Method and apparatus of manufacturing piezoelectric vibrating reed, piezoelectric vibration reed, piezoelectric vibrator, oscillator, electronic apparatus and radio-controlled timepiece

A technology of piezoelectric vibrating piece and manufacturing method, which is applied in the field of radio clocks, and can solve problems such as difficult simultaneous suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] (Piezoelectric vibrating piece)

[0074] First, a piezoelectric vibrating reed according to an embodiment of the present invention will be described with reference to the drawings.

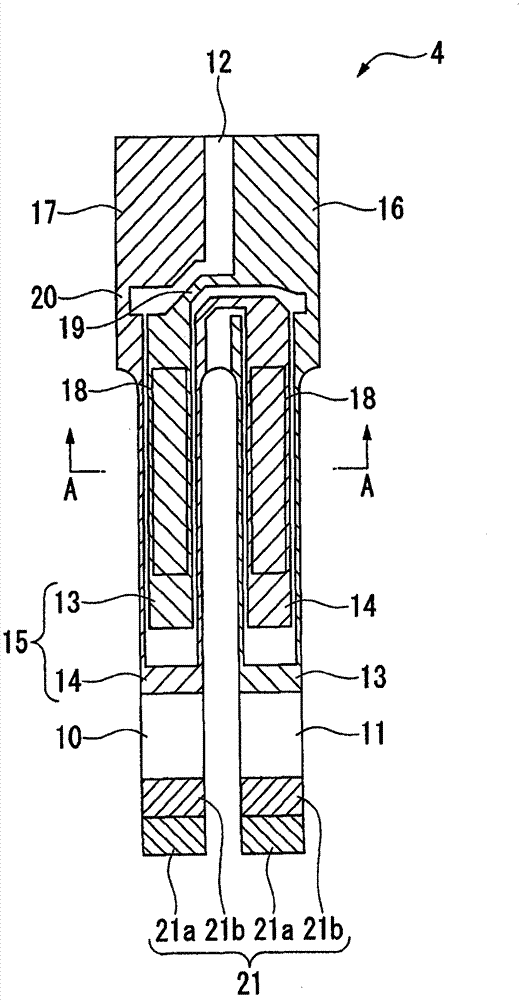

[0075] figure 1 is a plan view of the piezoelectric vibrating piece 4 .

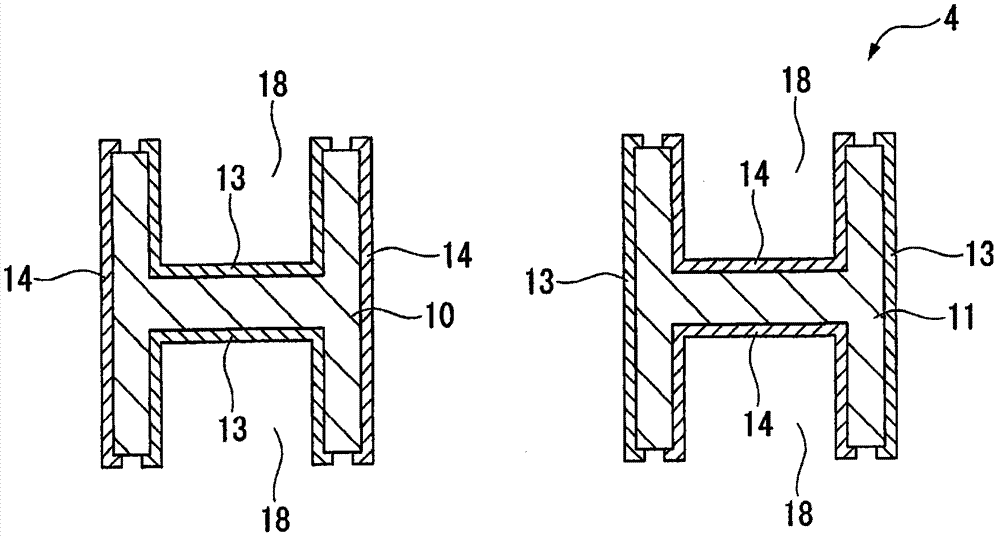

[0076] figure 2 Yes figure 1 The cross-sectional view at the section line A-A.

[0077] like figure 1 As shown, the piezoelectric vibrating piece 4 of this embodiment is a tuning-fork type vibrating piece formed of a square crystal wafer (hereinafter referred to as “square wafer”), and vibrates when a predetermined voltage is applied. The piezoelectric vibrating reed 4 includes: a pair of vibrating arm portions 10, 11 arranged in parallel; a base portion 12 integrally fixing the proximal ends of the pair of vibrating arm portions 10, 11; Vibrating arm grooves 18 on both main surfaces of 11. The vibrating arm groove portion 18 is formed along the longitudinal direction of the vibrating arm portion 10 , 11 fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com