Mask plate and manufacture method thereof

A technology of mask plate and light-transmitting area, which is applied in the field of mask plate and its preparation, can solve problems such as uneven exposure of photoresist, uneven photoresist surface, photoresist inclination, over-etching of semiconductor layer, etc., to achieve exposure Uniformity, shorten exposure time, reduce the effect of channel overcut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

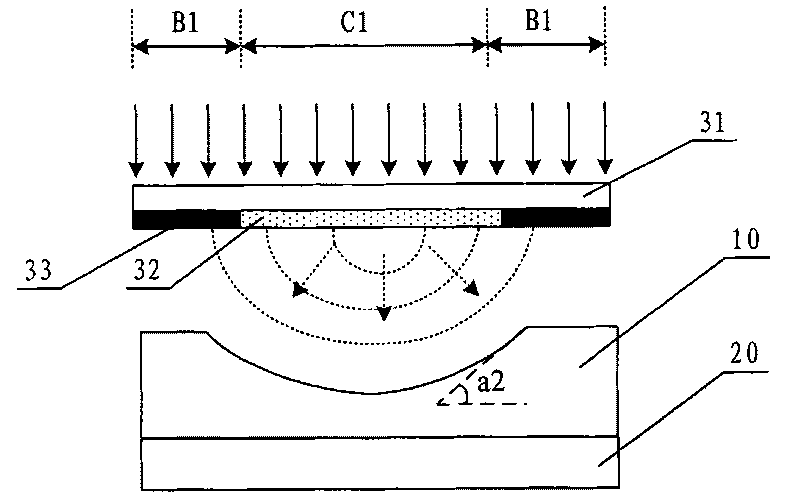

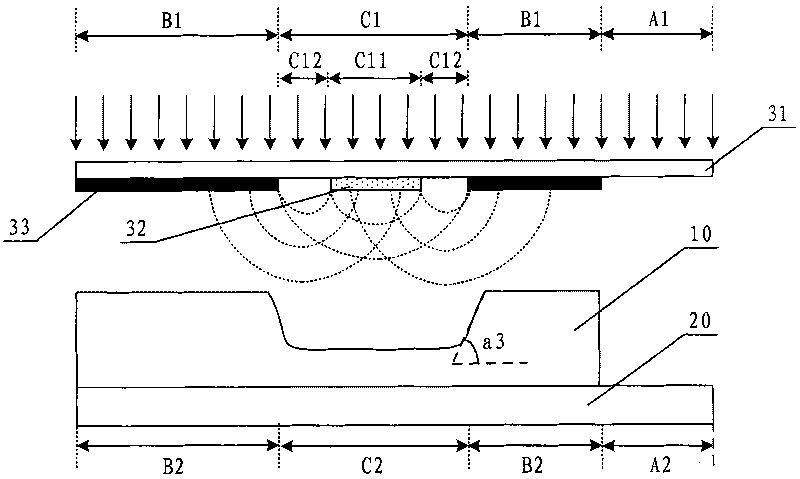

[0047] image 3 It is a schematic diagram of the mask plate of the present invention. The mask plate of the present invention is composed of a transparent substrate 31 , a translucent film 32 and an opaque film 33 , forming a completely transparent area A1 , an opaque area B1 and a partially transparent area C1 . The partially transparent region C1 is formed by alternating translucent parts C11 and transparent parts C12.

[0048] Preferably, the sum of the areas of the translucent parts C11 accounts for 50%-75% of the total area of the partially transparent regions C1. The translucent part C11 may specifically be a translucent film. The transparent part C12 can specifically be the slits formed by the alternate arrangement of translucent films, or the slits formed between the translucent films and the opaque films,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com