Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Avoid uneven film thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

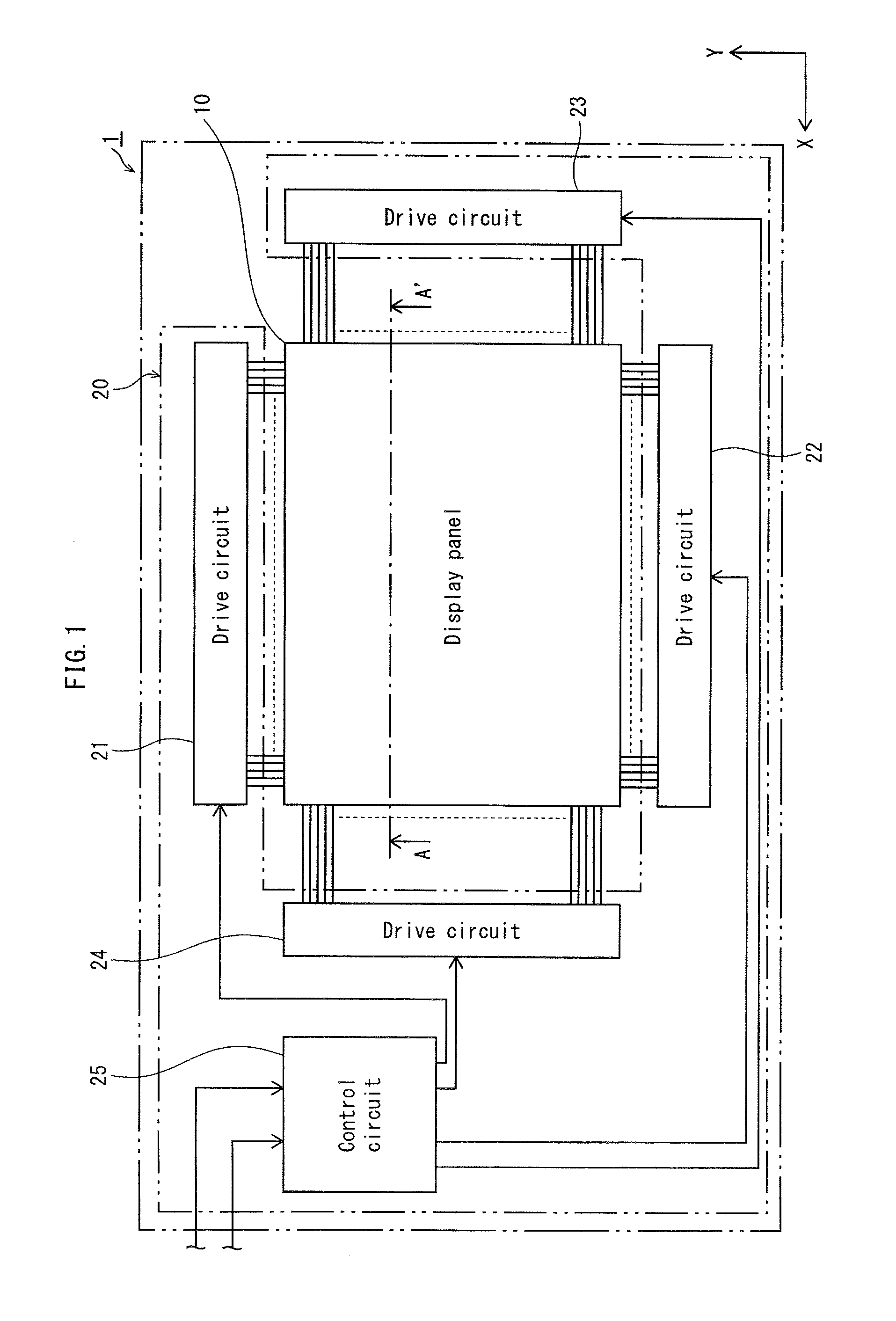

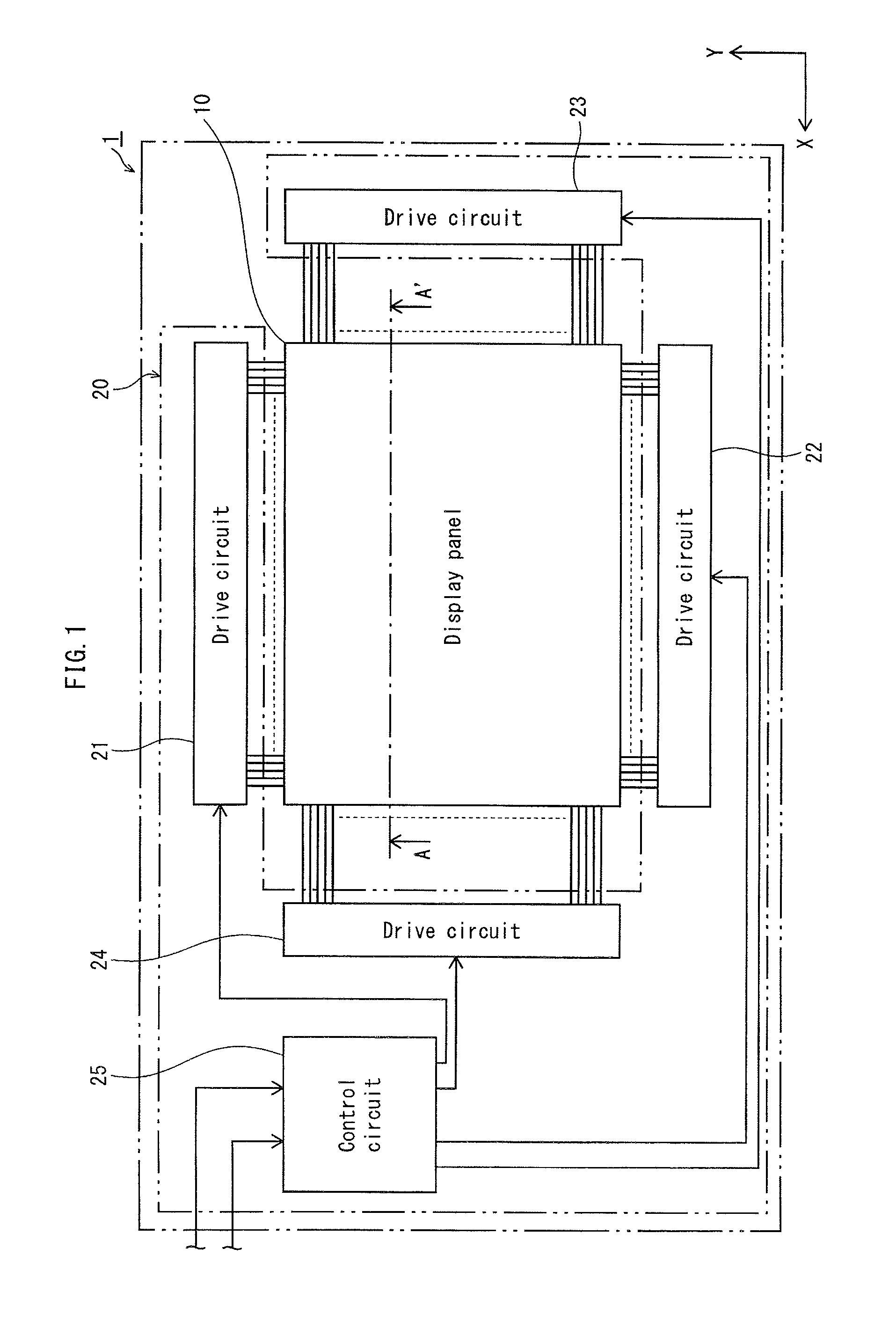

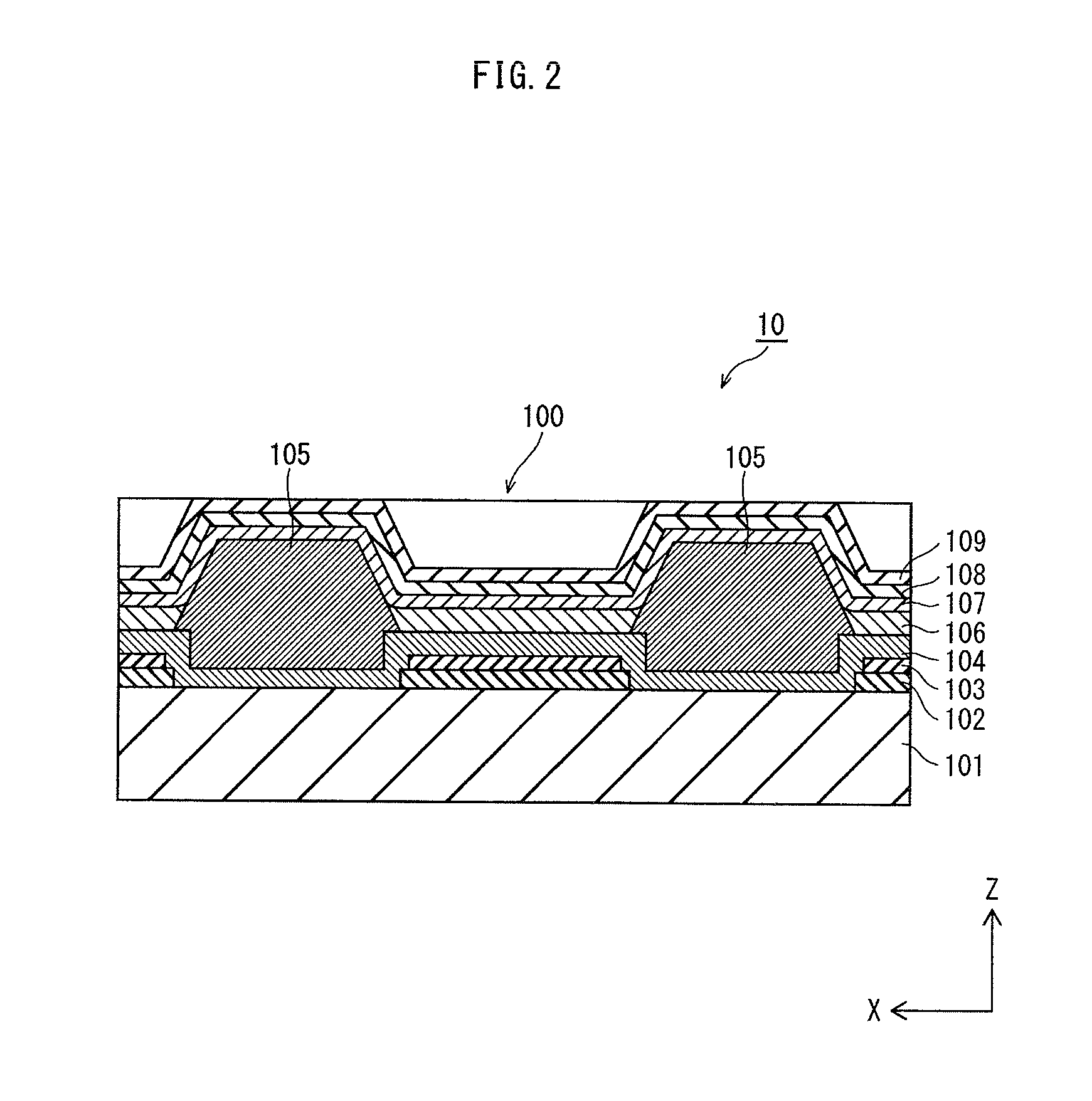

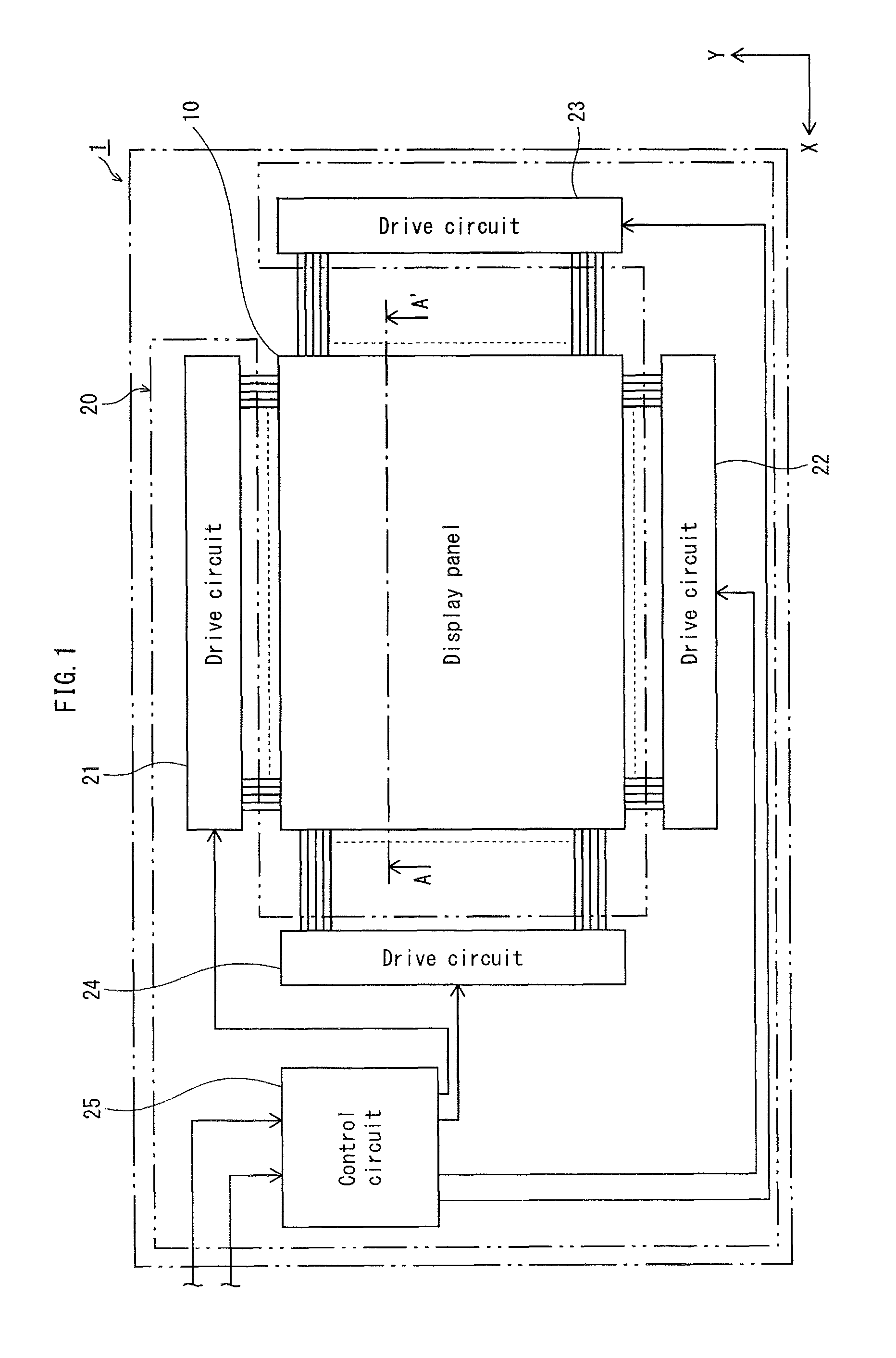

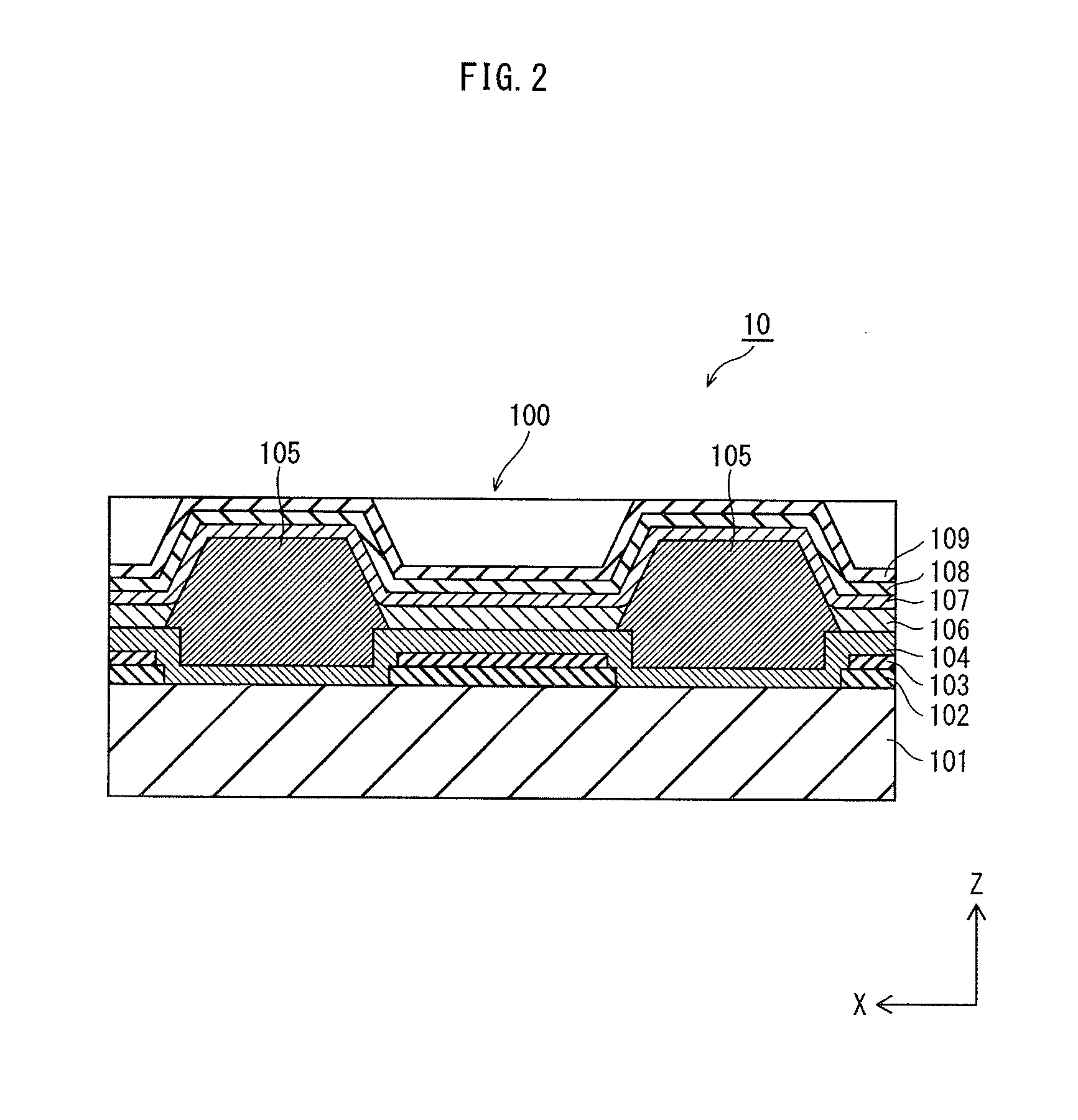

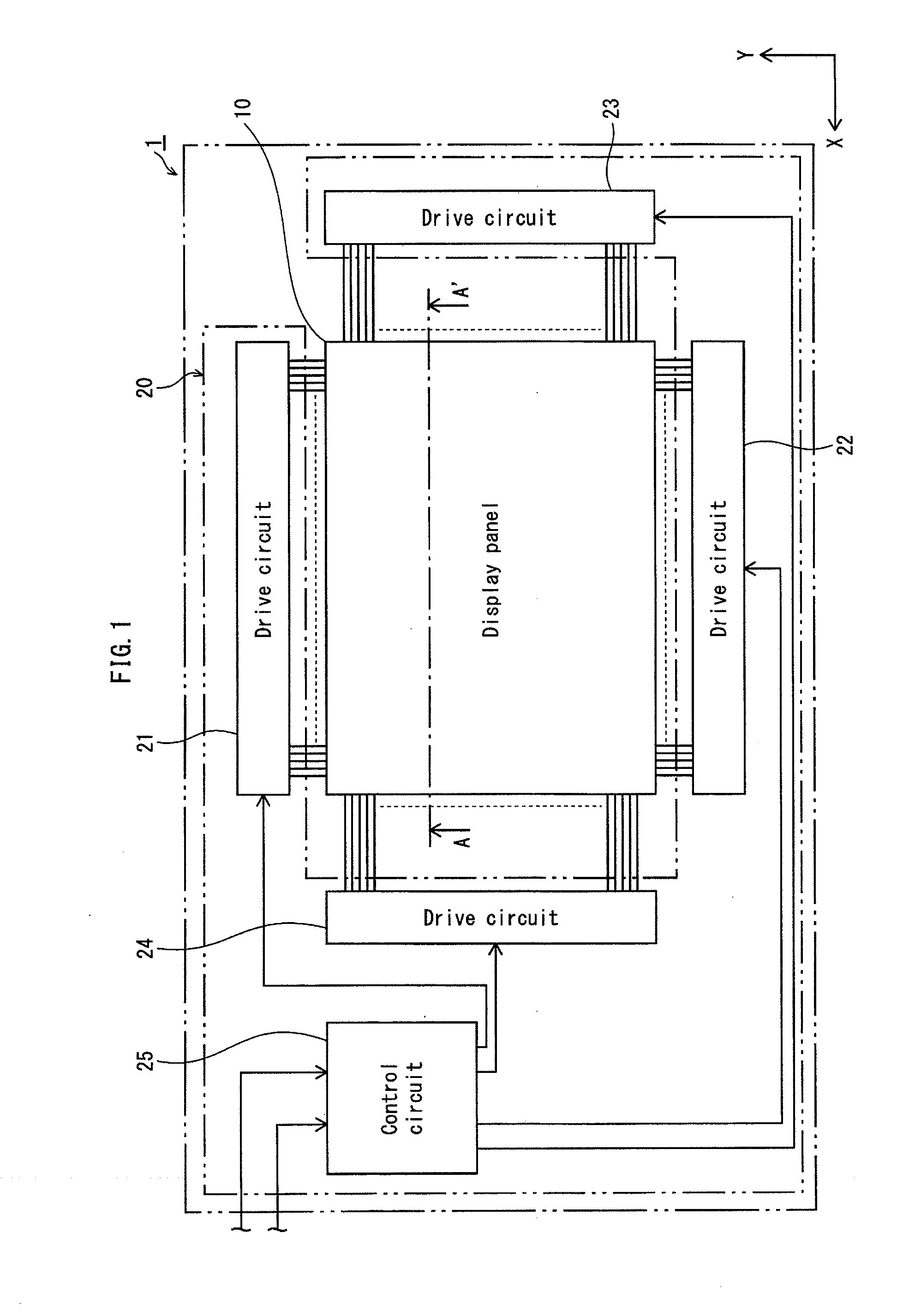

Organic light-emitting panel and manufacturing method thereof, and organic display device

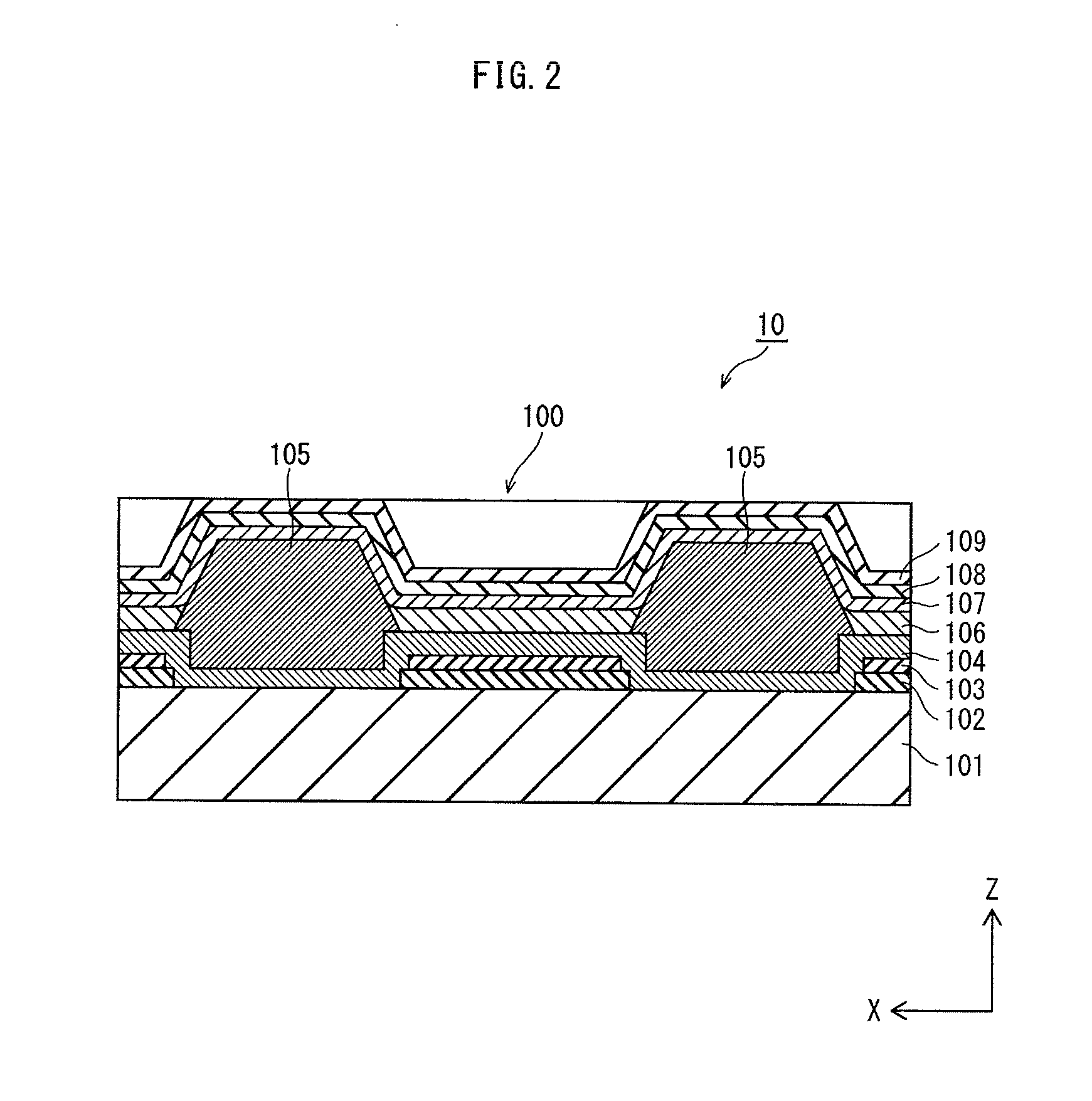

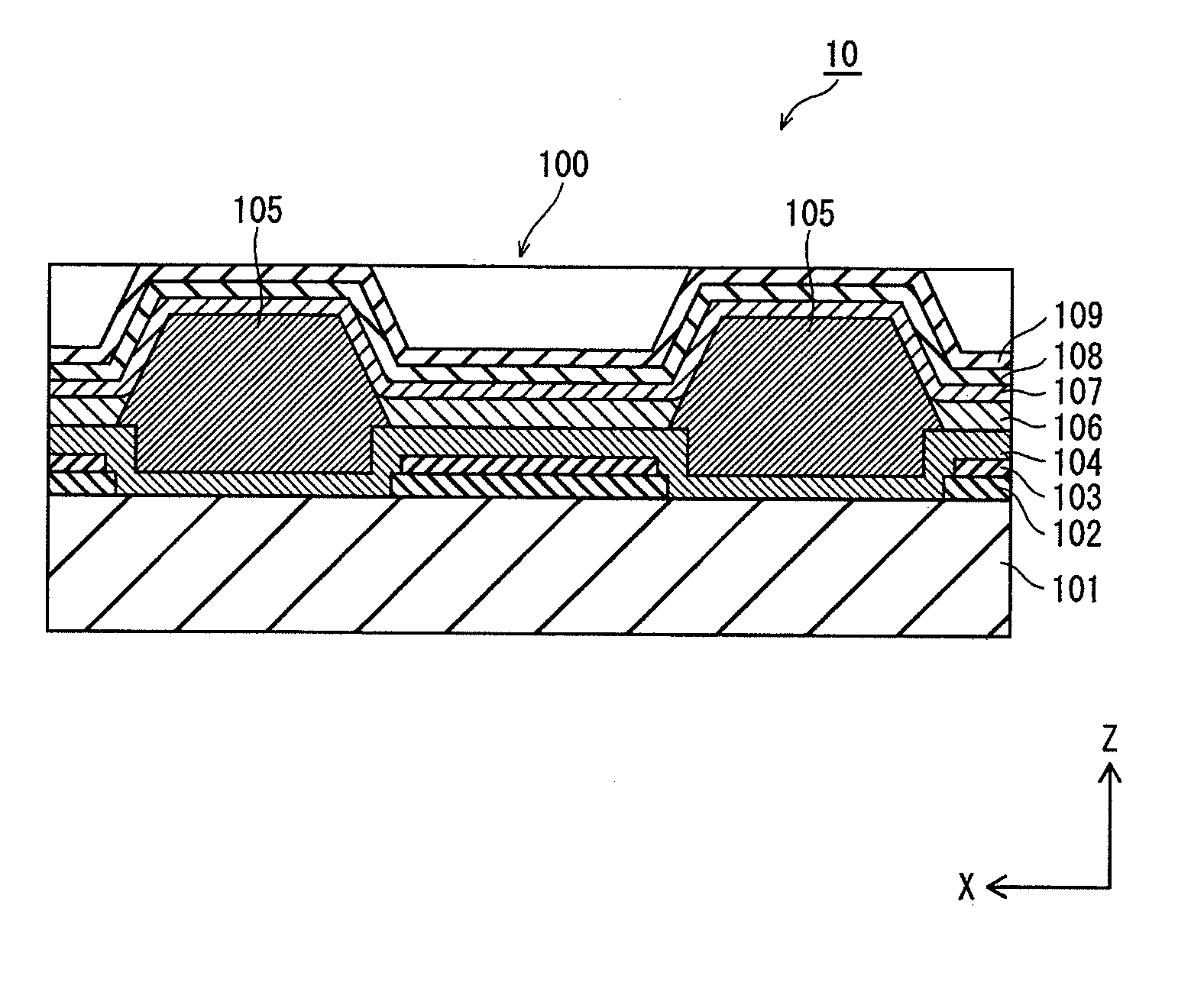

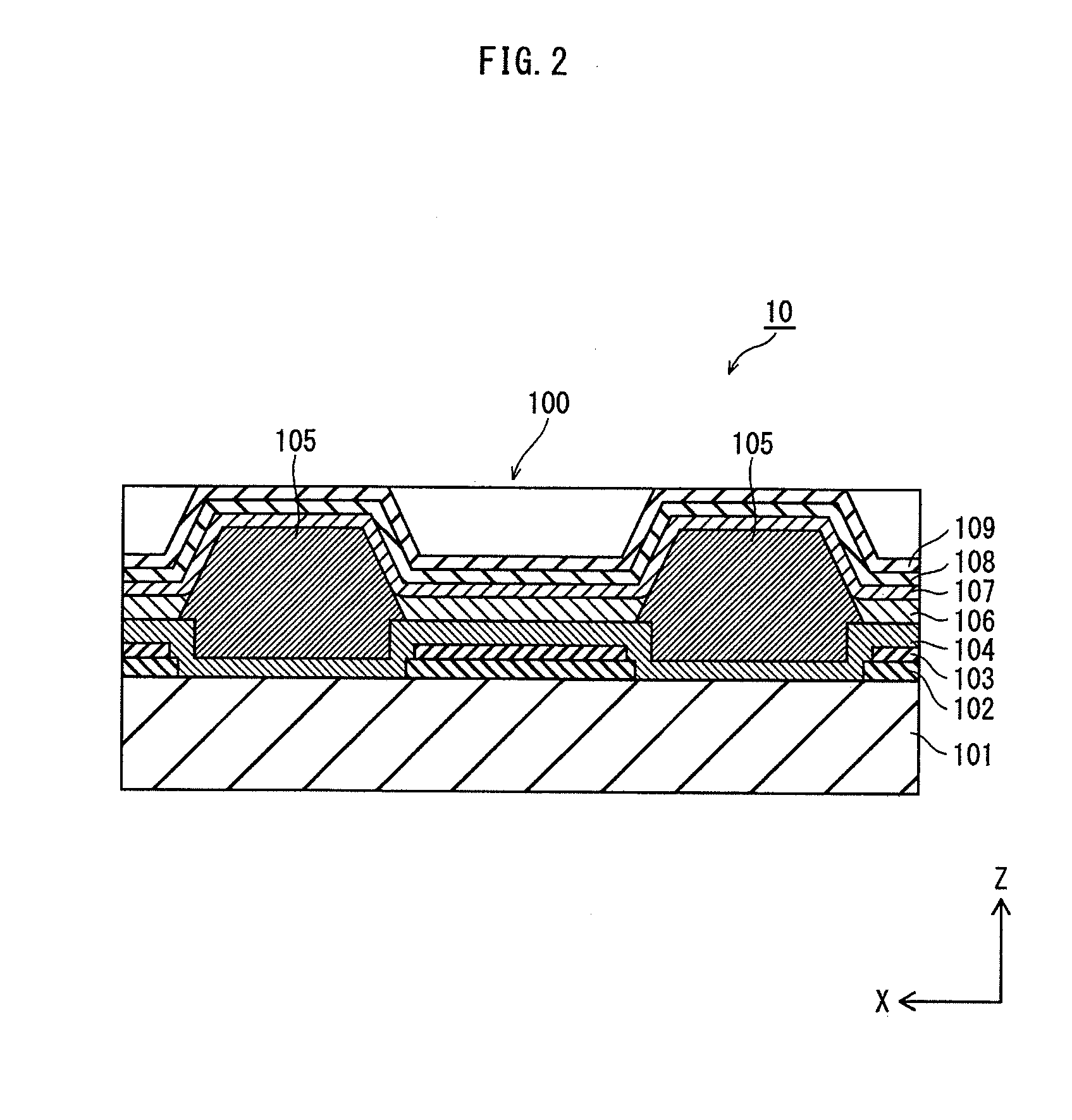

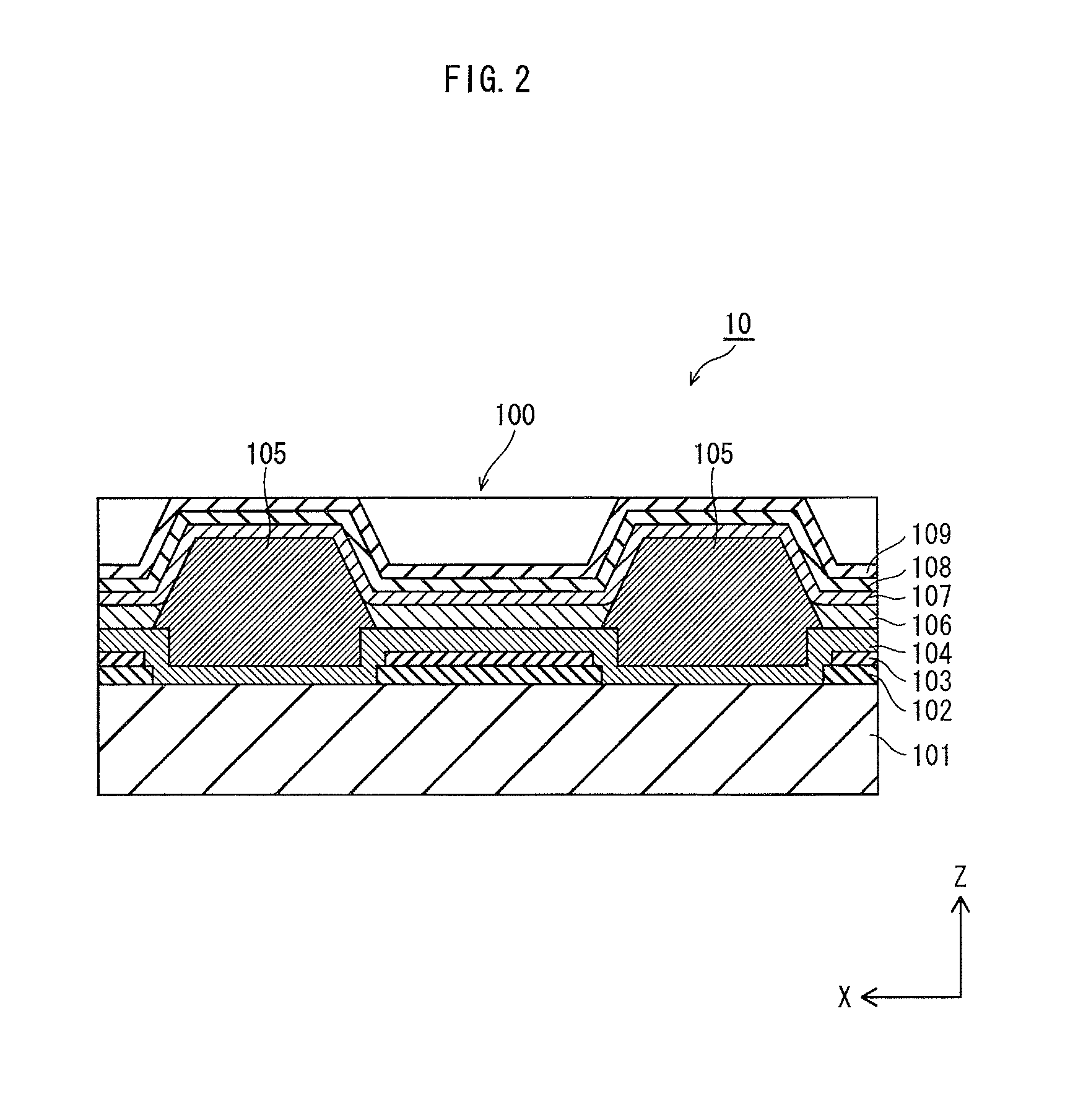

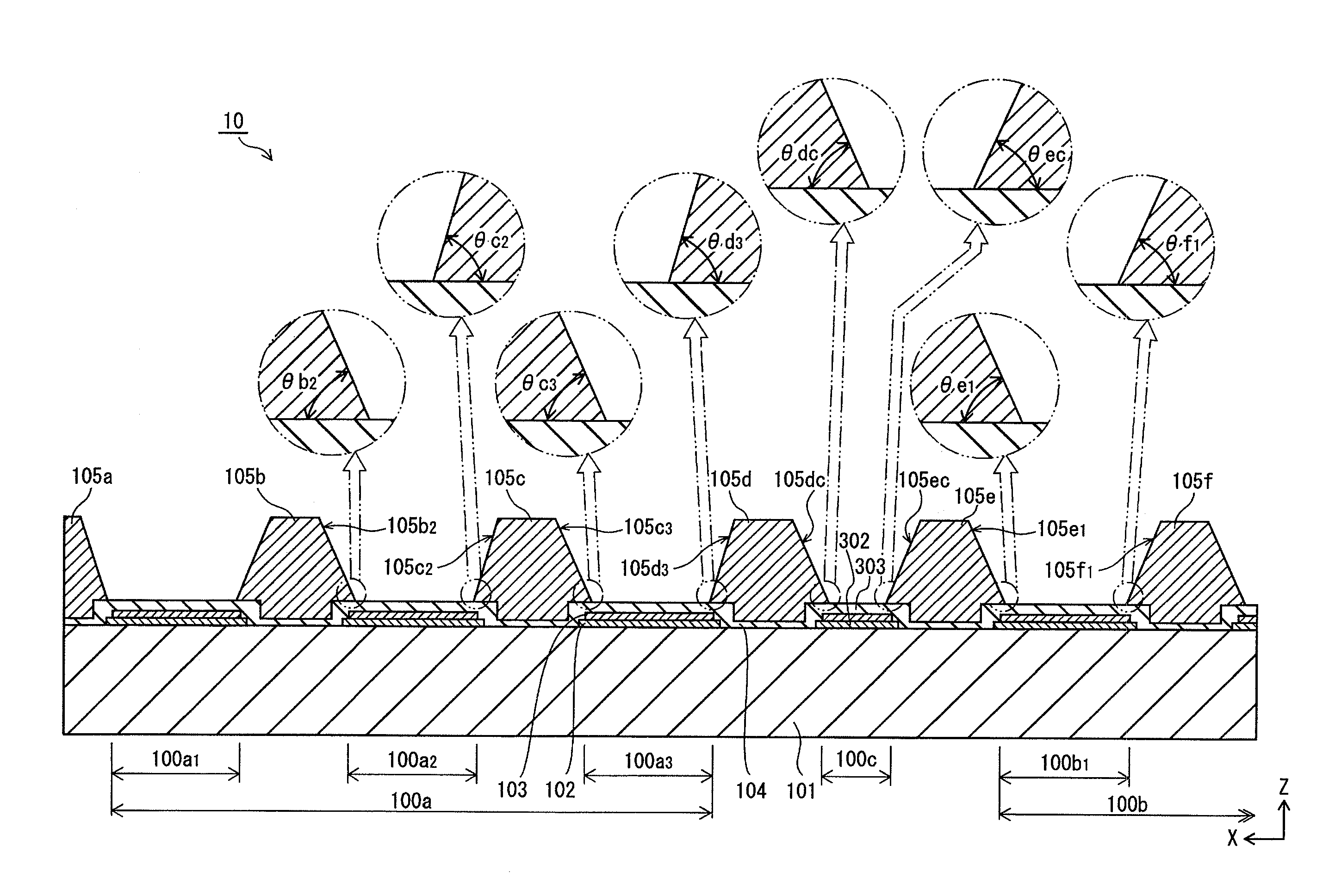

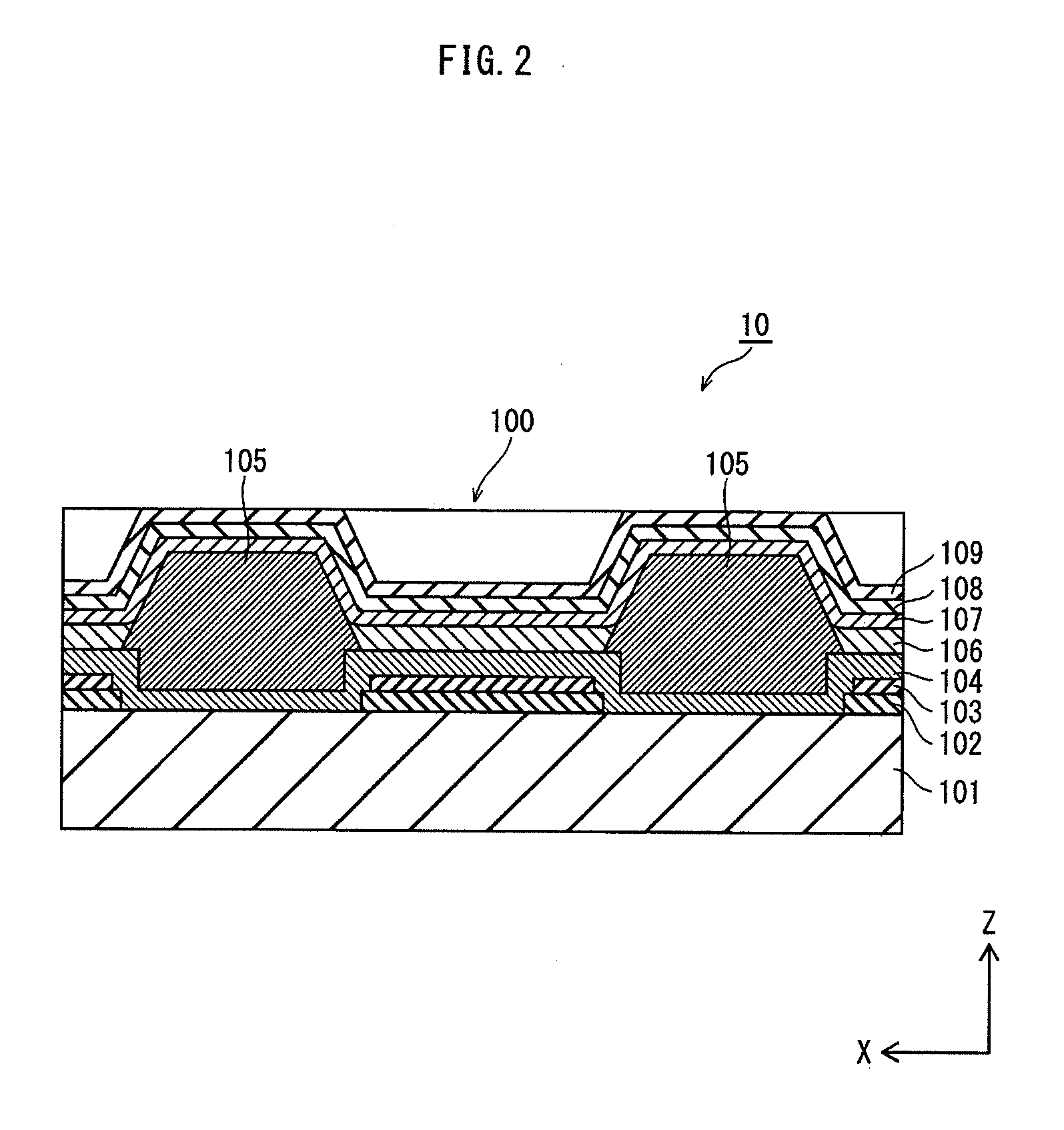

ActiveUS20120091483A1Avoid uneven film thicknessLarge inclinationSolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryDisplay device

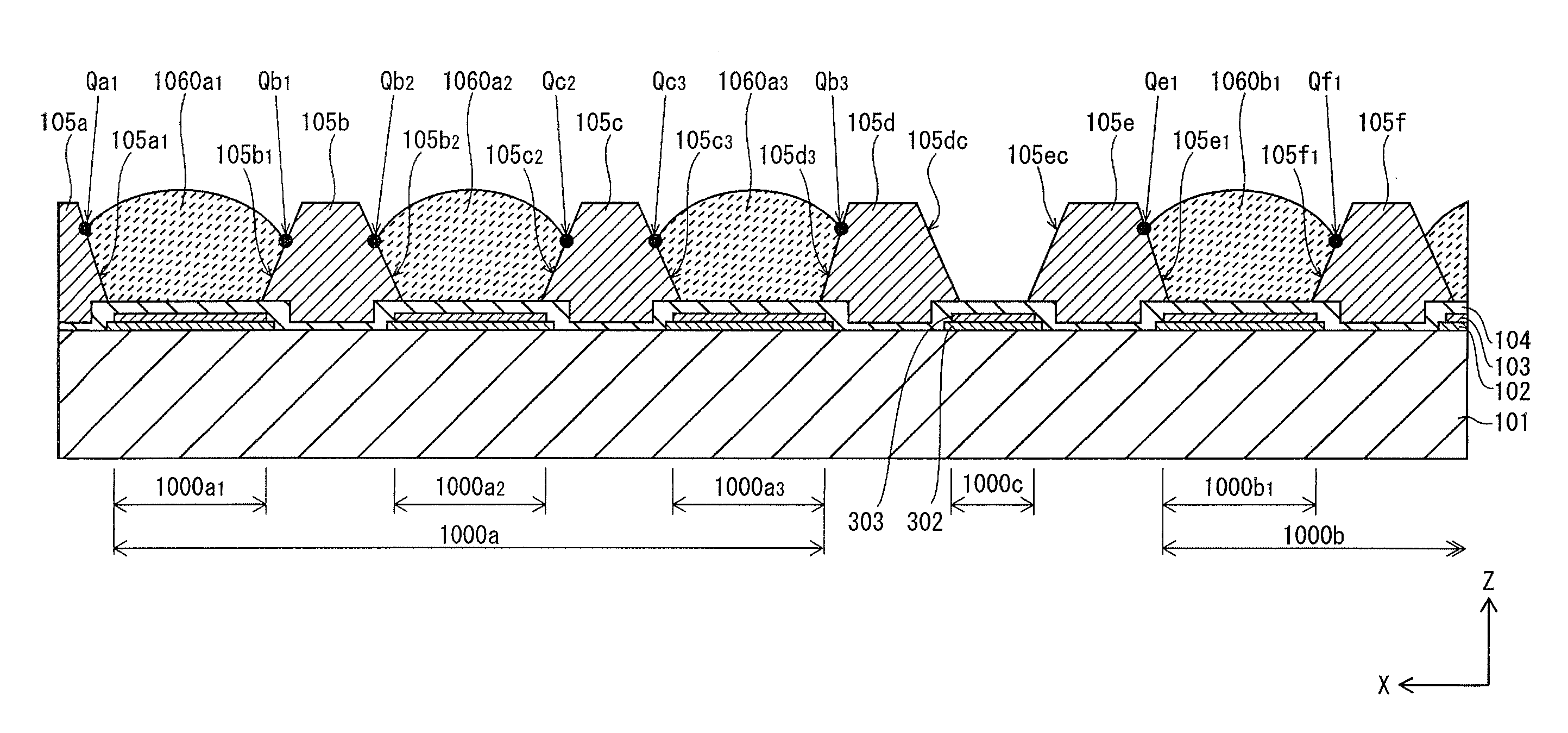

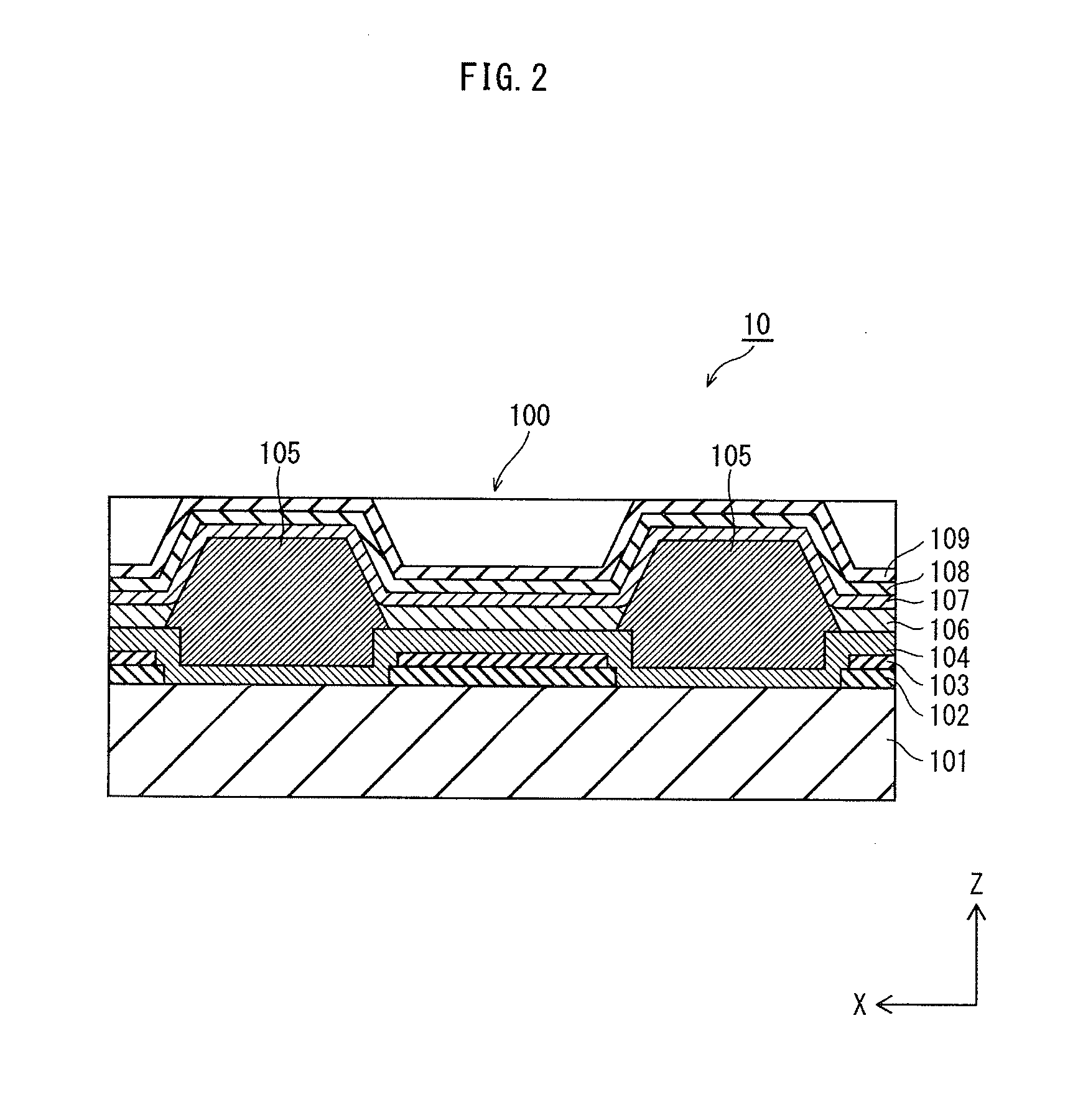

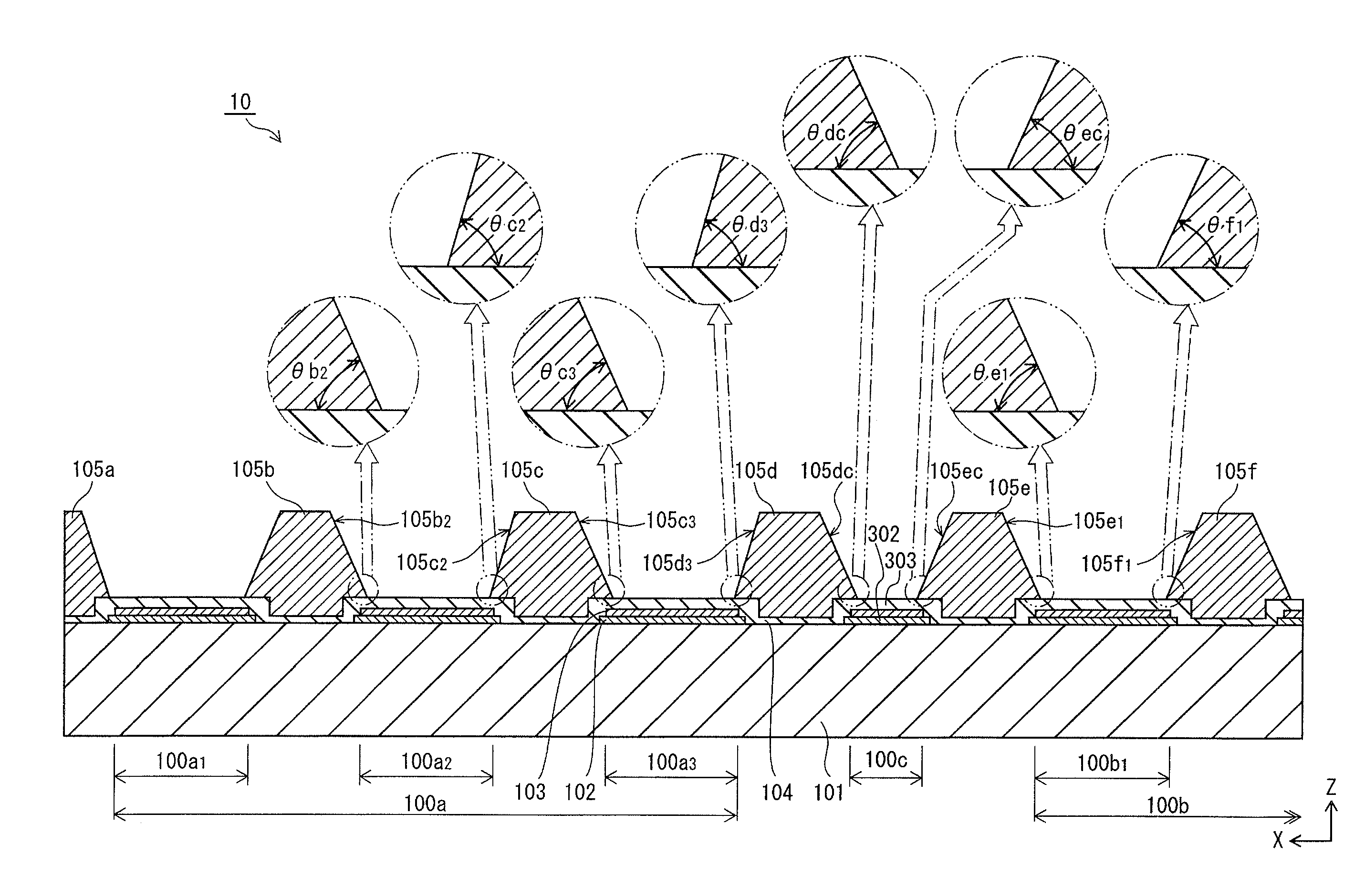

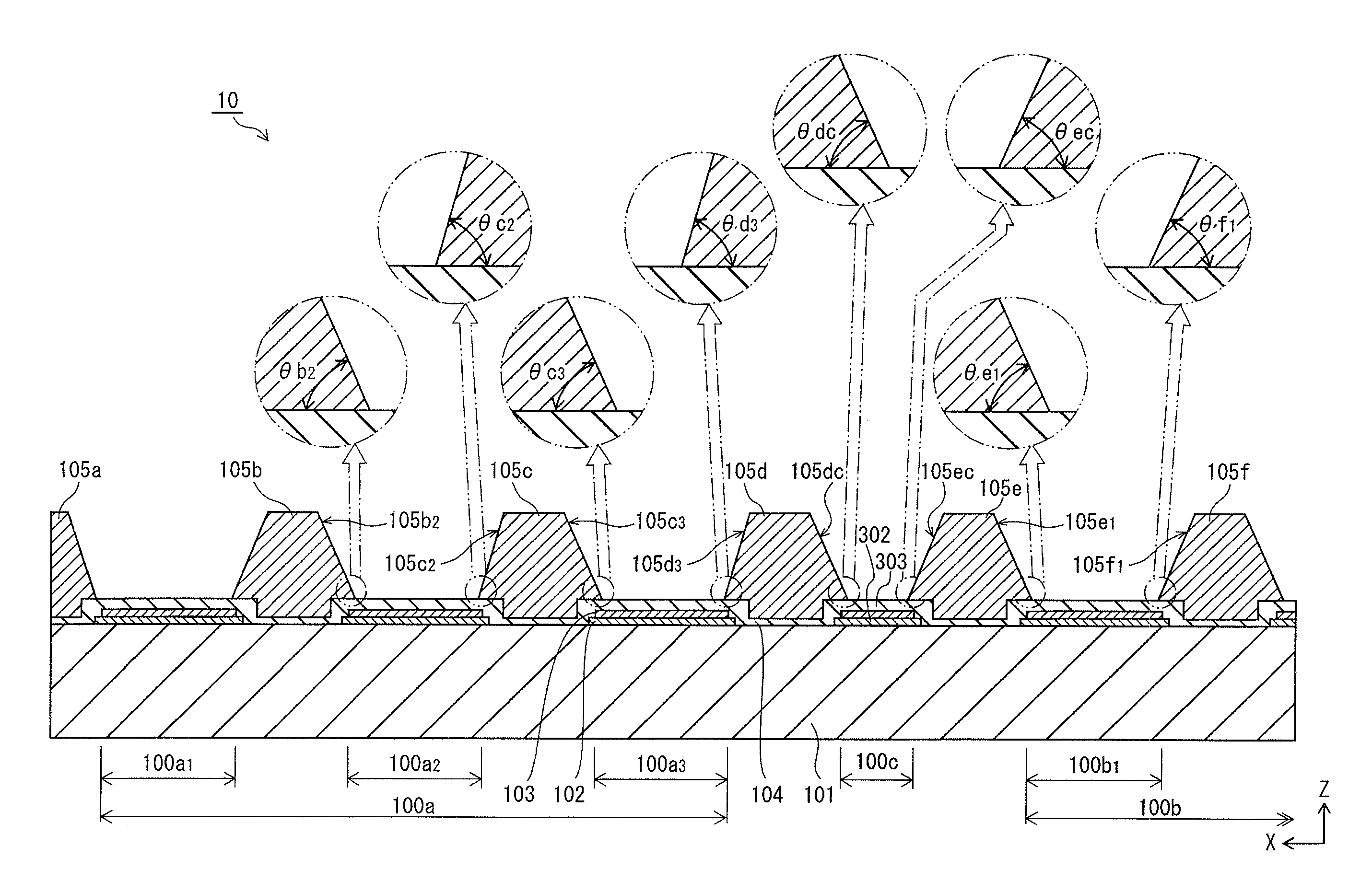

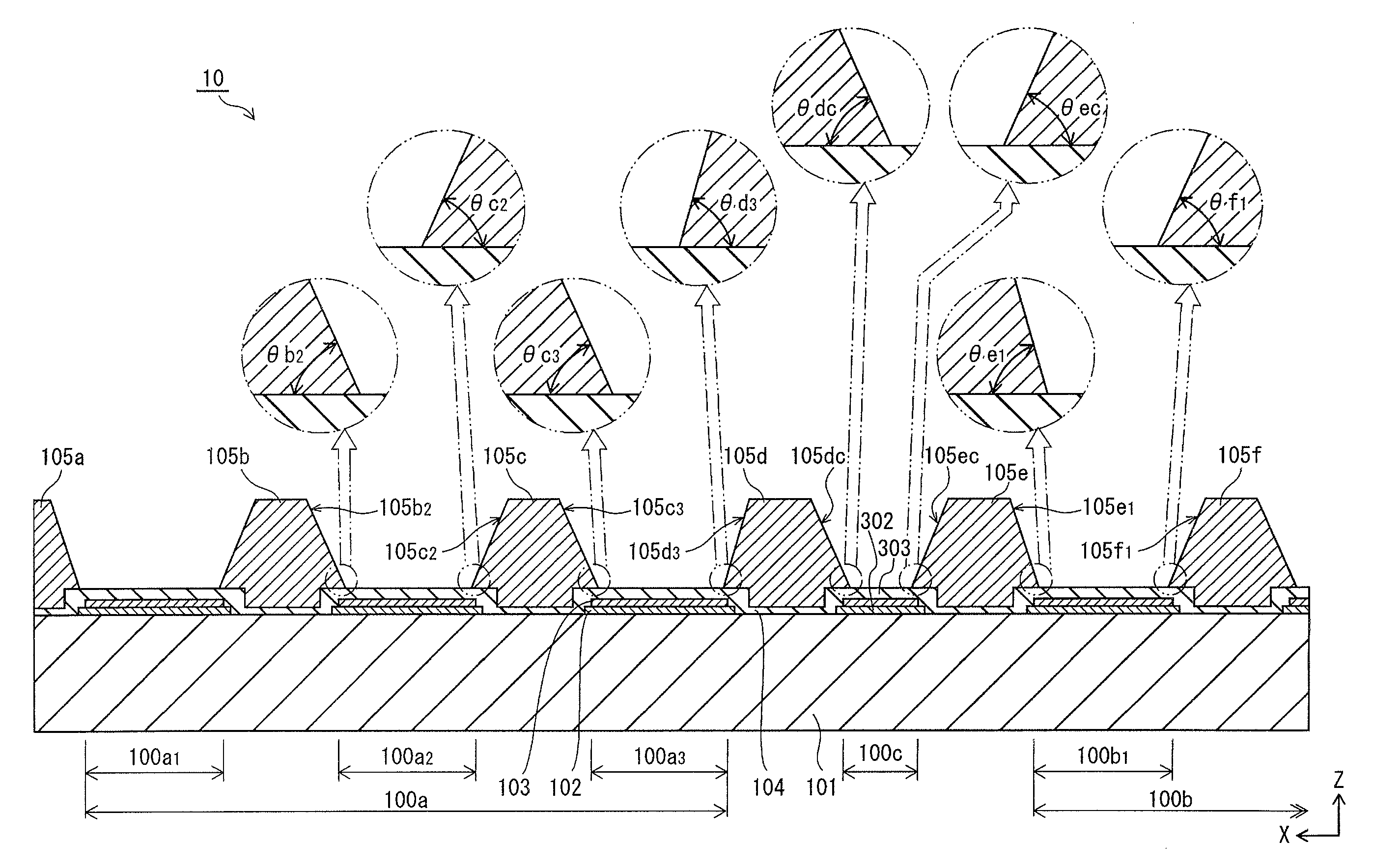

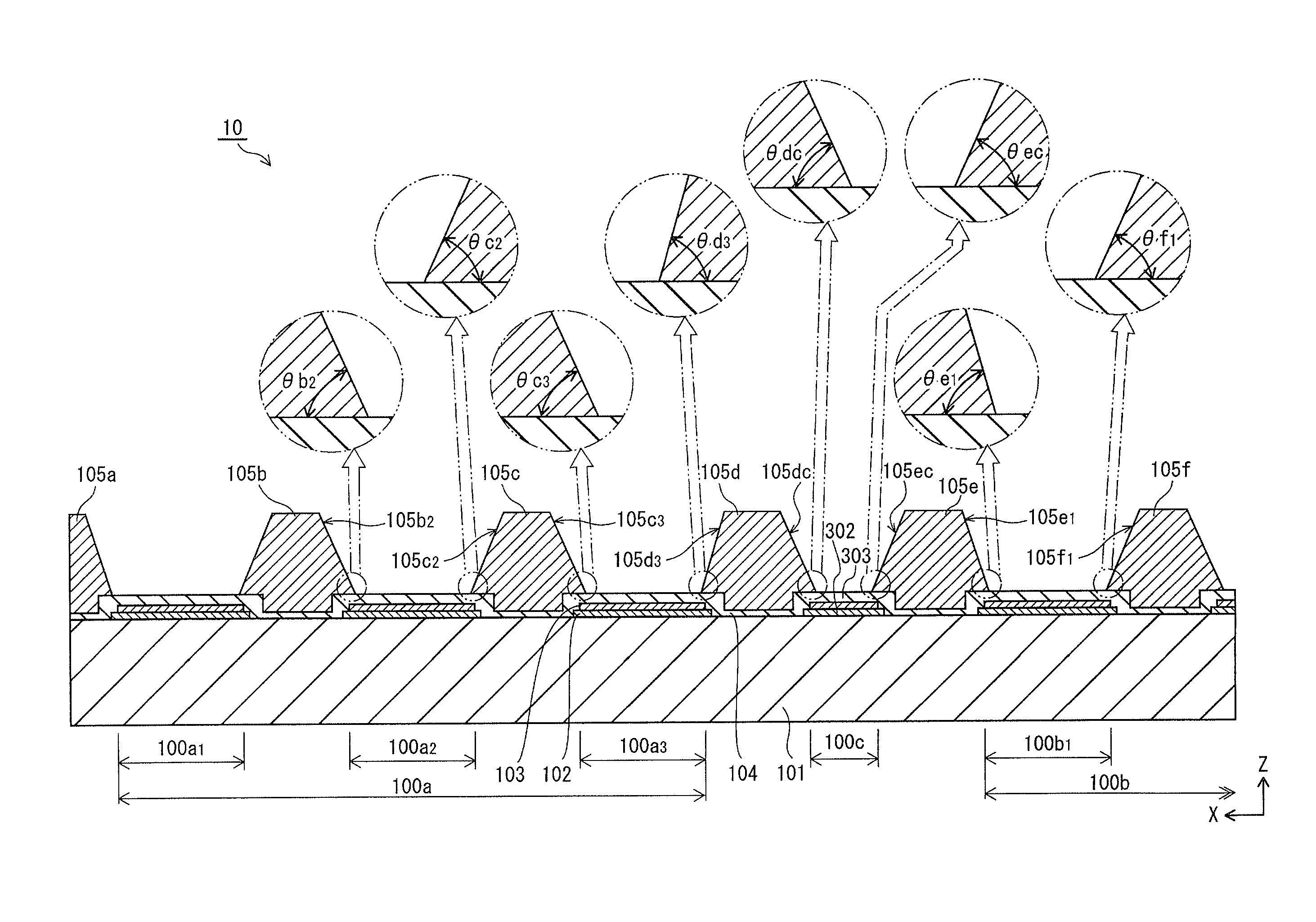

A non-light-emitting cell 100c is provided between pixels 100a and 100b. Ink for forming an organic light-emitting layer is dripped substantially simultaneously into sub-pixels 100a1, 100a2, and 100a3 in the pixel 100a and a sub-pixel 100b1 in the pixel 100b. On the other hand, such ink is not dripped into the non-light-emitting cell 100c since the organic light-emitting layer is not formed in the non-light-emitting cell 100c. In a bank 105d, an inclination angle θd3 of a wall 105d3 facing the sub-pixel 100a3 is larger than an inclination angle θdc of a wall 105dc facing the non-light-emitting cell 100c. Similarly, in a bank 105e, an inclination angle θe1 of a wall 105e1 facing the sub-pixel 100b1 is larger than an inclination angle θec of a wall 105ec facing the non-light-emitting cell 100c.

Owner:JOLED INC

Organic light-emitting panel and manufacturing method thereof, and organic display device

InactiveUS20120091441A1Avoid uneven film thicknessLarge inclinationSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

A non-light-emitting cell 100c is provided between pixels 100a and 100b. In formation of the pixel 100a, ink for forming an organic light-emitting layer is dripped into sub-pixels 100a1, 100a2, 100a3 in this order. This also applies to the pixel 100b. However, such ink is not dripped into the non-light-emitting cell 100c since the organic light-emitting layer is not formed in the non-light-emitting cell 100c. Regarding banks 105c and 105d defining the sub-pixel 100a3 of the pixel 100a, an inclination angle θd3 of a wall 105d3 of the bank 105d is larger than an inclination angle θc3 of a wall 105c3 of the bank 105c. Meanwhile, regarding banks 105e and 105f defining the sub-pixel 100b1, an inclination angle θe1 of a wall 105e1 of the bank 105e is equivalent to an inclination angle θe1 of a wall 105f1 of the bank 105f.

Owner:JOLED INC

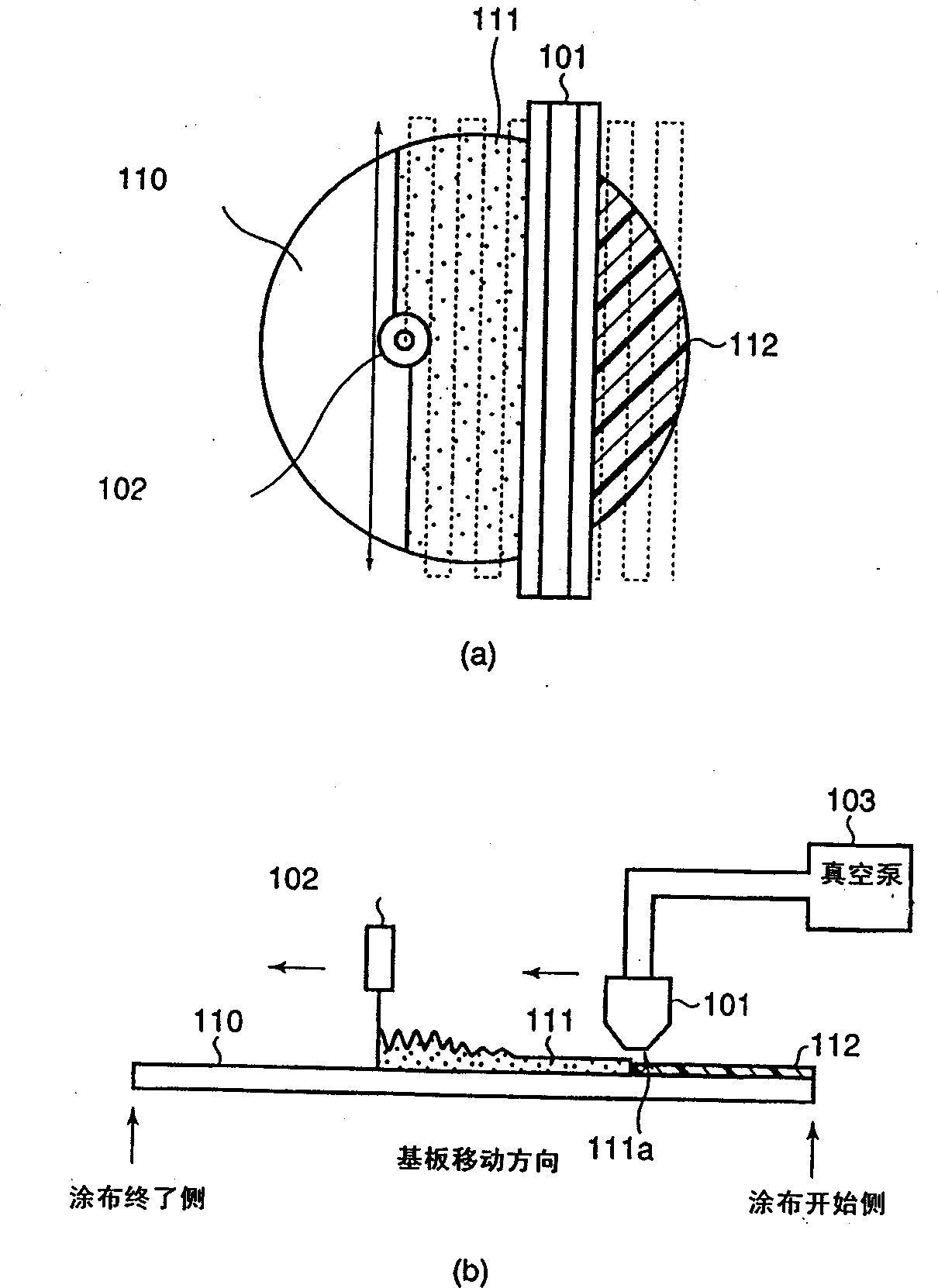

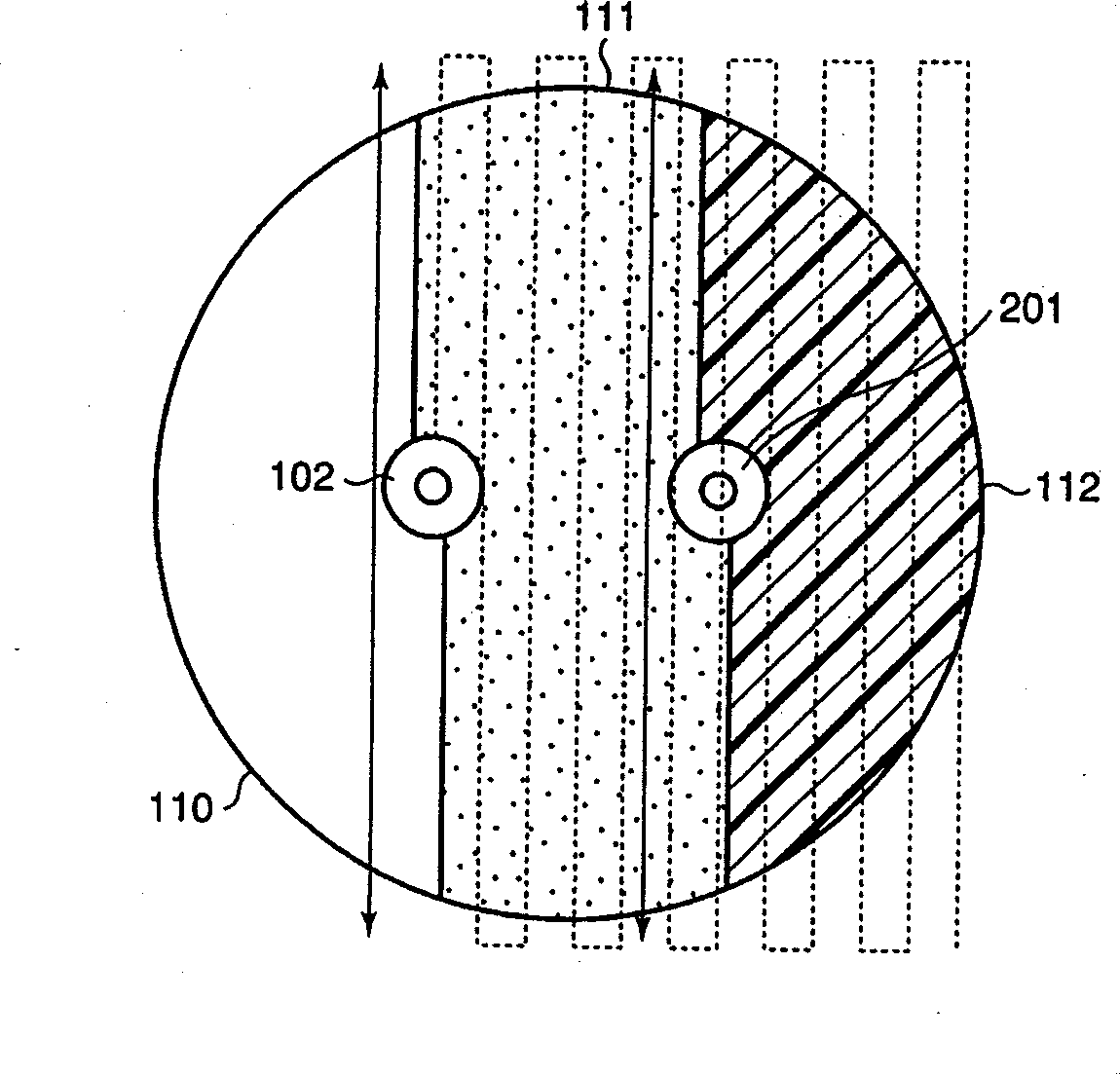

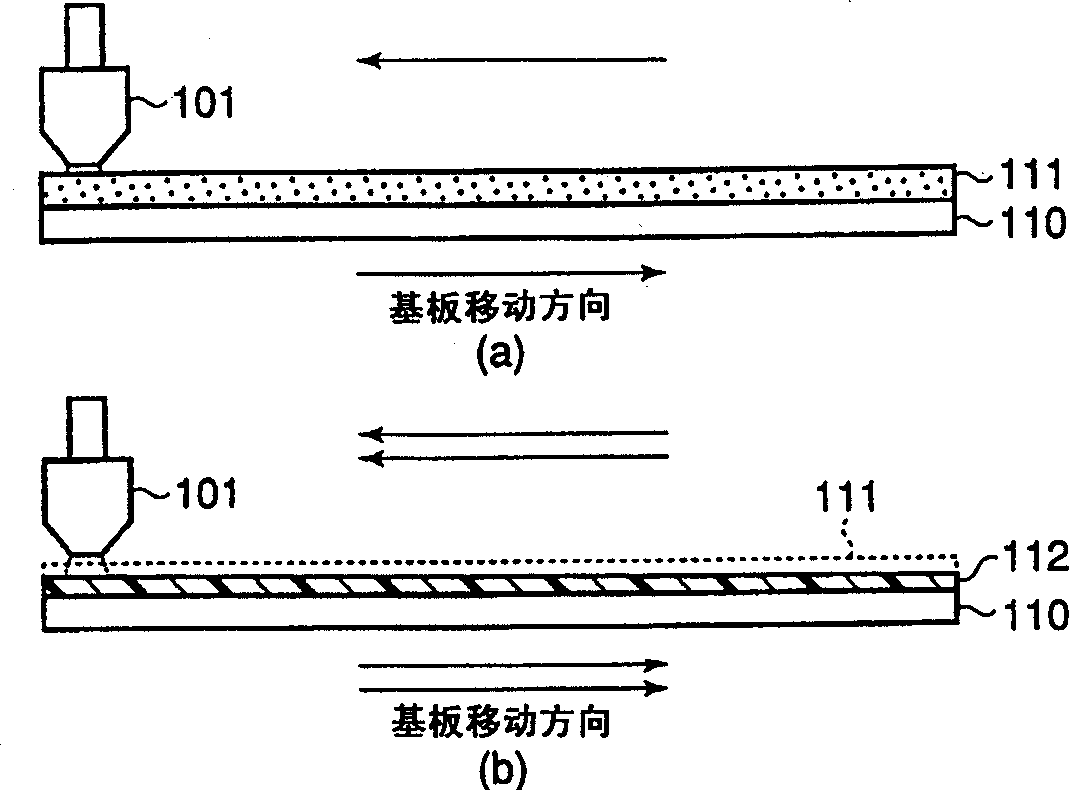

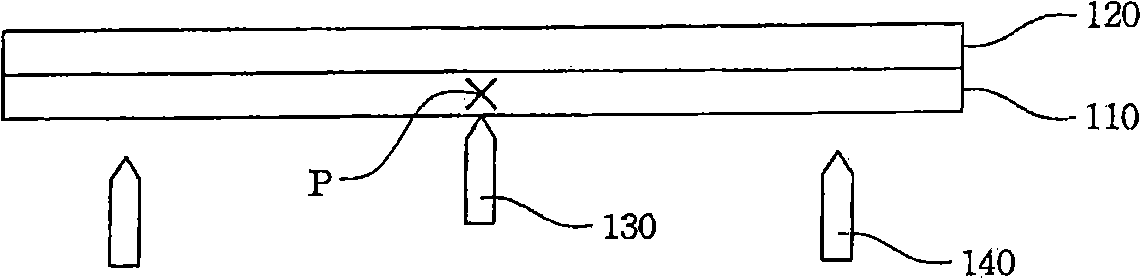

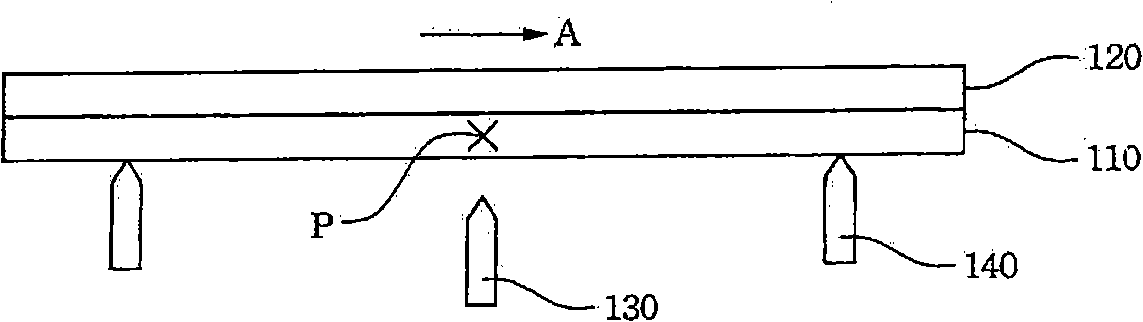

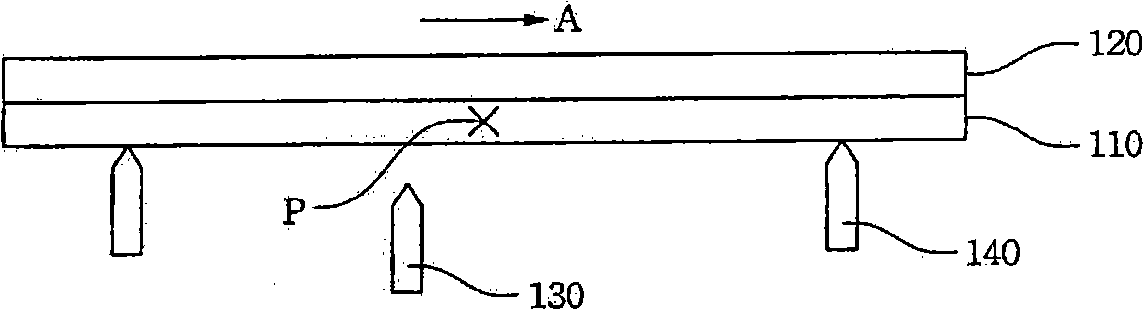

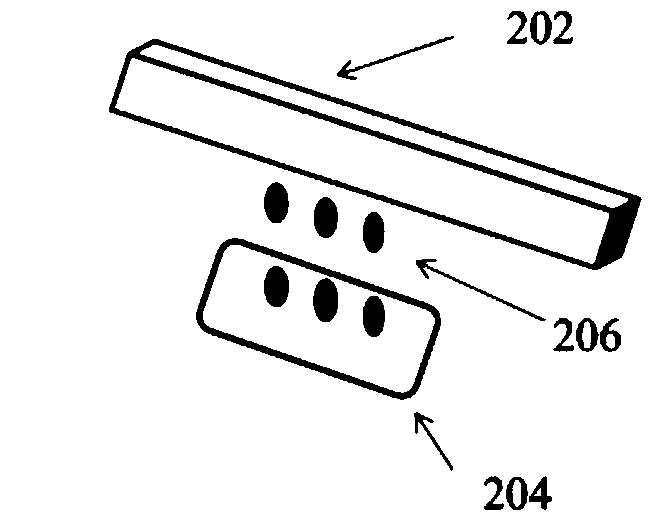

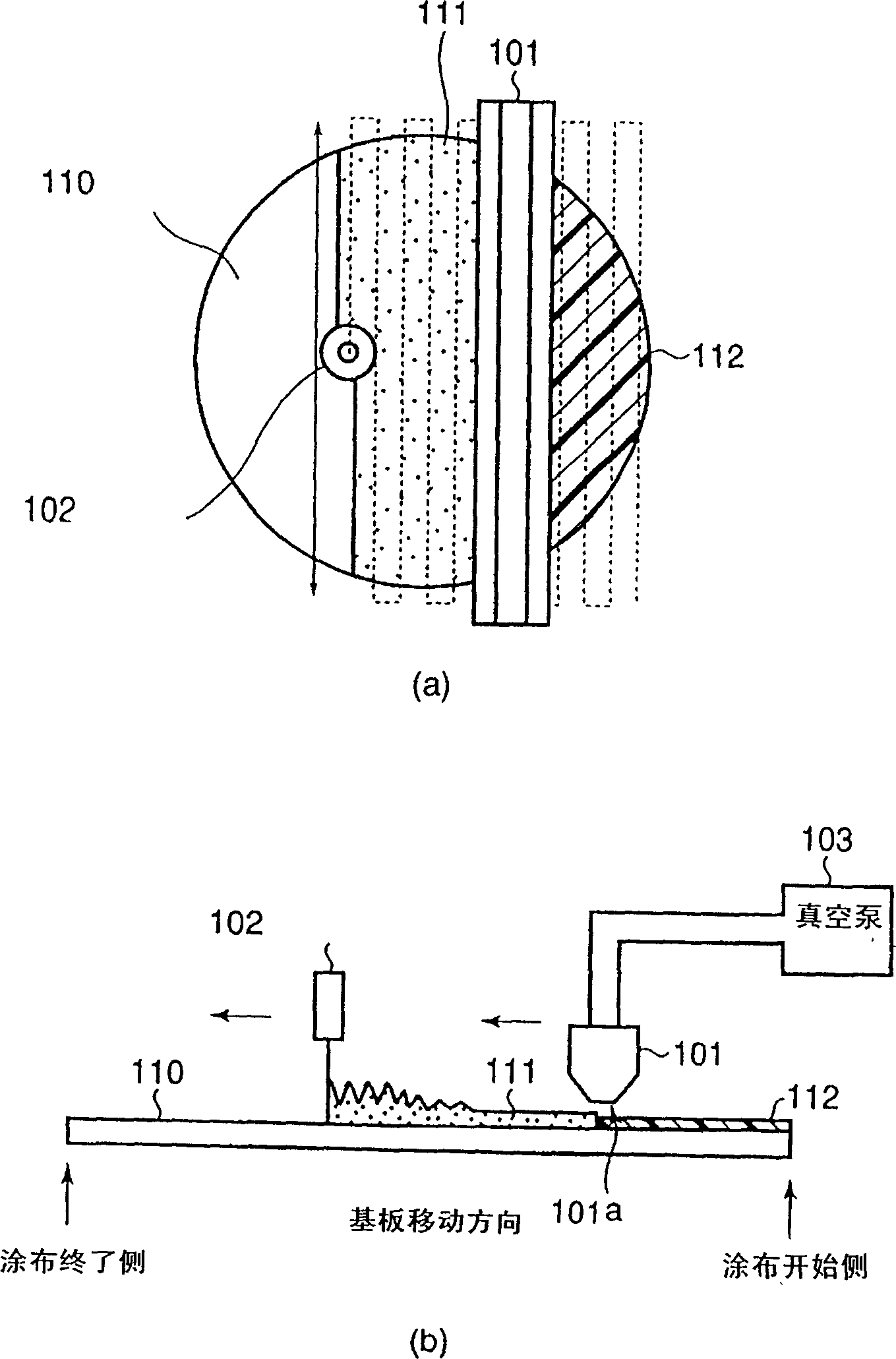

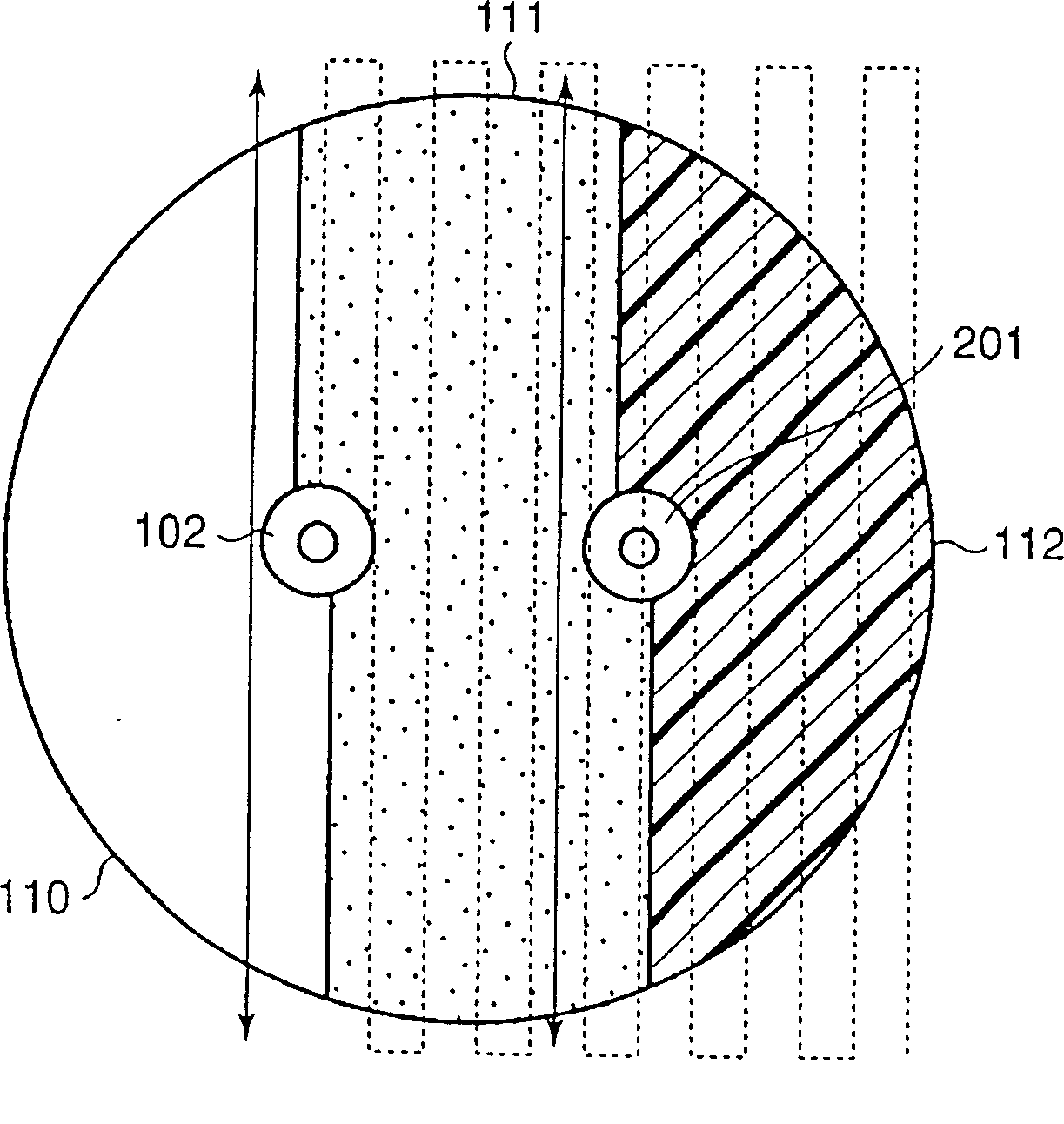

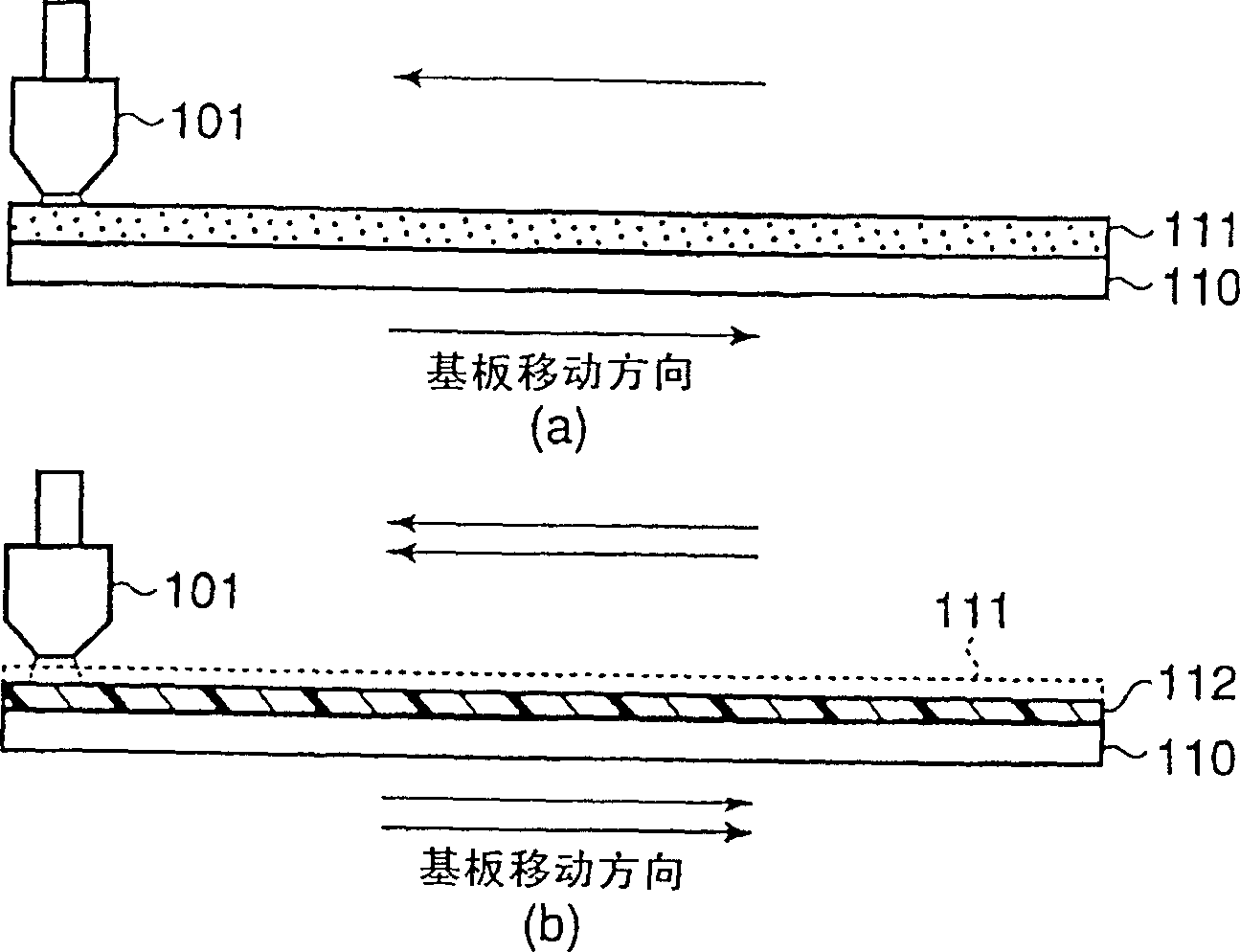

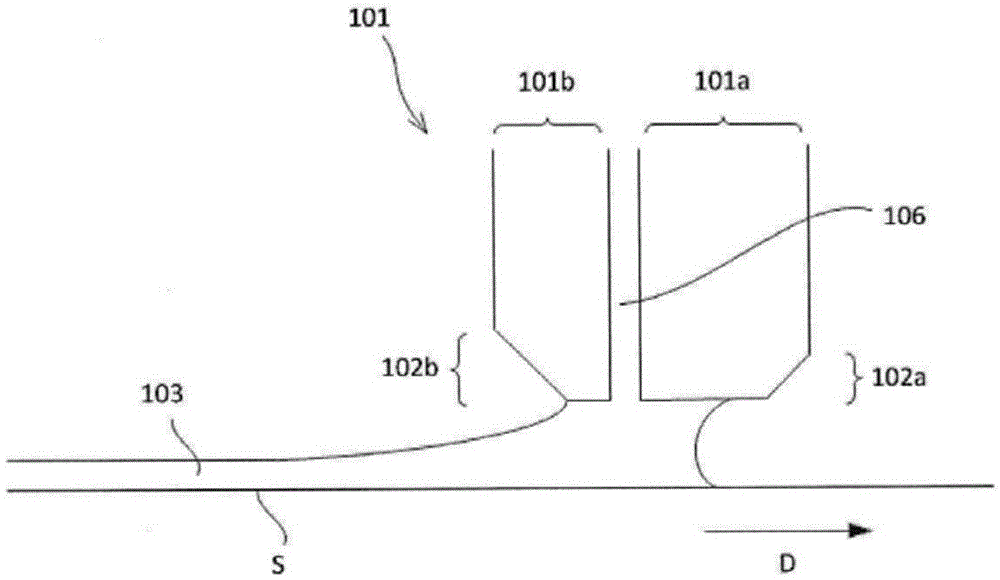

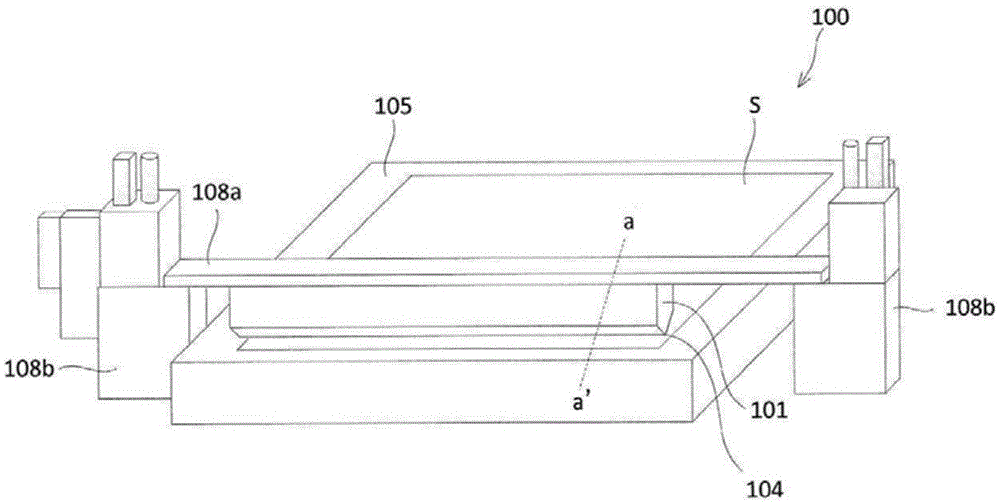

Filmforming method and device

InactiveCN1347137AAvoid uneven film thicknessShorten the timePretreated surfacesSemiconductor/solid-state device manufacturingTectorial membraneResist

The invention provides a film forming method and device. A liquid film formation section is composed of a resist dropping nozzle 102, a nozzle movement mechanism not shown in a figure that moves the resist dropping nozzle 102 in a y direction (a horizontal direction on page space), and the movement rest of the substrate 110 to be treated not shown in the figure where the substrate 110 to be treated having a diameter of 200 mm is installed and is moved in an x direction. A liquid film drying section is composed of a suction nozzle 101, and a vacuum pump 103 connected to the suction nozzle 101. Also, the movement rest of the substrate to be treated is also one of the components of the liquid film drying section. The invention is able to suppress the generation of film thickness distribution in an application film, and at the same time to shorten time for forming the application film.

Owner:KK TOSHIBA

Organic light-emitting panel and manufacturing method thereof, and organic display device

InactiveUS20120091440A1Avoid uneven film thicknessLarge inclinationElectroluminescent light sourcesSolid-state devicesDisplay deviceEngineering

A non-light-emitting cell 100c is provided between pixels 100a and 100b. In formation of the light-emitting cell 100a, ink for forming an organic light-emitting layer is dripped into sub-pixels 100a1, 100a2, 100a3 in this order. This also applies to the light-emitting cell 100b. However, such ink is not dripped into the non-light-emitting cell 100c since the organic light-emitting layer is not formed in the non-light-emitting cell 100c. Regarding a bank 105d between the sub-pixel 100a3 and the non-light-emitting cell 100c, an inclination angle θd3 of a wall 105d3 is larger than an inclination angle θdc of a wall 105dc. On the other hand, regarding a bank 105e between the sub-pixel 100b1 and the non-light-emitting cell 100c, an inclination angle θe1 of a wall 105e1 is equivalent to an inclination angle θec of a wall 105ec.

Owner:JOLED INC

Soft roasting method

The invention relates to a soft baking method which comprises the following steps: a substrate is heated by a heating plate, wherein, the heating plate is provided with at least one thimble for supporting the substrate; when the substrate is heated, the position where the thimble supports the substrate is changed. In the invention, the position where the thimble supports the substrate is changed when heating is carried out, and the thimble is not contacted with the same position of the glass substrate for a long time; therefore, the problem of uneven film thickness after drying caused by overhigh local temperature on the glass substrate can be avoided.

Owner:AU OPTRONICS CORP

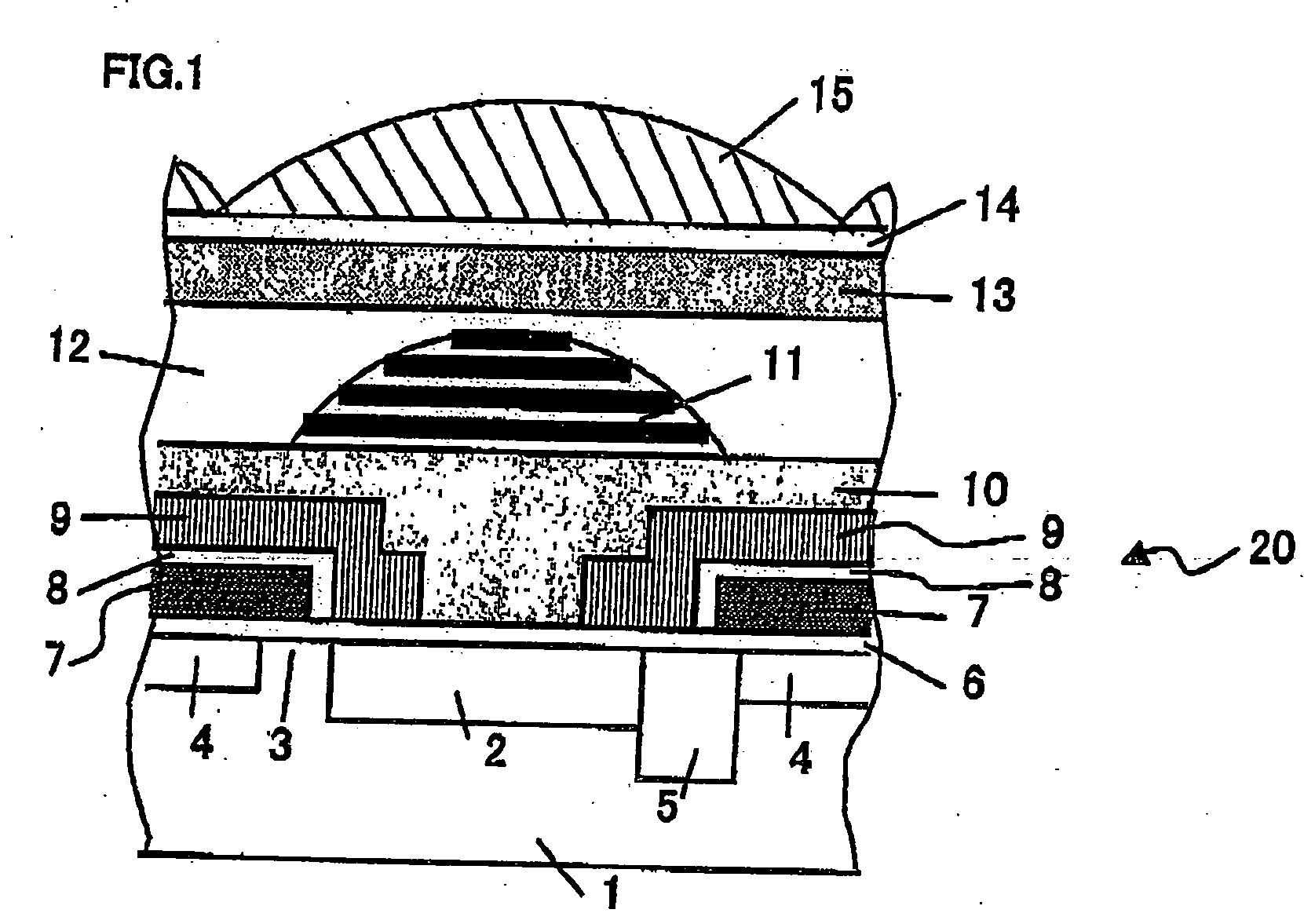

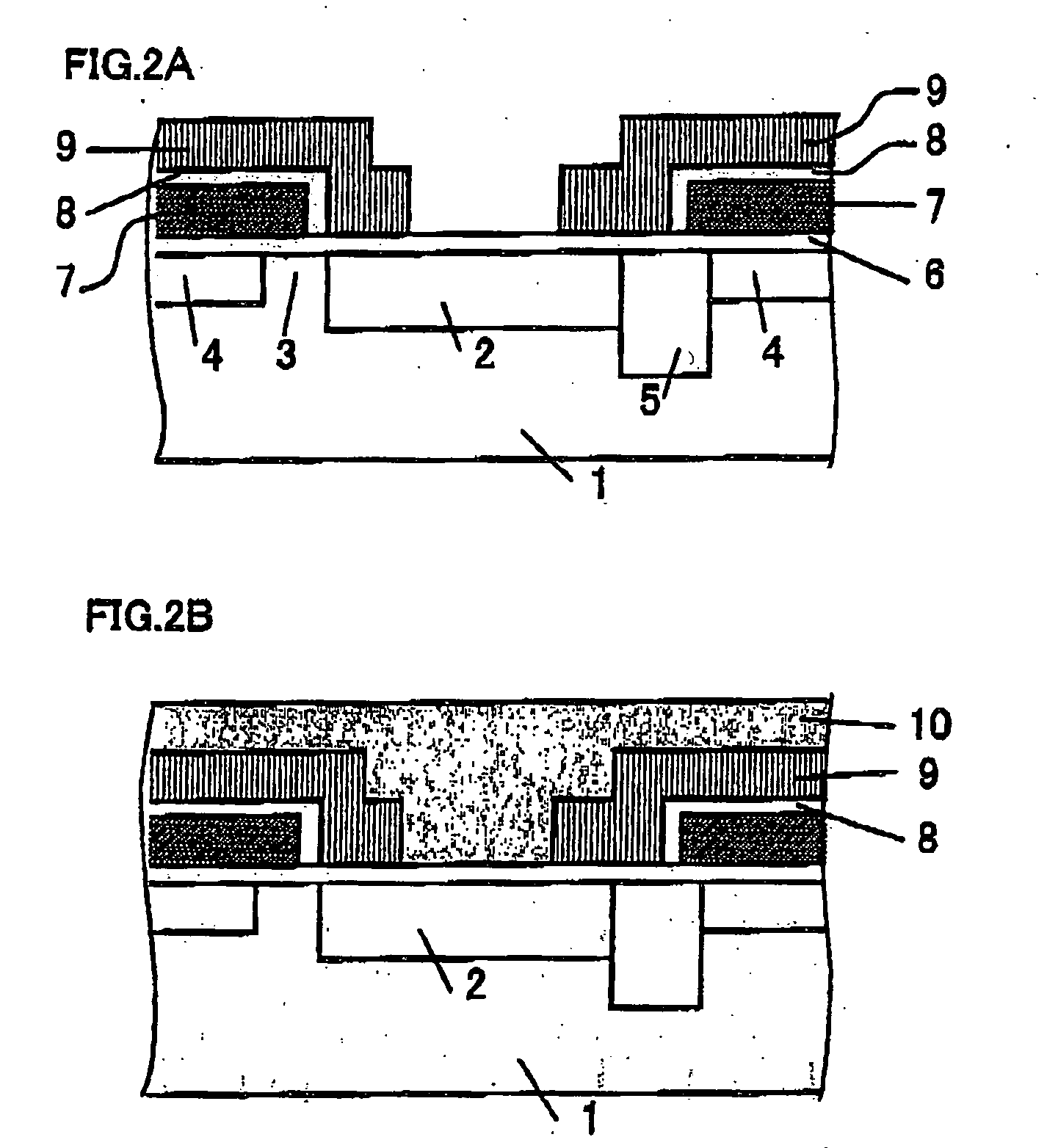

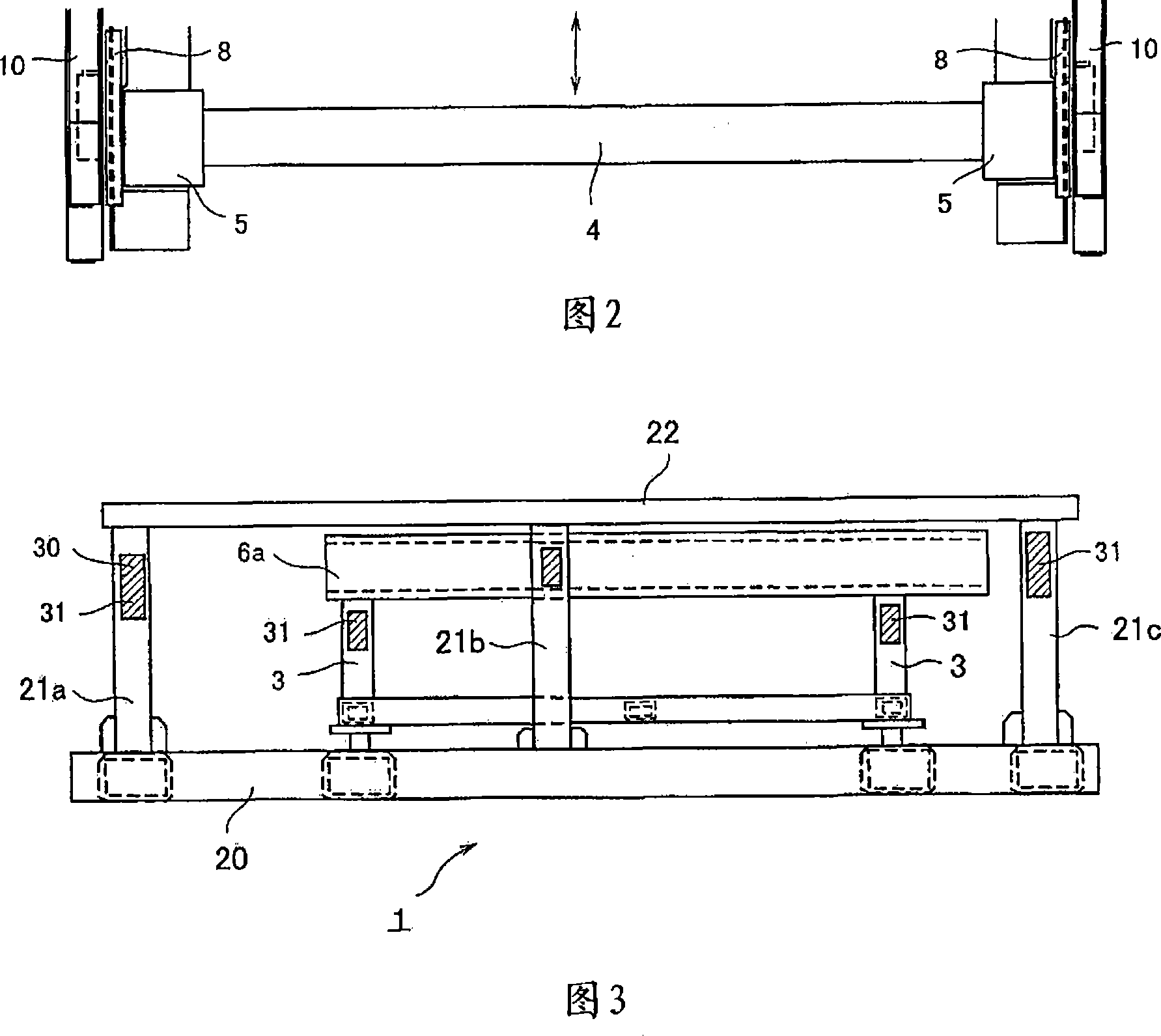

Semiconductor device and method for fabricating the same

InactiveUS20050179103A1Improve film thickness uniformityAvoid uneven film thicknessSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialRefractive index

A semiconductor device comprises a photoelectric conversion portion formed on a semiconductor substrate, a first transparent film provided on the photoelectric conversion portion, and an interlayer lens provided on the first transparent film at a position corresponding to the photoelectric conversion portion, in which the interlayer lens has a higher refractive index than the first transparent film, and at least one of upper and lower surfaces of a second transparent film formed with a thin film multilayer structure of two or more types of compounds is formed to have a protruded shape.

Owner:SHARP KK

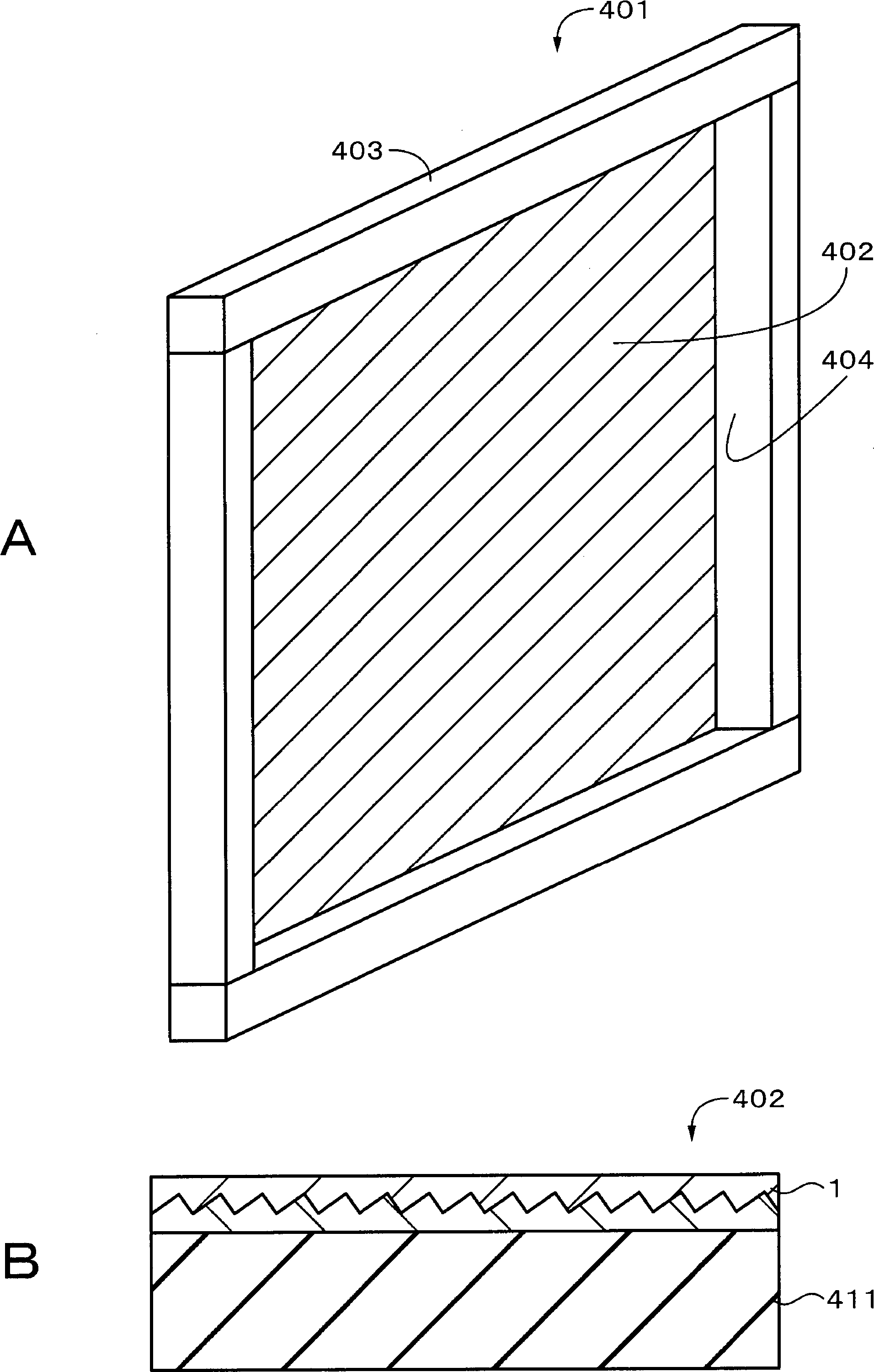

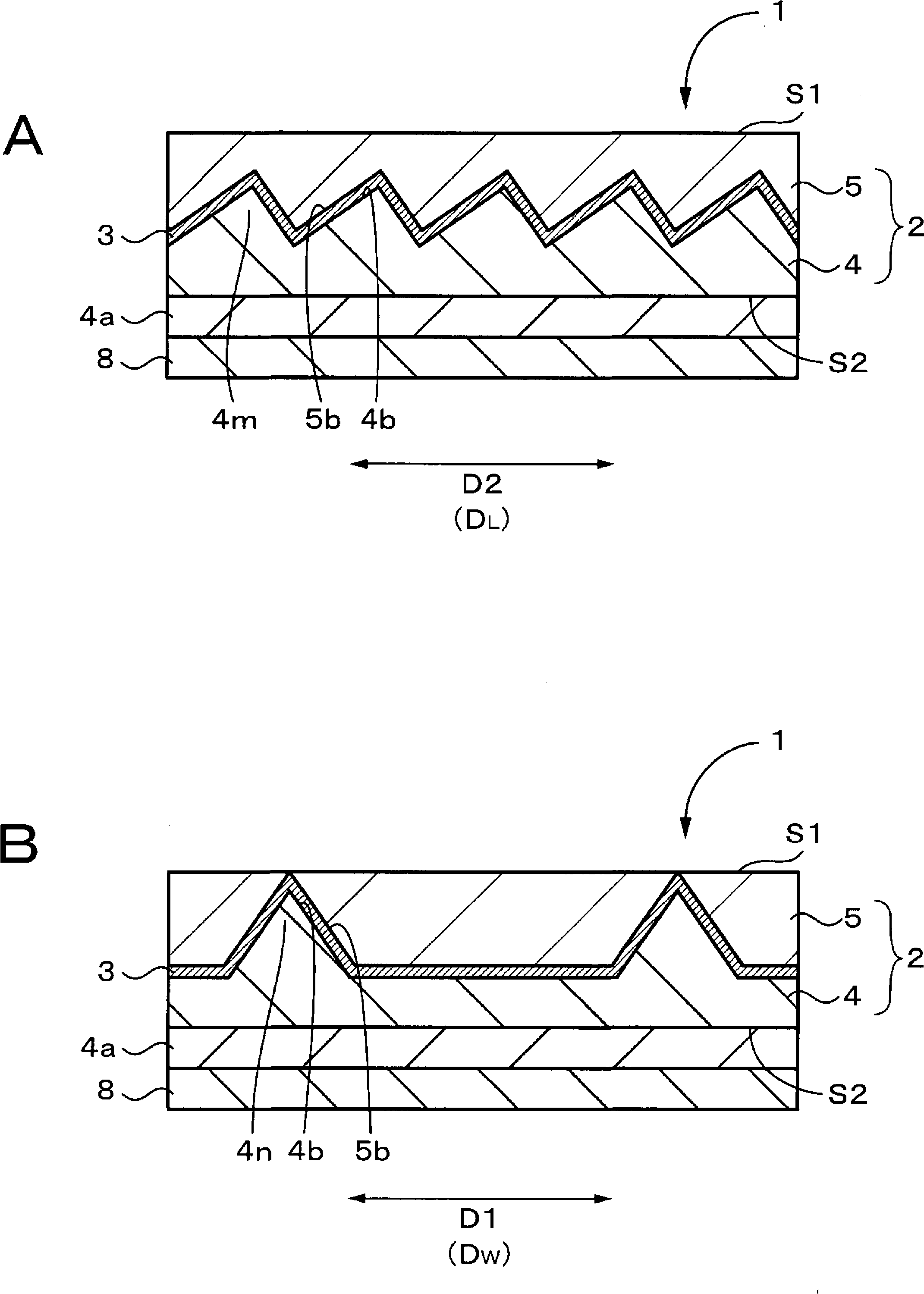

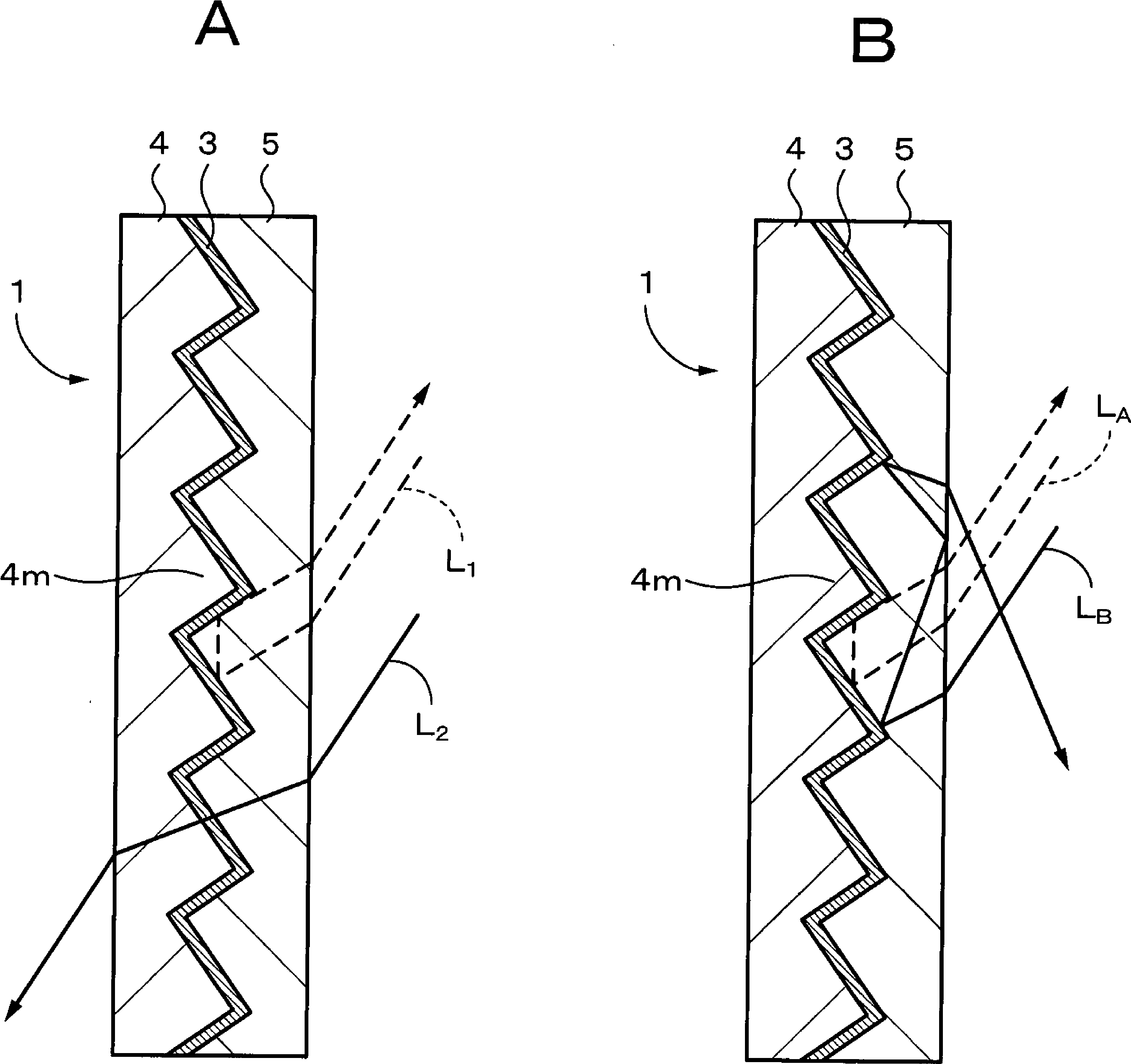

Optical element, window material, fitting, solar shading device, and building

An optical element is provided with an optical layer in which a concavo-convex surface is formed on the surface thereof, and a wavelength-selective reflection layer formed on the concavo-convex surface. The wavelength-selective reflection layer directionally reflects light having a specific wavelength band selectively, while transmitting light having wavelength bands other than the specific wavelength band. The concavo-convex surface is provided with a plurality of first structural elements that are extended in a first direction within the surface of the optical layer and a plurality of second structural elements that are extended in a second direction within the surface of the optical layer, and placed to be spaced apart from each other, with the first direction and the second direction intersecting with each other.

Owner:DEXERIALS CORP

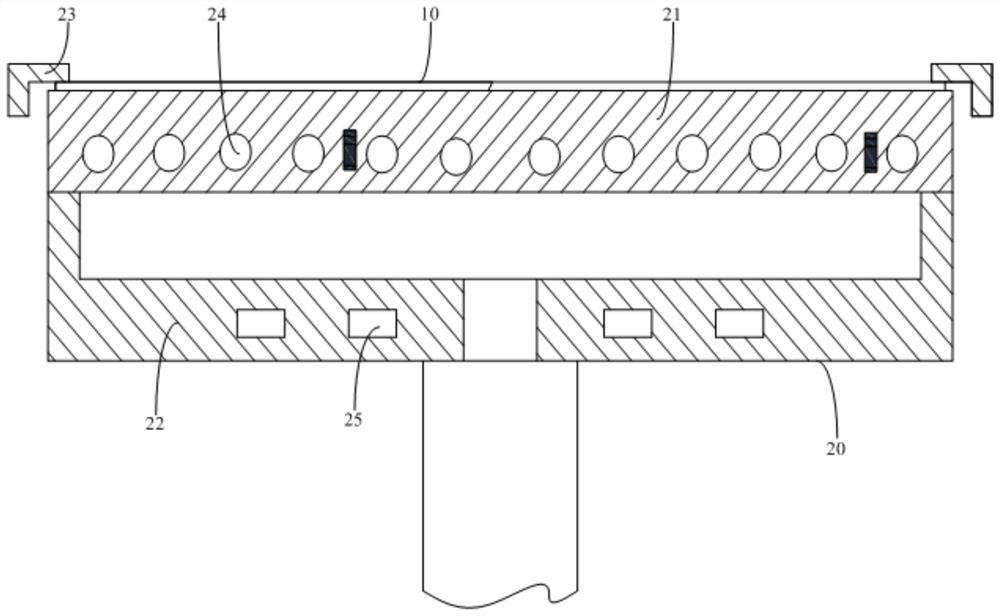

Coating drier with regulating air flow path function

ActiveCN1945437AUniform extractionExtended Airflow PathPhotomechanical coating apparatusOptical elementsResistEngineering

The invention discloses a coating drying equipment with function of adjusting the flow path, including: a reaction chamber, a vacuum system that connects the chamber to extract gas in the chamber, a loading platform that is set in the chamber and includes a loading surface to load a base plate, and a baffle plate structure that is set on the loading surface surrounding the base plate, and its height is more than the thickness of the base plate. Accordingly, when extracting the gas in the chamber, the vacuum system can uniformly extract the solvent in the photoresist layer.

Owner:AU OPTRONICS CORP

Organic light-emitting panel for controlling an organic light emitting layer thickness, and organic display device

InactiveUS8604494B2Avoid uneven film thicknessLarge inclinationSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

Owner:JOLED INC

Method for processing novel anti-dazzle glass

The invention discloses a method for processing novel anti-dazzle glass. The method comprises the following steps: step S1, providing a silicon resin liquid reagent and a glass base material; step S2, washing the surface of the glass base material by an ion electronic runner; step S3, using an IR tunnel kiln to preheat the glass at the heating temperature of 120-150 DEG C; step S4, spraying the silicon resin liquid reagent by a high-pressure atomizing spray gun to form a rough silicon resin film layer on the glass surface; step S5, baking the glass for 40-60 minutes at 180-200 DEG C. By adopting the method, the granularity on the glass surface is effectively reduced, the uniformity and the adhesive force of the film layer are increased, and the haze bias of the same glass is in a range of plus or minus 0.5%; the method is wide in application scope.

Owner:SHENZHEN E TOUCH TECH

Organic light-emitting panel for controlling an organic light emitting layer thickness and organic display device

ActiveUS8604495B2Avoid uneven film thicknessLarge inclinationSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

A non-light-emitting cell 100c is provided between pixels 100a and 100b. Ink for forming an organic light-emitting layer is dripped substantially simultaneously into sub-pixels 100a1, 100a2, and 100a3 in the pixel 100a and a sub-pixel 100b1 in the pixel 100b. On the other hand, such ink is not dripped into the non-light-emitting cell 100c since the organic light-emitting layer is not formed in the non-light-emitting cell 100c. In a bank 105d, an inclination angle θd3 of a wall 105d3 facing the sub-pixel 100a3 is larger than an inclination angle θdc of a wall 105dc facing the non-light-emitting cell 100c. Similarly, in a bank 105e, an inclination angle θe1 of a wall 105e1 facing the sub-pixel 100b1 is larger than an inclination angle θec of a wall 105ec facing the non-light-emitting cell 100c.

Owner:JOLED INC

Organic light-emitting panel for controlling an organic light emitting layer thickness and organic display device

ActiveUS8604492B2Avoid uneven film thicknessLarge inclinationElectroluminescent light sourcesSolid-state devicesDisplay deviceOptoelectronics

A non-light-emitting cell 100c is provided between pixels 100a and 100b. Ink for forming an organic light-emitting layer is dripped substantially simultaneously into sub-pixels 100a1, 100a2, and 100a3 in the pixel 100a and a sub-pixel 100b1 in the pixel 100b. On the other hand, such ink is not dripped into the non-light-emitting cell 100c since the organic light-emitting layer is not formed in the non-light-emitting cell 100c. Regarding two banks 105c and 105d defining the sub-pixel 100a3, an inclination angle θd3 of a wall 105d3 of the bank 105d is larger than an inclination angle θc3 of a wall 105c3 of the bank 105c. Similarly, regarding banks 105e and 105f defining the sub-pixel 100b1, an inclination angle θe1 of a wall 105e1 of the bank 105e is larger than an inclination angle θf1 of a wall 105f1 of the bank 105f.

Owner:JOLED INC

Organic light-emitting panel for controlling an organic light emitting layer thickness and organic display device

InactiveUS8604493B2Avoid uneven film thicknessLarge inclinationElectroluminescent light sourcesSolid-state devicesDisplay deviceEngineering

A non-light-emitting cell 100c is provided between pixels 100a and 100b. In formation of the light-emitting cell 100a, ink for forming an organic light-emitting layer is dripped into sub-pixels 100a1, 100a2, 100a3 in this order. This also applies to the light-emitting cell 100b. However, such ink is not dripped into the non-light-emitting cell 100c since the organic light-emitting layer is not formed in the non-light-emitting cell 100c. Regarding a bank 105d between the sub-pixel 100a3 and the non-light-emitting cell 100c, an inclination angle θd3 of a wall 105d3 is larger than an inclination angle θdc of a wall 105dc. On the other hand, regarding a bank 105e between the sub-pixel 100b1 and the non-light-emitting cell 100c, an inclination angle θe1 of a wall 105e1 is equivalent to an inclination angle θec of a wall 105ec.

Owner:JOLED INC

Ink-jet printing methods, devices, and system, computer equipment, and storage medium

ActiveCN110091592AShorten the intervalAvoid uneven film thicknessDuplicating/marking methodsTypewritersSpray nozzleComputer engineering

The invention relates to an ink-jet printing method, device, and system, computer equipment, and a storage medium. The ink-jet printing method includes the following steps: the number of multiple participation spray nozzles is obtained for multiple preset ink-jet angles; the number of the participation spray nozzles includes the number of spray nozzles participating in ink-jet when a printing taskis performed; an ink-jet angle with a maximum number of the participation spray nozzles is utilized as a target ink-jet angle; and the target ink-jet angle is transmitted to ink-jet printing equipment for the ink-jet printing equipment to perform the printing task according to the target ink-jet angle. Through the ink-jet printing method of the invention, the performance of an OLED device is improved.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

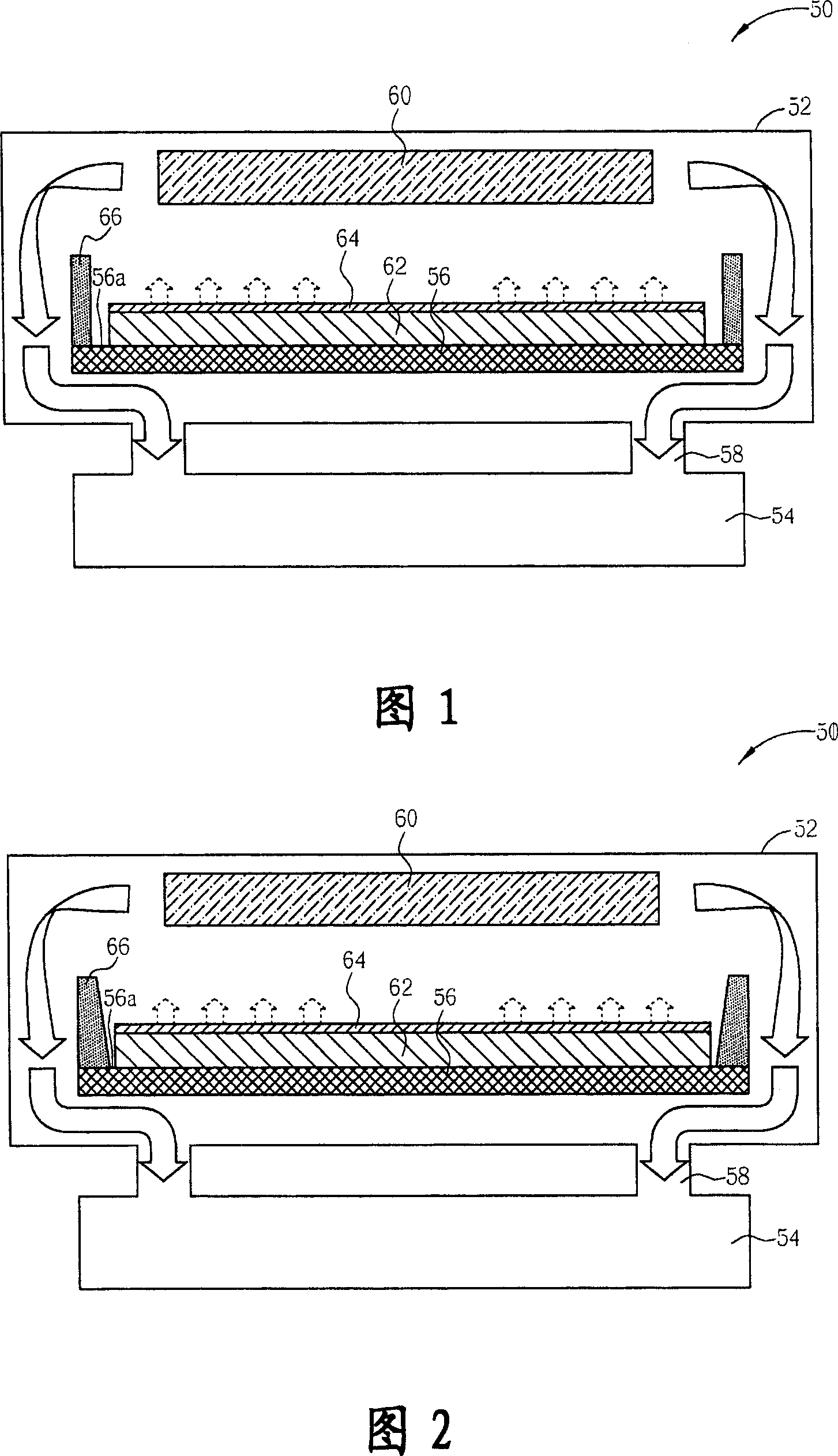

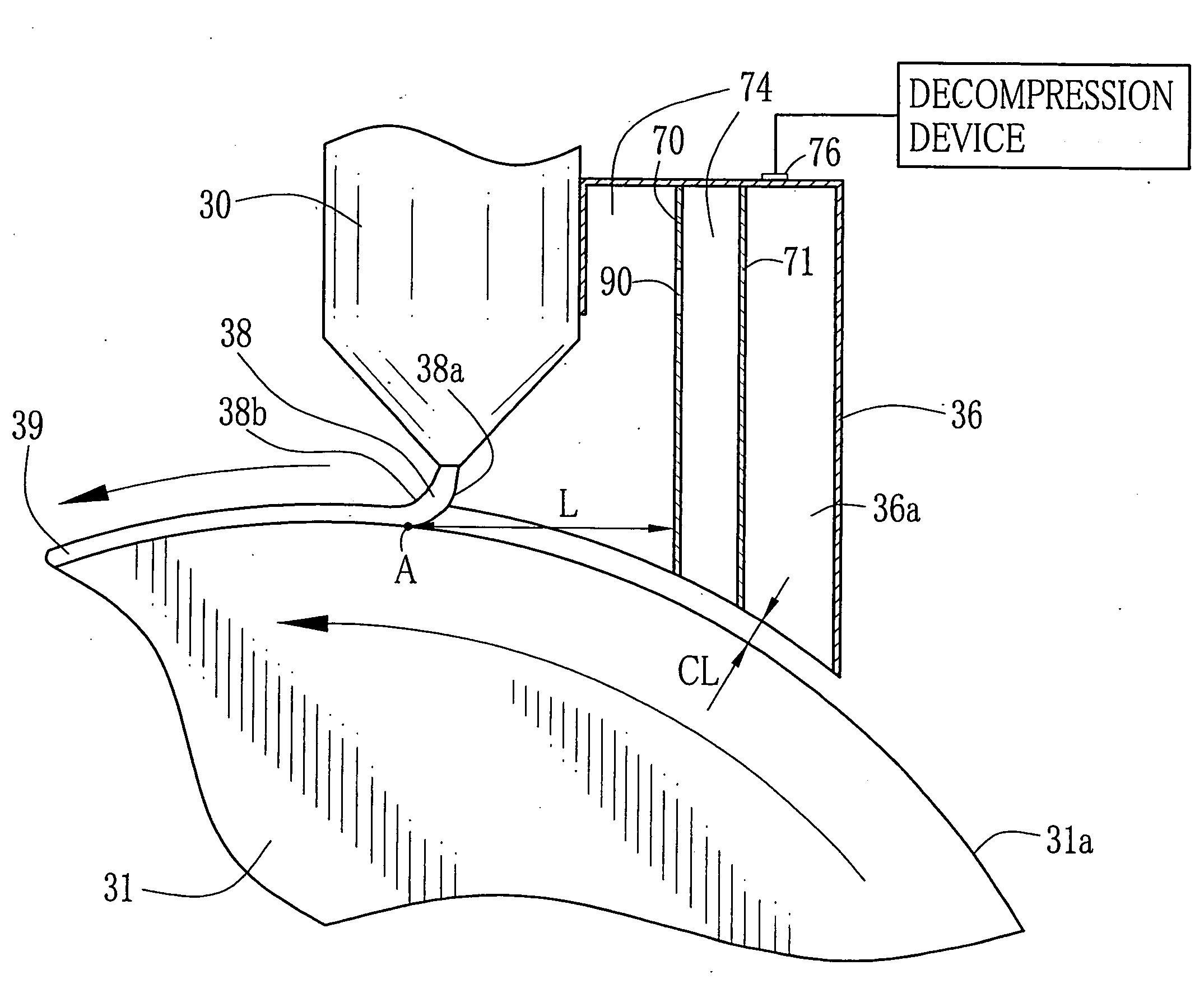

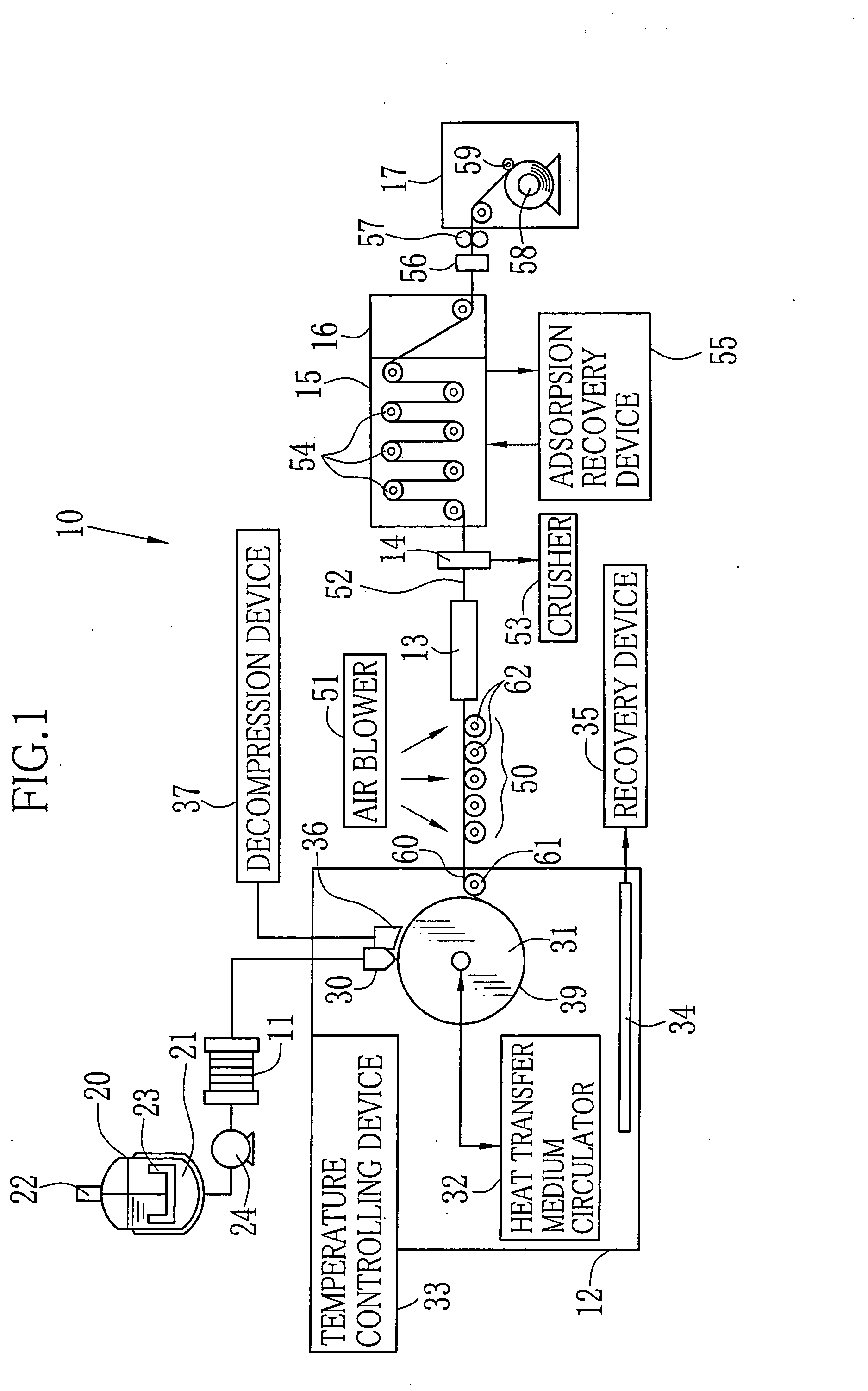

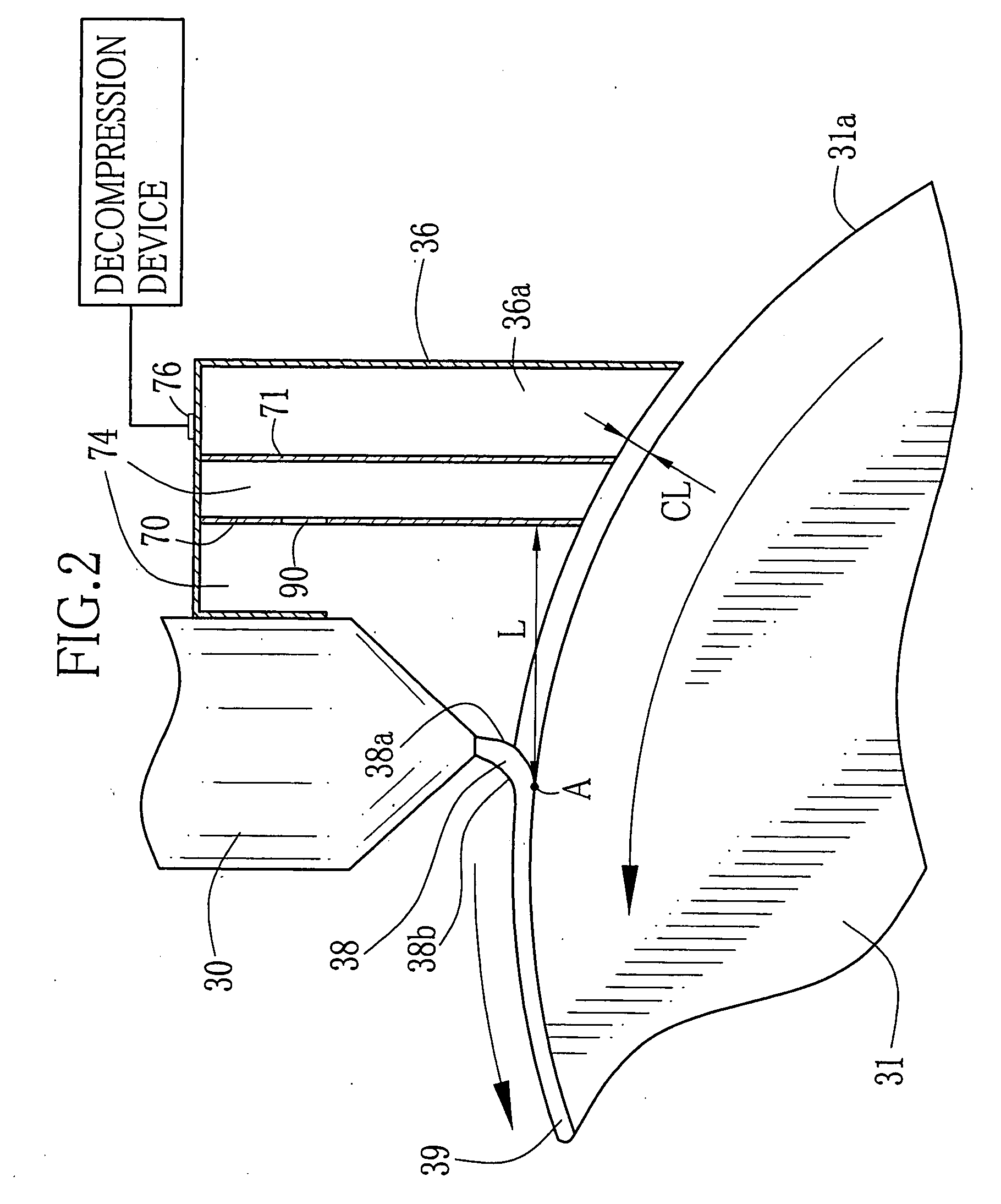

Solution Casting Method

InactiveUS20080191376A1Avoid changeAvoid uneven film thicknessFlat articlesCoatingsDecompression chamberAtmospheric pressure

A dope including a polymer and a solvent is discharged from a casting die (30) to a casting drum (31) while forming a casting bead (38). An upstream side (38a) area of the casting bead (38) is decompressed by a decompression chamber (36) to (atmospheric pressure—300)Pa. Air shielding plates (70, 71) are provided inside the decompression chamber (36). Openings (90) are respectively formed in upper half portions of the air shielding plates (70, 71). A distance L (mm) between a contact position A of the casting bead (38) and the air shielding plate (70) is set in the range of 20 mm to 100 mm. After the casting bead (38) forms a casting film (39) on the casting drum (31), the casting film (39) is peeled and dried to obtain a TAC film.

Owner:FUJIFILM CORP

Filmforming method and device

InactiveCN1184667CAvoid uneven film thicknessShorten the timePretreated surfacesSemiconductor/solid-state device manufacturingTectorial membraneResist

The invention provides a film forming method and device. A liquid film formation section is composed of a resist dropping nozzle 102, a nozzle movement mechanism not shown in a figure that moves the resist dropping nozzle 102 in a y direction (a horizontal direction on page space), and the movement rest of the substrate 110 to be treated not shown in the figure where the substrate 110 to be treated having a diameter of 200 mm is installed and is moved in an x direction. A liquid film drying section is composed of a suction nozzle 101, and a vacuum pump 103 connected to the suction nozzle 101. Also, the movement rest of the substrate to be treated is also one of the components of the liquid film drying section. The invention is able to suppress the generation of film thickness distribution in an application film, and at the same time to shorten time for forming the application film.

Owner:KK TOSHIBA

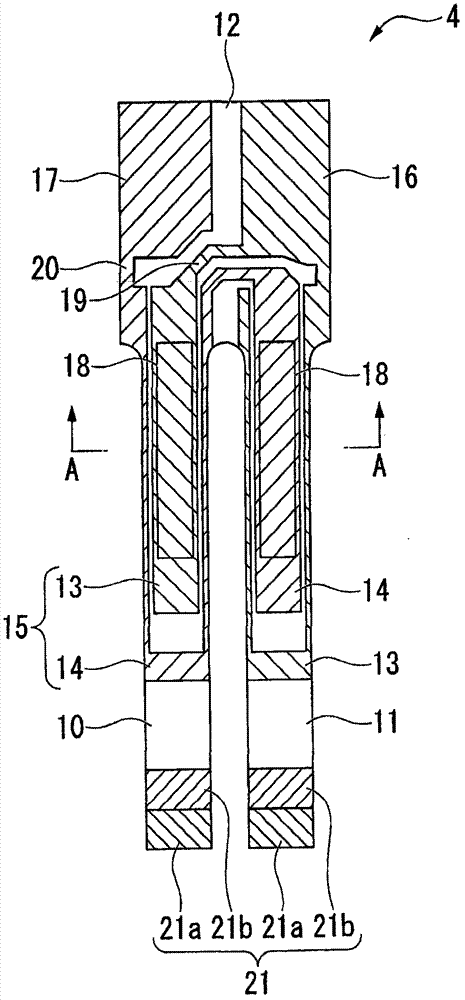

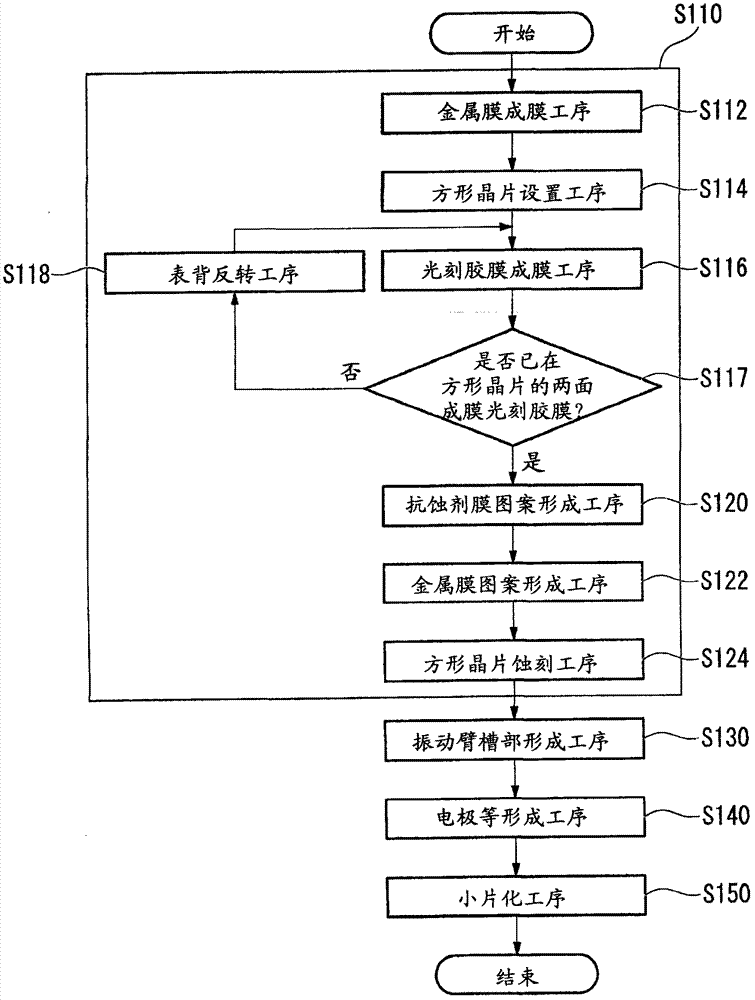

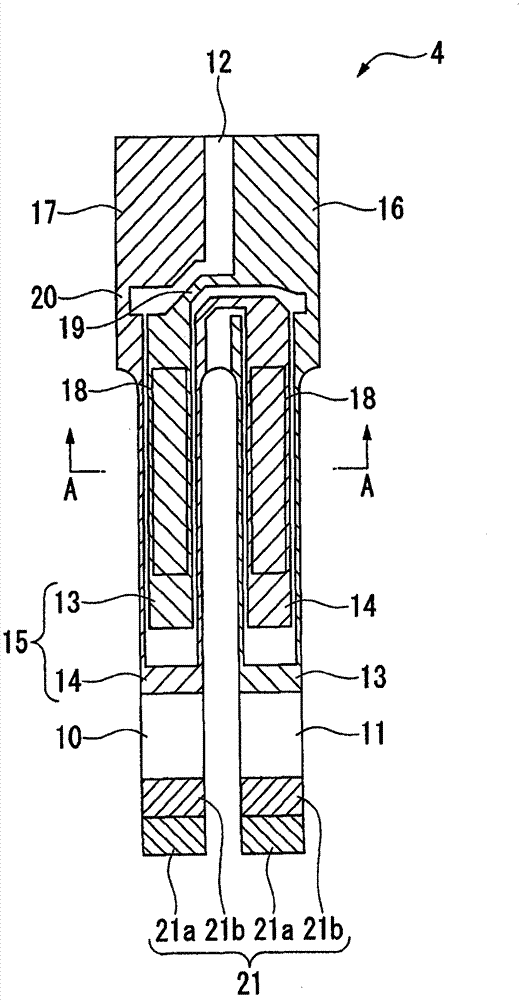

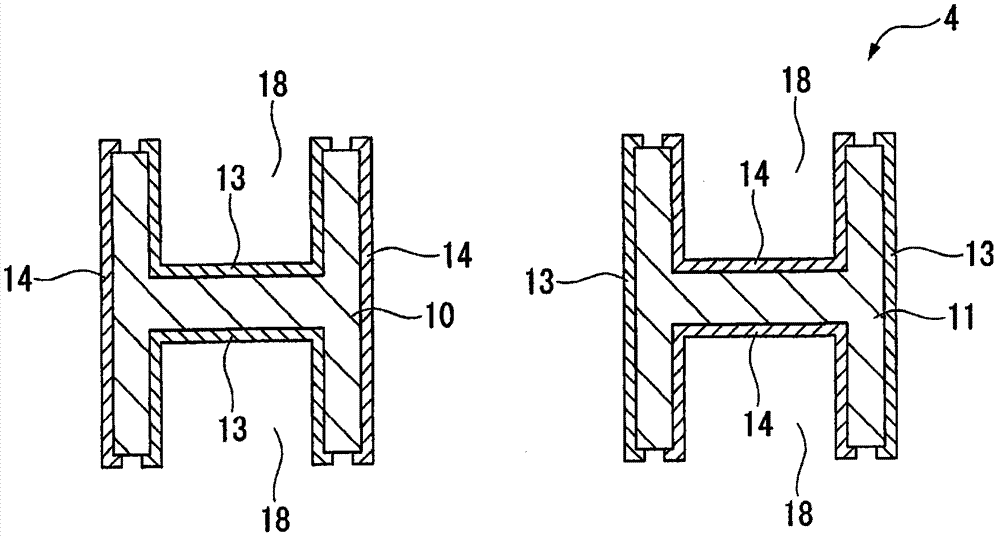

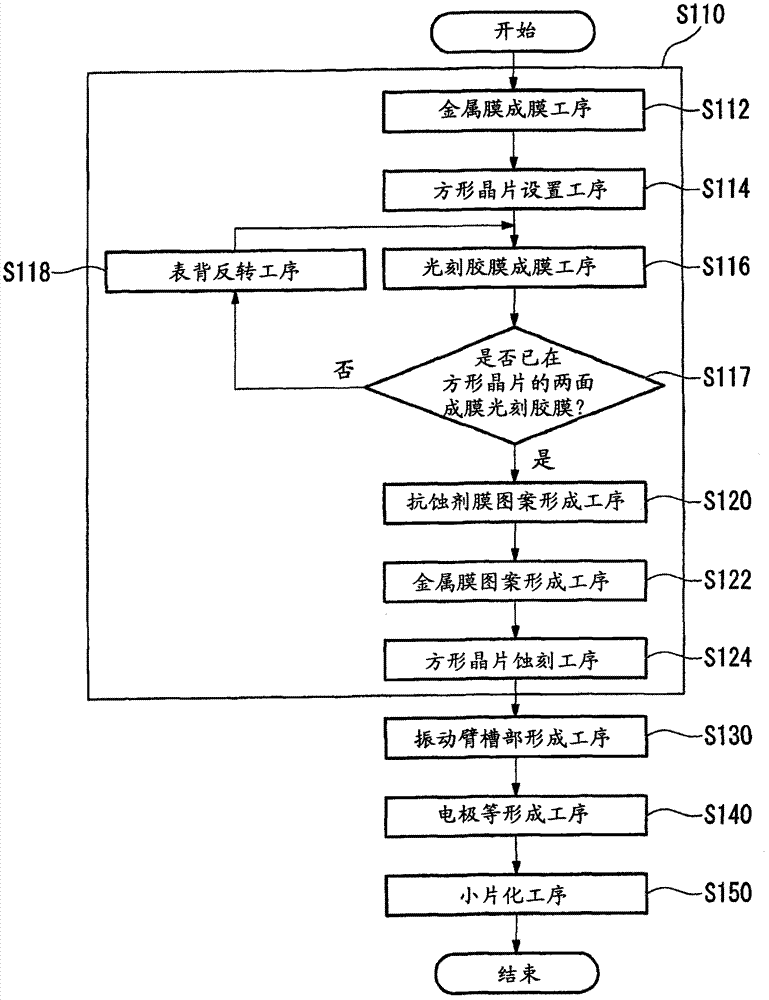

Method and apparatus of manufacturing piezoelectric vibrating reed, piezoelectric vibration reed, piezoelectric vibrator, oscillator, electronic apparatus and radio-controlled timepiece

InactiveCN102780466ALow costGuaranteed flow ratePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksCentre of rotationEngineering

Owner:SEIKO INSTR INC

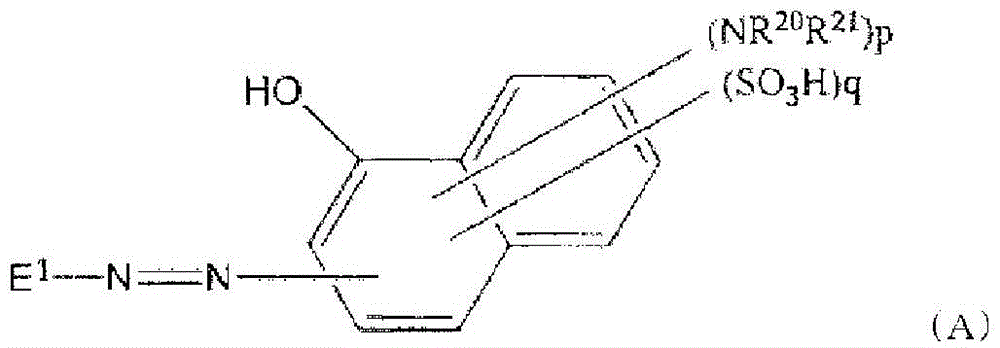

Method for manufacturing anisotropic dye film, anisotropic dye film manufactured by said manufacturing method, optical element including said anisotropic dye film, and liquid crystal element including said optical element

ActiveCN105531037AImprove polarization performanceAvoid uneven film thicknessLiquid surface applicatorsPolarising elementsViscosityLiquid crystal

The problem addressed by the present invention is providing a die having a lip with a specific shape so as to be able to obtain a uniformly applied film with minimal occurrences of variations in thickness and application streaking when applying a composition for anisotropic dye film formation. The problem above is addressed by a method for manufacturing an anisotropic dye film that includes a step for applying a composition for anisotropic dye film formation onto a substrate using a die coater. The method for manufacturing the anisotropic dye film is characterized by the die coater having a front lip positioned on the direction of travel side of the die coater and a rear lip positioned on the side opposite to the direction of travel, and both lips having respective lip lower edge surfaces facing the substrate. Letting A be the length for the lower edge surface of the front lip along the direction of travel and B be the length of the lower edge surface of the rear lip along the direction of travel, A>B. The viscosity of the composition for anisotropic dye film formation is 10 cP or greater.

Owner:MITSUBISHI RAYON CO LTD

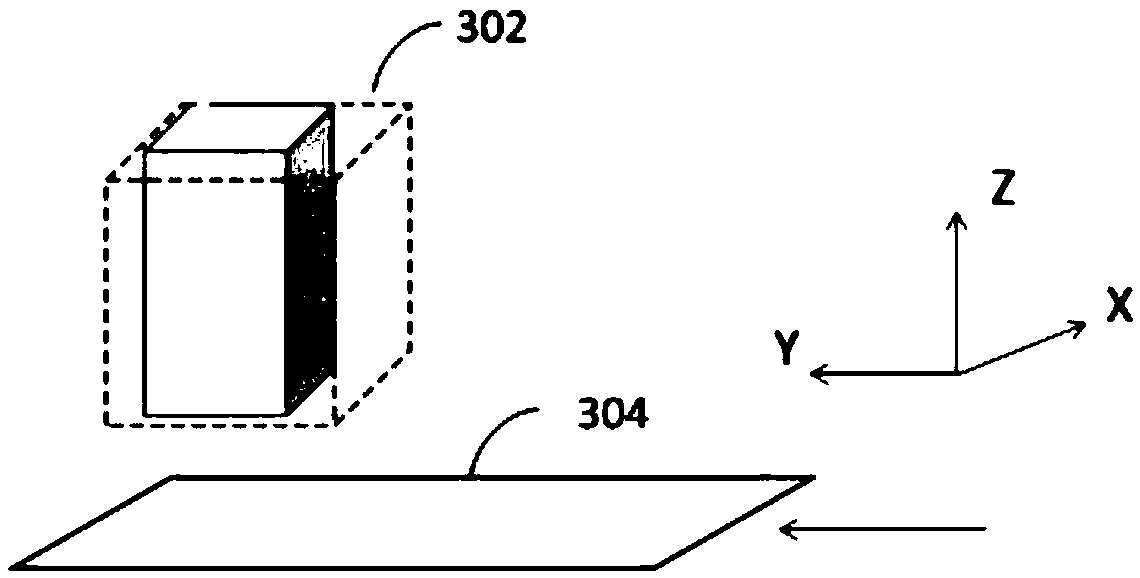

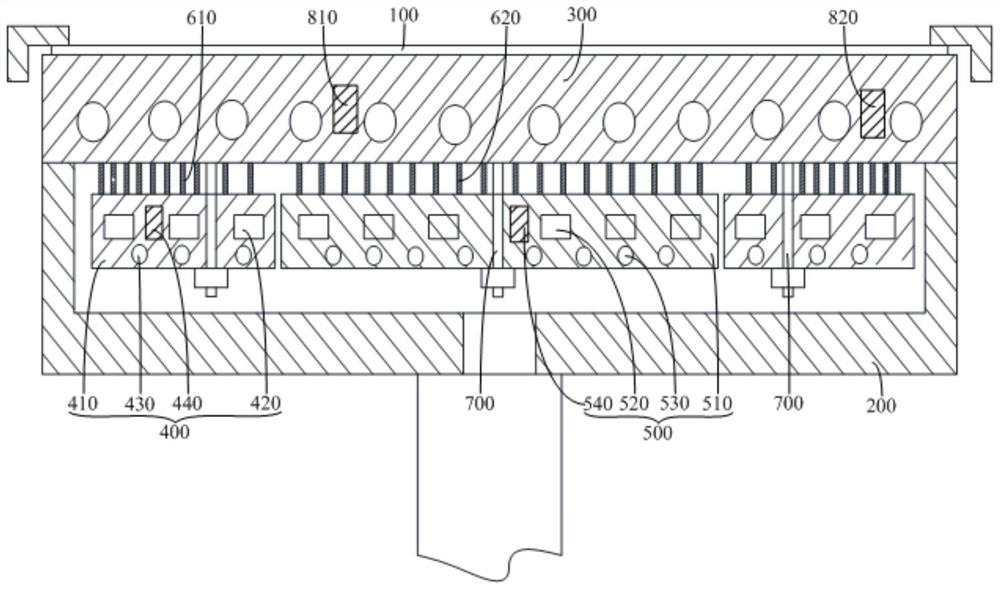

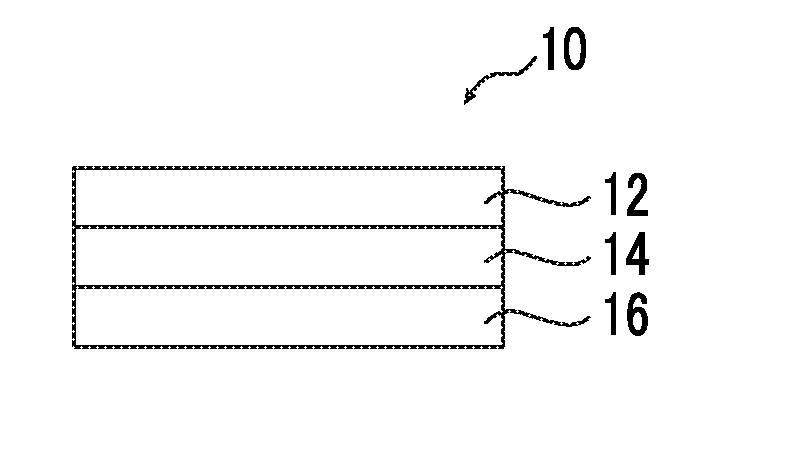

Base assembly and semiconductor processing equipment

ActiveCN112144033AUniform temperature distributionGood film uniformityVacuum evaporation coatingSputtering coatingMechanical engineeringSemiconductor

The invention discloses a base assembly and semiconductor processing equipment. The base assembly is used for bearing and heating a to-be-processed workpiece (100) in the semiconductor processing equipment, the base assembly comprises a bearing part (300) and a cooling module, wherein a first surface of the bearing part (300) bears the to-be-processed workpiece (100), and the cooling module comprises a first cooling mechanism (400) and a second cooling mechanism (500); the first cooling mechanism (400) and the second cooling mechanism (500) are both in heat conduction connection with a secondsurface, deviating from the first surface, of the bearing part (300); and the cooling capacity of the first cooling mechanism (400) and the cooling capacity of the second cooling mechanism (500) are adjustable. The scheme can solve the problem that the temperature of an outer edge area of a heating plate is higher than that of the middle area.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

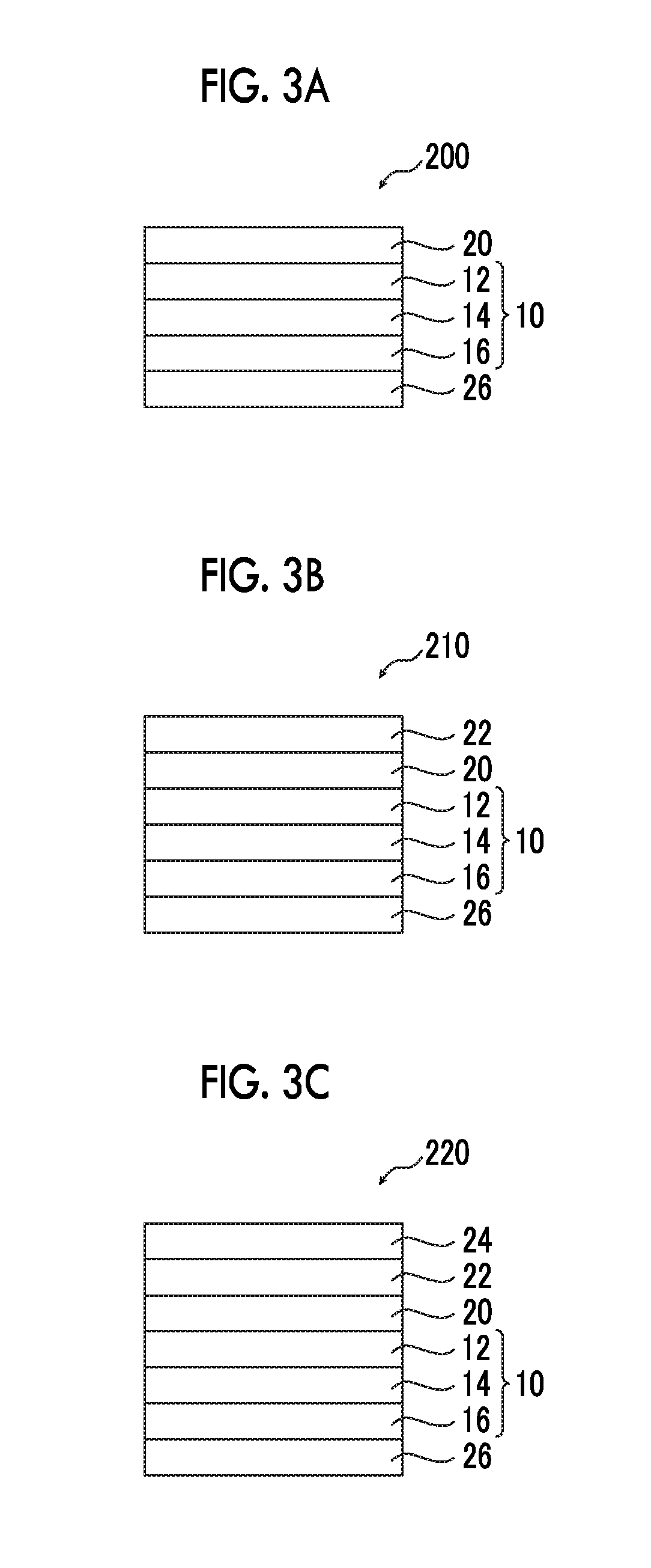

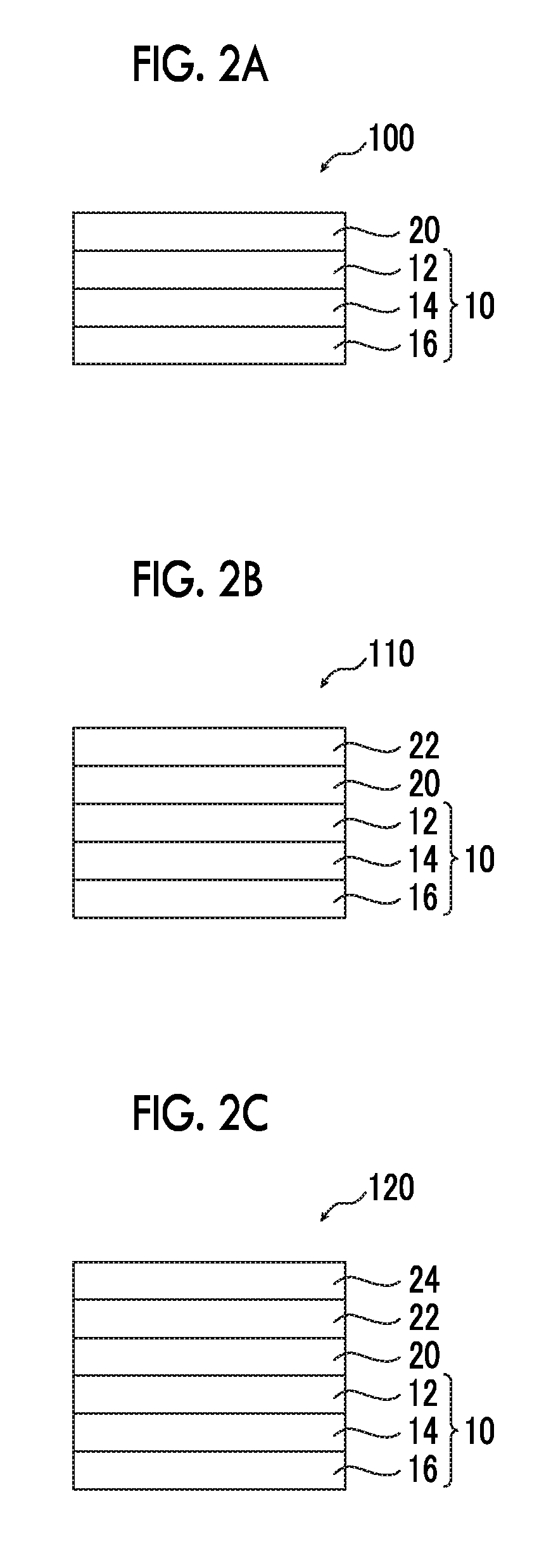

Optical laminate, polarizing plate and organic EL display device

ActiveUS10459136B2High surface energyLower surface energyLiquid crystal compositionsLayered productsDisplay devicePolarizer

The present invention provides an optical laminate in which cissing occurring when an optically anisotropic layer is formed and film thickness unevenness are suppressed, and a polarizing plate and an organic EL display device using the same. The optical laminate includes an optically anisotropic layer A, and an optically anisotropic layer B, where layer A and layer B come into direct contact, either or both of layer A and layer B are formed of a composition containing a liquid crystal compound, surface energy A of a surface of layer A on a side in contact with layer B is 30 to 40 mN / m, surface energy B1 of a surface of layer B on a side in contact with layer A is 35 mN / m or more, and surface energy B2 of a surface of layer B opposite to the side in contact with layer A is 25 mN / m or less.

Owner:FUJIFILM CORP

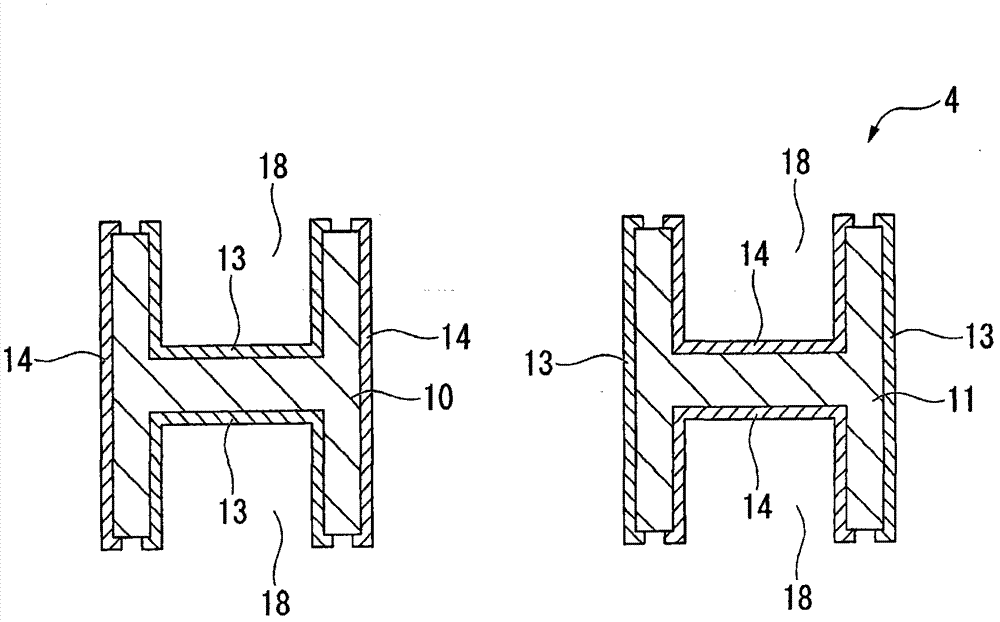

Method and apparatus of manufacturing piezoelectric vibrating reed, piezoelectric vibration reed, piezoelectric vibrator, oscillator, electronic apparatus and radio-controlled timepiece

InactiveCN102780465ACurb spreadInhibit handlingImpedence networksElectric windingGreek letter betaPiezoelectric actuators

A photoresist film forming process to form a film through a spin coating method is included, a plurality of groove portions (90) and a plurality of wall portions (95) are formed in an upper surface (88a) of a flow regulating plate (88), among the plurality of groove portions (90), the diameter of the outer side surface (91a) of a first groove portion (91) is set to be smaller than the longest distance (alpha) from the rotation center (K) to the outer edge (66) of the square wafer (65), and is set to be larger than the shortest distance (beta) from the rotation center (K) to the outer edge (66) of the square wafer (65), and among the plurality of groove portions (90), the diameter of the outer side surface (92a) of a second groove portion (92) is set to be smaller than the shortest distance (beta) from the rotation center (K) to the outer edge (66) of the square wafer (65).

Owner:SEIKO INSTR INC

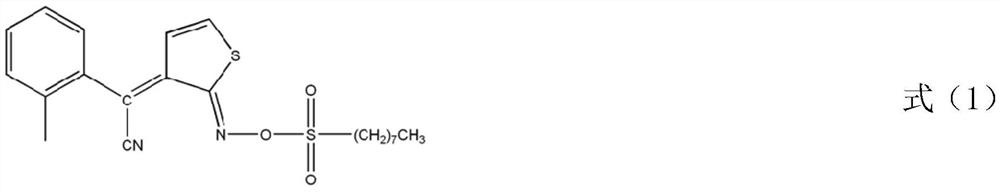

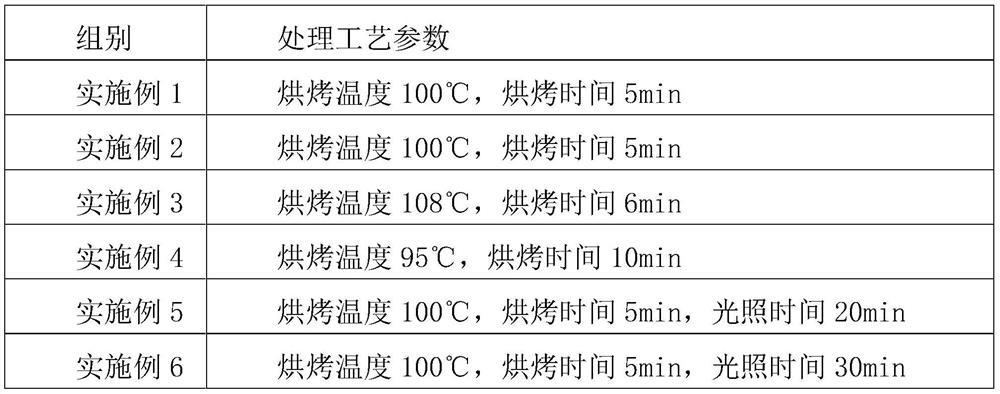

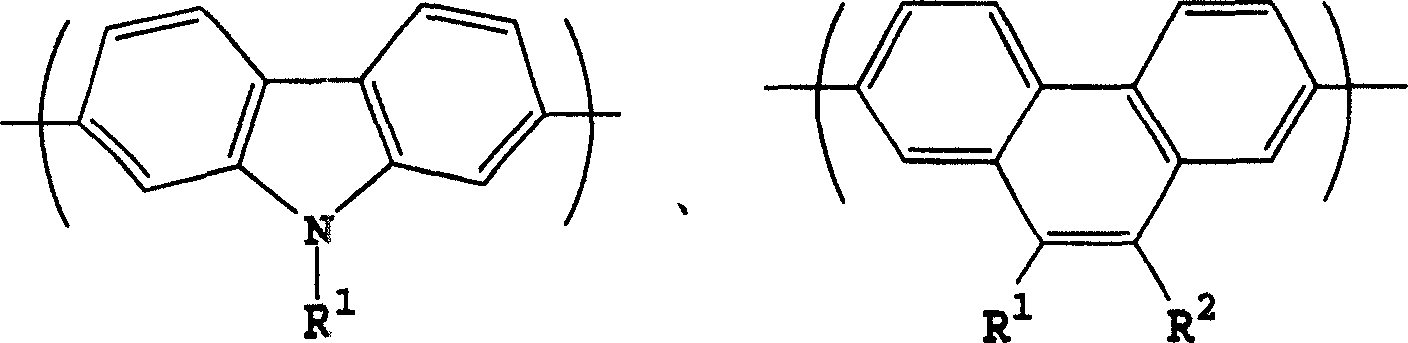

A polysilazane coating material, preparation method and application method

ActiveCN110157332BHigh molecular weightAchieve solidificationPretreated surfacesCoatingsAlkanePolymer science

The invention relates to the field of coating materials, in particular to a preparation method and an application method of a polysilazane coating material. The preparation method of the polysilazane coating material specifically includes: obtaining a polysilazane solution through a predetermined synthesis method; diluting the polysilazane solution and adding an initiator to obtain a mixed solution; The solution is filtered through a filter to obtain the coating material. By adding an initiator to the polysilazane solution, heating or light after coating will generate free radicals to promote the increase of the molecular weight of the resin and the hinge reaction to increase the molecular weight, making the conversion process faster, and curing the resin at low temperature to prevent the occurrence of film The problem of uneven thickness.

Owner:福建恒晶新材料科技有限公司

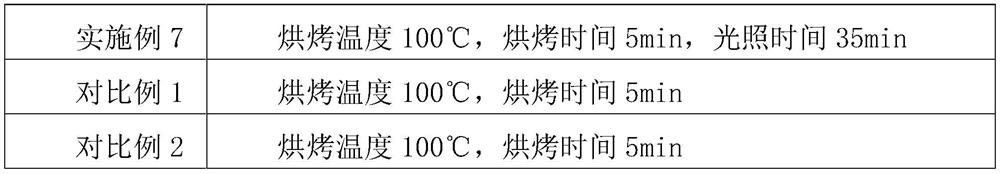

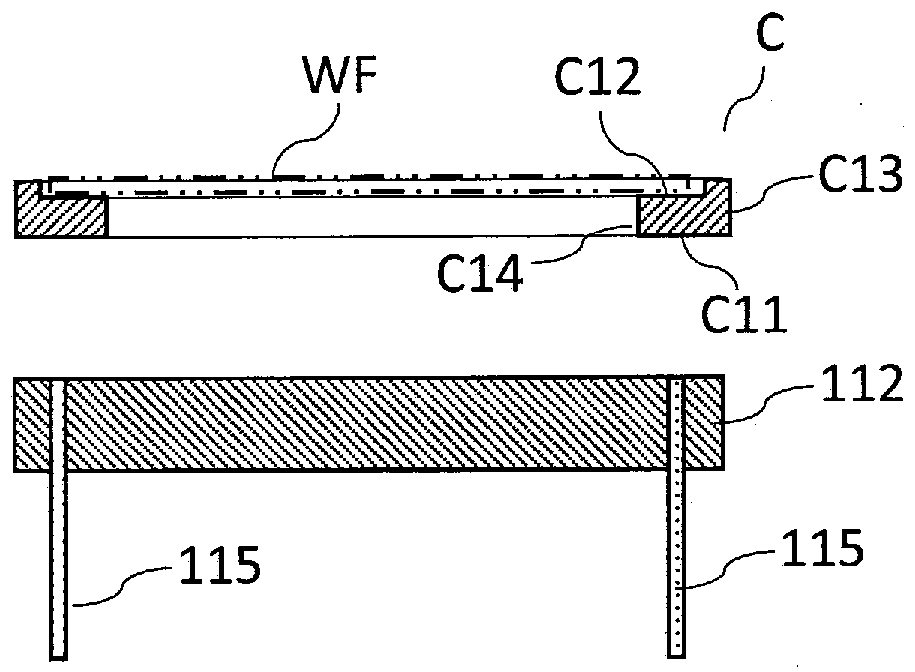

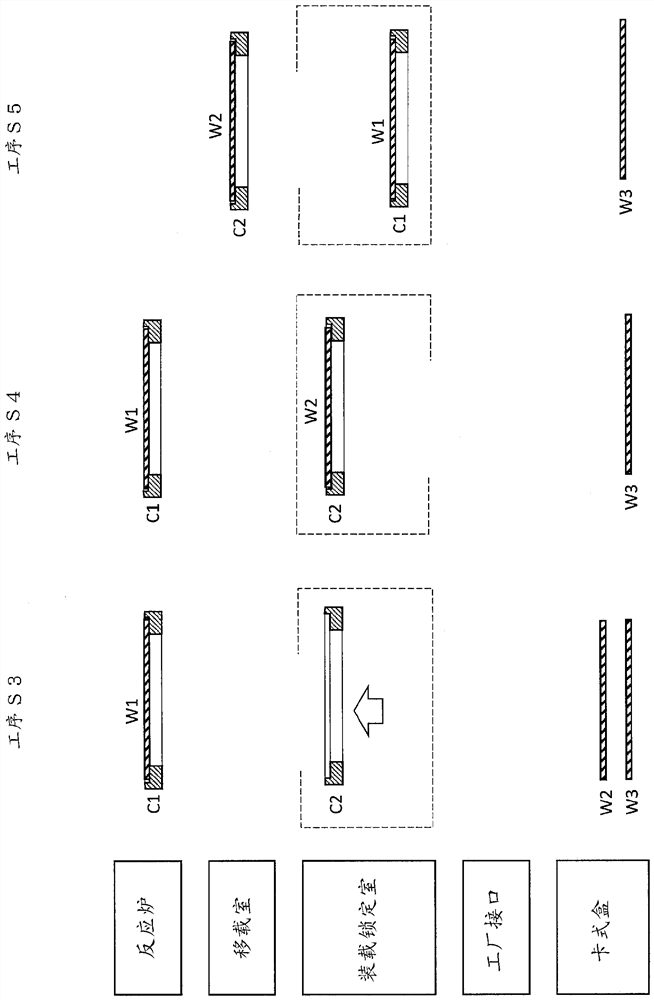

Vapor phase growth device and carrier used in same

PendingCN113544319AAvoid uneven film thicknessUniform film thicknessAfter-treatment apparatusPolycrystalline material growthSusceptorCrystal orientation

Provided is a vapor phase growth device by which the thickness of a CVD film on the edge of a wafer can be made uniform. A carrier (C) is formed into an endless ring shape and includes: a bottom surface (C11) mounted on the top surface of a susceptor (112); a top surface (C12) that contacts the outer edge of the rear surface of a wafer (WF) and supports same; an outer circumferential wall surface (C13); and an inner circumferential wall surface (C14). The structure or shape of the top surface (C12) in the circumferential direction is a structure or shape having a correspondence relationship with respect to the crystal orientation in the circumferential direction of the wafer (WF). A wafer that has yet to be processed is mounted on the carrier such that the crystal orientation in the circumferential direction of the wafer that has yet to be processed and the structure or shape of the wafer in the circumferential direction have a correspondence relationship.

Owner:SUMCO CORP

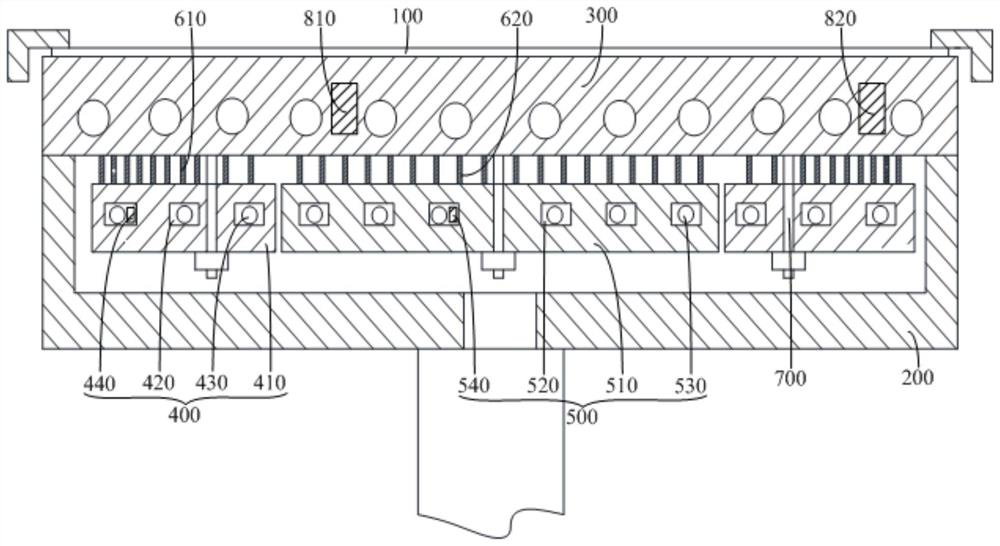

Method of producing optical laminate, optical laminate, polarizing plate and organic el display device

ActiveUS9977165B2Avoid uneven film thicknessPoint defectLiquid crystal compositionsElectroluminescent light sourcesComposition BDisplay device

The present invention provides an optical laminate which is suppressed in film thickness unevenness of an optically anisotropic layer and is free from point defects, a method of producing the same, and a polarizing plate and an organic EL display device using the optical laminate. The method of producing an optical laminate having an optically anisotropic layer A and an optically anisotropic layer B, includes where the layer A and the layer B are provided in direct contact with each other. The method further includes where both a composition a for forming the layer A and a composition b for forming the layer B contain a fluorine compound, and when the layer A is formed using composition a and layer B is formed using composition b, layer A and layer B are formed in this order under the condition that composition a and composition b satisfy predetermined surface tension relationships.

Owner:FUJIFILM CORP

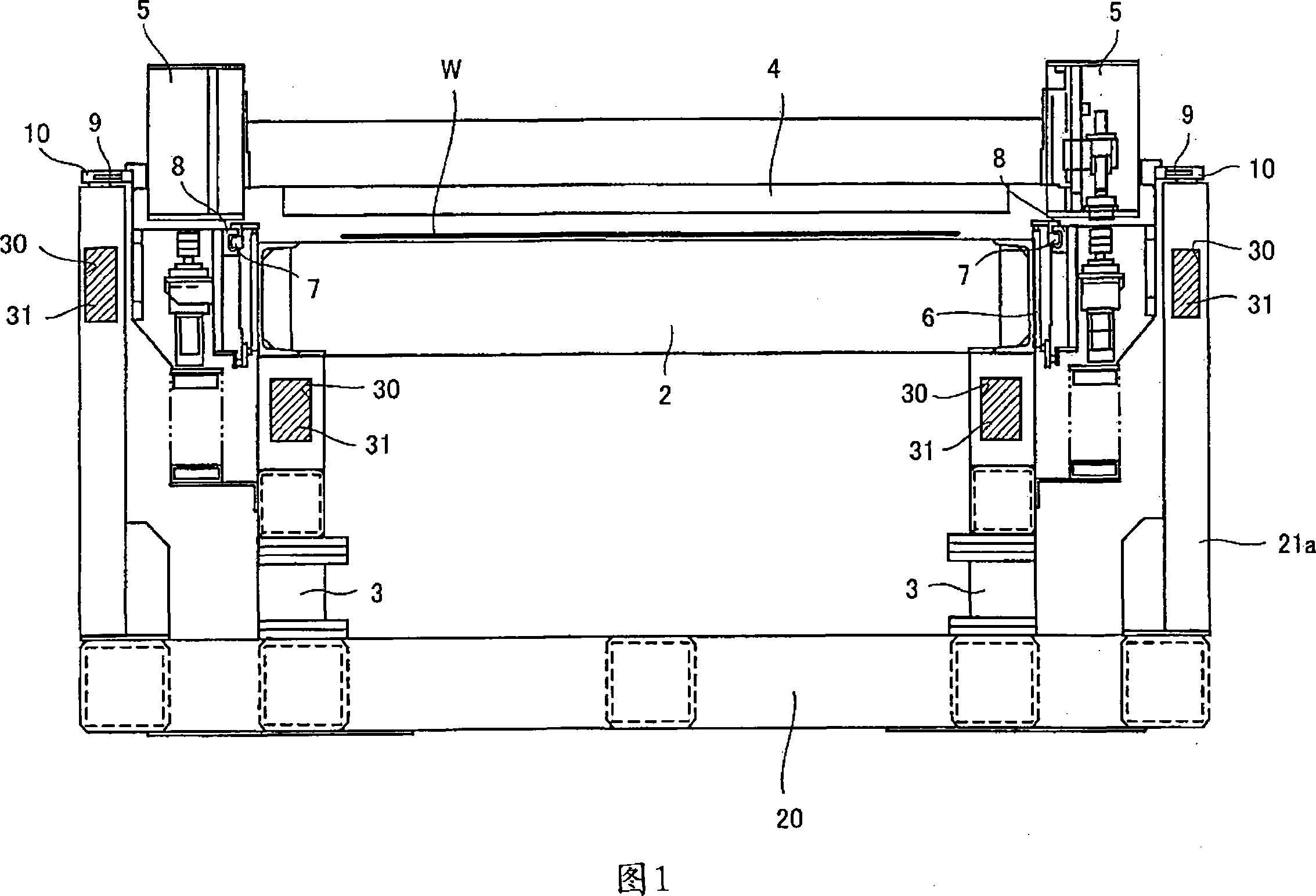

Coating device

InactiveCN101134189APrevent resonanceAvoid uneven film thicknessLiquid surface applicatorsSemiconductor/solid-state device manufacturingResonanceEngineering

The invention provides a coating device for weakening the influence of external vibration, in particular for inhibitting resonance caused by external vibration effectively. An anti-resonance portion (31) is filled in a suppoting carrier (2) and a cove (30) of square pipes (20, 21a-21c) of a slit nozzle travel mechanism. Beacuse filling the anti-resonance portion in square pipes can change the natural vibration frequency of a base (1), a resonance state can not be got because of external vibration.

Owner:TOKYO OHKA KOGYO CO LTD +1

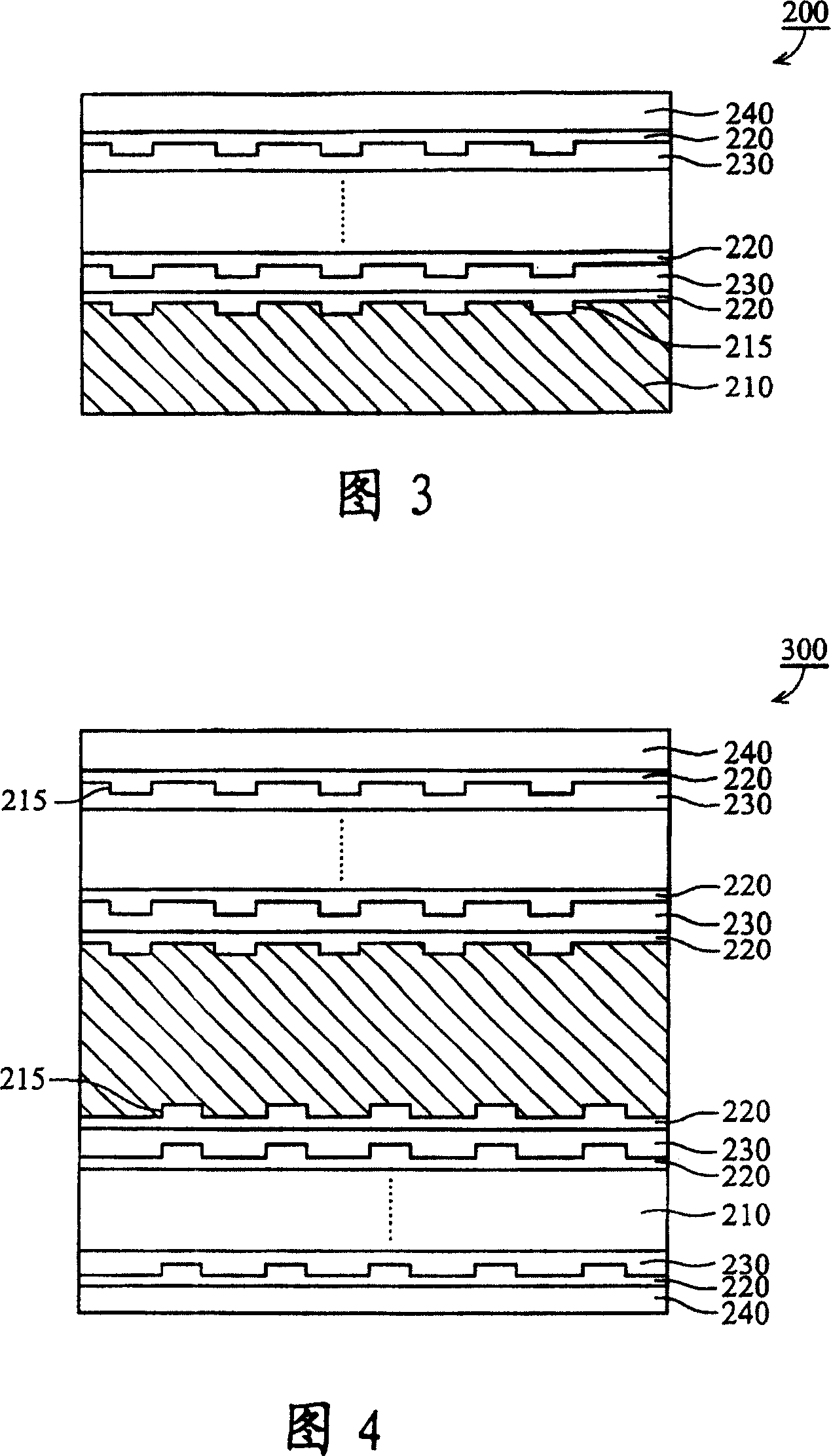

Optical recording medium having three-dimensional data graphics and method for making same

InactiveCN100372006CIncrease storage capacityLow costRecord information storageOptical record carrier manufactureLaser lightPolymerization

The invention supplies an optical recording medium with three-dimensional data image and its preparation method, which comprises a base plate and complex recoding layer that composes a luminescent material of low degree of polymerization and forms on base plate. For there is high quantum efficiency and Stoke shift for the luminescent material, when use laser light t read the medium, the recording layer will be excited luminescence signal with enough strength. Thereby, the medium of this invention has very fine recording sensitivity and read characteristic without adding signal amplification structure or material.

Owner:IND TECH RES INST

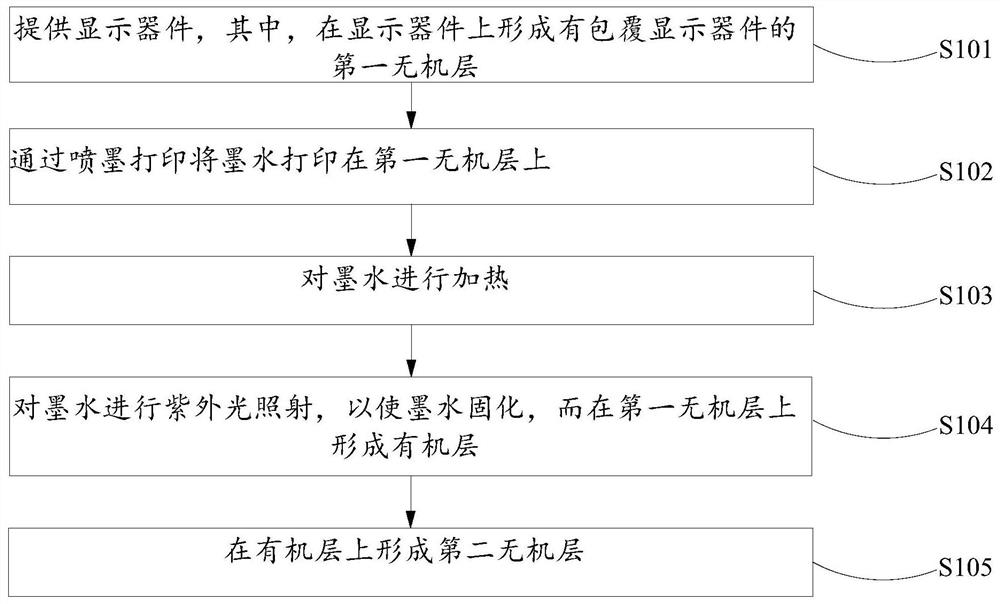

Display device packaging method

PendingCN113682064ASolve uneven film thicknessImprove mura defectDuplicating/marking methodsSolid-state devicesPhysicsComposite material

The invention provides a display device packaging method, which comprises the following steps: providing a display device on which a first inorganic layer covering the display device is formed; printing ink on the first inorganic layer by inkjet printing; heating the ink; irradiating the ink by the ultraviolet light to cure the ink, forming an organic layer on the first inorganic layer, and heating the ink before being cured, so that the ink is quickly leveled, the problem of non-uniform film thickness of the organic layer formed by the ink is solved, and the mura defect is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

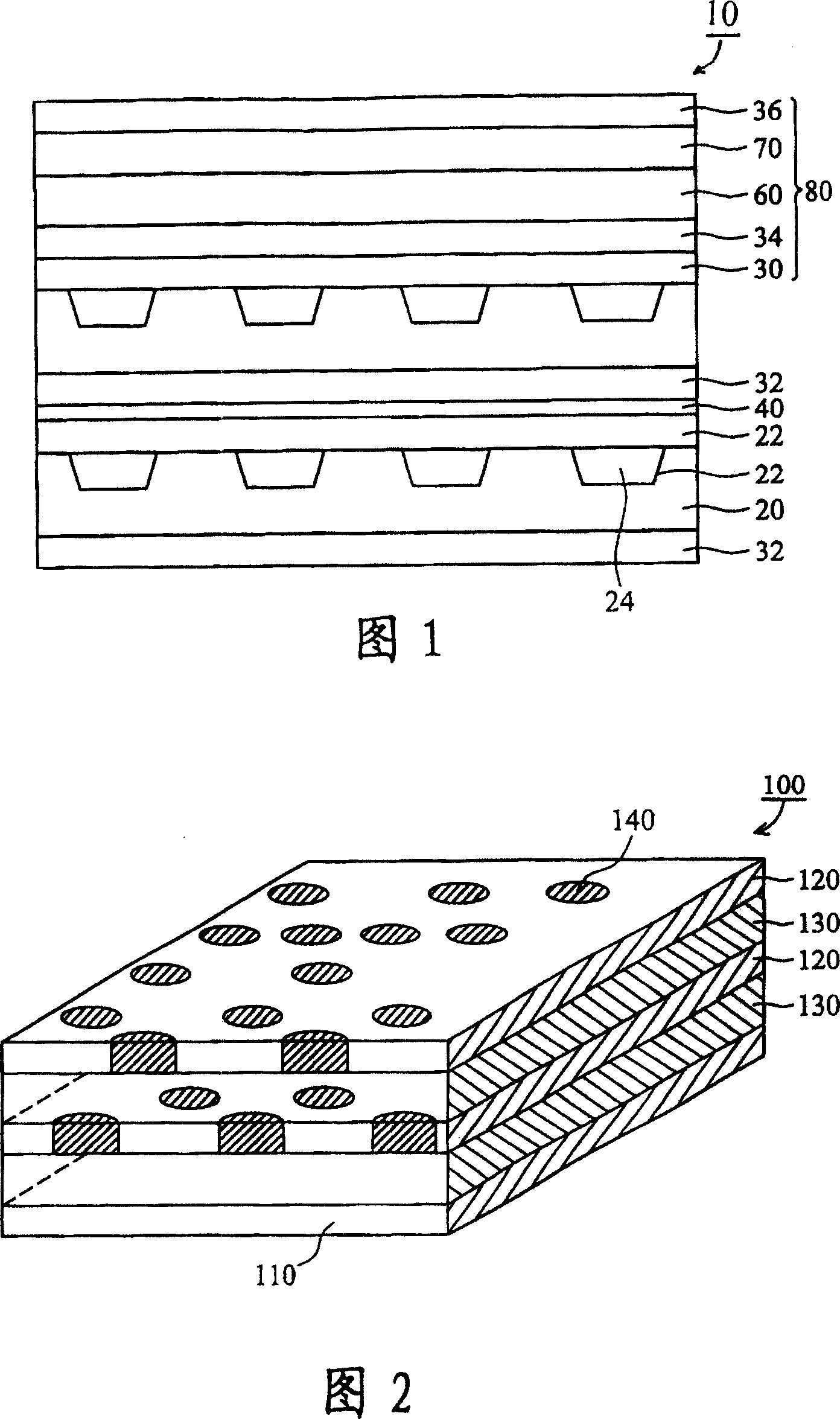

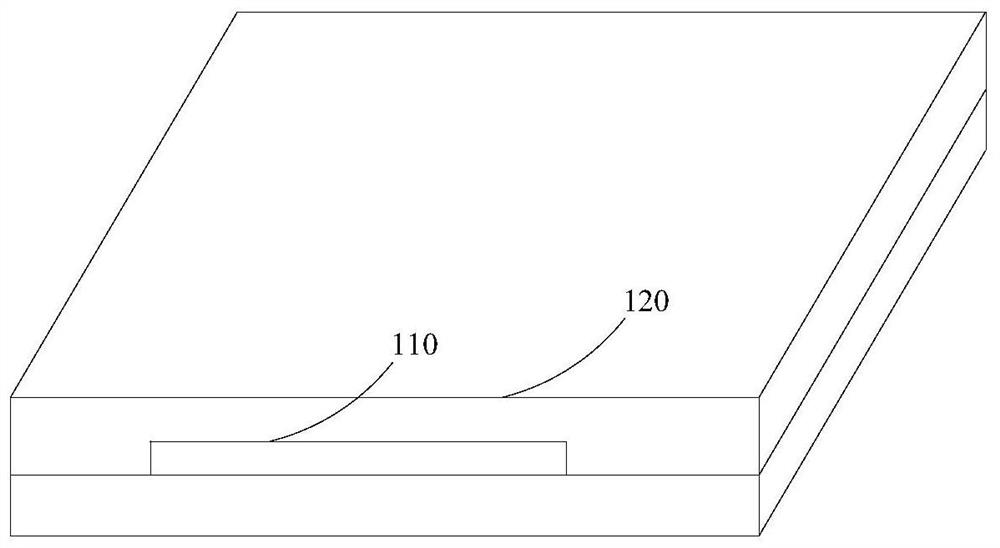

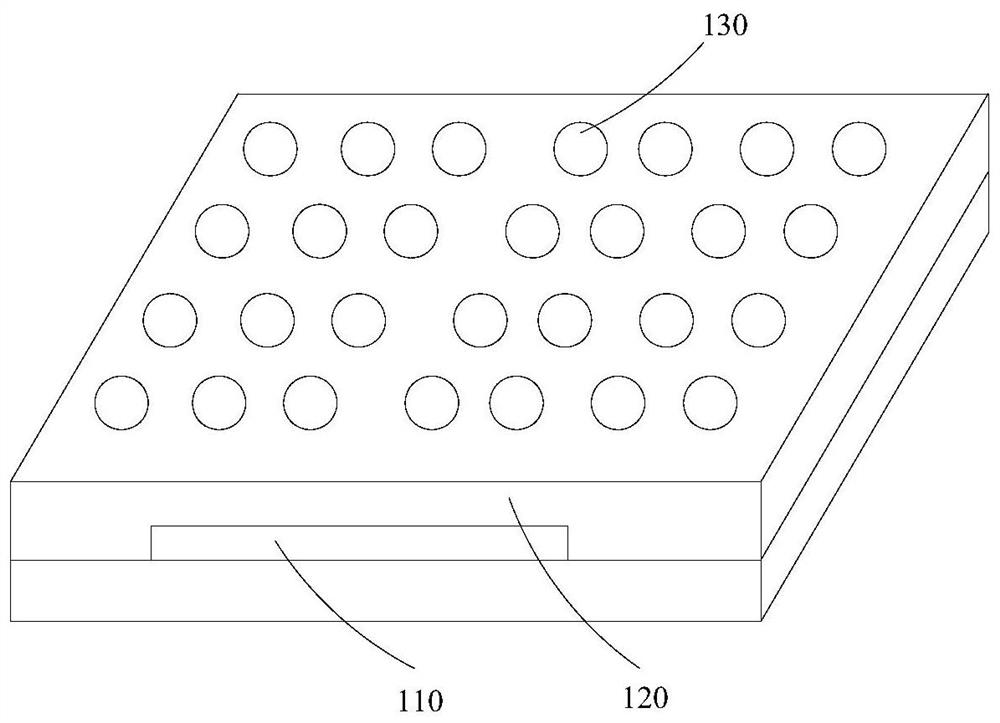

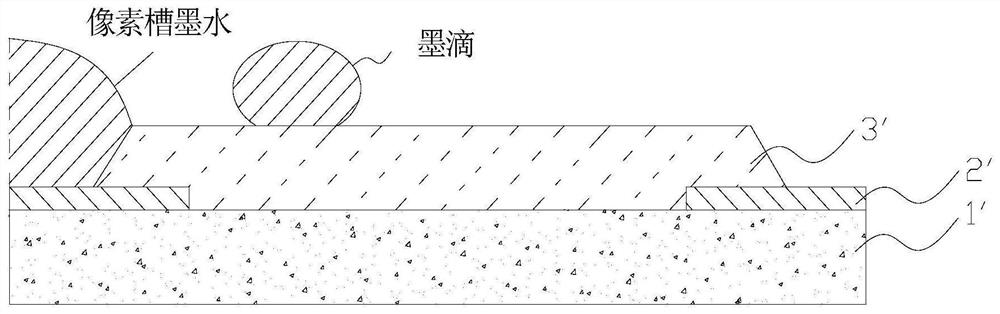

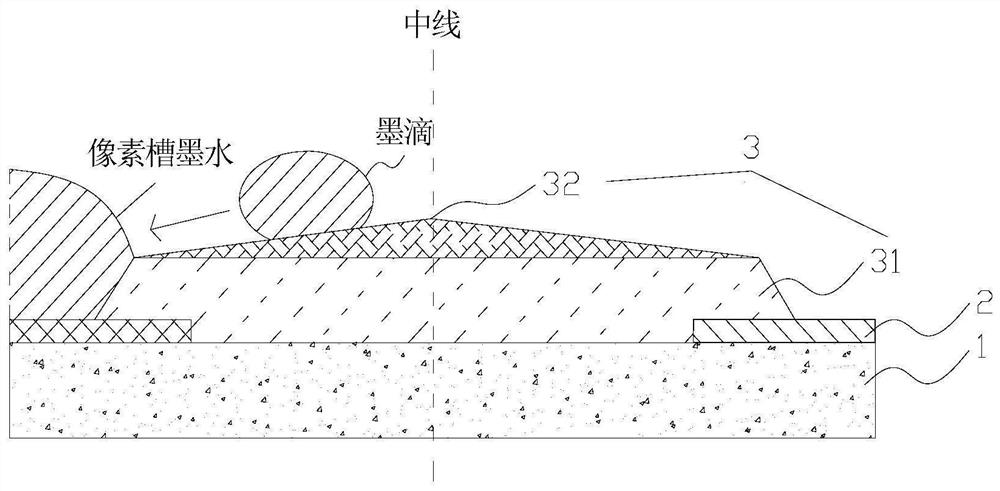

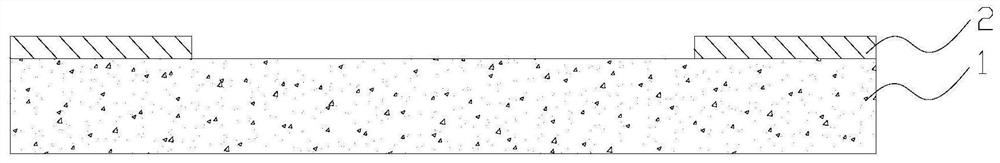

Pixel bank structure suitable for manufacturing display by printing process and preparation method thereof

ActiveCN106356396BAvoid uneven film thicknessAvoid offsetSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceMaterials science

The invention provides a pixel bank structure suitable for preparing a display by a printing process and a preparation method thereof. A pixel bank structure suitable for preparing a display by a printing process, including a substrate, a patterned pixel electrode, and a pixel bank layer, the pixel bank layer including a first pixel bank arranged on the substrate and a first pixel bank arranged on the first pixel bank The second pixel Bank on the surface, wherein the first pixel Bank is a Bank structure with a narrow top and a wide bottom, and the first pixel Bank is made of a lyophilic material; the second pixel Bank includes a pair of mutual offset The height of the ink guiding slope is gradually increased along the direction in which the mutually abutting ink guiding slopes approach each other, and the second pixel Bank is made of a liquid-repellent material.

Owner:武汉国创科光电装备有限公司

Inkjet printing method, device, system, computer equipment and storage medium

ActiveCN110091592BShorten the intervalAvoid uneven film thicknessDuplicating/marking methodsTypewritersSpray nozzleEngineering

The invention relates to an ink-jet printing method, device, and system, computer equipment, and a storage medium. The ink-jet printing method includes the following steps: the number of multiple participation spray nozzles is obtained for multiple preset ink-jet angles; the number of the participation spray nozzles includes the number of spray nozzles participating in ink-jet when a printing taskis performed; an ink-jet angle with a maximum number of the participation spray nozzles is utilized as a target ink-jet angle; and the target ink-jet angle is transmitted to ink-jet printing equipment for the ink-jet printing equipment to perform the printing task according to the target ink-jet angle. Through the ink-jet printing method of the invention, the performance of an OLED device is improved.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

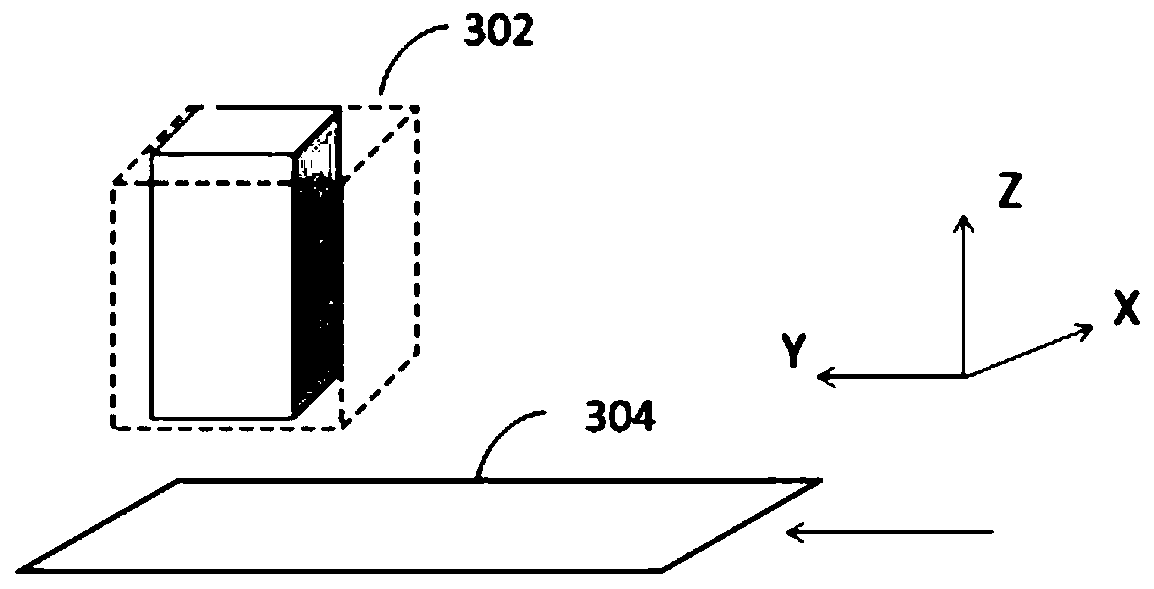

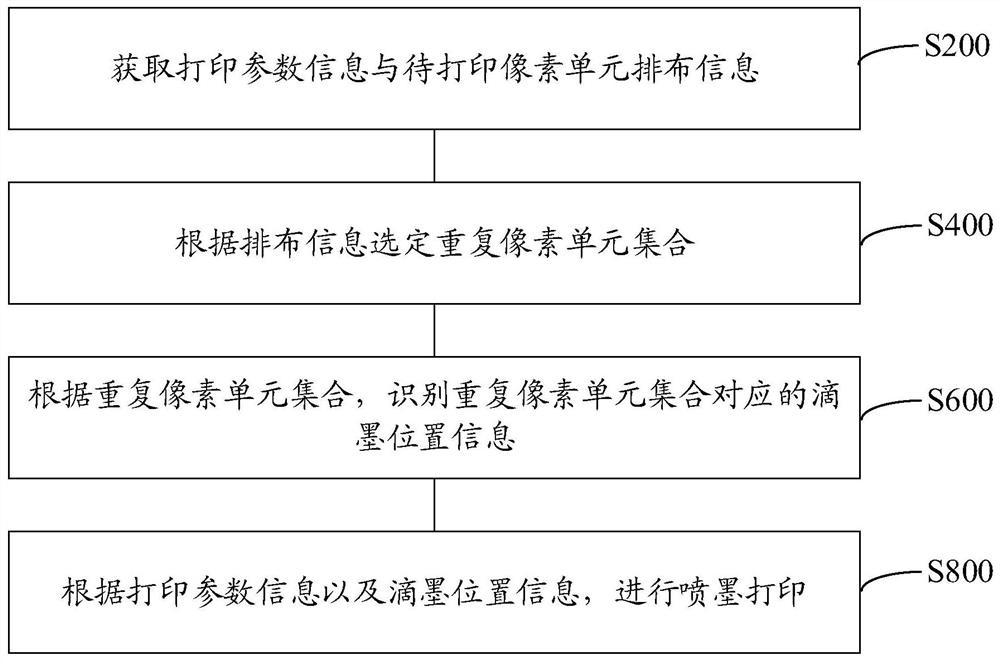

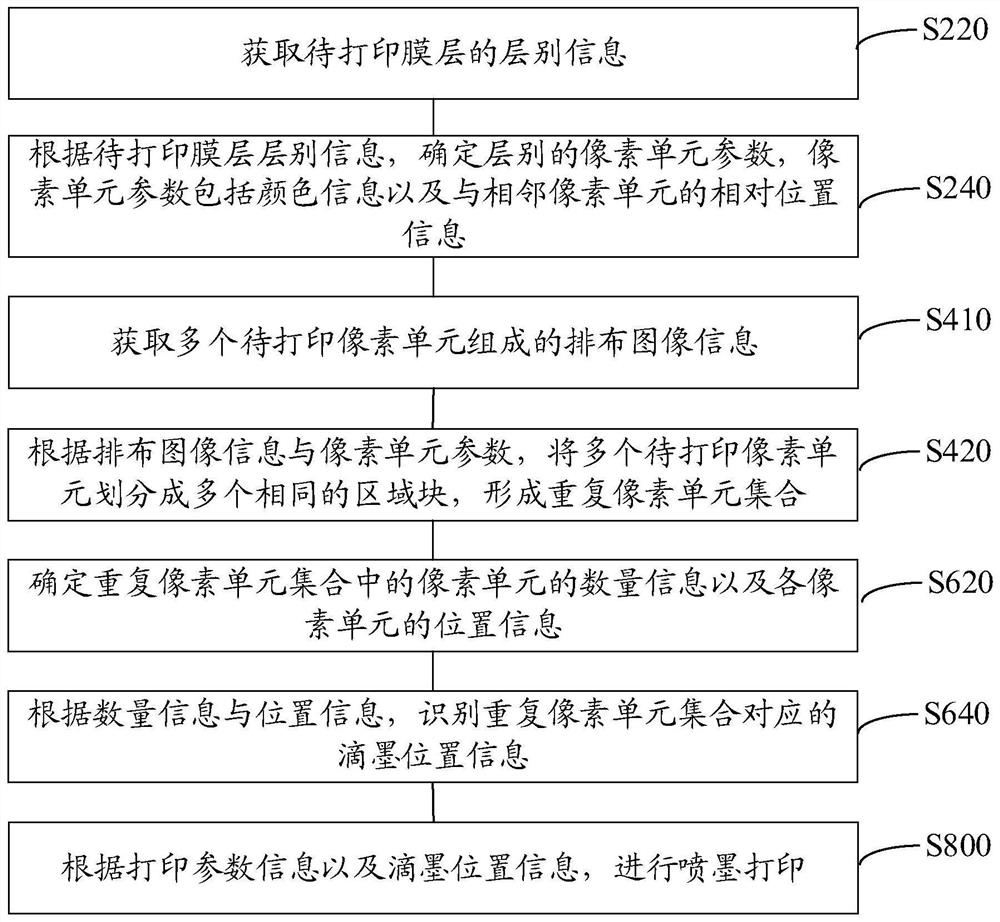

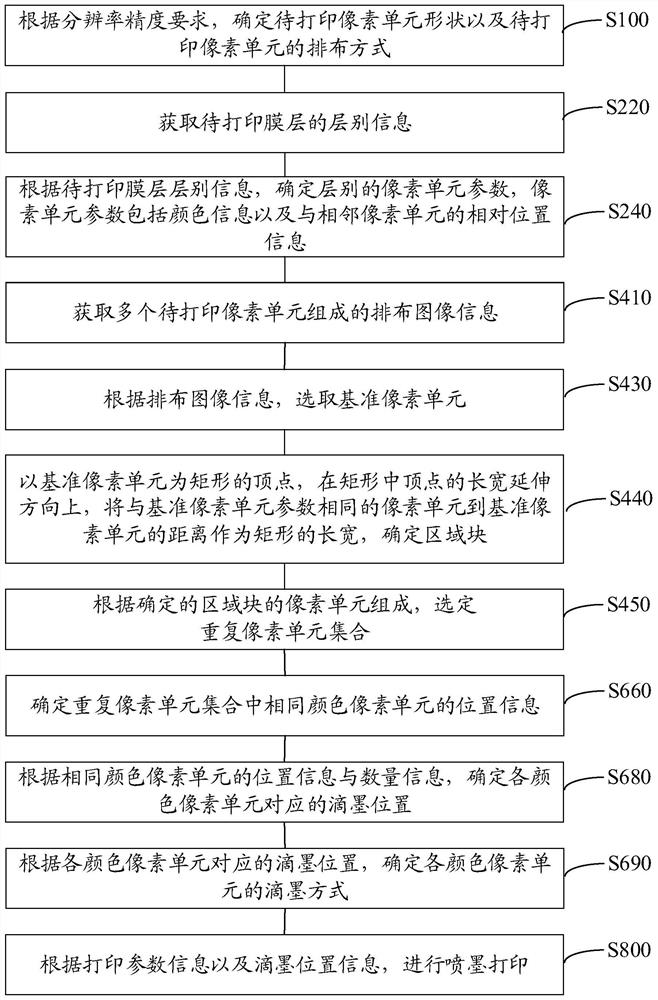

Inkjet printing method, apparatus, computer equipment and storage medium

ActiveCN109733080BAvoid uneven film thicknessOvercome the difficulty of printing precision controlPrintingSoftware engineeringMechanical engineering

The invention relates to an inkjet printing method and device, computer equipment and a storage medium. The inkjet printing method comprises the steps that printing parameter information and to-be-printed pixel unit arrangement information are obtained, a repeated pixel unit set is selected according to the arrangement information, ink dripping position information corresponding to the repeated pixel unit set is identified according to the repeated pixel unit set, and inkjet printing is conducted according to the printing parameter information and the ink dripping position information. By adopting the inkjet printing method to conduct inkjet printing, the printing efficiency can be improved, the problem that the printing time is excessively long in the inkjet printing process is solved, the phenomenon of uneven film thickness after an ink material is dried is avoided, and the better printing effect is achieved.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com