Thermal insulation cotton and preparation method thereof, and battery module using thermal insulation cotton

A technology of thermal insulation cotton and thermal insulation material, which is applied in battery pack parts, secondary batteries, and secondary battery repair/maintenance, etc. Preparation method and other problems, to achieve the effect of great practical value, prevent fire and improve safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The following steps are used to prepare thermal insulation cotton 1:

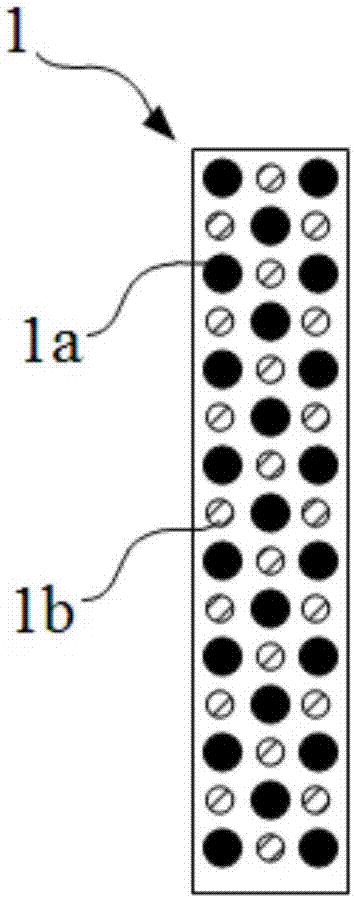

[0028] Add 250g of zirconia (particle size D50 is 0.9μm), 250g of melamine cyanurate (D50 is 1.7μm) and 10g of SBR emulsion into 125g of water and stir for 60min, pour the resulting slurry into a paper sample machine for dilution and molding . Cover the forming paper with a felt cloth, then gently roll it with a cylinder, stick the paper sheet to the felt cloth, then put the felt cloth and wet paper sheet into a vacuum dryer and vacuum dry for 50-60 seconds, take it out and peel off the felt cloth , place the incompletely dried paper sheets in an electric constant temperature blast drying oven for drying, wherein the temperature is set at 105°C, and dry for 100-120 minutes until completely dry. The resulting material is thermal insulation cotton 1 (such as figure 2 Shown), its thickness is 1mm, then cut into 160mm long, 120mm wide sheets for future use.

[0029] The battery module was prepared by...

Embodiment 2

[0036] The zirconia in Example 1 is replaced by alumina (D50 is 0.7 μm), and the rest are the same as in Example 1.

Embodiment 3

[0038] The melamine cyanurate in Example 1 was replaced by aluminum hydroxide (D50 being 3.2 μm), and the rest were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com