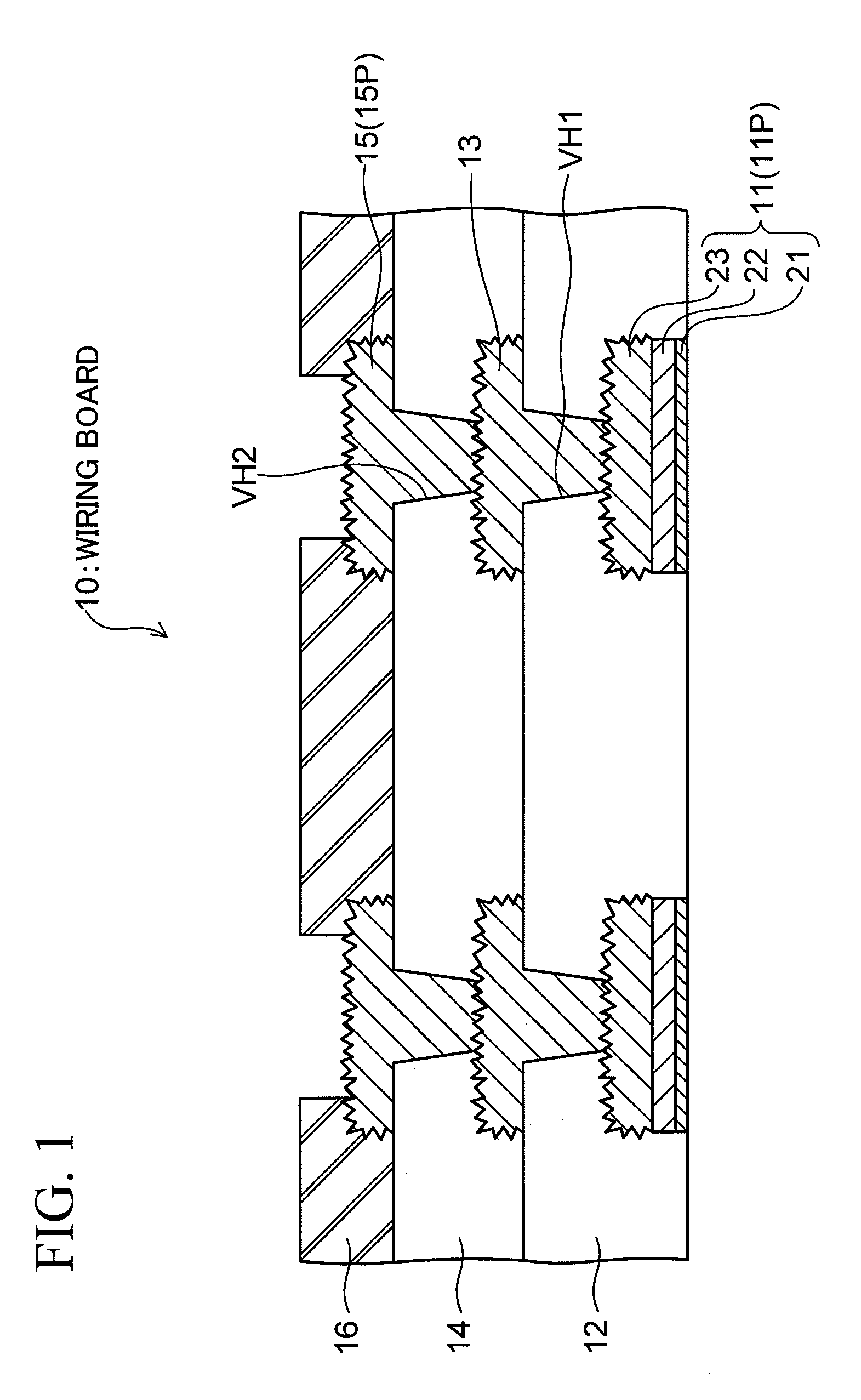

Wiring board and method of manufacturing the same

ActiveUS20100065322A1Improve tensile strengthDecreasingSemiconductor/solid-state device detailsSolid-state devicesMetalMaterials science

A wiring board includes a pad exposed from an opening portion of an outermost insulating layer. The pad includes: a first metal layer a surface of which is exposed from the wiring board; a second metal layer provided on the first metal layer and formed of a material effective in preventing a metal contained in a via inside the board from diffusing into the first metal layer; and a third metal layer provided between the second metal layer and the via, and formed of a material harder to be oxidized than that of the second metal layer. The thickness of the third metal layer is relatively thick, and is preferably selected to be three times or greater than a thickness of the second metal layer. A side surface of the third metal layer and a surface of the third metal layer to which the via is to be connected are roughed.

Owner:SHINKO ELECTRIC IND CO LTD

Hole Cutter With Minimum Tooth Pitch to Blade Body Thickness Ratio

ActiveUS20110170970A1Avoid collectingSmall volumeTransportation and packagingCircular sawsEngineeringMechanical engineering

A hole cutter for cutting a work piece, such as a wood and / or metal work piece, has a substantially cylindrical blade body defining a wall thickness within the range of about 0.032 inch to about 0.038 inch, and a cutting edge formed on one end of the blade body including a plurality of teeth defining an average tooth pitch within the range of about 3.5 TPI to about 5.5 TPI for cutting the work piece and forming chips therefrom. The substantially cylindrical blade body and cutting edge define an average tooth pitch to blade body thickness ratio of at least about 110.

Owner:BLACK & DECKER INC

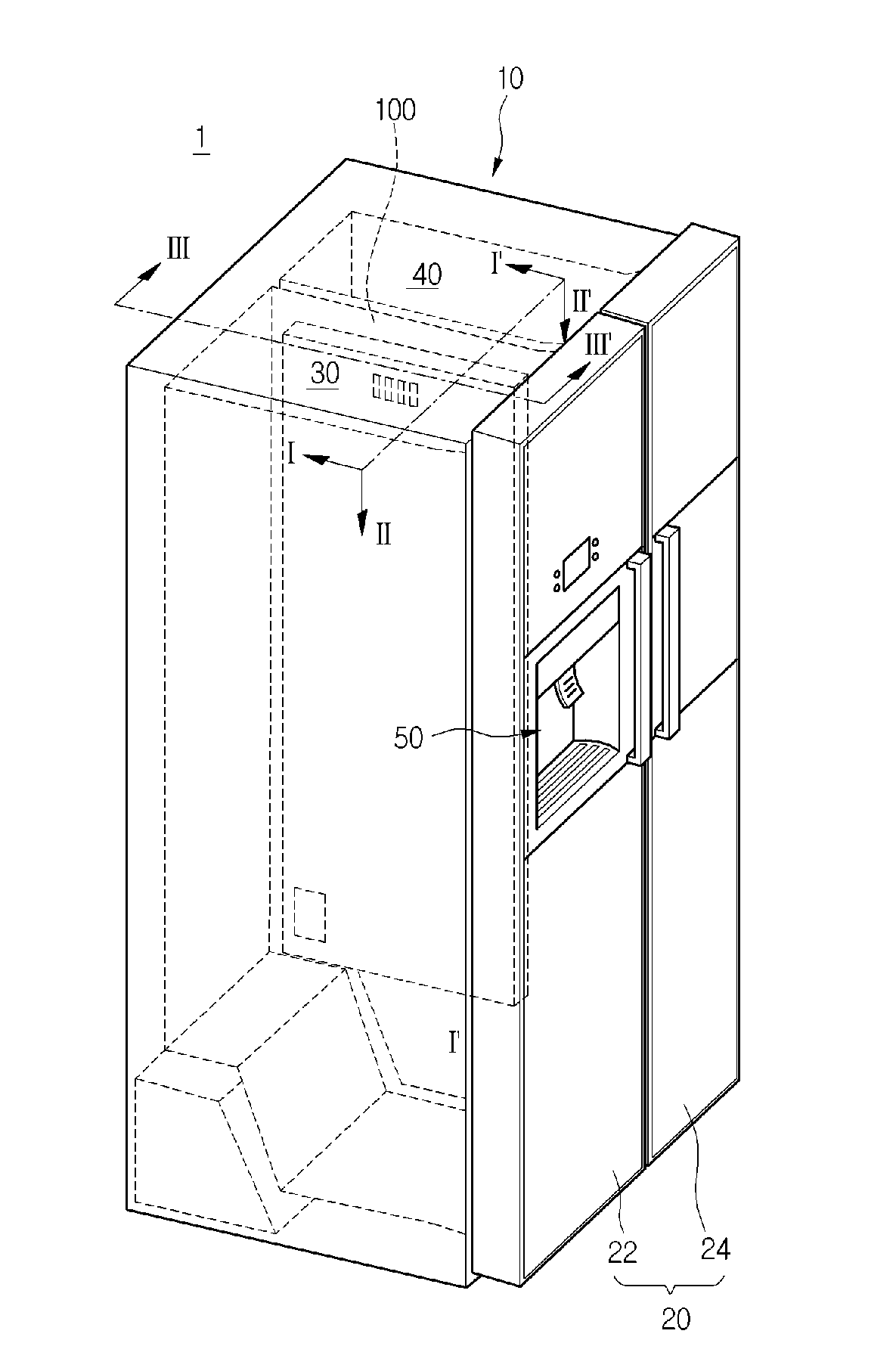

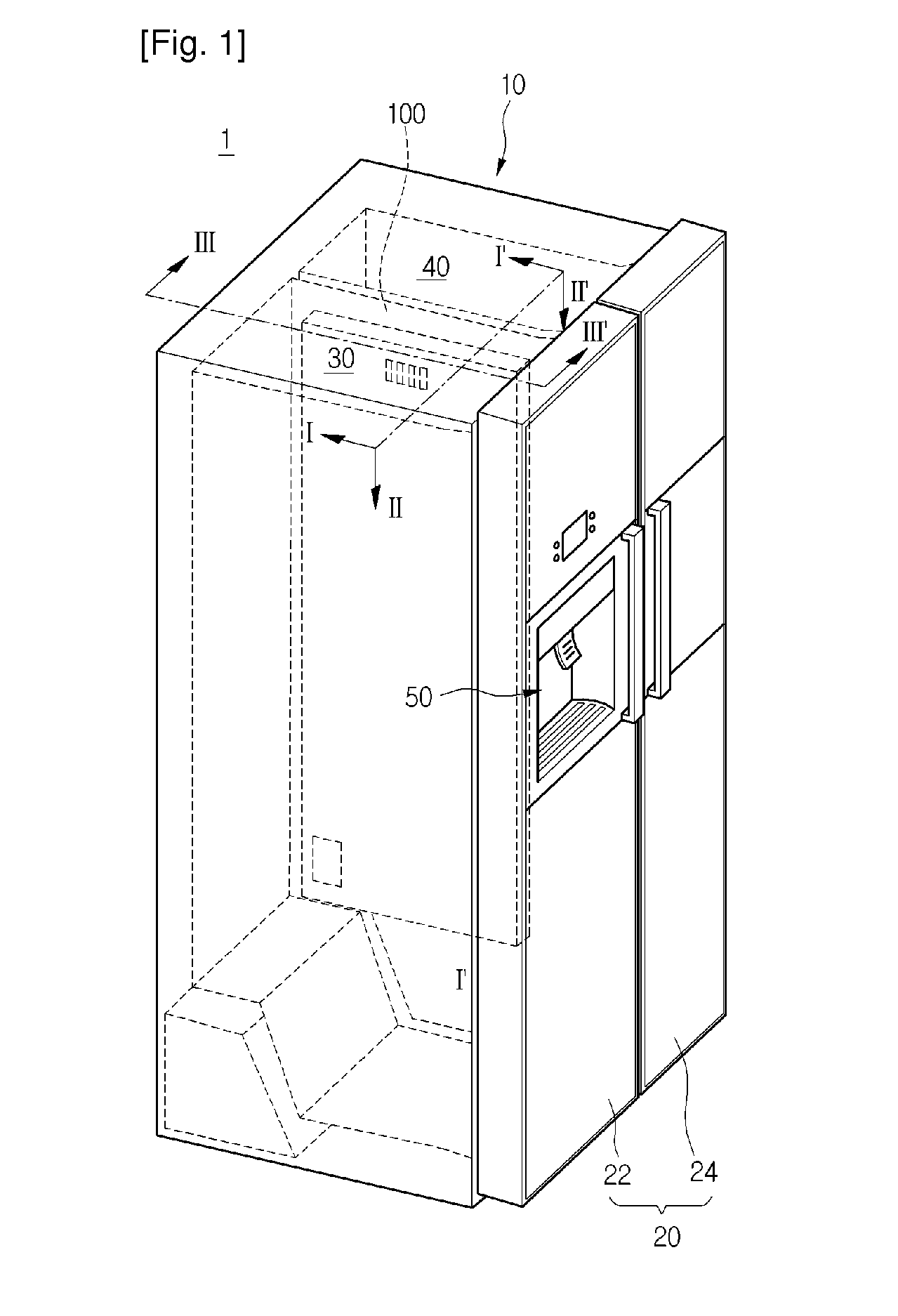

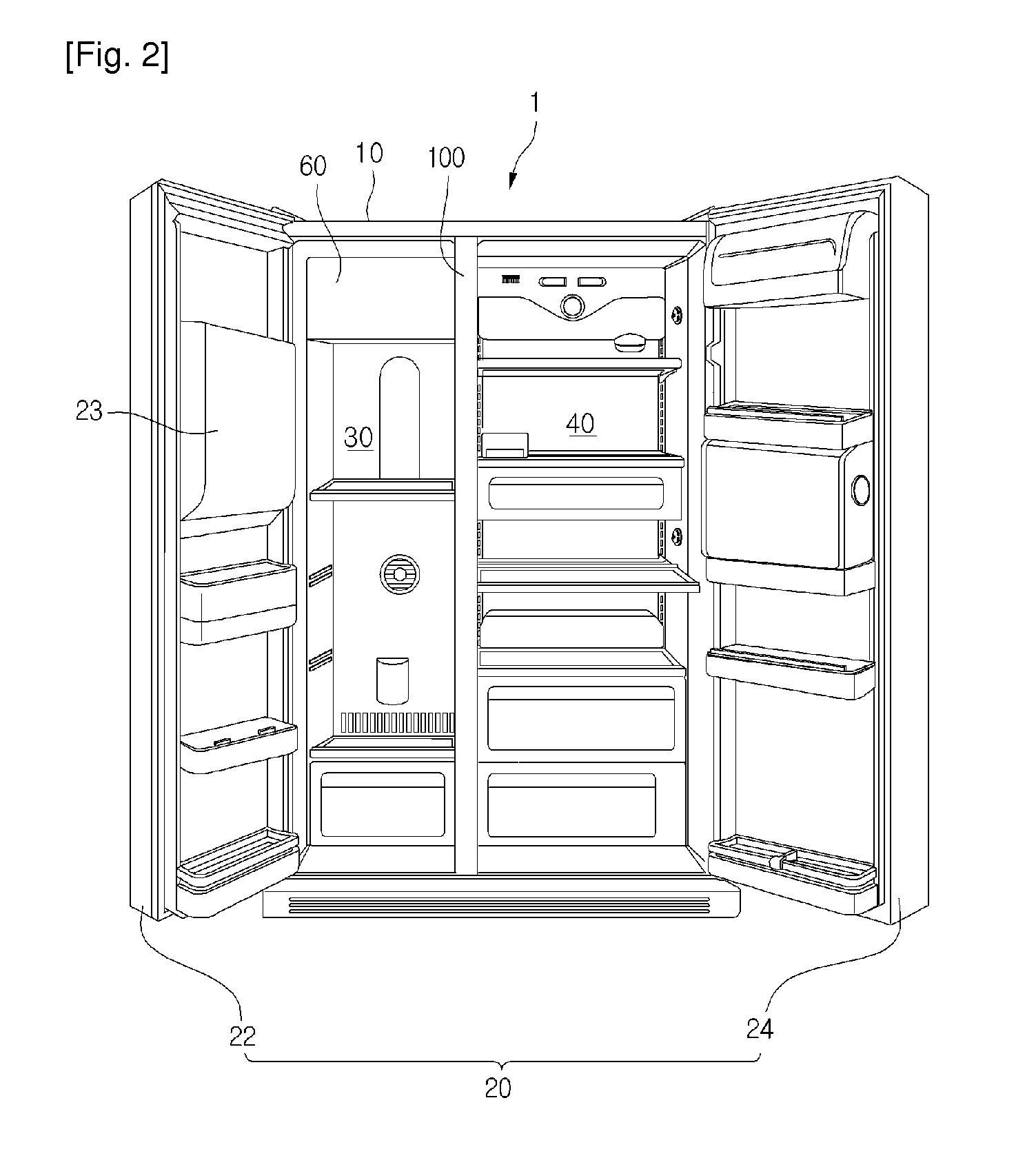

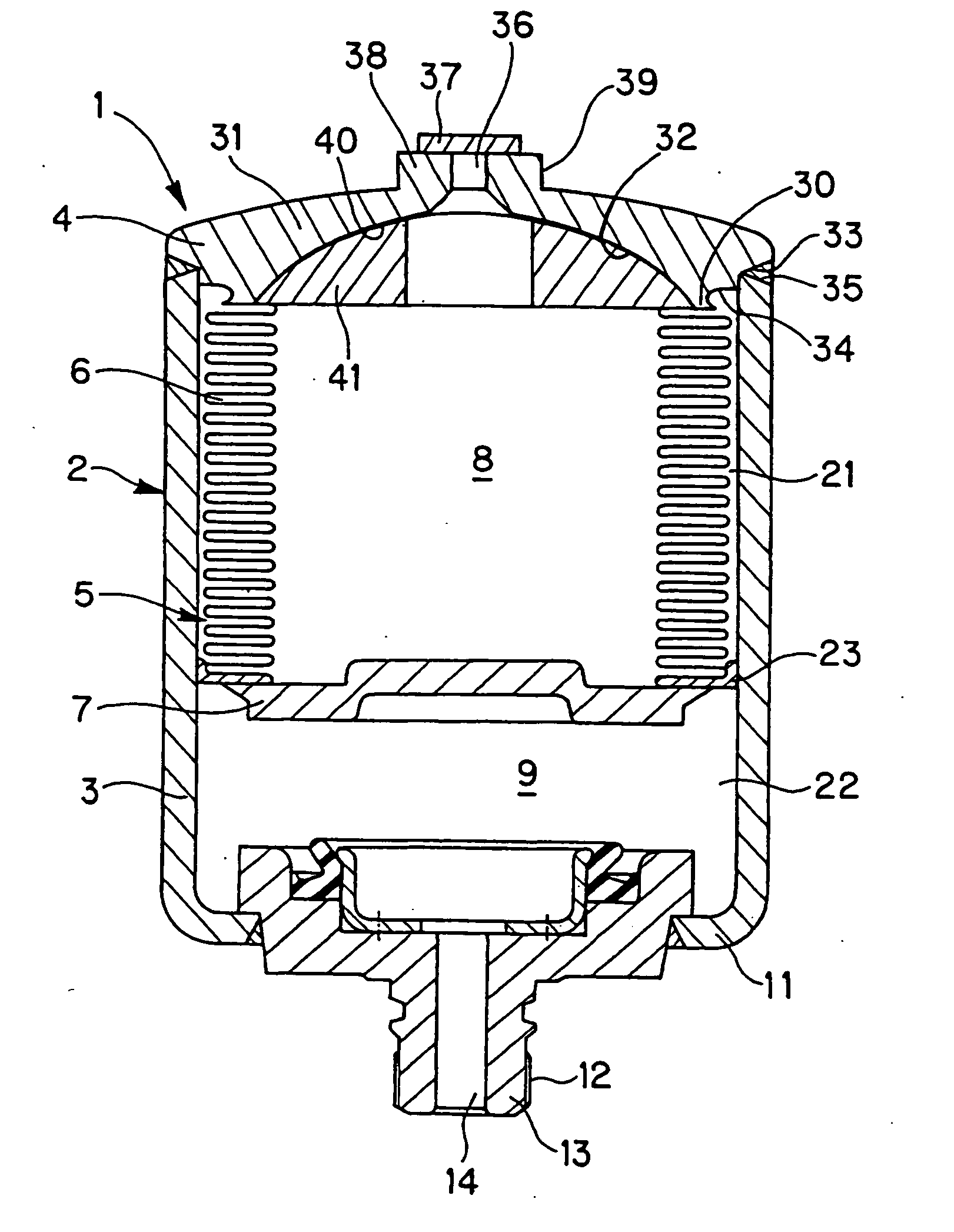

Refrigerator and control method thereof

InactiveUS20120272670A1Thin thicknessAvoid thickness thinningLighting and heating apparatusCooling fluid circulationCold airEngineering

A refrigerator includes a cabinet having a storage space; a barrier to divide the storage space into a freezing compartment and a refrigerating compartment, filled with a heat insulator, and having a depression part formed on one side surface thereof; an evaporator accommodated in a part of the depression part; a blowing unit accommodated in another part of the depression part corresponding to a upper side of the evaporator; a barrier cover to shield the depression part by covering one side surface of the barrier. The depression part includes an evaporator accommodating part to accommodate the evaporator, a blowing unit accommodating part configured to accommodate the blowing unit, and a cold air passage extended from the blowing unit accommodating part to allow the cold air to be guided into the freezing compartment and to refrigerating compartment. The blowing unit accommodating part is depressed greater than the evaporator accommodating part.

Owner:LG ELECTRONICS INC

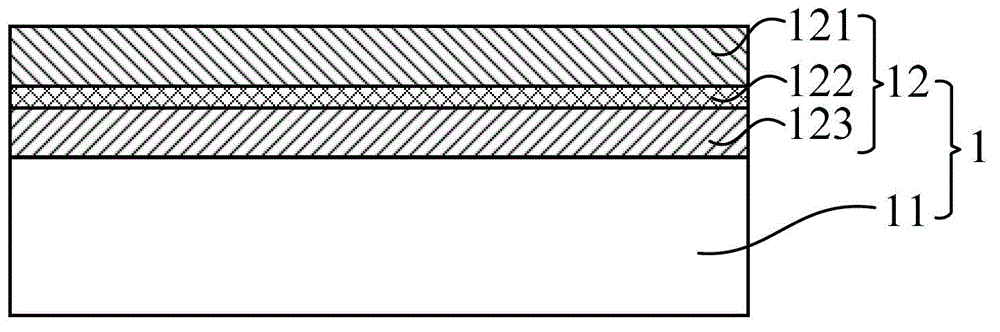

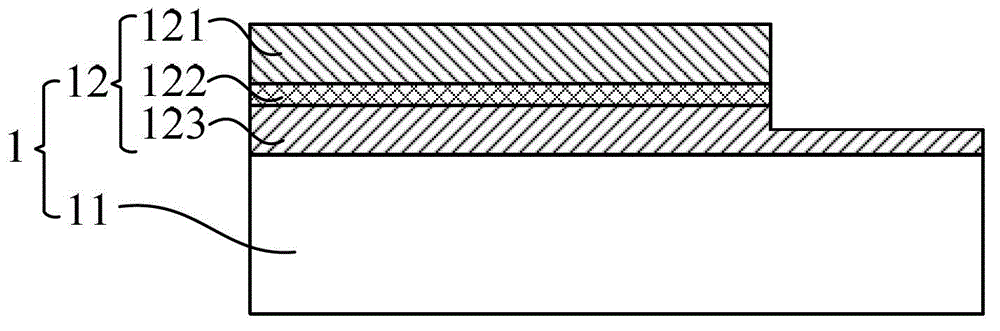

LED (Light Emitting Diode) chip provided with stepped current blocking structure and fabricating method thereof

ActiveCN102751410AImprove electro-optical conversion efficiencyIncrease brightnessSemiconductor devicesPower flowEngineering

The invention provides an LED (Light Emitting Diode) chip provided with a stepped current blocking structure and a fabricating method thereof. The fabricating method comprises the steps of: providing at least one LED epitaxial wafer comprising a substrate and a light emitting epitaxial structure on the LED epitaxial wafer; fabricating the stepped current blocking structure on the surface of the LED epitaxial wafer vertical to a region of a first electrode correspondingly prefabricated; and fabricating transparent conductive layers on the surfaces of the LED epitaxial wafer and the stepped current blocking structure, and then fabricating a first electrode, a second electrode and a protective layer correspondingly. According to the LED chip provided with a stepped current blocking structure and the fabricating method of the LED chip provided with the stepped current blocking structure provided by the invention, the gradient at the edge of the stepped current blocking structure is slowed so that the contact area of the transparent conductive layer and the stepped current blocking structure is increased, the situation that the transparent conductive layer (ITO) on the side wall (at the step) at the edge of the current blocking structure becomes thinner and even breaks can be avoided, the step covering capacity of the transparent conductive layer is improved, the current spreading capacity of the transparent conductive layer is further improved, the electro-optical conversion efficiency of the LED chip is increased, and the brightness of the LED chip is enhanced.

Owner:宁波安芯美半导体有限公司

High electron mobility transistor having reduced threshold voltage variation and method of manufacturing the same

ActiveUS20130099285A1Reduce variation of threshold voltageReduce surface roughnessTransistorEngineeringElectron

According to example embodiments a transistor includes a channel layer on a substrate, a first channel supply layer on the channel, a depletion layer, a second channel supply layer, source and drain electrodes on the first channel supply layer, and a gate electrode on the depletion layer. The channel includes a 2DEG channel configured to generate a two-dimensional electron gas and a depletion area. The first channel supply layer corresponds to the 2DEG channel and defines an opening that exposes the depletion area. The depletion layer is on the depletion area of the channel layer. The second channel supply layer is between the depletion layer and the depletion area.

Owner:SAMSUNG ELECTRONICS CO LTD

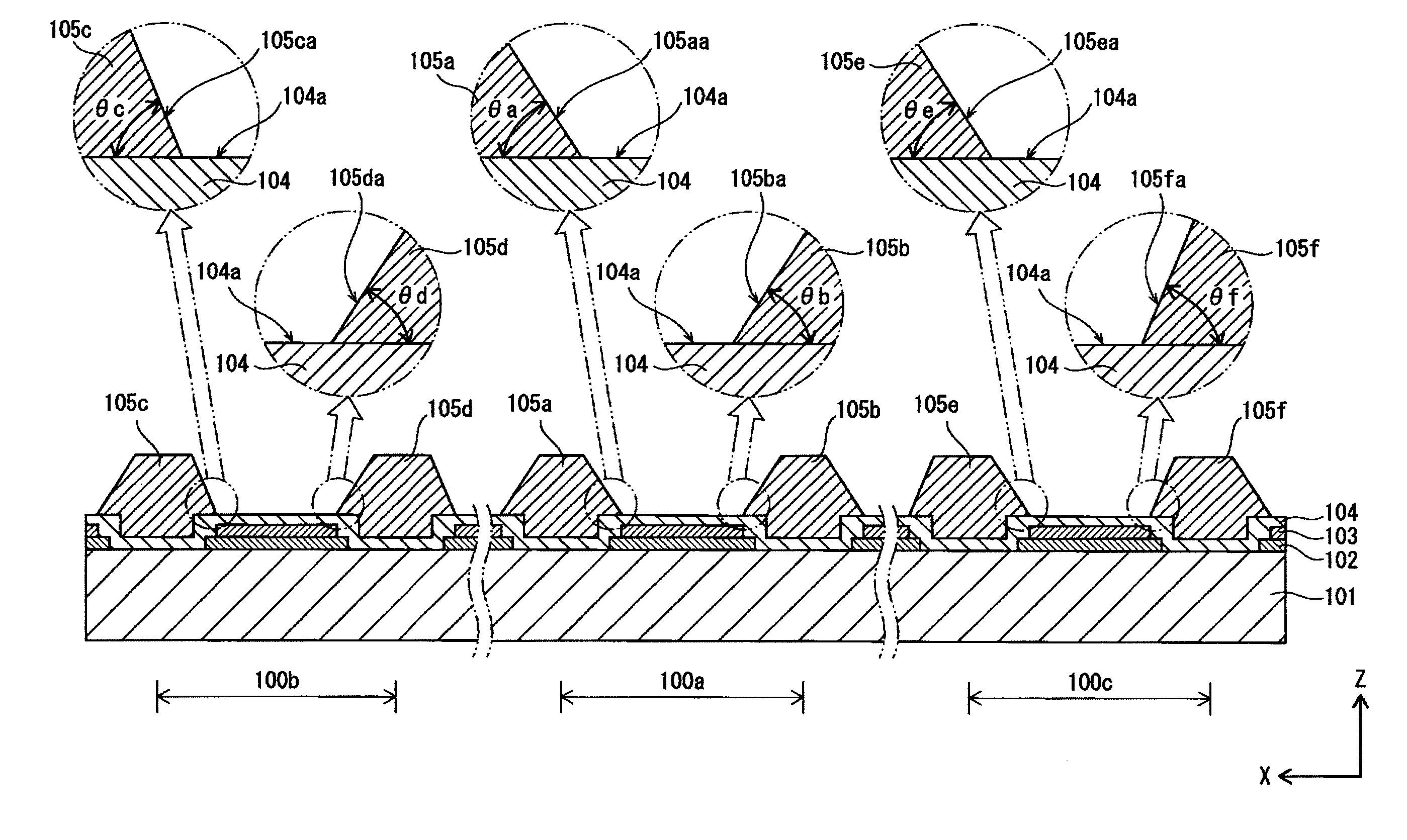

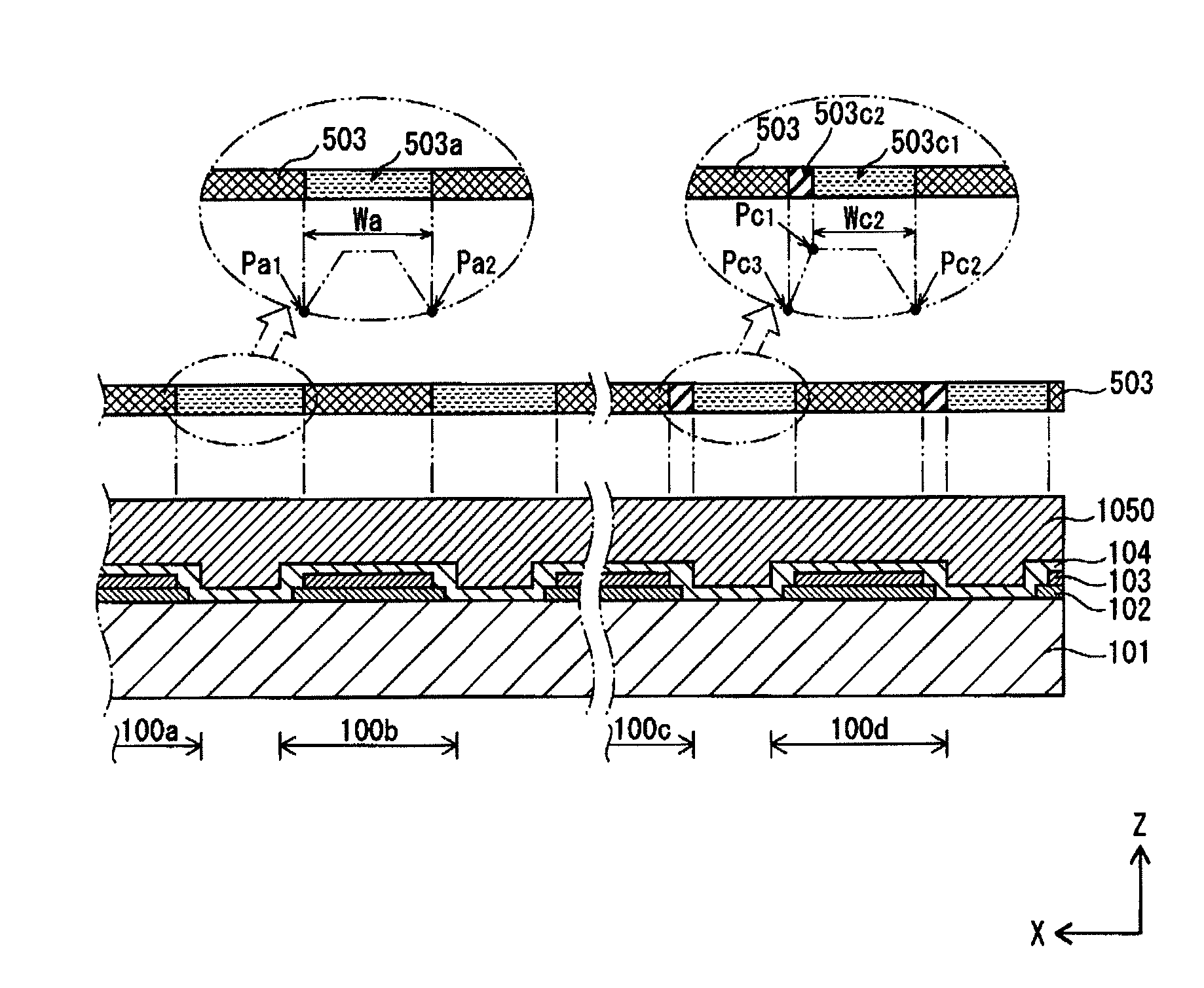

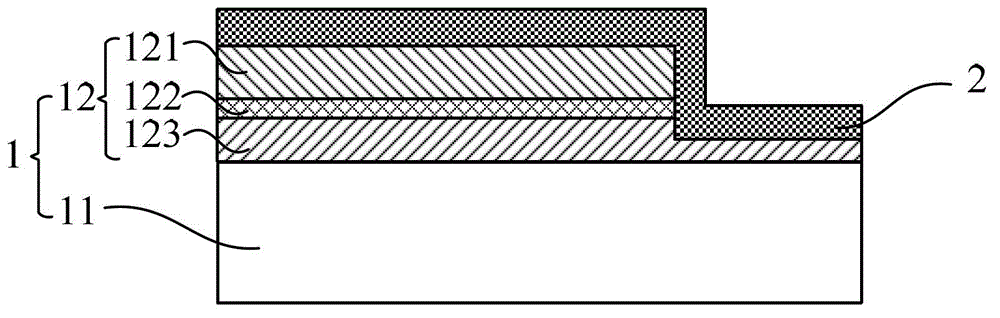

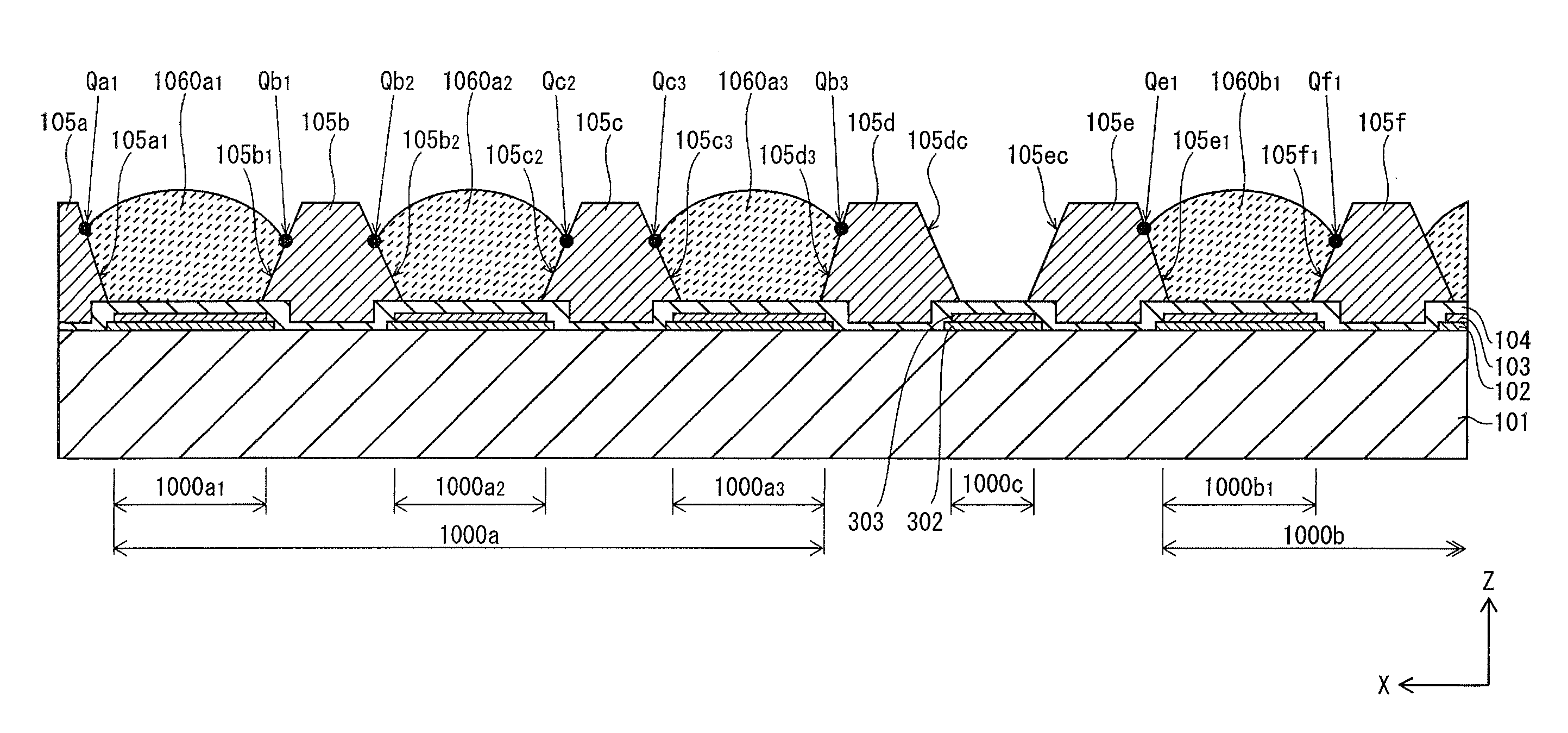

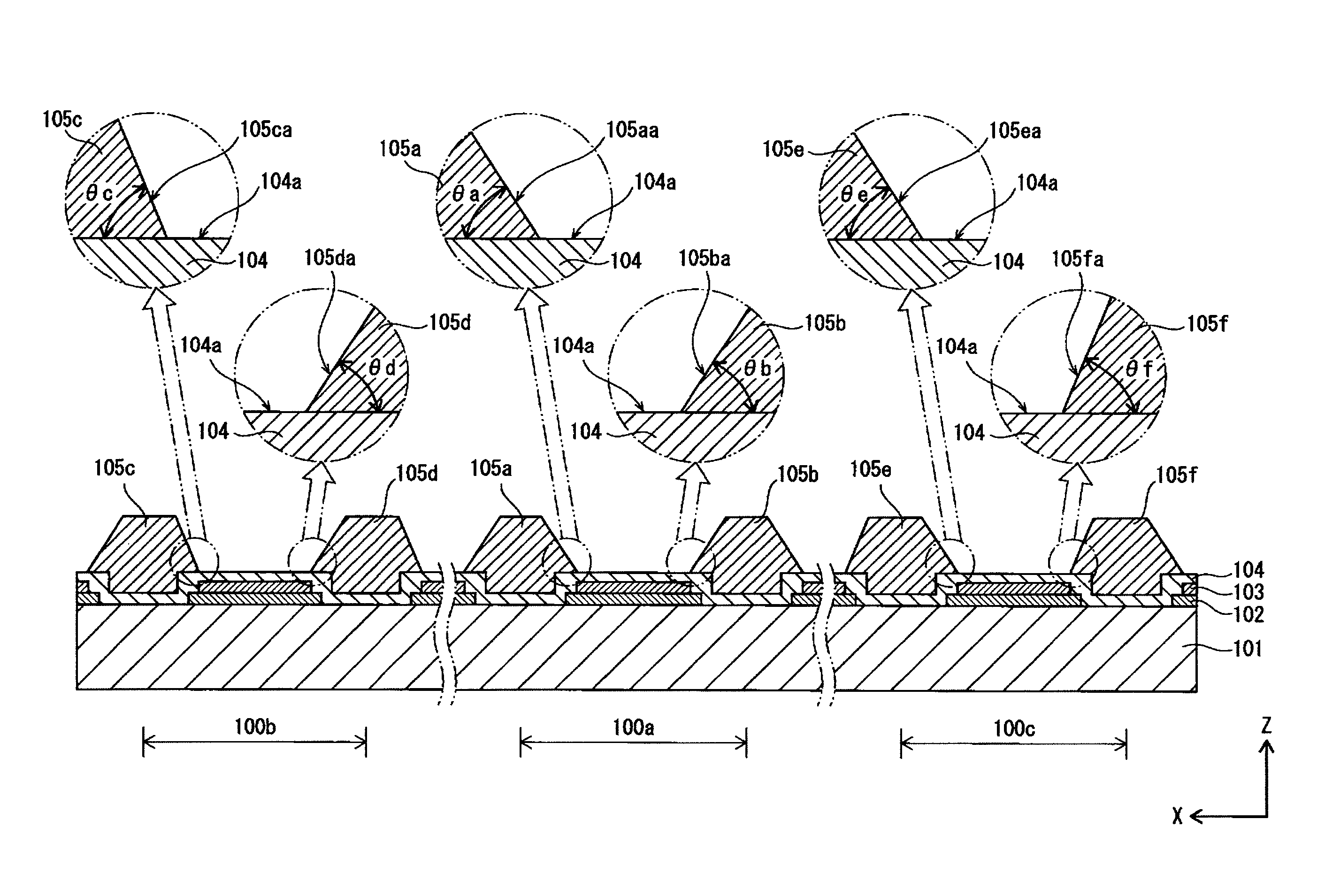

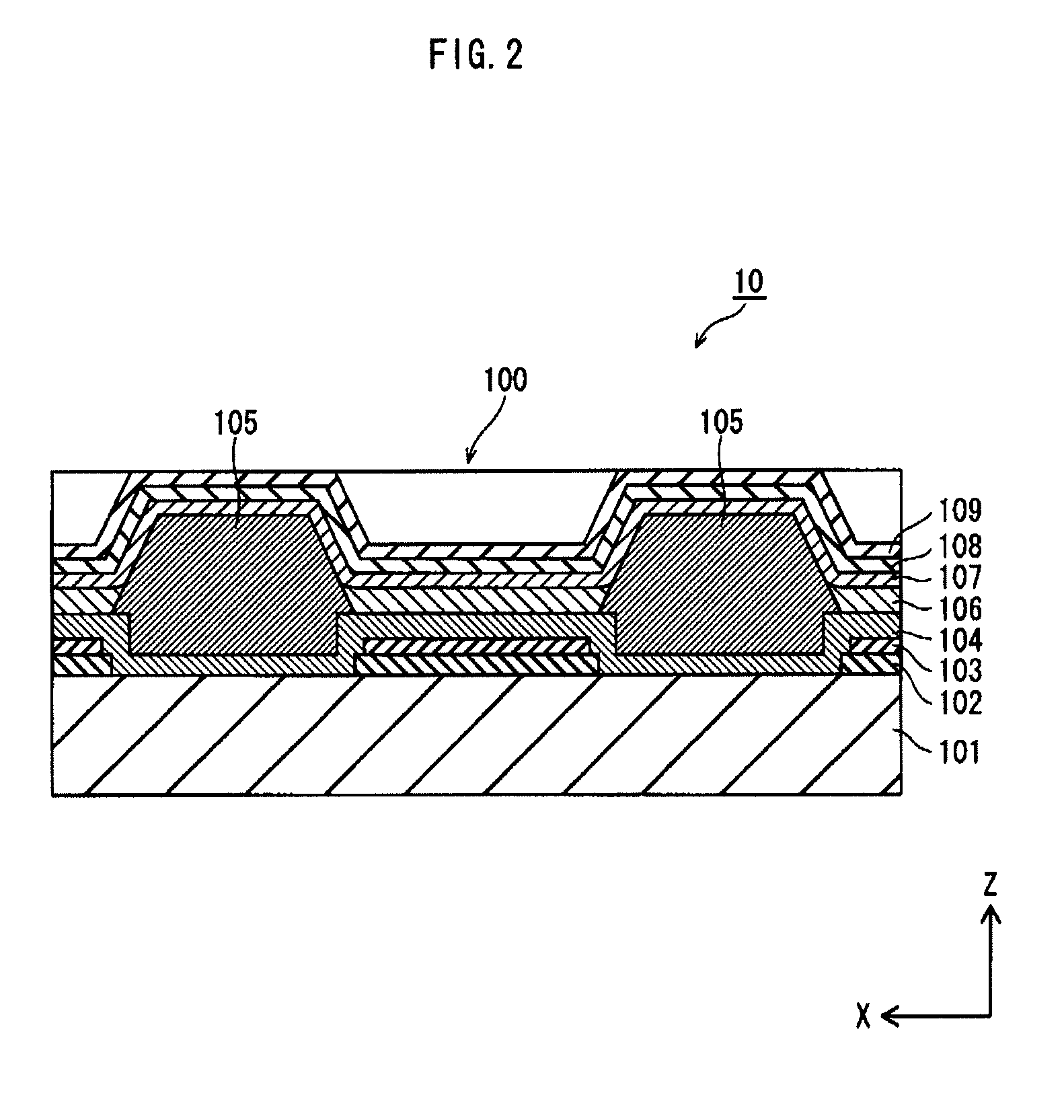

Organic light-emitting panel and manufacturing method thereof, and organic display device

ActiveUS20120138973A1Avoid uneven film thicknessLarge inclinationElectroluminescent light sourcesSolid-state devicesDisplay deviceEngineering

A non-light-emitting cell 100c is provided between pixels 100a and 100b. Ink for forming an organic light-emitting layer is dripped substantially simultaneously into sub-pixels 100a1, 100a2, and 100a3 in the pixel 100a and a sub-pixel 100b1 in the pixel 100b. On the other hand, such ink is not dripped into the non-light-emitting cell 100c since the organic light-emitting layer is not formed in the non-light-emitting cell 100c. Regarding two banks 105c and 105d defining the sub-pixel 100a3, an inclination angle θd3 of a wall 105d3 of the bank 105d is larger than an inclination angle θc3 of a wall 105c3 of the bank 105c. Similarly, regarding banks 105e and 105f defining the sub-pixel 100b1, an inclination angle θe1 of a wall 105e1 of the bank 105e is larger than an inclination angle θf1 of a wall 105f1 of the bank 105f.

Owner:JOLED INC

Accumulator

InactiveUS20070102052A1Made smallSolve large capacityAccumulator installationsPipe elementsEngineeringWeld penetration

An accumulator in which a pressure sealed chamber and a pressure flow-in chamber are formed by an operation member including a metallic bellows provided within a housing constituted by a gas end cover and a bottomed tubular shell, wherein a cross sectional inner outline of a peripheral edge portion of the gas end cover is an oval shape which is concave to the pressure sealed chamber side, and a dead space is not formed, so that a capacity of a volume adjusting spacer is reduced by eliminating a dead space, a working step is reduced by simplifying a shape of the gas end cover, and a margin of welding penetration depth is increased by thickening of a backing metal portion.

Owner:NOK CORP

Organic light-emitting panel and manufacturing method thereof, and organic display device

ActiveUS20120091483A1Avoid uneven film thicknessLarge inclinationSolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryDisplay device

A non-light-emitting cell 100c is provided between pixels 100a and 100b. Ink for forming an organic light-emitting layer is dripped substantially simultaneously into sub-pixels 100a1, 100a2, and 100a3 in the pixel 100a and a sub-pixel 100b1 in the pixel 100b. On the other hand, such ink is not dripped into the non-light-emitting cell 100c since the organic light-emitting layer is not formed in the non-light-emitting cell 100c. In a bank 105d, an inclination angle θd3 of a wall 105d3 facing the sub-pixel 100a3 is larger than an inclination angle θdc of a wall 105dc facing the non-light-emitting cell 100c. Similarly, in a bank 105e, an inclination angle θe1 of a wall 105e1 facing the sub-pixel 100b1 is larger than an inclination angle θec of a wall 105ec facing the non-light-emitting cell 100c.

Owner:JOLED INC

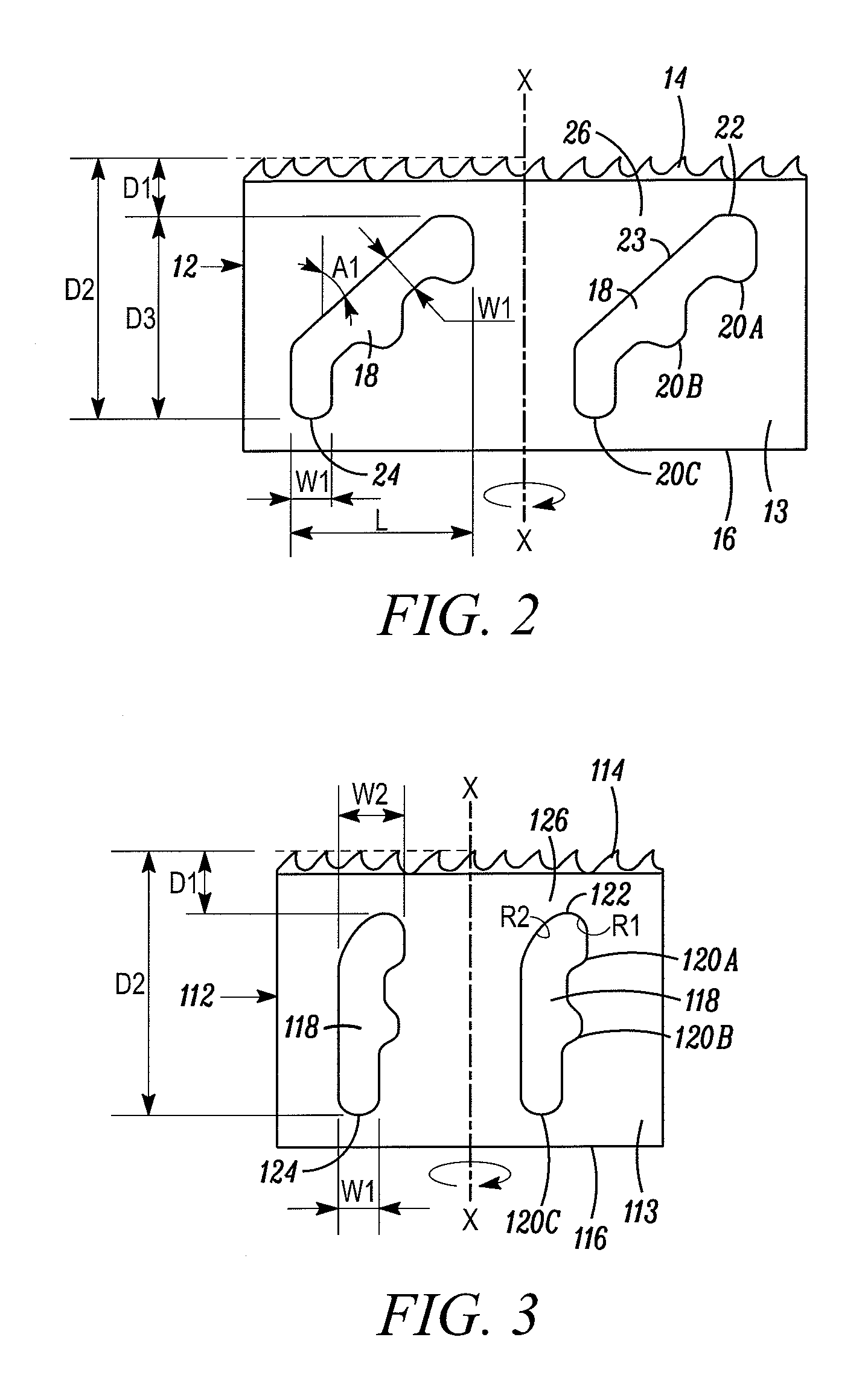

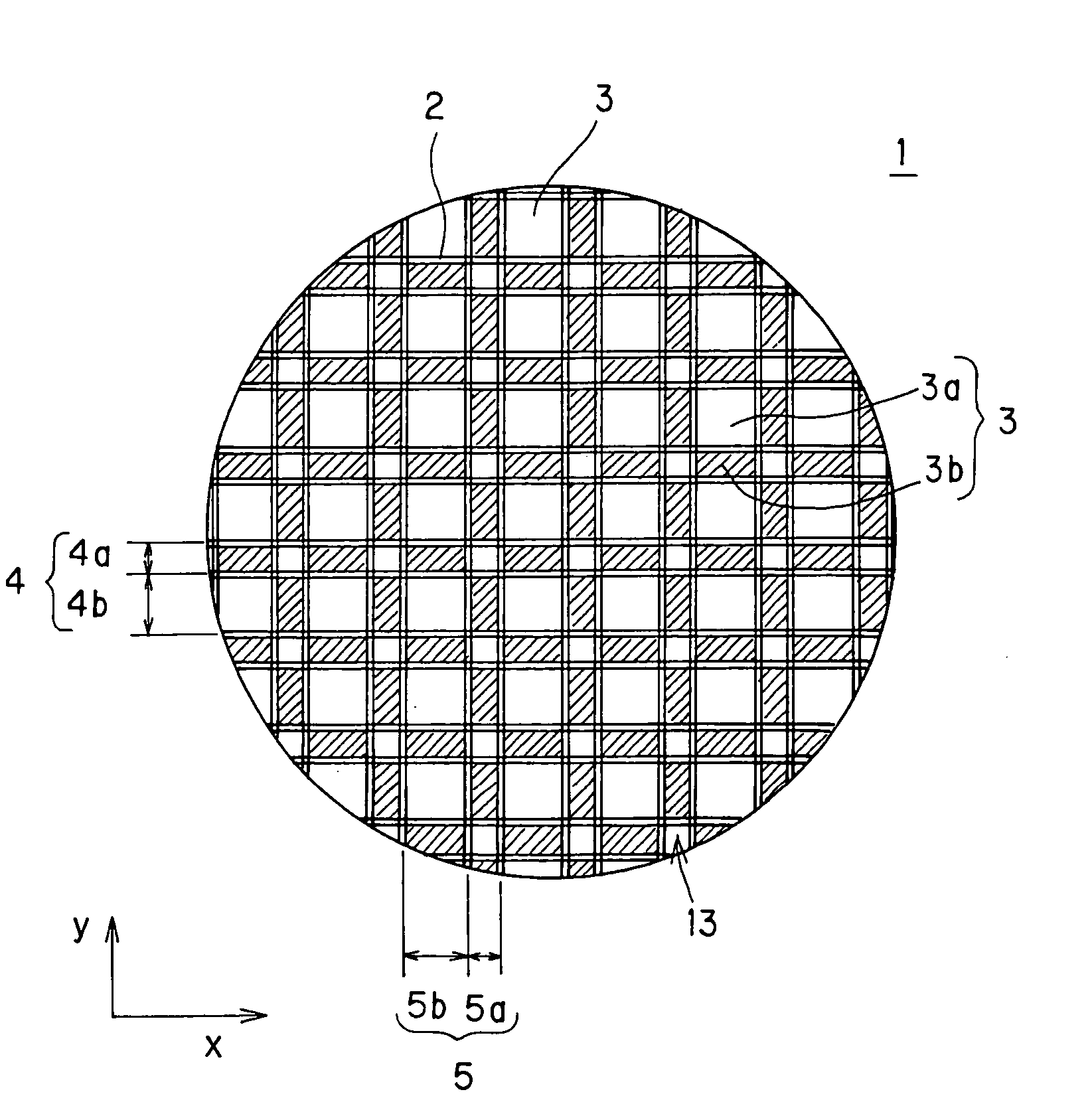

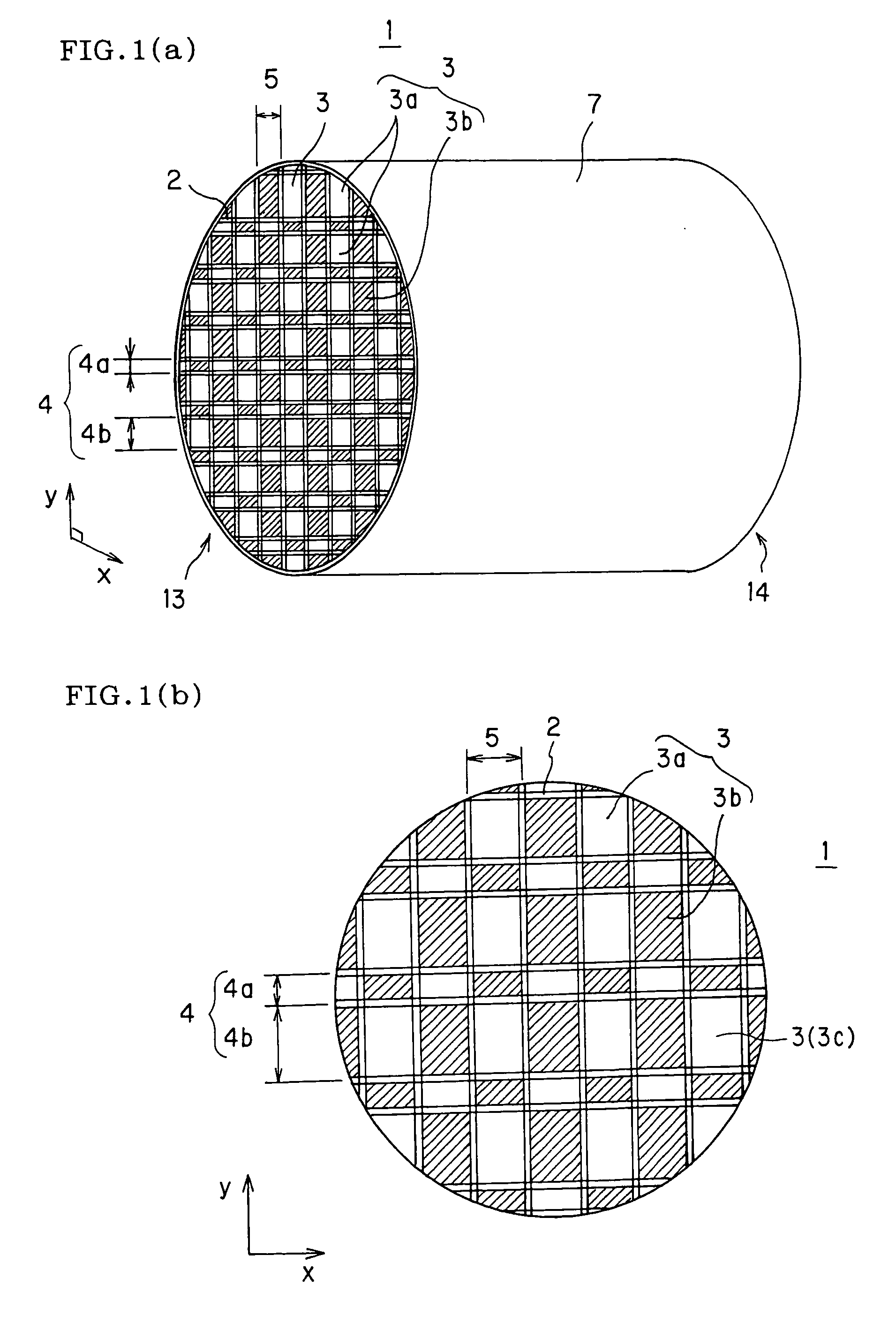

Honeycomb structural body and die for forming honeycomb structural body by extrusion

ActiveUS7208214B2Avoid thickness thinningCombination devicesDispersed particle filtrationGratingEngineering

A honeycomb structural body having a plurality of cells and partition walls defining the cells, wherein a cross-section of each partition wall perpendicular to the flow direction of a fluid to be permeated has a grille shape of which gratings cross in x axis and Y axis directions, and there are at least two kinds of cells different in their cross-sectional areas perpendicular to the flow direction of a fluid to be filtered by virtue of changing intervals of the partition walls in the x axis direction and / or intervals of the partition walls in the y axis direction, as predetermined. Each cell is defined by two parallel partition walls having the same length and another two parallel partition walls having the same length crossing each other and being formed at the predetermined intervals. A die usable for forming such a honeycomb structure is also disclosed.

Owner:NGK INSULATORS LTD

Method for manufacturing wiring, thin film transistor, light emitting device and liquid crystal display device, and droplet discharge apparatus for forming the same

InactiveUS7332432B2Easy to controlAvoid spreadingTransistorPhysical/chemical process catalystsLiquid-crystal displayEngineering

As a semiconductor device, specifically, a pixel portion included in a semiconductor device is made to have higher precision and higher aperture ratio, it is required to form a smaller wiring in width. In the case of forming a wiring by using an ink-jet method, a dot spreads on a wiring formation surface, and it is difficult to narrow width of a wiring. In the present invention, a photocatalytic substance typified by TiO2 is formed on a wiring formation surface, and a wiring is formed by utilizing photocatalytic activity of the photocatalytic substance. According to the present invention, a narrower wiring, that is, a smaller wiring in width than a diameter of a dot formed by an ink-jet method can be formed.

Owner:SEMICON ENERGY LAB CO LTD

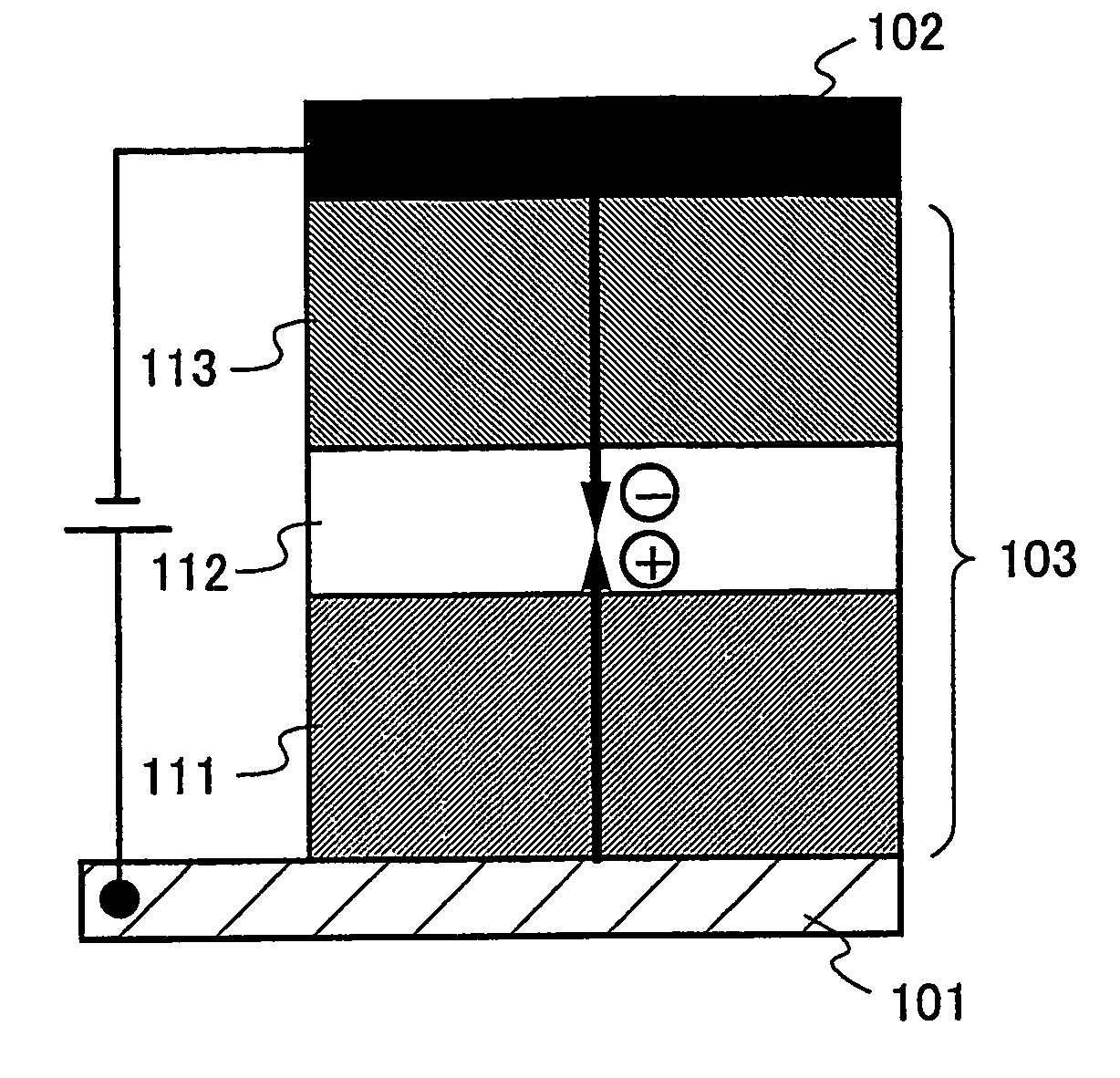

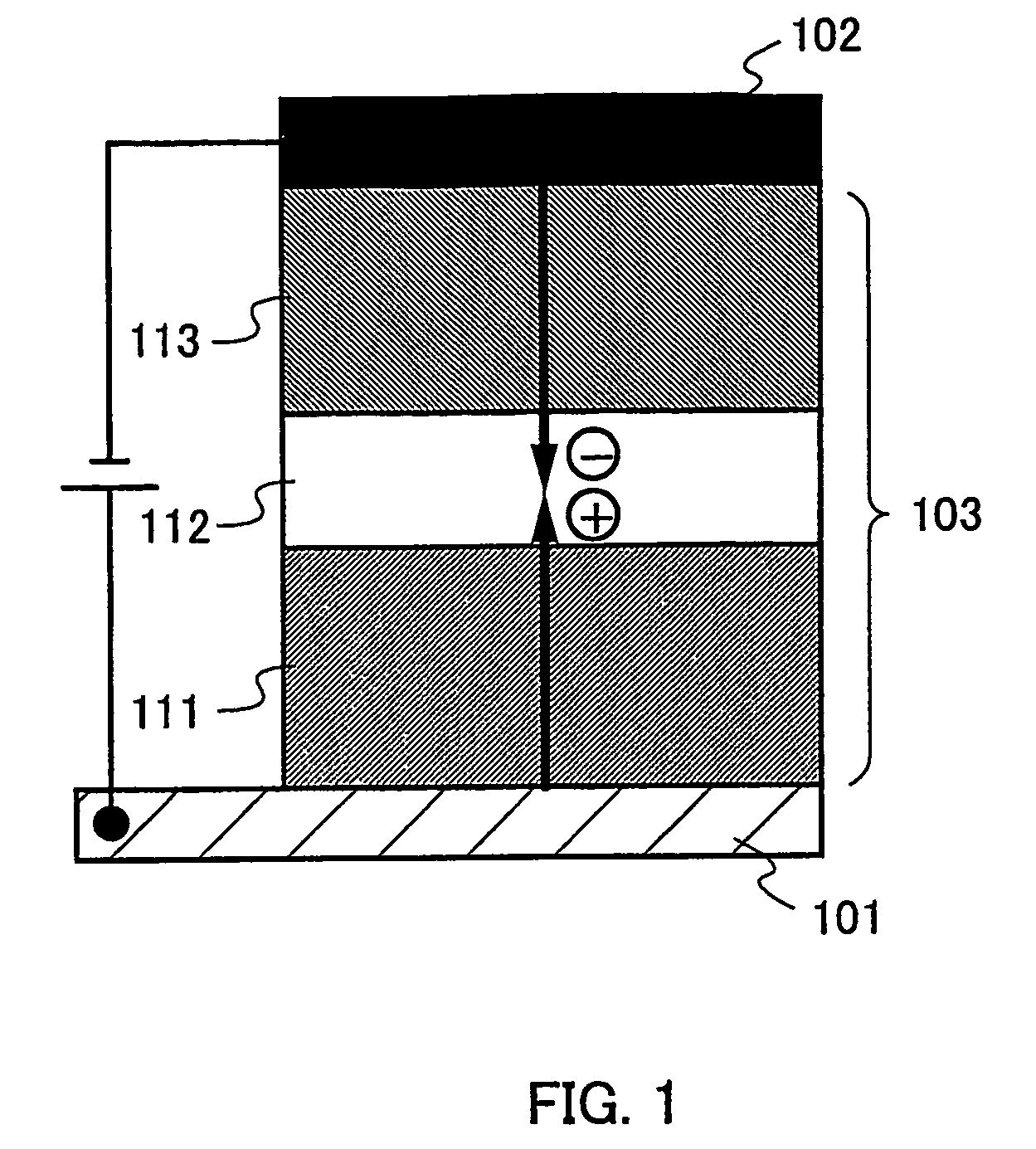

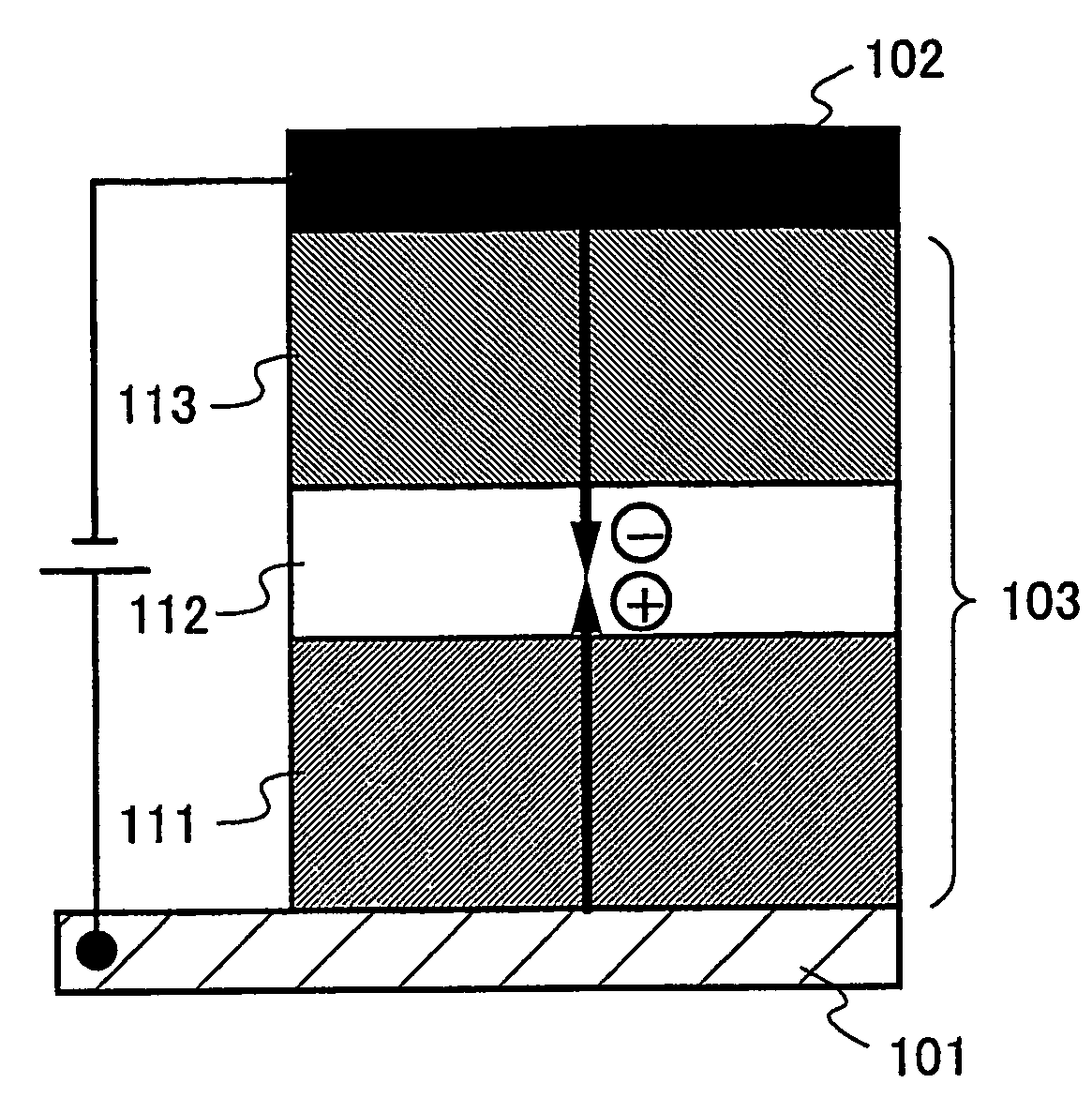

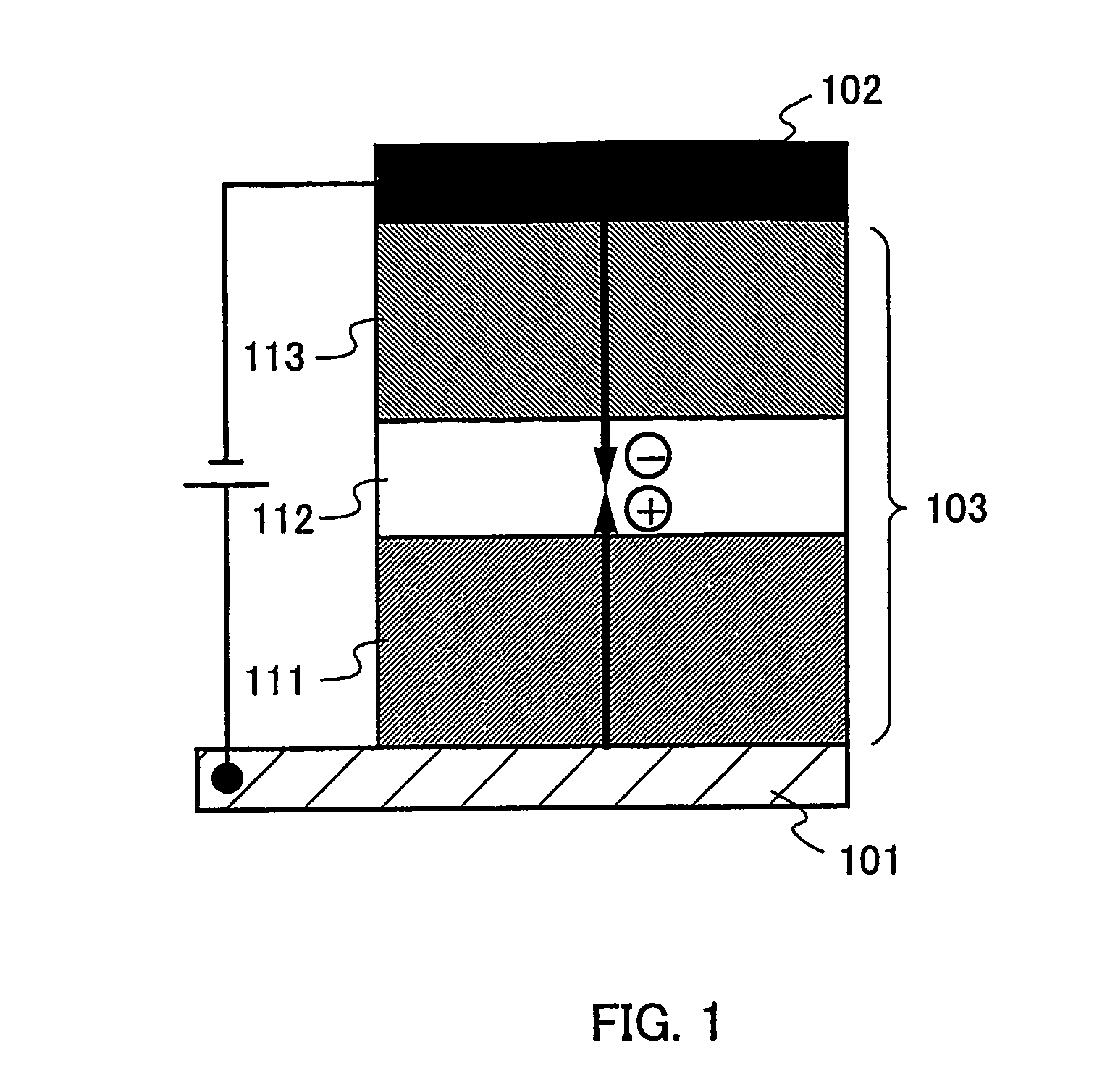

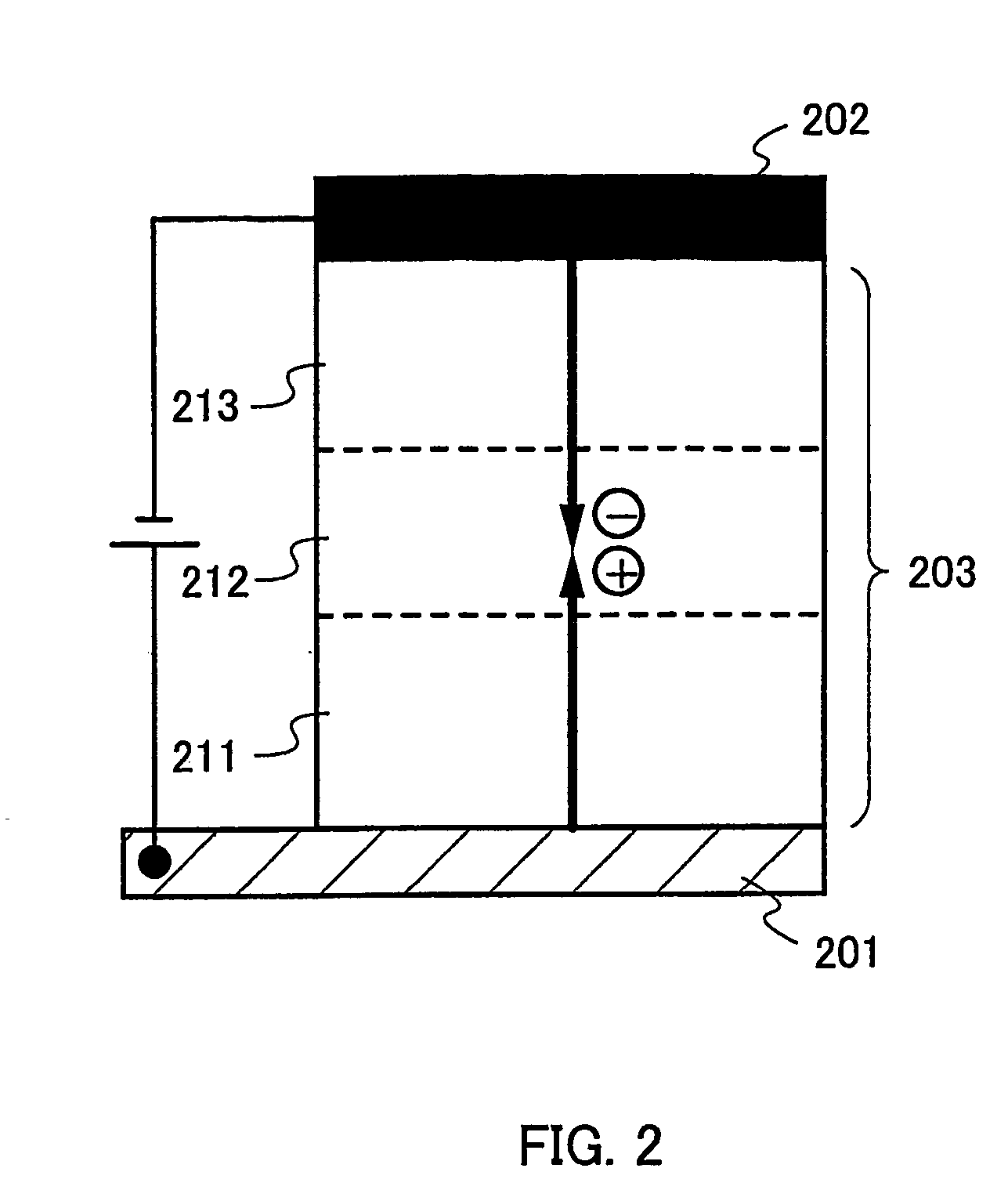

Light-emitting-element

InactiveUS7750560B2Suppress short circuitNot be made thinDischarge tube luminescnet screensElectroluminescent light sourcesInorganic compoundOrganic compound

The present invention provides a light-emitting element sandwiching a composite layer in which an organic compound and an inorganic compound are mixed between a first electrode and a second electrode, where the composite layer includes a first layer including a first organic compound and a first inorganic compound that exhibits an electron accepting property to the first organic compound (serves as an electron acceptor), a second layer including a second organic compound and a second inorganic compound, and a third layer including a third organic compound and a third inorganic compound that exhibits an electron donating property to the third organic compound (serves as an electron acceptor).

Owner:SEMICON ENERGY LAB CO LTD

Photoelectric conversion device and imaging device

InactiveUS20070045520A1High light transmittanceLow resistivitySolid-state devicesMaterial analysis by optical meansPhotoelectric conversion

A photoelectric conversion device comprising: a substrate; a conducting layer; a photoelectric conversion layer; and a transparent conducting layer provided in this order, wherein the transparent conducting layer has a thickness of not more than ⅕ of that of the photoelectric conversion layer.

Owner:FUJIFILM CORP +1

Common mode noise filter

InactiveUS20130141206A1Improve impedance characteristicsHigh precision fine line widthTransformers/inductances coils/windings/connectionsPrinted inductancesInsulation layerFerrite powder

Disclosed herein is a common mode noise filter including: a plurality of insulation layers configuring a laminated body formed on a substrate; internal electrode coils included in the plurality of insulation layers; external electrode terminals connected to an end portion of the internal electrode coils; and a magnetic layer formed on a surface of the laminated body. According to the present invention, the common mode noise filter has the magnetic layer including the conductive metal on the uppermost layer thereof, such that the permeability of the ferrite composite may be increased and the ferrite powder may be effectively compensated for the eddy current loss of the internal electrode coil, thereby making it possible to improve the impedance characteristics of the common mode noise filter.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

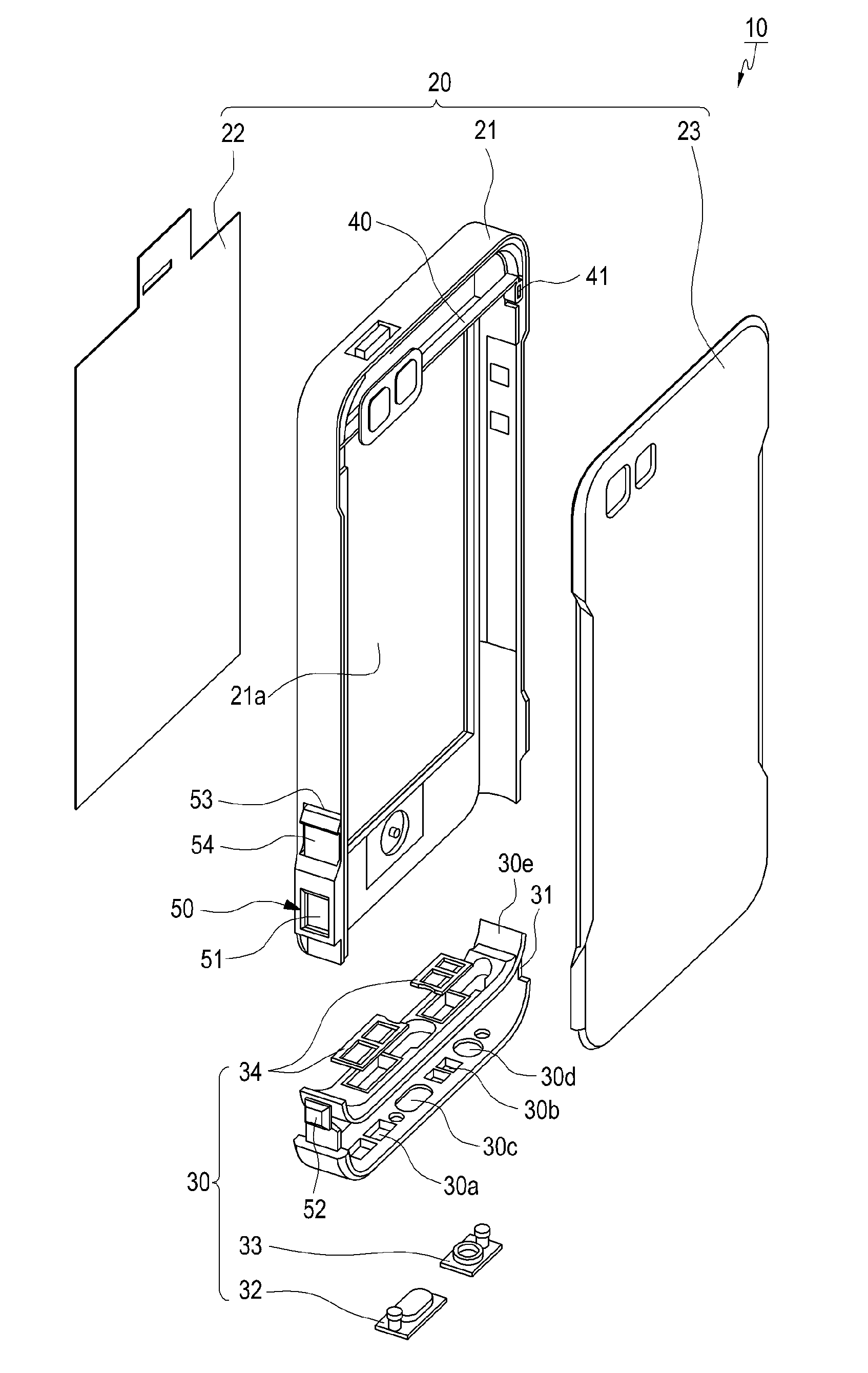

Waterproof case for electronic device

InactiveUS20140353179A1Avoid damageEasily being opened and closedDigital data processing detailsOther accessoriesEngineeringMechanical engineering

Owner:KIM JUSTIN CHIWON

Light Emitting Element and Light Emitting Device

InactiveUS20080252199A1Reduce the driving voltageEasy to solveDischarge tube luminescnet screensElectroluminescent light sourcesInorganic compoundOrganic compound

The present invention provides a light-emitting element sandwiching a composite layer in which an organic compound and an inorganic compound are mixed between a first electrode and a second electrode, where the composite layer includes a first layer including a first organic compound and a first inorganic compound that exhibits an electron accepting property to the first organic compound (serves as an electron acceptor), a second layer including a second organic compound and a second inorganic compound, and a third layer including a third organic compound and a third inorganic compound that exhibits an electron donating property to the third organic compound (serves as an electron acceptor).

Owner:SEMICON ENERGY LAB CO LTD

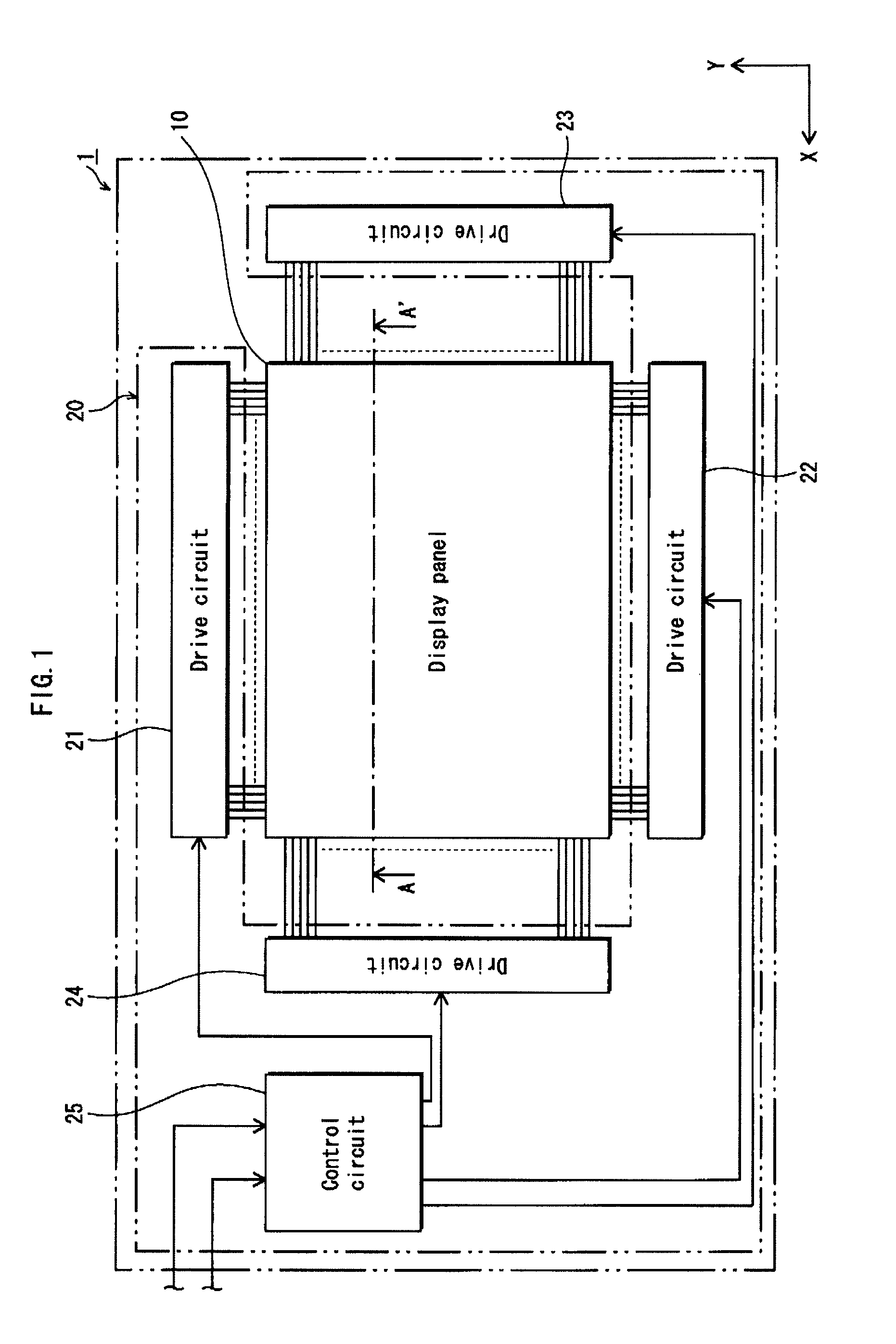

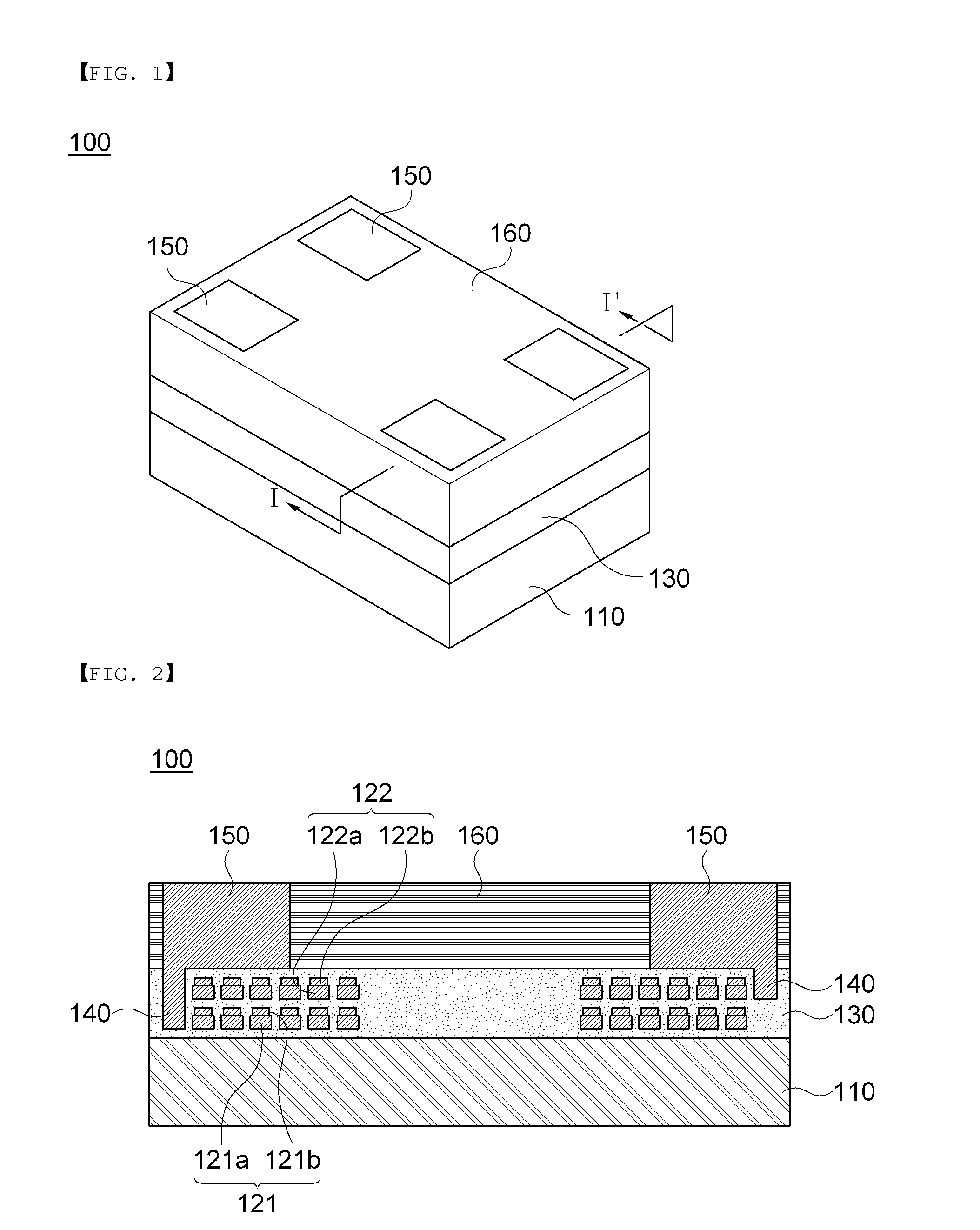

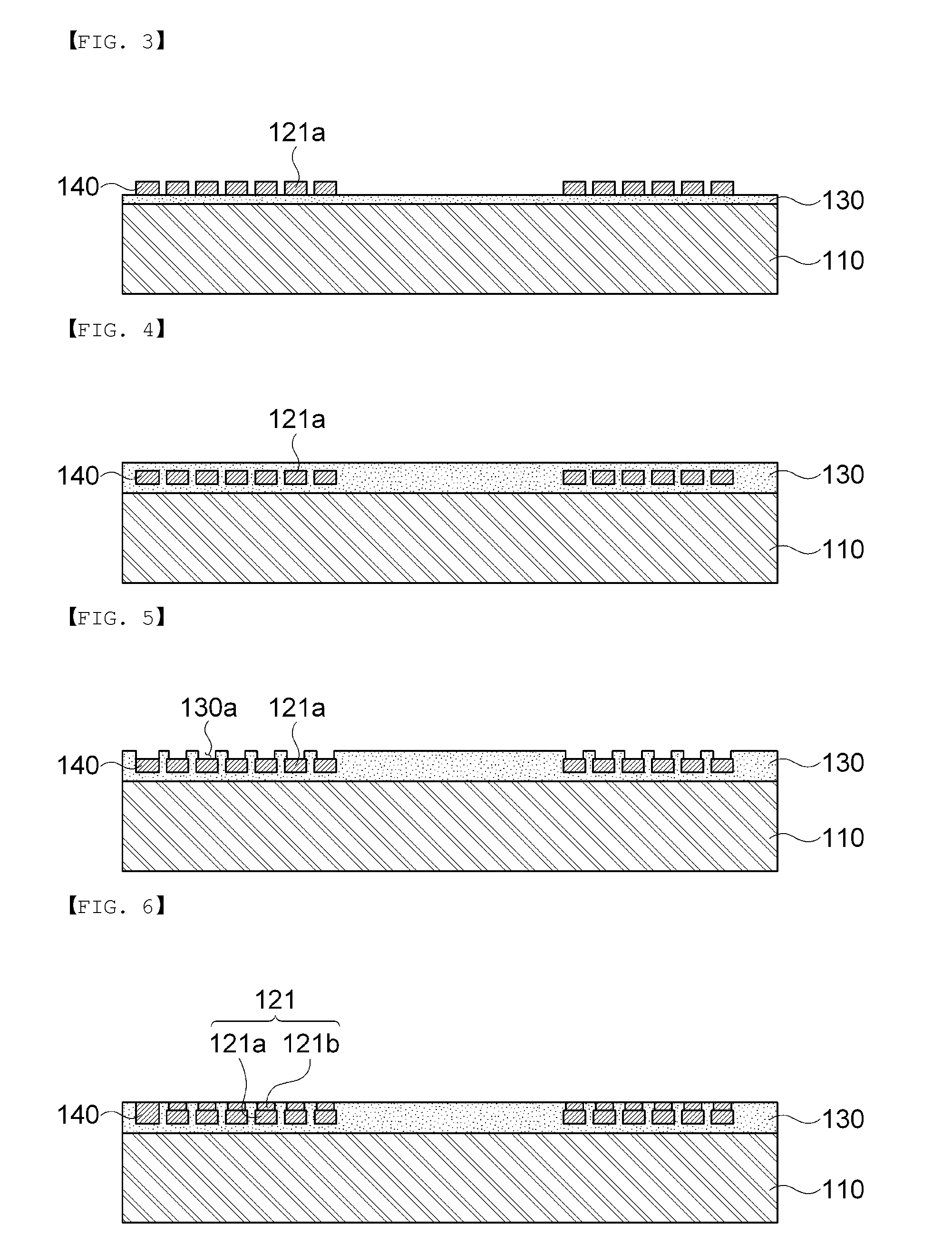

Display device for controlling an organic light emitting layer thickness

ActiveUS8546820B2Avoid thickness thinningUniform shapeDischarge tube luminescnet screensLamp detailsDisplay deviceLayer thickness

A display device includes an array of light emitting cells. Each of the light emitting cells includes a first electrode, a second electrode, and an organic light emitting layer located between the first electrode and the second electrode. Banks are above the first electrode that partition the organic light emitting layer to define each of the light emitting cells. The light emitting cells include a peripheral light emitting cell that is located in a peripheral region of the array. The banks include first and second banks that each border the peripheral light emitting cell. The first bank is closer to a periphery of the array than the second bank. An inclination angle of an innermost sidewall of the first bank that is adjacent the peripheral light emitting cell is greater than an inclination angle of an outermost sidewall of the second bank that is adjacent the peripheral light emitting cell.

Owner:JOLED INC

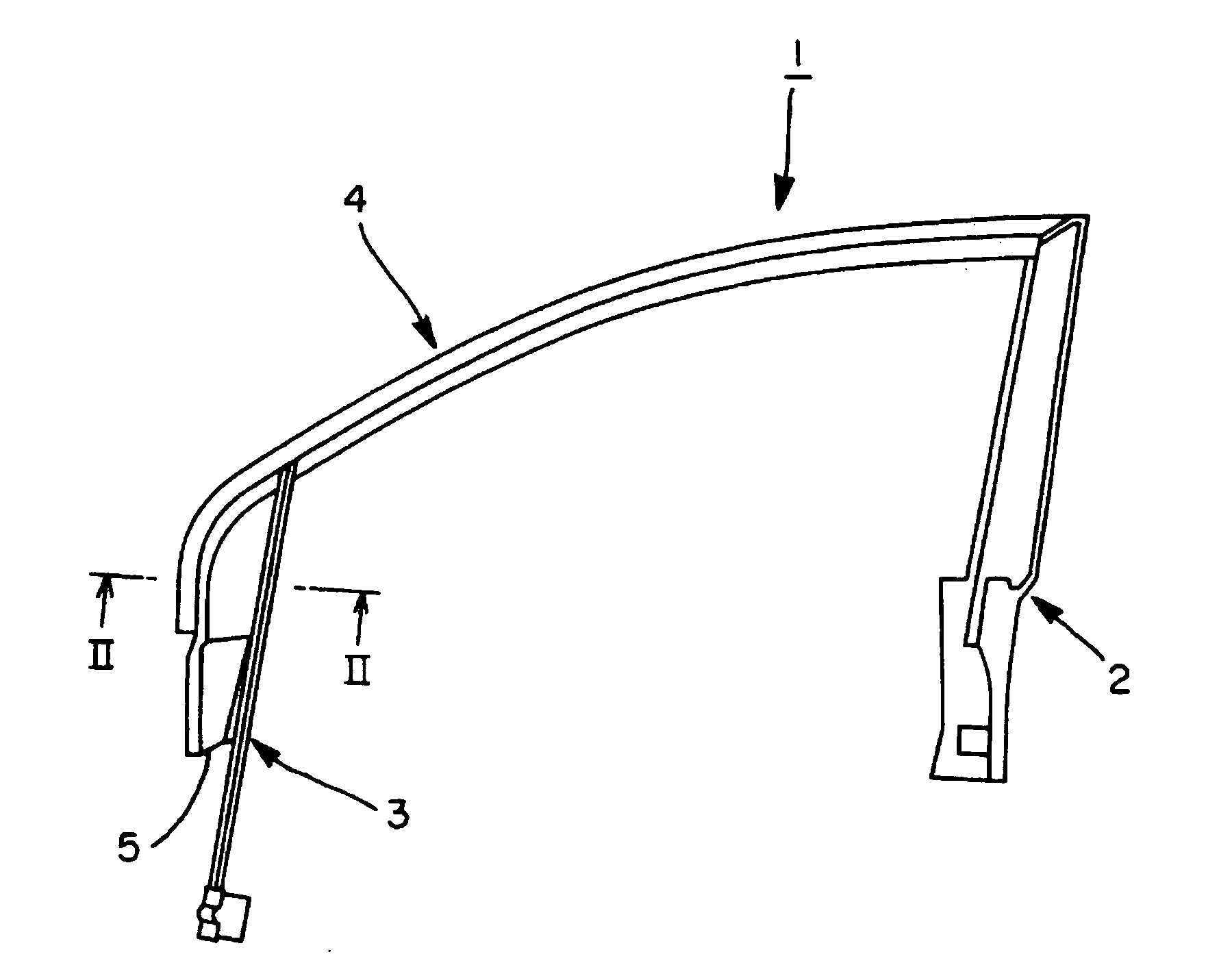

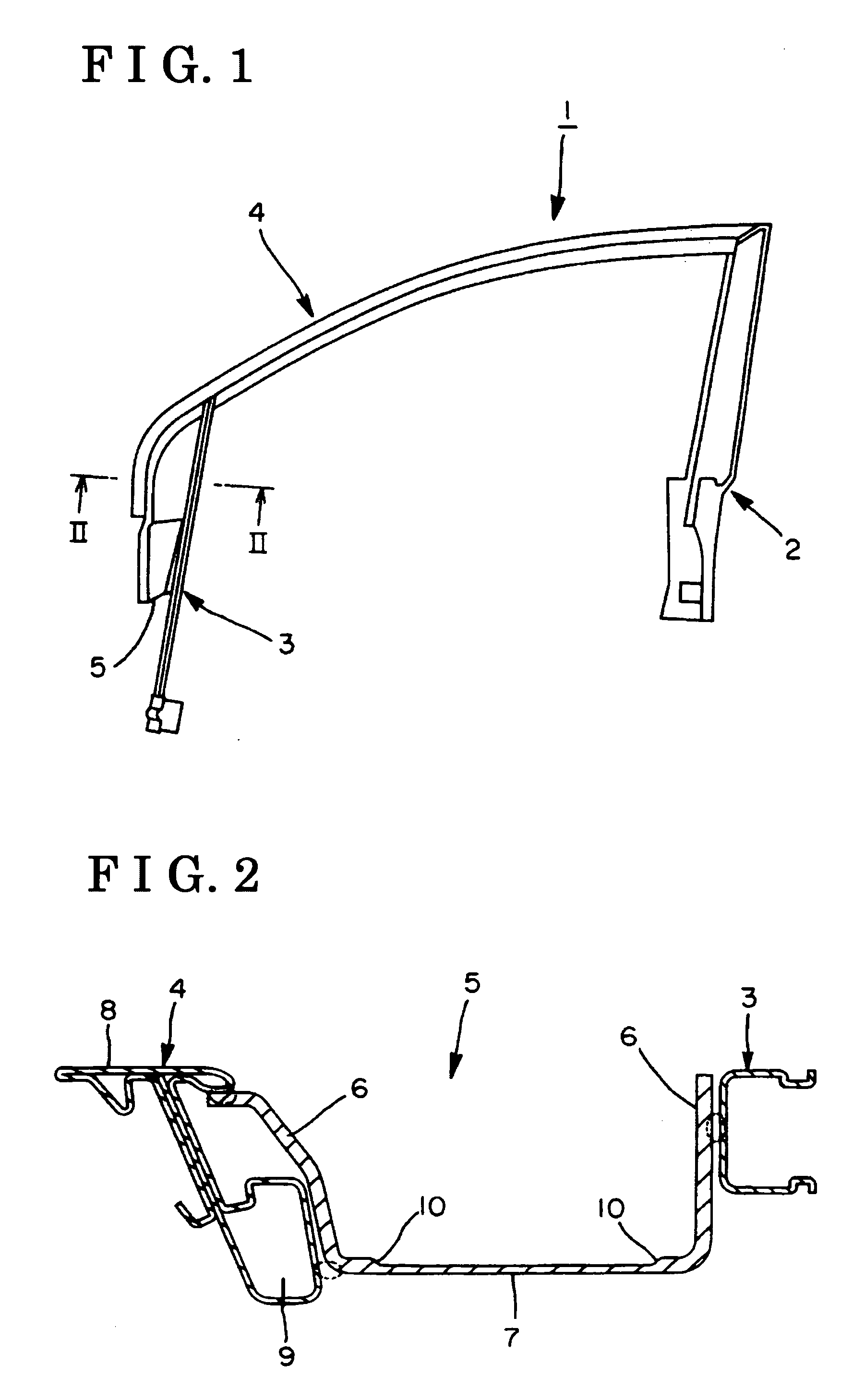

Door frame

InactiveUS20050102953A1Avoid thickness thinningImprove rigidityWindowsWindscreensTop dead centerEngineering

A door frame for a vehicle includes a lower frame for guiding an up / down movement of a window glass, a main frame connected to the lower frame for determining a top dead center of the window glass, and a bracket for attaching a door mirror secured to the lower frame and the main frame, the bracket having a bottom portion and a pair of opposing side wall portions extended from both sides of the bottom portion, and each having a thickness thicker than that of the bottom portion.

Owner:AISIN SEIKI KK

Conductive paste for multilayer electronic part

ActiveUS7410601B2Avoid thickness thinningImprove accuracyDuplicating/marking methodsFixed capacitor dielectricConductive pasteDynamic viscoelasticity

Disclosed is a conductive paste for a multilayer electronic part to be screen-printed on a ceramic green sheet, comprising 70-95 weight % of conductive metal powder, a resin, and a solvent, wherein a phase angle δ in a dynamic viscoelastic measurement is within a range of from 43° to 72° at a frequency of 0.05 Hz and is within a range of 63° or less at a frequency of 30 Hz.

Owner:SHOEI CHEM IND CO LTD +1

Common mode filter and method of manufacturing the same

InactiveUS20140313005A1Thicker thicknessAvoid thickness thinningTransformers/inductances coils/windings/connectionsConductive/insulating/magnetic material on magnetic film applicationEngineeringElectrical and Electronics engineering

Disclosed herein is a common mode filter capable of increasing a thickness of the coil electrode in a more simple and stable scheme. The common mode filter includes: a magnetic substrate; a coil electrode formed on one surface of the magnetic substrate and enclosed by an insulating resin; and external electrode terminals connected to both ends of the coil electrode, wherein the coil electrode includes a first metal pattern layer and a second metal pattern layer formed on the first metal pattern layer by performing electroplating using the first metal pattern layer as a lead wire.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

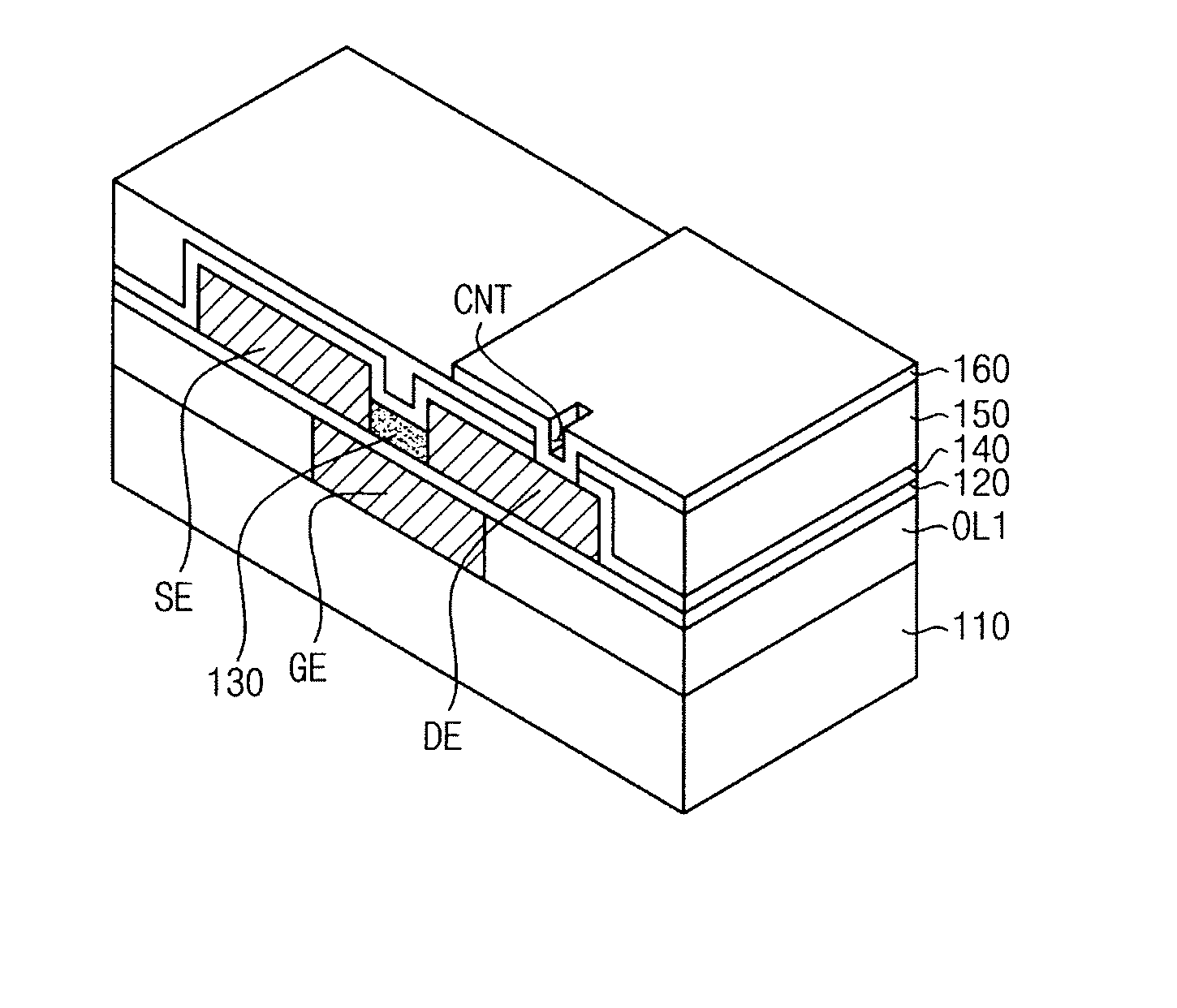

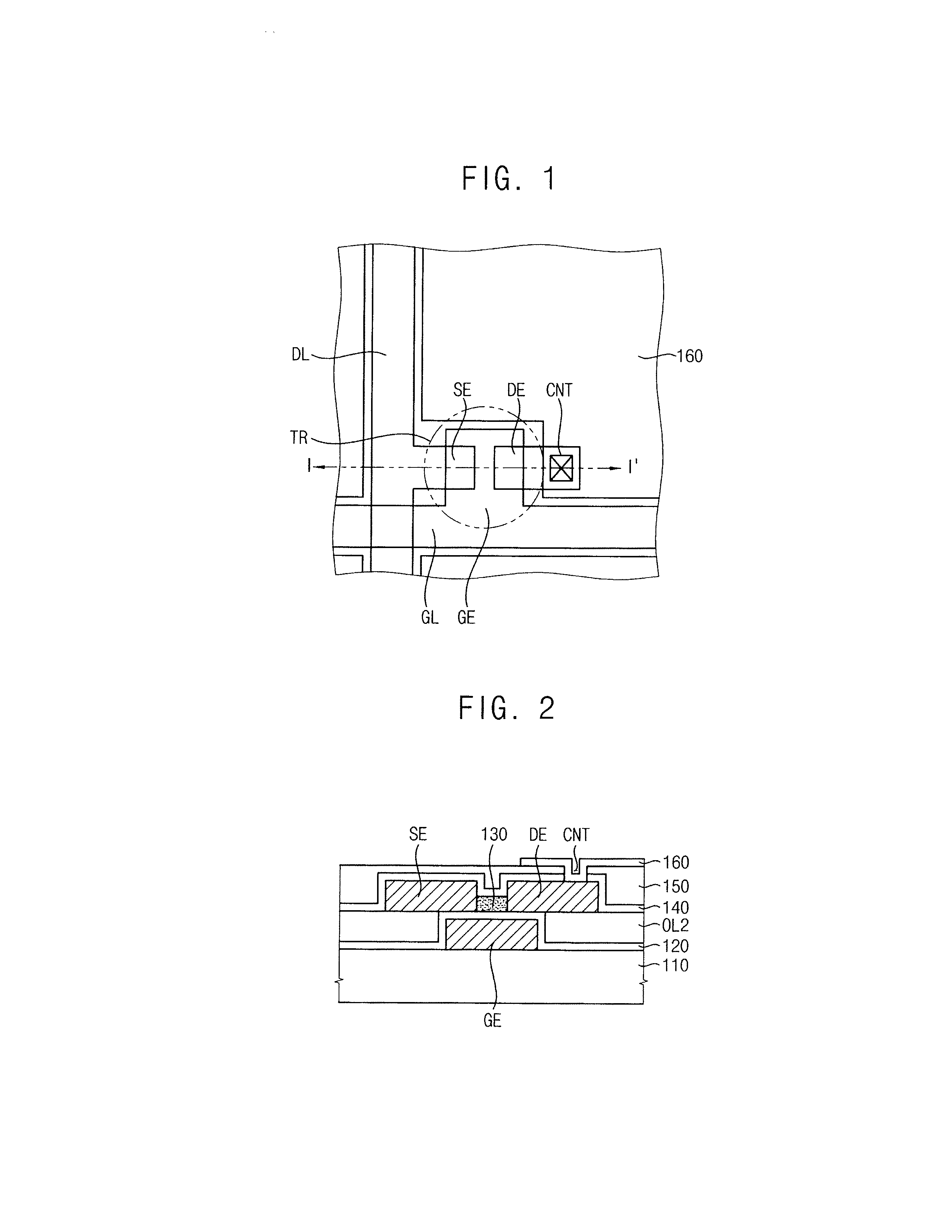

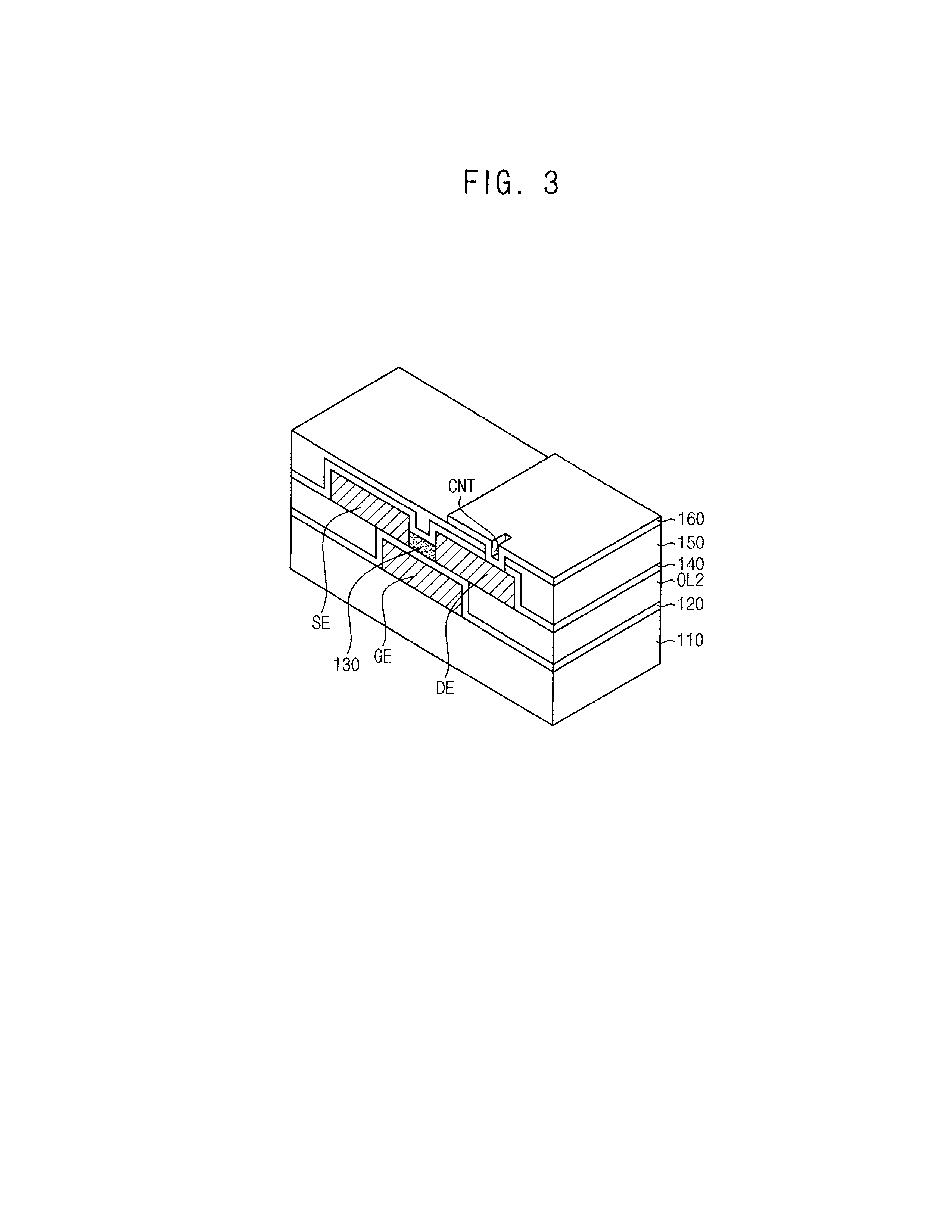

Thin film transistor and method of manufacturing the same

InactiveUS20130175505A1Thicker thicknessResistance and area of be increaseSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorTransistor

A thin film transistor (“TFT”) includes a gate electrode, a gate insulating layer, a source electrode, a drain electrode and a semiconductor layer. The gate insulating layer is disposed on the gate electrode. The source electrode is disposed on the gate insulating layer. The drain electrode is disposed on the gate insulating layer. The drain electrode is spaced apart from the source electrode. The semiconductor layer is disposed on the gate insulating layer. The semiconductor layer makes contact with a side surface of the source electrode and a side surface of the drain electrode.

Owner:SAMSUNG DISPLAY CO LTD

Conductive paste for multilayer electronic part

ActiveUS20080083909A1Thicker film thicknessImprove accuracyNon-metal conductorsDuplicating/marking methodsConductive pasteDynamic viscoelasticity

Disclosed is a conductive paste for a multilayer electronic part to be screen-printed on a ceramic green sheet, comprising 70-95 weight % of conductive metal powder, a resin, and a solvent, wherein a phase angle δ in a dynamic viscoelastic measurement is within a range of from 43° to 72° at a frequency of 0.05 Hz and is within a range of 63° or less at a frequency of 30 Hz.

Owner:SHOEI CHEM IND CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com