Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

176results about How to "Large inclination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light deflection element and light source apparatus using the same

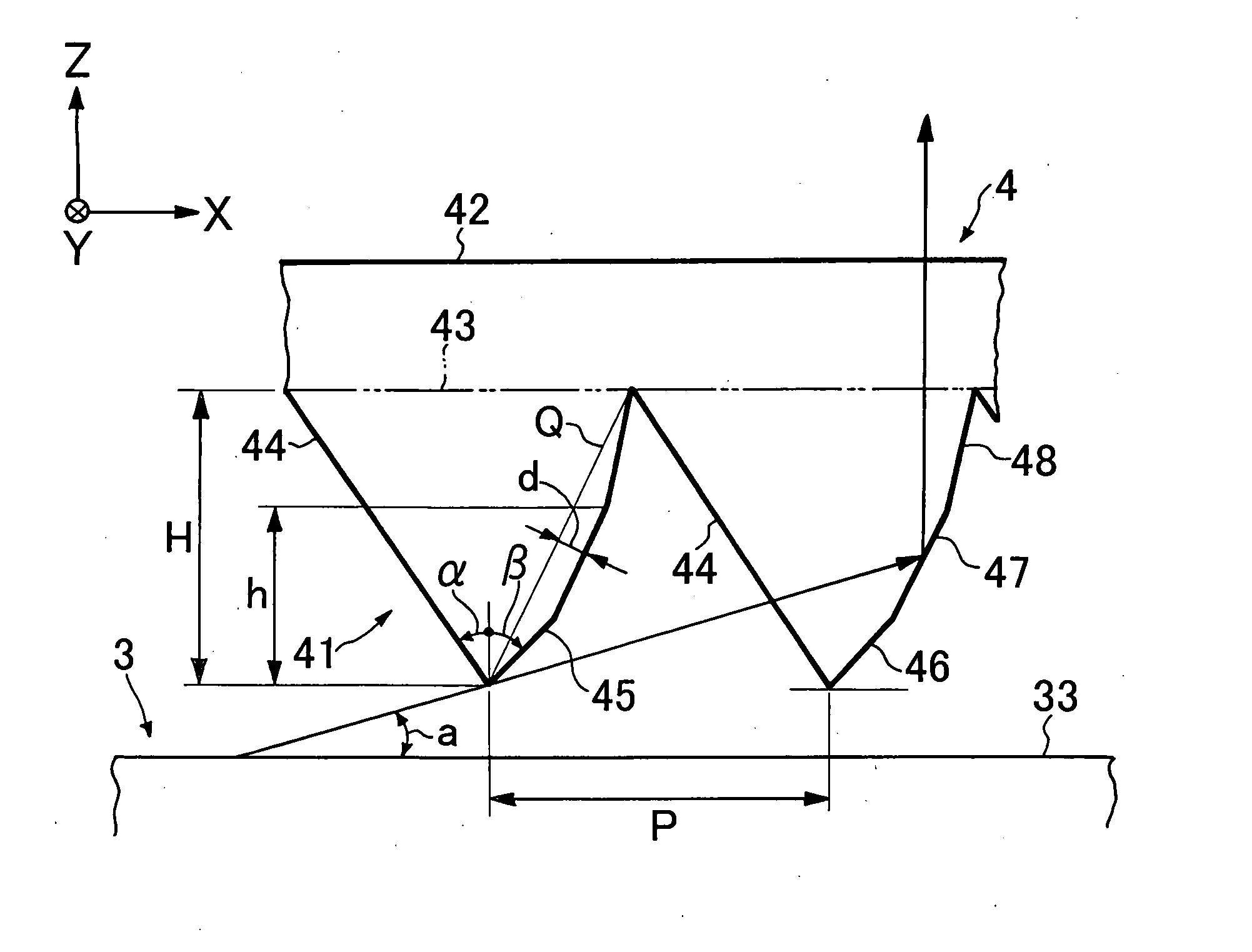

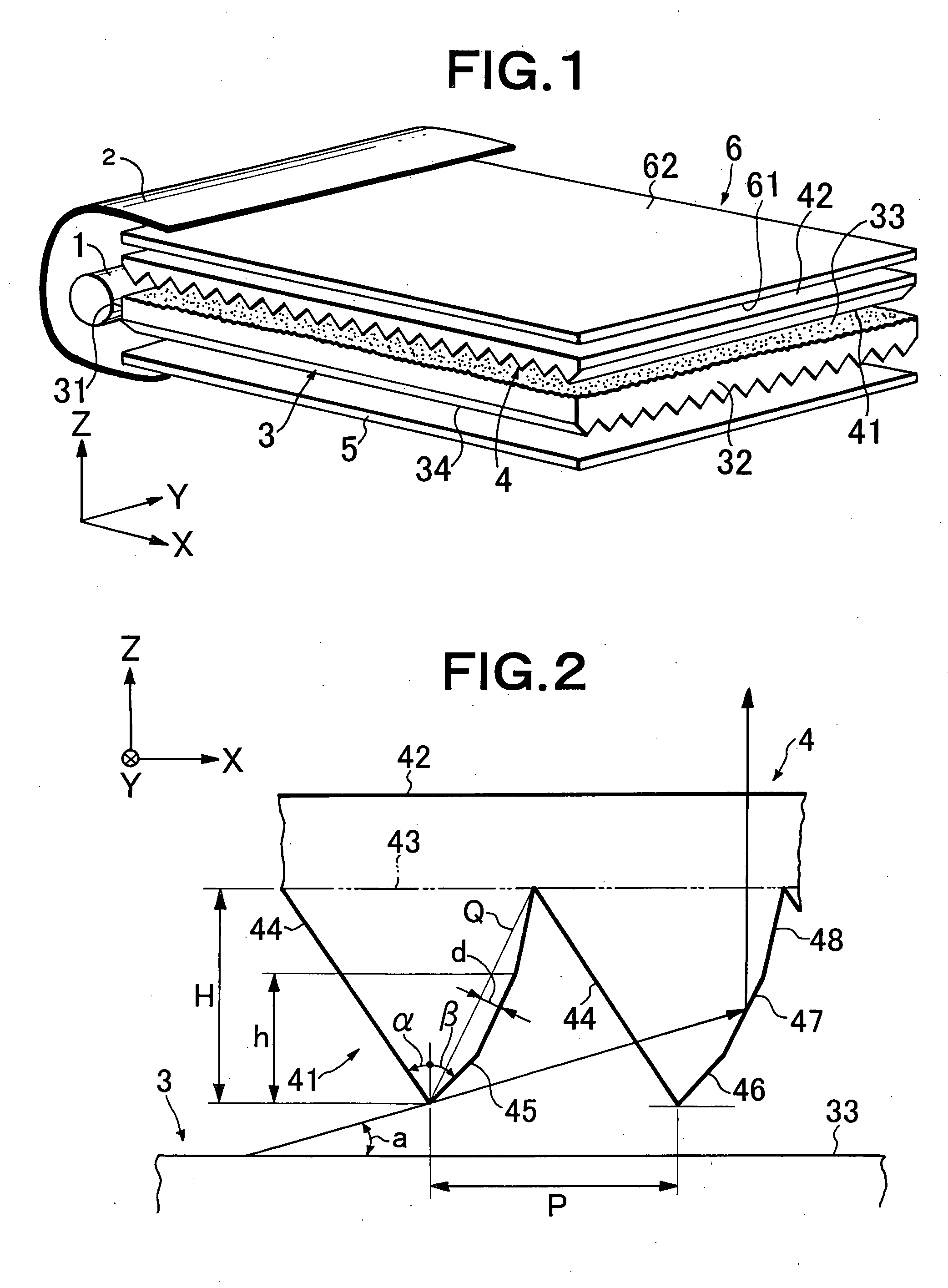

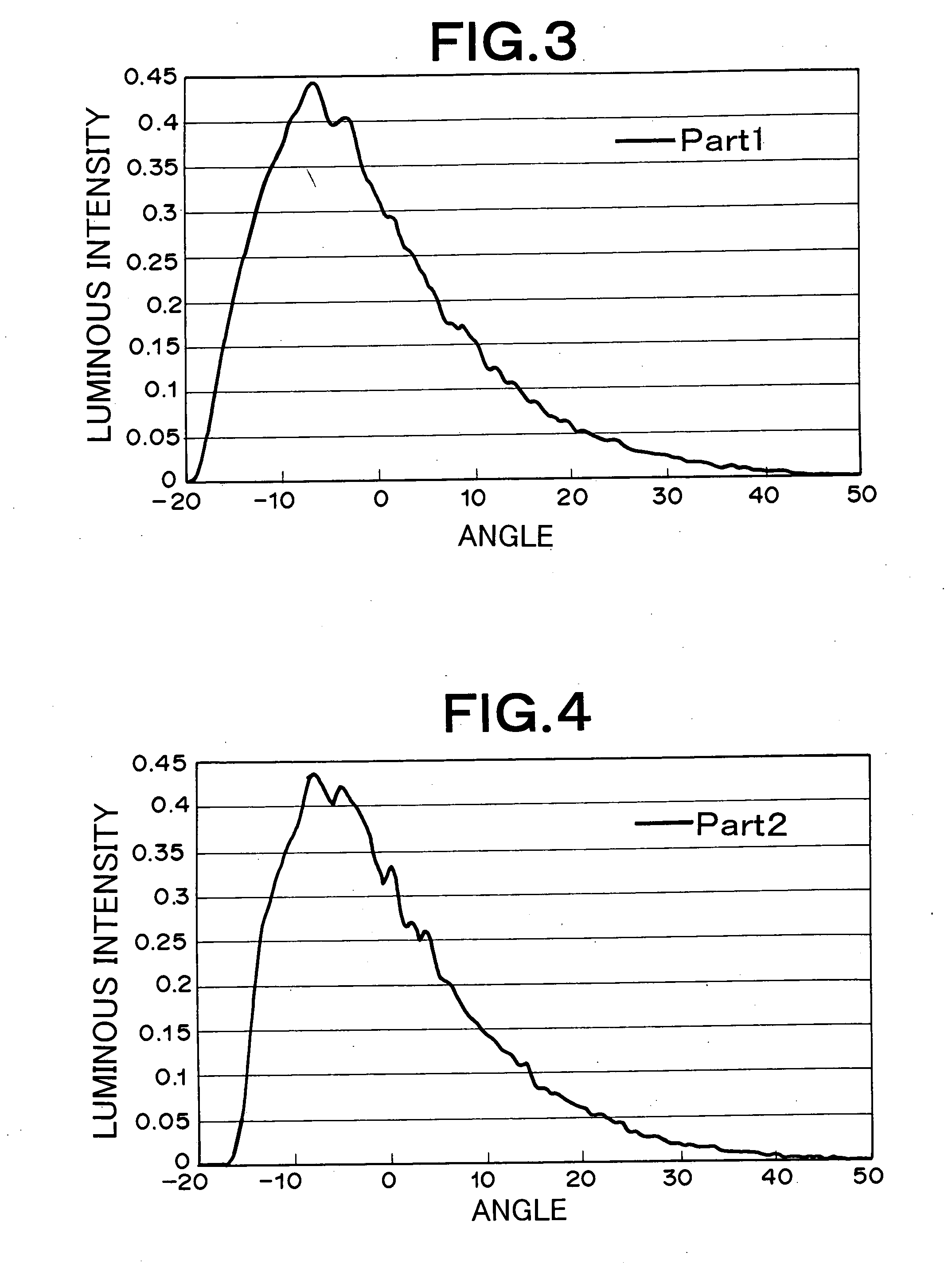

A surface light source apparatus includes a primary light source (1), an optical guide (3) for guiding light emitted from the primary light source and having a light incoming surface (31) and a light outgoing surface (32), a light deflection element (4) arranged adjacent to the light outgoing surface of the optical guide and having a light incoming surface (41) and a light outgoing surface (42), and a light diffusion element (6) arranged adjacent to the light outgoing surface of the light deflection element. The light incoming surface (41) of the light deflection element has a plurality of prism strings arranged substantially parallel to each other and each having two prism surfaces. At least one of the prism surfaces of these prism strings has a prism surface consisting of at least two planes having different inclination angles. As the plane approaches the light outgoing surface, the inclination becomes larger. The difference between the inclination angle of the plane nearest to the light outgoing surface and that of the plane farthest from the light outgoing surface is 15 degrees or below.

Owner:LMS

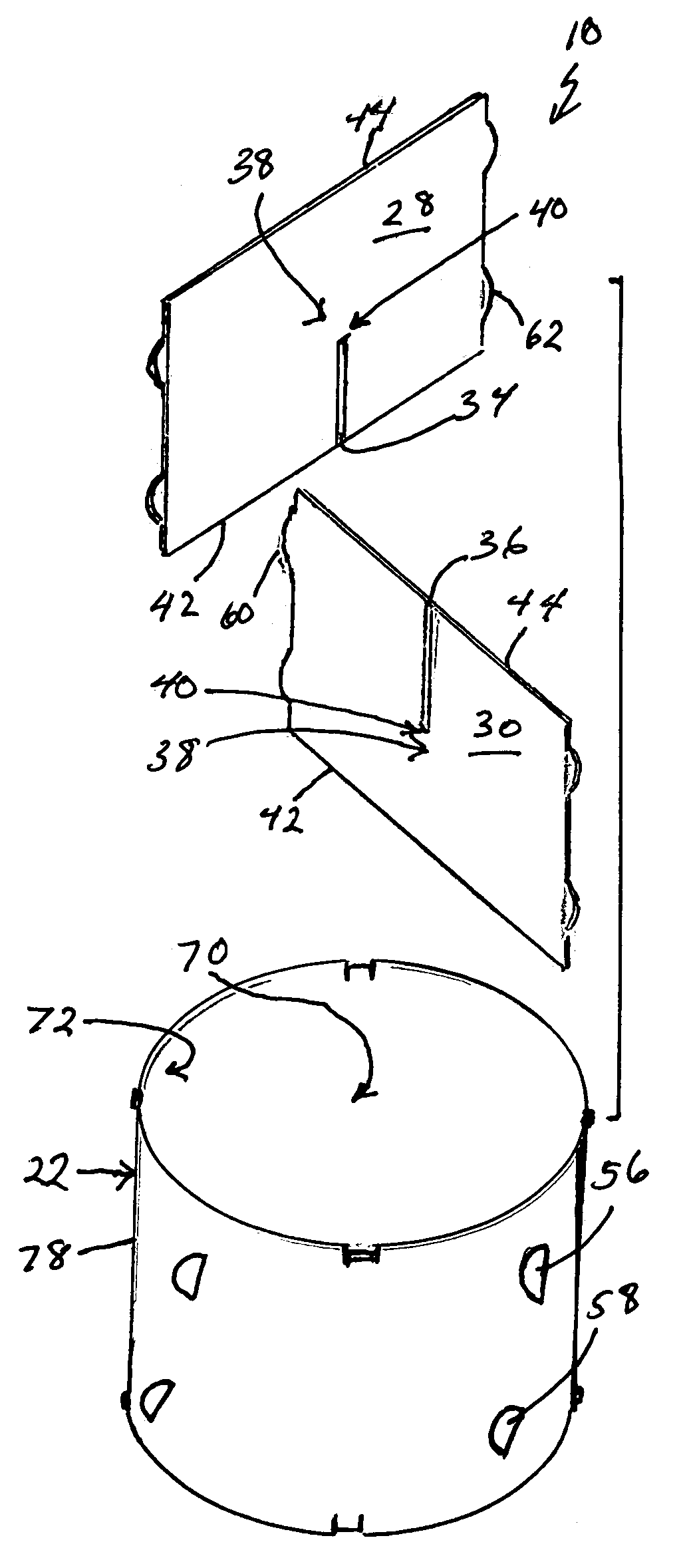

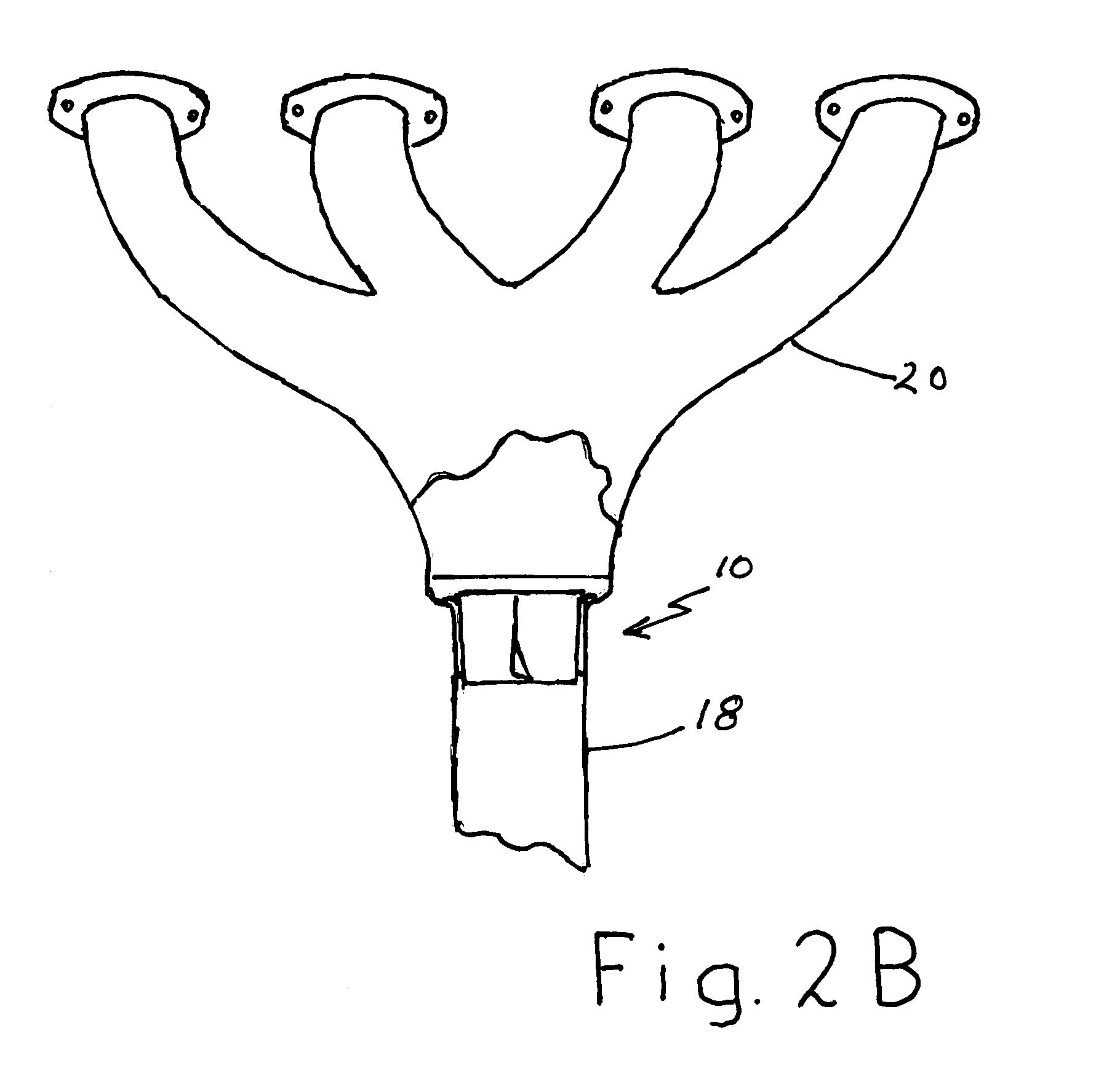

Fluid swirling device

InactiveUS7028663B1Minimizes force actingIncrease airflowInternal combustion piston enginesExhaust apparatusComplete mixingExhaust gas

The device includes a pair of flat planar vanes securely mounted within a cylindrical housing. The vanes have a medial slit extending from the center to a longitudinal end of the vane. The vanes are interconnected at the slits so that they are in criss-cross positioning. The vanes are axially angled so that when positioned in an intake air duct the vanes impart a swirling motion to the air entering the engine providing more complete mixing of the air and fuel and when positioned in an exhaust passageway the vanes impart a swirling motion to the exhaust gases exiting the engine providing scavenging of the exhaust gases.

Owner:KIM JAY S

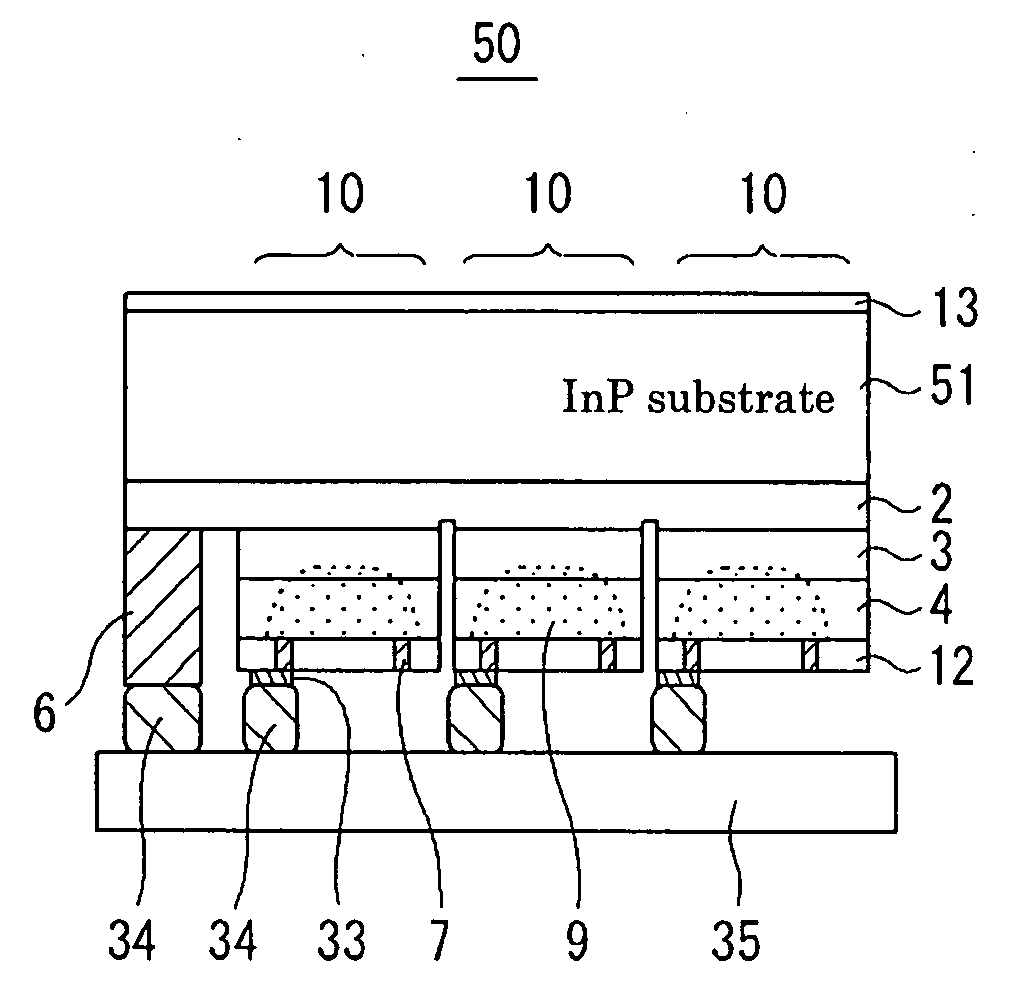

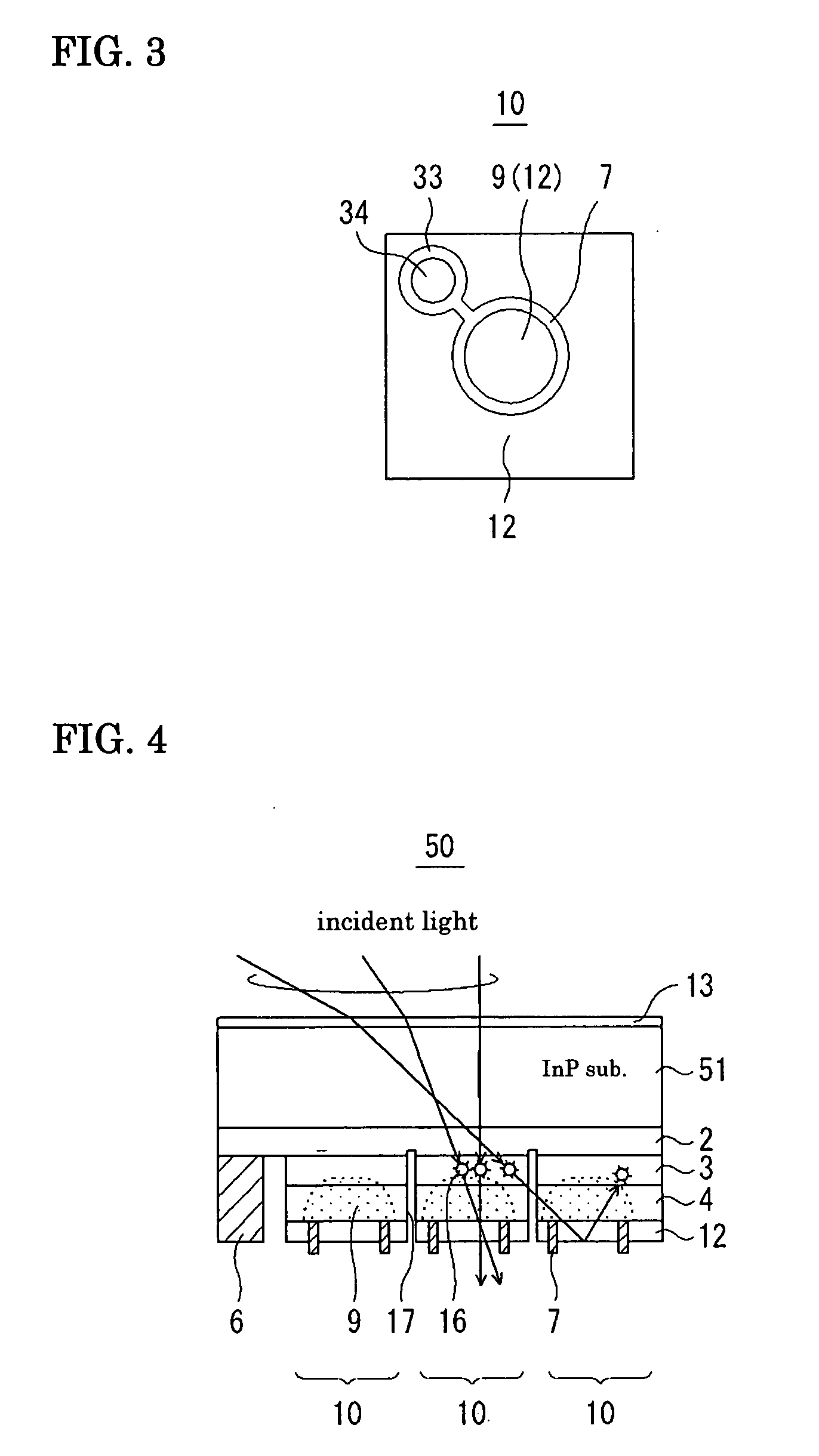

Photodetector

ActiveUS20070194401A1Reduce crosstalkImprove crosstalk characteristicTelevision system detailsSolid-state devicesPhotovoltaic detectorsPhotodetector

A photodetector having a mechanism of suppressing light crosstalk includes a plurality of photodiodes disposed on a common semiconductor substrate, each photodiode including an absorption layer epitaxially grown on the common semiconductor substrate and being provided with an epitaxial-side electrode. Each photodiode is provided with at least one of a ring-shaped or crescent-shaped epitaxial-side electrode, an incident-side-limited condensing part which condenses incident light that is directed to the corresponding photodiode only, and emission means which is disposed on a side opposite to a light-incident side of the absorption layer and which allows light entering from the light-incident side to be easily emitted out of the photodiode.

Owner:SUMITOMO ELECTRIC IND LTD

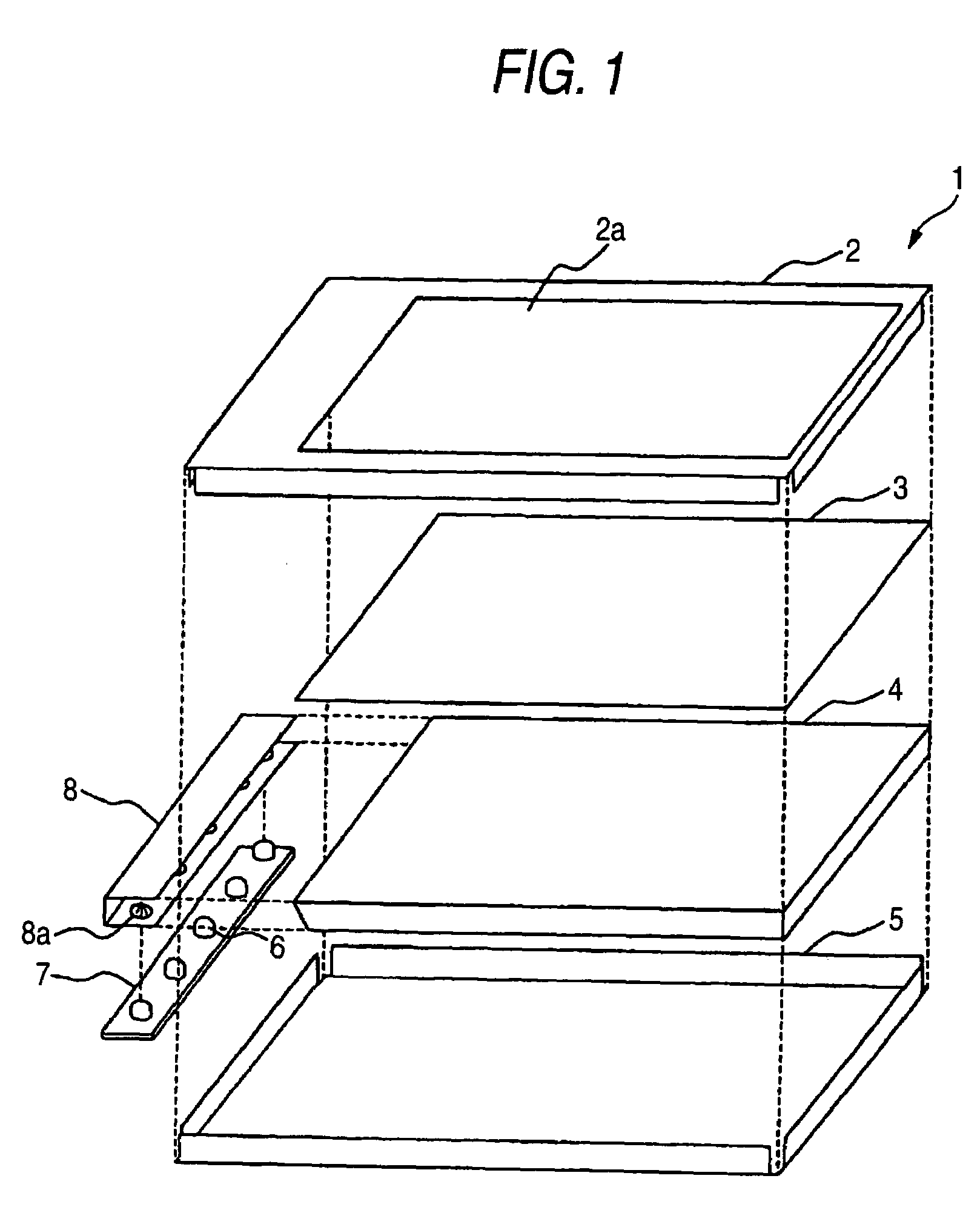

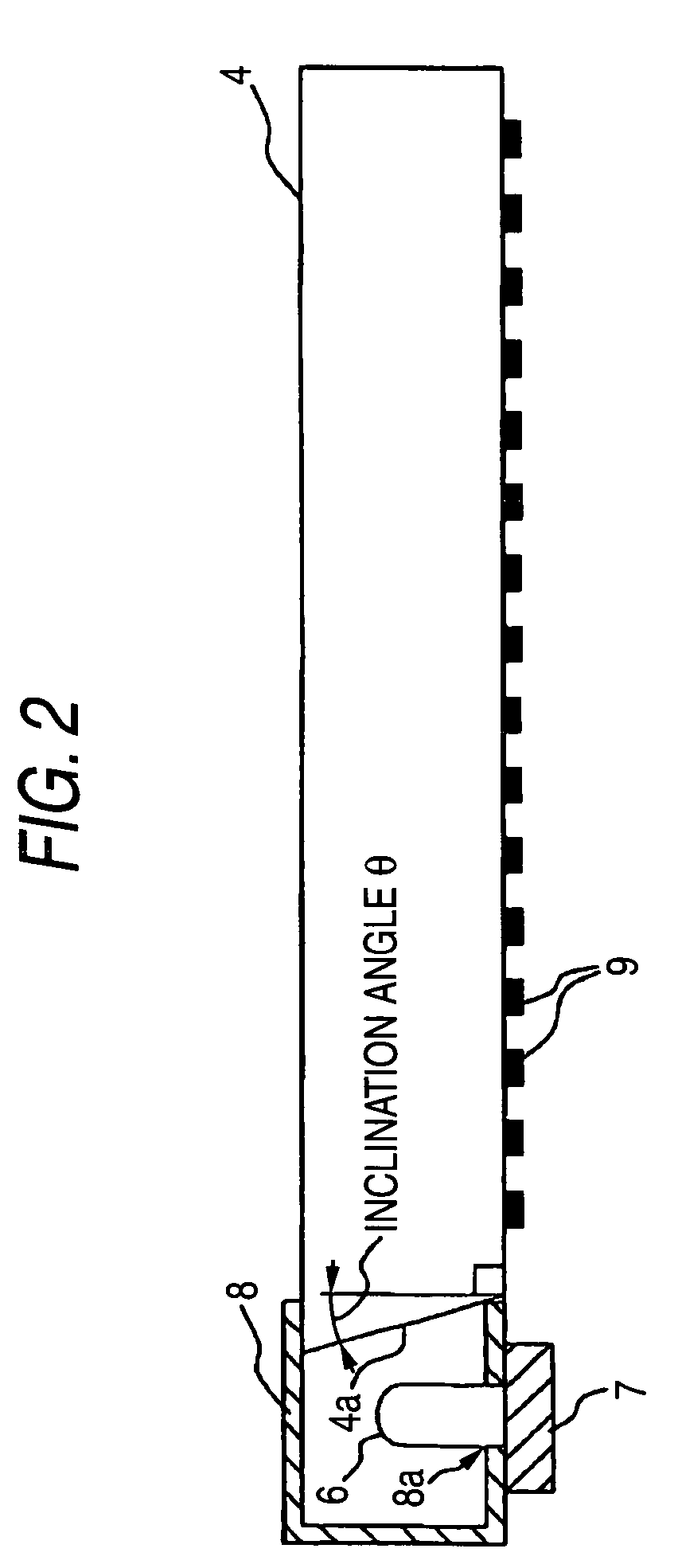

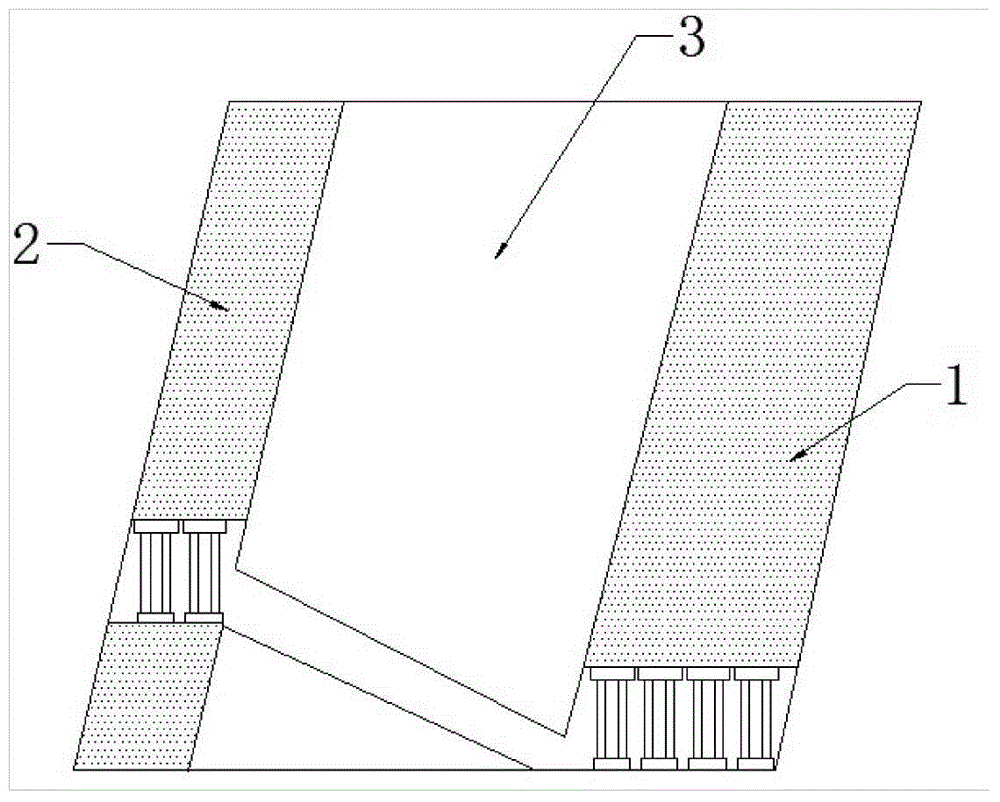

Surface light source device

ActiveUS20060007704A1Improve display qualityAvoid uneven brightnessPoint-like light sourceElongate light sourcesPoint lightLight guide

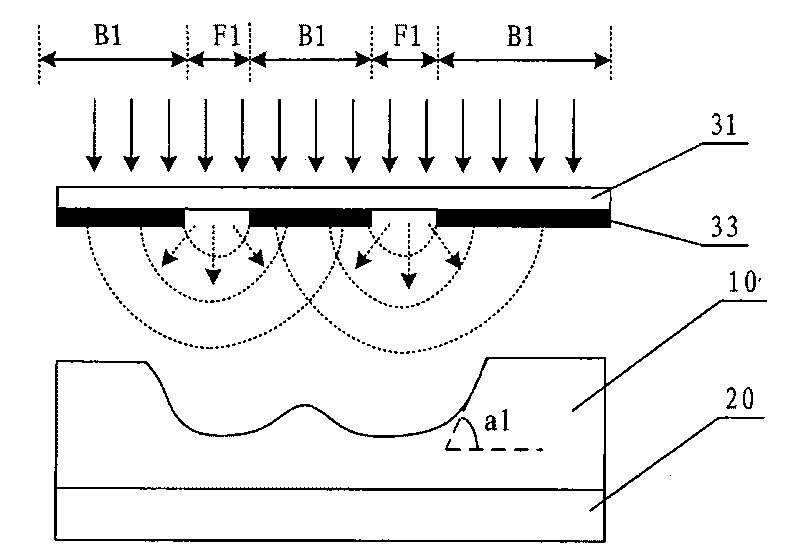

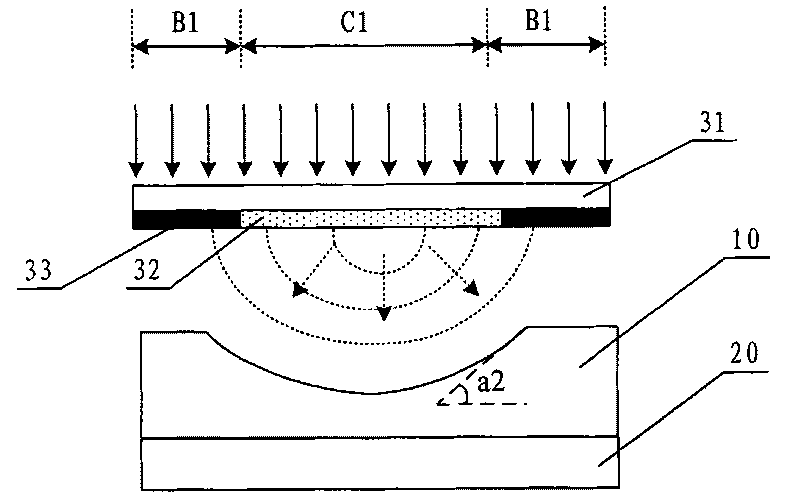

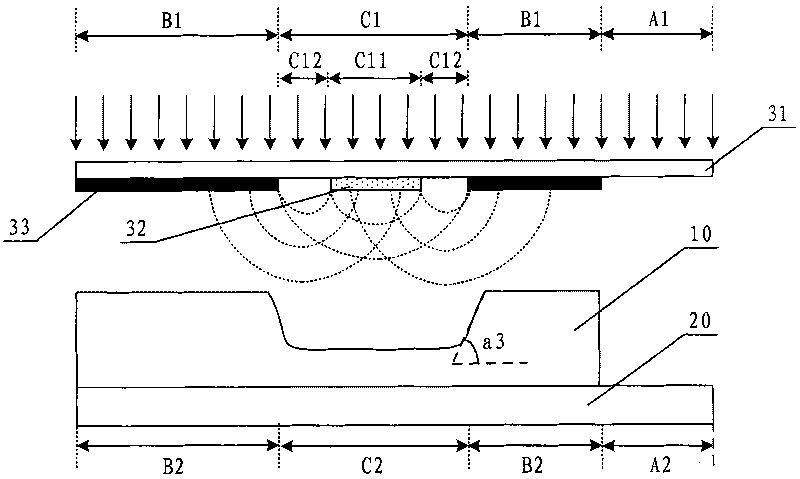

A surface light source device includes two or more point light sources that are arranged linearly, a light guide plate having an incident surface on which light emitted from each of the point light sources shines, for outputting input light from a front surface thereof, and light diffusing means provided on a back surface of the light guide plate, for diffusing light. The incident surface of the light guide plate is inclined toward a back side.

Owner:MITSUBISHI ELECTRIC CORP +1

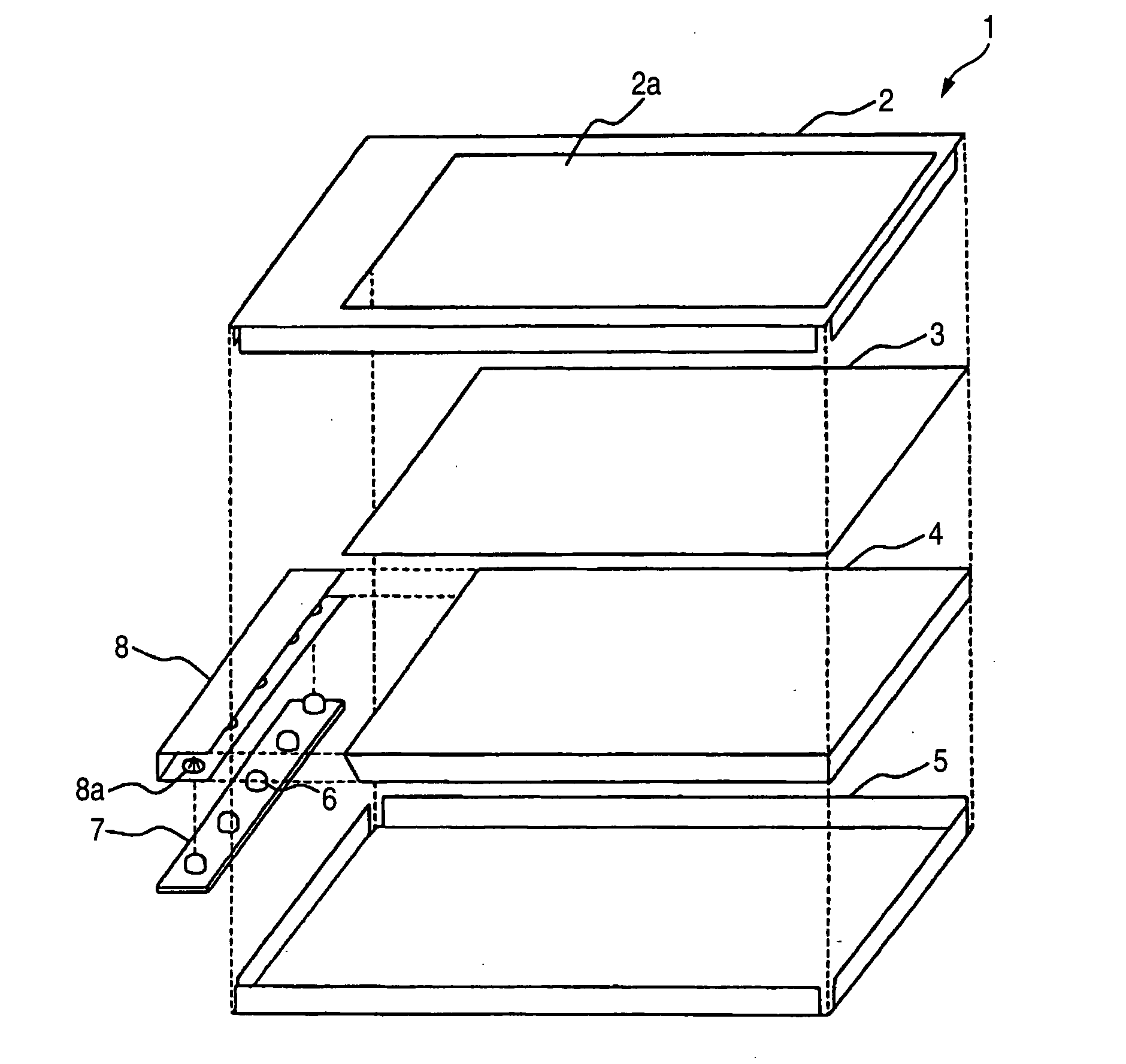

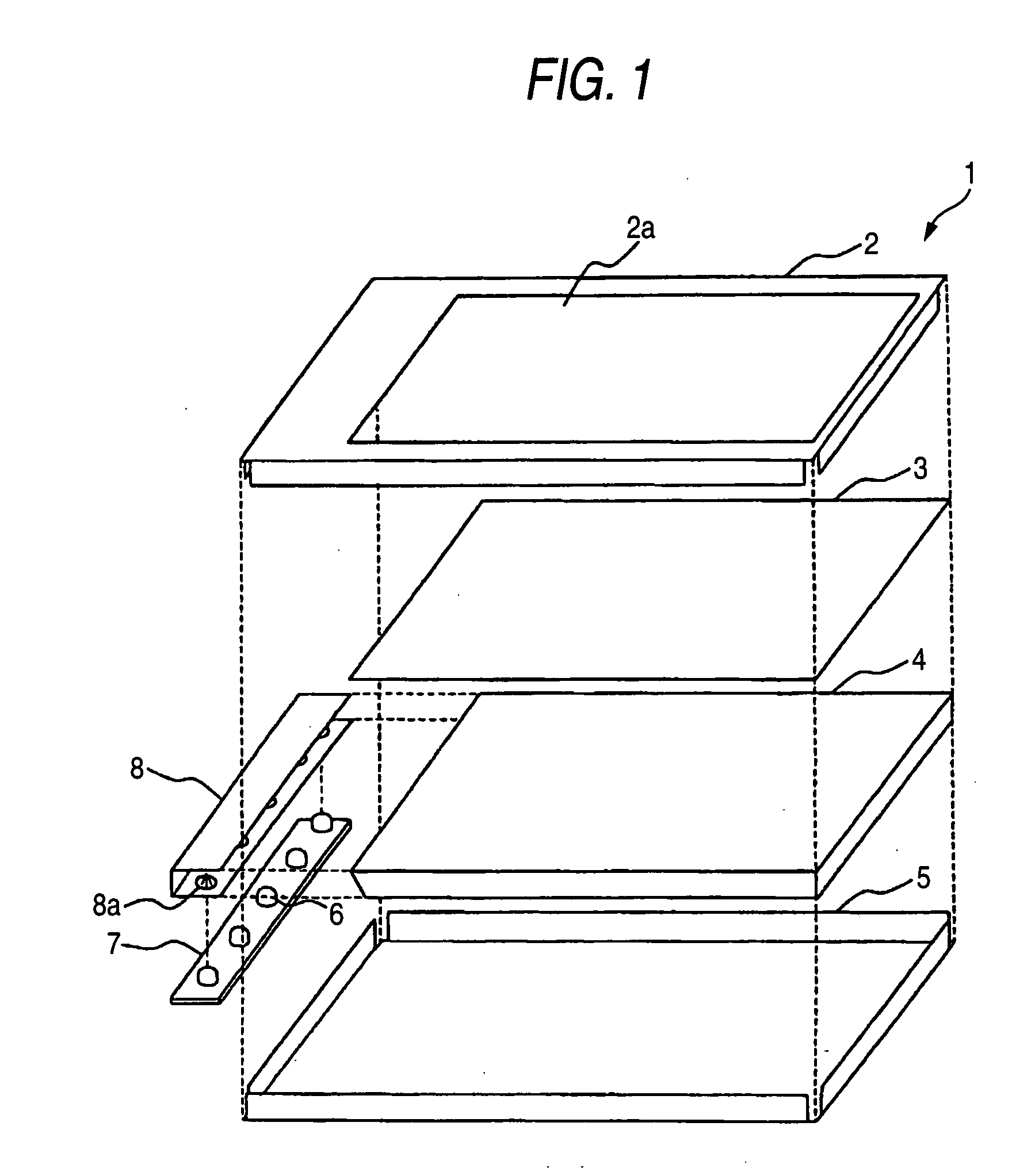

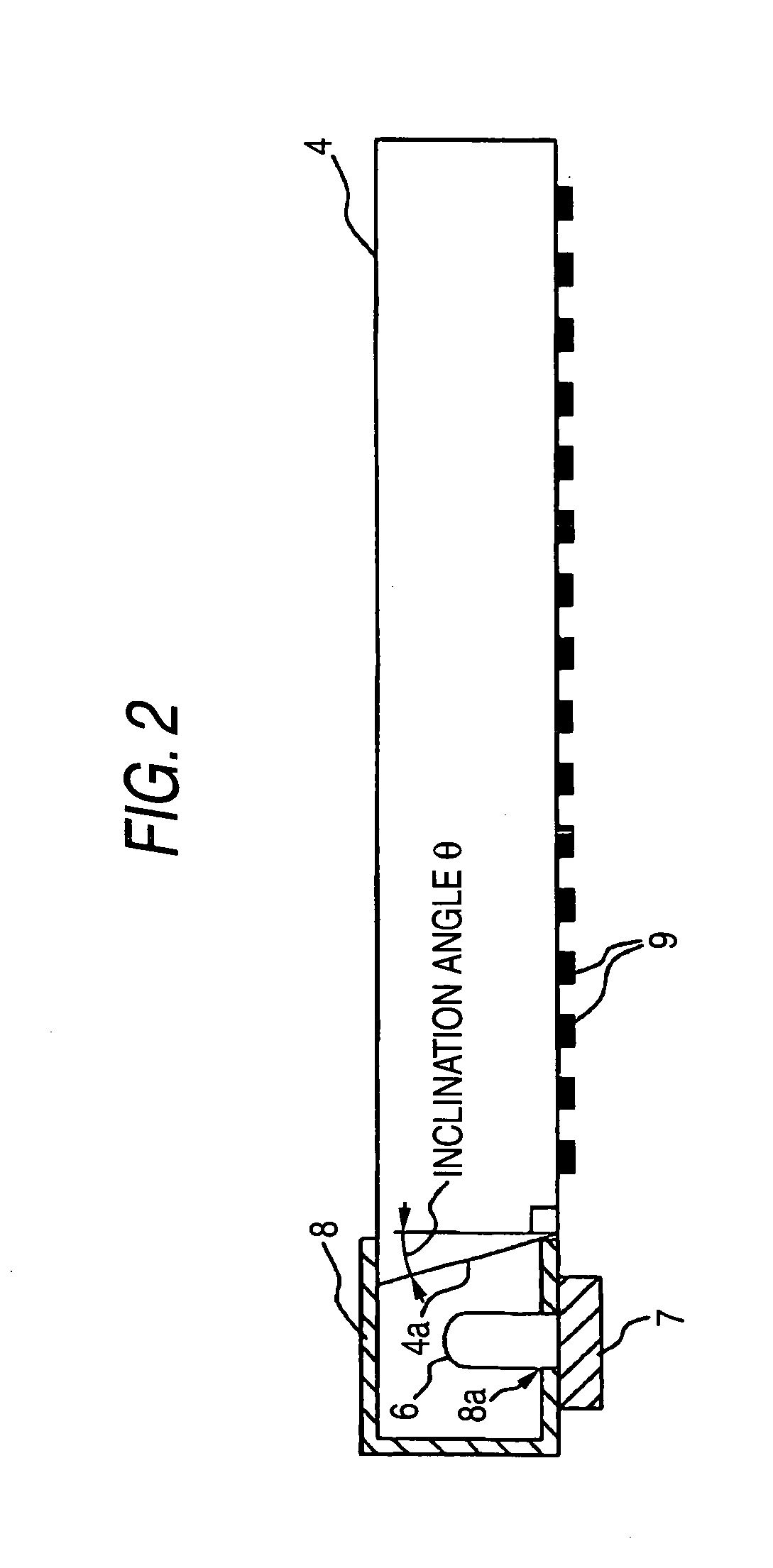

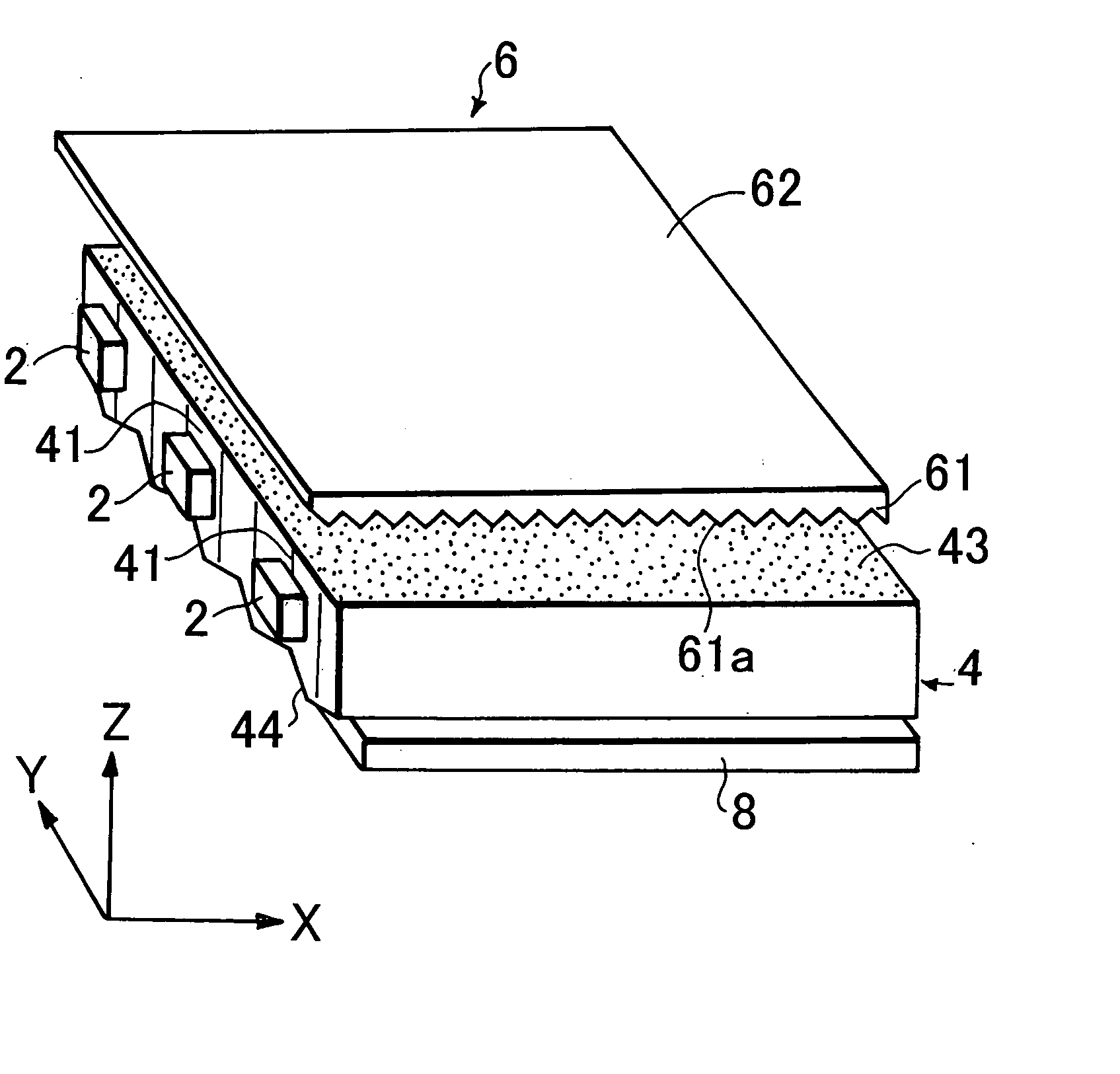

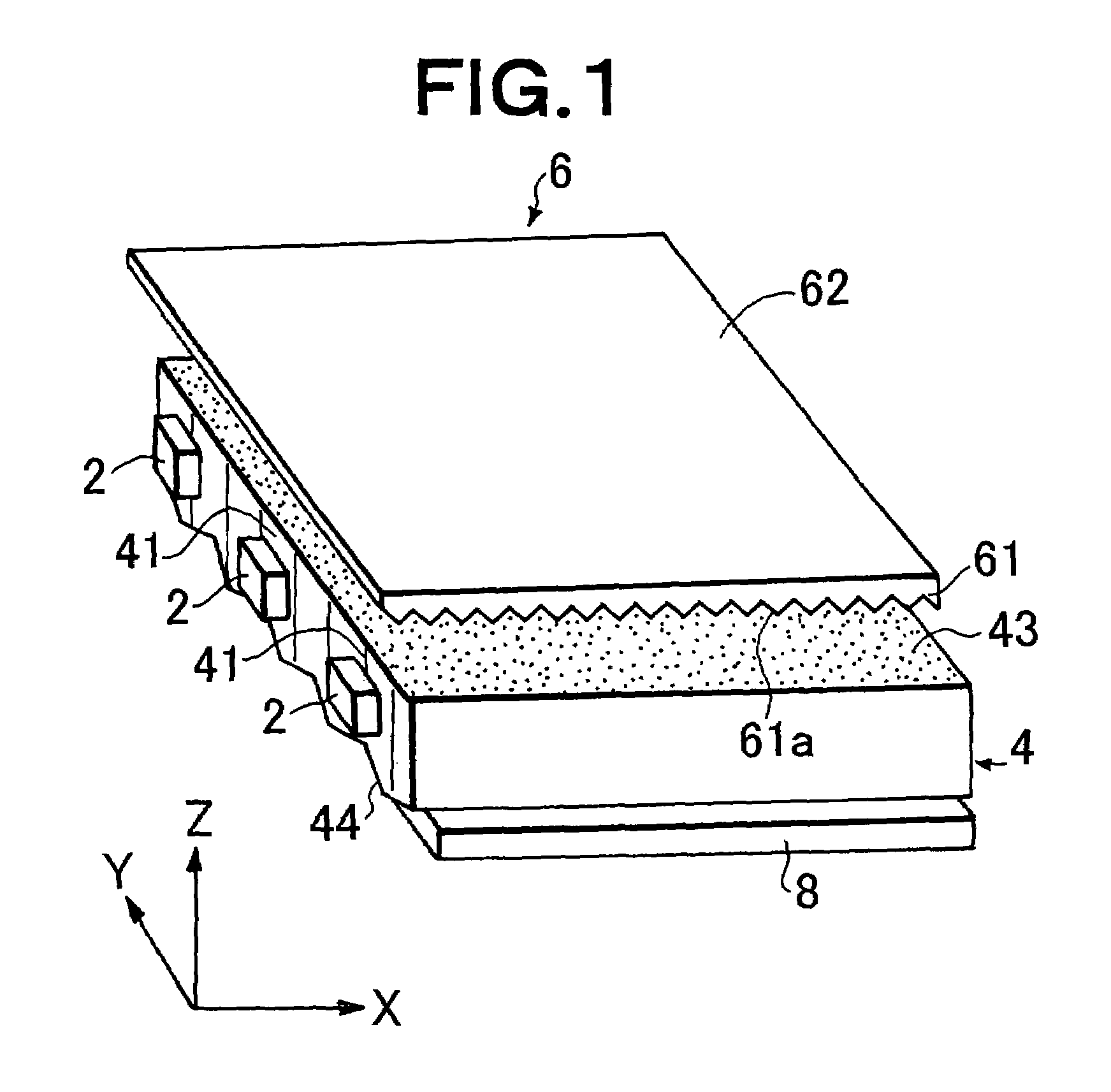

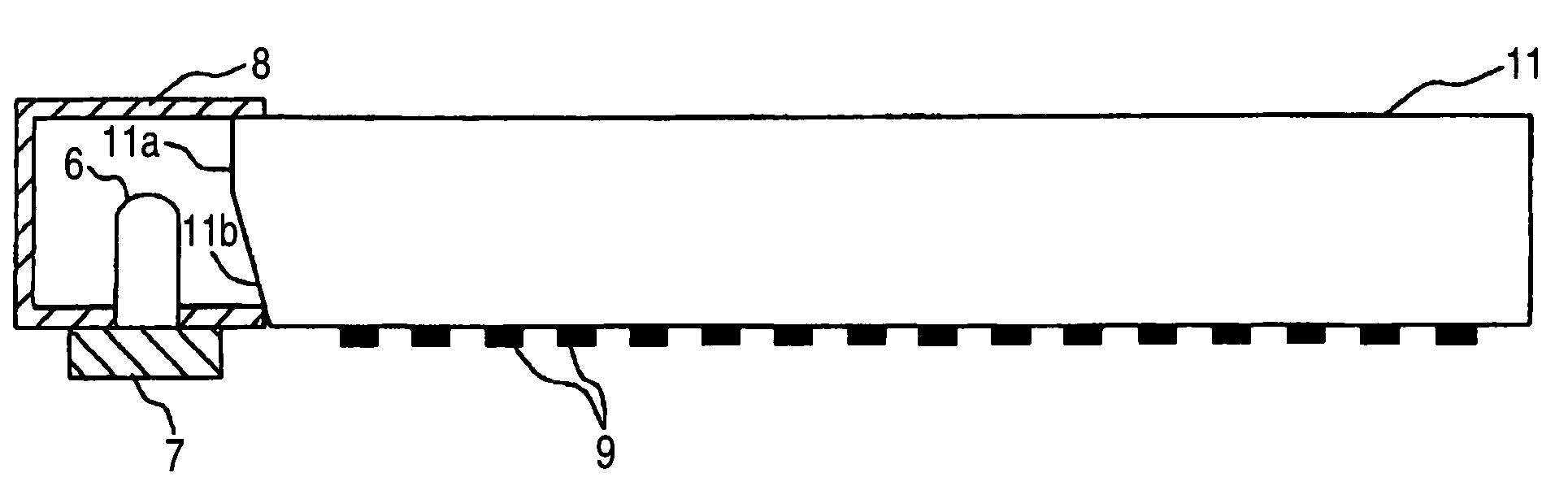

Surface light source device and light guide used therefor

InactiveUS20050174803A1Reduce power consumptionQuality improvementMechanical apparatusPlanar/plate-like light guidesLight guideOptoelectronics

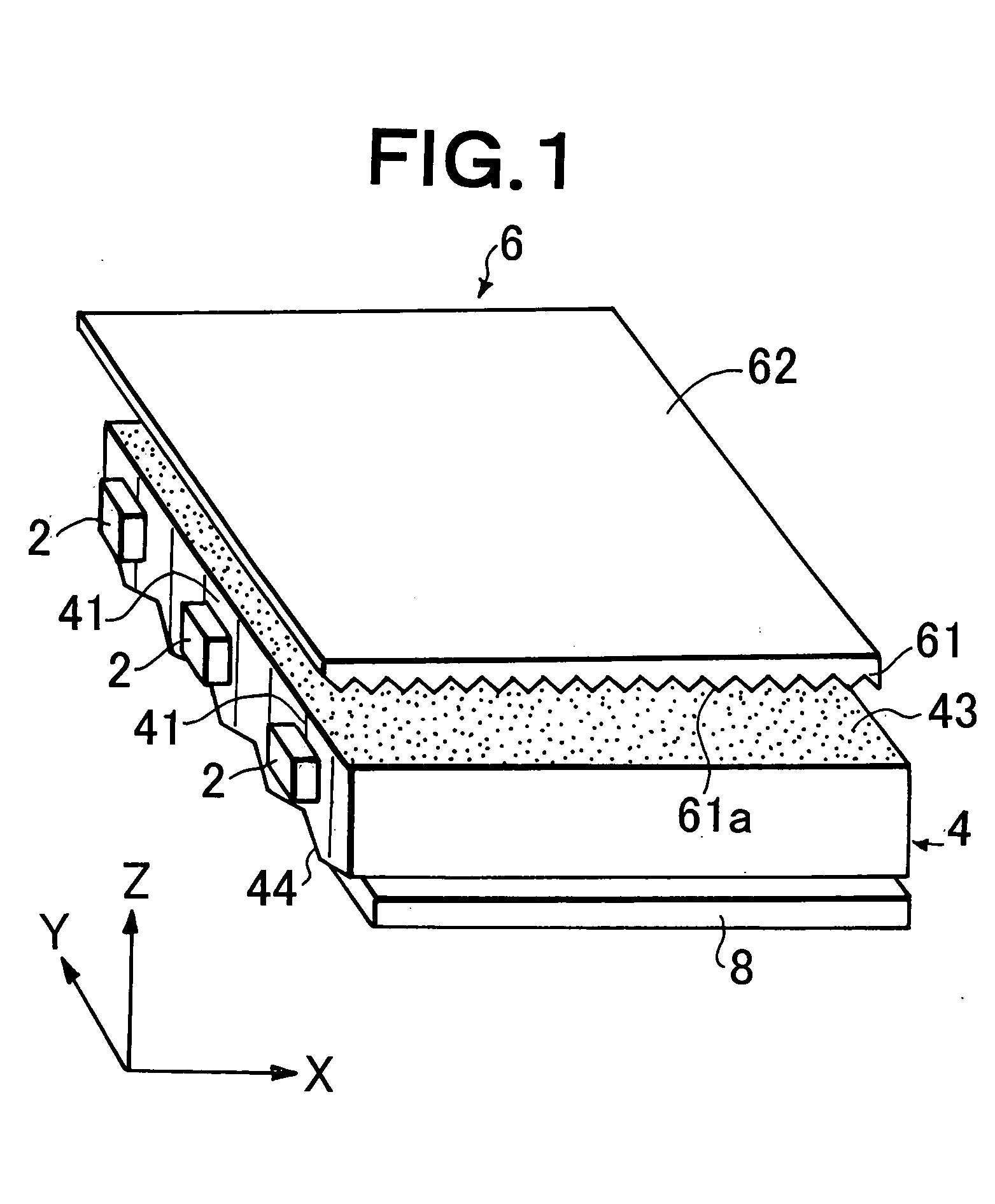

A platy light guide (4) which guides light emitted from an LED (2) and has a light incident end surface (41) for receiving light from the LED (2) and a light outputting surface (43) for outputting a guided light, wherein a plurality of lens rows extending along the directivity direction (X direction) of a light guide incident light in a plane along the light outputting surface (43) and arranged in parallel to each other are formed on a rear surface (44). In the vicinity of the LED (2), the shape of the section perpendicular to their extending directions of the plurality of lens rows is such that the existence proportion of an angle component having an absolute value of at least 20° and up to 50° of an inclination angle formed by a tangent and a lens row forming surface in each fine area is at least 10%. A light deflection element (6) disposed adjacent to the light guide light outputting surface (43) is provided on the light entrance surface (61) thereof with a plurality of lens rows (61a) extending in a direction parallel to the light guide light incident end surface (41) and being parallel to each other. Accordingly, a high-quality surface light source device free from brightness unevenness caused by a fewer LEDs used is provided.

Owner:MITSUBISHI CHEM CORP

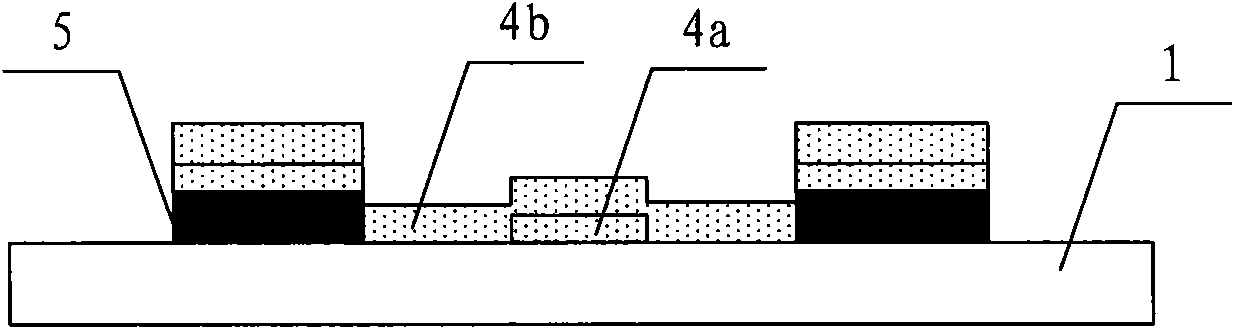

Mask plate and manufacture method thereof

ActiveCN101738846AImprove yield rateImprove electrical performanceSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentEngineeringPhotoresist

The invention relates to a mask plate and a manufacture method thereof. The mask plate comprises a lightproof region, a fully transparent region and a partial transparent region; the partial transparent region is formed in a such way that a semi-transparent part and a transparent part are alternatively arranged. The invention is a new mask plate manufactured by combining a grey mask plate technique and halftone mask plate technique; the mask plate ensures that the exposure of photoresist at the lower part of the partial nonopaque region is uniform when in use, which is beneficial to forming the smooth surface of a partial maintaining region of the photoresist, thereby facilitating the TFT groove etch and improving the yield of array substrates, at the same time, the obliquity of the photoresist at the edge of the partial maintaining region of the photoresist is increased, thereby the technique can be accurately controlled in the process of forming the TFT groove.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

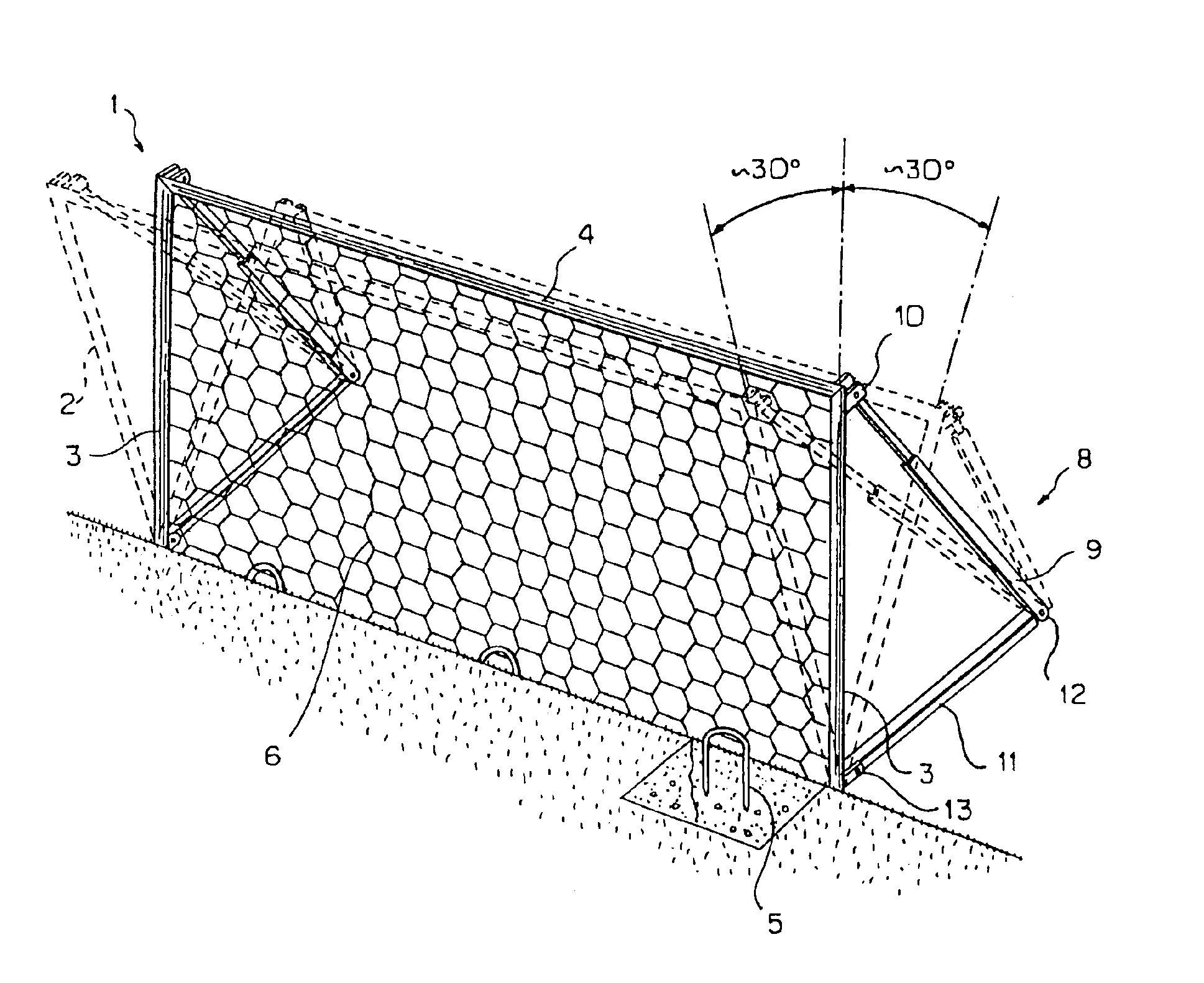

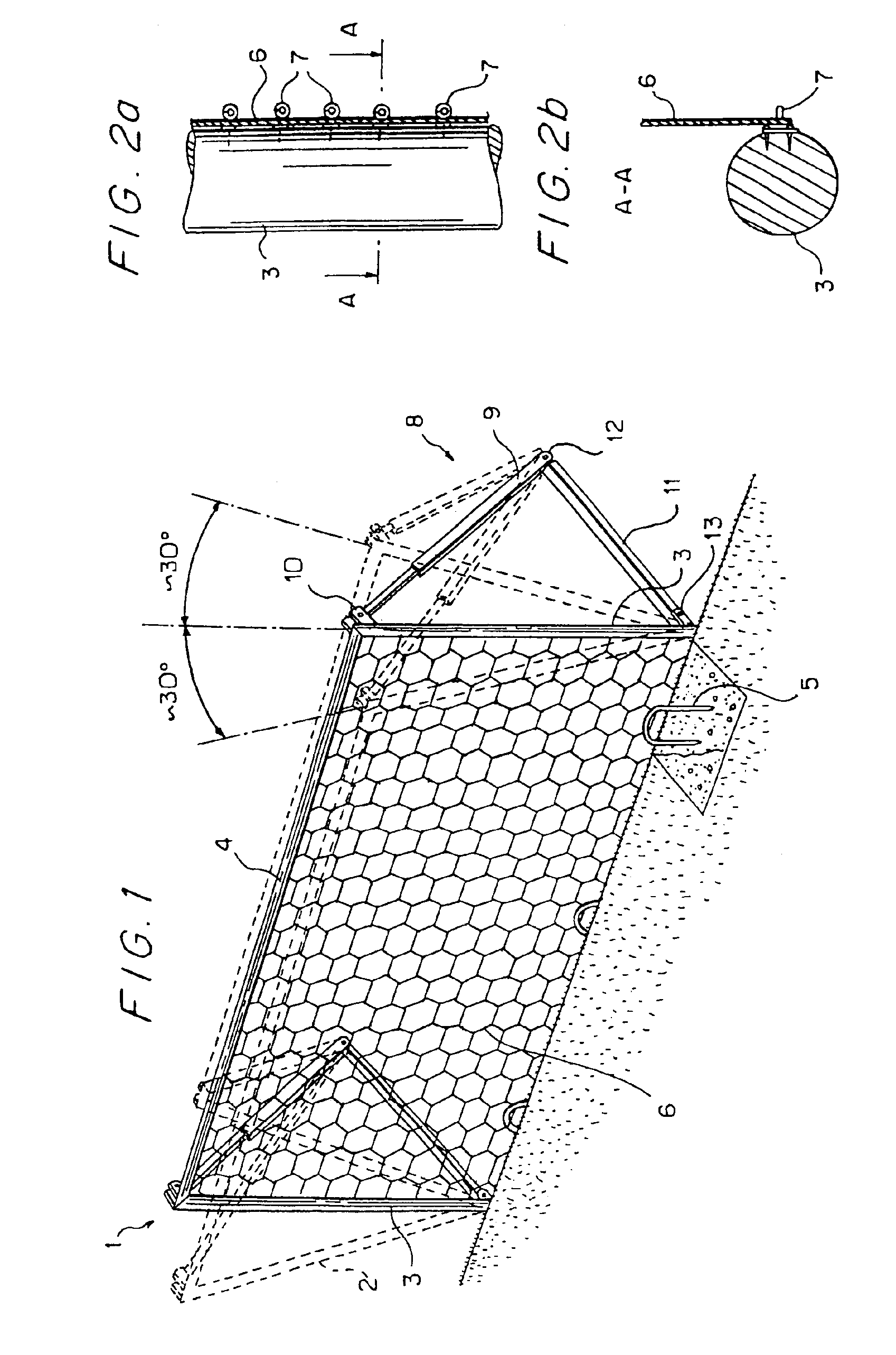

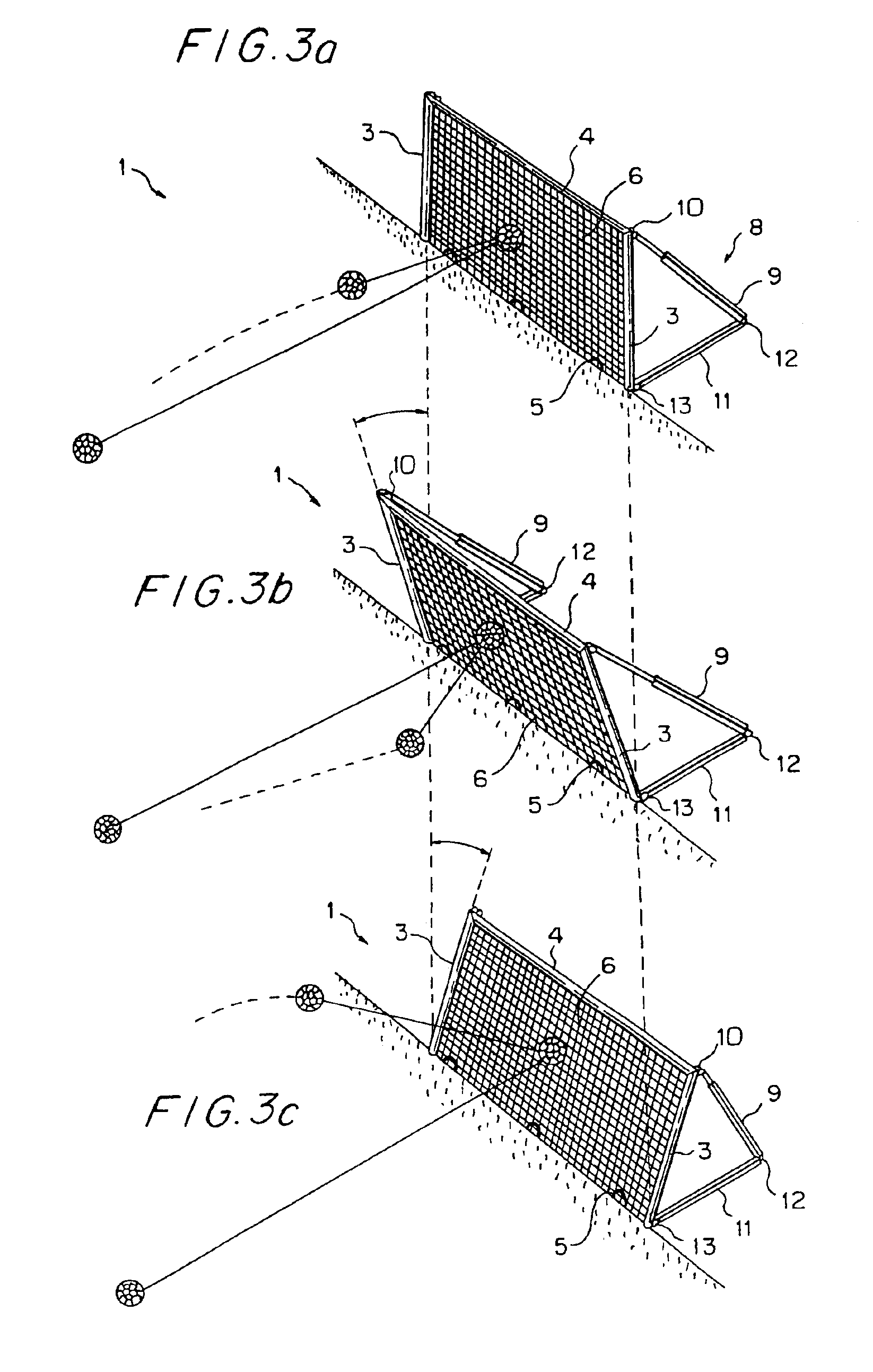

Training tool for ball games

Owner:PIRAS FAUSTO +1

Surface light source device and light guide used therefor

InactiveUS7226197B2Reduce power consumptionQuality improvementMechanical apparatusPlanar/plate-like light guidesLight guideOptoelectronics

A light guide which guides light emitted from an LED includes a light incident end surface for receiving light, a light outputting surface for outputting a guided light, and a lens forming surface that has a plurality of elongated lenses arranged in parallel to each other and formed along the directivity of light incident from the LED, such that a plurality of micro regions are defined over the plurality of elongated lens. In the vicinity of the LED, a distribution of micro regions having an inclination angle between 20° and 50° is at least 10% over all micro regions. A light deflection element disposed adjacent to the light guide light outputting surface includes a light entrance surface having a plurality of lenses formed thereon that are parallel to each other and extend in a direction parallel to the light guide light incident end surface.

Owner:MITSUBISHI CHEM CORP

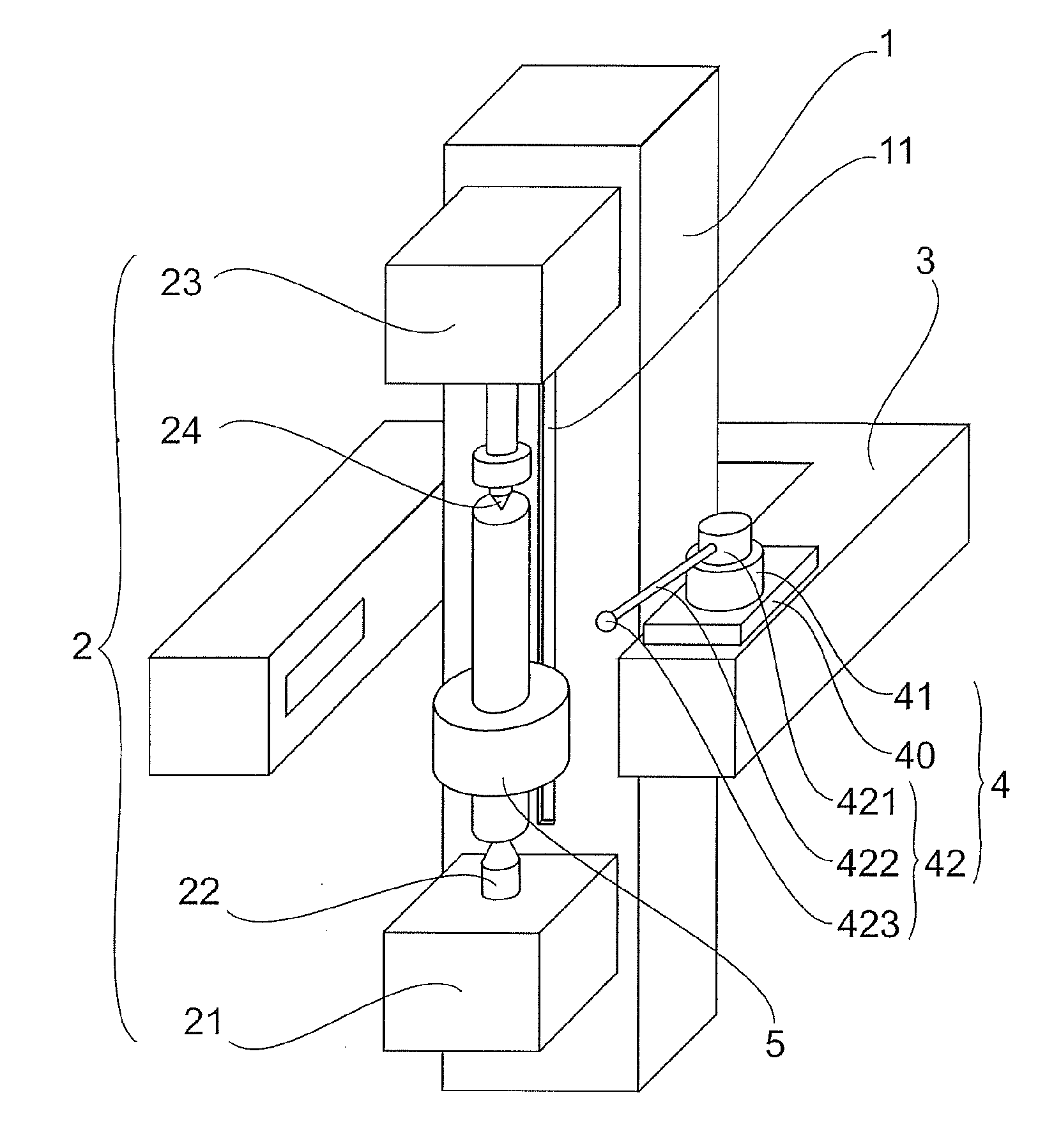

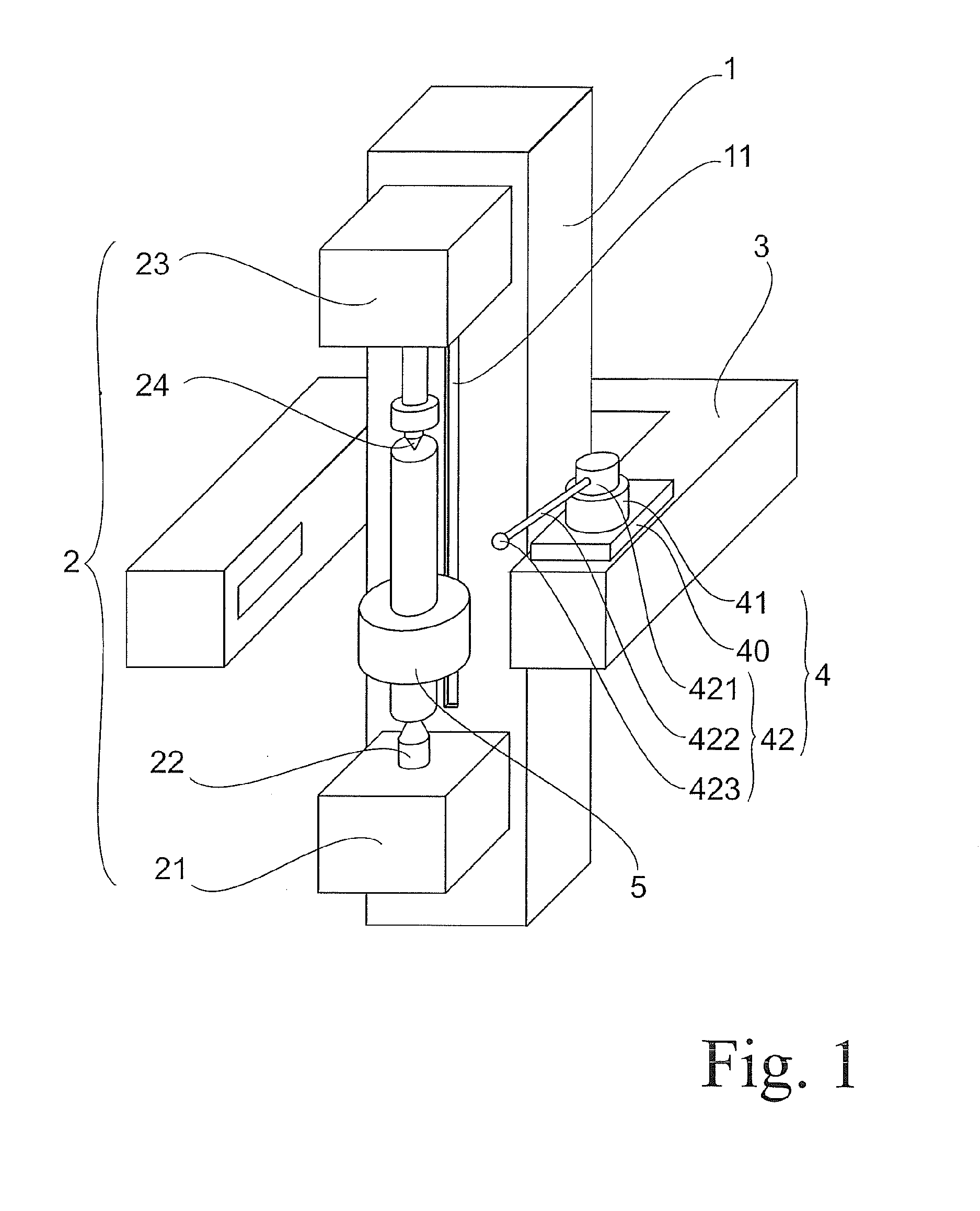

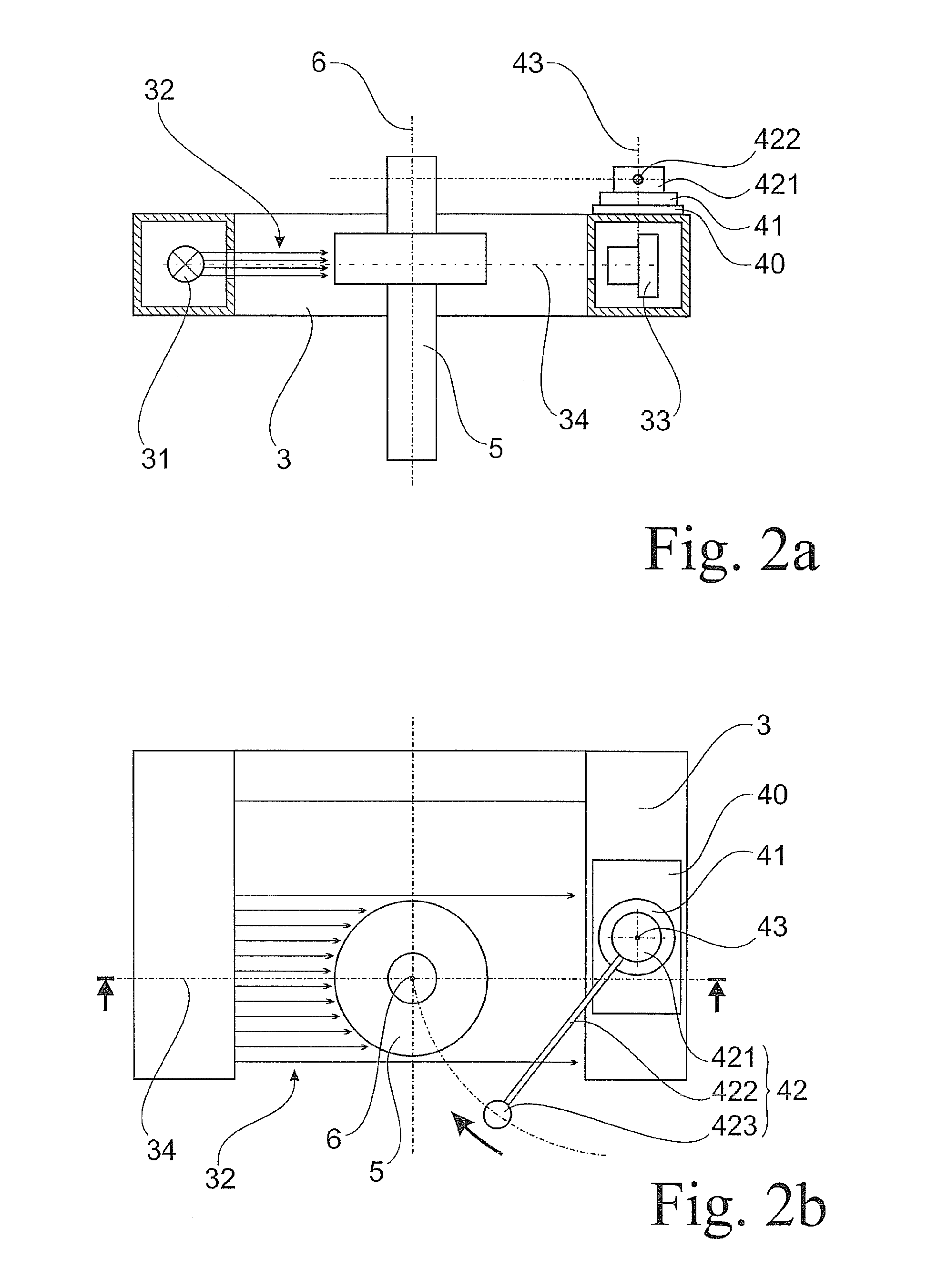

Device and Method for Measuring Form Attributes, Position Attributes and Dimension Attributes of Machine Elements

InactiveUS20130300861A1High measurement accuracyReduce expenditureColor television detailsClosed circuit television systemsRotational axisCamera module

A device and a method for measuring form attributes, position attributes and dimension attributes of rotatable machine elements are described. It is the object of the invention to find a possibility for measuring form attributes, position attributes or dimension attributes of a rotatable machine element which also allows axially probeable surfaces having hidden regions to be measured with high accuracy with a lower expenditure on construction. According to the invention, this object is met in that a mechanical measuring unit having a tactile measuring probe for measuring the machine element in axial direction is provided in addition to an optical measuring unit with illumination module and camera module which captures a shadow image of the machine element. The mechanical measuring unit is fixed to the optical measuring unit and has a swiveling device for swiveling the tactile measuring probe orthogonal to the rotational axis of the machine element.

Owner:JENOPTIK IND METROLOGY GERMANY

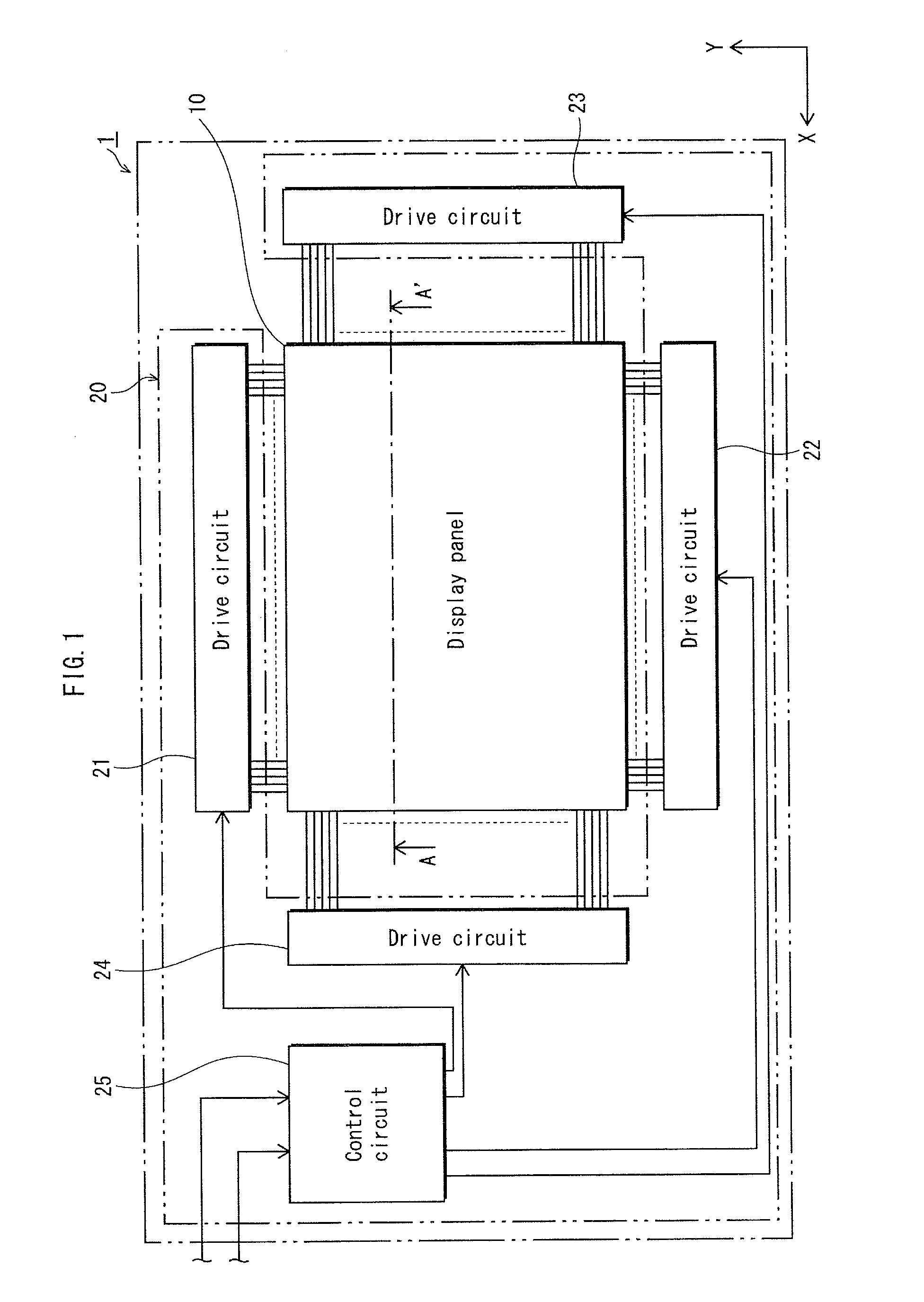

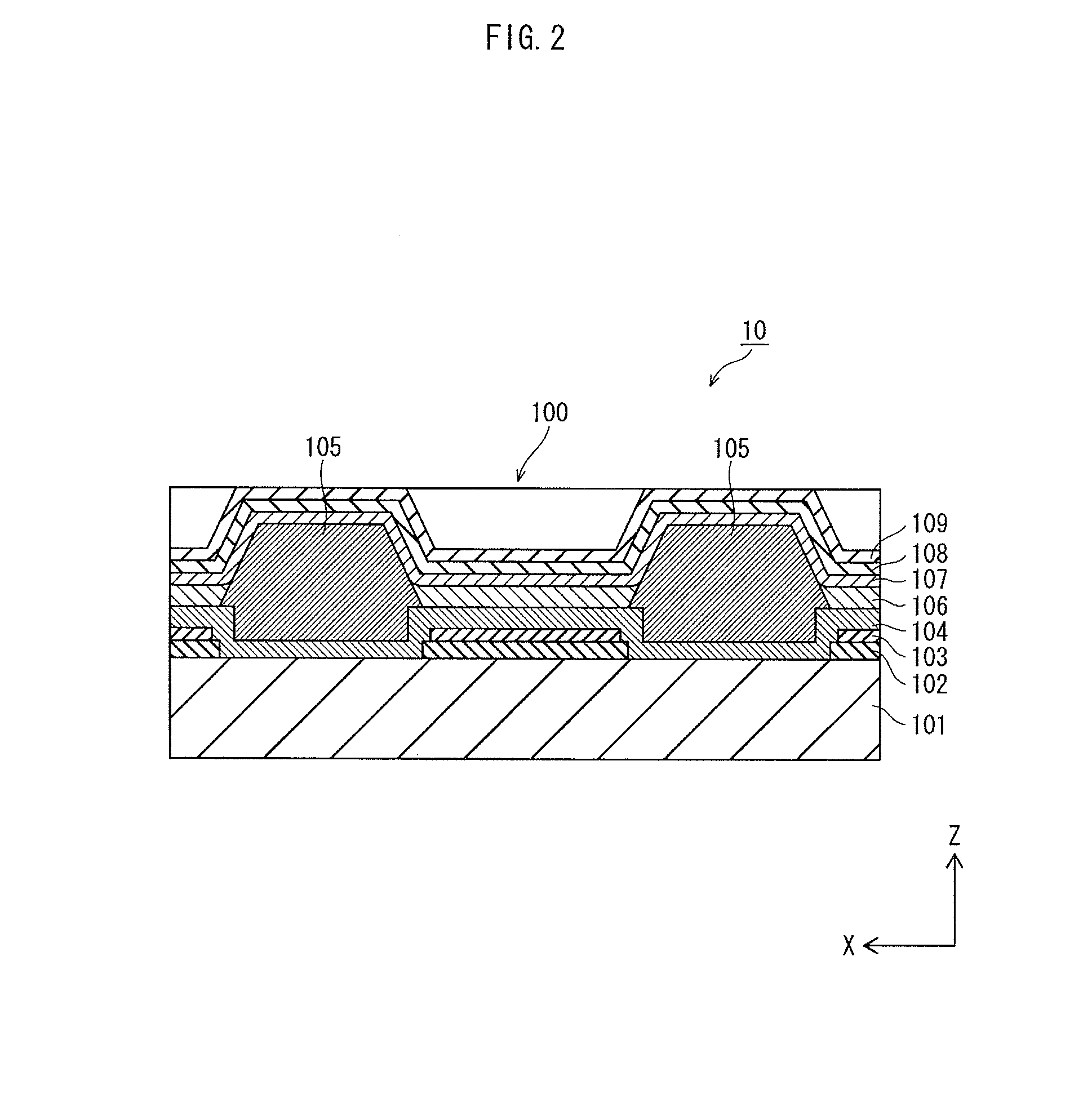

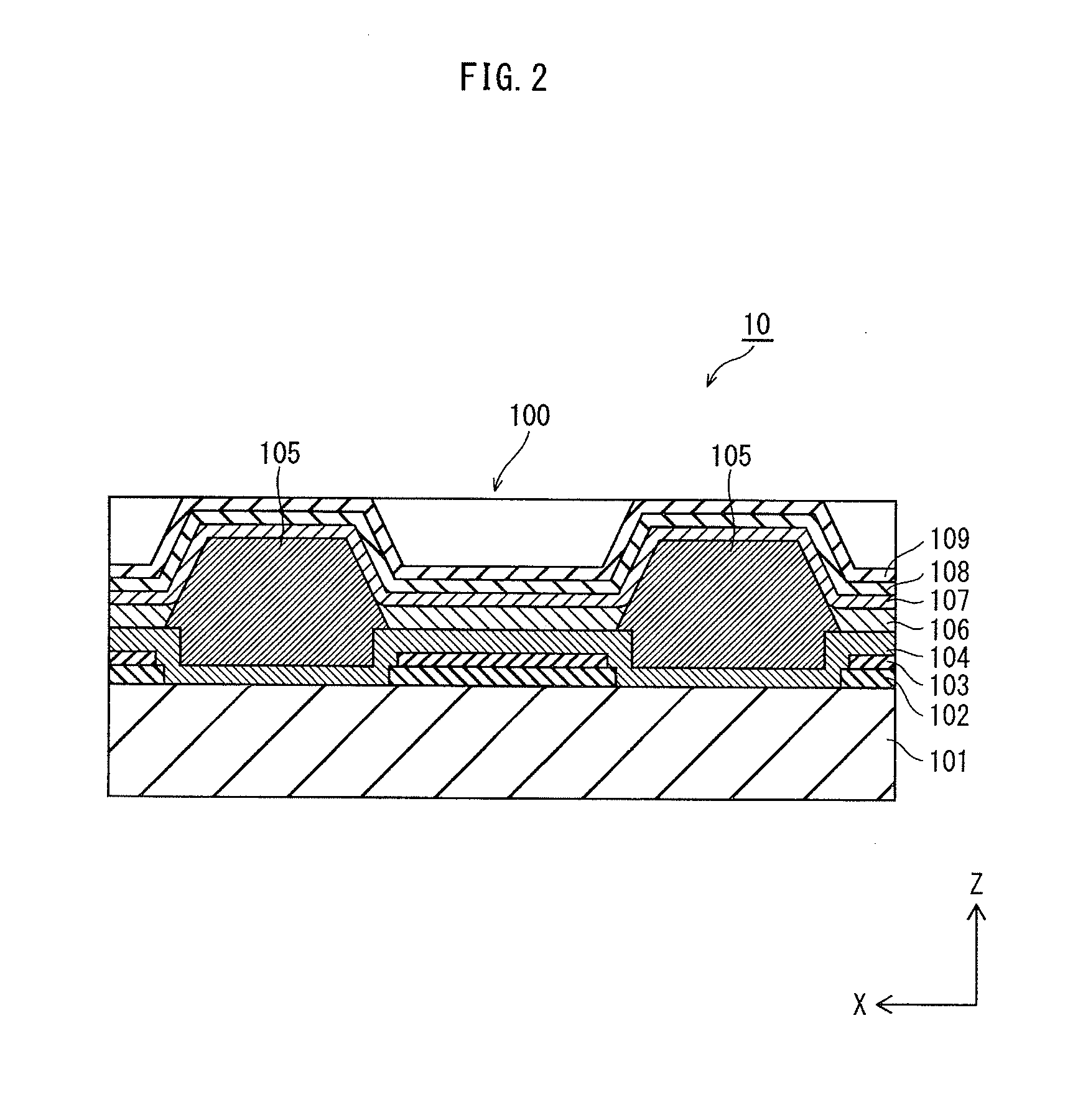

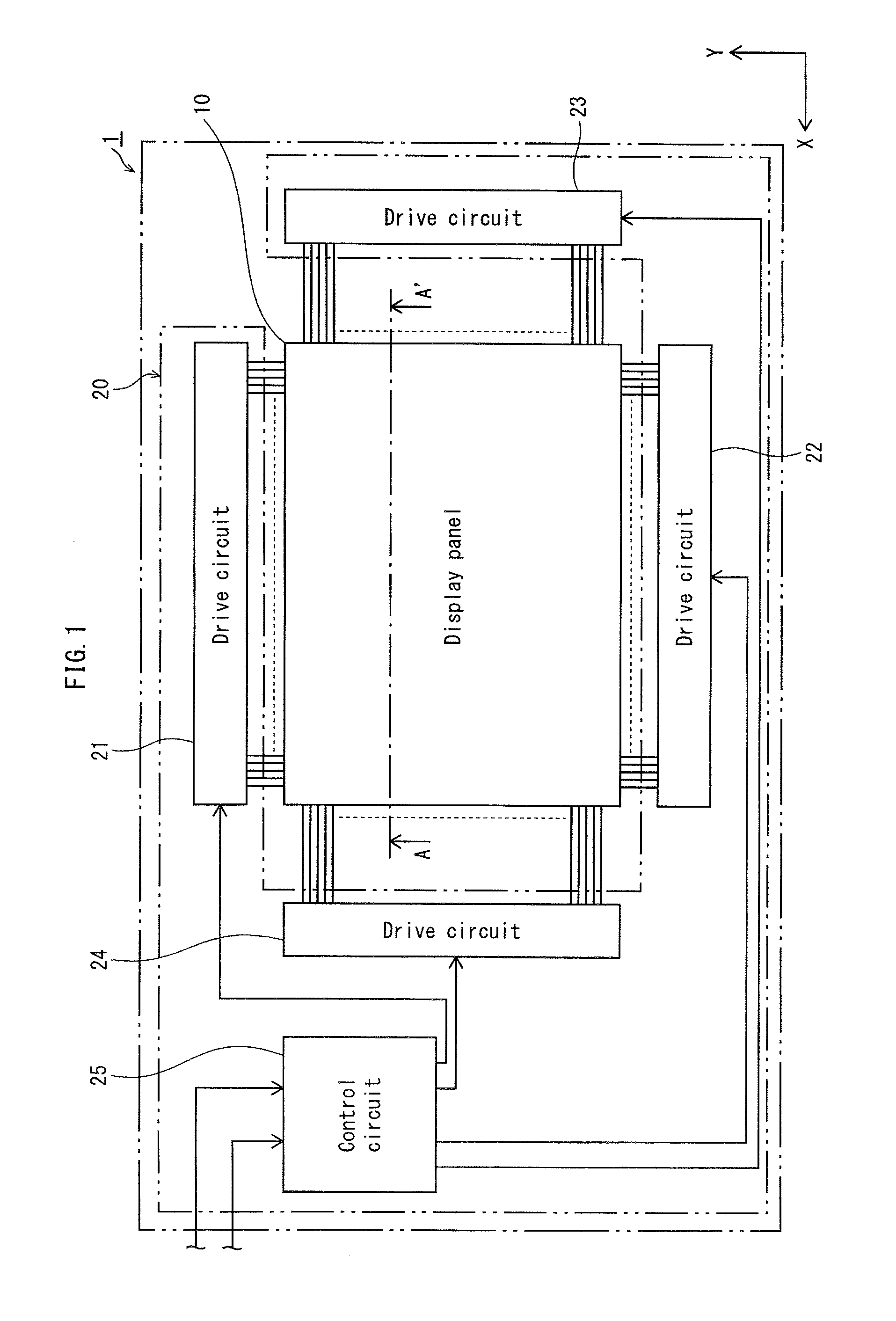

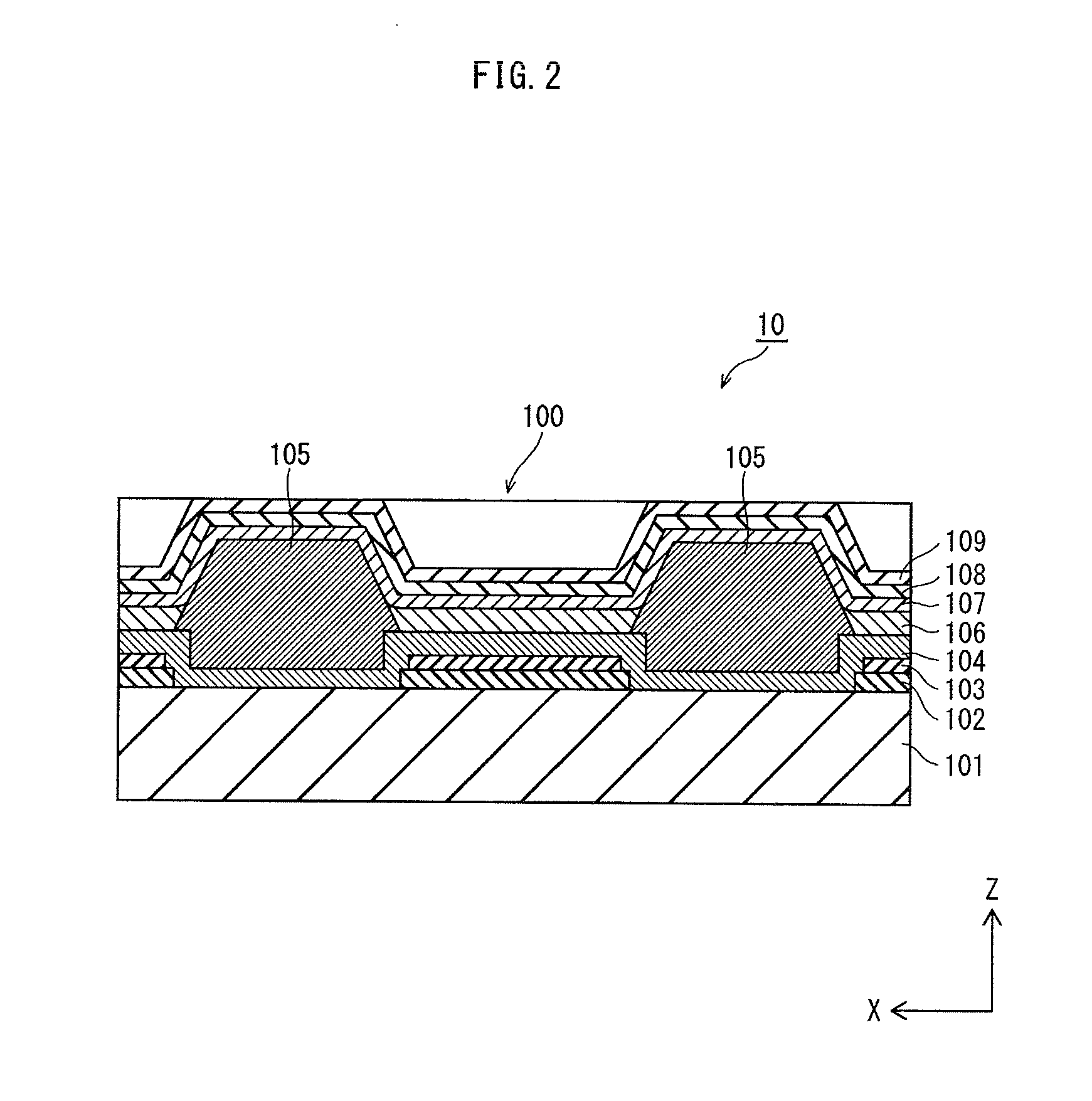

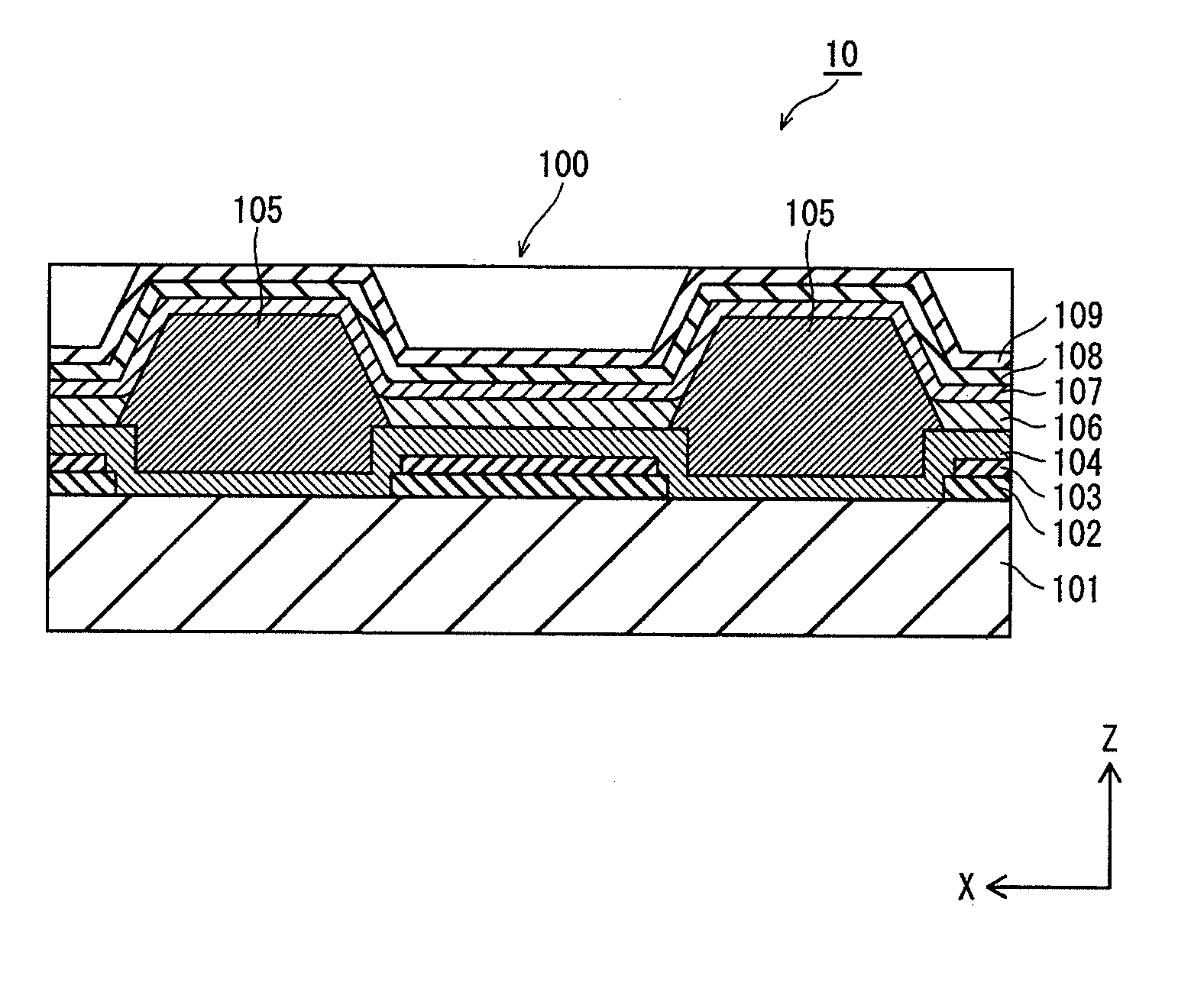

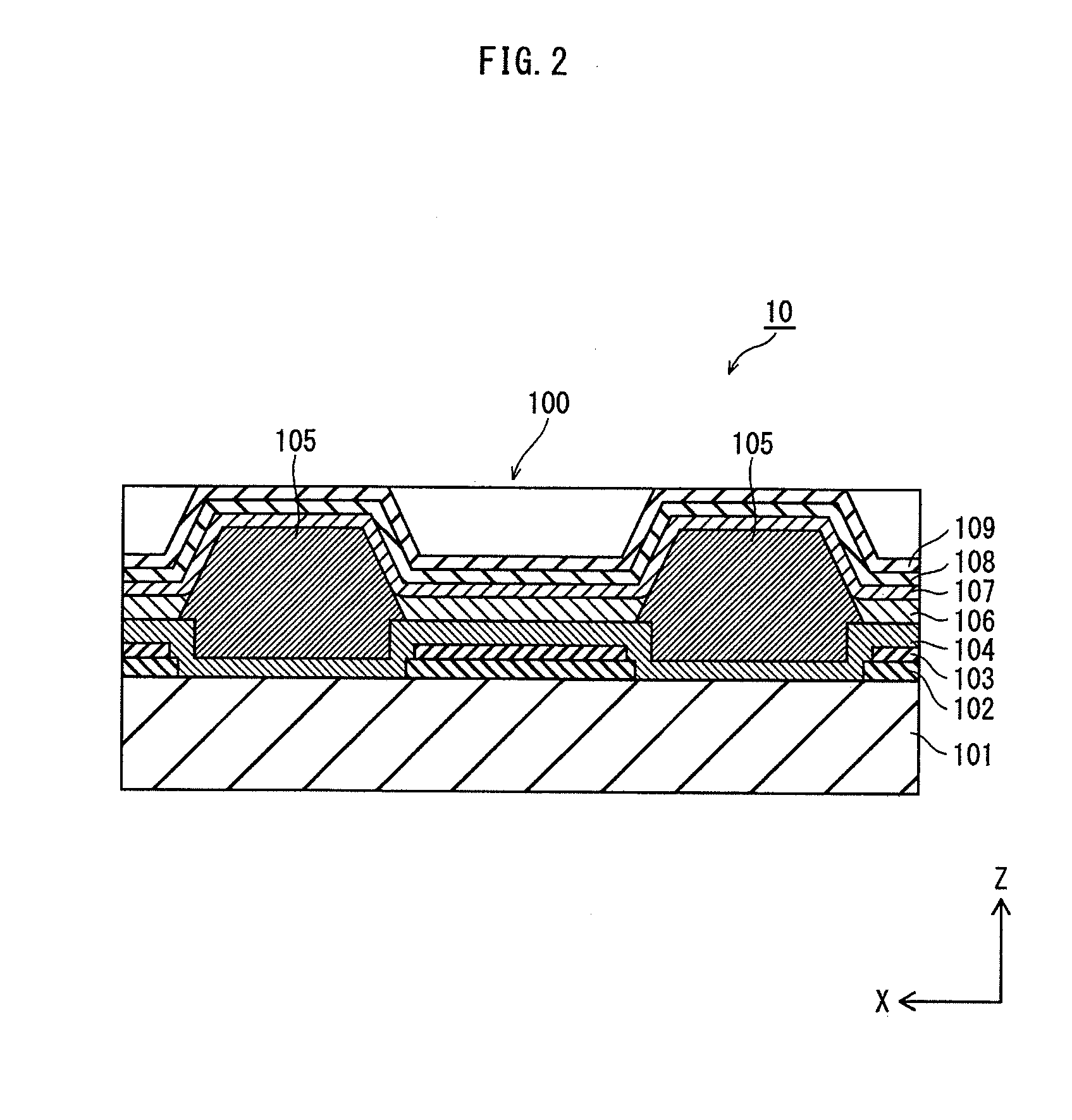

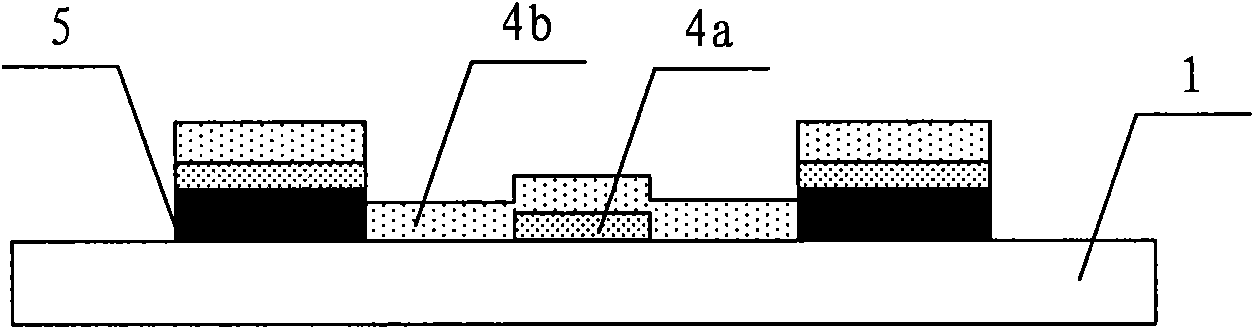

Organic light-emitting panel, manufacturing method thereof, and organic display device

ActiveUS20120193658A1High vapor concentrationLarge film thicknessElectroluminescent light sourcesSolid-state devicesDisplay deviceEngineering

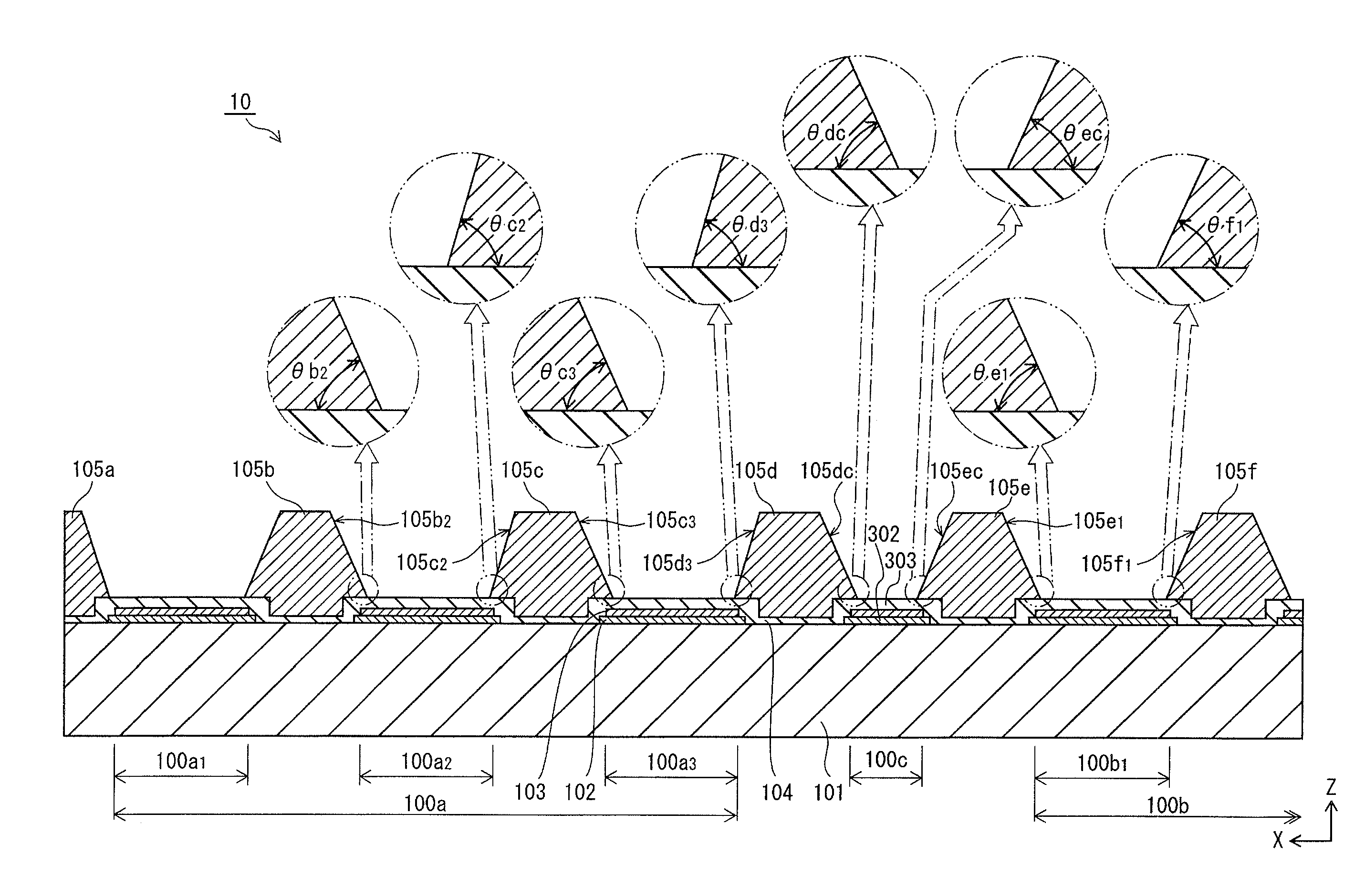

A pixel in the panel includes sub-pixels 100a, 100b, and 100c. Non-light-emitting cells 100d and 100e are provided between the pixel and adjacent pixels on both sides thereof, respectively. The organic light-emitting layer of sub-pixel 100a and non-light-emitting cell 100d are separated by bank 105a. Similarly, the organic light-emitting layer of sub-pixel 100c and non-light-emitting cell 100e are separated by bank 105d; the organic light-emitting layers of sub-pixels 100a and 100b are separated by bank 105b; and the organic light-emitting layers of sub-pixels 100b and 100c are separated by bank 105c. Inclination angle θaa of sidewall 105aa of bank 105a adjacent to sib-pixel 100a and inclination angle θdc of sidewall 105dc of bank 105d adjacent to sib-pixel 100c are larger than other inclination angles θba, θbb, θcb, and θcc.

Owner:JOLED INC

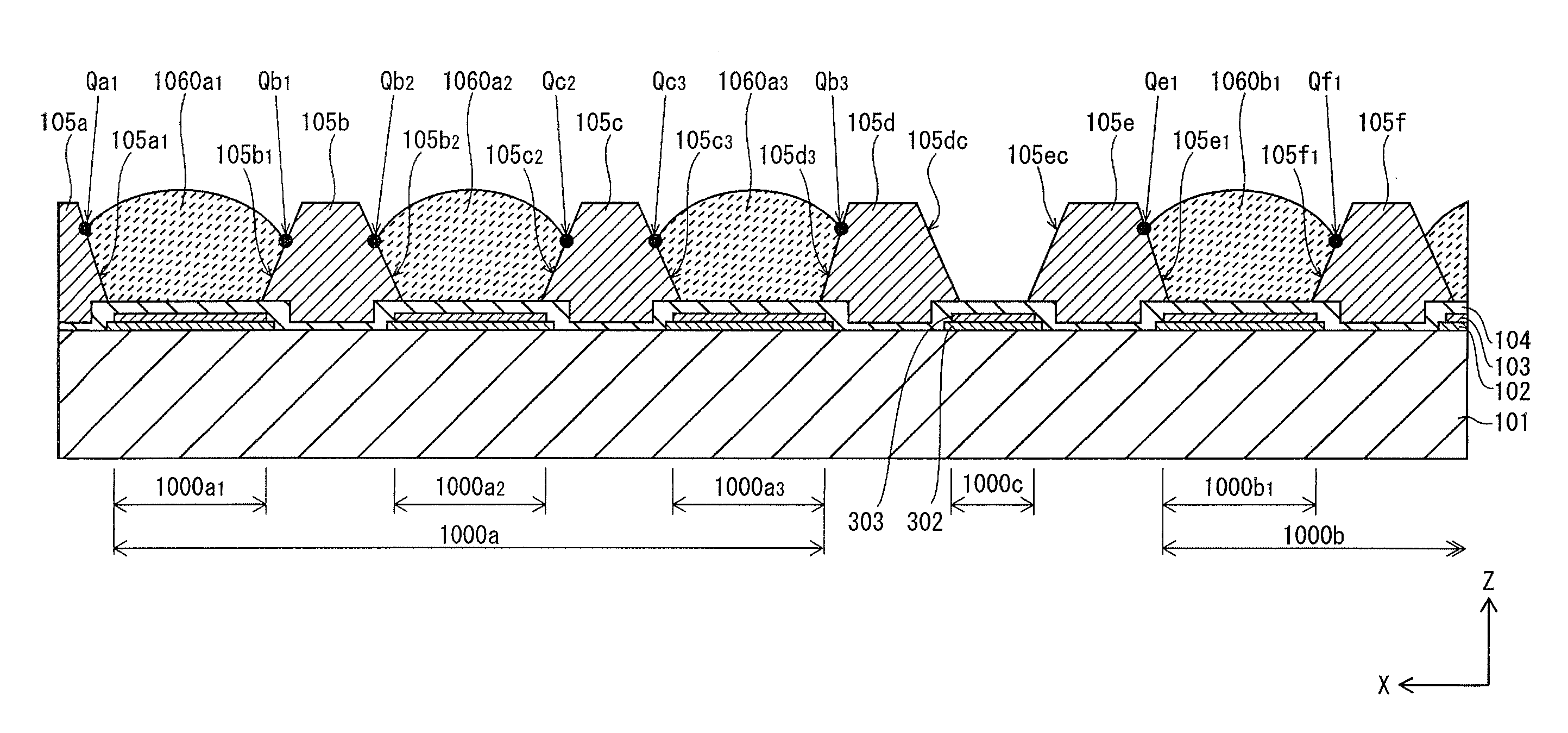

Organic light-emitting panel and manufacturing method thereof, and organic display device

ActiveUS20120091483A1Avoid uneven film thicknessLarge inclinationSolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryDisplay device

A non-light-emitting cell 100c is provided between pixels 100a and 100b. Ink for forming an organic light-emitting layer is dripped substantially simultaneously into sub-pixels 100a1, 100a2, and 100a3 in the pixel 100a and a sub-pixel 100b1 in the pixel 100b. On the other hand, such ink is not dripped into the non-light-emitting cell 100c since the organic light-emitting layer is not formed in the non-light-emitting cell 100c. In a bank 105d, an inclination angle θd3 of a wall 105d3 facing the sub-pixel 100a3 is larger than an inclination angle θdc of a wall 105dc facing the non-light-emitting cell 100c. Similarly, in a bank 105e, an inclination angle θe1 of a wall 105e1 facing the sub-pixel 100b1 is larger than an inclination angle θec of a wall 105ec facing the non-light-emitting cell 100c.

Owner:JOLED INC

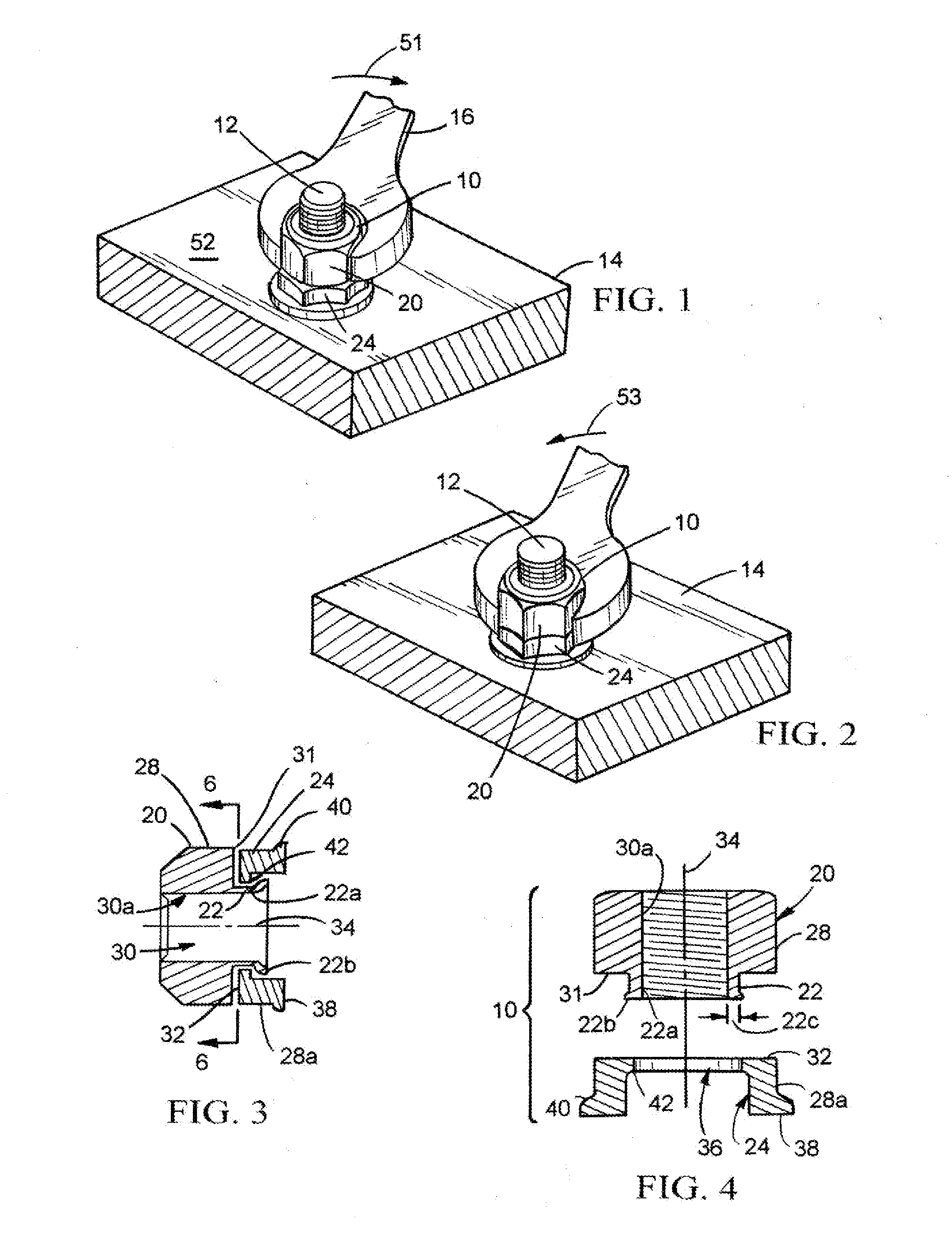

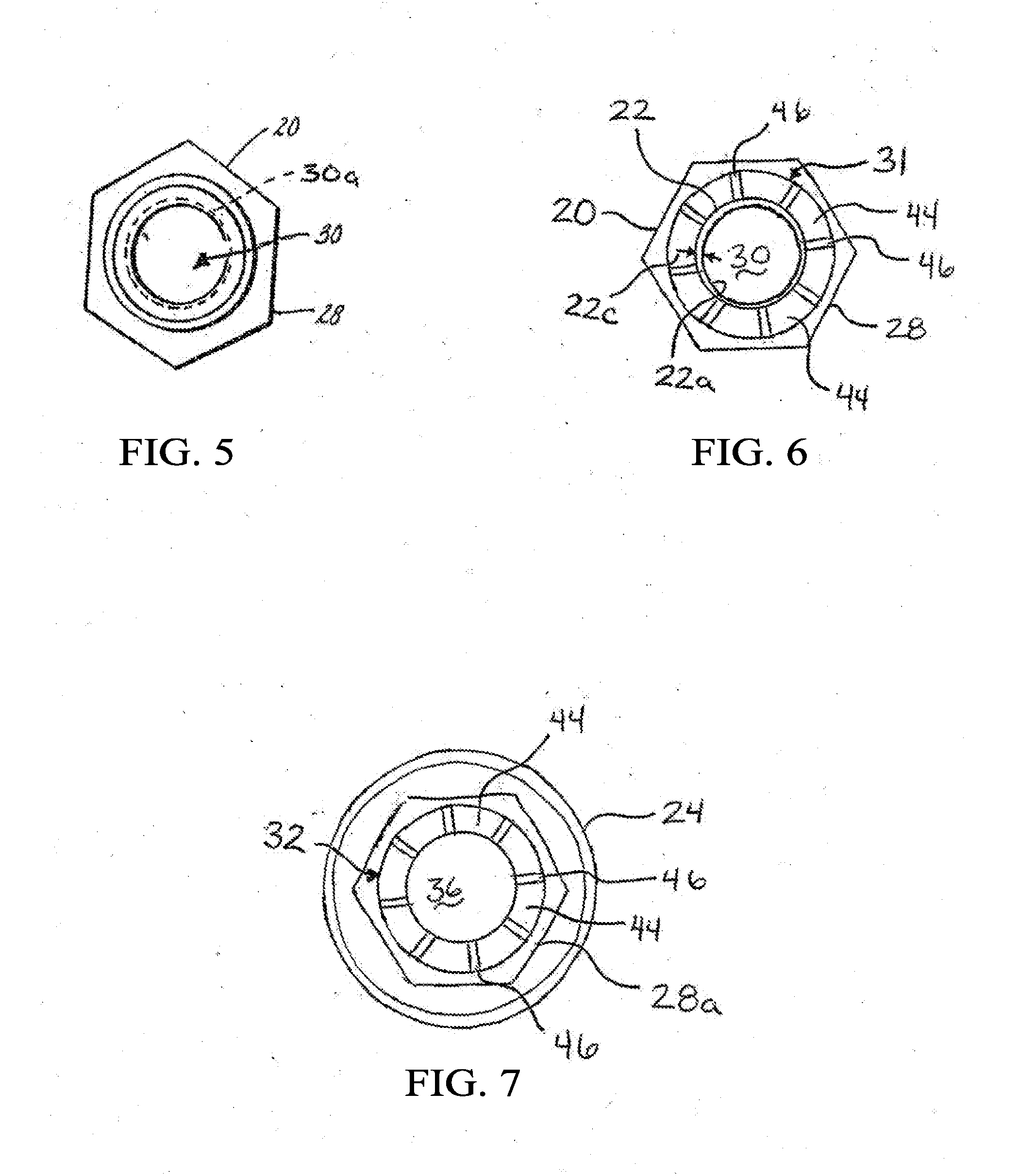

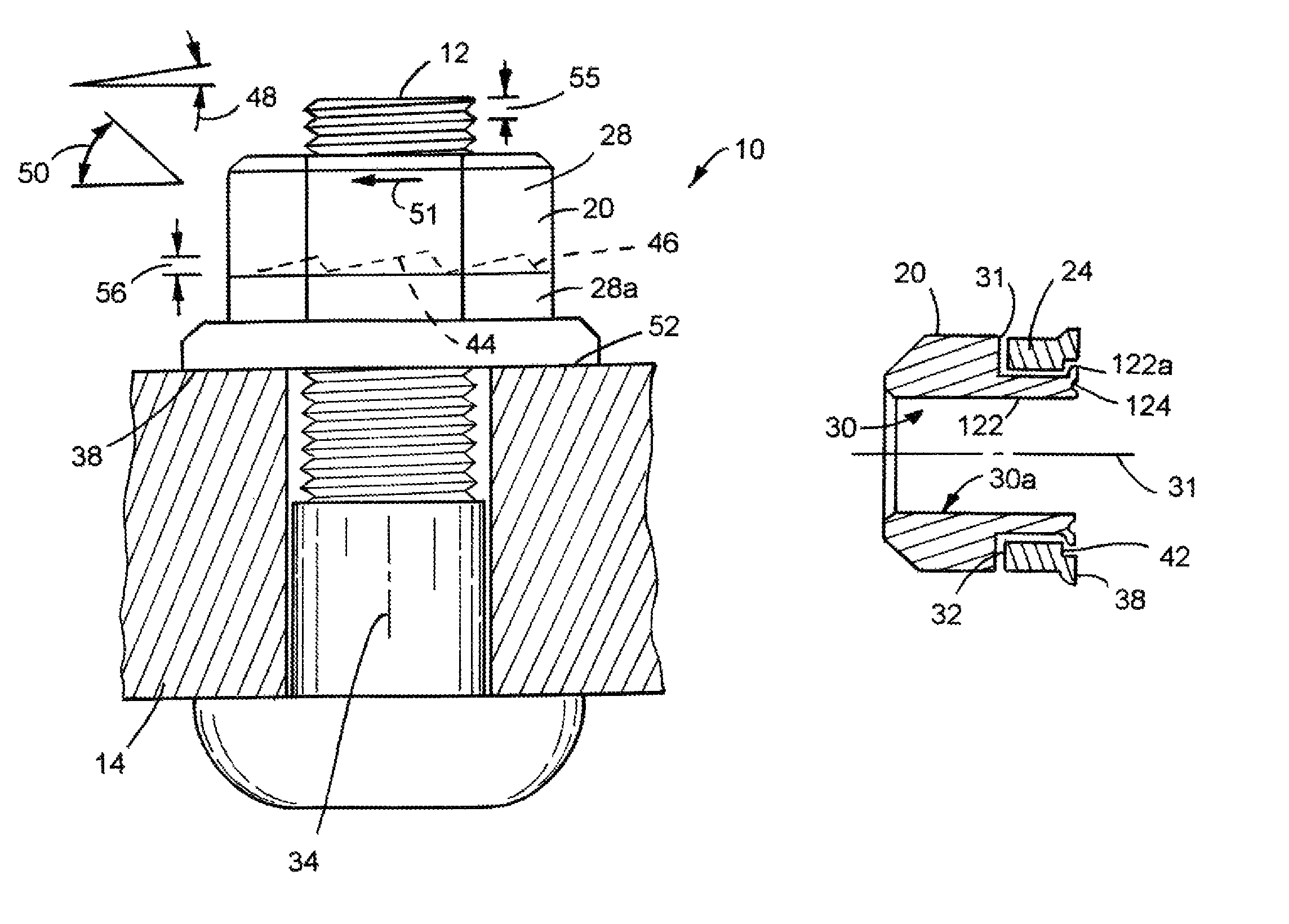

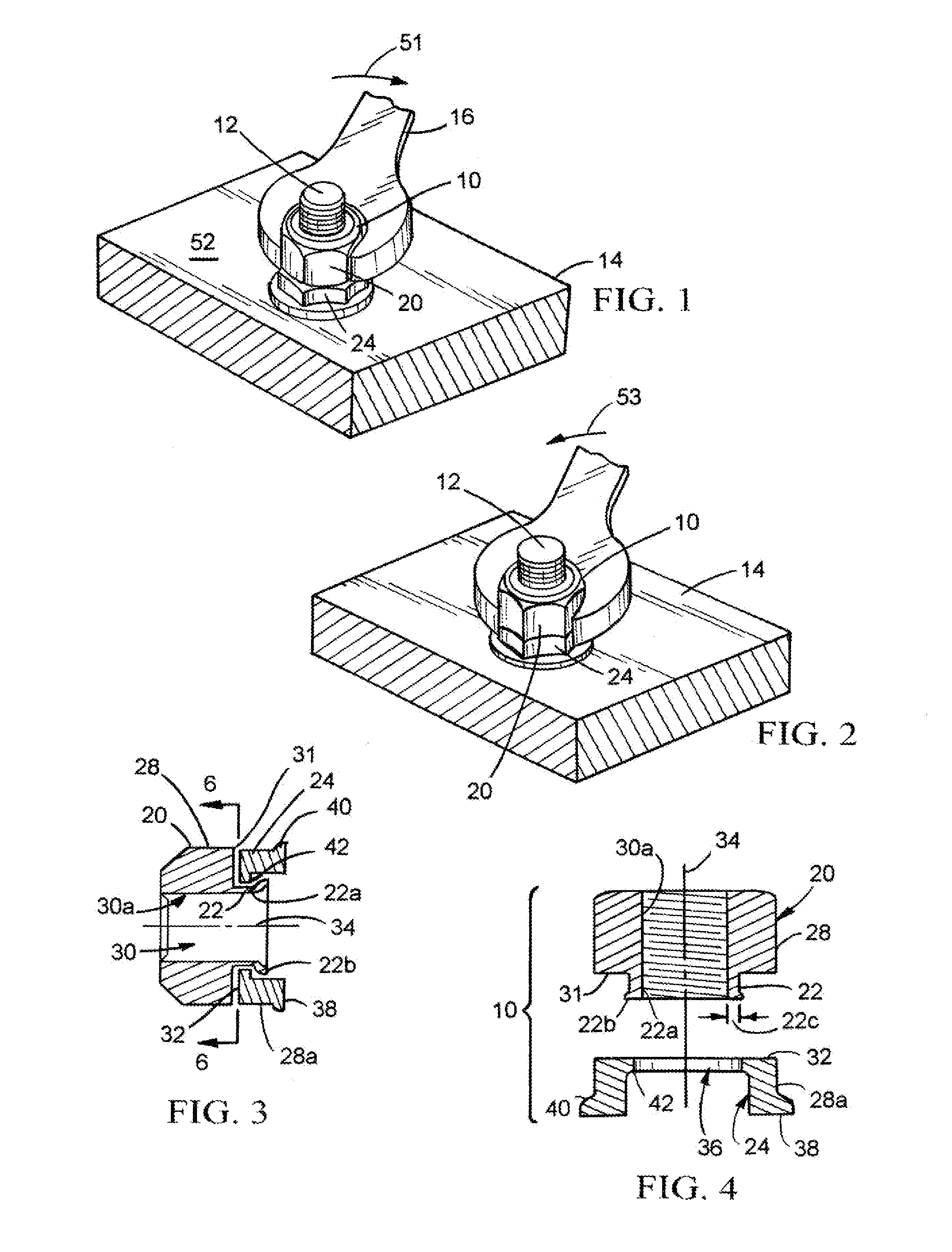

Anti-back-out fastener for applications under vibration

A fastener is disclosed for use in a high vibration application wherein the fastener is engaged to a blind hole. The fastener includes a lock washer including wedge locking action fastening features and a head of the fastener including mating wedge locking action fastening features. The wedge locking action fastening features include a greater inclination than a pitch angle of the fastener such that the fastener is prevented from backing out.

Owner:DISC LOCK LLC

Anti-back-out fastener for applications under vibration

A fastener is disclosed for use in a high vibration application wherein the fastener is engaged to a blind hole. The fastener includes a lock washer including wedge locking action fastening features and a head of the fastener including mating wedge locking action fastening features. The wedge locking action fastening features include a greater inclination than a pitch angle of the fastener such that the fastener is prevented from backing out.

Owner:DISC LOCK LLC

Organic light-emitting panel and manufacturing method thereof, and organic display device

InactiveUS20120091441A1Avoid uneven film thicknessLarge inclinationSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

A non-light-emitting cell 100c is provided between pixels 100a and 100b. In formation of the pixel 100a, ink for forming an organic light-emitting layer is dripped into sub-pixels 100a1, 100a2, 100a3 in this order. This also applies to the pixel 100b. However, such ink is not dripped into the non-light-emitting cell 100c since the organic light-emitting layer is not formed in the non-light-emitting cell 100c. Regarding banks 105c and 105d defining the sub-pixel 100a3 of the pixel 100a, an inclination angle θd3 of a wall 105d3 of the bank 105d is larger than an inclination angle θc3 of a wall 105c3 of the bank 105c. Meanwhile, regarding banks 105e and 105f defining the sub-pixel 100b1, an inclination angle θe1 of a wall 105e1 of the bank 105e is equivalent to an inclination angle θe1 of a wall 105f1 of the bank 105f.

Owner:JOLED INC

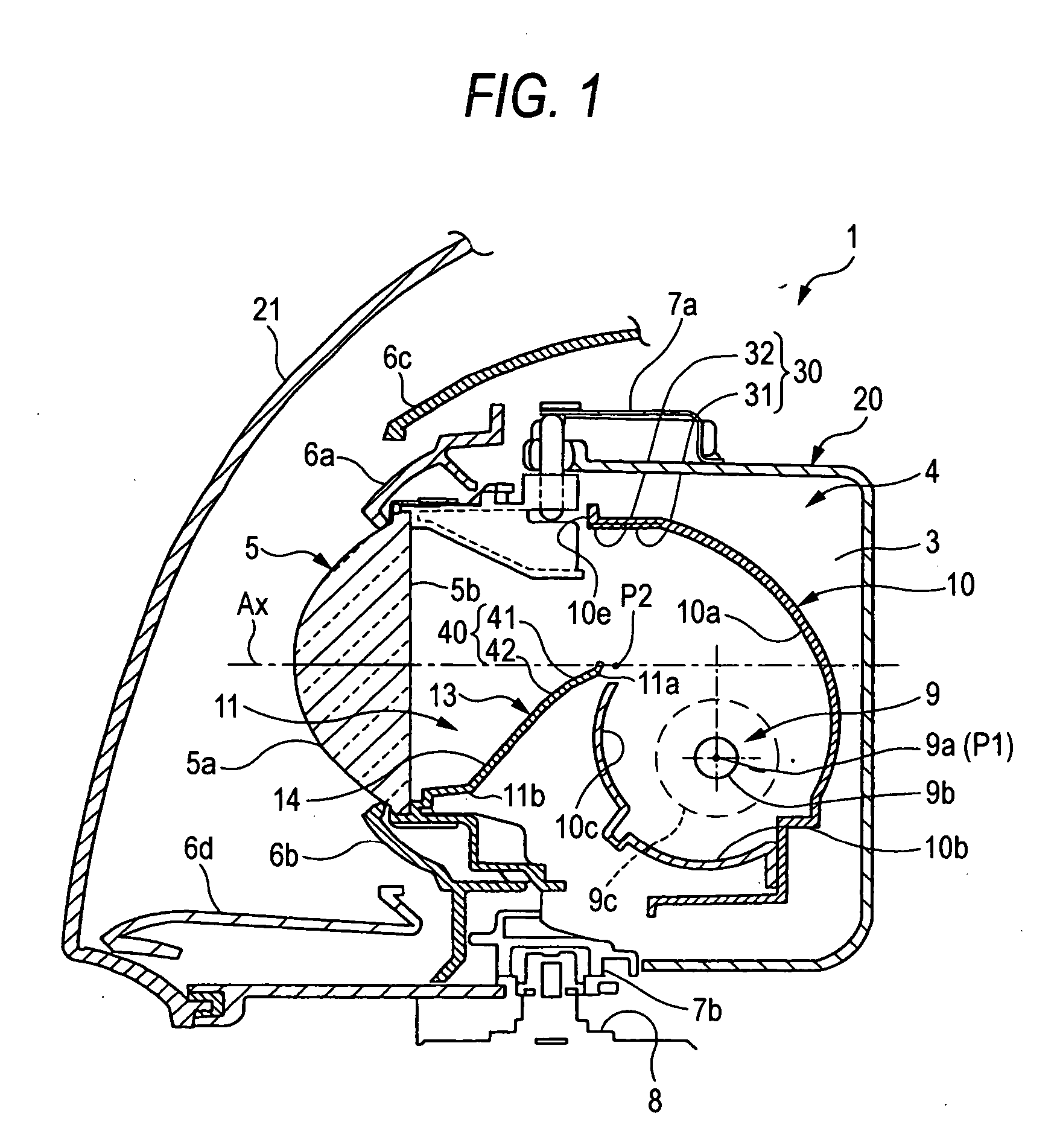

Vehicle lamp

InactiveUS20070019431A1Increase exposureConvenient lightingVehicle headlampsVehicle interior lightingOptical axisLens hood

A vehicle lamp is provided with a projection lens; a light source; a shade, which forms a cutoff line; a reflector, which reflects a light from the light source toward the projection lens such that the light passes near an upper end portion of the shade so as to irradiate a forward direction along an optical axis with the light emitted from the projection lens; an overhead sign reflecting surface, which is provided near an upper end edge of the reflector and reflects the light from the light source; and an overhead sign light receiving surface, which is provided near the upper end portion of the shade and reflects the light from the reflecting surface toward the projection lens so as to irradiate upward irradiation light from the projection lens. The overhead sign reflecting surface includes a plurality of reflecting surfaces, which emit reflected light of different patterns.

Owner:KOITO MFG CO LTD

Pneumatic tire

ActiveUS20110088826A1Inhibit temperature riseTire durability is improvedInflatable tyresTyre sidewallsTire rotationAutomotive engineering

The aspect of the present invention is a pneumatic tire comprising a plurality of radial protrusions 60 each extending in a tire radial direction on a tire surface 31 and having a shape protruding from the tire surface outward in a tire width direction, wherein the plurality of radial protrusions 60 are provided radially with a tire rotation axis as a center, the plurality of radial protrusions 60 each have a low protrusion portion 63 and a high protrusion portion 64, and a height of the low protrusion portion measured in the tire width direction hs is lower than a maximum height of the high protrusion portion h measured in the tire width direction.

Owner:BRIDGESTONE CORP

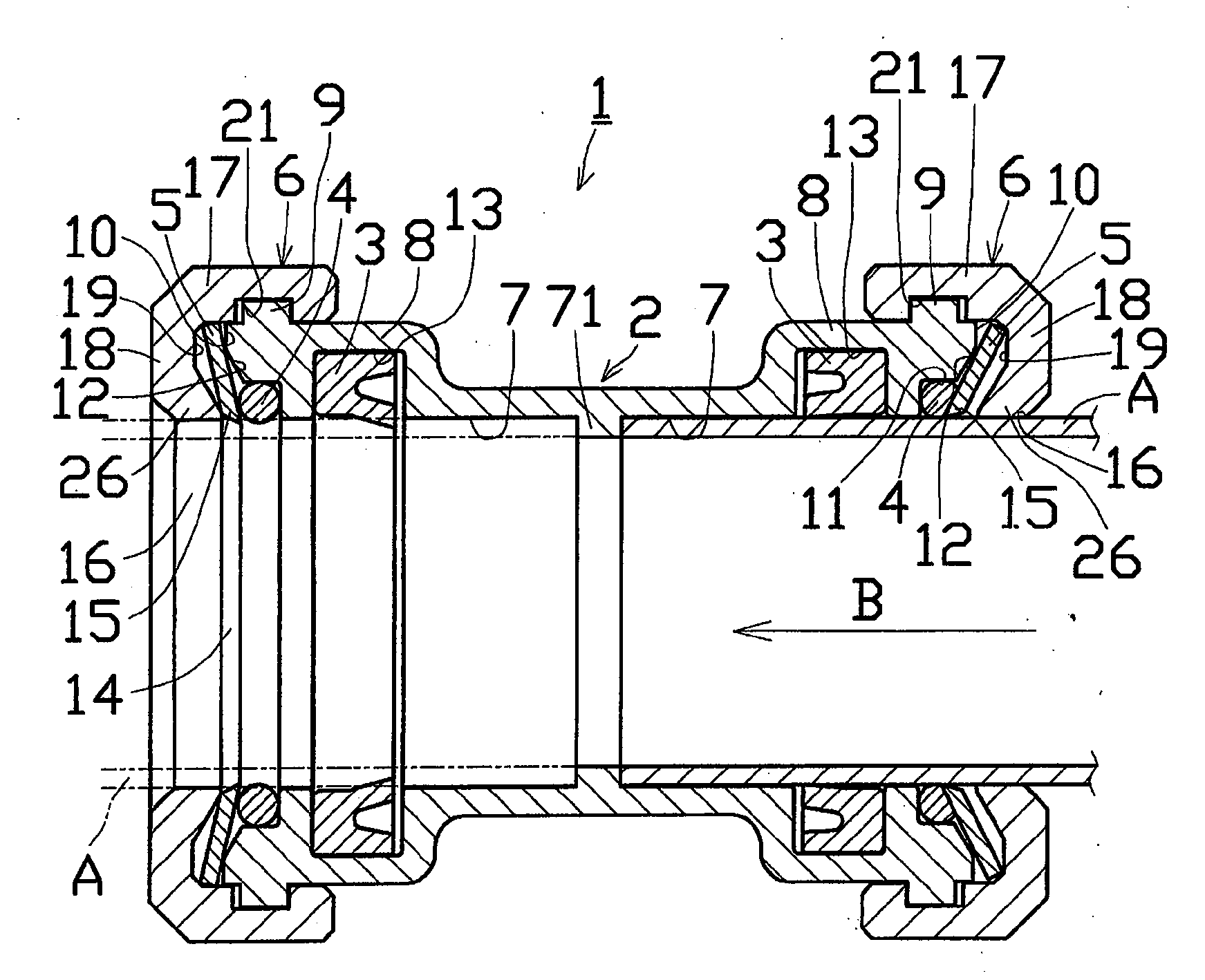

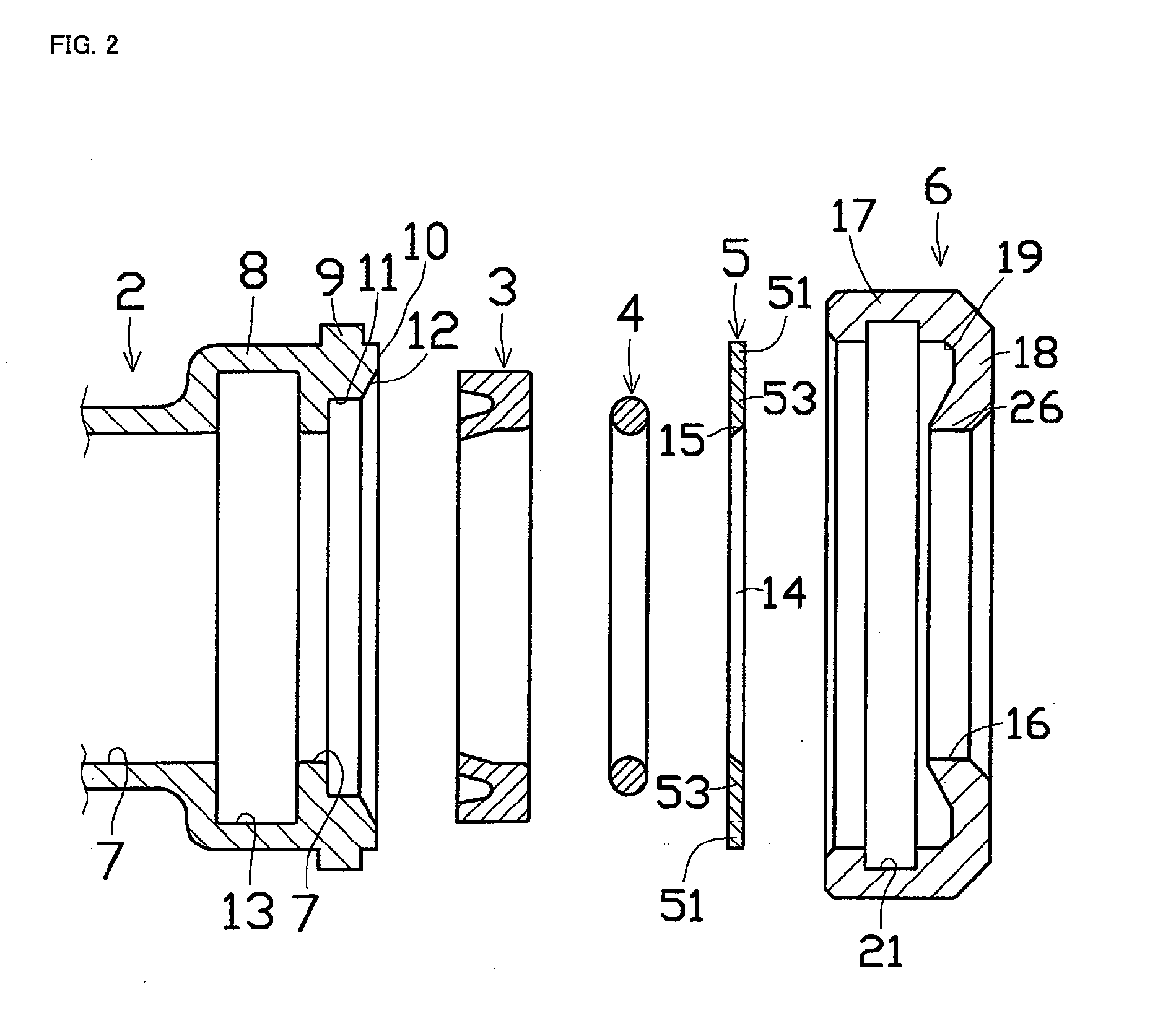

One touch pipe joint

InactiveUS20100314863A1Improve work efficiencyHigh frictional forceSleeve/socket jointsCouplingsPipingEngineering

[Problems] A one-touch joint for piping has an advantage of one-touch connection between the joint and piping but has a problem that the connection between the piping and a joint body easily becomes loose.[Means for Solving Problems] A one-touch joint (1) of the invention includes a joint body (2) having an engagement receiving section (9, 23) on the outer periphery of an opening-side end section of the joint body, a lock ring holder (6) having an engaging ring section (17) having, formed on its inner side, an engaging section (20, 21, 24) engageable with and disengageable from the engagement receiving section (9, 23), a planar lock ring (5) placed between a recess (19) formed in an inner surface of the lock ring holder (6) and an opening-side inner surface (10) of the joint body (2) and having, in its center hole (14), a cutting edge (15) of an engaging section (53), an O-ring (4) received in a cutout section (11) of the joint body (2), rubber packing (3) fitted in a packing insertion hole (13) located closer to the inner side of the joint than the cutout section (11), and a stop projection (71) projecting in a piping insertion hole (7) of the joint body (2).

Owner:ON IND

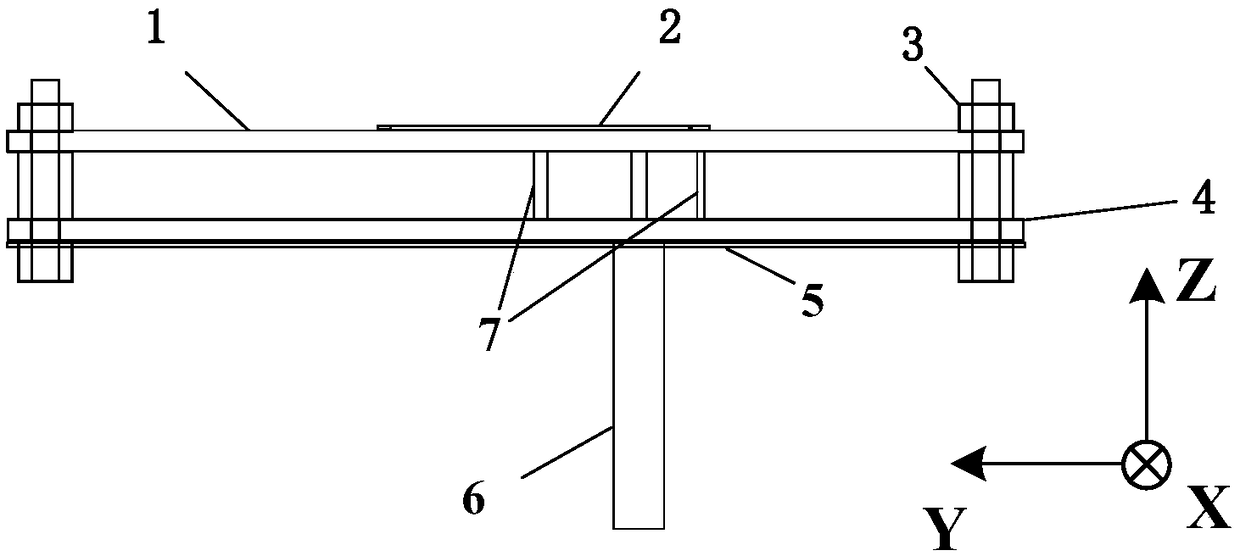

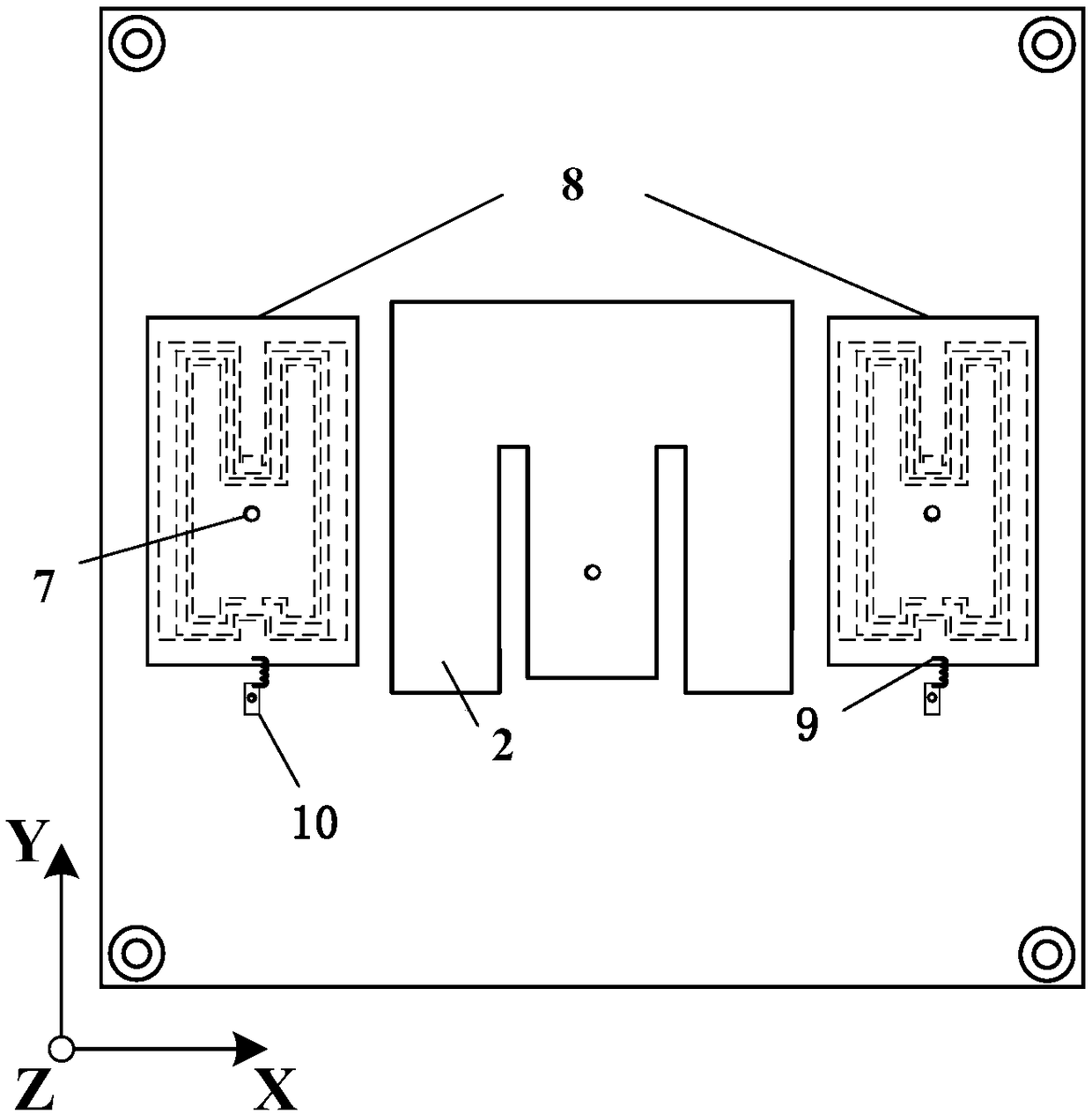

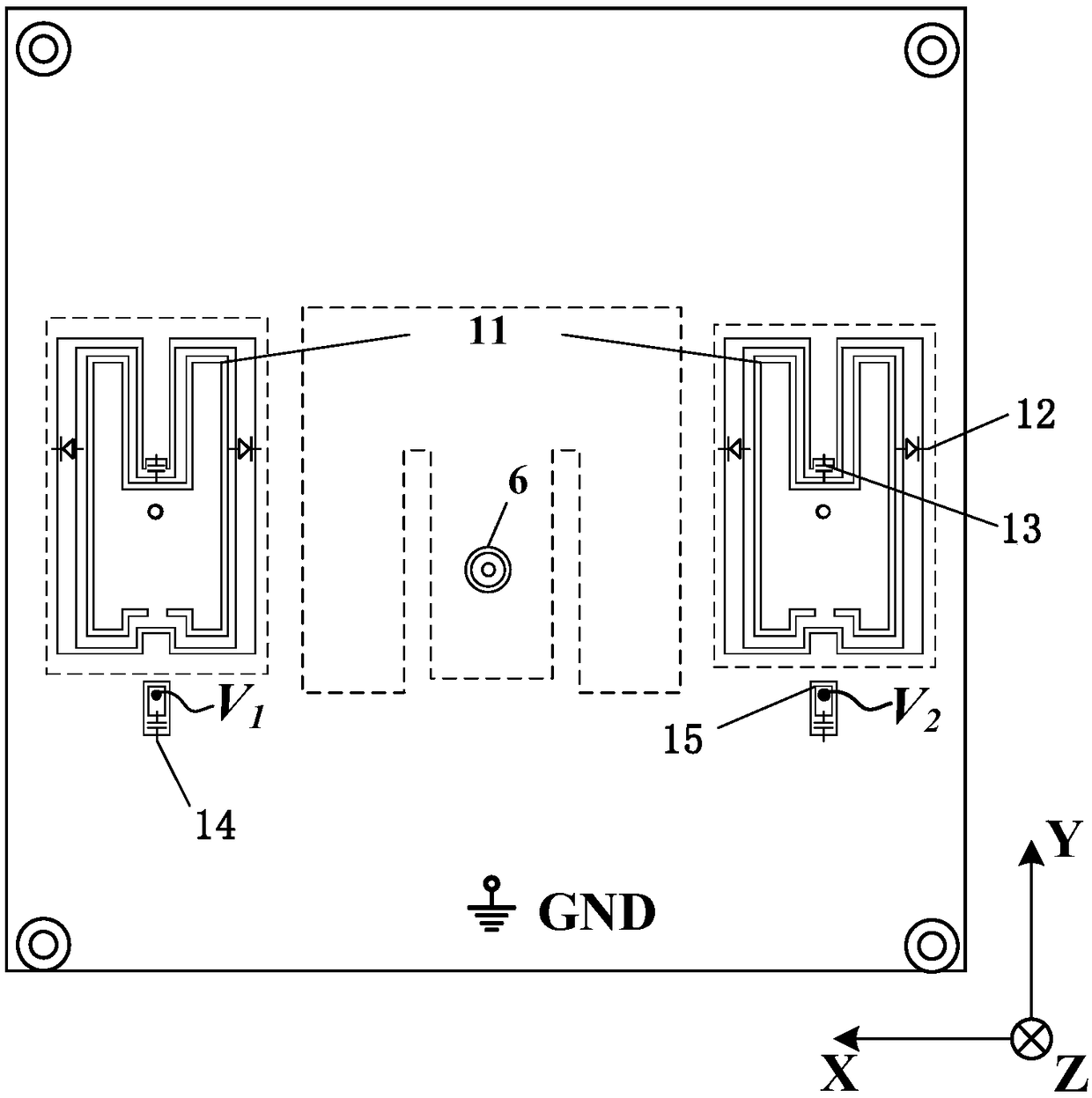

Small-size beam controllable patch antenna based on reconfigurable parasitic element

PendingCN109390699ASmall sizeReduce volumeAntenna earthingsAntennas earthing switches associationDielectric substrateBeam scanning

The invention discloses a small-size beam controllable patch antenna based on a reconfigurable parasitic element, and the antenna comprises an E-shaped main radiation patch, a left parasitic patch anda right parasitic patch. Through employing a CSRR structure, the antenna reduces the electrical length of a parasitic patch, and facilitates the miniaturization of the parasitic patch. A PIN diode isadded to CSRR structure for providing different DC bias voltages, thereby enabling a single parasitic element to work at two states: a director and a reflector. The combination of different states ofthe left and right parasitic elements can enable the main lobe direction of a radiation beam of the antenna to be switched among 0 degree, -30 degree, and 30 degrees, thereby achieving the beam controllable performance of the antenna, and effectively enlarging the beam scanning range of the antenna. The antenna employs the coaxial feed E-shaped main radiation patch and introduces an air layer structure between two dielectric substrates, thereby effectively enlarging the work bandwidth of the antenna. The antenna is high in gain, is high in front-to-rear ratio, and is low in profile.

Owner:SOUTH CHINA UNIV OF TECH

Surface light source device

ActiveUS7690831B2Significant proportionReduce in quantityPoint-like light sourceElongate light sourcesPoint lightLight guide

A surface light source device includes two or more point light sources that are arranged linearly, a light guide plate having an incident surface on which light emitted from each of the point light sources shines, for outputting input light from a front surface thereof, and light diffusing means provided on a back surface of the light guide plate, for diffusing light. The incident surface of the light guide plate is inclined toward a back side.

Owner:MITSUBISHI ELECTRIC CORP +1

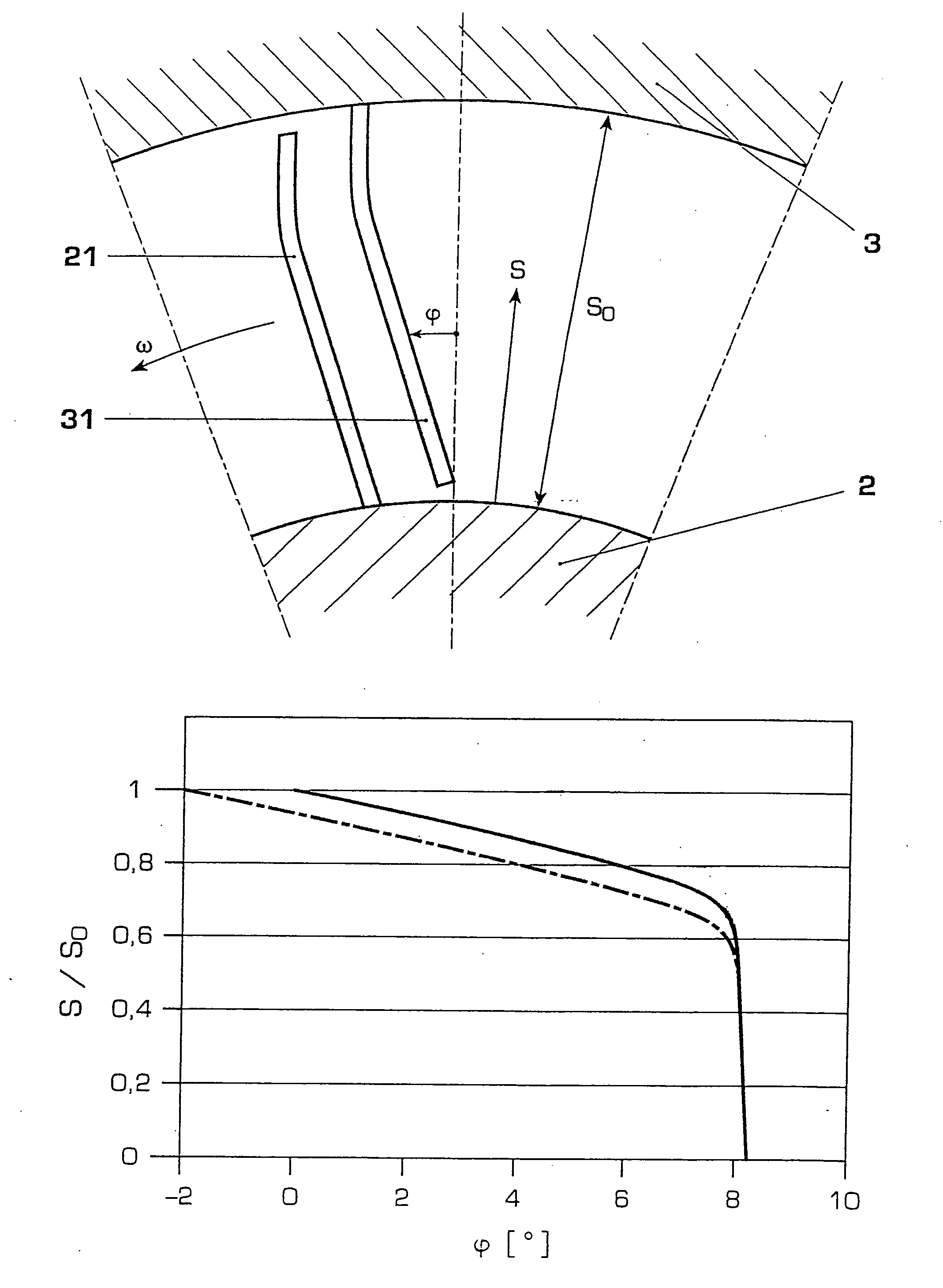

Turbomachine blade

InactiveUS20080152501A1Avoid disadvantagesLarge inclinationPropellersEngine manufactureTurbine bladeMechanical engineering

Owner:GENERAL ELECTRIC TECH GMBH

Organic light-emitting panel and manufacturing method thereof, and organic display device

InactiveUS20120091440A1Avoid uneven film thicknessLarge inclinationElectroluminescent light sourcesSolid-state devicesDisplay deviceEngineering

A non-light-emitting cell 100c is provided between pixels 100a and 100b. In formation of the light-emitting cell 100a, ink for forming an organic light-emitting layer is dripped into sub-pixels 100a1, 100a2, 100a3 in this order. This also applies to the light-emitting cell 100b. However, such ink is not dripped into the non-light-emitting cell 100c since the organic light-emitting layer is not formed in the non-light-emitting cell 100c. Regarding a bank 105d between the sub-pixel 100a3 and the non-light-emitting cell 100c, an inclination angle θd3 of a wall 105d3 is larger than an inclination angle θdc of a wall 105dc. On the other hand, regarding a bank 105e between the sub-pixel 100b1 and the non-light-emitting cell 100c, an inclination angle θe1 of a wall 105e1 is equivalent to an inclination angle θec of a wall 105ec.

Owner:JOLED INC

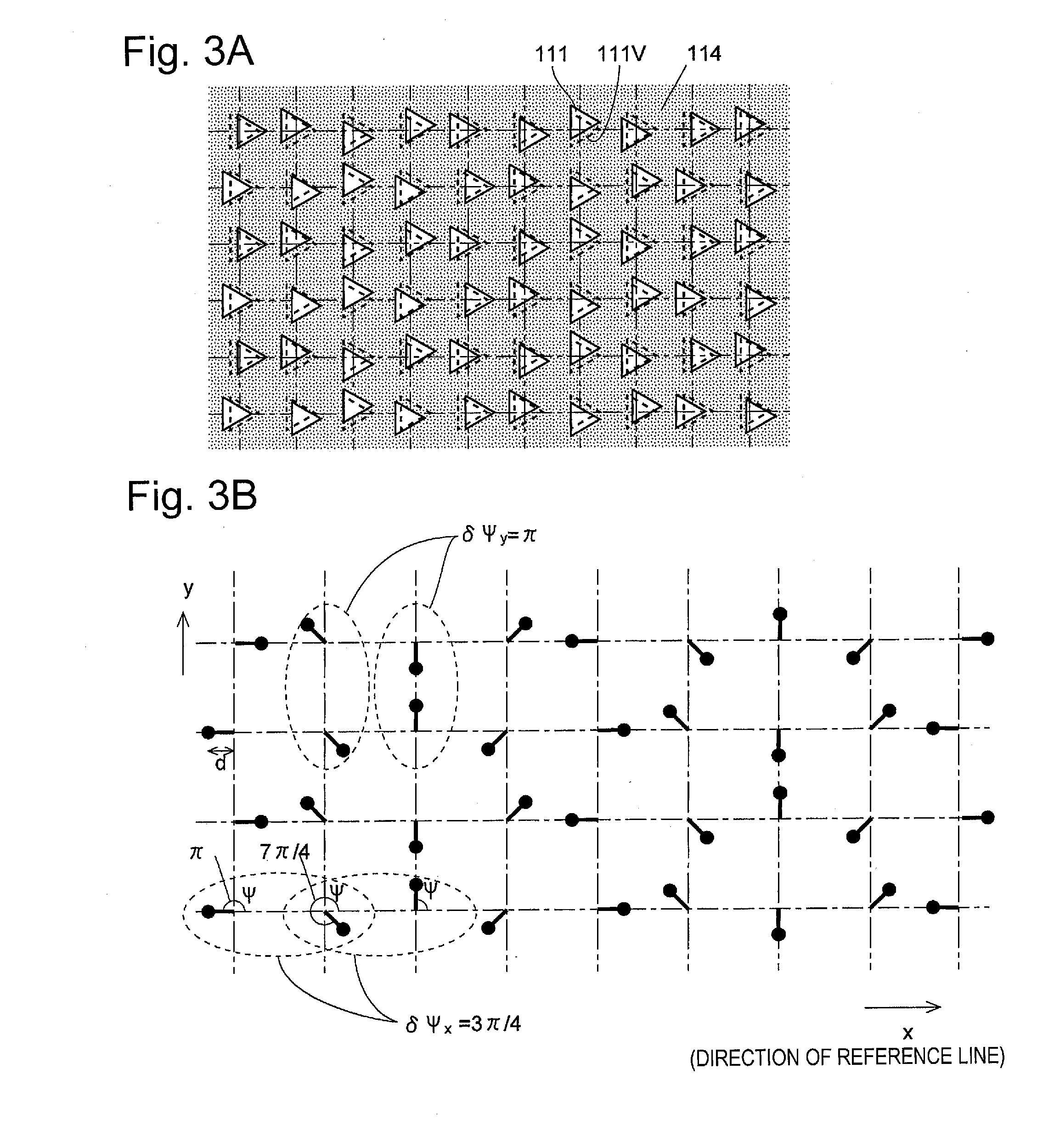

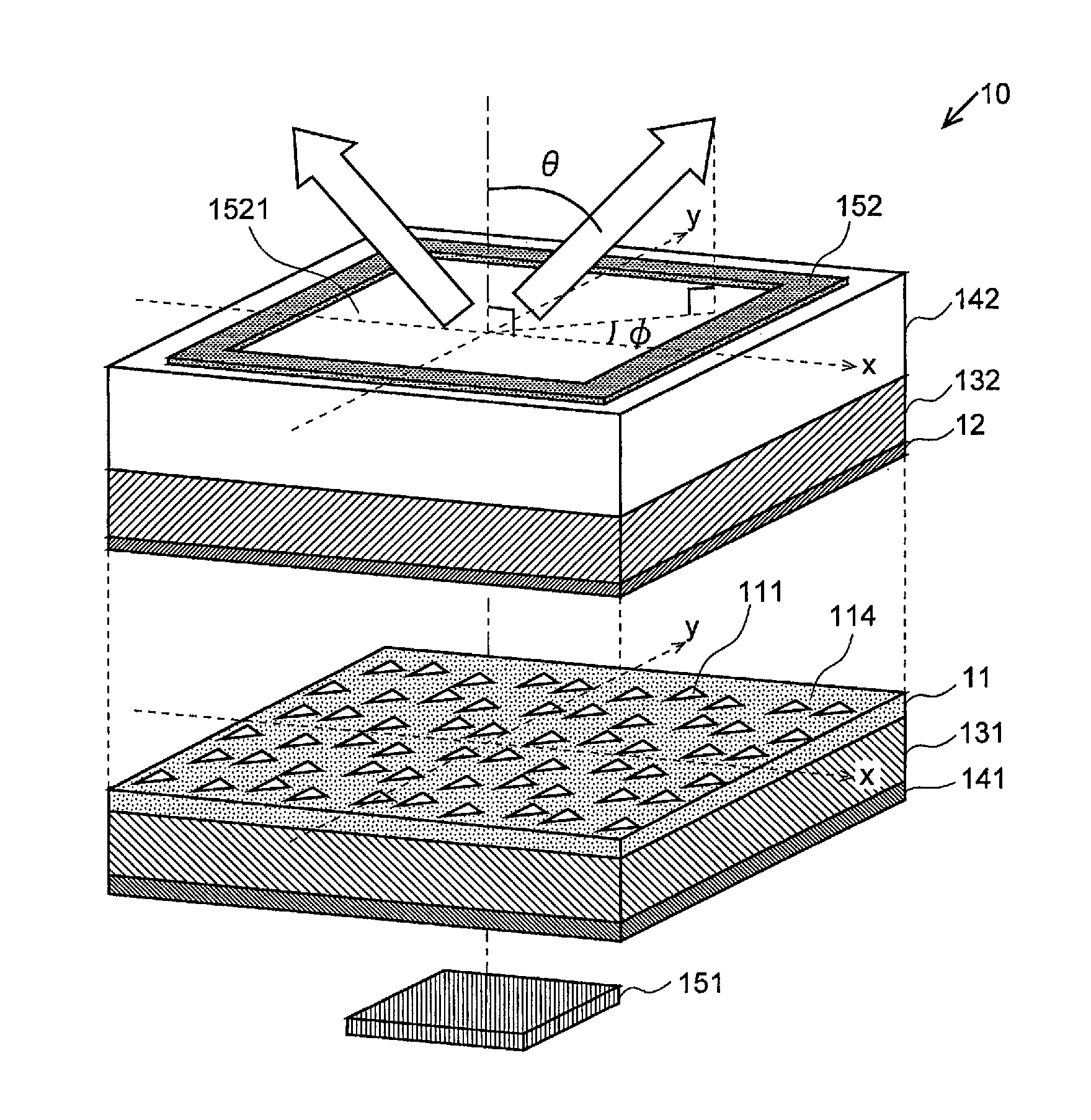

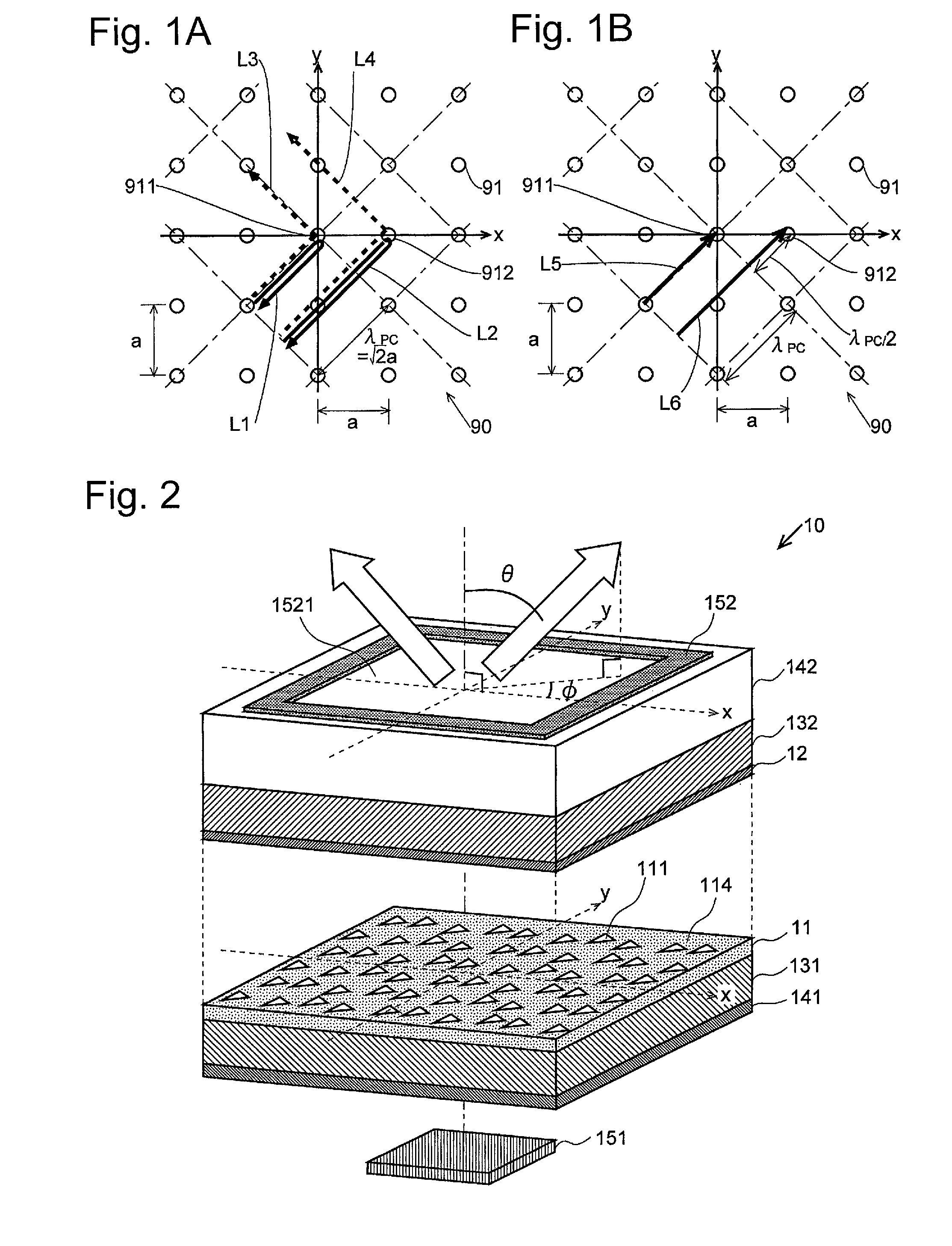

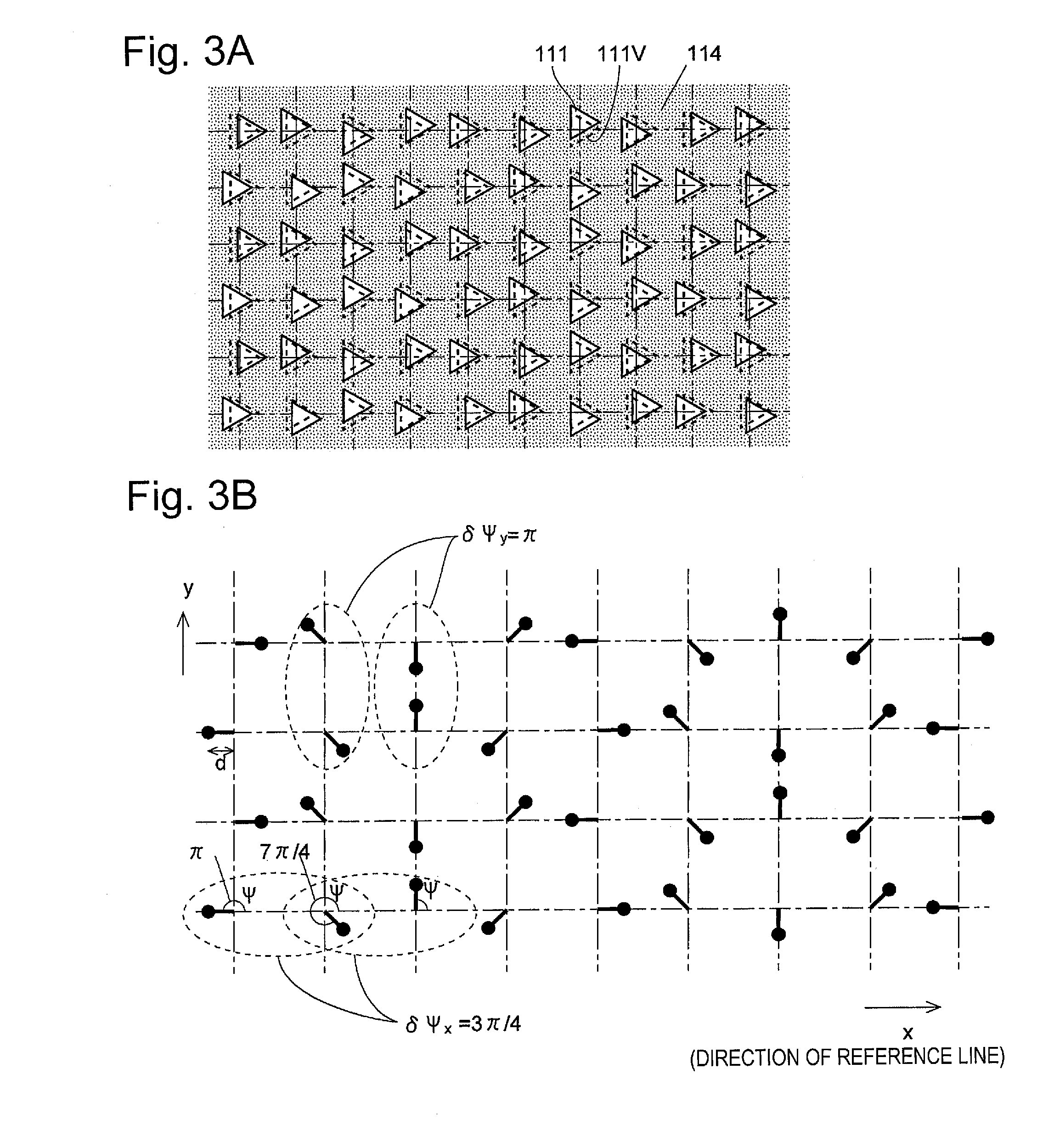

Two-dimensional photonic crystal surface-emitting laser

ActiveUS20160261093A1Small lossLarge inclinationLaser detailsLaser optical resonator constructionPhotonic crystalPower flow

A two-dimensional photonic crystal surface emitting laser has a laminated structure including: a two-dimensional photonic crystal (2DPC) layer in which refractive index distribution is formed by two-dimensionally arranging air holes in a plate-shaped base member; and an active layer for generating light with wavelength λL by receiving an injection of electric current. The two-dimensional photonic crystal surface emitting laser emits a laser beam in the direction of an inclination angle θ from normal to the 2DPC layer.

Owner:JAPAN SCI & TECH CORP

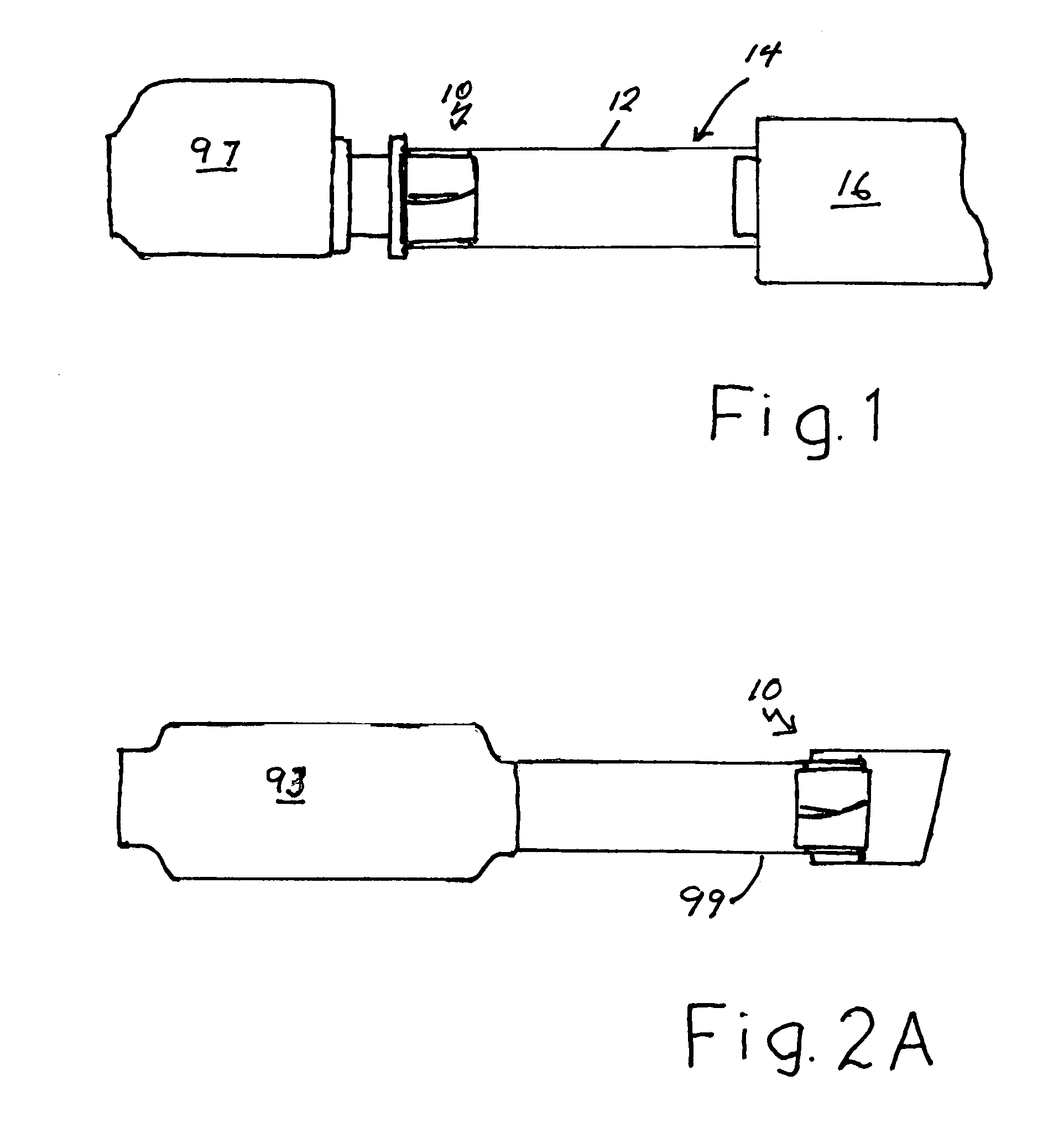

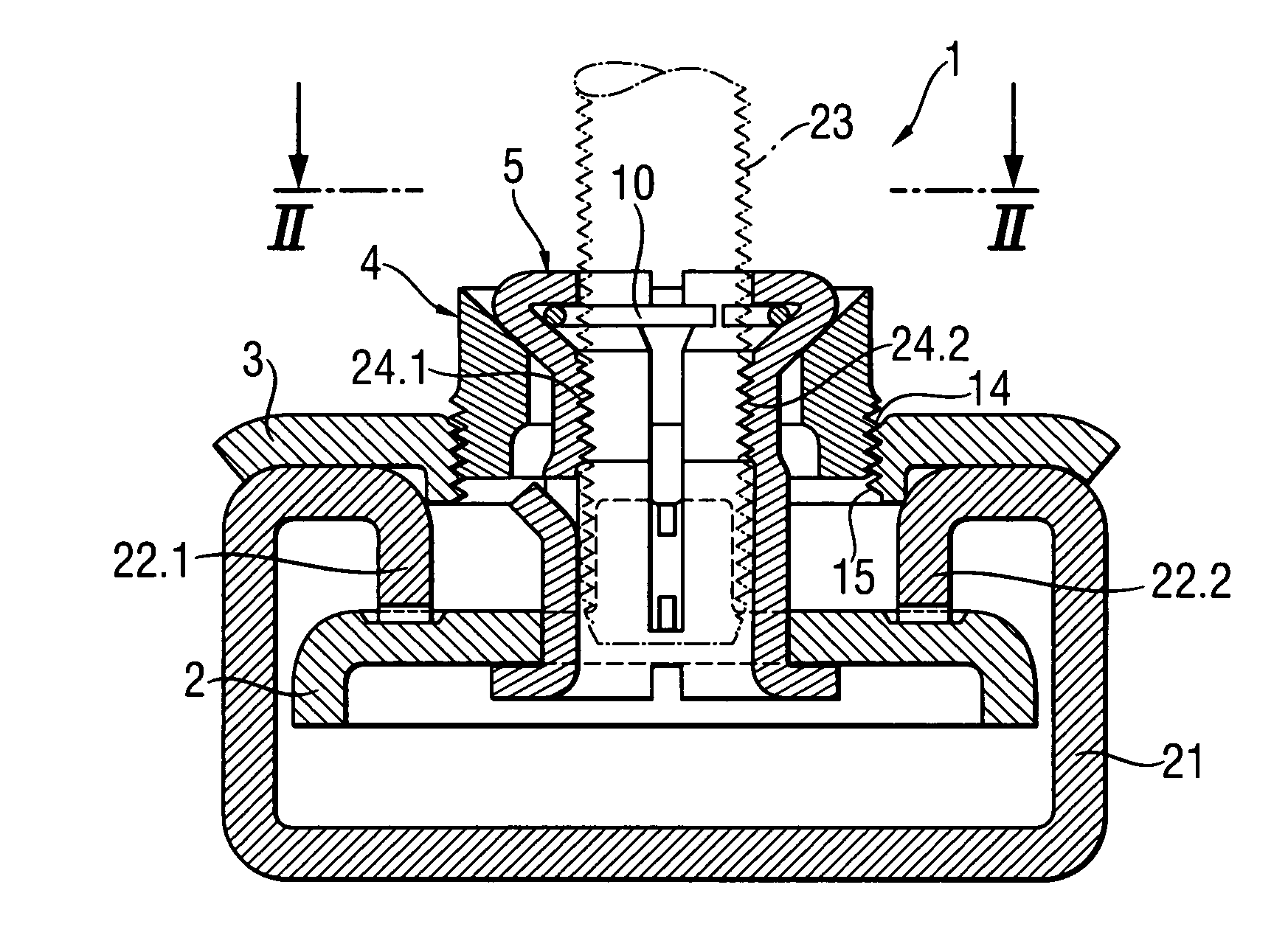

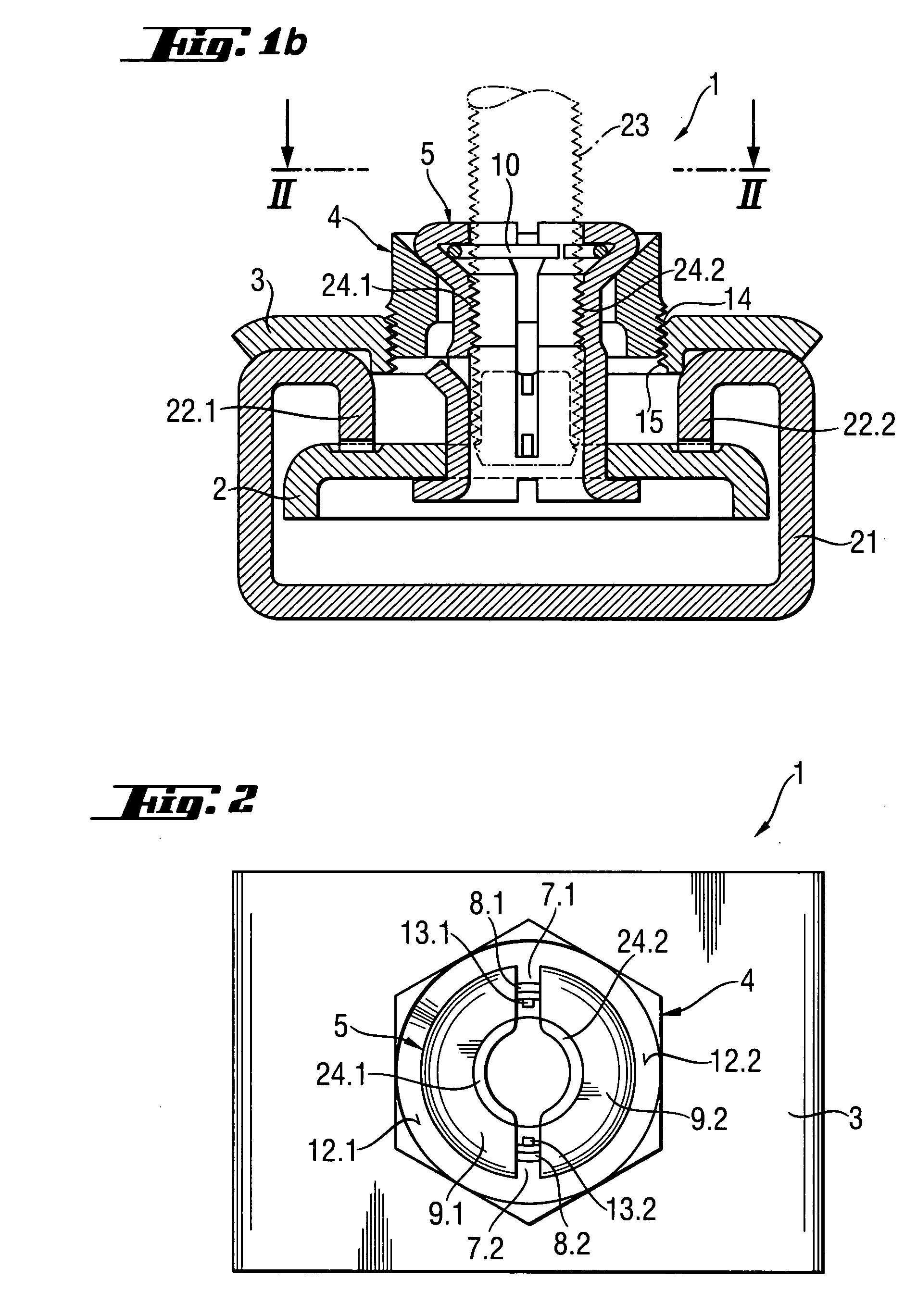

Attachment system

InactiveUS7101131B2Easy to slideLarge inclinationNutsBoltsEngineeringElectrical and Electronics engineering

An attachment system for securing a rod member in a mounting opening of a constructional component (44; 74; 97) includes a receiving sleeve (5; 37; 64; 73; 93) for receiving the rod member (23; 40), and an actuation member (4; 35; 62; 72; 81; 92) connected with the receiving sleeve (5; 37; 64; 73; 93) for substantially radially displacing the engagement elements (24.1; 24.2; 49.1; 49.1; 69.1; 69.2; 98.1; 98.2) of the receiving sleeve, which engage the rod member, from a first position in which the rod member is received in the receiving sleeve (5; 37; 64; 73; 93) to a second position in which the rod member is locked in the receiving sleeve.

Owner:HILTI AG

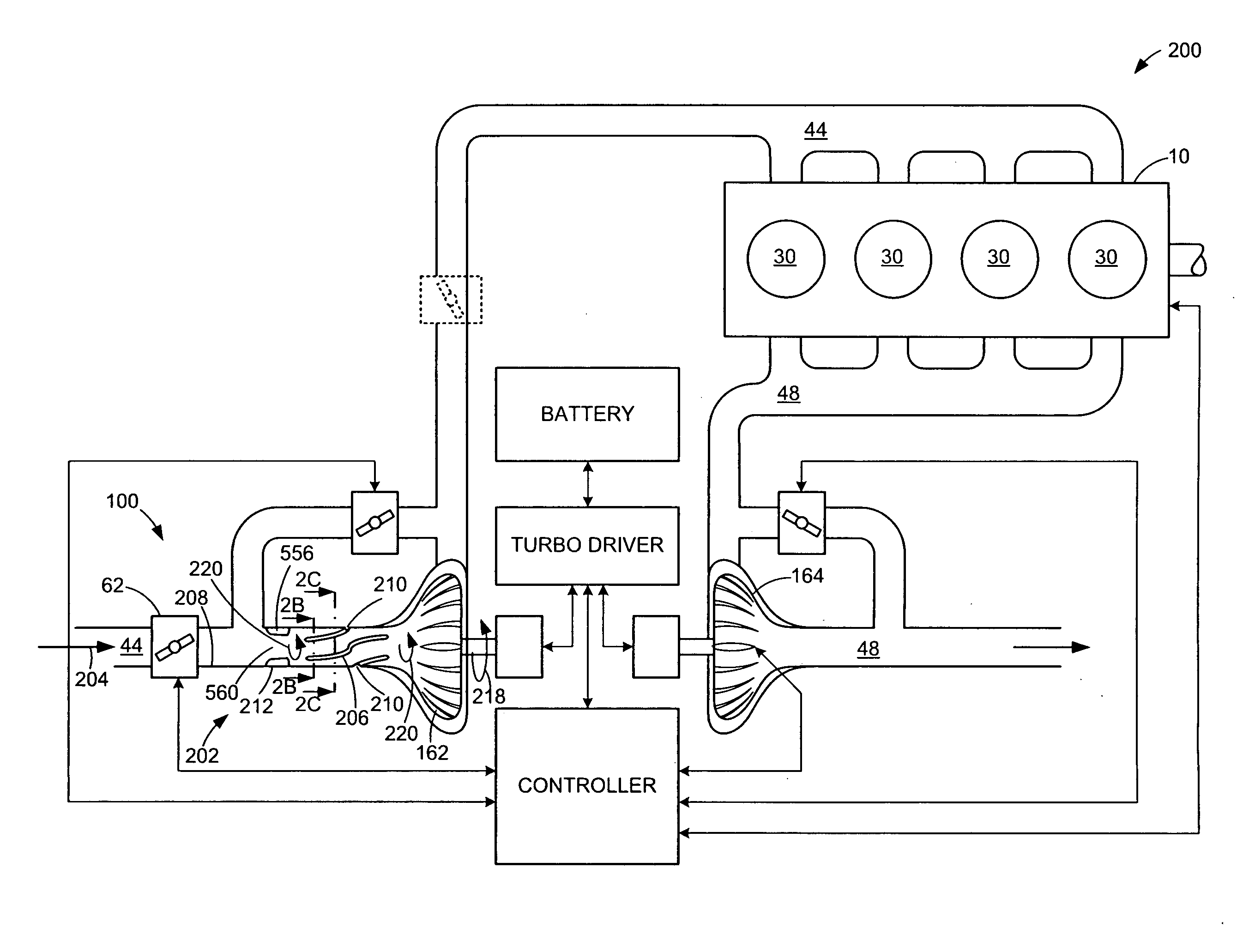

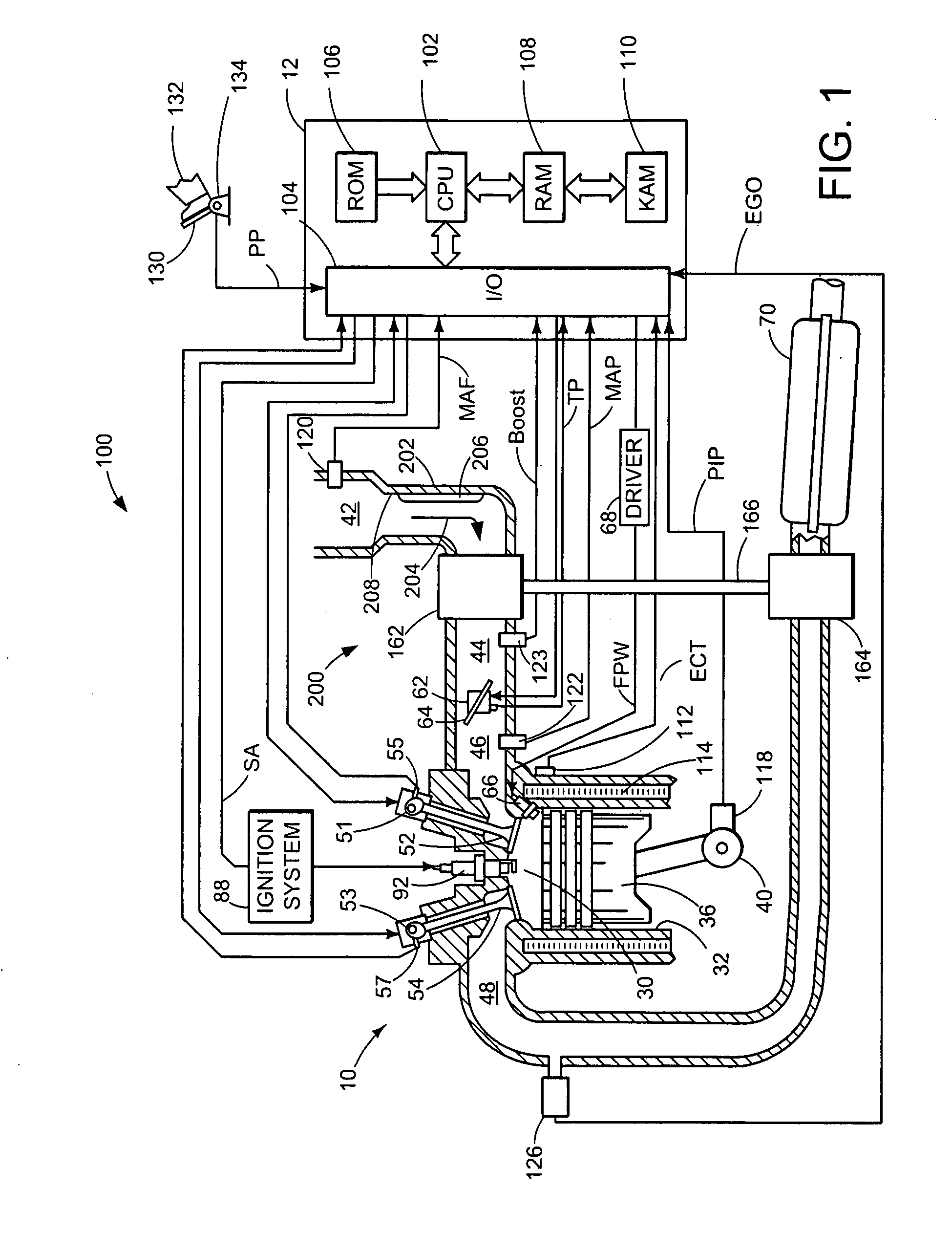

Inlet Swirl Control for Turbochargers

ActiveUS20100266395A1Reduce noise generateAffect efficiencyInternal combustion piston enginesWind motor controlInduction systemBiomedical engineering

An inlet duct, an induction system, and a system are disclosed for directing an inlet flow into an inlet compressor for use in an internal combustion engine. An example inlet duct may include one or more relief features disposed on an inner surface of the inlet duct. The one or more relief features may be made integral with the inlet duct. The one or more relief features may be disposed to protrude into the inlet flow to cause the inlet flow to swirl before reaching the inlet compressor.

Owner:FORD GLOBAL TECH LLC

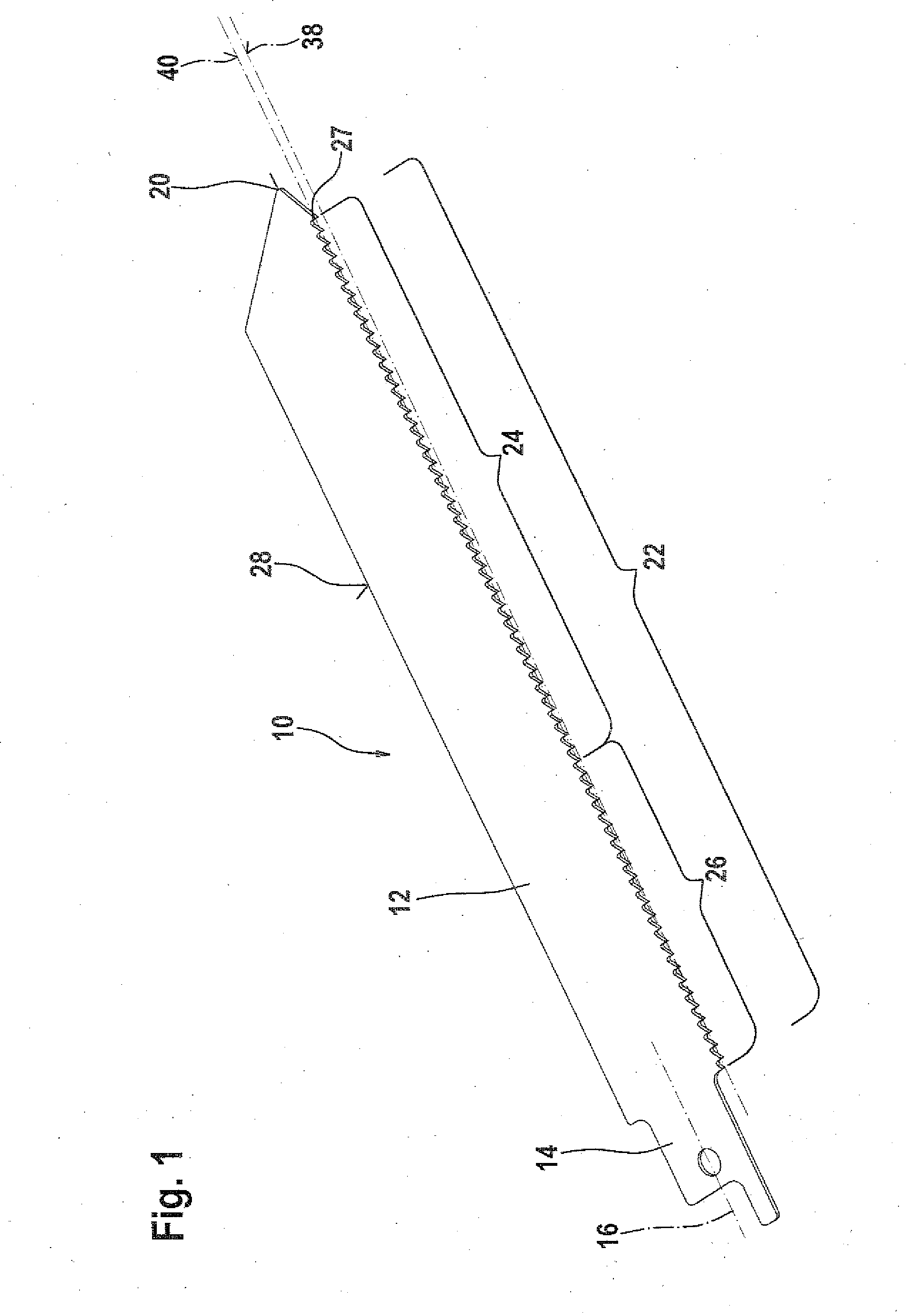

Jigsaw blade for hand-held power jigsaws

InactiveUS20100126328A1Improve cutting performanceImprove cut qualityMetal sawing devicesMetal sawing toolsHand heldEngineering

A jigsaw blade having a clamping end and, adjoining it, a blade-like working body that has a row of saw teeth that is inclined in relation to the clamping end, a spine on the opposite side from the row of teeth, and a tip at the front is therefore safer, easier to use, has higher performance, and is more precise. The jigsaw blade has two tooth row regions of the row of saw teeth that are inclined at different angles in relation to the clamping end.

Owner:ROBERT BOSCH GMBH

Mask and production method thereof

ActiveCN101650526ALarge inclinationDecrease the inclinationPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringPhotoresist

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

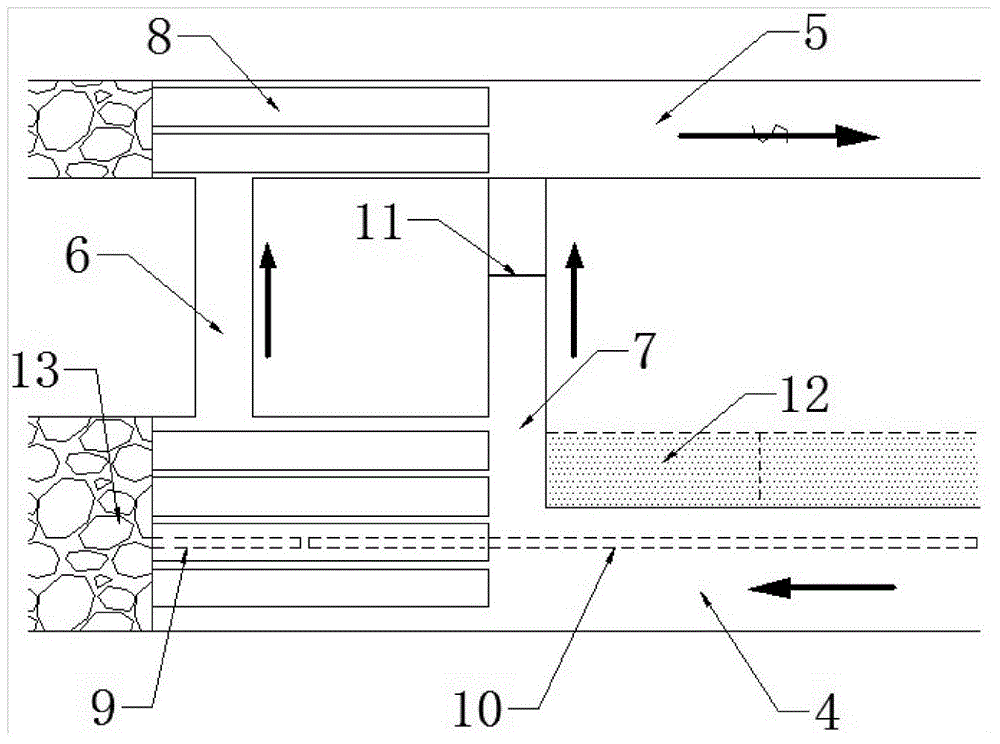

High-dipping extremely-close-distance coal seam top coal caving mining method

InactiveCN104088643AHigh-yield and efficient miningLarge inclinationUnderground miningSurface miningTelecommunicationsCoal

The invention provides a high-dipping extremely-close-distance coal seam top coal caving mining method. According to the method, a transportation gateway is constructed along one side of a coal layer bottom plate and an air returning gateway is constructed on the other coal layer; the elevation of a bottom plate of the air returning gateway is 4-4.5m higher than that of a bottom plate of the transportation gateway; rectangular roadways are constructed between the two gateways at an interval of 10m and are used as connection roadways; hydraulic brackets are distributed on two coal layers along the thickness directions of the coal layers; each circulating unit advance of a worktable bracket is the same as the distance of the connection roadways; in a top coal caving process, top coal discharged by the coal layers of the transportation gateway and manually-mined falling coal in a manner of manually shoveling coal and filling into a scraper plate conveyor to be transported out; the top coal discharged by the coal layers of the air returning gateway is filled into enamel chutes of the connection roadways in a manner of manually shoveling the coal to flow into a bracket tail beam of the coal layers of the transportation gateway, and is put into the scraper plate conveyor to be transported out by manually shoveling the coal. The high-dipping extremely-close-distance coal seam top coal caving mining method has the advantages of being simple in arrangement of a working surface, strong in adaptability, good in ventilation, relatively good in safety degree, large in supporting space and high in production efficiency.

Owner:SHANDONG UNIV OF SCI & TECH

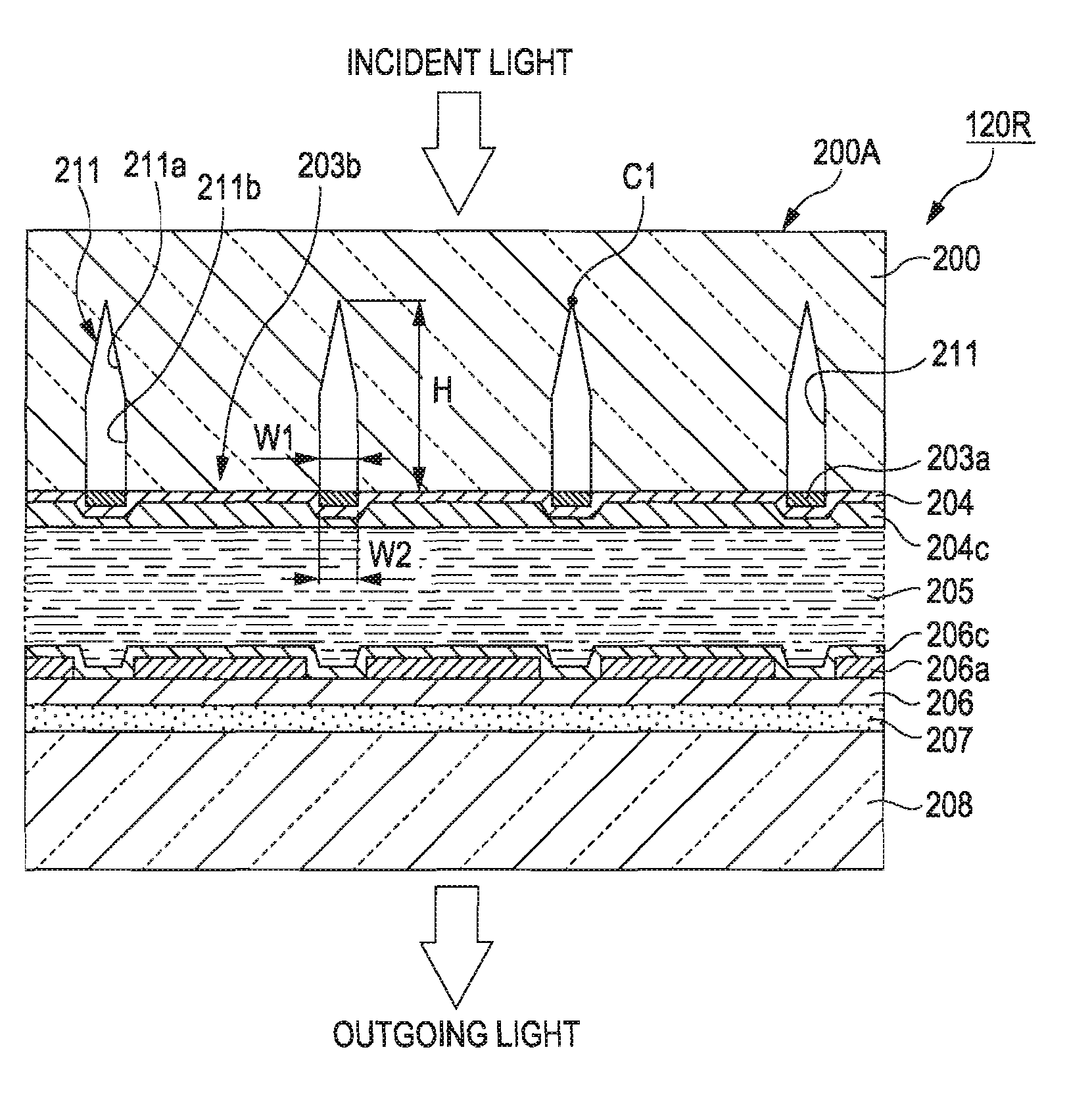

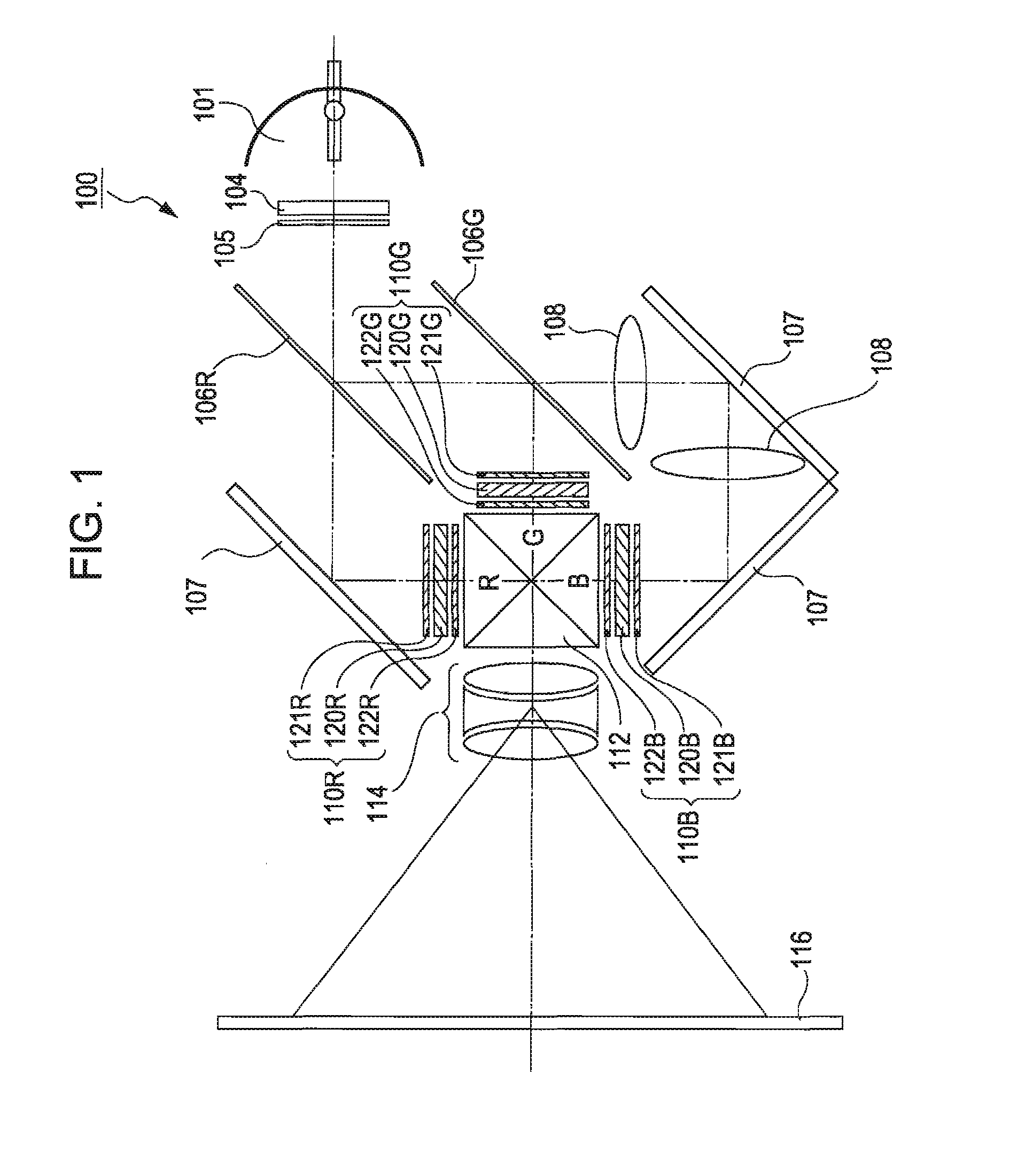

Converging substrate, electro-optic device, substrate for electro-optic device, projector, and electronic apparatus

InactiveUS20070183016A1Bright is obtainedIncrease display contrastColor television detailsNon-linear opticsPrismMatrix pattern

An electro-optic device having a plurality of pixels arranged in a matrix pattern, including: a converging substrate formed of a transparent substrate having groove-shaped prism elements formed in an array pattern, wherein the prism elements are arranged along boundary areas of the pixels, wherein the prism elements each include a plurality of beveled portions arranged on side walls thereof in the direction of the thickness of the converging substrate, and wherein the inclination angle of the beveled portions arranged on an opening end side of each of the prism elements with respect to the normal line of the converging substrate on which the prism elements are formed is smaller than the inclination angle of the other beveled portions.

Owner:SEIKO EPSON CORP

Two-dimensional photonic crystal surface-emitting laser

ActiveUS9531160B2Little lossLarge inclinationLaser detailsLaser optical resonator constructionPhotonic crystalRefractive index

A two-dimensional photonic crystal surface emitting laser has a laminated structure including: a two-dimensional photonic crystal (2DPC) layer in which refractive index distribution is formed by two-dimensionally arranging air holes in a plate-shaped base member; and an active layer for generating light with wavelength λL by receiving an injection of electric current. The two-dimensional photonic crystal surface emitting laser emits a laser beam in the direction of an inclination angle θ from normal to the 2DPC layer.

Owner:JAPAN SCI & TECH CORP

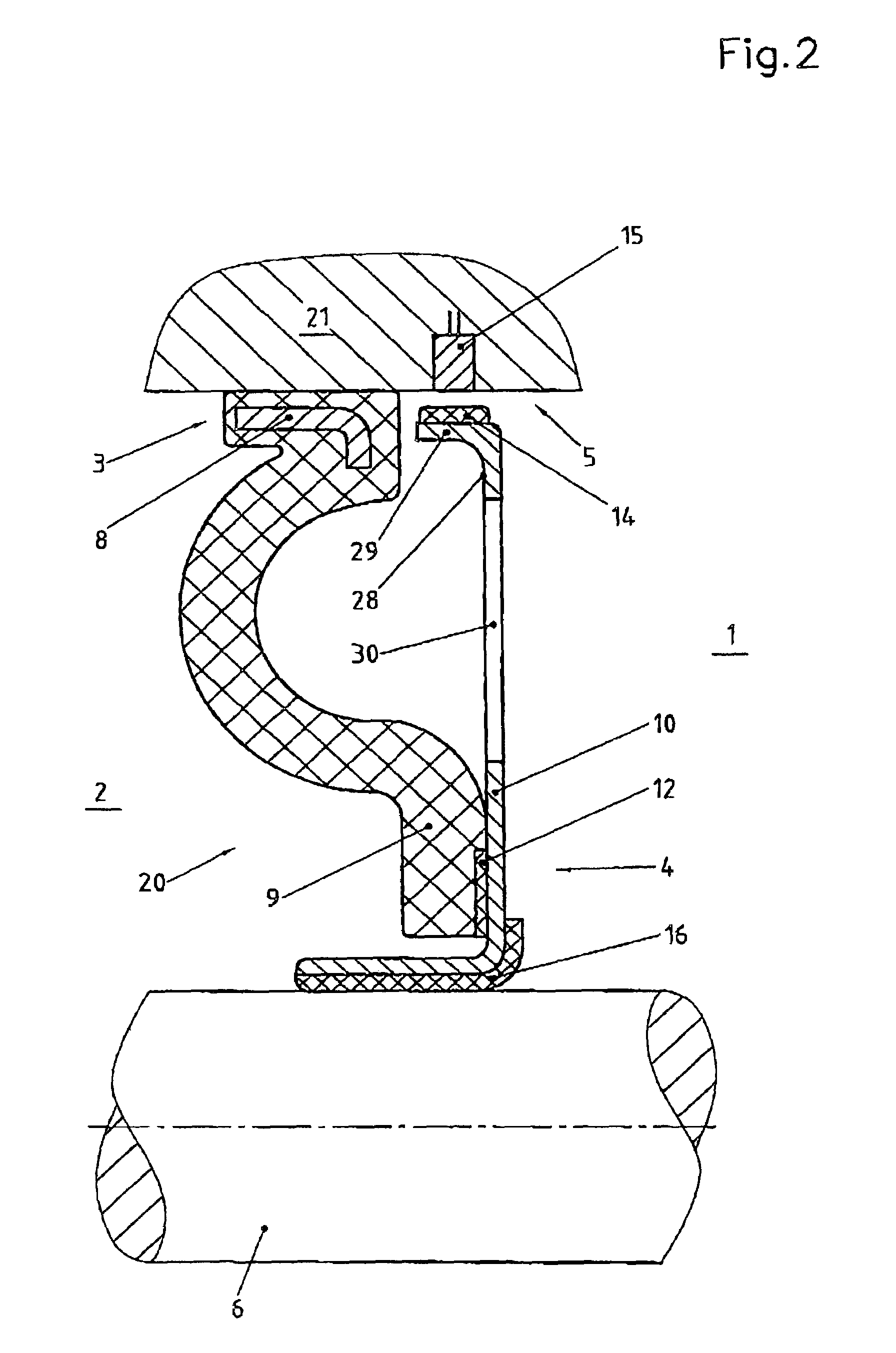

Axial shaft seal

An axial shaft seal disposed between a housing wall and a rotating shaft includes an outer ring insertable into the housing wall in a stationary and sealing manner and an inner ring connectable to the shaft in a non-twisting and sealing manner. The outer ring includes a sleeve having a polymer material extending radially inward and having a spring bellows form. A radially inward end portion of the sleeve has a first sealing surface. The inner ring includes a ring flange extending radially outward so as to provide a second sealing surface for axially mating the first sealing face.

Owner:CARL FREUDENBERG KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com