Door frame

a door frame and frame technology, applied in the field of door frames, can solve the problems of increased weight, cost, and man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0020] the present invention will be explained with reference to the illustrations of the drawing figures as follows.

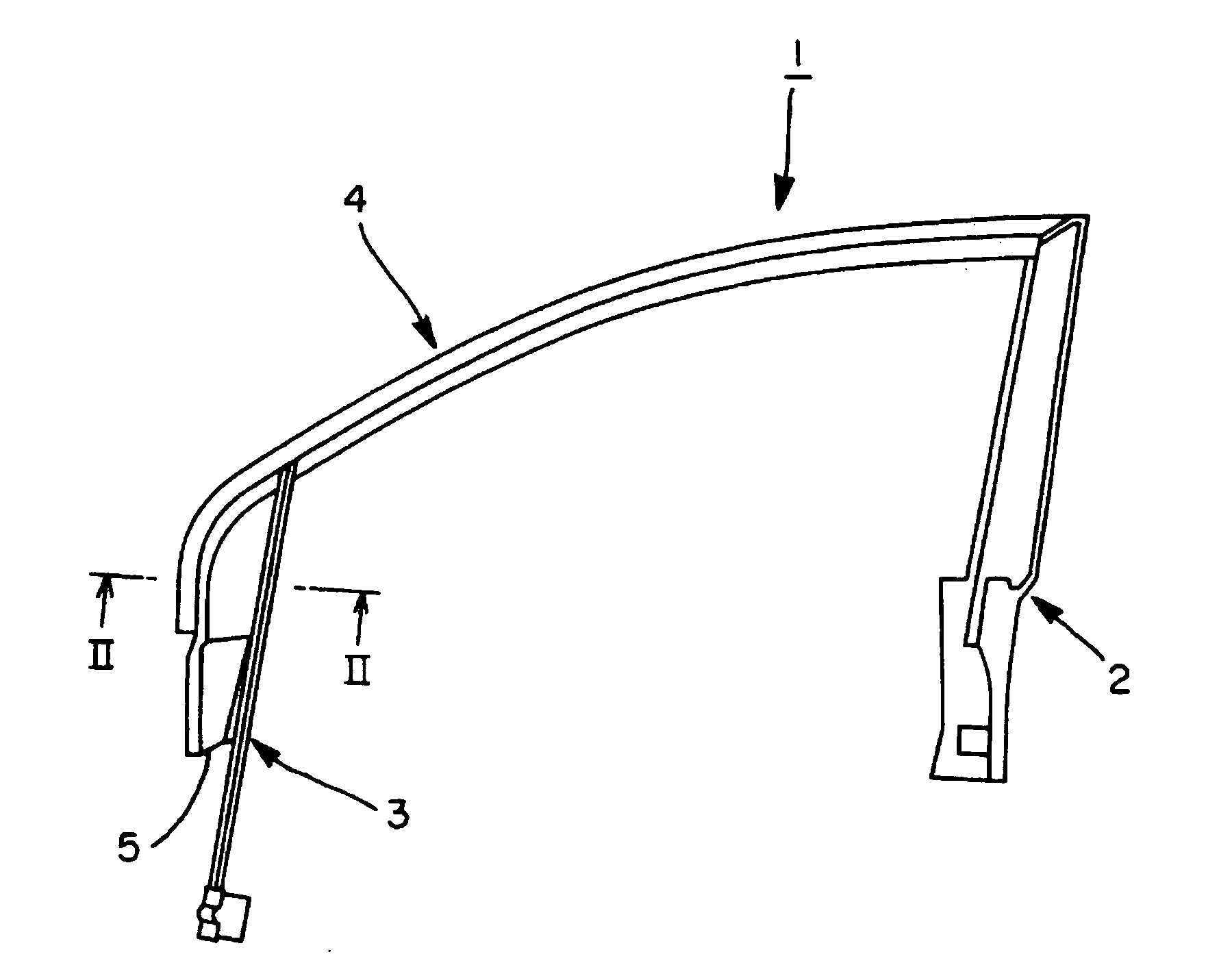

[0021] As shown in FIG. 1, a door frame 1 includes a center pillar 2 for guiding an up / down movement of a window glass and for making a vehicle to be locked / unlocked condition, a lower frame 3 provided apart from the center pillar 2, the lower frame 3 for guiding the up / down movement of the window glass, a main frame 4 for connecting the lower frame 3 to the center pillar 2 and for determining a top dead center of the window glass, and a bracket 5 for attaching a door mirror provided between a front end portion of the main frame 4 and the lower frame 3 and secured to both main and lower frames 4, 3.

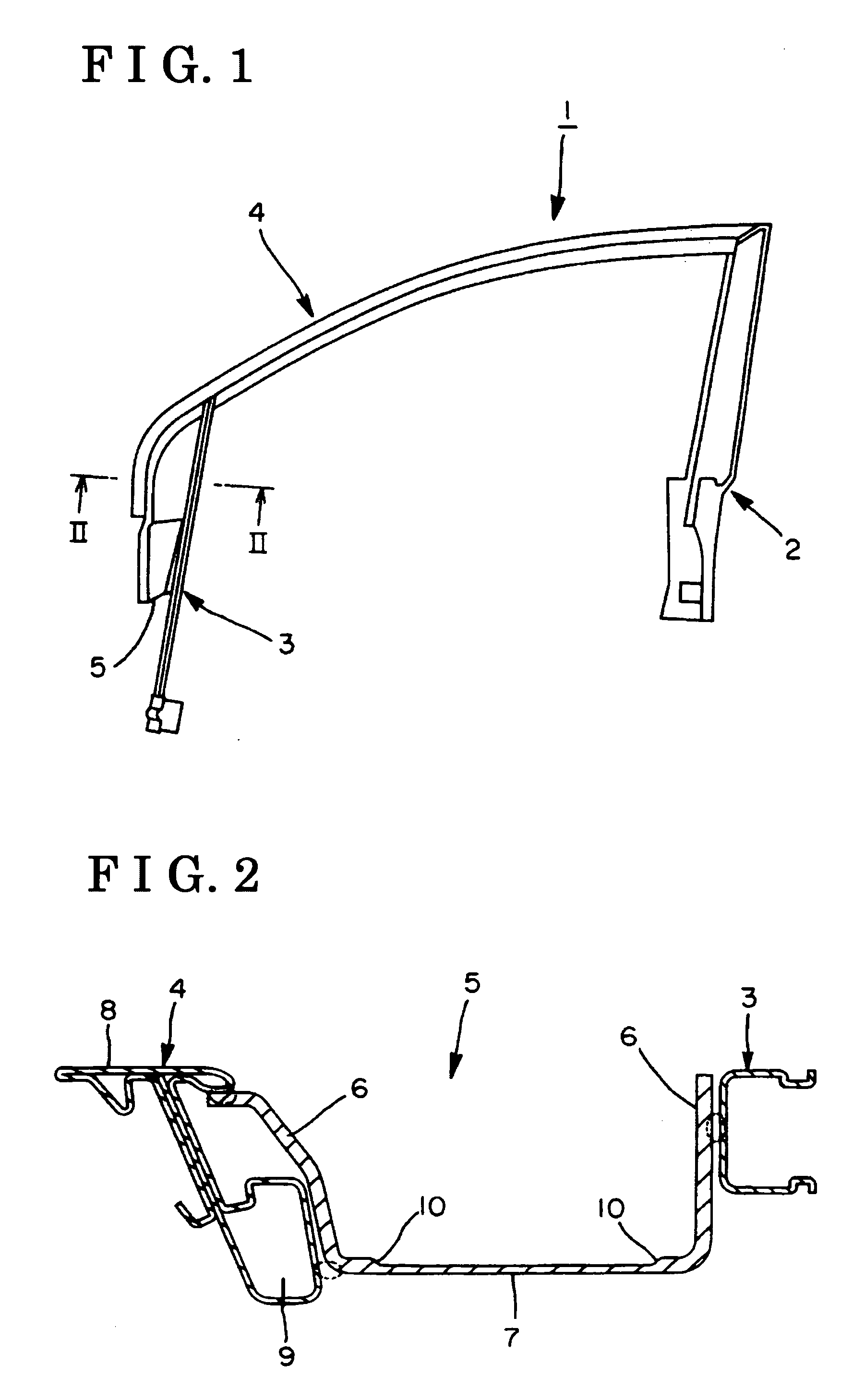

[0022] As shown in FIG. 2, the bracket 5 has an approximately U-shape cross-section. The bracket 5 is welded together with the lower frame 3 and the main frame 4. The bracket 5 includes a pair of opposing side wall portions 6 and a bottom portion 7. The bottom portion 7 of...

second embodiment

[0028] the present invention will be explained with reference to the illustrations of the drawing figures as follows.

[0029] As shown in FIG. 4, a door frame 1 includes a center pillar 2 and a lower frame 3 for guiding an open / close movement of a window glass, a main frame 4 for supporting the center pillar 2 and the lower frame 3 at apart position each other and for determining a top dead center of the window glass, and a bracket 5 secured to the main frame 4 and the lower frame 3. Preferably, the main frame 4 is made of, but not limited to, light alloy by extrusion. The main frame 4 may be made of steel, or the like.

[0030] To obtain the door frame 1 having increased rigidity without increase of weight, cost, and man-hour, the bracket 5 is made of light alloy by casting and includes ribs projecting in a vehicle width direction side by side. Light alloy includes aluminum alloy, magnesium alloy, and titanium series alloy, or the like.

[0031]FIG. 5 shows an example of the bracket 5 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com